Automatic oil coating device for large flange

A technology for oiling devices and large flanges, which is applied in spraying devices, wind power generation, etc., can solve problems such as not being able to meet the oiling needs of large flanges, and achieve the effects of stable and reliable transmission structure, convenient oiling, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

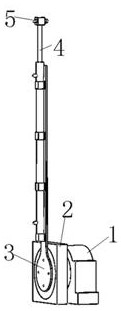

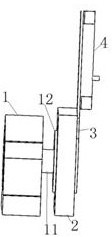

[0037] Attached below Figure 1-9 The present invention is further described as attached figure 1 and 2 The large flange automatic oiling device shown includes a driving device 1, a slewing bearing device 2, a rotating plate 3, a linear telescopic device 4 and an anti-rust oil atomizing nozzle 5.

[0038] like Image 6 As shown, the slewing ring device 2 includes a slewing ring bearing 22 and a bearing seat 21, the outer ring of the slewing ring bearing 22 is mounted on the bearing seat 21, and the bearing seat 21 is fixed on the mounting platform.

[0039] like figure 1 and 3 As shown, the drive device 1 is drivingly connected to the inner ring of the slewing support bearing 22; one end of the rotating plate 3 in the length direction is fixedly or detachably connected to the inner ring of the slewing support bearing 22 away from the drive device 1 side.

[0040] like figure 1 and 2 As shown, the linear telescopic device 4 is installed on the rotating plate 3 , and the ...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is: Figure 9 As shown, in this embodiment, the large flange automatic oiling device is installed on the mobile lifting platform, and the large flange can be oiled at the flange use site.

[0054] The working principle of the large-scale flange automatic oiling device of the present invention:

[0055] The installation platform of the large flange automatic oiling device is a fixed platform (Example 1) or a mobile lifting platform (Example 2). During use, by adjusting the large flange or mobile lifting platform, the slewing bearing device 2 and the large flange can be adjusted. Then adjust the extension length of the movable end of the linear expansion device 4 so that the movable end of the linear expansion device 4 can reach the annular area of the large flange; , so that the spraying range of the anti-rust oil atomizing nozzle 5 coincides with the width of the annular area of the large flange, or is smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com