Blind-hole-conduction double-sided circuit board and processing method thereof

A processing method and circuit board technology, which are applied in the directions of printed circuit components, the formation of electrical connection of printed components, and the electrical connection of printed components, etc., can solve the problems of reduced quality assurance factor, narrowed application range, and surface layer copper foil damage, etc. Achieve the effect of reducing production costs, reducing energy consumption, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

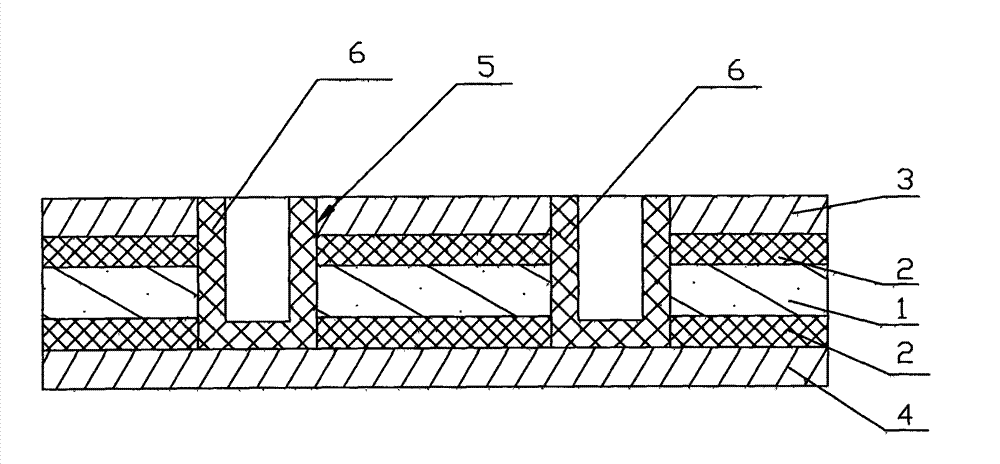

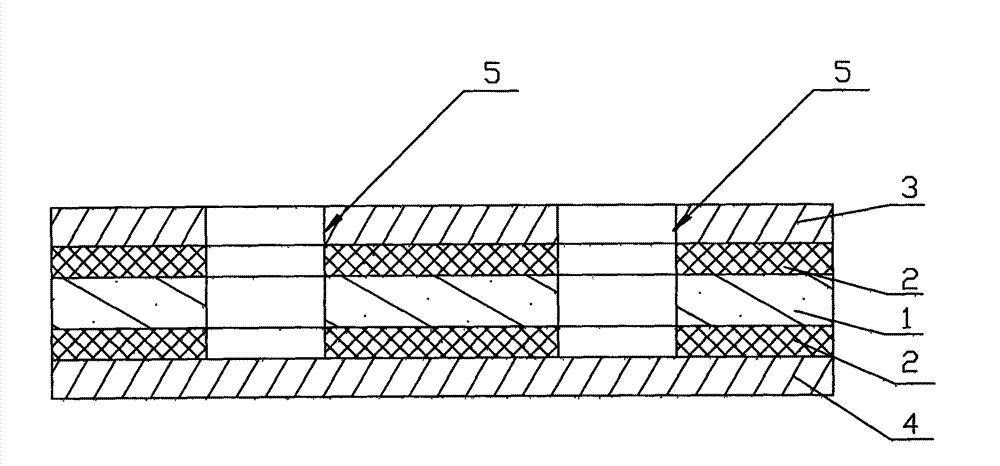

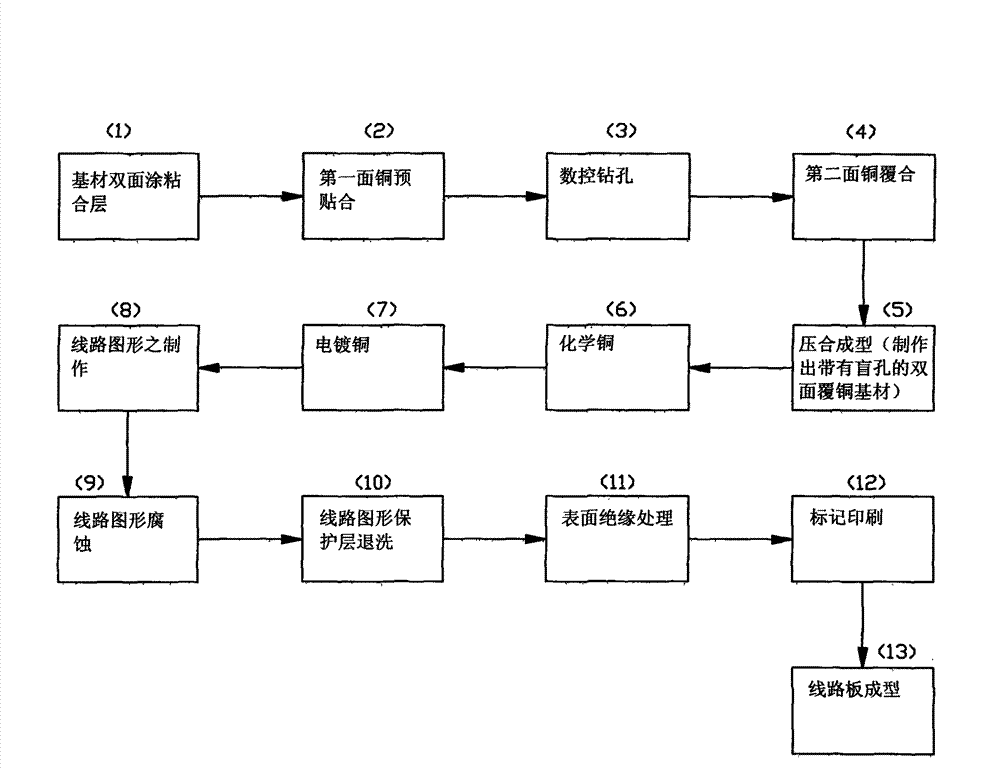

[0027] Such as Figure 1 ~ Figure 2 As shown, a double-sided circuit board with blind vias of the present invention comprises a base material layer 1 and upper and lower circuit layers 3 and 4 that are bonded together by an adhesive layer 2 respectively. The upper circuit layer 3 and the substrate layer 1 are provided with conduction blind holes 5 , along the walls of the conduction blind holes 5 , electroplated conduction walls 6 for conducting the upper and lower circuit layers 3 and 4 are electroplated.

[0028] The surface of the circuit layer 3 is provided with an electroplating surface layer integrally plated on one side with the electroplating conduction wall 6 , and the electroplating surface layer forms a part of the upper circuit layer 3 .

[0029] The line layer is pure copper foil or alloy copper foil, and the electroplated via wall 6 and the electroplated surface layer are correspondingly copper or alloy copper electroplated via layers.

[0030] The substrate layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com