Engine cylinder head oil passage hole oiling device

A technology of an engine cylinder and an oiling device, which is applied in the direction of the device and coating of the surface coating liquid, which can solve the problems of low oiling efficiency and poor oiling quality of the oil channel hole, and achieve simple and practical structure, oiling Good quality, effect of reducing flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

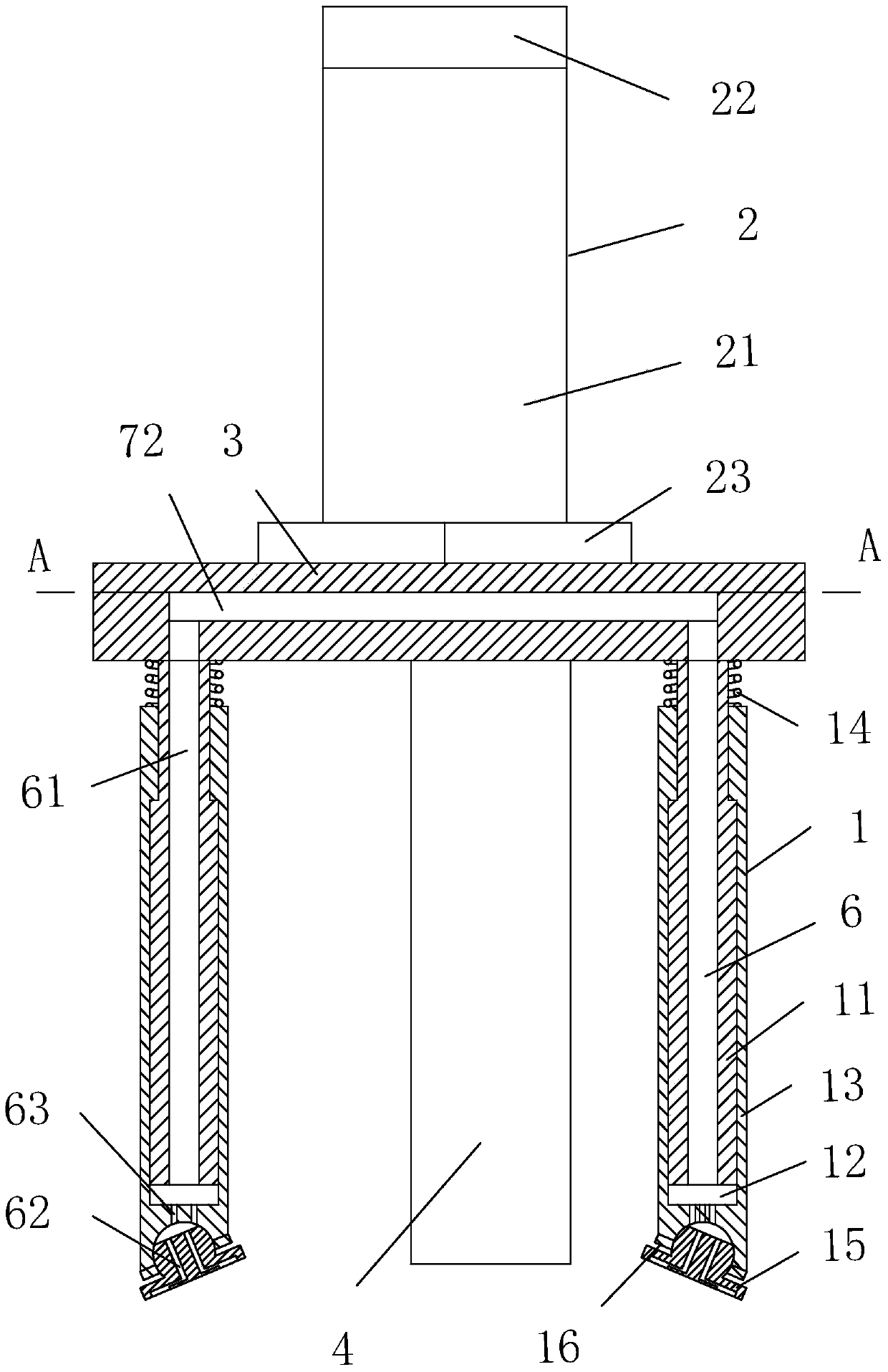

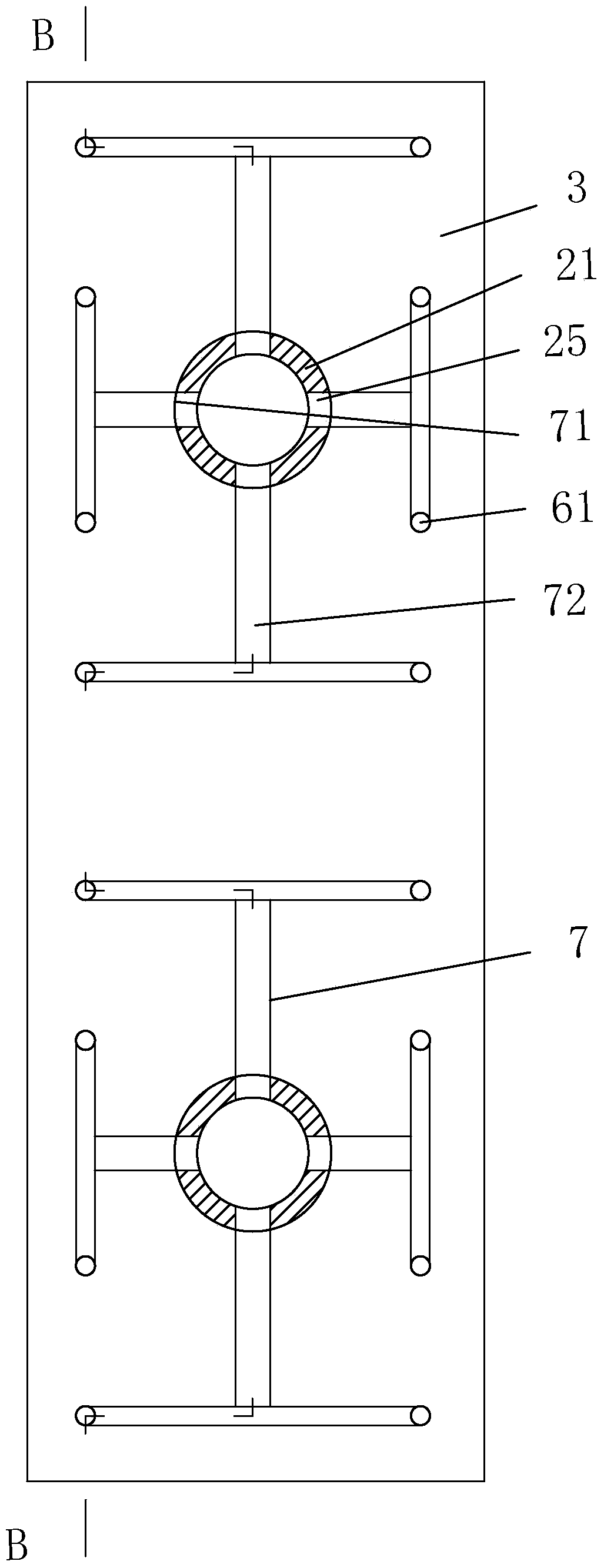

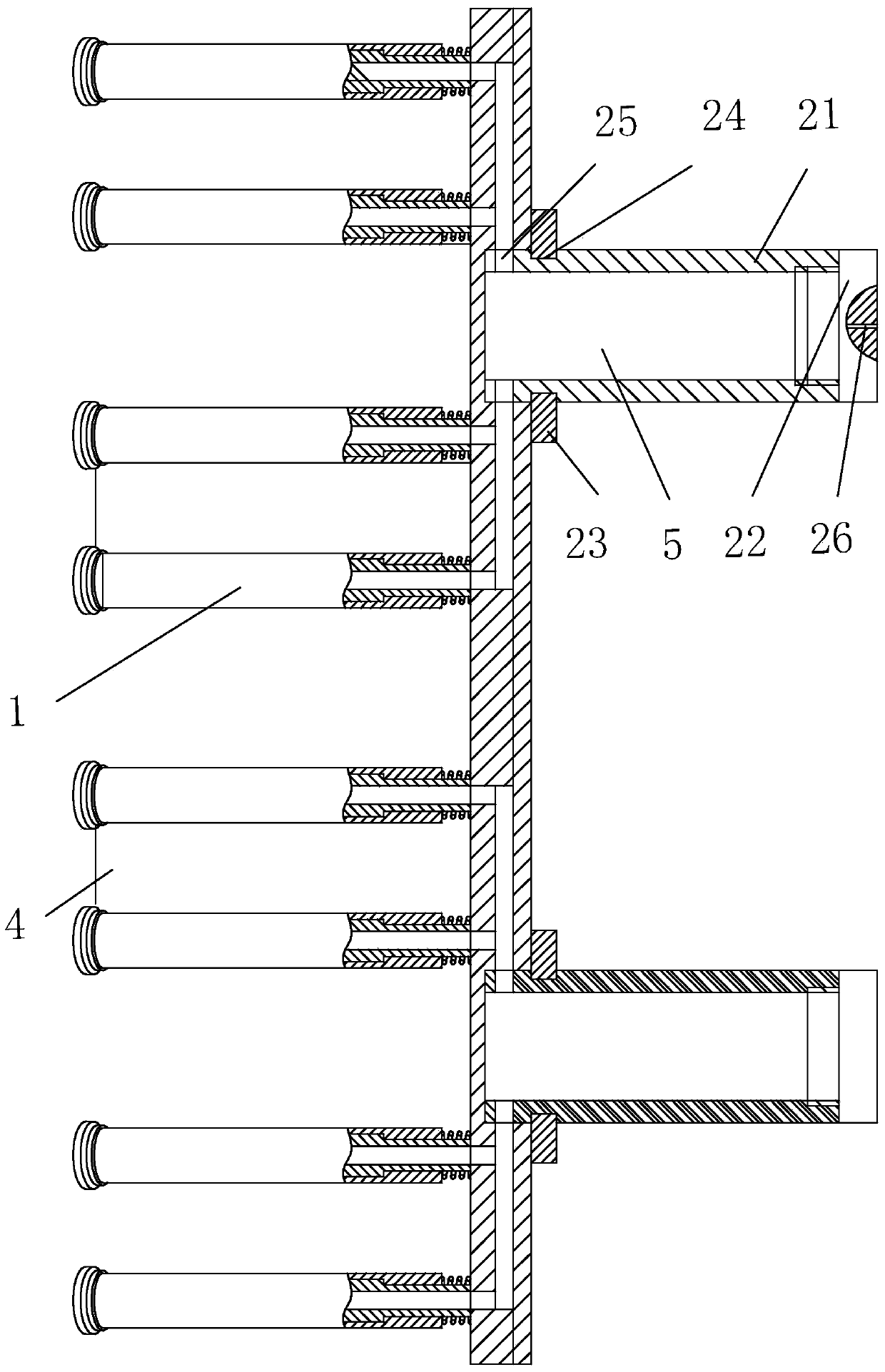

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] as attached figure 1 , attached figure 2 , attached image 3 Shown: an engine cylinder head oil passage hole oiling device, including a fuel rod 1, a mounting plate 3 with a handle 2 on the upper end, a row of positioning columns 4 whose upper end is welded to the lower end of the mounting plate 3; The lower ends of the mounting plates 3 are respectively located in two rows on one side of a row of positioning posts 4 . There are two positioning posts 4 in a row.

[0020] The handle 2 is provided with an oil storage chamber 5; the fuel rod 1 is provided with an oil outlet 6; the mounting plate 3 is provided with a connecting oil passage 7 communicating with the oil storage chamber 5 and the oil outlet 6 respectively.

[0021] The refueling rod 1 includes a stepped mandrel 11 whose small end is welded to the lower end of the mounting plate 3 , and a sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com