Patents

Literature

153results about How to "Improve oiling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

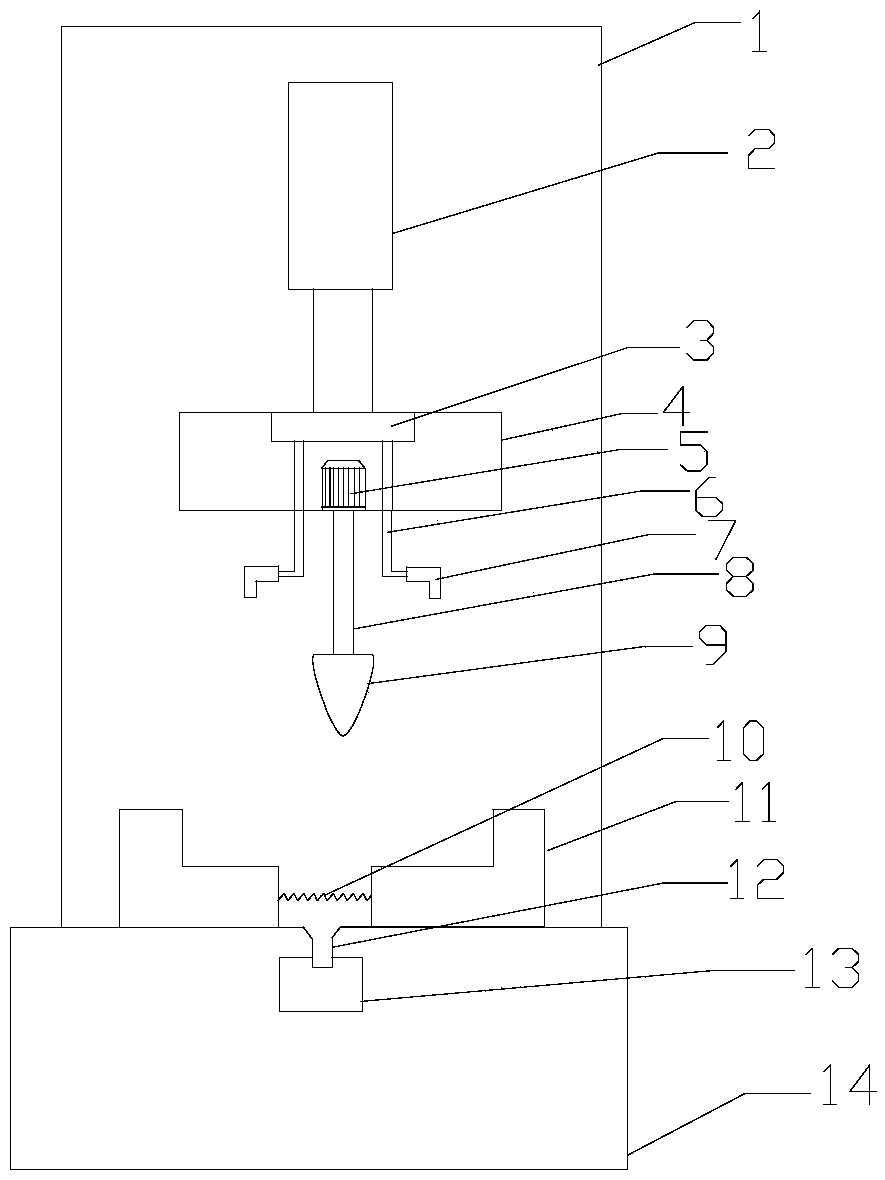

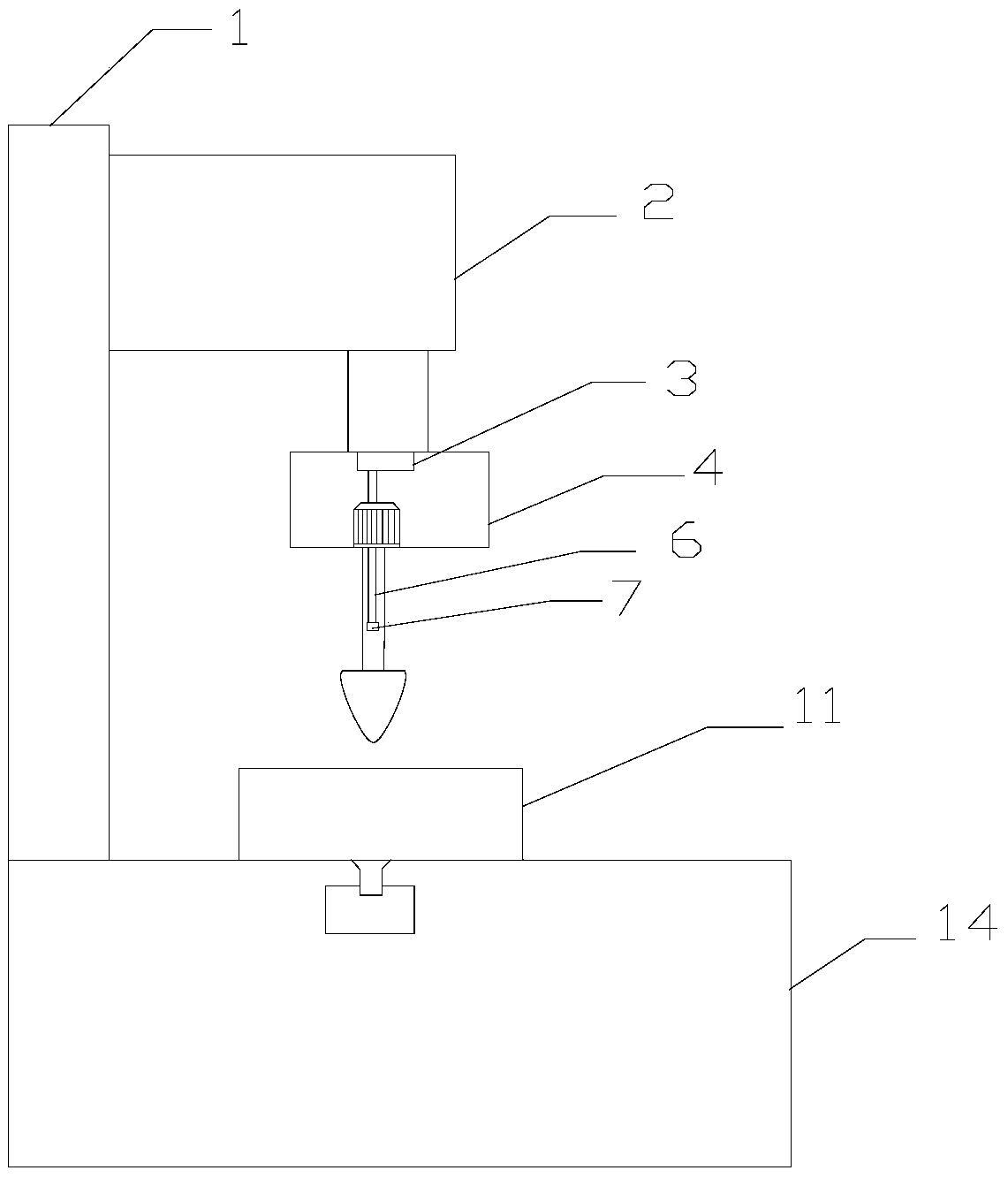

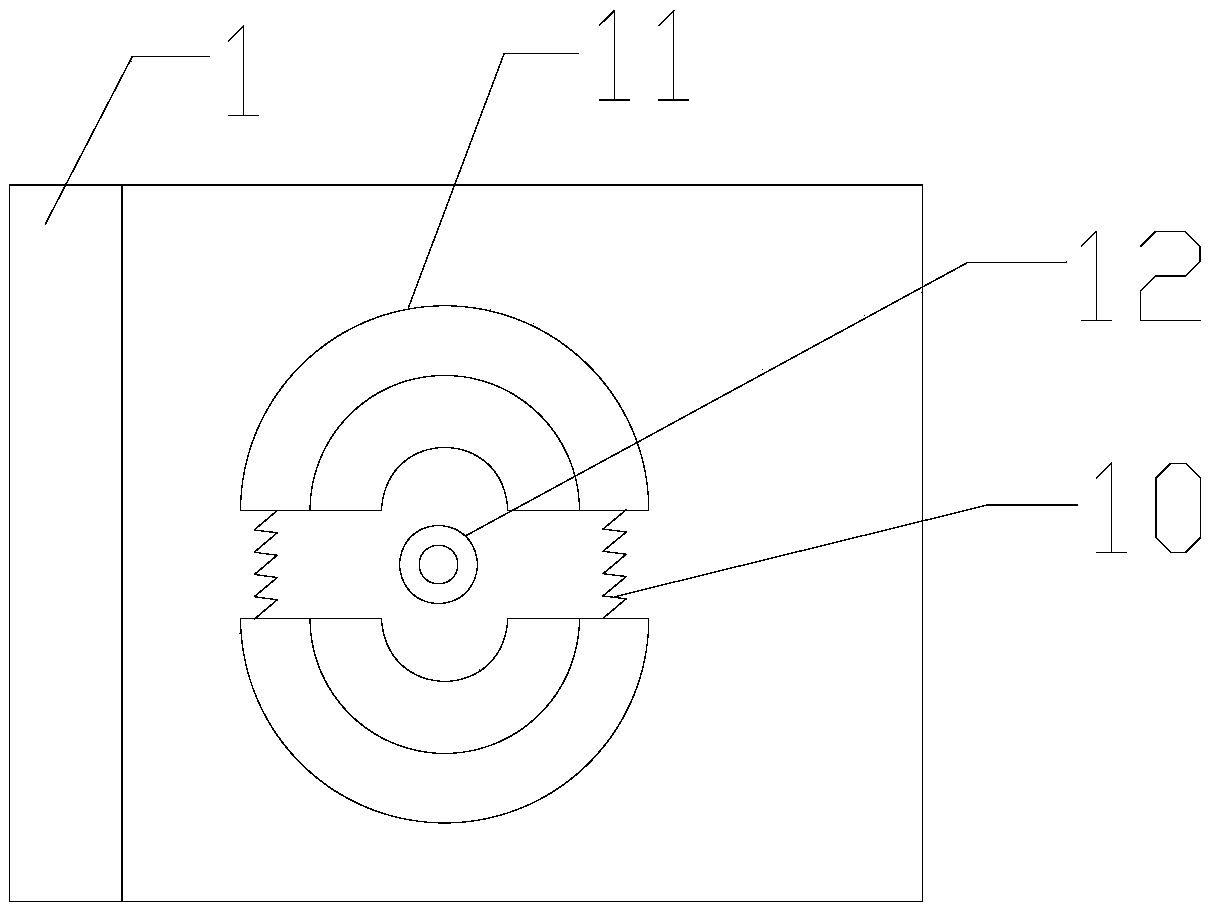

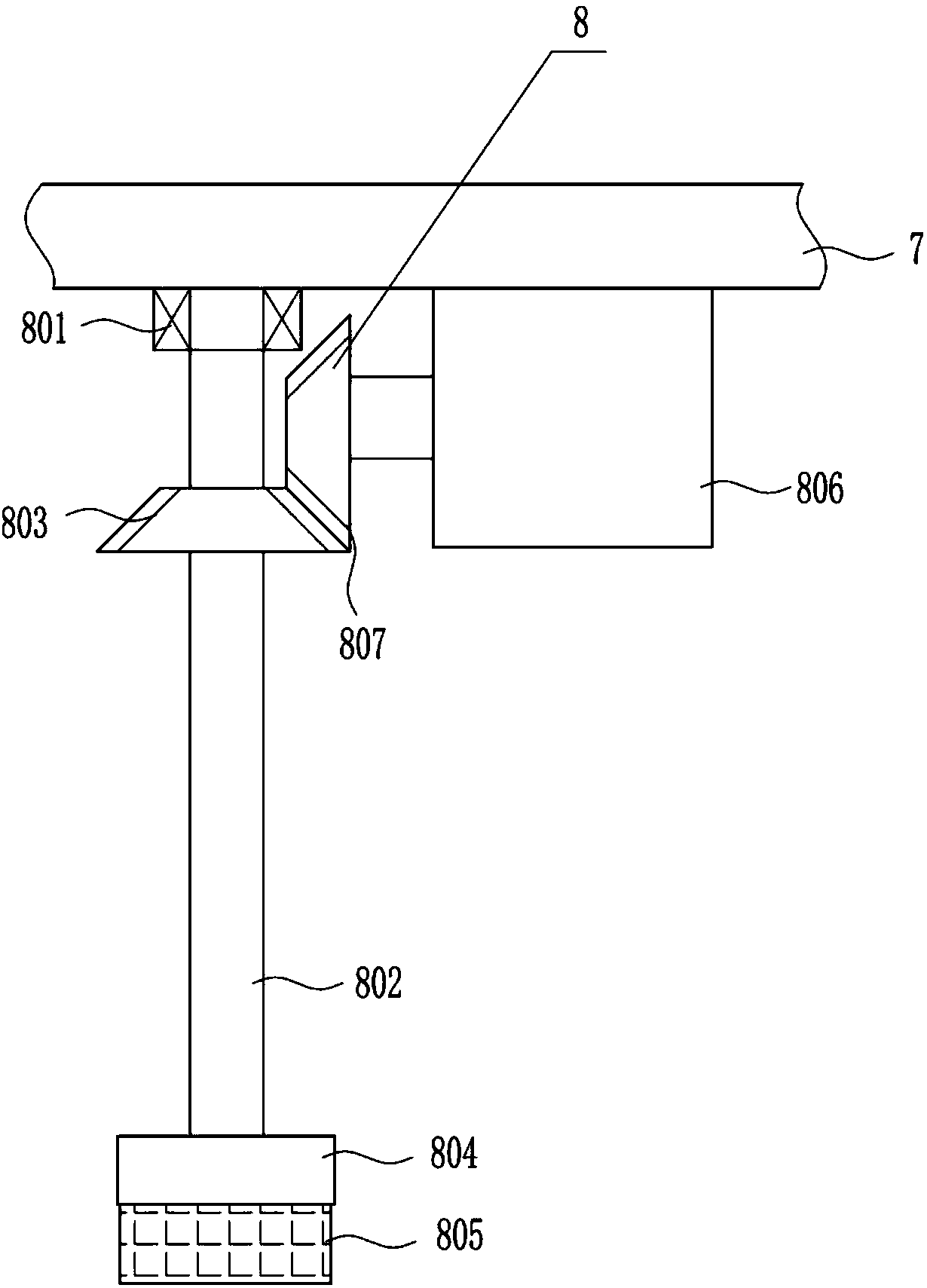

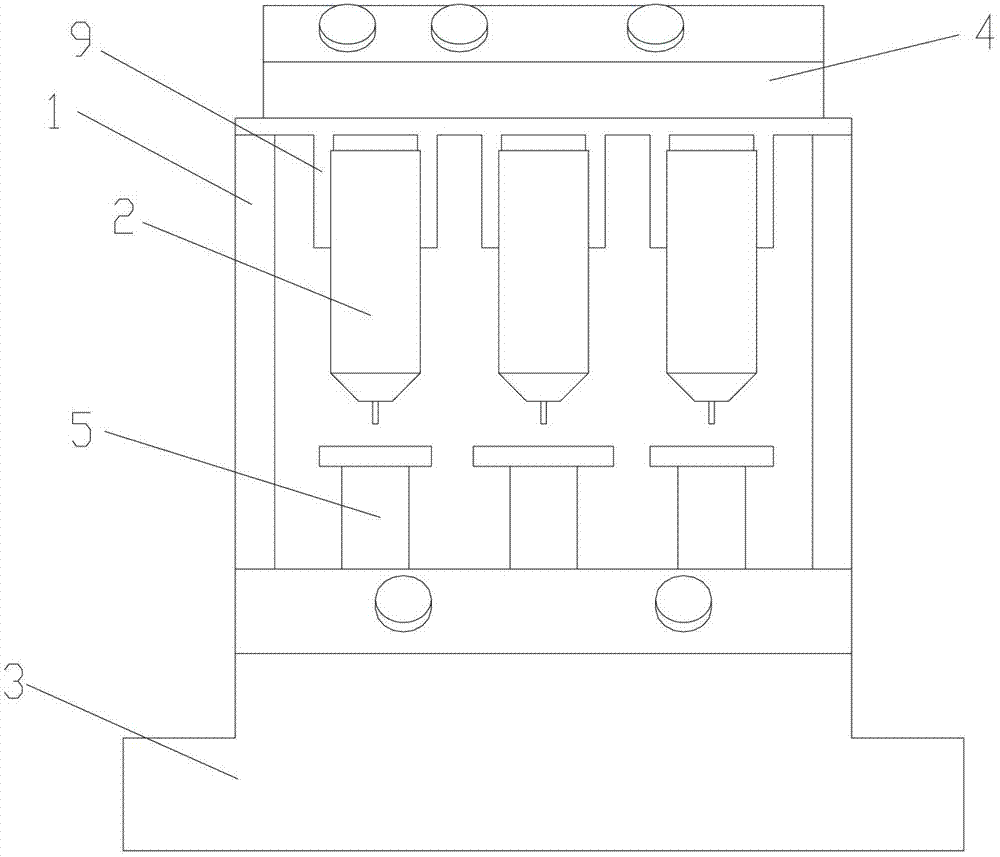

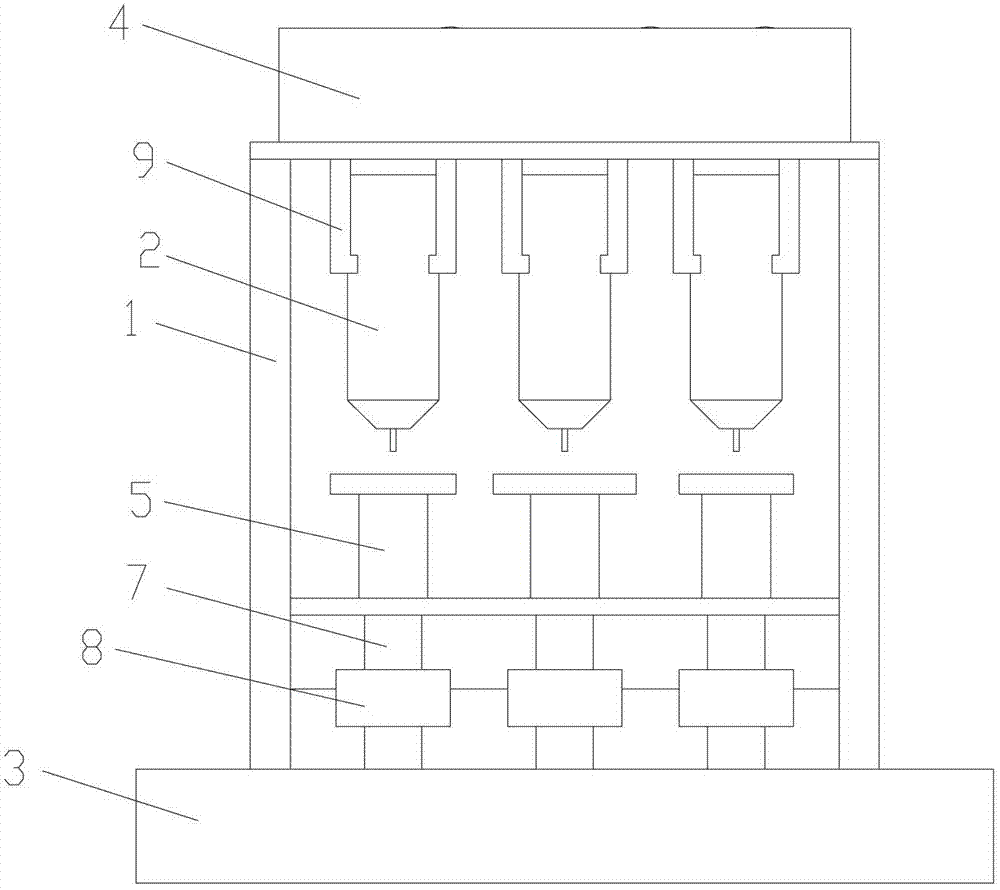

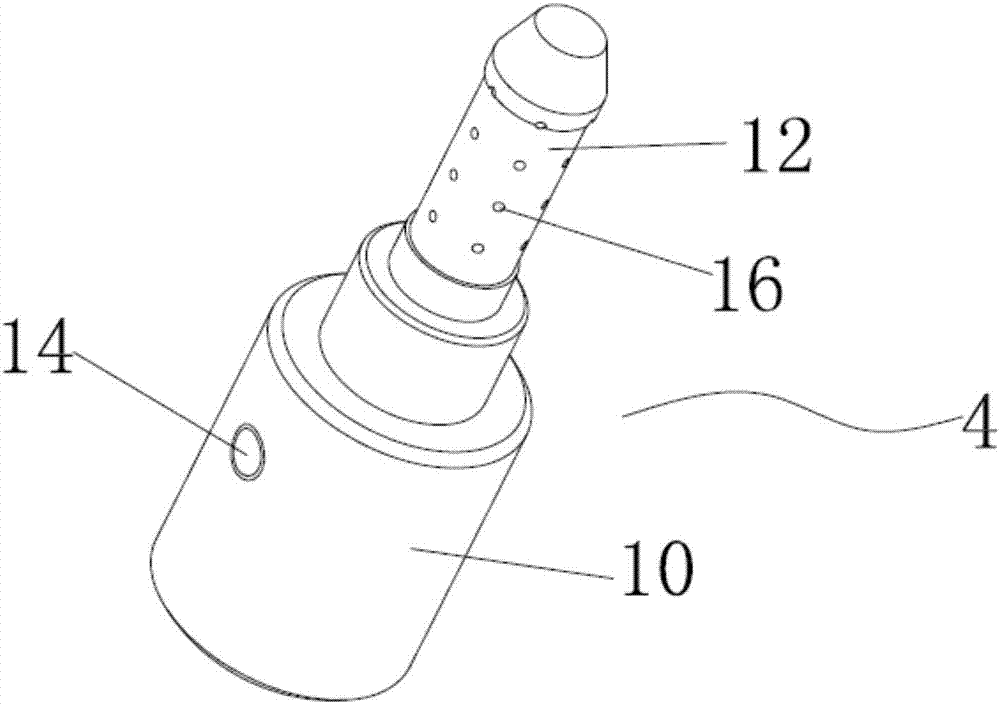

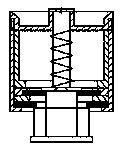

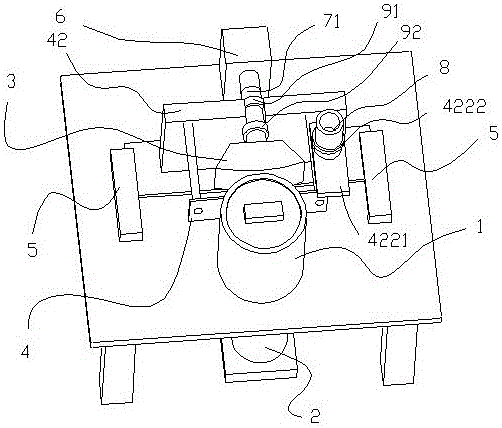

Bearing oil-coating device

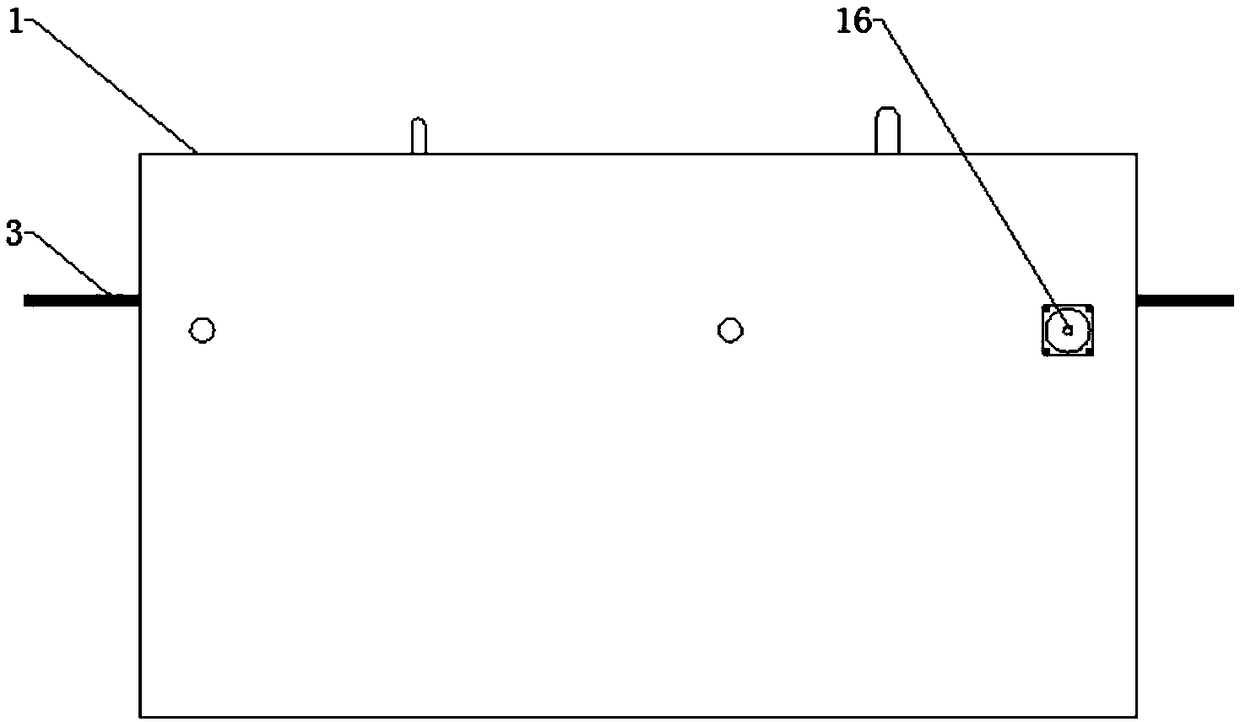

ActiveCN105499022AOil evenlyImprove oiling efficiencyLiquid spraying apparatusRotational axisHydraulic cylinder

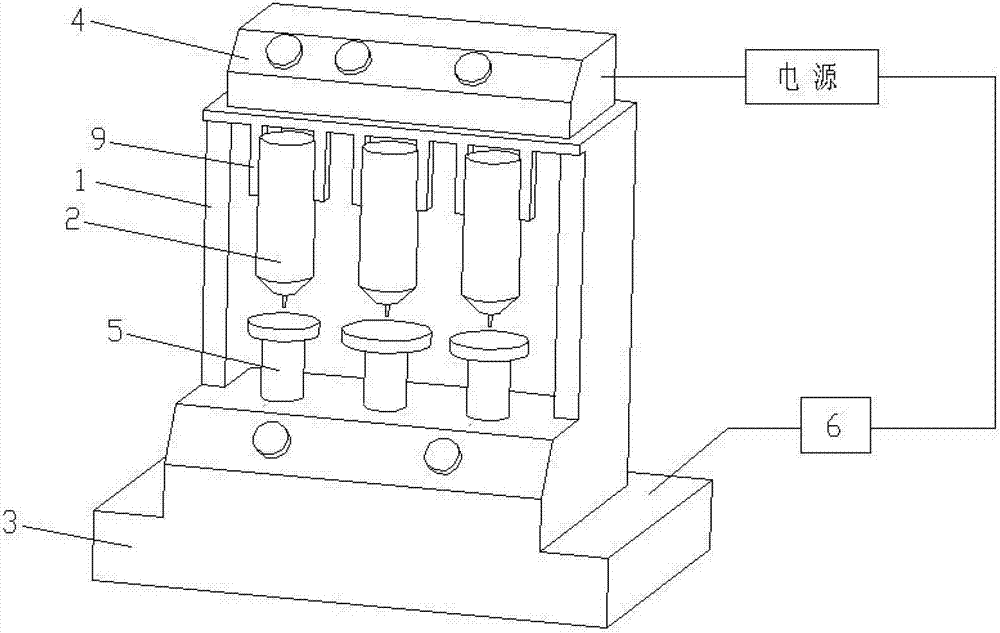

The invention discloses a bearing oil-coating device. The bearing oil-coating device comprises a platform, a fixing support, a hydraulic cylinder, a fixing cover, an oil injection pump, spray pipes, atomized oil spray heads, a rotation motor, a rotation shaft, a tensioning swivel and fixing blocks, wherein the fixing support is vertically fixed at the top of the side surface of the platform; the hydraulic cylinder is fixed at the top of the fixing support; the fixing cover is connected to the lower part of the hydraulic cylinder; the oil fuel injection pump and the rotation motor are installed in the fixing cover; the spray pipes are connected to the oil fuel injection pump; the atomized oil spray heads are installed at the tail ends of the spray pipes; the rotation shaft is connected to the lower part of the rotation motor; the tensioning swivel is installed at the lower end of the rotation shaft; the fixing blocks are installed at the top of the platform; and a waste oil recovery hole is formed in the top of the platform. According to the invention, bearing oil-coating can be automatically carried out, lubricant oil can be saved, the oil-coating efficiency is high, and the oil-coating is uniform; and the equipment is simple in structure, low in investment cost and capable of coating different types of bearings.

Owner:新昌县林泉轴承有限公司

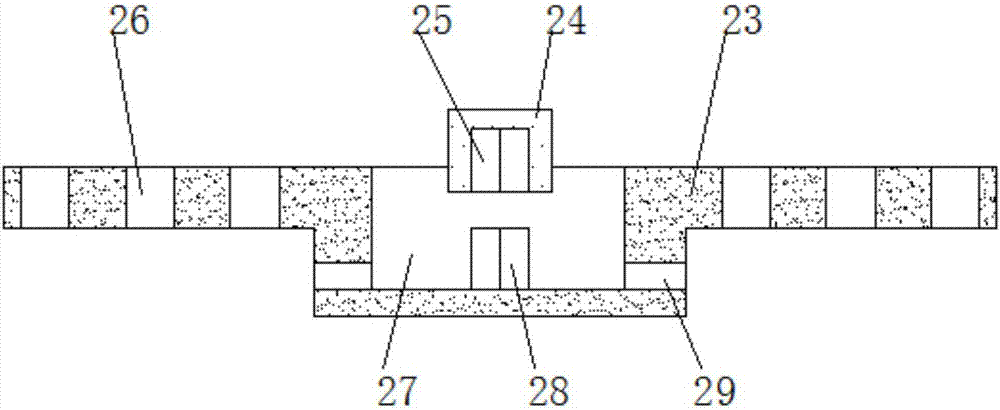

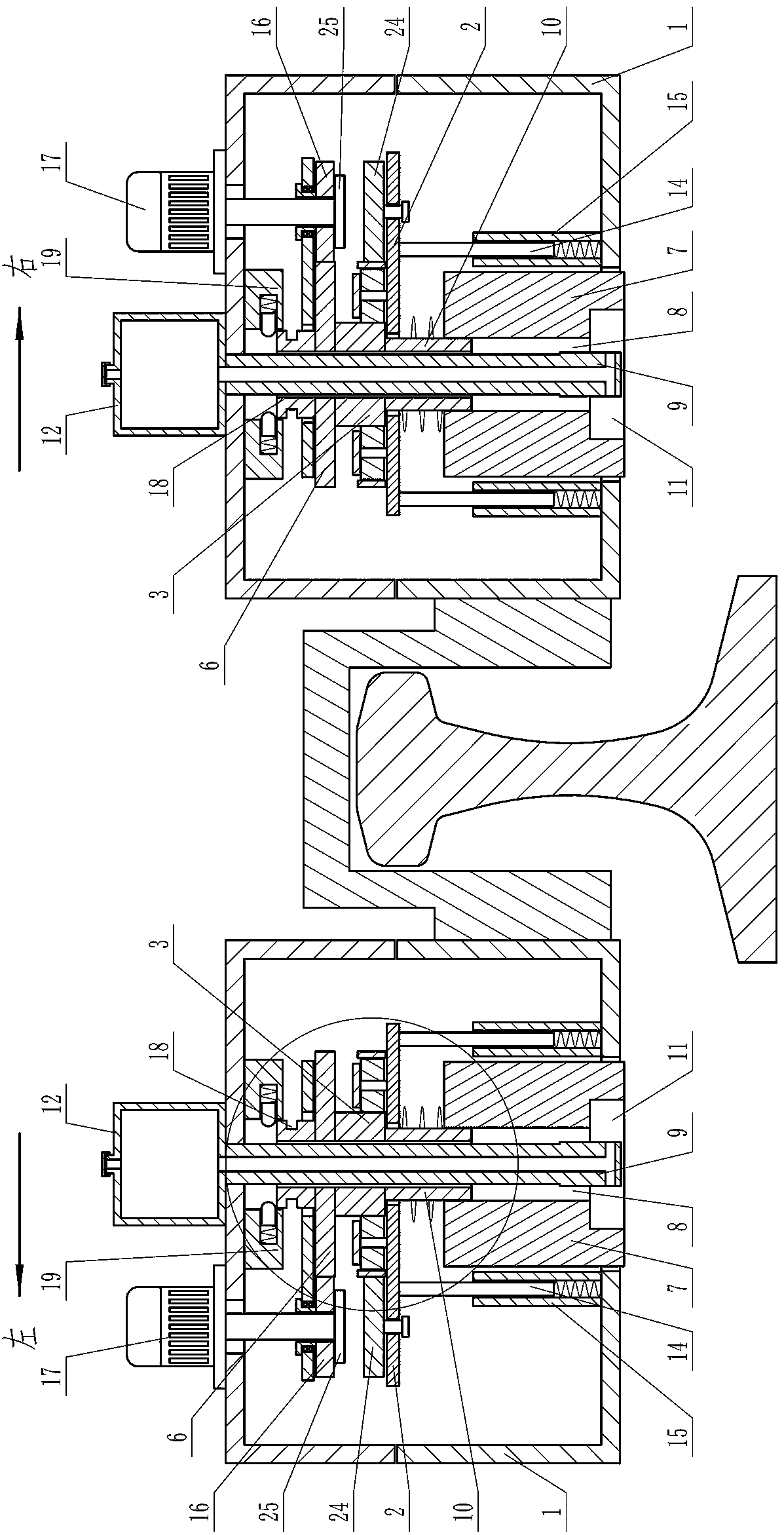

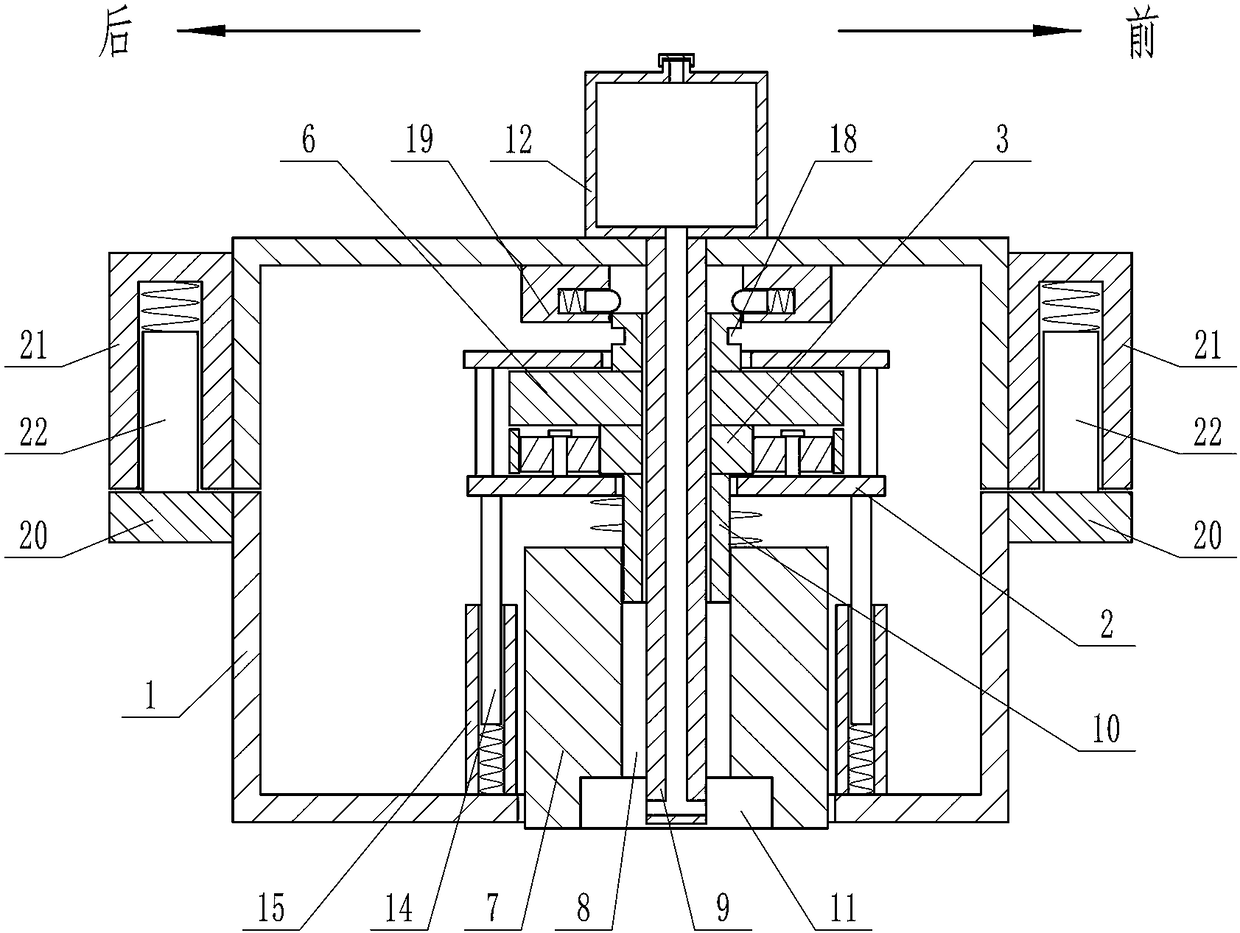

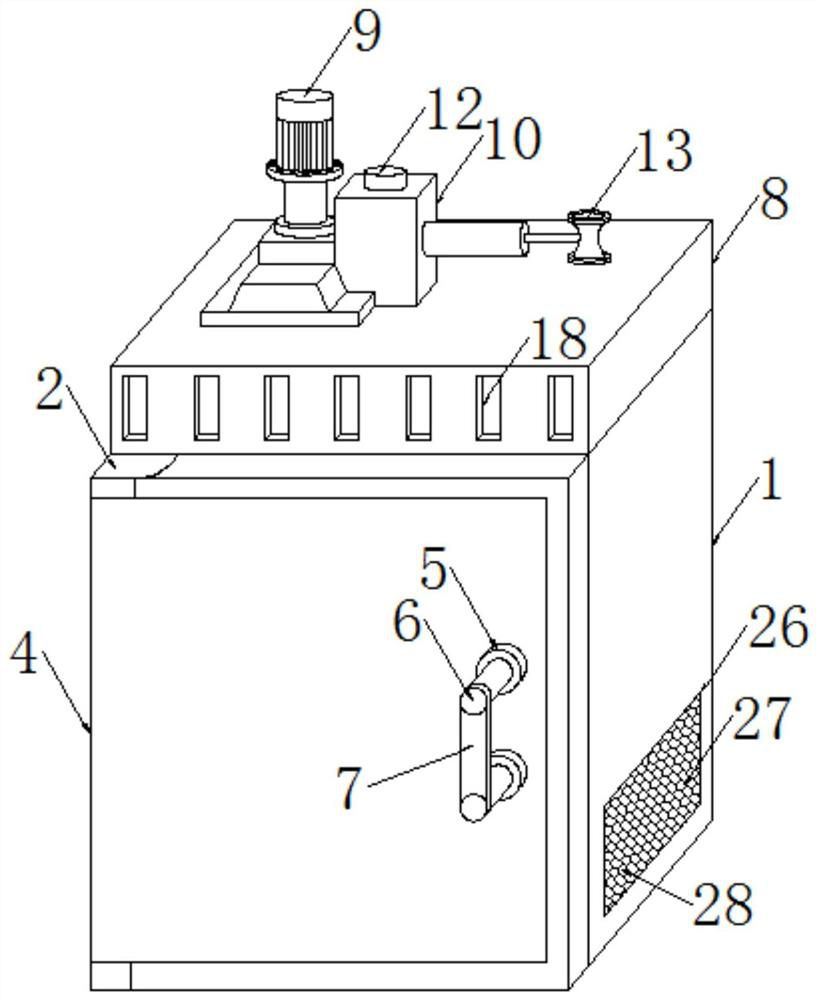

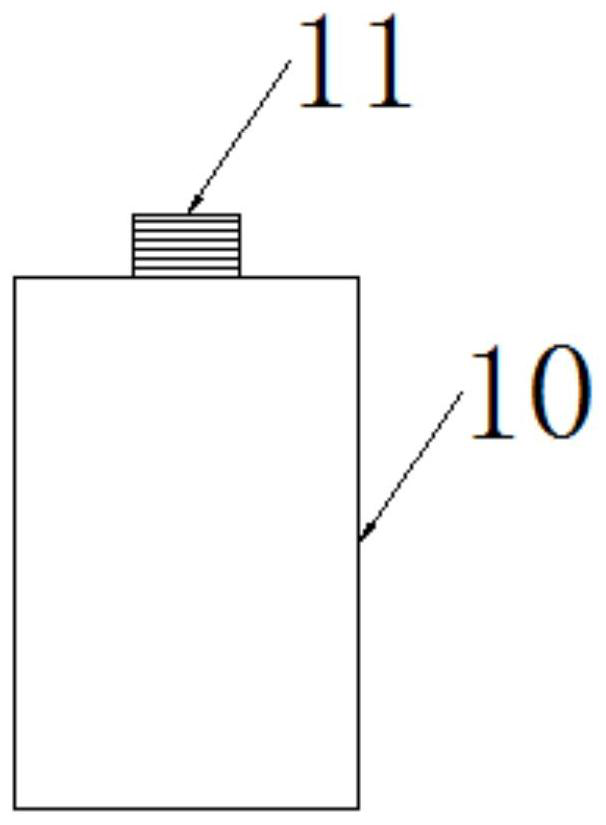

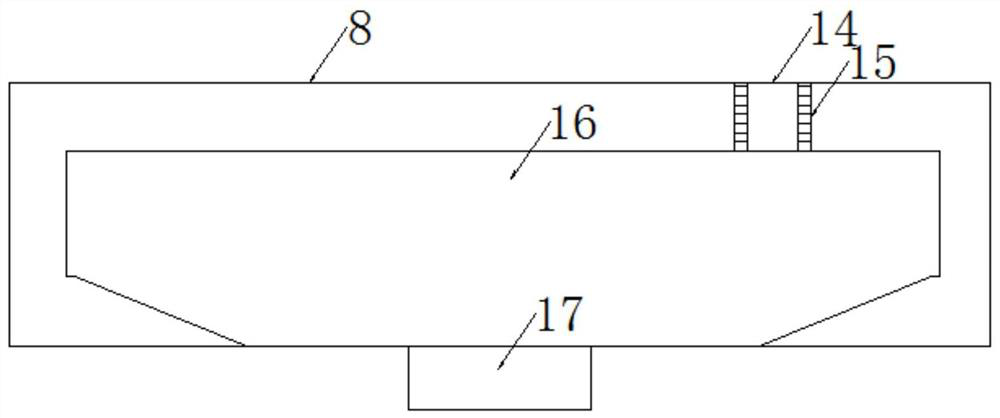

Uniformly-scattered oil-saving type coupler oiling device

The invention discloses a uniformly-scattered oil-saving type coupler oiling device which comprises a workbench; an oil tank is placed below the workbench, the bottom of the inner wall of the oil tank is provided with a filtering mesh hood, four corners of the bottom face of the workbench are all provided with supporting legs in a welded manner, and the four corners of the upper surface of the workbench are provided with supporting pillars in a welded manner. According to the uniformly-scattered oil-saving type coupler oiling device, a drive motor drives a rotary table to rotate and thus drives a coupler to rotate, therefore lubricating oil sprayed on the surface of the coupler by a spray pipe is scattered uniformly under the effects of centrifugal force and gravity, and oiling performed on the coupler is uniform; and meanwhile, oiling efficiency is high, the rotary table is provided with first through holes and second through holes, the lubricating oil of the coupler on the rotary table is discharged into an oil collection slot conveniently, the dropped lubricating oil is collected through the oil collection slot, the lubricating oil is guided into the oil tank through an oil guiding pipe for reuse, utilization of the lubricating oil is thorough, and the oil-saving effect is good.

Owner:徐州海马机械制造有限公司

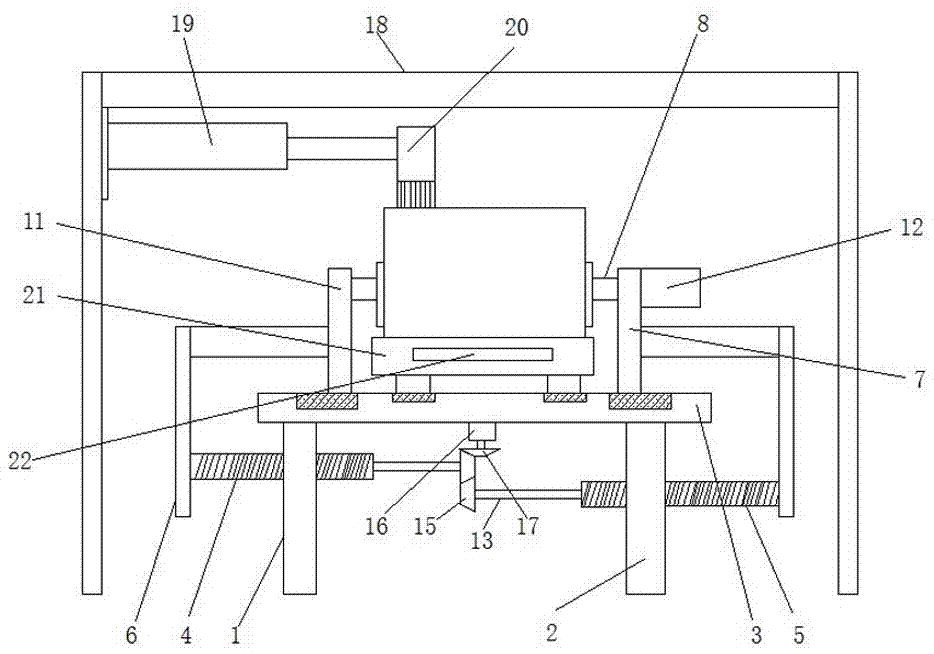

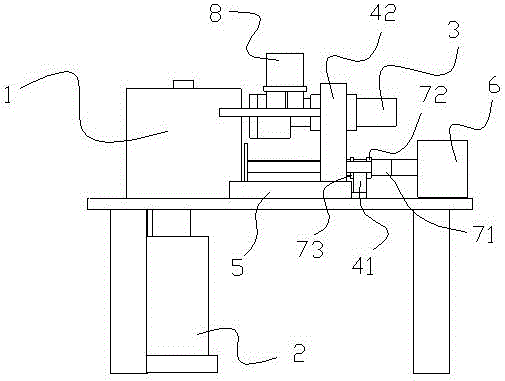

Automatic oil painting device for automobile part

InactiveCN107225068APractical and convenientHigh oiling quality and efficiencyLiquid surface applicatorsCoatingsSlide plateThreaded rod

The invention discloses an automatic oil painting device for an automobile part. The automatic oil painting device comprises a first vertical supporting plate and a second vertical supporting plate. A horizontal supporting plate is fixedly installed at the top ends of the first vertical supporting plate and the second vertical supporting plate, a first threaded hole and a second threaded hole are formed in the first vertical supporting plate and the second vertical supporting plate correspondingly, and the first threaded hole and the second threaded hole are internally in threaded connection with a first threaded rod and a second threaded rod correspondingly; the ends, away from each other, of the first threaded rod and the second threaded rod are fixedly connected with fixing rods, and the top ends of the two fixing rods are fixedly connected with a first sliding plate and a second sliding plate correspondingly; and the first sliding plate is slidably connected with the top end of the horizontal supporting plate, and the second sliding plate is slidably connected with the top end of the horizontal supporting plate. According to the automatic oil painting device, the structure is reasonable, use is convenient, the automobile part can be automatically clamped and painted with oil, the oil painting quality is better, and efficiency is higher.

Owner:合肥杰代机电科技有限公司

Leather bag oiling device used for leather production

InactiveCN107790321AAchieve the purpose of oilingIncrease productivityPretreated surfacesSkins/hides/leather/fur manufacturing apparatusEngineering

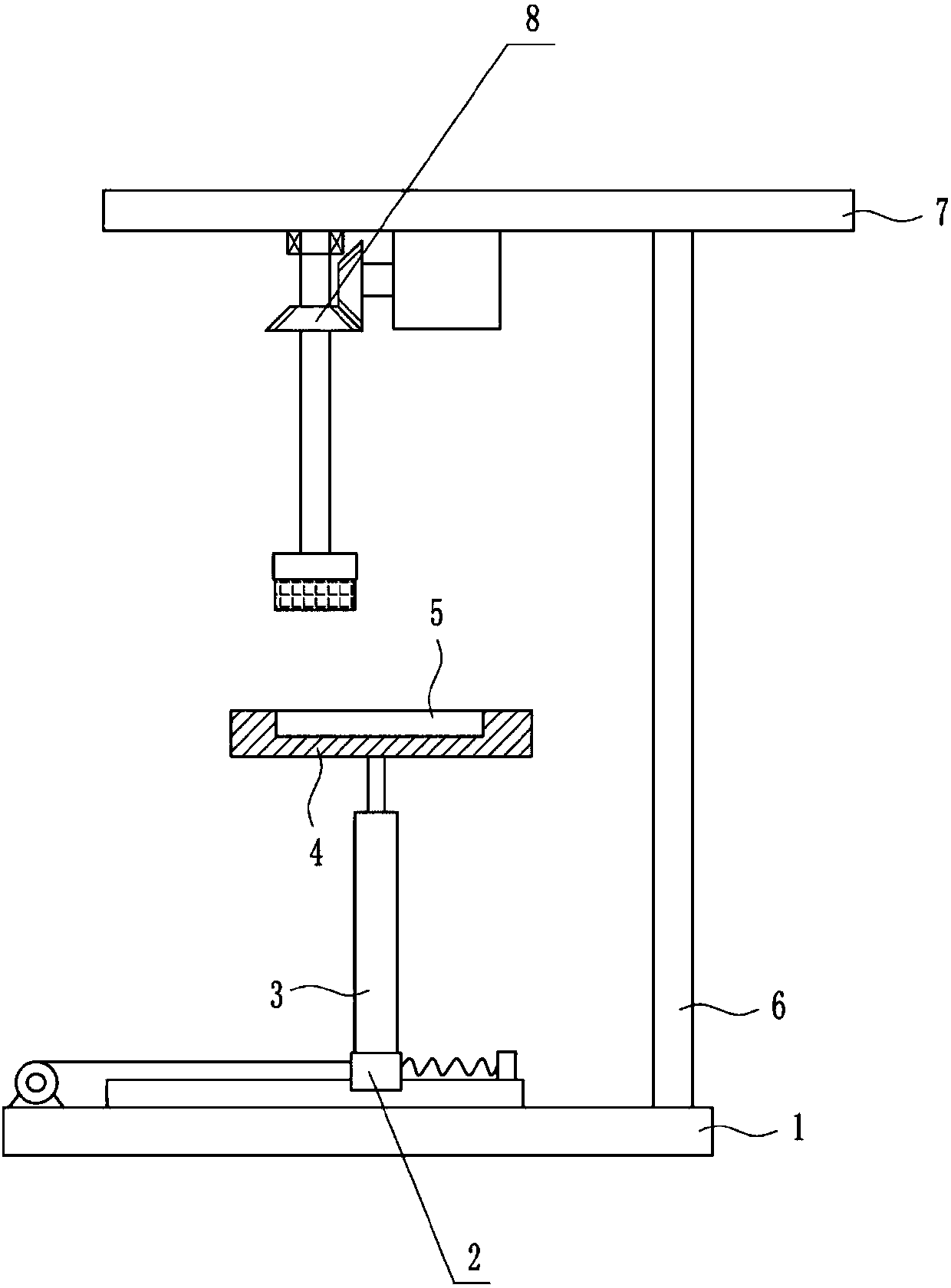

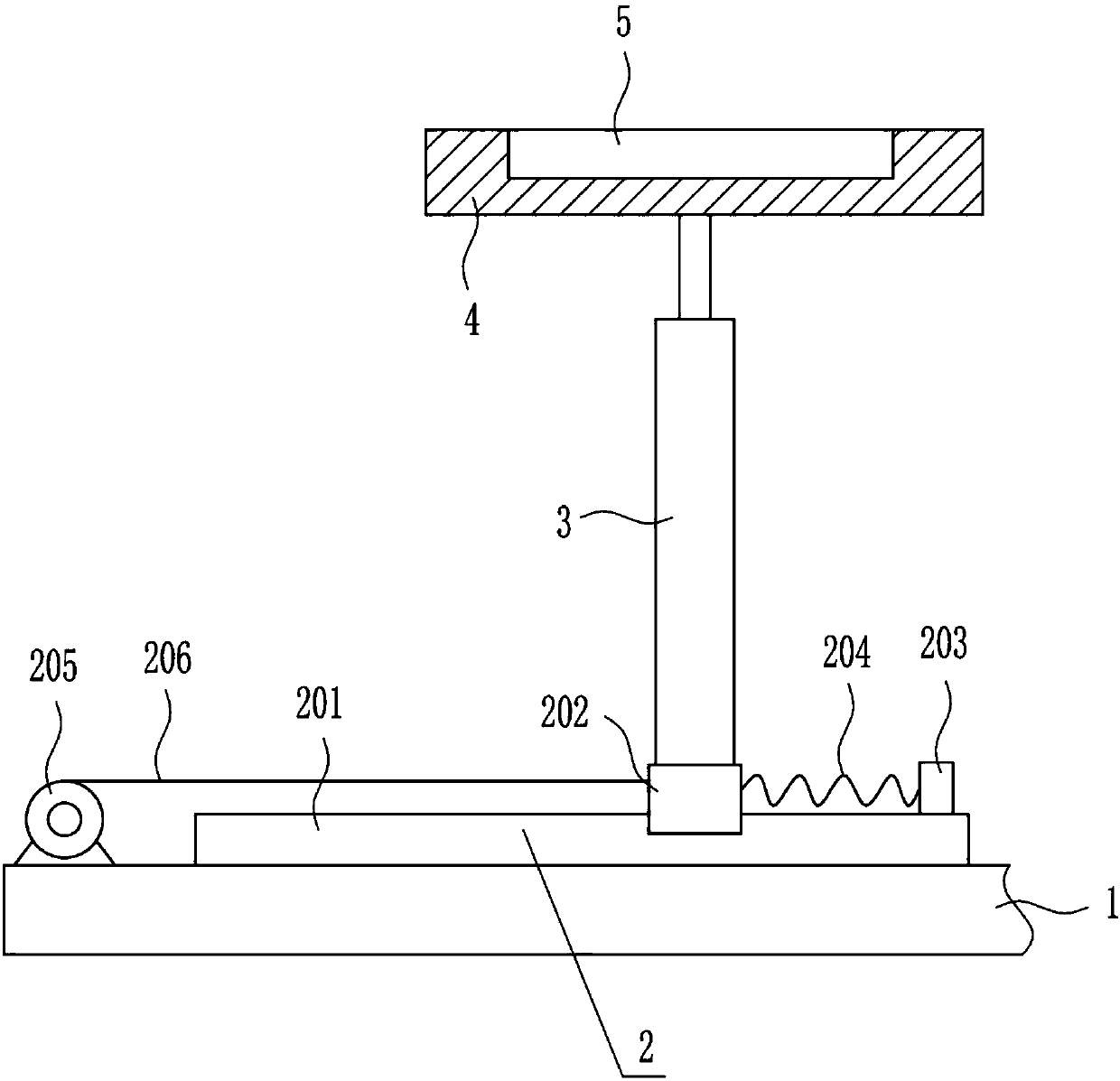

The invention relates to an oiling device used for leather production, in particular to a leather bag oiling device used for leather production. According to the technical purpose, the leather bag oiling device used for leather production can be used for relieving the labor intensity of workers and improving the oiling efficiency and the production efficiency of leather bags. To achieve the technical purpose, the leather bag oiling device used for leather production is provided and comprise a bottom plate and the like; and a left-right moving device is arranged at the top of the bottom plate,a first air cylinder is mounted on the left-right moving device, a telescopic rod of the first air cylinder is connected with a holding plate through a bolt, a holding groove is formed in the top of the holding plate, and the top of the portion, at the right side of the left-right moving device, of the bottom plate is vertically connected with a supporting plate through a bolt. According to the oiling device, horse oil can be smeared on the leather bags through a smearing device, so that the purpose of oiling of the leather bags is achieved, and accordingly, the effects that the labor intensity of the workers is relieved, and the oiling efficiency and the production efficiency of the leather bags can be improved are achieved.

Owner:孙梦

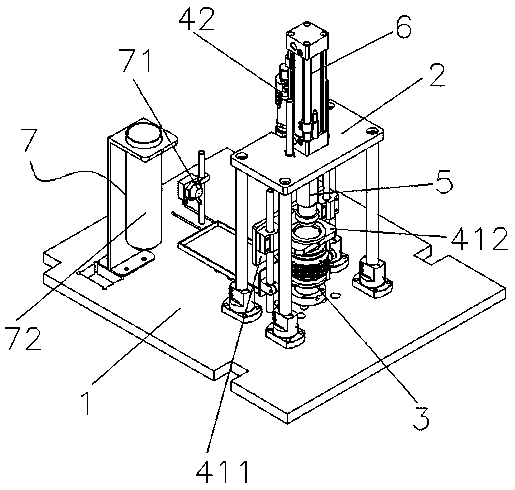

Quick oiling equipment for bearing

InactiveCN108126863AFast oilOiling is efficient and fastLiquid surface applicatorsCoatingsFuel tankEngineering

The invention discloses quick oiling equipment for a bearing. The quick oiling equipment comprises a base, a rack, a mounting plate, a sink tank, a motor, poke rods, an oil storage tank, an oil suction tank, a sponge mat, an oil outlet, an oil storage box, an aspirator pump, a discharge port, a sponge layer, a material receiving box and a discharging hopper, wherein the rack is fixedly arranged atone end of the base; the horizontally arranged mounting plate is fixedly arranged on the lateral part of the rack; the round sink tank is formed in the upper part of the mounting plate; a motor, theoutput shaft of which is vertically arranged upward, is fixedly arranged right below the sink tank on the upper portion of the base; the output shaft of the motor penetrates through the center of circle of the sink tank and extends to the upper side of the sink tank; and the plurality of uniformly distributed poke rods are fixedly arranged on the lateral part of the upper end of the output shaft of the motor radially. Compared with the prior art, the quick oiling equipment disclosed by the invention can oil the bearing efficiently and quickly, so that the oiling efficiency and effect of the bearing are enhanced, the processing environment is prevented from being polluted by residual lubricating oil effectively, and the labor intensity of workers is reduced.

Owner:XINCHANG SANYUAN BEARING CO LTD

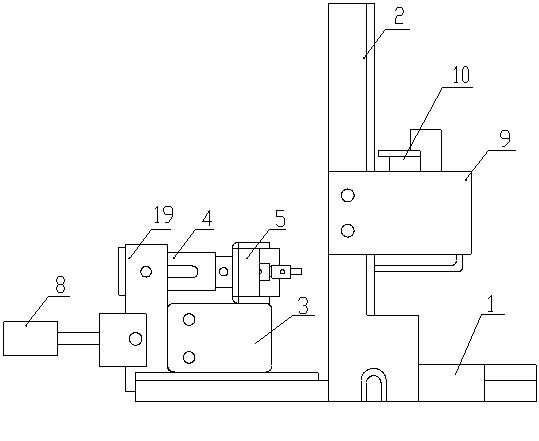

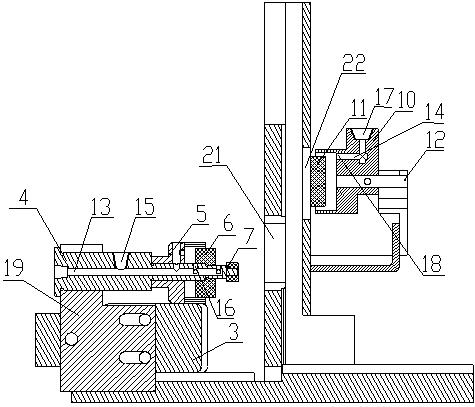

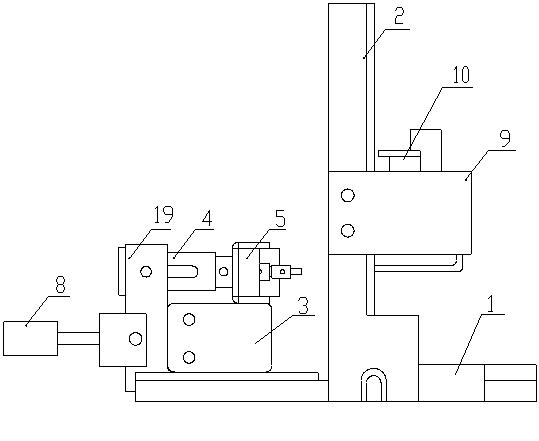

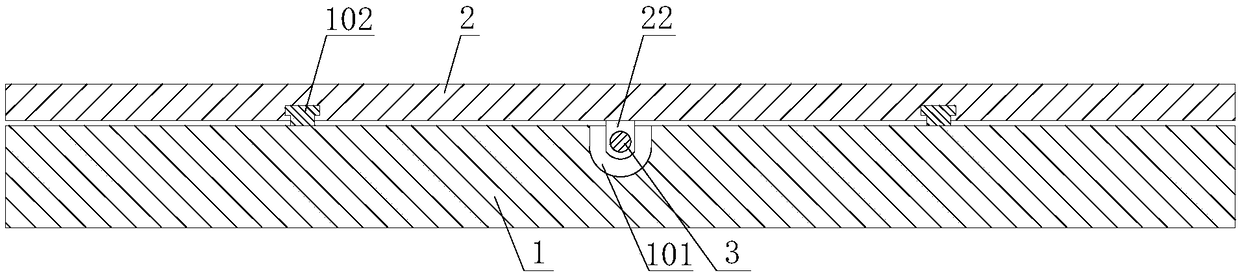

Full automatic bearing oiling device

InactiveCN102029238AReduce oiling timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineering

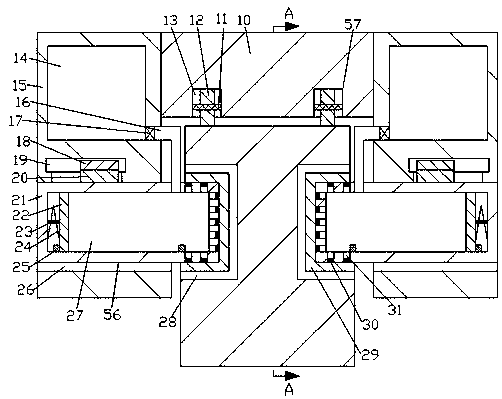

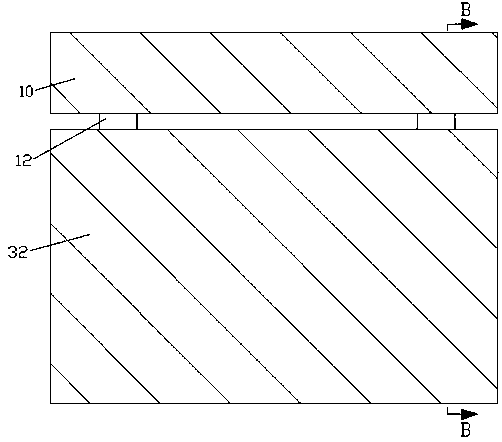

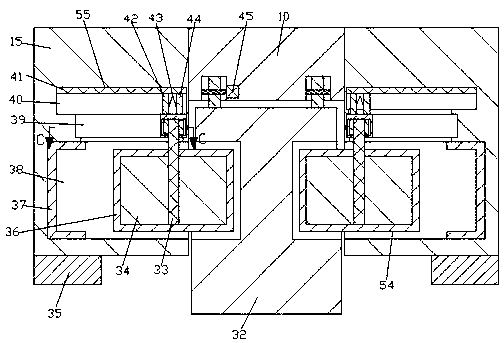

The invention discloses a full automatic bearing oiling device, and relates to an oiling device. The full automatic bearing oiling device comprises a base, wherein the middle part of the base is fixedly connected with a vertically arranged bearing channel; a support is arranged on the left side of the bearing channel; a sliding block is connected with the support in a sliding mode in the transverse direction; the upper top end of the sliding block is fixedly connected with a material pushing shaft; the left end of the sliding block is connected with a first cylinder; the right part of the material pushing shaft is sleeved with an erasing head clip; the right end of the erasing head clip is fixedly connected with a big sponge block on the left side; the right end of the material pushing shaft is fixedly connected with a small sponge block on the left side; the middle part on the right side of the bearing channel is fixedly connected with a fixed plate; the fixed plate is fixedly connected with a fixed block; a pull rod is arranged in the middle part of the fixed block; one end, facing the bearing channel, of the fixed block is fixedly connected with a big sponge block on the right side; one end of the push rod is fixedly arranged in the fixed block; and the other end of the push rod is connected with a second cylinder. The invention ensures that the oiling of a bearing is performed automatically, the oiling time is shortened, and the oiling efficiency and the production efficiency are greatly improved.

Owner:JIANGSU YILITONG TECH

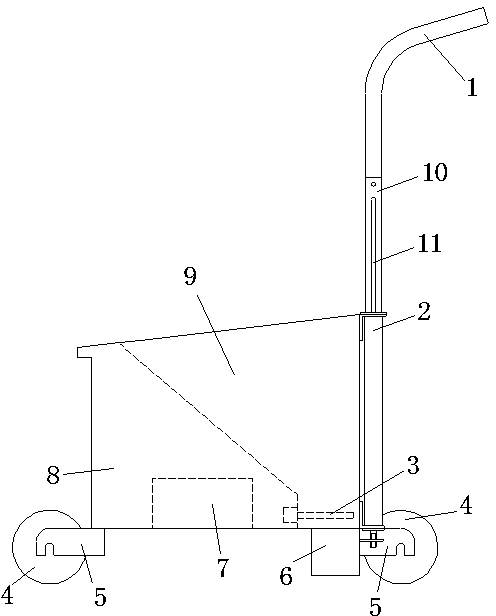

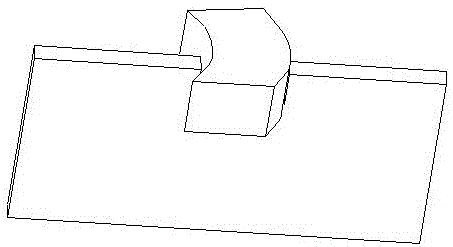

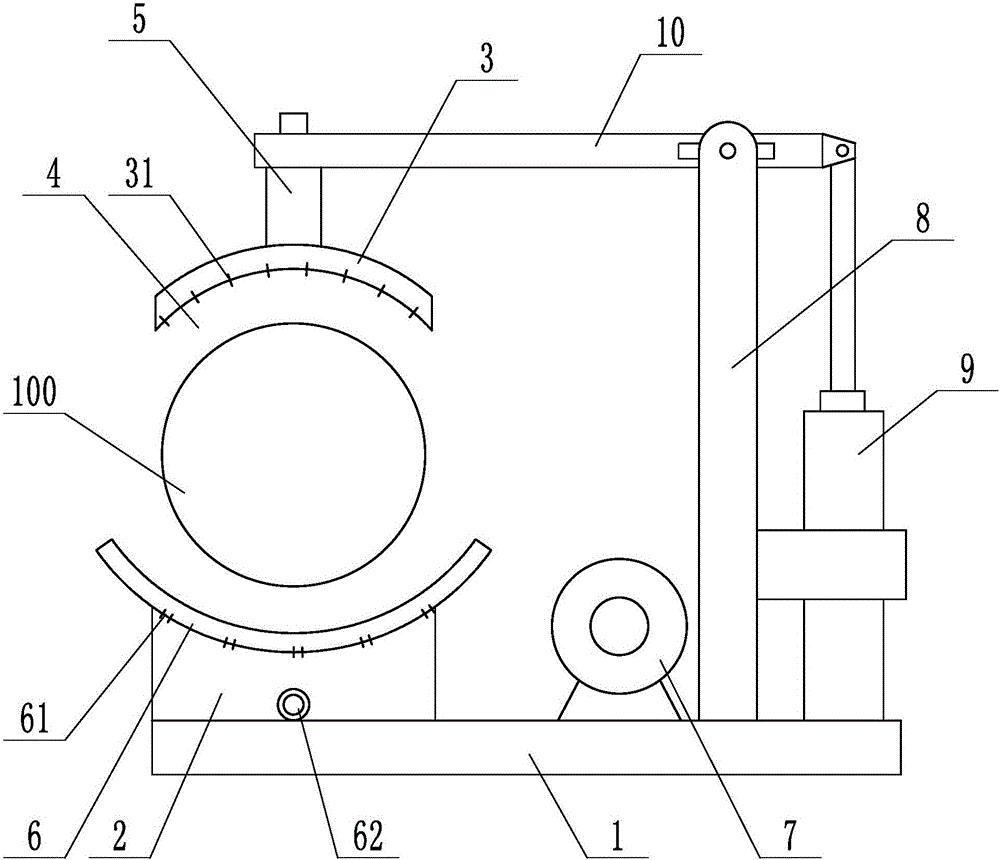

Crane track cleaning and oil-coating equipment

ActiveCN110844776ASimple structureEasy to operateCleaning using toolsConduits/junctionsMarine engineeringMechanical engineering

The invention discloses crane track cleaning and oil-coating equipment. The crane track cleaning and oil-coating equipment comprises a track, wherein two track slots which communicate with an externalspace are formed in the track; the upper side of the track is equipped with a supporting block for supporting the device; a rolling mechanism capable of being driven to move is arranged in the supporting block; left and right ends of the supporting block are fixedly equipped with supporting tables; oil-coating mechanisms capable of realizing automatic oil-coating on the track slots are arranged in the supporting tables; and each oil-coating mechanism penetrates through a moving cavity at the lower end of each supporting table. The equipment is simple in structure, is convenient in operation,can accomplish track cleaning under a relatively small abrasion condition by moving cleaning sponge; moreover, oil-coating can be immediately accomplished after cleaning, so that oil-coating efficiency is improved; and in a cleaning process, clearing and collecting for an oil and dust mixture adhered on the cleaning sponge are automatically accomplished, and therefore, follow-up cleaning quality is guaranteed.

Owner:浙江金果知识产权有限公司

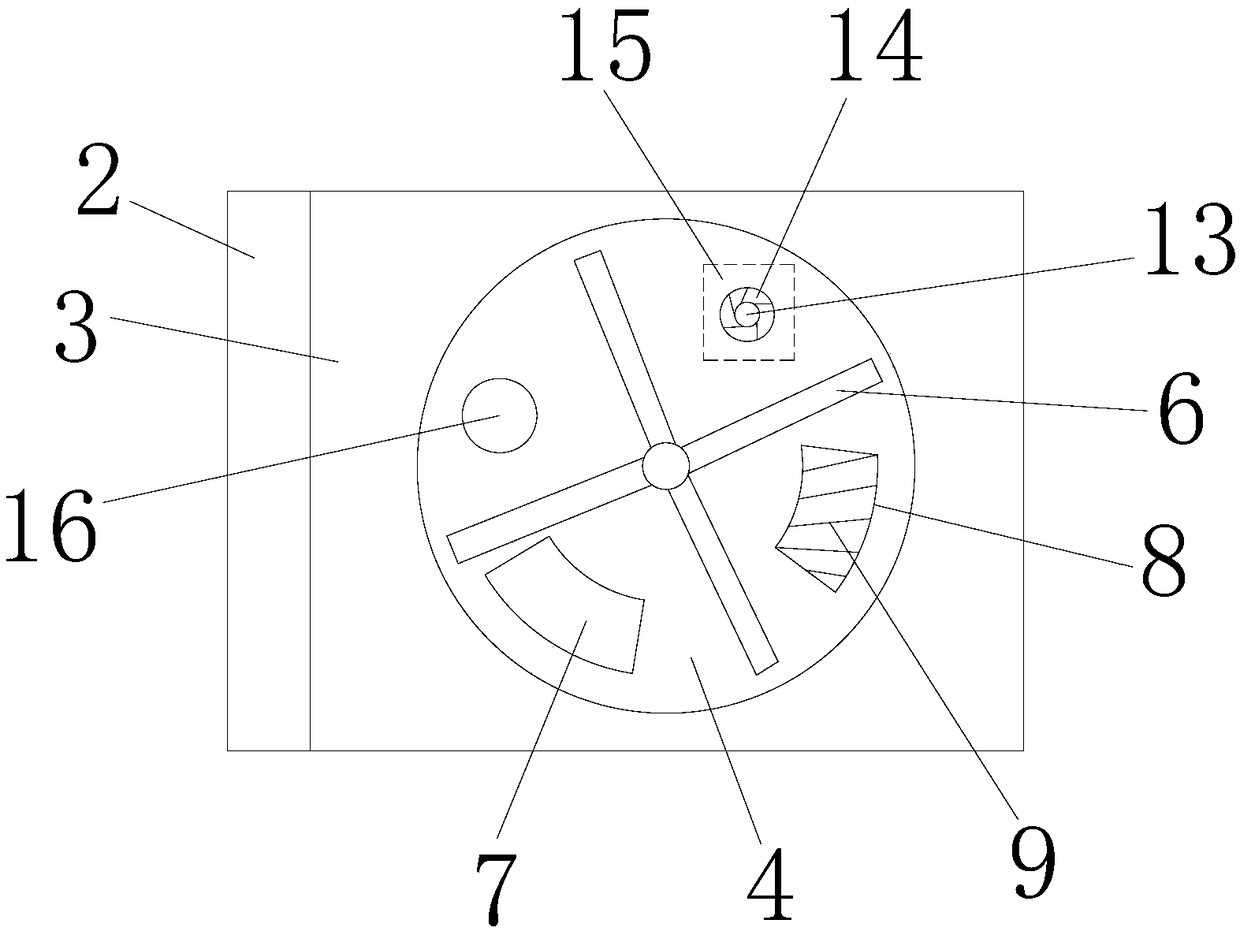

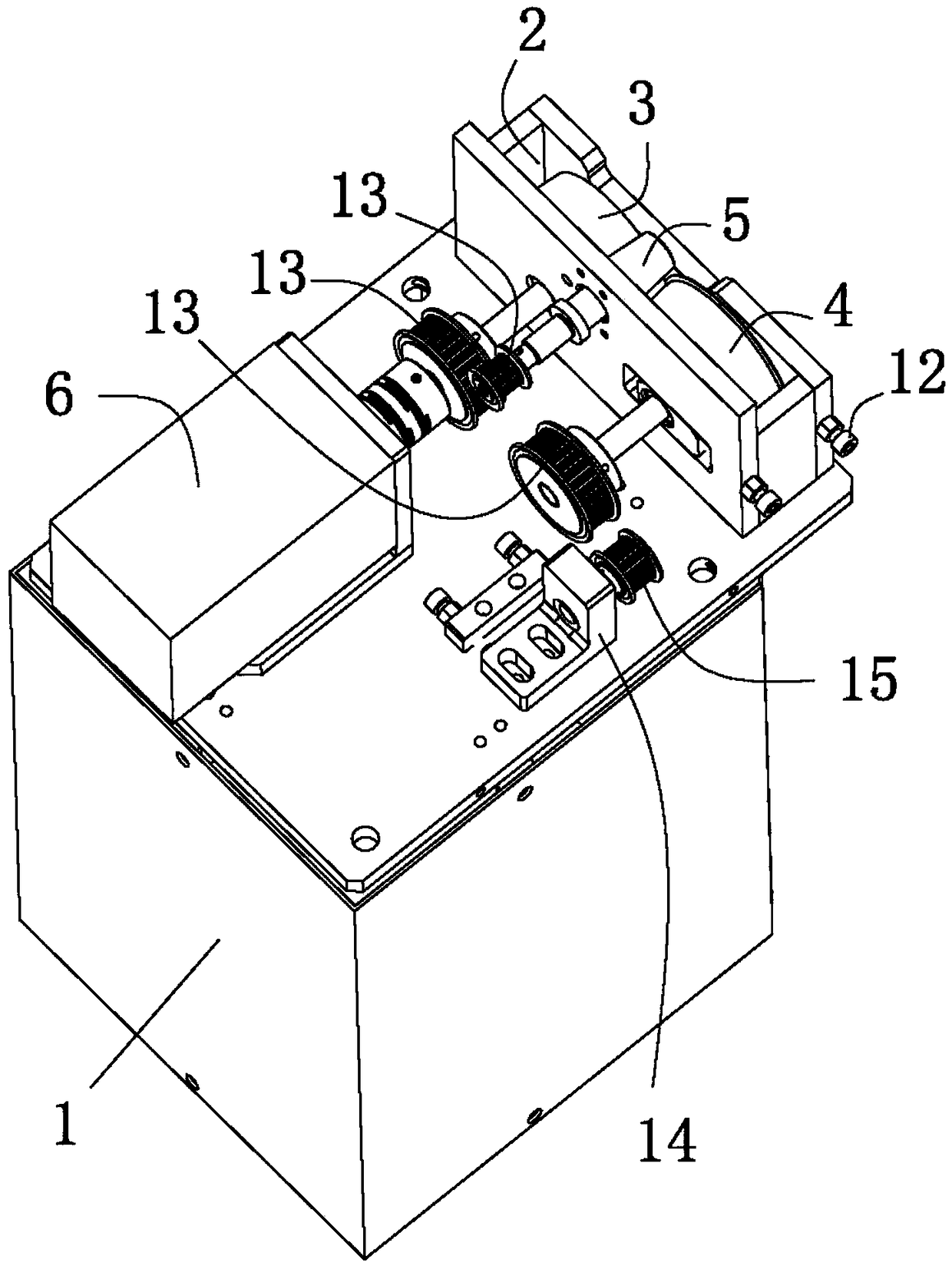

Oiling device for spring part of clock

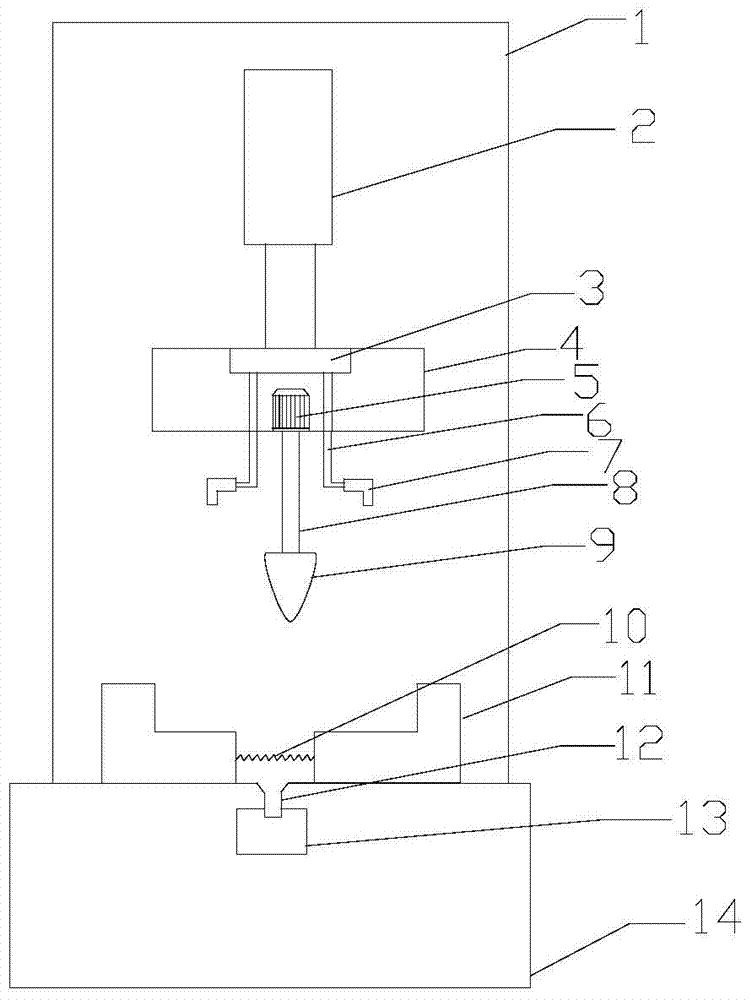

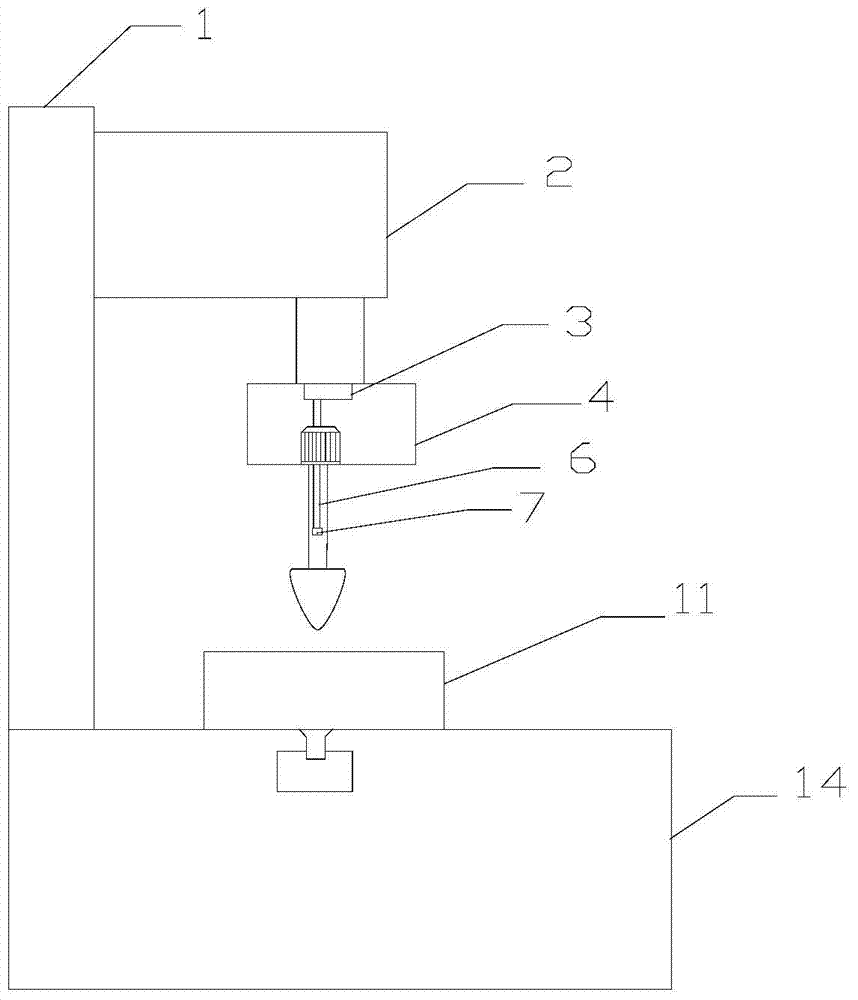

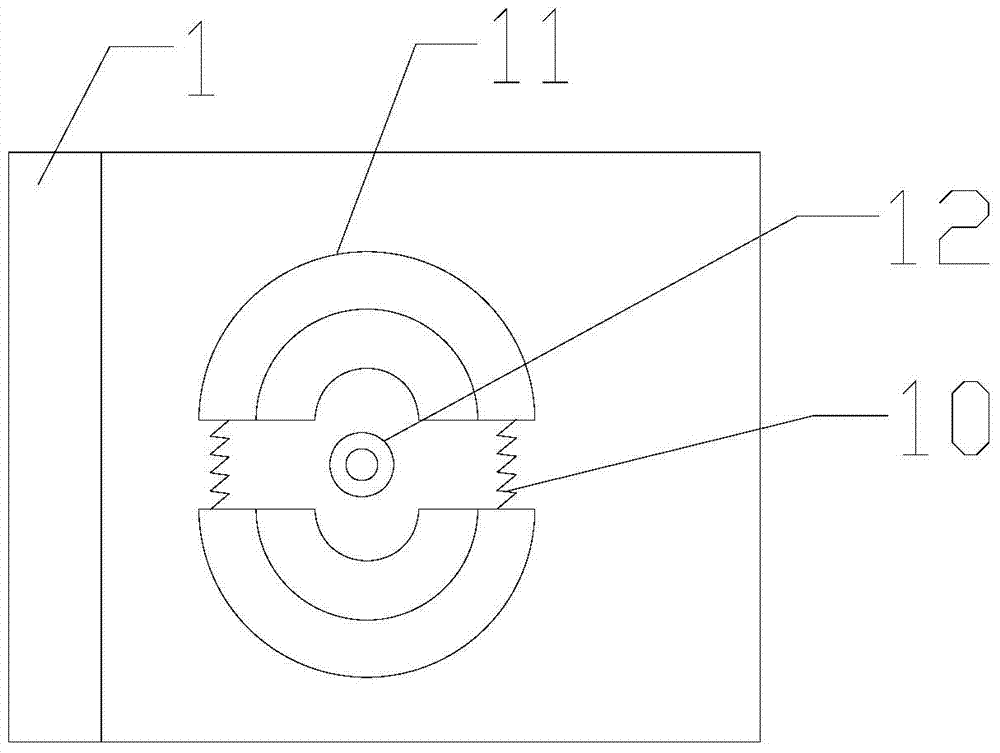

InactiveCN102829310AEasy oiling operationMeet production requirementsEngine lubricationMotor driveFixed frame

The invention discloses an oiling device for a spring part of a clock. The oiling device for the spring part of the clock comprises a base, a shell arranged on the base and a spraying assembly installed on the shell. The spraying assembly further comprises an oiling tube and a fixed frame for fixing the oiling tube. The oiling device further comprises a pressure adjustor arranged above the shell for providing pressure for the oiling tube, a driving mechanism installed on the base, a synchronous servo motor driving the driving mechanism to work and a rotary table driven by the driving mechanism. The rotary table is arranged right below the oiling tube. The oiling device for the spring part of the clock provided by the invention uses gear transmission and is simple in structure, and not only is the surface of the spring part of the clock oiled uniformly and the work efficiency improved, but also the service life of the device is prolonged, and the oiling efficiency of the spring part of the clock is improved. A baffle is further arranged in the oiling device with a plurality of spraying assemblies so that oil mists sprayed by the oiling tubes of different spraying assemblies are effectively blocked, interference among the oil mists is prevented, and the demand of meeting the actual production is better met.

Owner:昌辉汽车电器(黄山)股份公司

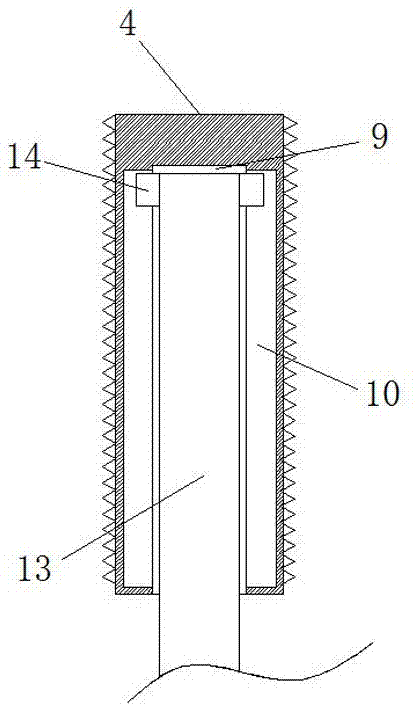

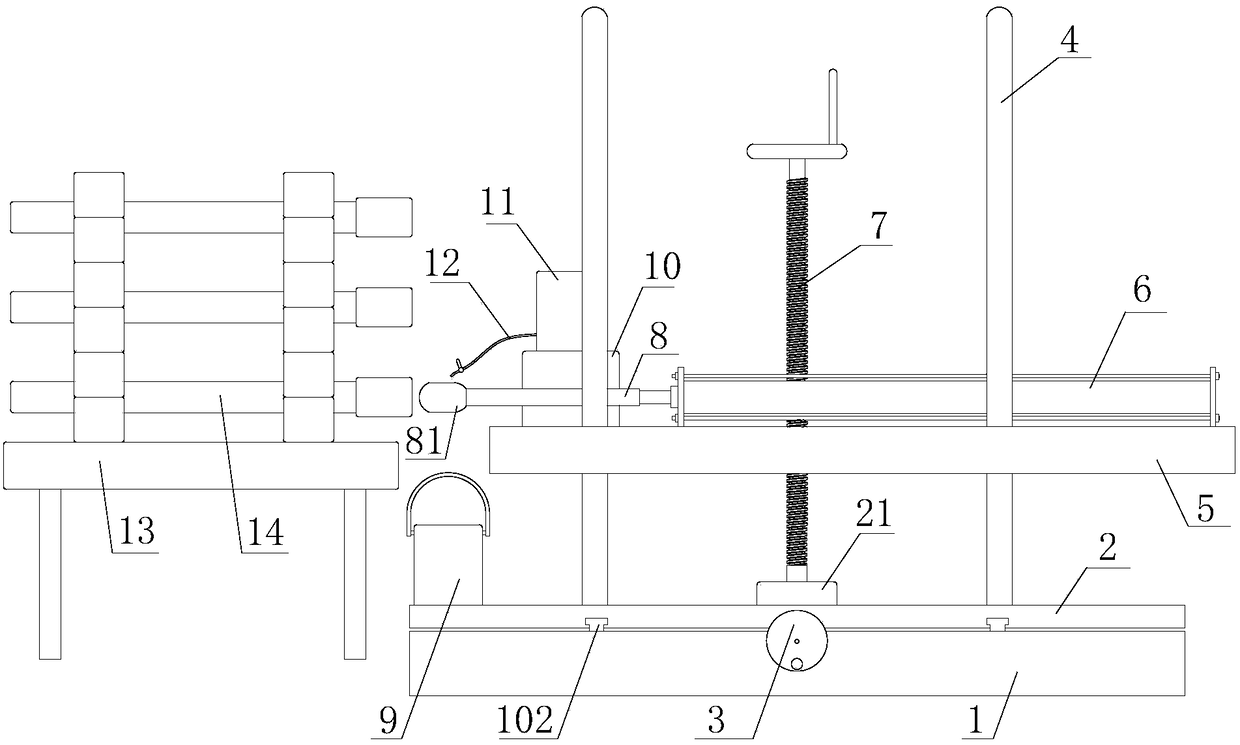

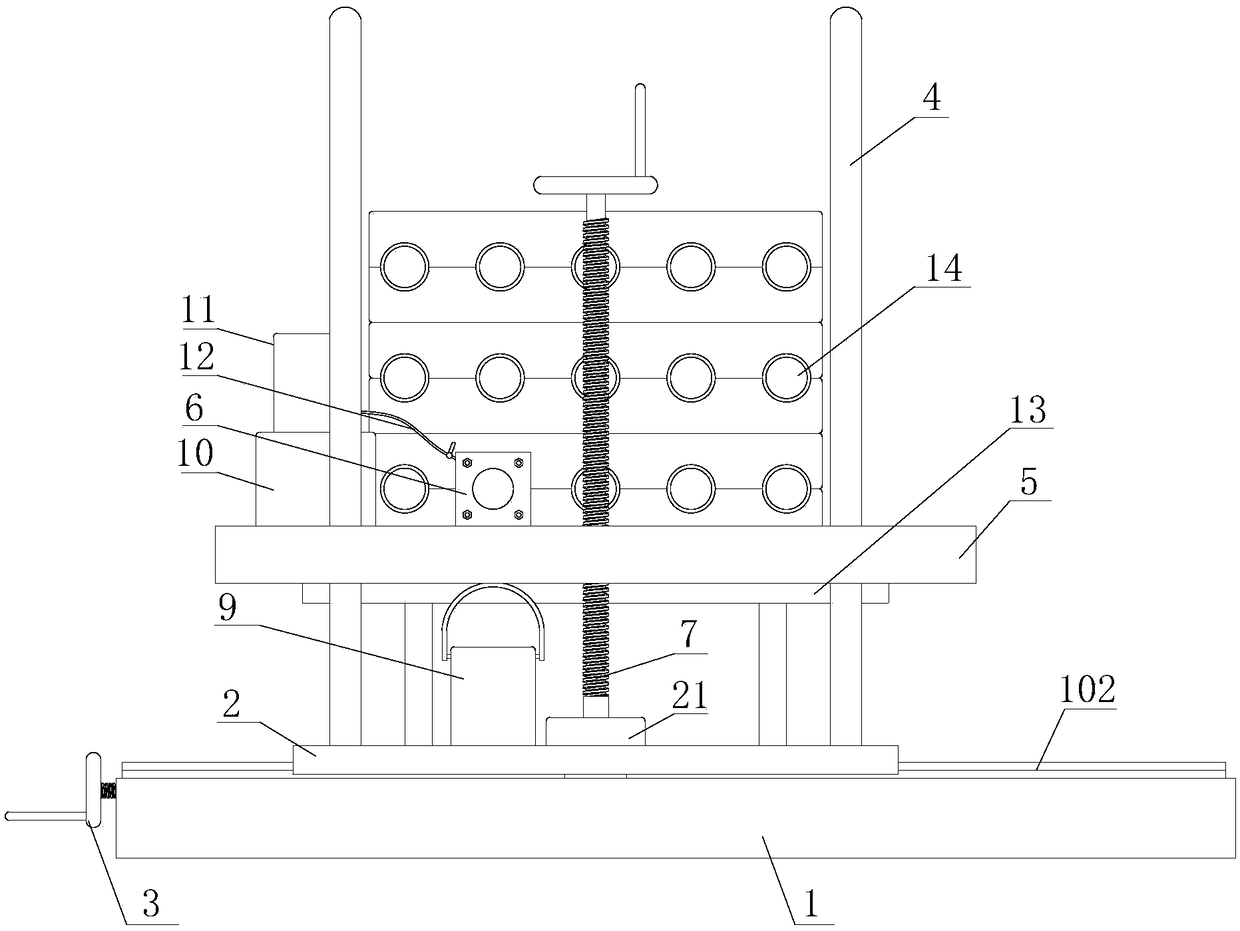

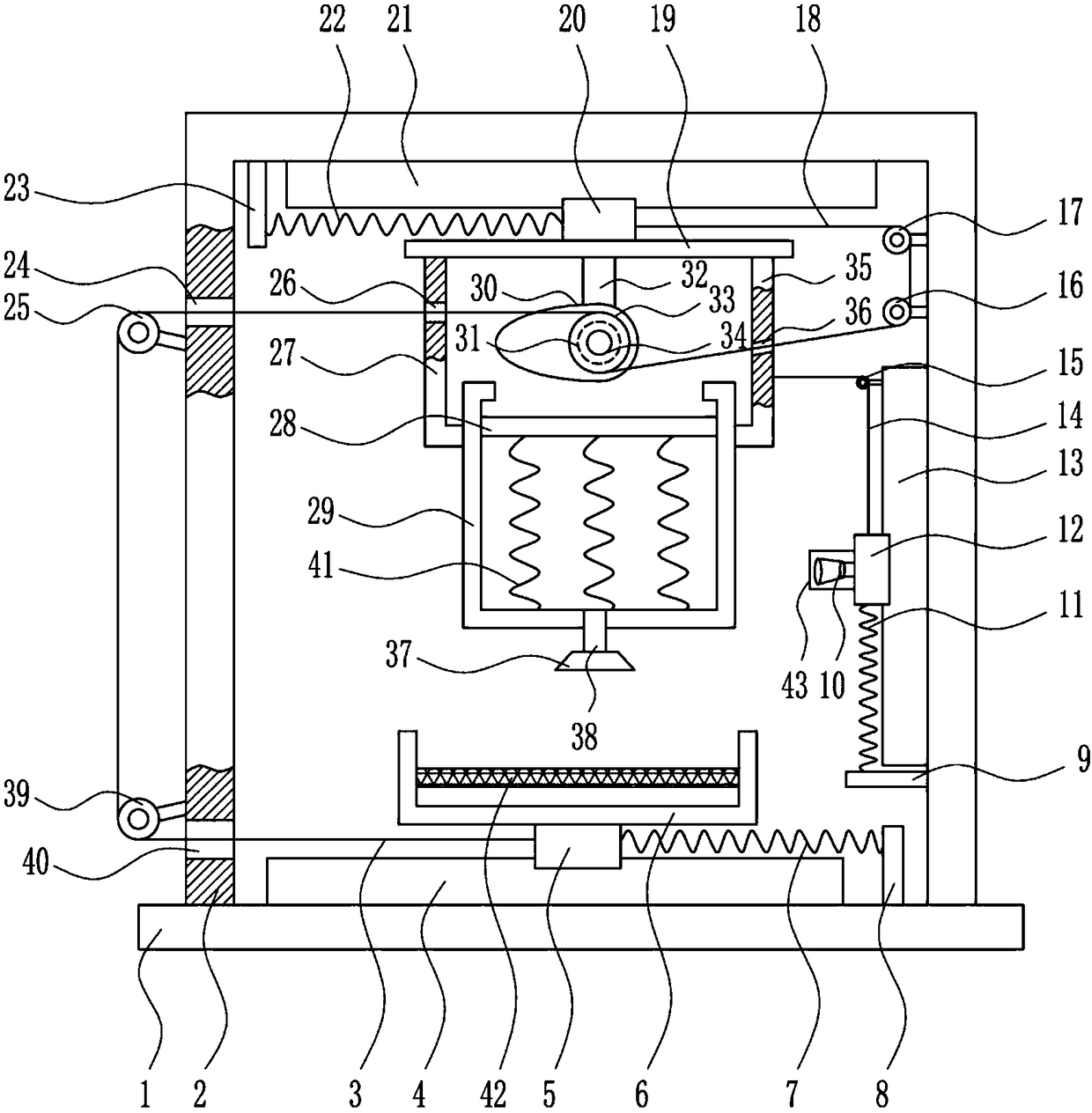

Oiling and cleaning device for oil well short pipe, and operation method thereof

PendingCN108435721ASave energyImprove oiling efficiencyLiquid surface applicatorsHollow article cleaningOil wellPhysical strength

The invention discloses an oiling and cleaning device for an oil well short pipe, and an operation method thereof. The oiling and cleaning device for the oil well short pipe comprises a bottom plate,a middle plate, a horizontal screw rod, guide rods, an upper plate, a push air cylinder, a vertical screw rod and an oiling rod, wherein the horizontal screw rod is horizontally arranged on the bottomplate; T-shaped guide rails are arranged on the top part of the bottom plate in parallel; the middle plate is clamped and embedded into the T-shaped guide rails; the guide rods movably penetrate through the upper plate; the upper plate sleeves on the vertical screw rod and is in threaded connection with the vertical screw rod; the push air cylinder is horizontally arranged on the top part of theupper plate; and an output rod of the push air cylinder is fixedly connected with the oiling rod pointing at the oil well short pipe. According to the oiling and cleaning device for the oil well shortpipe, and the operation method thereof, the push air cylinder pushes the oiling rod and an oiling block stained with diesel oil to be inserted into the oil well short pipe back and forth in a reciprocating way and completely penetrate out, so that an inner wall of the oil well short pipe can be oiled so as to be prevented from getting rusty, inner scrap iron impurities are cleared up, directly manual oiling and cleaning are replaced, a large amount of physical strength is saved, and the oiling and cleaning efficiency is improved.

Owner:MAANSHAN RUNMA MACHINERY MFG

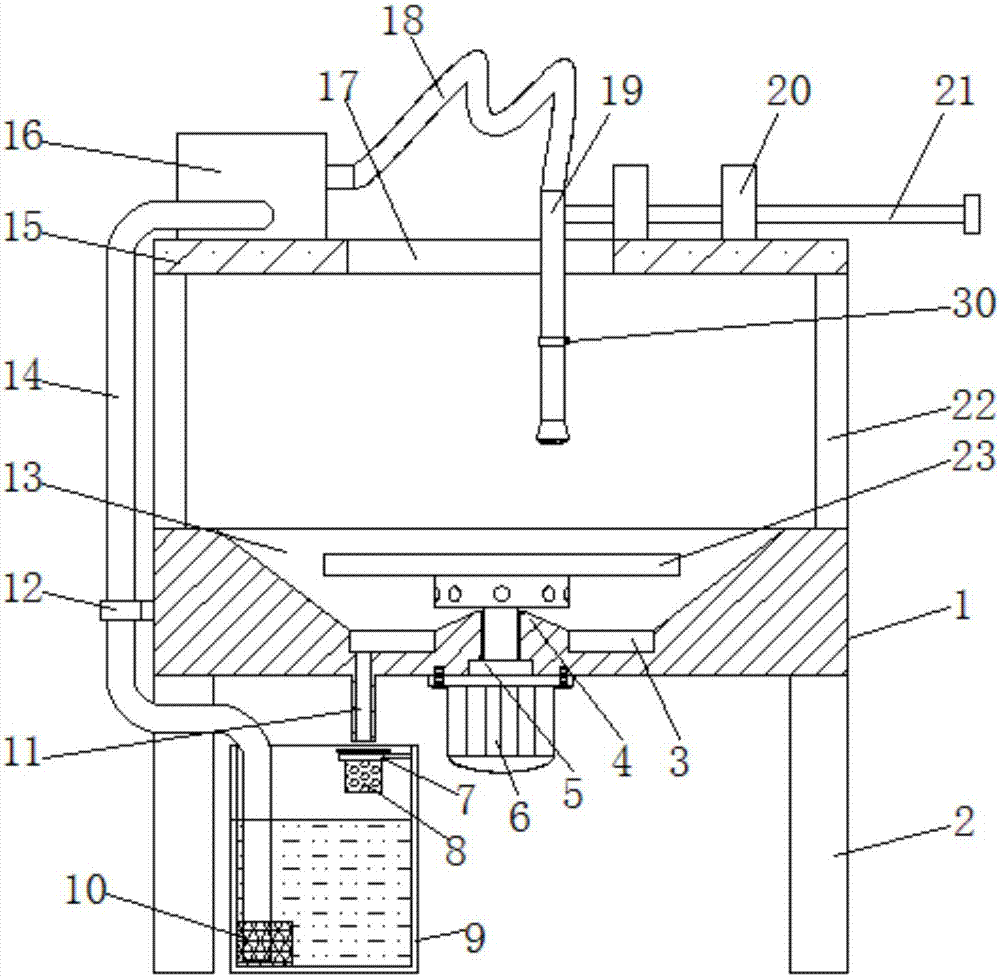

Efficient environmental-friendly oil tank for steel tube production

ActiveCN103372526AStable structureImprove oiling efficiencyLiquid surface applicatorsCoatingsEnvironmental engineeringPipe

The invention relates to the field of equipment for pipe production, and particularly an efficient environmental-friendly oil tank for pipe production. The oil tank comprises a tank body; the tank body comprises an oil storage tank and a collecting tank; the oil storage tank is provided with a row of bearing rods capable of bearing steel tubes; the bearing rods are fixed on a rotating shaft allowing bearing rods to convey the steel tubes to the direction of the collecting tank; and the upper part of the tank body is also provided with a row of transition oil filter frames cooperating with the bearing rods; and the collecting tank is provided with a row of collection frames cooperating with the transition oil filter frames. The efficient environmental-friendly oil tank for pipe production has the advantages of simple structure, high oil painting efficiency and environmental-friendliness.

Owner:ANJI PENGDA STEEL PIPE

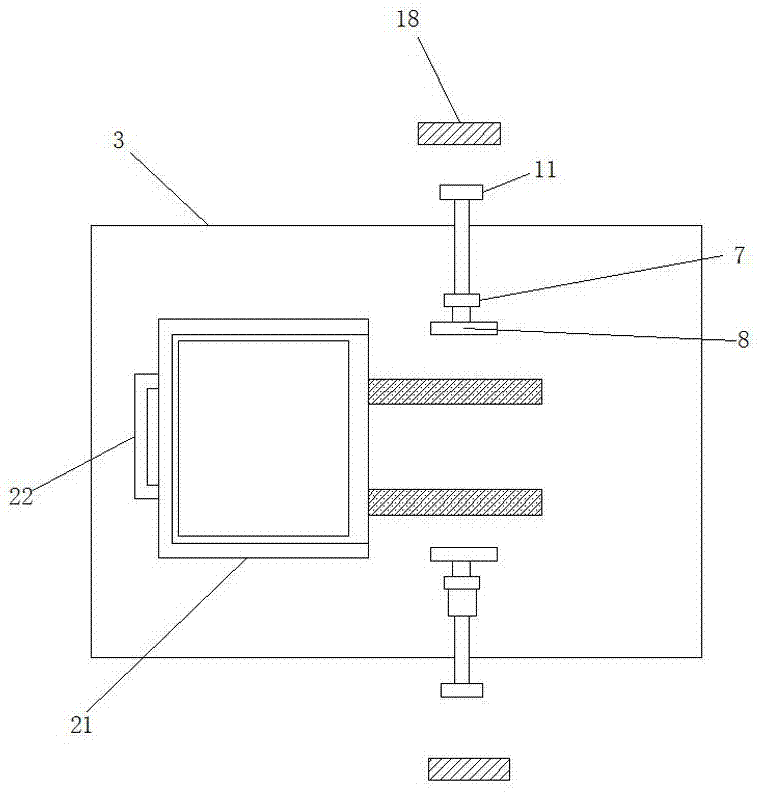

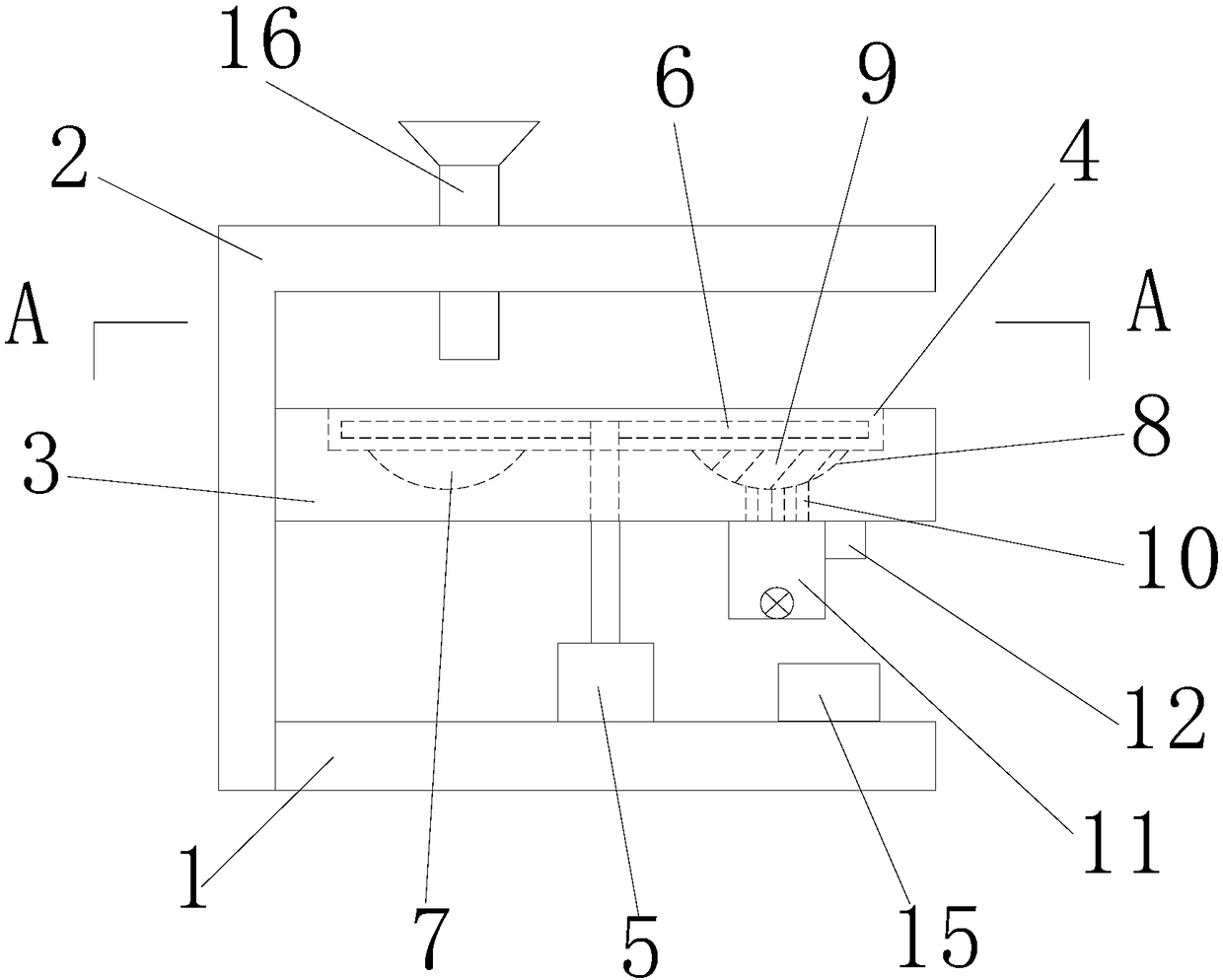

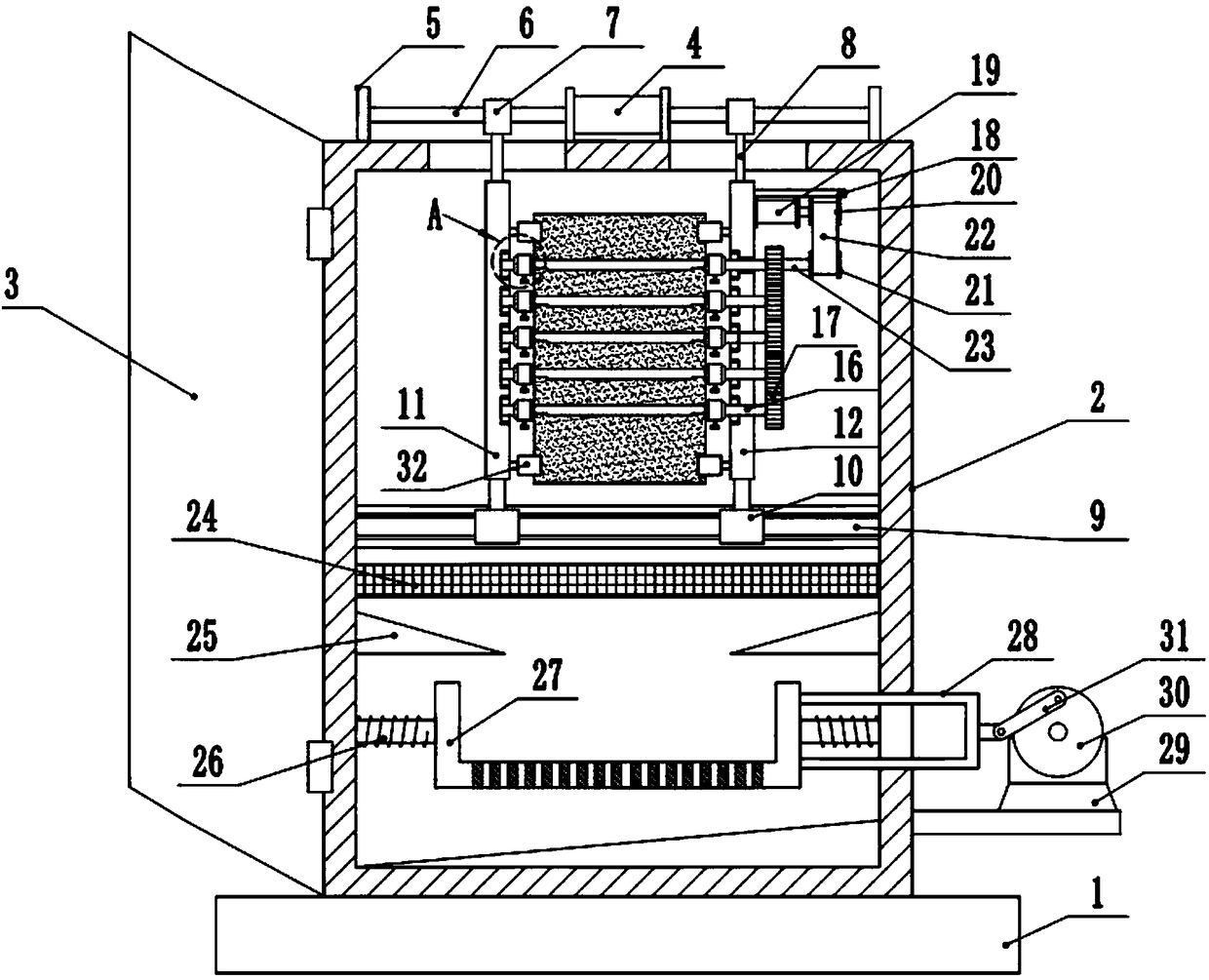

Equipment for applying rust-proof oil to stator core

PendingCN110224557AGuaranteed uniformityPrevent fallingLiquid surface applicatorsManufacturing stator/rotor bodiesMotor driveRust

The invention discloses a piece of equipment for applying rust-proof oil to a stator core, which comprises a workbench. A rack is arranged on the workbench. A stator holder is arranged on the workbench, and the stator holder is movably connected with the workbench. A stator clamp is arranged on the rack. An oil applying brush is arranged on the rack, and an oil applying cylinder is arranged on theoil applying brush. An oil sprayer is arranged on one side of the rack, and the oil sprayer is fixedly connected with the workbench. A rotary motor is arranged under the workbench, and the rotary motor is connected with the stator holder. The stator core is put on the stator holder, and the stator clamp and the stator holder work together to prevent the stator core from falling off. When the rotary motor is started, the rotary motor drives the stator holder to rotate, the oil applying cylinder acts and drives the oil applying brush to move downward and apply oil to the inside of the stator core, and the oil sprayer sprays atomized rust-proof oil onto the outside of the stator core. Oil can be simultaneously applied to the inside and outside of the stator core. The oil applying efficiencyis high, and uniformity of oil applying is ensured.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

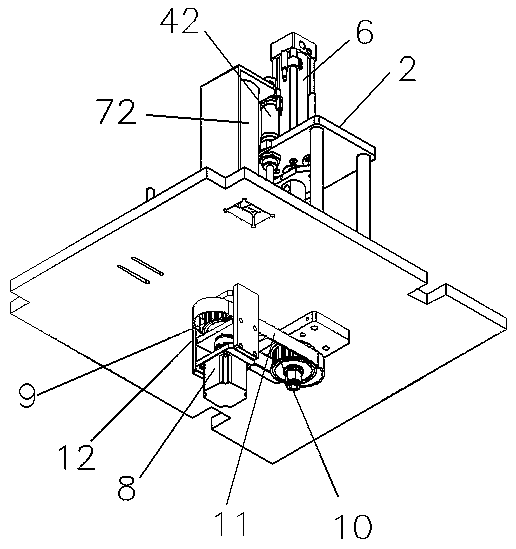

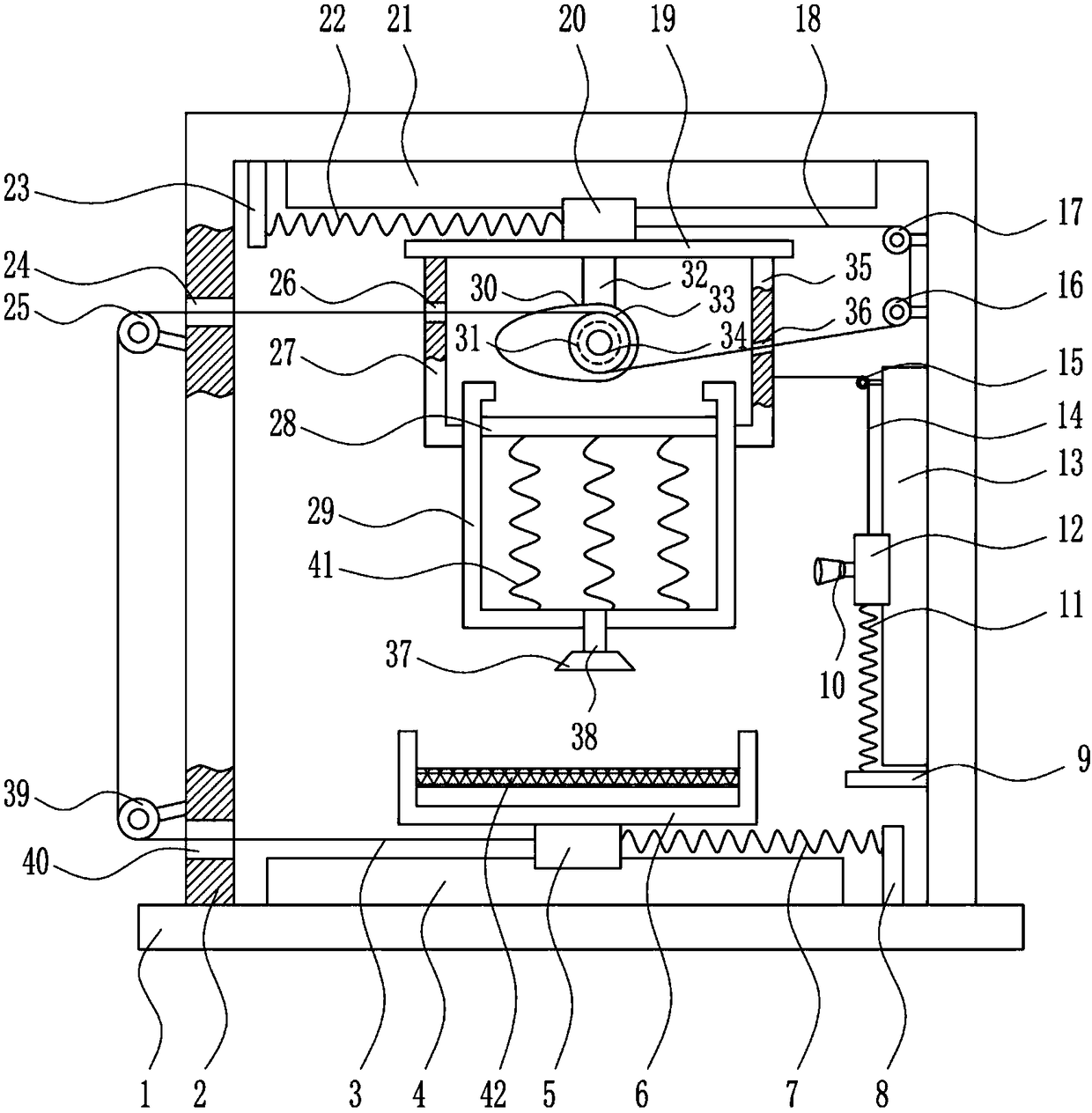

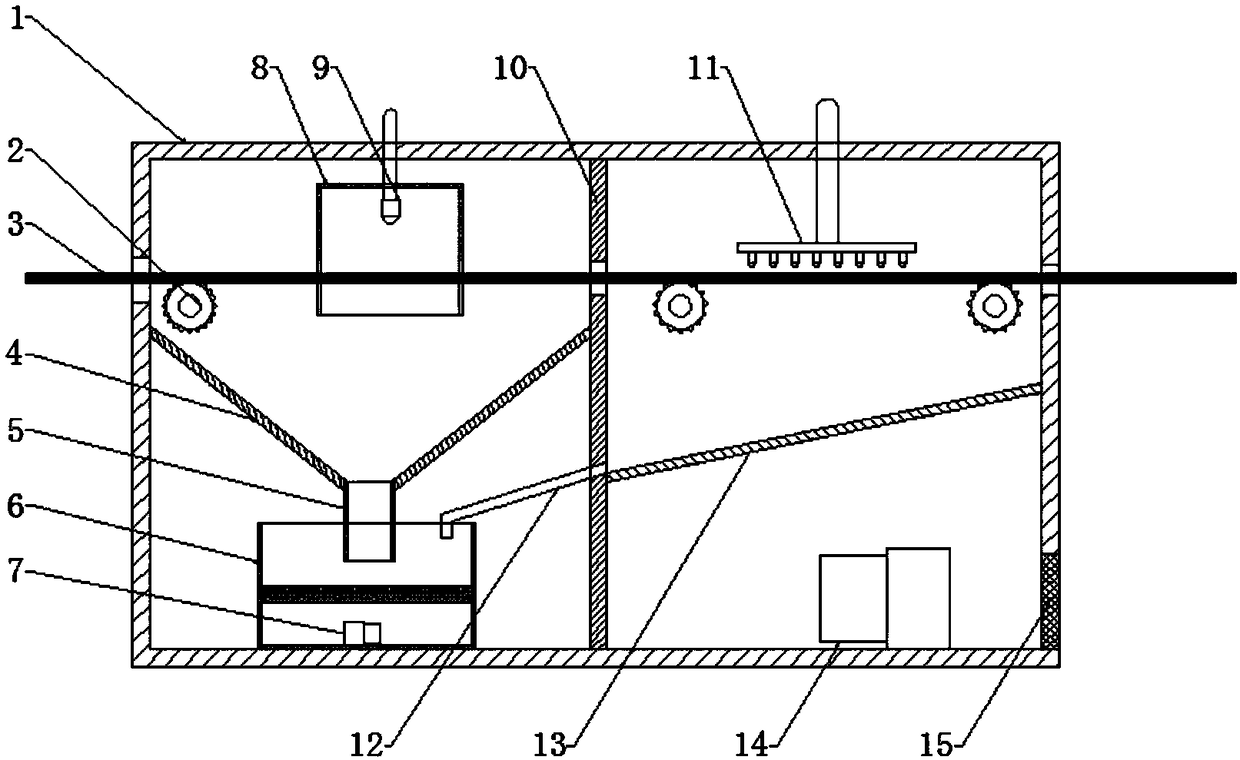

Quick oiling machine for regular maintenance of massage equipment

InactiveCN109099299AImprove oiling efficiencyTime-consuming and laborious to solveEngine lubricationMassageLeft wall

The invention relates to an oiling machine for massage equipment, in particular to a quick oiling machine for regular maintenance of the massage equipment. The quick oiling machine for regular maintenance of the massage equipment is efficient, low in cost and easy to operate. The quick oiling machine for regular maintenance of the massage equipment comprises a bottom plate, a bracket, a first pullrope, a first sliding rail, a first sliding block, a placement frame, a first elastic element, a first baffle, a second baffle, a fan, a second elastic element and the like; and the first sliding rail is located in the bracket, a first through hole and a second through hole are formed in the left wall of the bracket, the first through hole is located on the upper portion of the second through hole, and a fifth fixed pulley is fixedly connected to the lower portion of the left wall of the bracket. The quick oiling machine has the effects that the oiling efficiency for the massage equipment ishigh, and the quick oiling machine is simple in structure and easy to operate.

Owner:陈闺艳

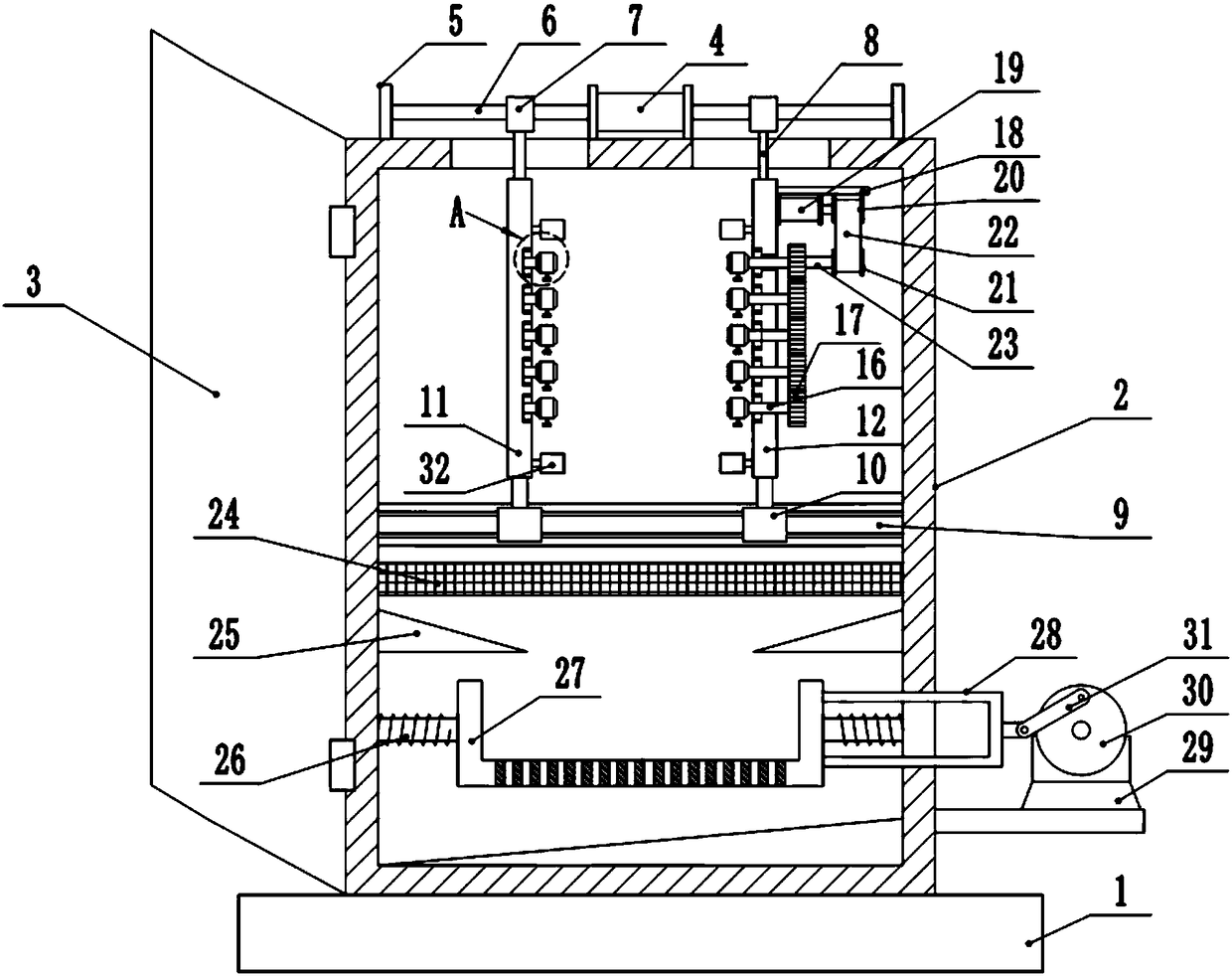

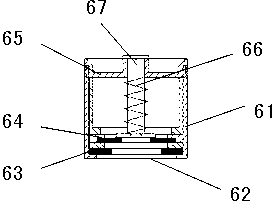

Sleeper bolt automatically greasing device

InactiveCN108382419AImprove efficiencyQuality improvementRail lubricationRail wetting/lubricationWrenchEngineering

The invention relates to a sleeper bolt automatically greasing device and belongs to the technical field of railway maintenance tools. According to the sleeper bolt automatically greasing device, a rotating mechanism drives a rotating shaft, a rotating shaft is provided with a guide rail, the guide rail is provided with a lifting device, and the lifting device is connected with an electric wrench;bolts on a steel rail are unscrewed through the electric wrench and then conveyed into a greasing device through a rotating shaft, an oil jetting hole inside the greasing device uniformly greases thebolts, and meanwhile prestored greased bolts are mounted onto the steel rail. Therefore, the sleeper bolt automatically greasing device can effectively improve the steel rail greasing efficiency; meanwhile, the greasing device can uniformly grease the unscrewed bolts to effectively improve the greasing quality; superfluous lubricating oil during a greasing process can flow back into the greasingdevice to effectively reduce consumption of lubricating oil.

Owner:朱东洋

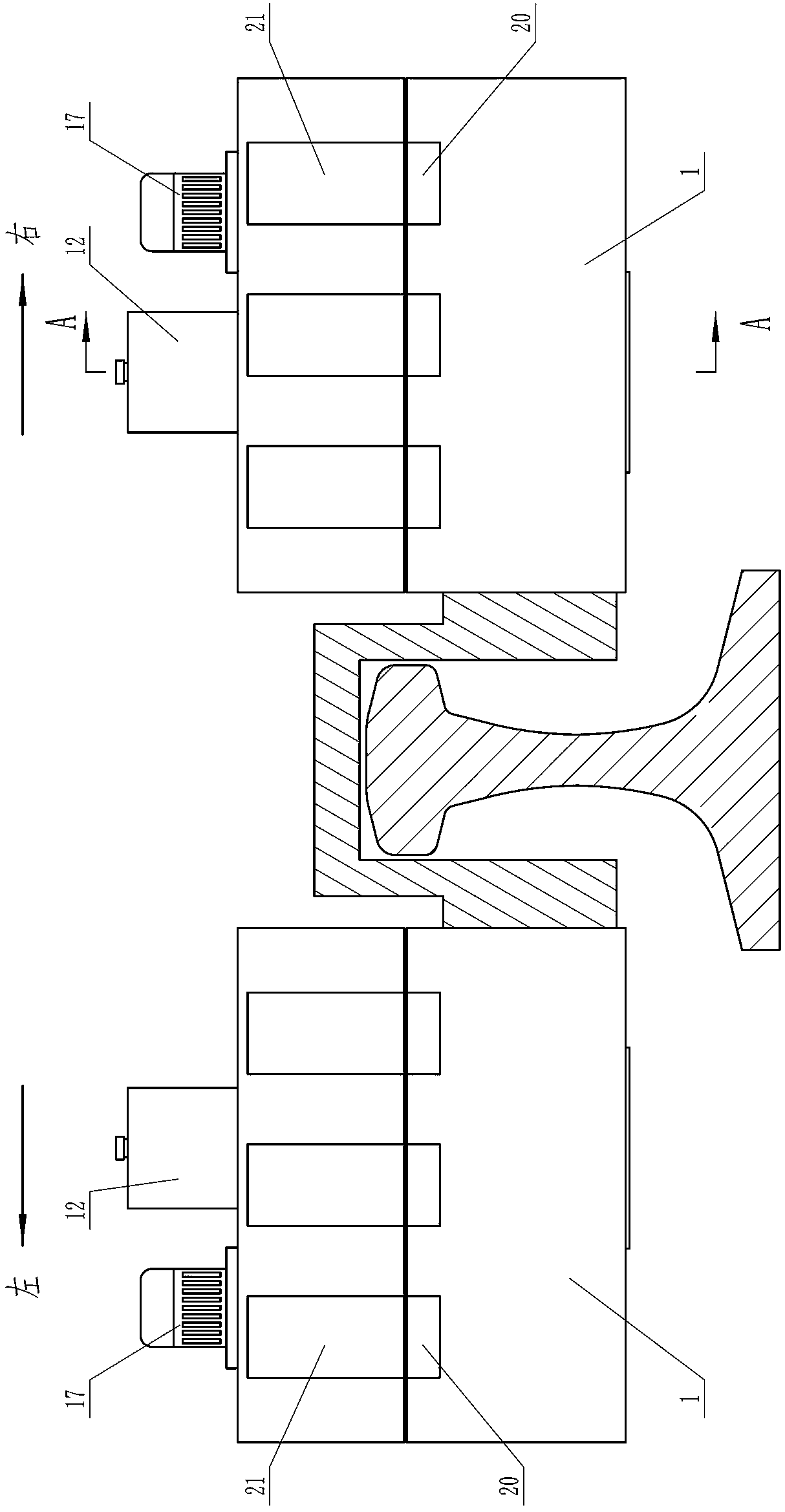

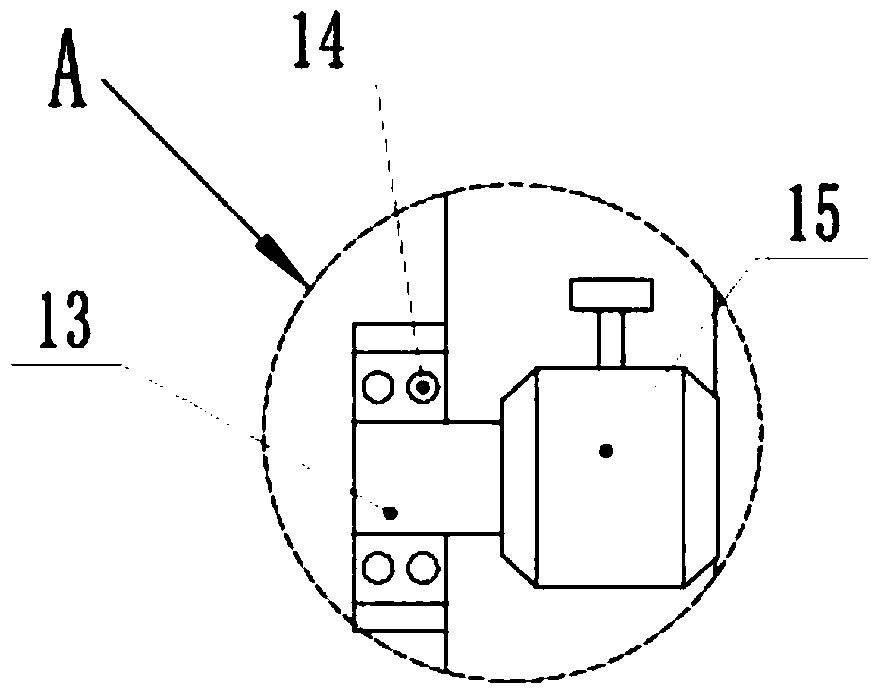

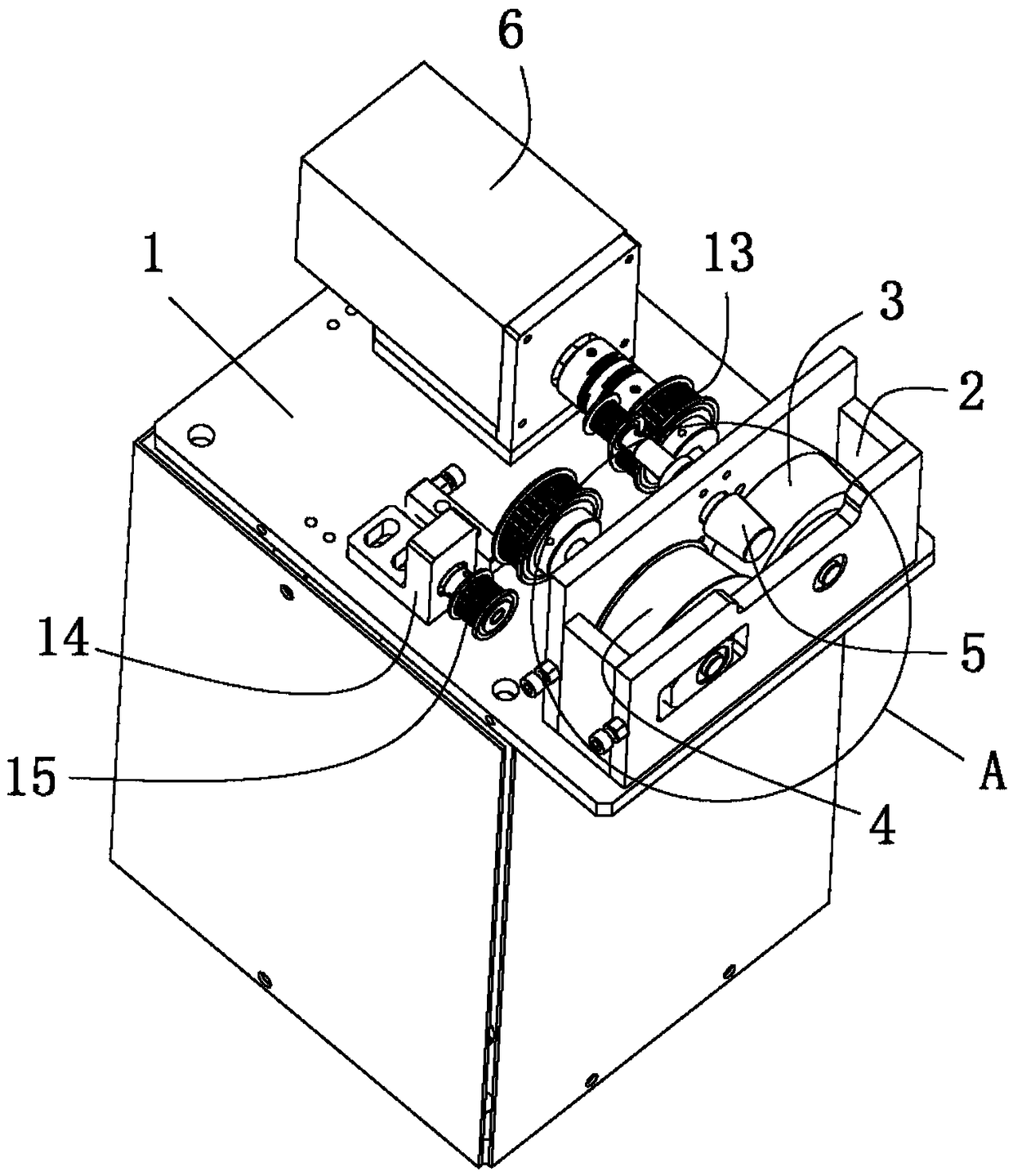

Oil coating device for railway sleeper bolt

ActiveCN108970893AHigh degree of automationIngenious structureLiquid surface applicatorsCoatingsGear wheelEngineering

The invention provides an oil coating device for a railway sleeper bolt. The oil coating device effectively solves the problems of larger amount of workers, low efficiency, high labor intensity, and easiness in fatigue in the railway maintenance process. The oil coating device adopts the technical scheme that the oil coating device comprises a casing, wherein a flat plate is arranged in the casing; a sun gear is arranged at the upper end surface of the flat plate; the surrounding of the sun gear is engaged with a plurality of planetary gears; the outer side of each planetary gear is engaged with an inner toothed ring, and a first gear is arranged at the upper end of the sun gear; a cylindrical block is arranged in the casing, a spline hole is formed in the cylindrical block, a hollow pipeis arranged in the spline hole, a first cylinder is arranged on the hollow pipe, the outer circumference surface of the first cylinder is of a spline structure, the sun gear is rotated to drive the cylindrical block to rotate through the first cylinder, the lower end of the cylindrical block penetrates through a lower side plate of the casing, and a polygonal screw nut sleeve hole is formed in thelower end of the cylindrical block, is provided with a downward opening, and is concentric with the spline hole. The oil coating device has the advantages that the structure is skillful, the number of required workers in the railway maintenance is effectively reduced, the oil coating efficiency is greatly improved, the labor intensity is decreased, and the automation degree in railway maintenanceis improved.

Owner:盐城鹤翔化工设备制造有限公司

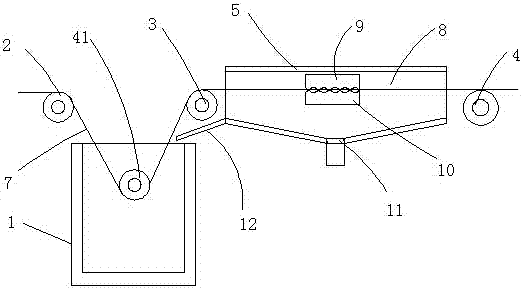

Fast oil applying device for chain

InactiveCN107143741ASimple structureEasy to operateChain elementsLubrication elementsOil canFuel tank

Owner:SUZHOU SHUNGE INTELLIGENT TECH

Screw rod adjusting type automatic oiling device for rotating shafts of direct-current coil motor

InactiveCN108212643ASpeed up filteringIncrease profitLiquid surface applicatorsCoatingsInterference fitCoupling

The invention discloses a screw rod adjusting type automatic oiling device for rotating shafts of a direct-current coil motor. The screw rod adjusting type automatic oiling device comprises a base, afirst driving motor, a first vertical plate, a second vertical plate, couplings, a second driving motor and a filtering tank. A transverse rod is horizontally arranged in a device box. The filtering tank is slidably mounted on the transverse rod. A pull rod is welded on the right side of the filtering tank. A third driving motor is fixedly mounted on the right side of the device box through a support. An output shaft of the third driving motor is faced forward, and a rotating wheel is mounted on the output shaft of the third driving motor in an interference fit manner. A second connecting rodis rotationally and eccentrically mounted on the front surface of the rotating wheel. The other end of the second connecting rod is hinged to the pull rod. By the adoption of the rotating shaft oilingdevice, excess anti-rust oil can be collected into the filtering tank, and then by indirectly driving the filtering tank to move left and right, the filtering speed of the anti-rust oil is increasedgreatly; meanwhile, the filtered anti-rust oil can be reused, the utilization rate of the anti-rust oil is increased greatly, and the cost is saved.

Owner:台州来智科技有限公司

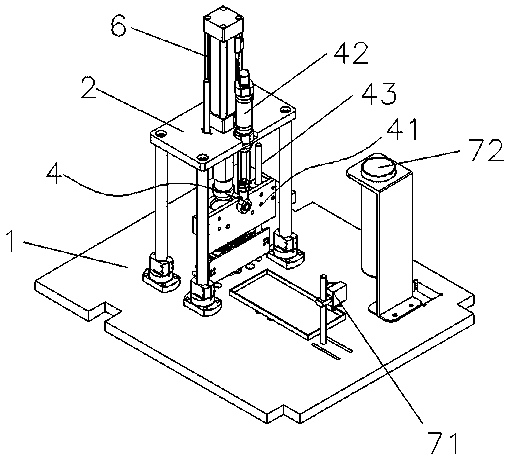

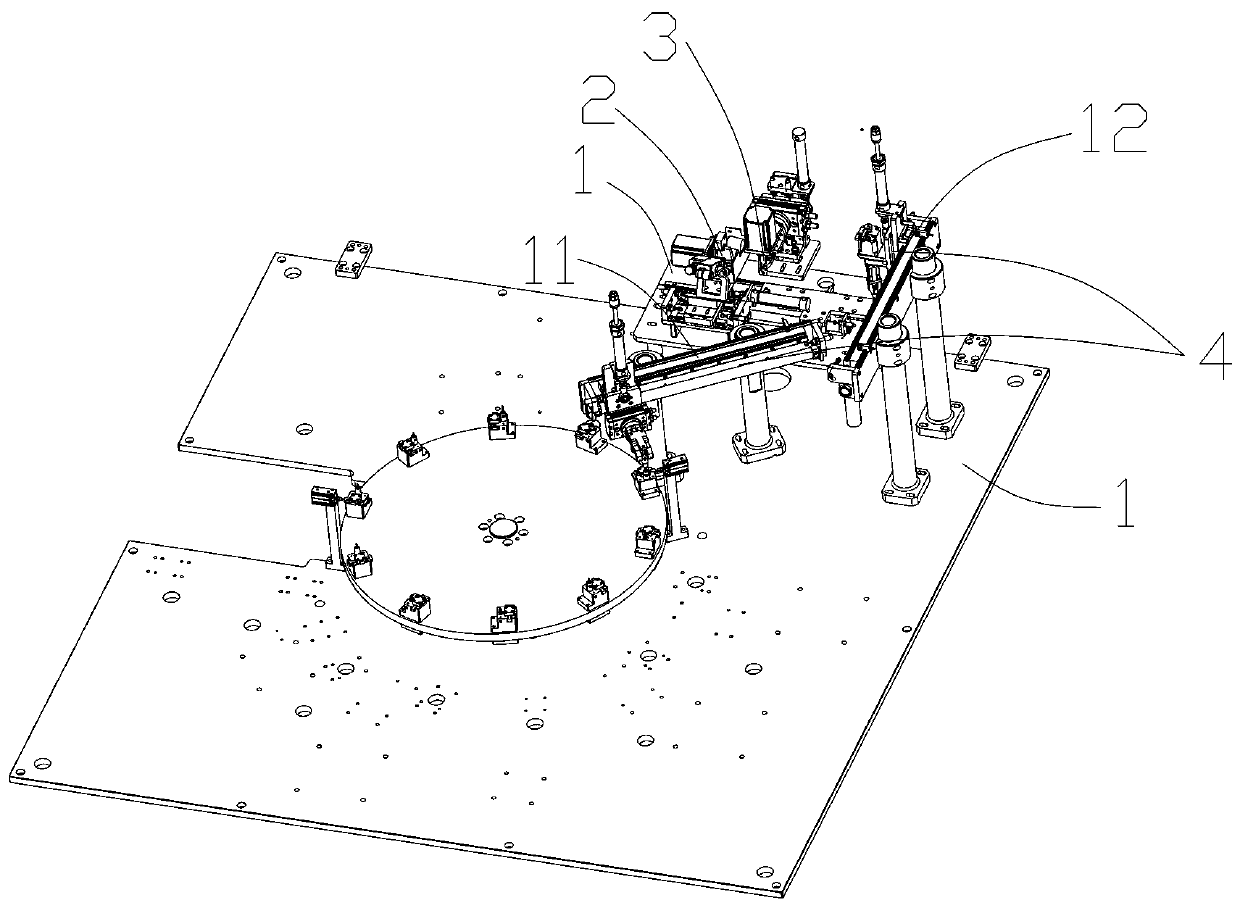

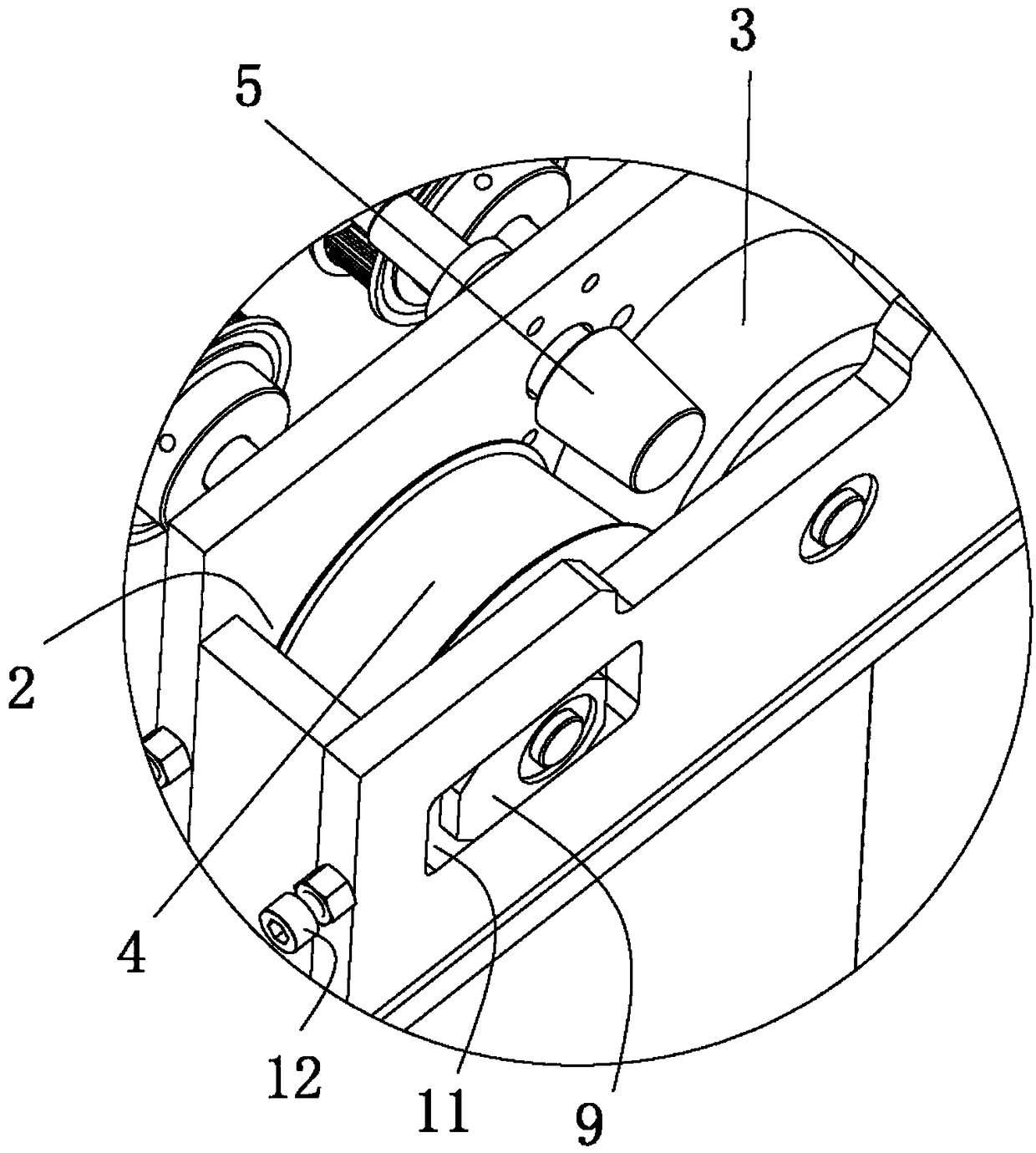

Valve core oil coating device

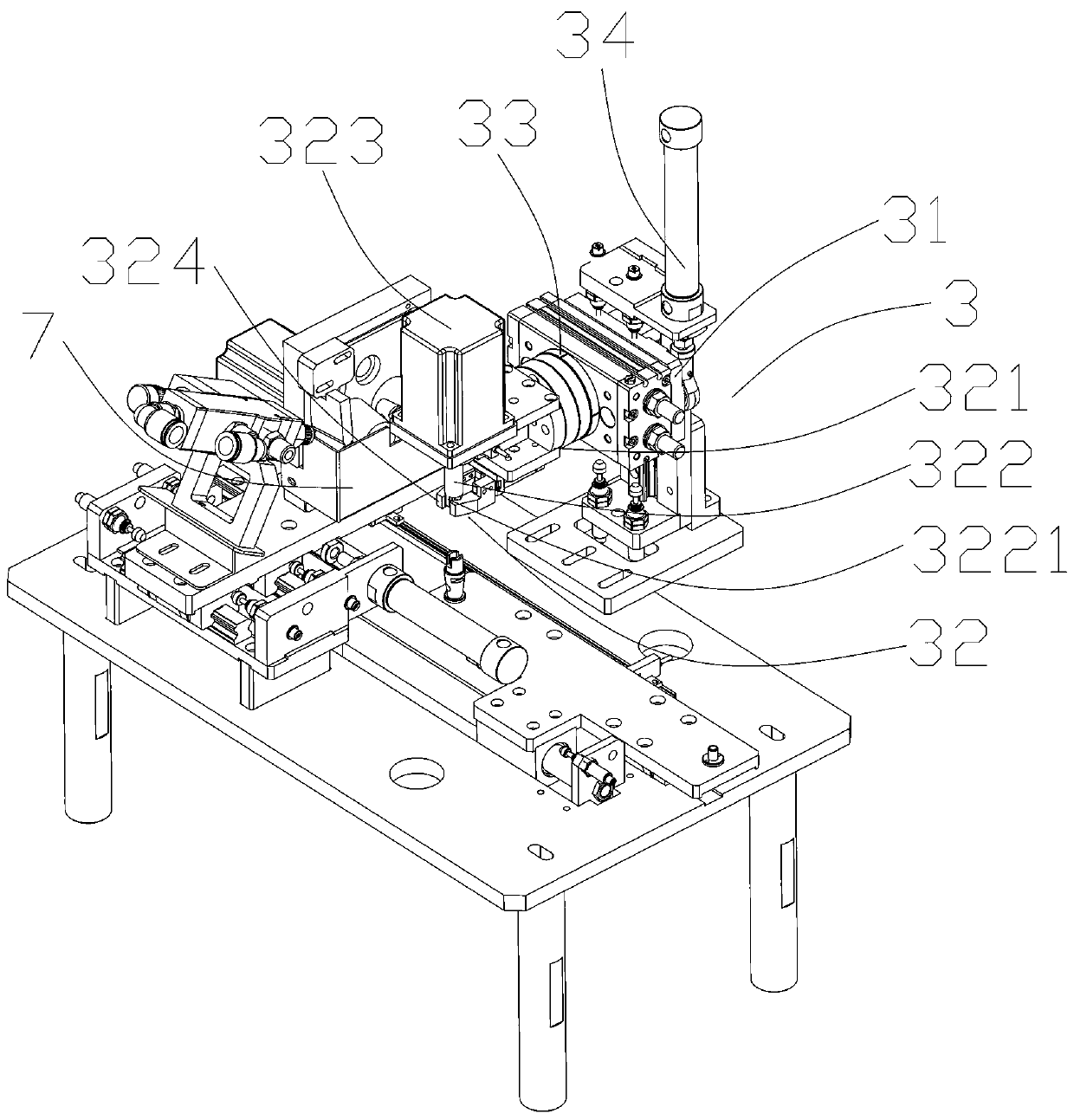

PendingCN110404724ARealize automatic oilingImprove oiling efficiencyLiquid surface applicatorsCoatingsMechanical engineeringCoating

The invention relates to a valve core oil coating device. The device solves the problem that an existing valve core is low in manual oil coating efficiency. The device comprises an machine frame, a valve core oil coating mechanism, a valve core feeding mechanism, a valve core supplying mechanism, wherein the valve core oil coating mechanism is arranged on the machine frame and is used for coatingoil on a valve core, and the valve core feeding mechanism is used for feeding for the valve core oil coating mechanism; the valve core feeding mechanism comprises a feeding supporting plate, a valve core feeding clamping mechanism and a first rotating air cylinder, wherein the feeding supporting plate is arranged on the machine frame, the first rotating air cylinder are used for driving the valvecore feeding clamping mechanism to rotate and feed; and the valve core oil coating mechanism comprises an oil coating wheel mechanism which is used for coating oil to the valve core through rotation,an oil suction wheel which is opposite to the oil coating mechanism and is used for coating oil to the oil coating wheel mechanism, a point oil mechanism used for spraying oil to the oil suction wheel, and a scraping plate used for scraping and coating the oil on the oil suction wheel. According to the device, the valve core feeding mechanism is used for feeding and transferring the valve core, the valve core feeding mechanism is used for automatic feeding of the valve core, the valve core oil coating mechanism is used for automatically coating the valve core, so that automatic oil coating ofthe valve core is realized, the oil coating efficiency is high, and the labor cost is saved.

Owner:深圳市佳宇精密机电科技有限公司

Adjustable conveying pipeline connecting piece oiling machine

ActiveCN111871711AEasy to adjustImprove oiling efficiencyLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention belongs to the technical field of pipeline oiling, and particularly relates to an adjustable conveying pipeline connecting piece oiling machine, which comprises a worktable and coating modules. A rectangular through hole is formed in the middle of a top plate of the worktable. In the adjustable conveying pipeline connecting piece oiling machine, by arranging the two coating modules,the spacing between the two coating modules can be adjusted through air cylinders, rotation of the two coating module can be controlled through a motor, mounting frames between adjacent first mountingdiscs and second mounting discs are separated from each other through the air cylinders and torsional springs between the mounting frames and connecting seats, the outer side wall of a pipeline connecting piece is oiled through outer coating rollers, and elastic coating rollers on the mounting frames make contact with the inner side wall of the pipeline connecting piece, so that the inner side wall and the outer side wall of the pipeline connecting piece are both oiled, the rotating mounting frames are utilized to drive elastic coating sleeves to rotate to oil the inner side wall of the pipeline connecting piece, and thus the oiling efficiency of the inner side and the outer side of the pipeline connecting piece is improved advantageously.

Owner:滕州潍达智能科技有限公司

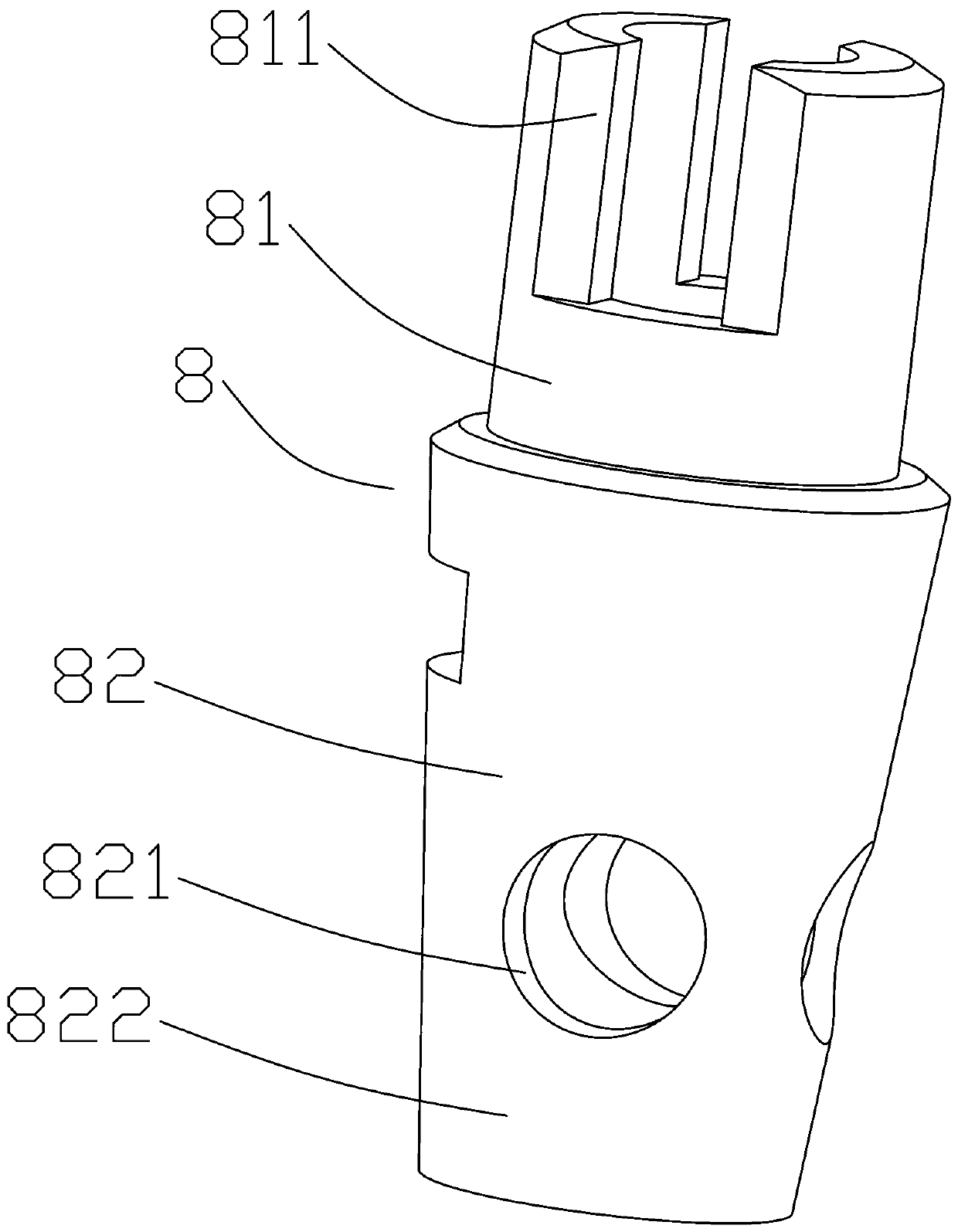

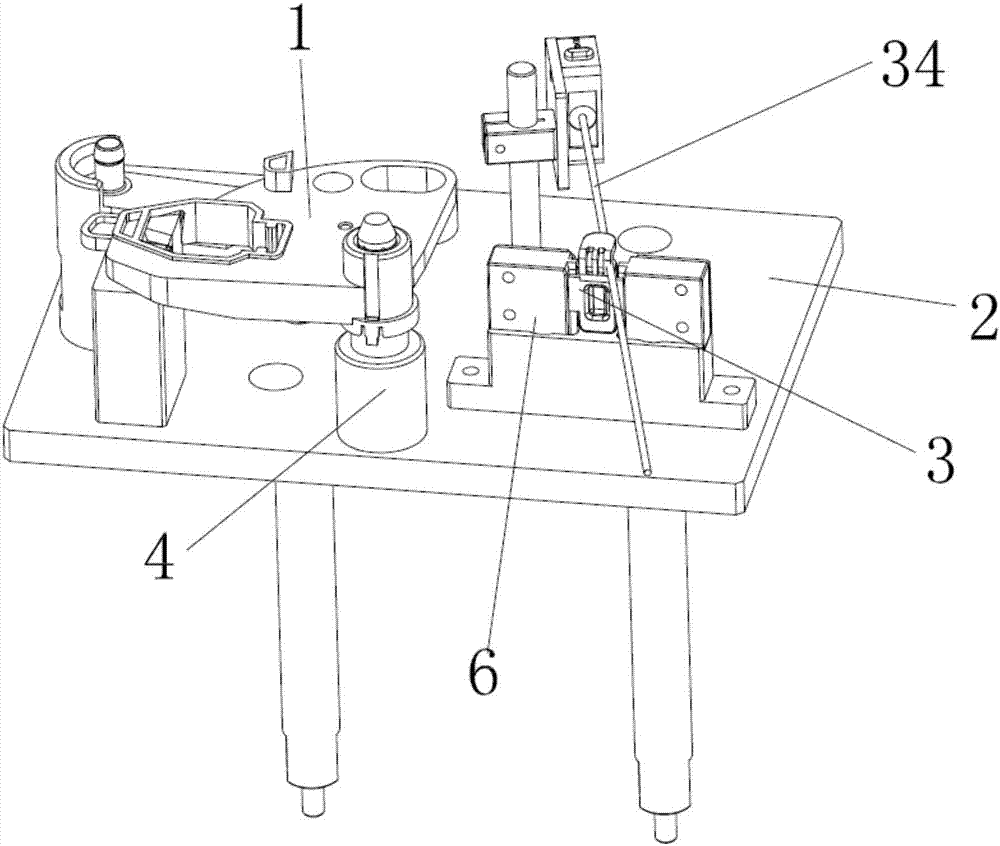

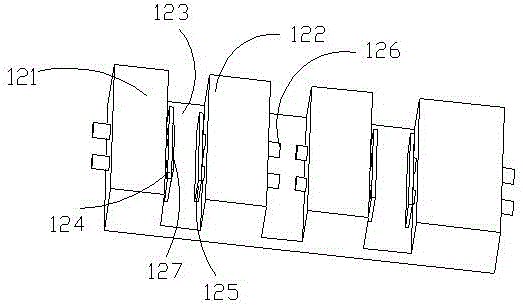

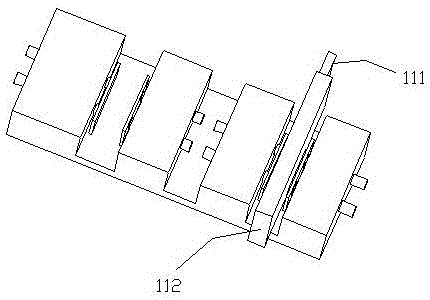

Lubricating oil automatic applying device for gear shifting device

ActiveCN107191776AEnsure that the shifting service life meets the requirementsImprove oiling efficiencyLubricant transferProcess engineeringShunt valve

The invention provides a lubricating oil automatic applying device for a gear shifting device. The lubricating oil automatic applying device comprises a first oil applying tool, a second oil applying tool and an oil supplying mechanism. The first oil applying tool comprises a connecting base and a hollow oil outlet column arranged on the connecting base. A first oil inlet hole is formed in the connecting base. A first oil outlet hole is formed in the oil outlet column. One end of the first oil inlet hole is connected with the oil supply mechanism, and the other end of the first oil inlet hole communicates with the first oil outlet hole. The second oil applying tool comprises an oil outlet base. A profiling block is arranged at one end of the oil outlet base. A second oil outlet hole is formed in the profiling block. A second oil inlet hole is formed in the oil outlet base. One end of the second oil inlet hole is connected with the oil supplying mechanism, and the other end of the second oil inlet hole communicates with the second oil outlet hole. When the lubricating oil automatic applying device is used, a foot plate is manually placed on the first oil applying tool, a sliding block is manually placed on the second oil applying tool, a diverter valve of the oil supplying mechanism is opened, lubricating oil enters the foot plate and the sliding block through the first oil outlet hole and the second oil outlet hole, a traditional manual oil applying mode is replaced, the oil applying efficiency is improved by a large margin, and the oil is applied uniformly without the dead angle.

Owner:SUZHOU CHENGFENG MECHANICAL & ELECTRICAL EQUIP

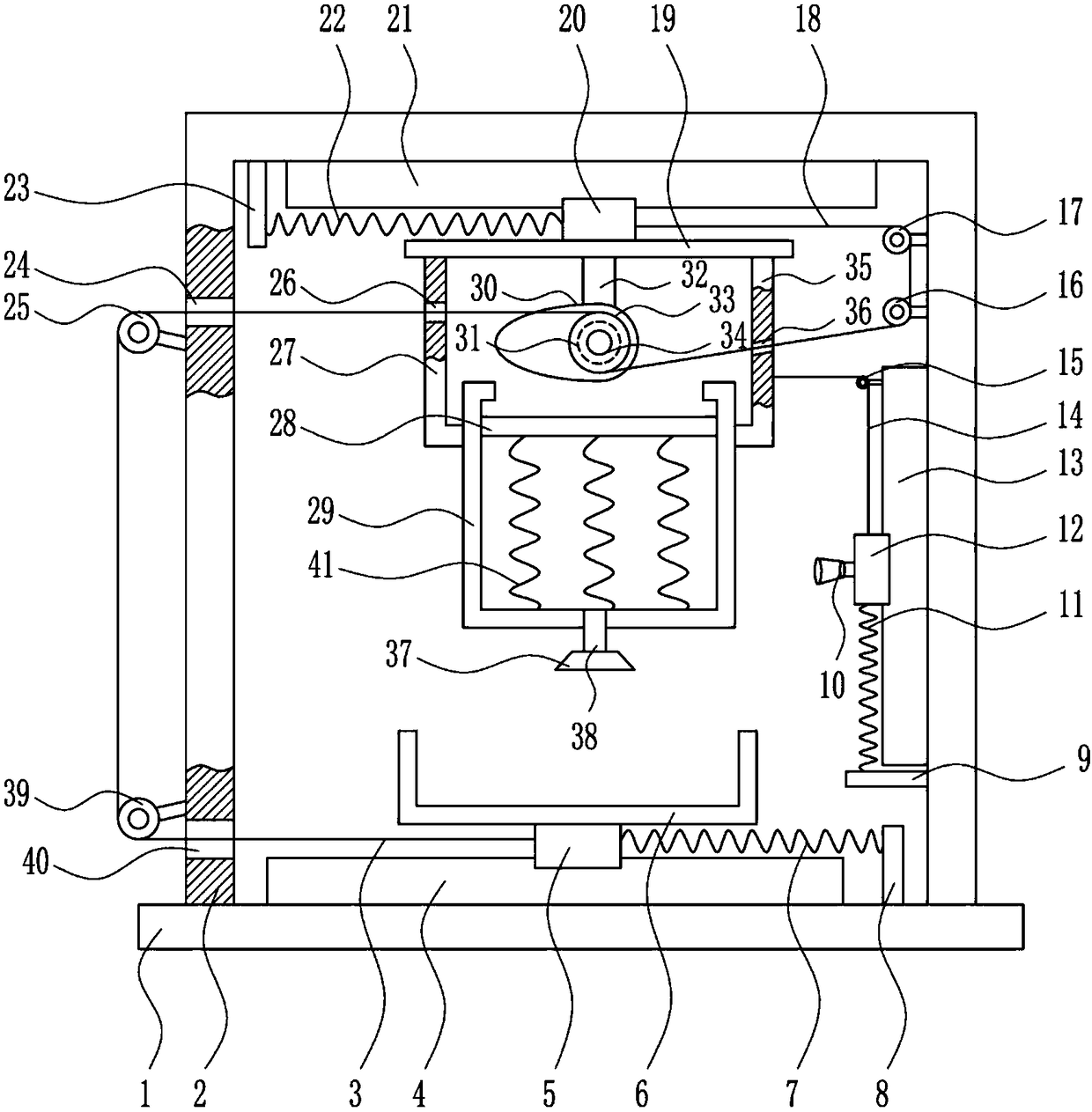

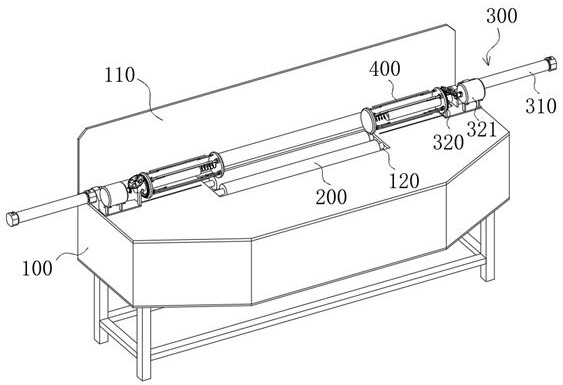

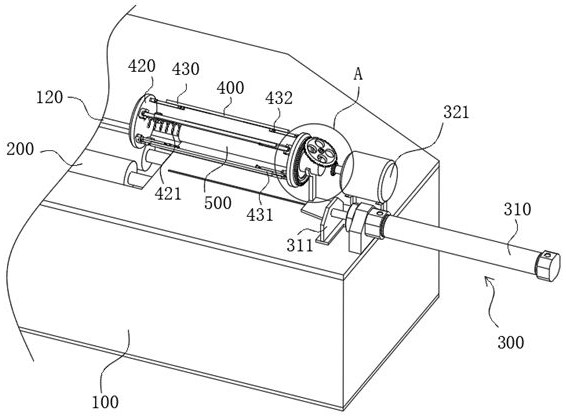

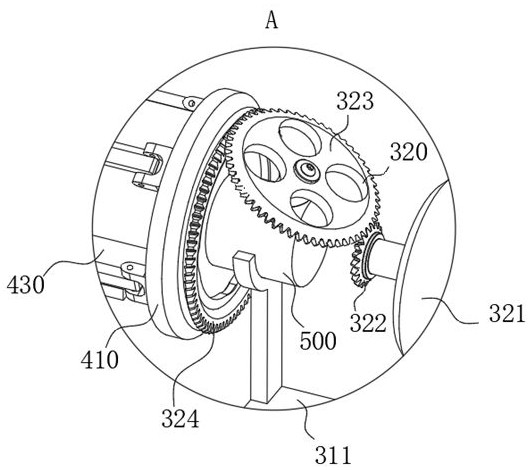

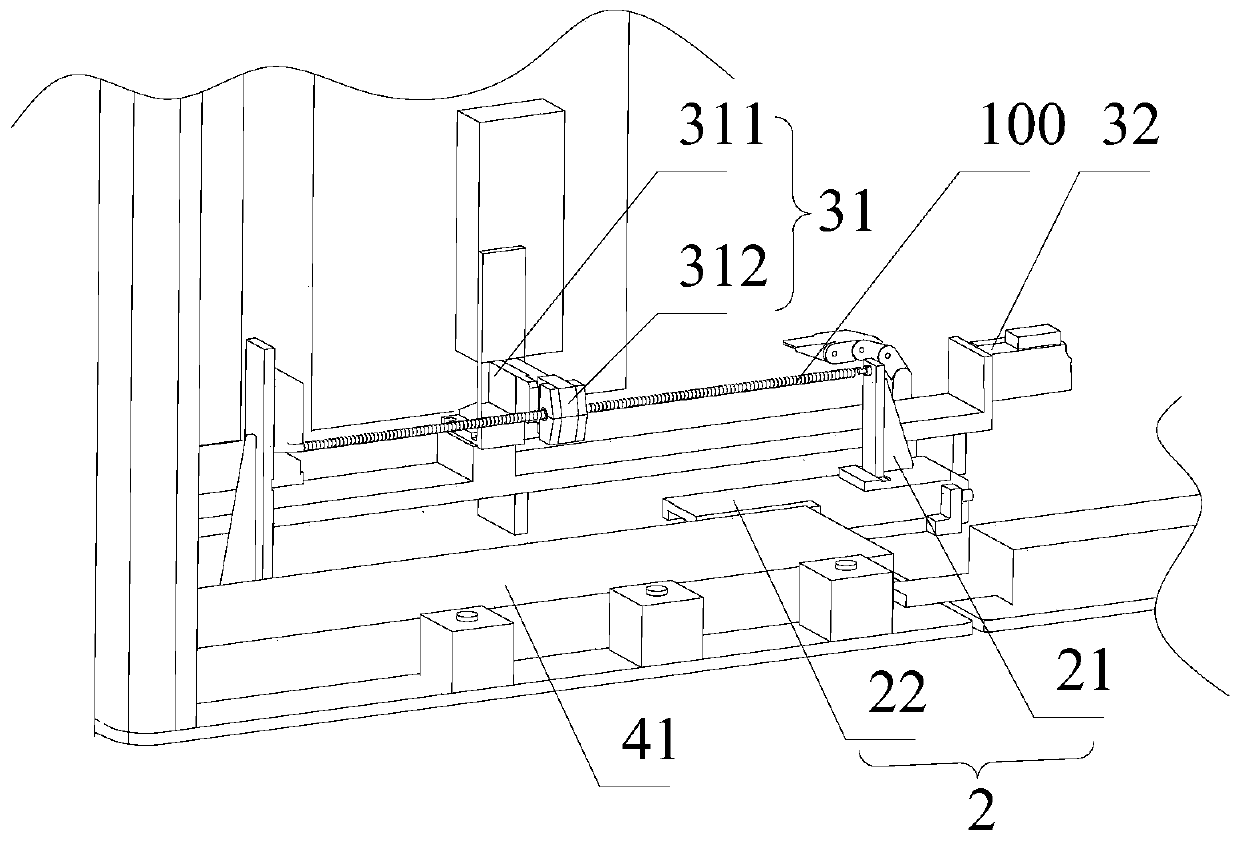

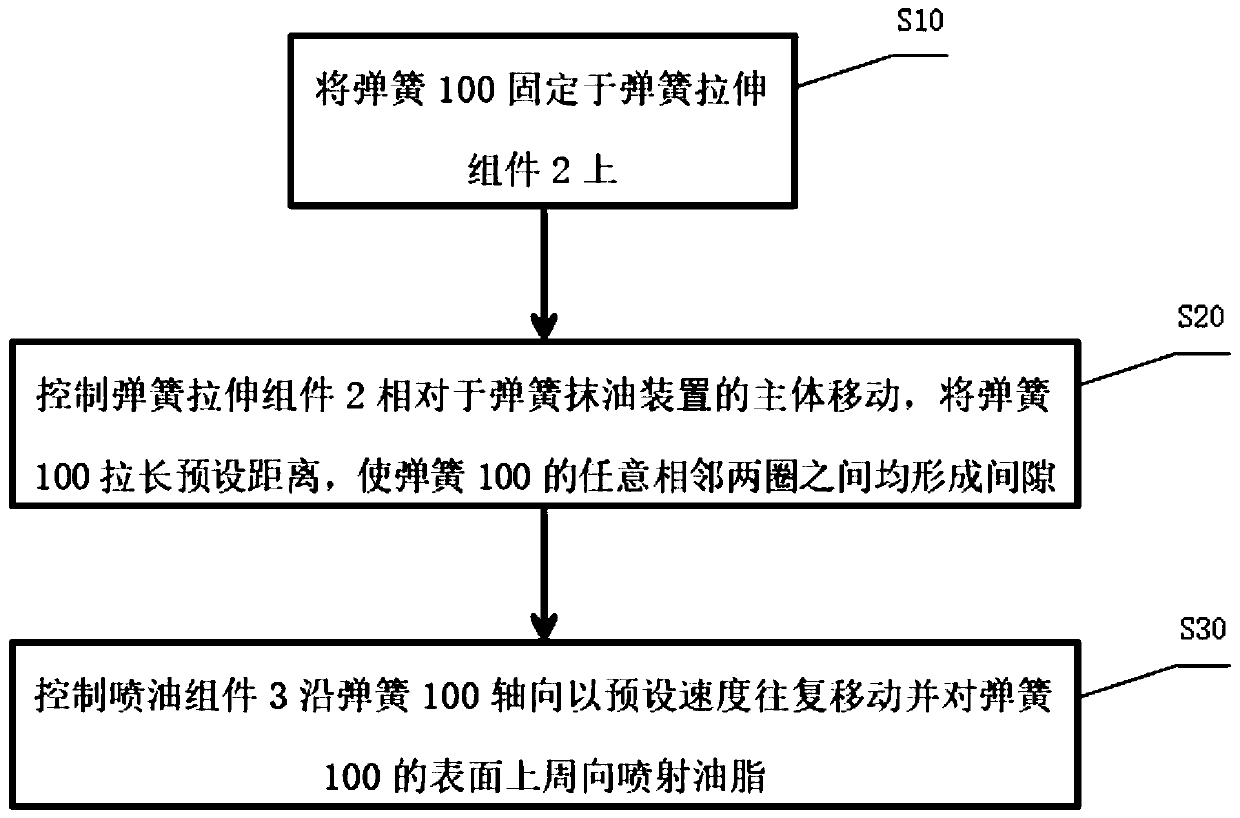

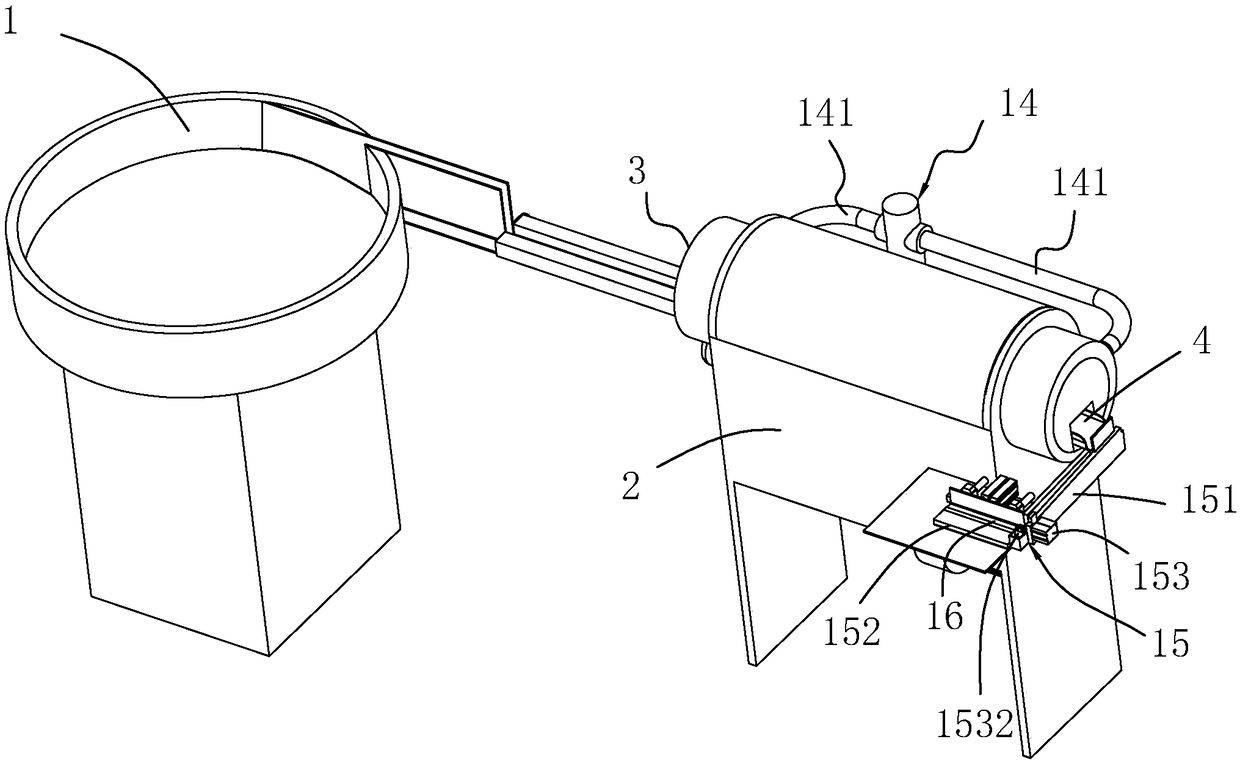

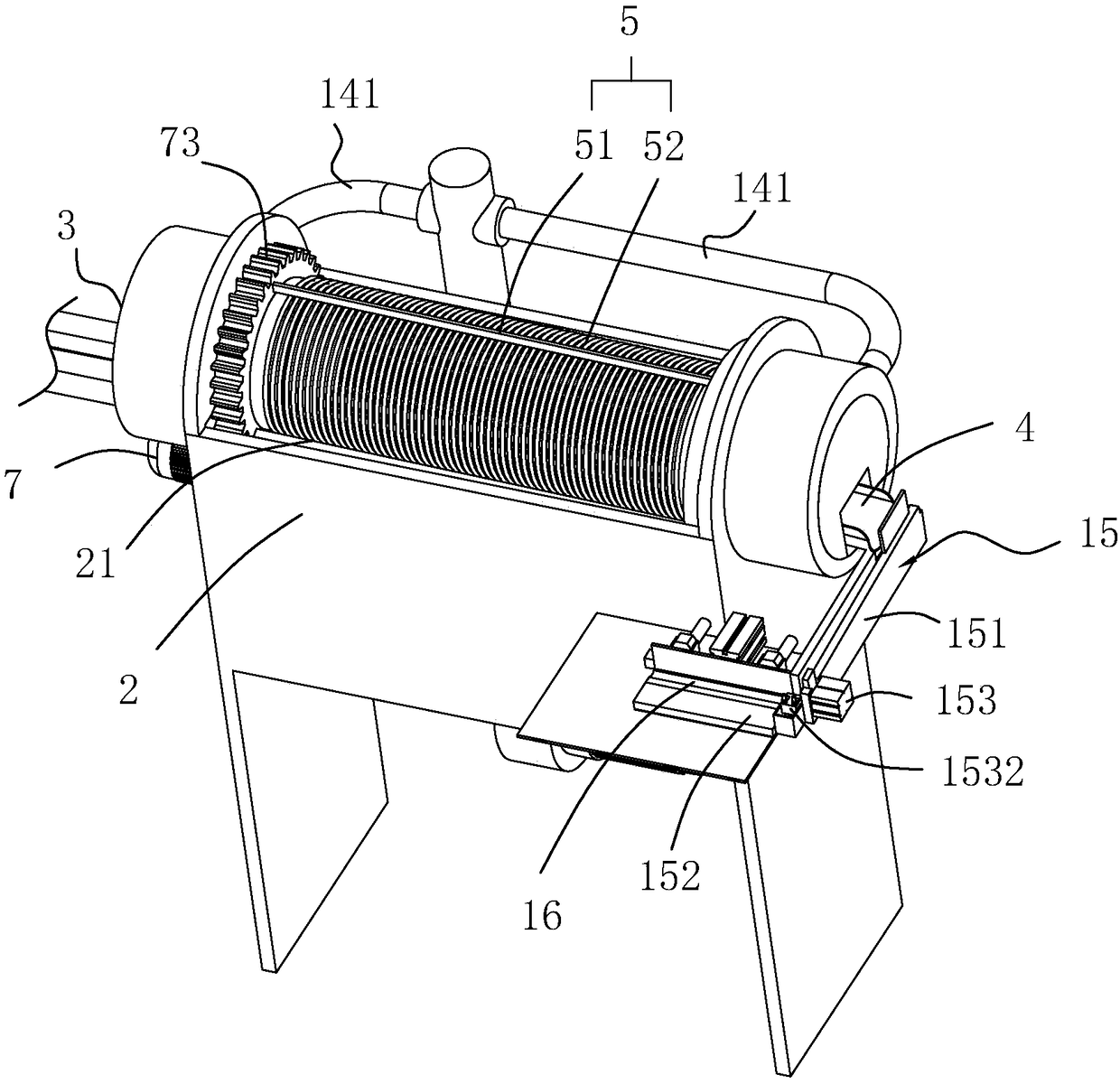

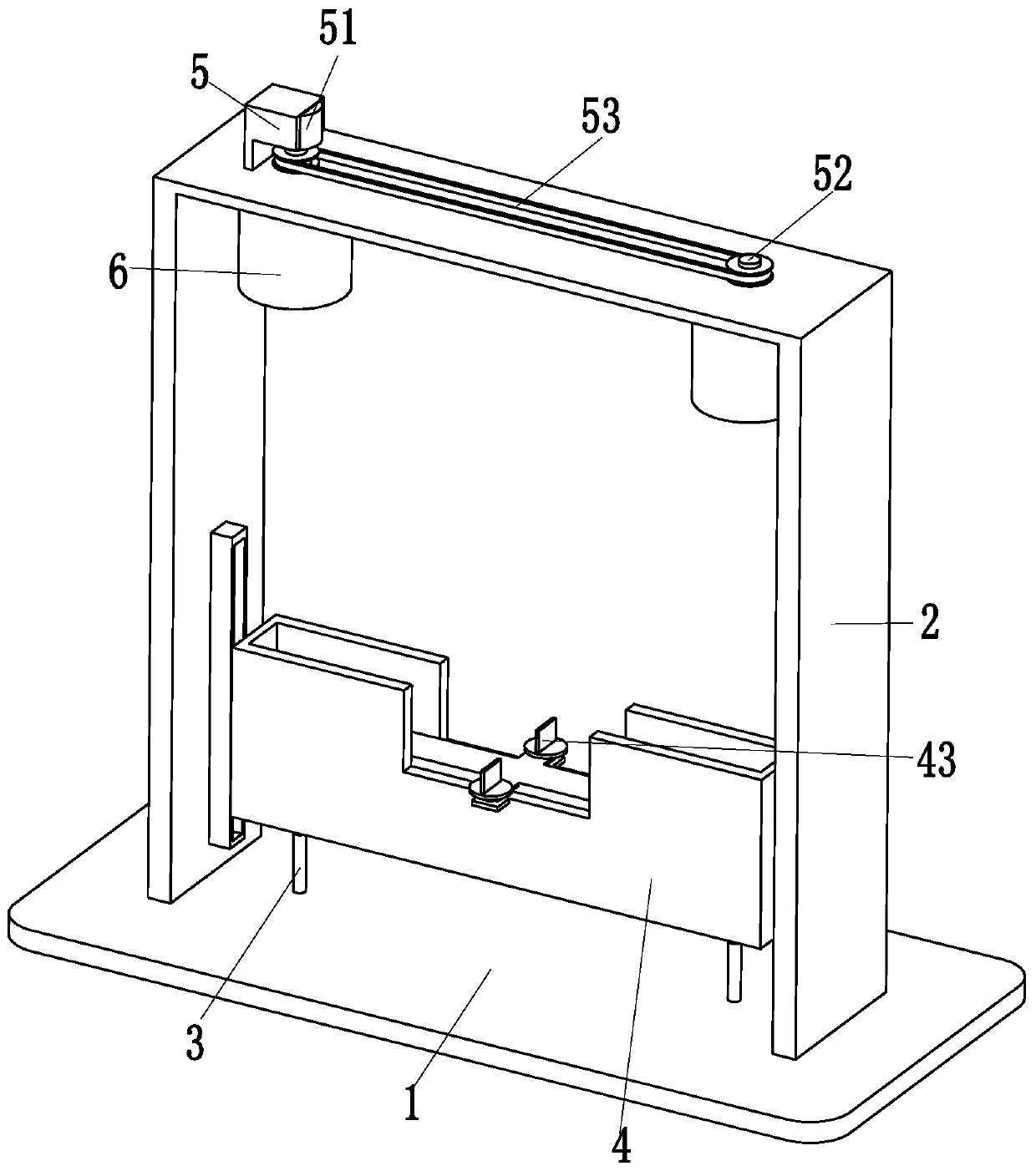

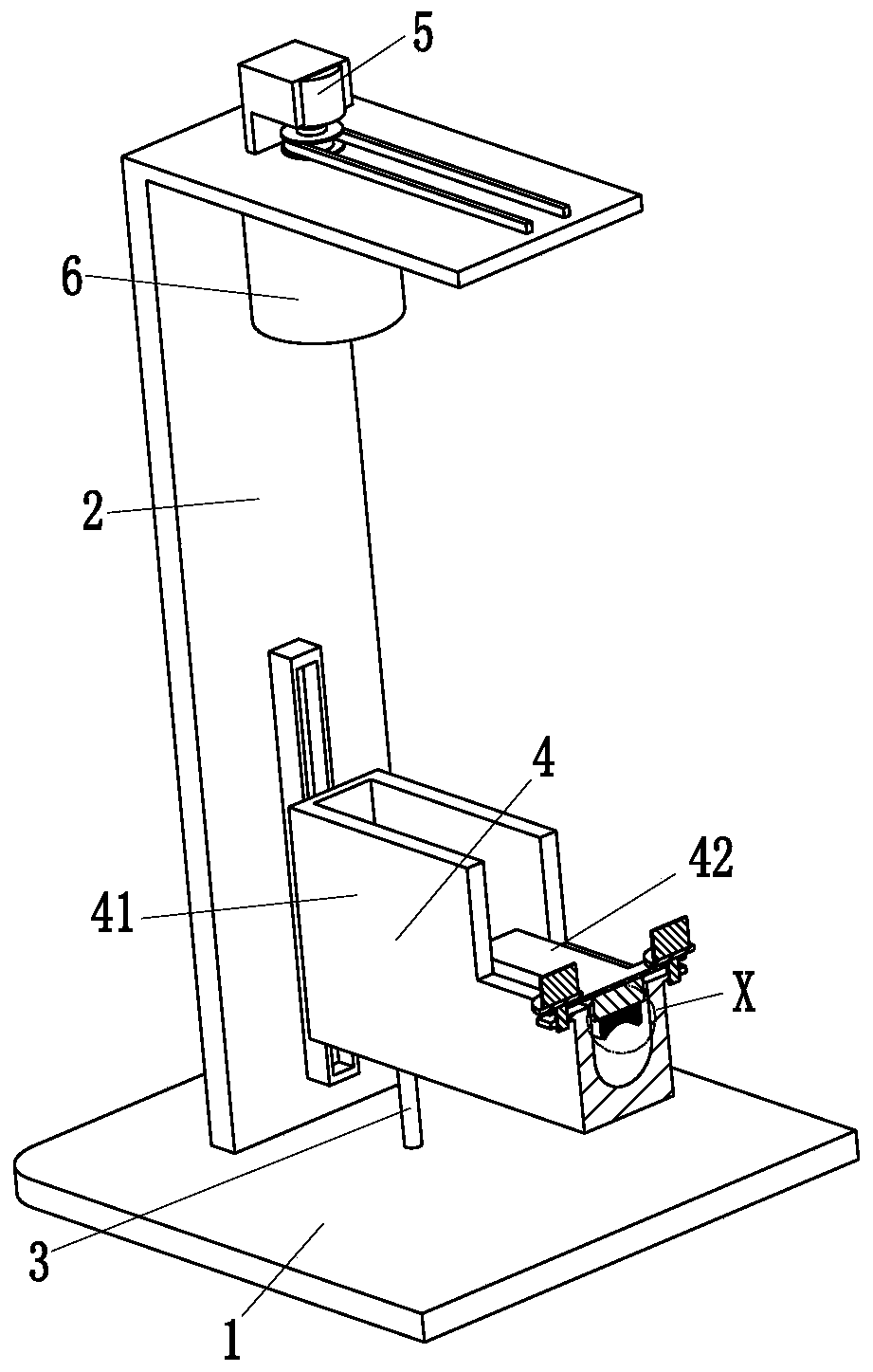

Spring oiling device and method

ActiveCN110433981AImprove uniformityReduce wasteLiquid surface applicatorsLiquid spraying apparatusEngineeringMachining

The invention relates to the technical field of spring machining and discloses a spring oiling device and method. The spring oiling device comprises a grease conveying assembly, a spring stretching assembly, a grease injection assembly and a grease collection assembly. The grease conveying assembly is used for extracting grease and pressurizing the grease. The spring stretching assembly is configured to be used for stretching a spring. The grease injection assembly communicates with the grease conveying assembly. The grease is sprayed on the stretched spring. The grease injection assembly canreciprocate along the spring. The grease injection quantity of the grease injection assembly and movement speed of the grease injection assembly are set to be adjustable. The grease collection assembly is located below the spring and is used for receiving the grease dripping from the spring. With the above structure, through the spring oiling device and method, labor intensity of operators can belowered, spring oiling efficiency can also be improved, the spring oiling quantity is controlled, oiling uniformity is improved, and grease waste is reduced.

Owner:KUNSHAN LONGTAI AUTO SPARE PARTS CO LTD

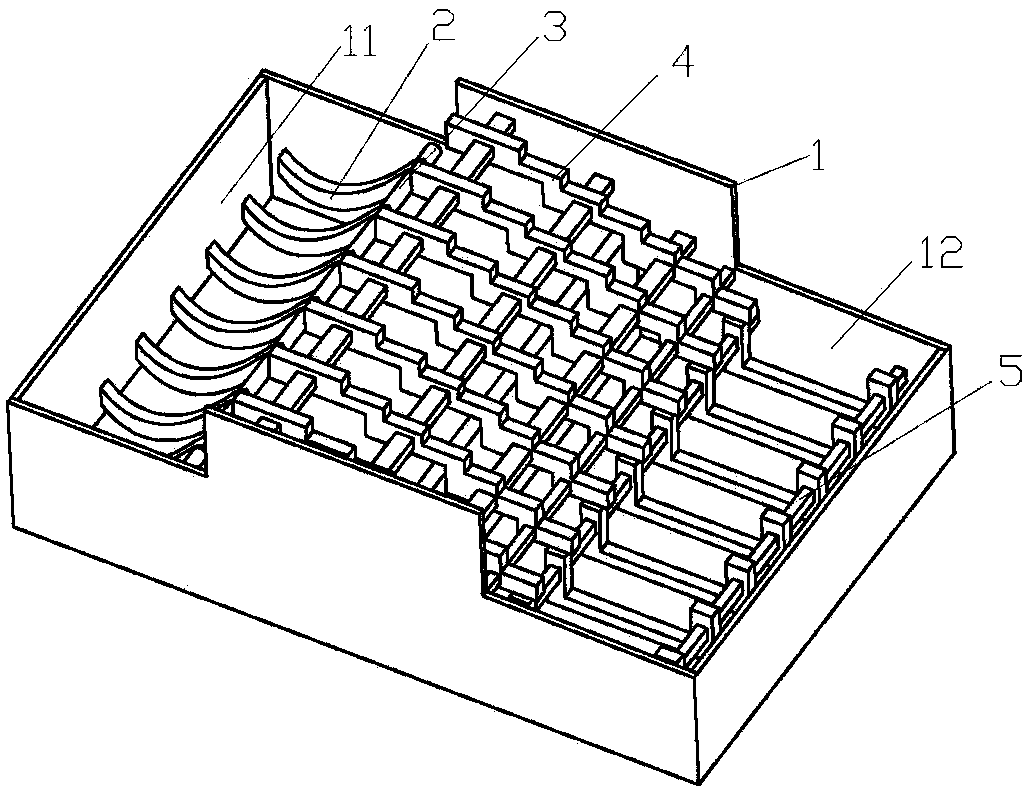

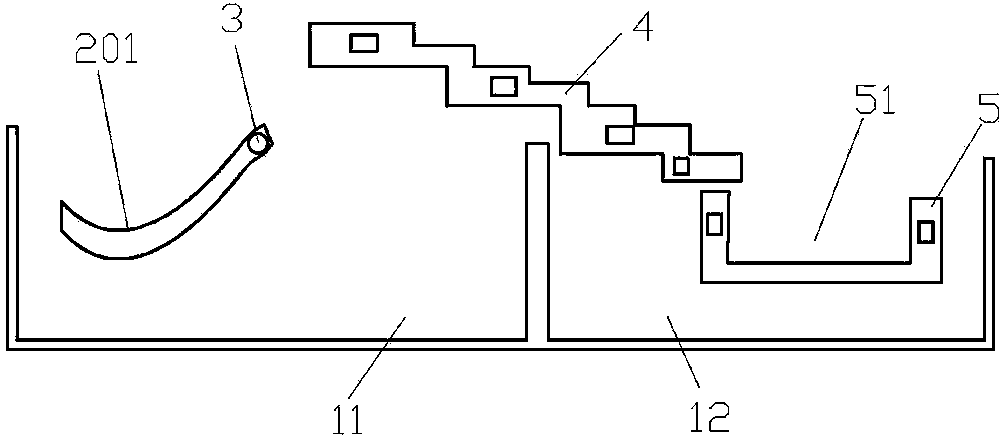

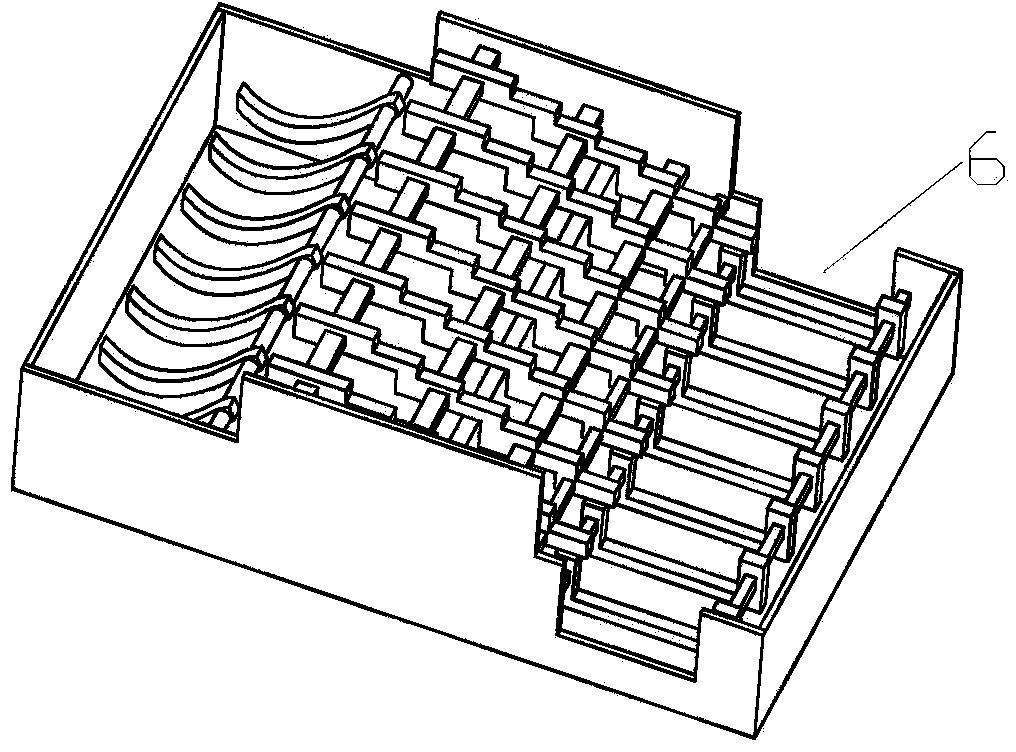

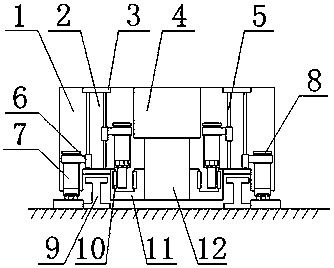

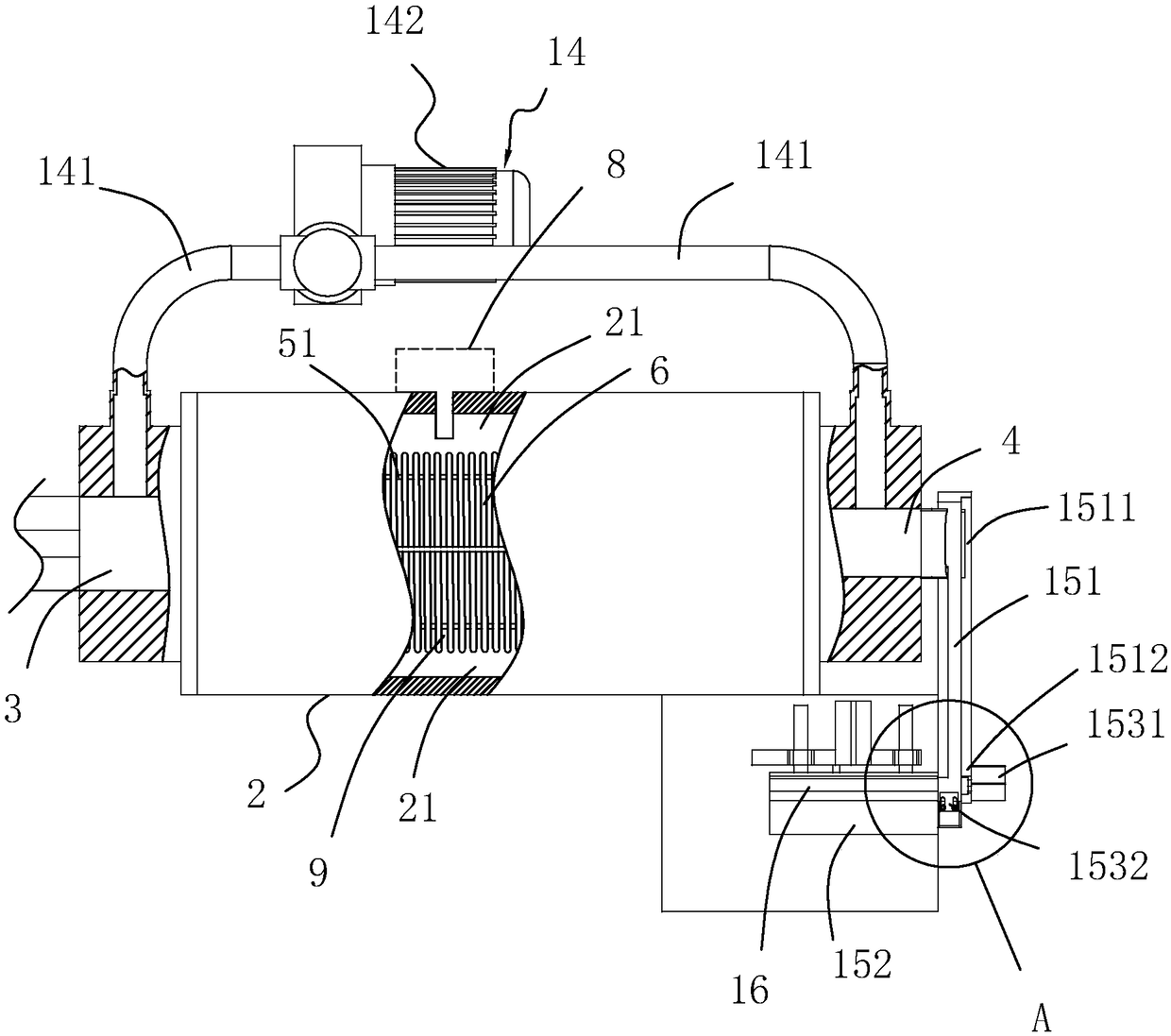

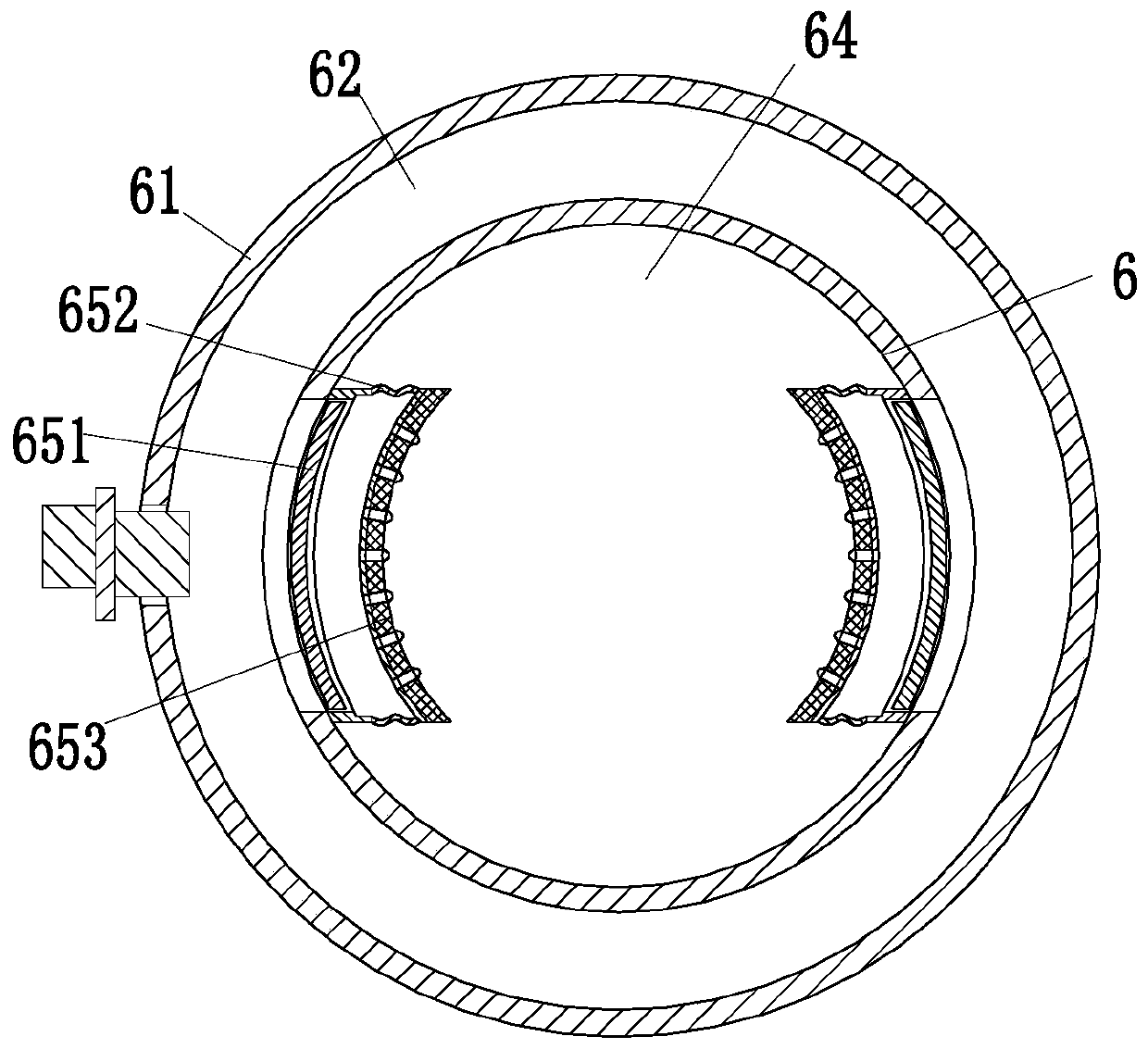

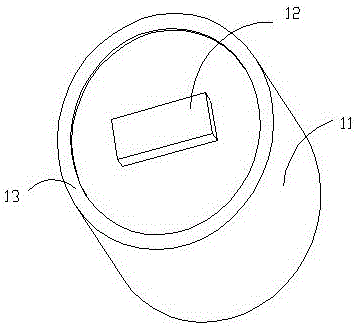

A Bearing Oiling Alignment Machine

ActiveCN106975584BMeet oiling needsImprove rust resistanceLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a bearing oiling orderly arranging machine. According to the technical scheme, the bearing oiling orderly arranging machine is characterized by comprising a feeding mechanism, a discharging mechanism and a machine body; the machine body is internally provided with an oiling cavity, a feeding channel and a discharging channel; the oiling cavity is internally provided with an oiling barrel, a driving part and an atomization oil injection part; one end of the oiling barrel is connected with the feeding channel, and the other end of the oiling barrel is connected with the discharging channel; the oiling barrel is obliquely arranged overall and is provided with a plurality of clearance channels; the atomization oil injection part is used for conducting atomization oil injection on the oiling barrel; the feeding mechanism is located on one side of the feeding channel of the machine body and used for transporting to-be-oiled bearings to the feeding channel; and the discharging mechanism is located on one side of the discharging channel of the machine body and used for orderly arranging the oiled bearings. According to the bearing oiling orderly arranging machine, automatic oiling is conducted in the whole action process, not only is the oiling efficiency very high, but also the oiling uniformity is very high, the large-batch bearing oiling requirements can be met, and the bearings oiled through the oiling orderly arranging machine is good in antirust property.

Owner:浙江万通轴承股份有限公司

Bolt surface fine treatment system and treatment method thereof

ActiveCN110899047AControl oiling rangeEasy to useLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention relates to a bolt surface fine treatment system and a treatment method thereof. The bolt surface fine treatment system comprises a bottom plate, a U-shaped frame, an air cylinder, a clamping device, a drive device and two treatment devices. The U-shaped frame is mounted on the bottom plate, the clamping device is arranged in the U-shaped frame, an air cylinder is connected between the clamping device and the bottom plate, the drive device is arranged above the U-shaped frame, and the two treatment devices are mounted on the left side and the right side of the lower end of the drive device. The problems that as the absorption capacity of a sponge is high, the oil quantity cannot be controlled in the manner that the sponge is dipped in anti-rust oil manually, part of oil possibly slides along a U-shaped bolt rod as the oil dipping quantity is excessive in the oil coating process, the rod end of the U-shaped bolt rod is contaminated while the oil is wasted, the manual oil coating efficiency is low, only one end of the U-shaped bolt rod is oiled once, and oiling regions cannot be controlled can be solved.

Owner:湖北明道新能源风电有限公司

A bearing oiling device

ActiveCN105499022BOil evenlyImprove oiling efficiencyLiquid spraying apparatusHydraulic cylinderInjection pump

Owner:新昌县林泉轴承有限公司

Automatic oiling machine

ActiveCN108636685AImprove uniformityReduce usageLiquid surface applicatorsCoatingsDrive motorExternal Liquid

The invention relates to the technical field of oiling devices, in particular to an automatic oiling machine. The automatic oiling machine comprises a machine platform. The machine platform is provided with an oil storage tank used for accommodating external liquid oil. The machine platform is rotatably provided with an oil supply wheel, an oil uniformizing wheel and a power wheel. The oil supplywheel is located in the oil storage tank. The oil supply wheel is used for bringing liquid oil in the oil storage tank in an adhering mode. The oil uniformizing wheel is used for adjusting the thickness of the liquid oil layer adhering to the oil supply wheel. When the automatic oiling machine is in use, the external liquid oil is added into the oil storage tank, an external material to be oiled is mounted on the power wheel, a driving motor drives the oil supply wheel, the oil uniformizing wheel and the power wheel to rotate to enable the outer side of the material to be automatically coatedwith the liquid oil without smearing the oil to the outer side of the material manually by an operator, and the oiling efficiency of the material is improved. The thickness of the liquid oil layer adhering to the oil supply wheel is adjusted through the oil uniformizing wheel, the oiling uniformity of the material is improved, and the usage amount of the liquid oil is reduced. Thus, the oiling cost is lowered.

Owner:东莞市科讯机械自动化设备有限公司

Oiling device

InactiveCN104259043ASimple structureImprove oiling efficiencyLiquid surface applicatorsCoatingsPhysicsEngineering

Owner:苏州路云机电设备有限公司

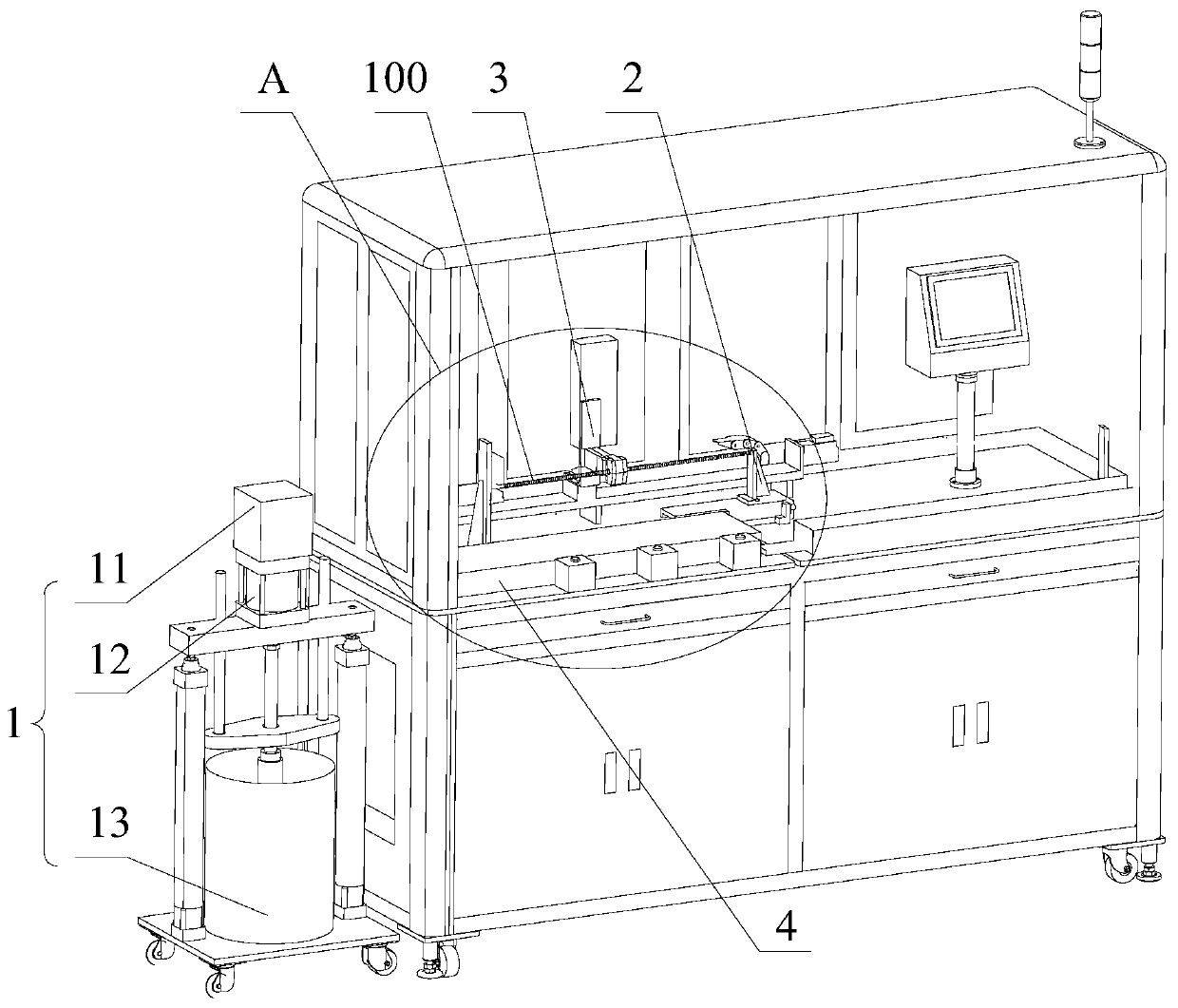

Piston processing method

The invention discloses a piston processing method which comprises the following steps of material selecting and smelting; pouring; thermal treatment; metal processing: carrying out neck ring turning, pinhole base hole processing and oil coating in sequence, wherein a neck ring turning device is adopted to carry out neck ring turning on a piston, a pinhole base hole processing device is adopted to carry out pinhole base hole drilling on the piston, and an automatic oil coating mechanism is adopted to carry out oil coating on the piston; and roundness test: adopting a piston roundness test device to test surface roundness of the piston. The piston processing method disclosed by the invention has the advantage of being high in strength and modulus, stable and precise in neck ring turning, stable in clamping, uniform in oil coating, high in oil coating efficiency, free of manual handheld measuring and wide in measuring position selectivity, and being capable of reducing tool abrasion, avoiding occurrence of oval holes during drilling, improving product quality, reducing a rejection rate and realizing simultaneously measuring roundness of the skirt part and the top part of the piston.

Owner:ANHUI HIGH TECH POWER TECH

An oiling device for downwind ball production

ActiveCN110000053BImprove oiling efficiencyHigh oil coverageLiquid surface applicatorsCoatingsCentrifugal forceMetering pump

The invention discloses an oiling device for producing a downwind ball. The oiling device comprises an oiling tank, fixing blocks are fixedly mounted at the two corners of one side face of the oilingtank, the two fixing blocks are distributed in axial symmetry with respect to the transverse center line of one side face of the oiling tank, the two fixing blocks are the same in specification, the corners on one side edges of the two fixing blocks are arranged in an arc shape, rotating holes are formed in the circle centers of the opposite sides of the two fixing blocks, and a box door is arranged on one side of the oiling tank; and rotating columns are fixedly mounted at the positions, close to the side edges, of the upper and lower end edges of the box door, the two rotating columns are designed to be matched with the two rotating holes, and the two rotating columns correspond to the two rotating holes in position. By means of the oiling device for producing the downwind ball, the downwind ball in an oiling die is oiled through a metering pump, meanwhile, a rotating mechanism at the bottom is started, the oiling die is driven to rotate, the downwind ball is accordingly driven to rotate, centrifugal force generated by rotation fully applies anti-rust oil on the downwind ball.

Owner:GUANGDONG YAOLONG METAL TECH CO LTD

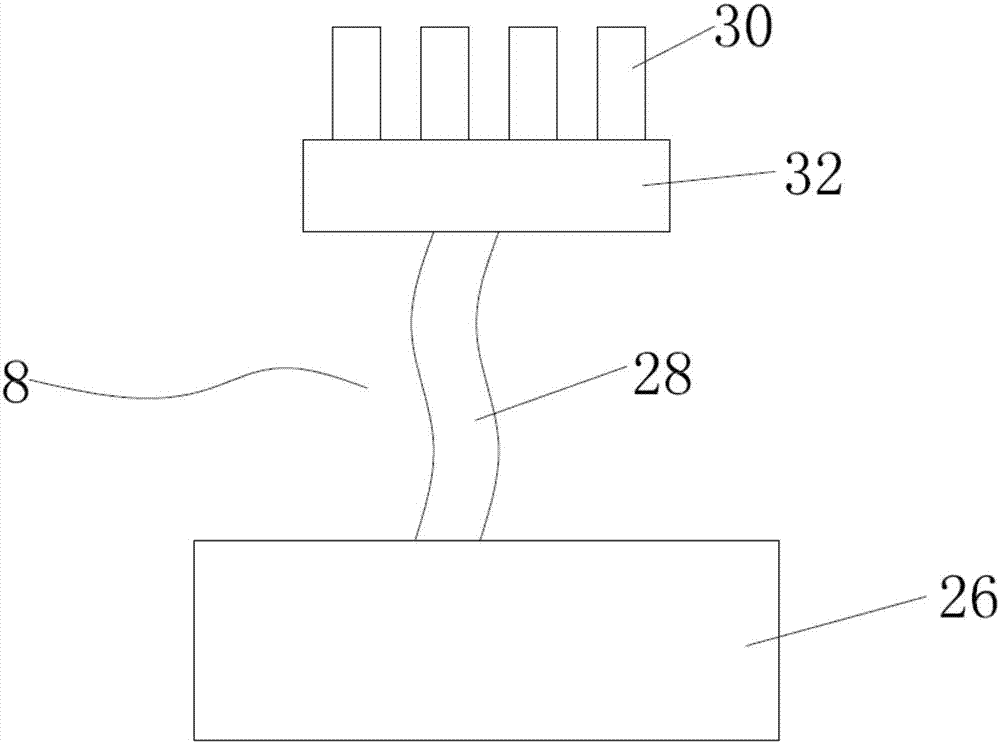

Automatic piston oiling mechanism and method

InactiveCN106540845AShorten the timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an automatic piston oiling mechanism. The automatic piston oiling mechanism comprises a positioning installation base, a motor, a brush, a holding rack assembly, guide rails and an air cylinder, wherein the motor is arranged at the bottom of the positioning installation base, and an output shaft of the motor is connected with the positioning installation base; the positioning installation base is used for storing a piston to be oiled; the holding rack assembly is used for clamping the brush and is in sliding fit with the guide rails; the oil brushing end of the brush can be attached to the surface of the piston to be oiled; and the piston rod end of the air cylinder is connected with the clamping rack assembly so that the clamping rack assembly can be driven to move close to or away from the positioning installation base along the guide rails. The invention further discloses an automatic piston oiling method. The automatic piston oiling mechanism and method have the advantages that the piston is installed stably and firmly, oiling is even, and the oiling efficiency is high.

Owner:ANHUI HIGH TECH POWER TECH

Oil coating device used during storage and transportation of drill rods

InactiveCN105903641ASimple structureImprove oiling efficiencyLiquid surface applicatorsCoatingsFuel tankUltimate tensile strength

The invention relates to an oil coating device used during storage and transportation of drill rods. The oil coating device comprises a base, wherein an oil storage tank is mounted on the base; an arched oil coating plate is arranged above the oil storage tank; a drill rod oil coating space is formed between the arched oil coating plate and the oil storage tank; the arched oil coating plate is of a housing structure with a cavity, an oil coating hole is formed in the inner arc surface of the arched oil coating plate, and an oil inlet head is mounted on the outer arc surface of the arched oil coating plate; an arc-shaped oil guide plate is mounted at the tank body opening of the oil storage tank; a plurality of oil guide holes are formed in the arc-shaped oil guide plate; the bottom of the oil storage tank is provided with an oil outlet; an oil pump, a vertical rod and a vertical hydraulic rod which are positioned at one side of the oil storage tank are mounted on the base; the upper end of the vertical rod is hinged with a transverse cantilever; one end of the transverse cantilever is connected with the oil inlet head; the other end of the transverse cantilever is hinged with the upper end of the hydraulic rod; and the input end and the output end of the oil pump are separately connected with the oil outlet and the oil inlet head through pipelines. The oil coating device replaces traditional manual oil coating with mechanical oil coating, so that the oil coating efficiency is improved and the labor intensity is reduced; and the drill rods do not need to be rotated during oil coating, so that the energy consumption is reduced.

Owner:WUXI ZHONGDI DRILLING EQUIP

Chain oiling device

The invention discloses a chain oiling device which comprises a tank, chain wheels, a chain, an oil pump, an air pump and a motor. The multiple chain wheels are arranged on the inner side of the tankfrom left to right; the chain sequentially bypasses the multiple chain wheels; a clapboard is arranged on the inner side of the tank; the inner side of the tank is divided into a left cavity and a right cavity through the clapboard; a mist spray cover is arranged at the position, located on the upper part of the chain, in the cavity on the left side; and oil mist nozzles are arranged on the innerside of the mist spray cover. Through arranging the oil mist nozzles, misty oil is sprayed for oiling the chain in all dimensions, so that an oiling effect is better, the excessive oiling is avoided,and the production cost is reduced; through arranging the mist spray cover, the oil mist activity range is limited, so that concentrated mist spraying is realized, and the oiling efficiency is improved; and meanwhile, through arranging a spray pipe and the multiple nozzles arranged on the spray pipe, redundant oil on the chain can be cleared through high-pressure gas and is recovered into an oil tank through an oil return plate and an oil return pipe, so that the occurrence of the phenomena of environment pollution and resource waste occurred since the redundant oil is carried out by the chainis avoided.

Owner:浙江德立坤链传动有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com