A Bearing Oiling Alignment Machine

An alignment machine and oiling technology, which is applied in the direction of coating, surface coating liquid device, etc., can solve the problem of low oiling efficiency and achieve the effect of high uniformity, good antirust performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

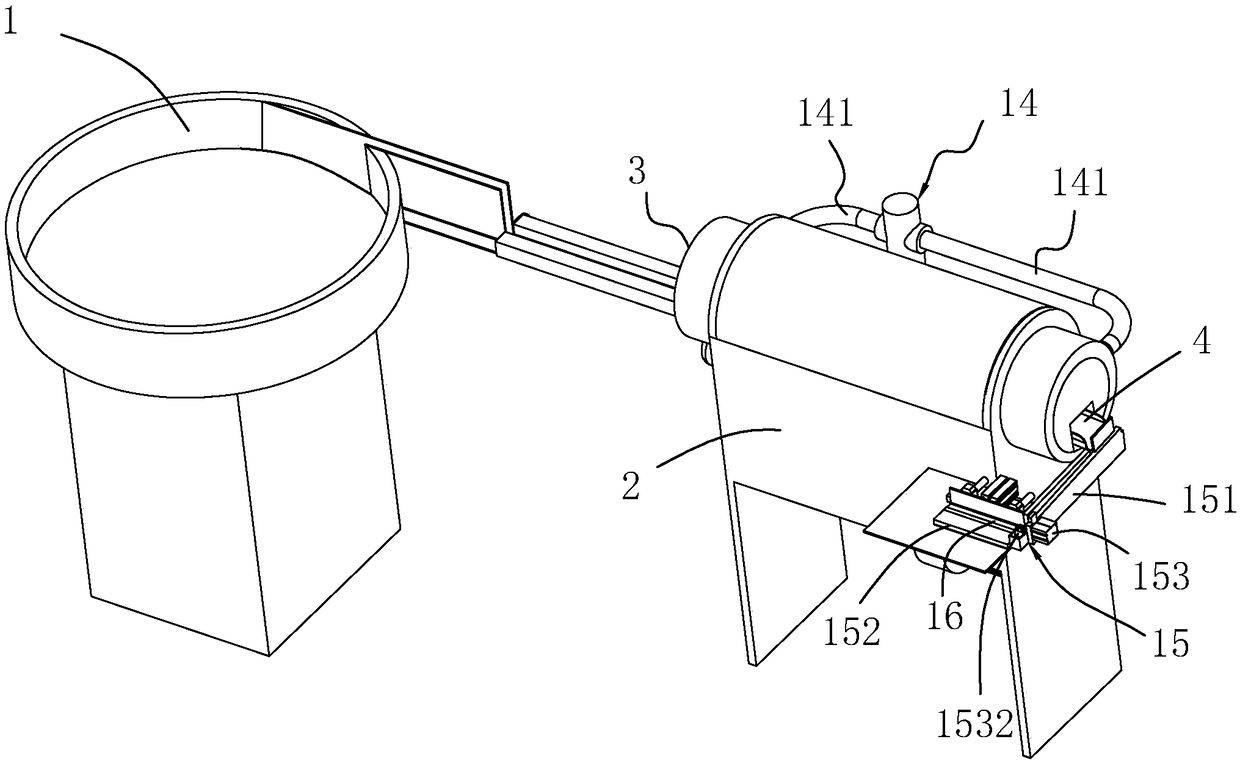

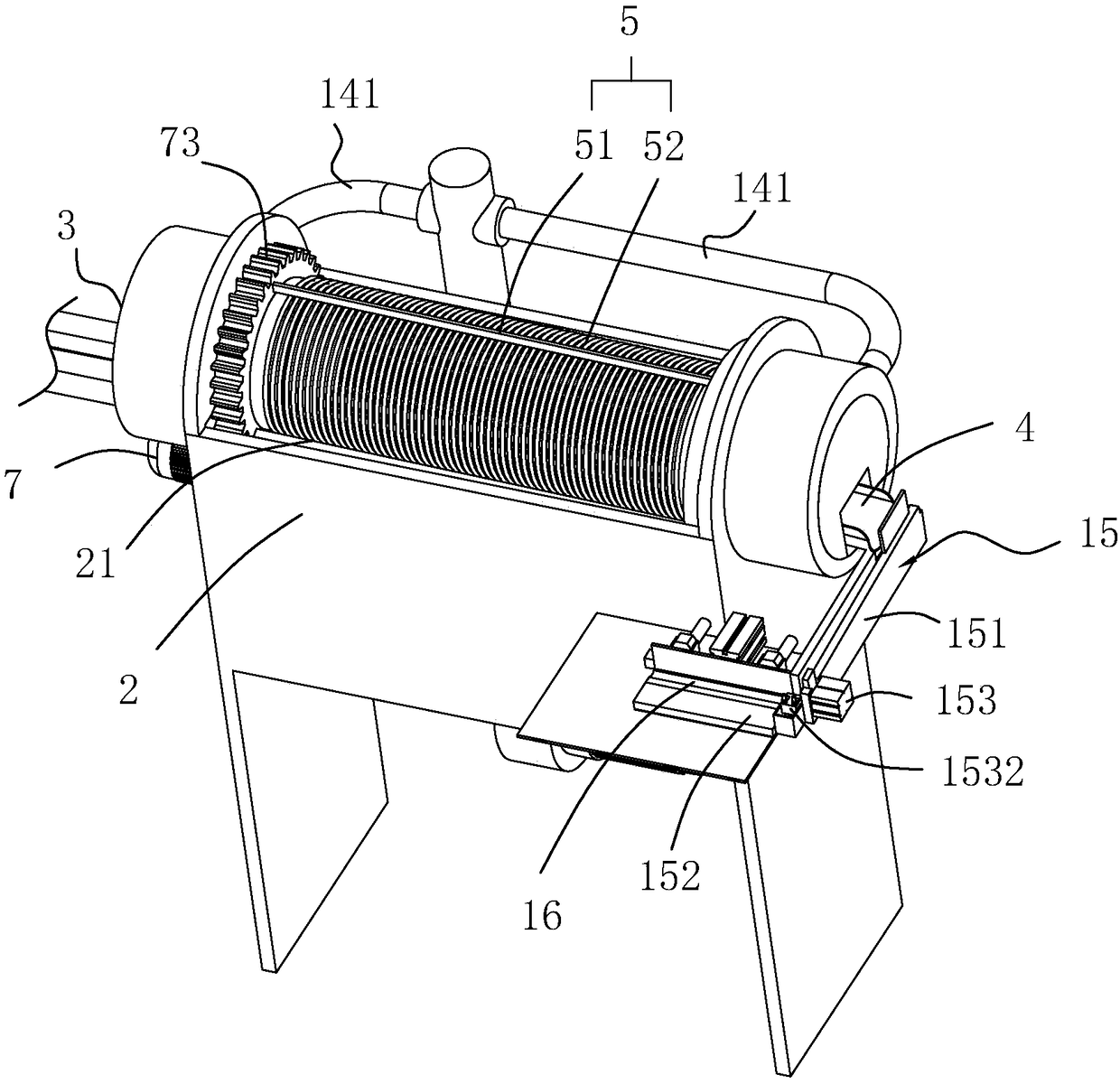

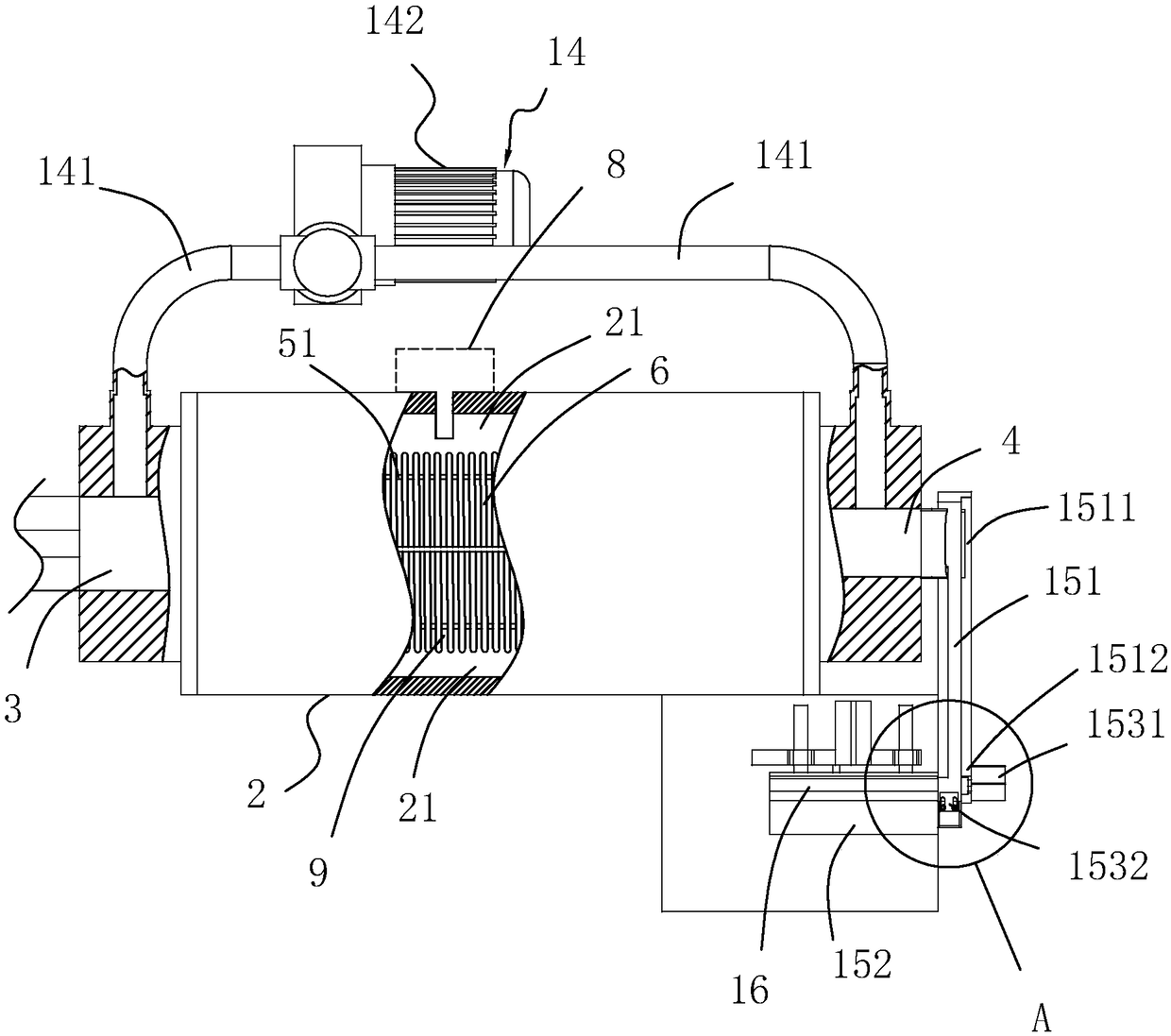

[0038] A bearing oiling alignment machine, see figure 1 , figure 2 as well as image 3 As shown, it includes a feeding mechanism 1, a machine body 2, and a feeding mechanism 15 respectively arranged from left to right, wherein the feeding mechanism 1 can choose a vibrating feeding tray structure, and the body 2 is provided with a feeding channel in turn from left to right 3. The oiling chamber 21, the discharge channel 4, the feeding mechanism 1 is connected to the oiling chamber 21 through the feeding channel 3, and the oiling chamber 21 is provided with an oiling cylinder 5, a driving part 7, an atomizing spray Oil part 8, the two ends of the oiling cylinder 5 are respectively connected with the feed passage 3 and the discharge passage 4, and several gap passages 9 are arranged on the outer cylinder wall of the oiling cylinder 5, and the oiling cylinder 5 One end close to the feed channel 3 is inclined toward the end of the oiling cylinder 5 close to the discharge channel...

Embodiment 2

[0044] Embodiment 2: The difference from Embodiment 1 is that, see Figure 5 As shown, the oiling frame 52 includes a helical spring-shaped oiling member 6, and the driving portion 7 includes a driving motor 71, which is installed on the body 2, and the driving end of the driving motor 71 extends into the coating of the body 2. In the oil chamber 21 and the driving end is connected with a driving gear 72, and the oiling cylinder part 5 is also fixedly provided with a driven toothed plate 73, and in the oiling chamber 21, two supporting frames 10 are vertically arranged, and the two supporting frames The upper end of the frame 10 is directly supported against the outer peripheral side wall of the paint cylinder; when the drive motor 71 is started, the drive gear 72 is engaged with the driven toothed disc 73, and the entire oil paint cylinder 5 can be rotated circumferentially.

[0045] see Figure 6 as well as Figure 7 As shown, several locking pieces 11 are also arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com