Auxiliary pressure relief valve

A technology for pressure relief valves and slide valves, which is applied in the direction of slide valves, valve details, safety valves, etc., and can solve problems such as incomplete pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

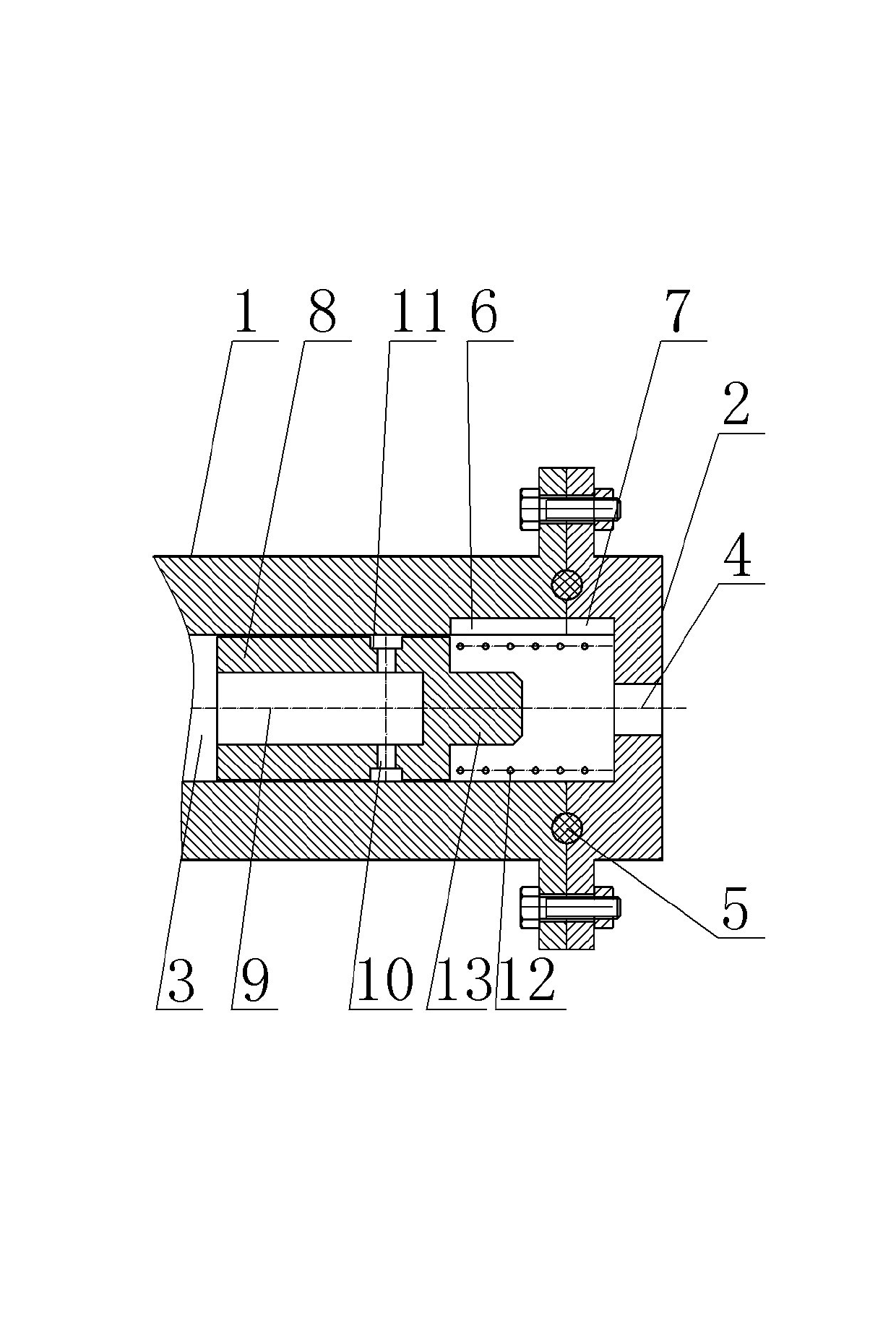

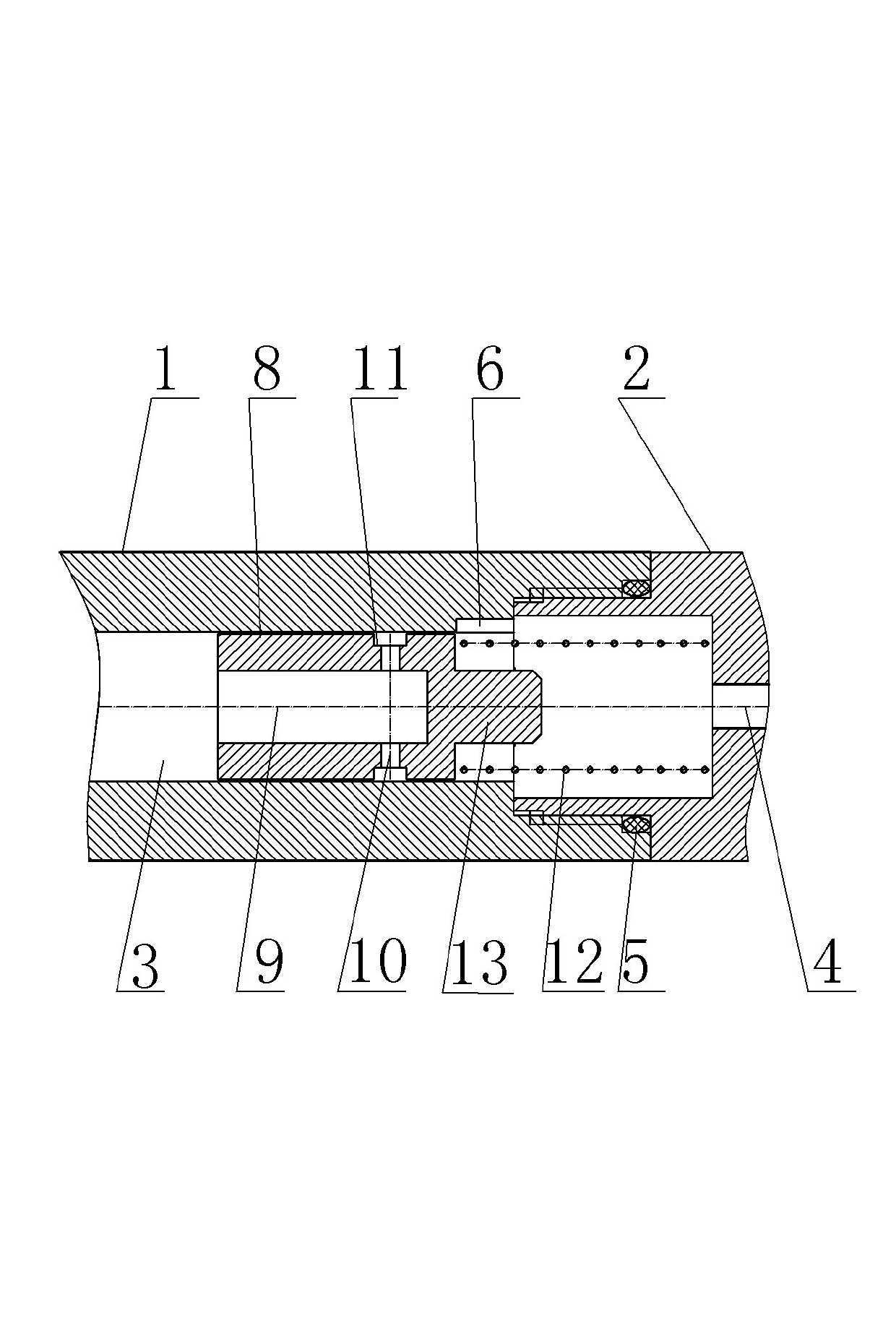

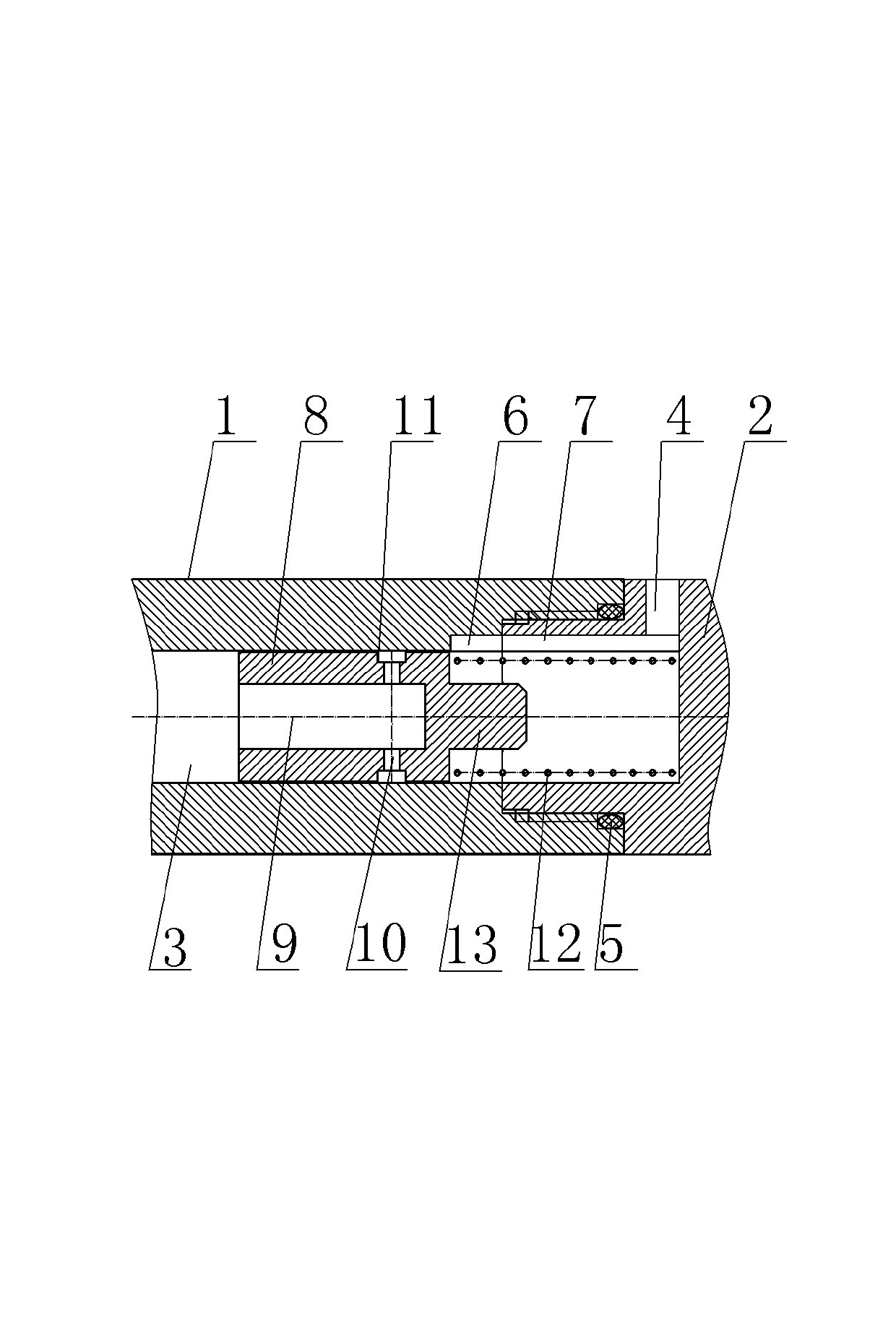

[0019] Embodiment 1 of the auxiliary pressure relief valve of the present invention, such as figure 1 As shown, the slide valve body includes a slide valve body body 1 and a matching body 2. The slide valve body body 1 is a cylindrical structure with two ends open. One end of the slide valve body body 1 has an oil inlet 3, and the other end is connected to the matching body 2 Fixed and sealed connection, the spool body body 1 has an oil outlet hole 4 through the inner and outer walls in the circumferential direction near the end of the fitting body 2, the fitting body 2 is a cylindrical structure with one end open, the opening end of the fitting body 2 and the slide valve body The main body 1 is screwed, and a sealing ring 5 is sandwiched between the mating body 2 and the spool body body 1. The inner wall surface of the end of the spool body body 1 close to the mating body 2 has a first axial length through its corresponding end face. Groove 6, the first long groove 6 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com