Turnover barbecue

A grill and carbon grill technology, applied in the field of grills, can solve the problems of low efficiency, uneven grilling, etc., and achieve the effects of high turning efficiency, improved grilling efficiency, and convenient oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

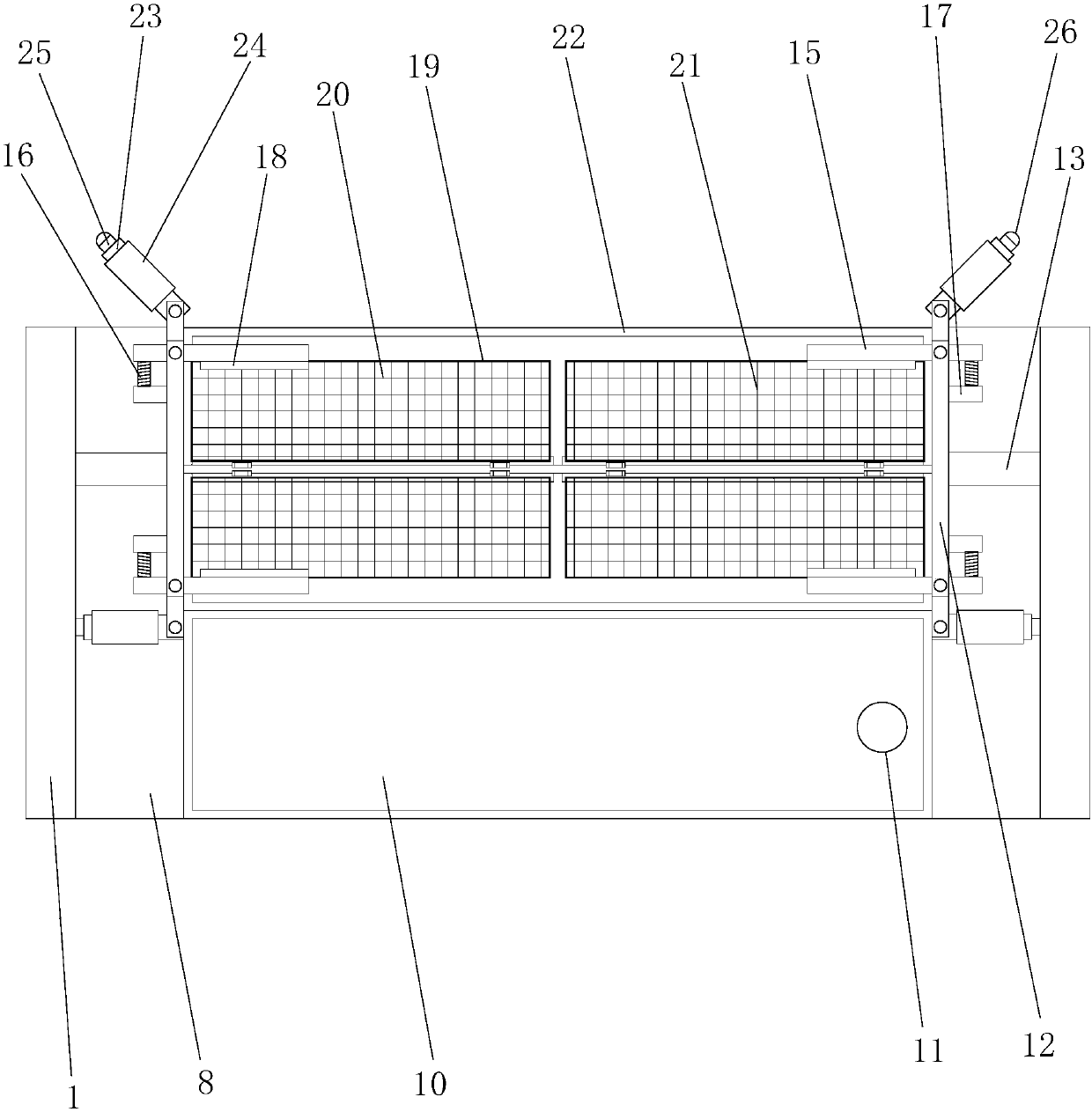

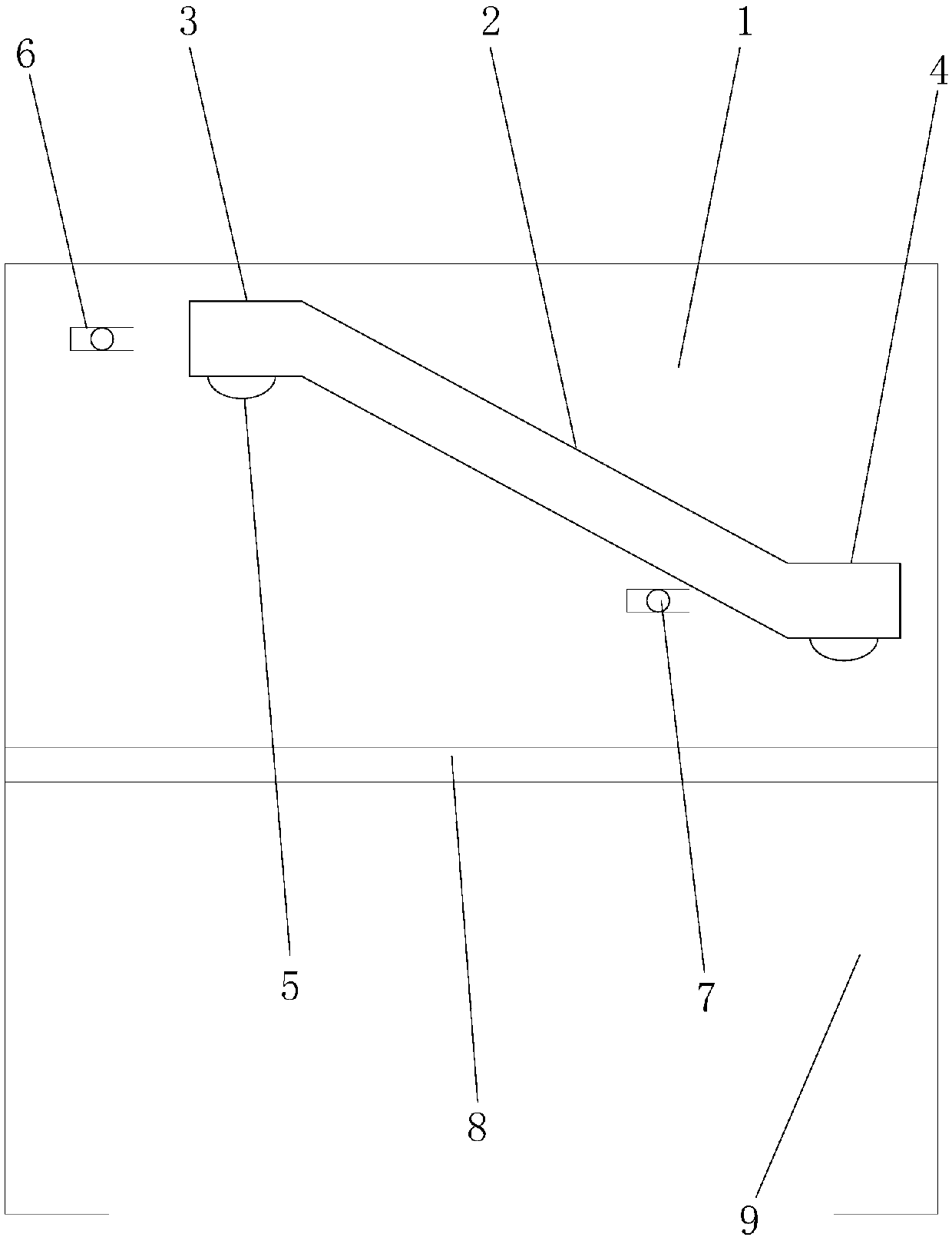

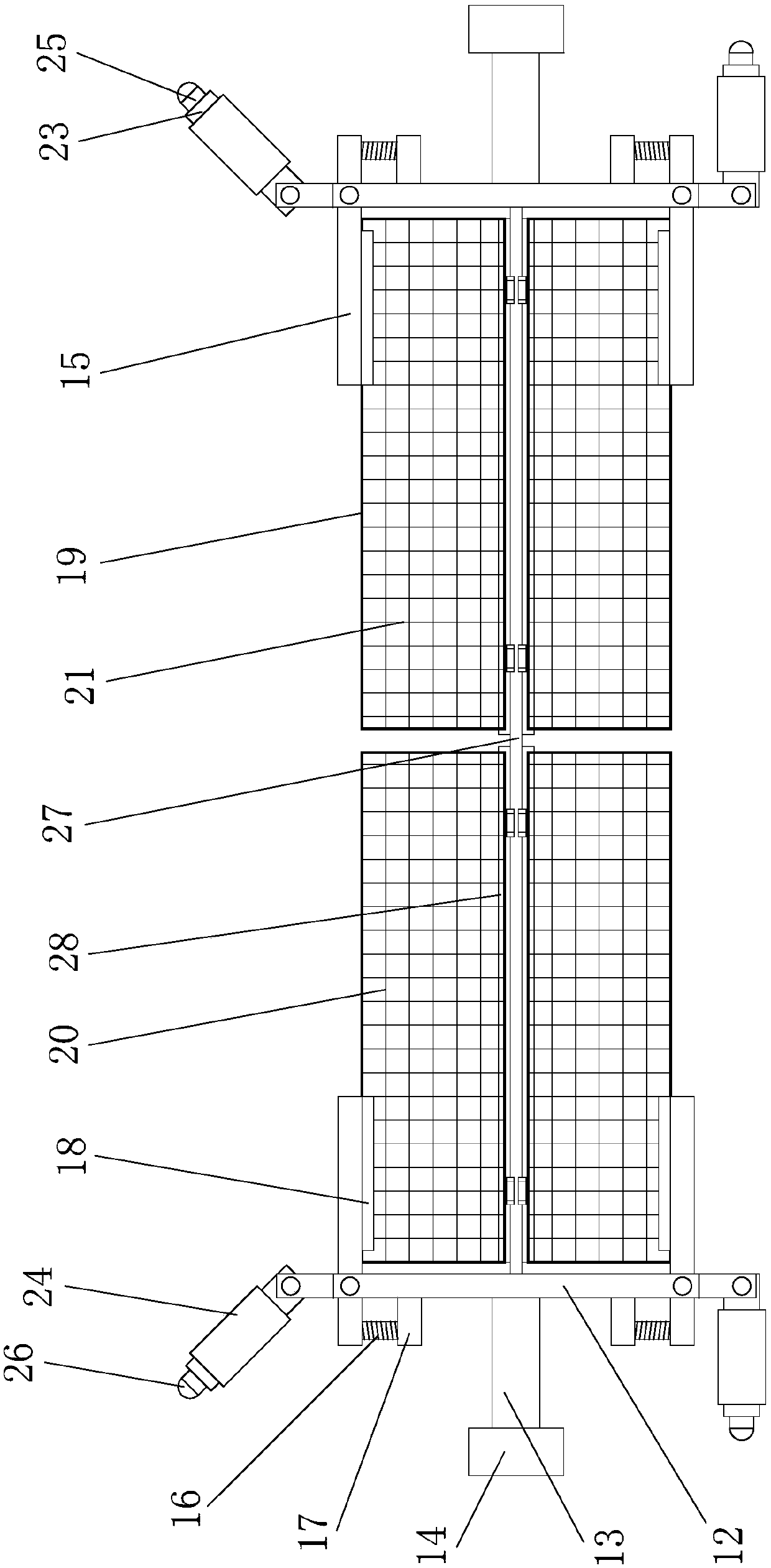

[0019] like Figure 1-4 As shown, the reversible grill disclosed by the present invention includes: two vertical side panels 1, a platform panel 8, a bar-shaped charcoal oven 22 and a flip frame; the two vertical side panels 1 are installed vertically in parallel On the left and right side edges of the platform board 8; a support leg 9 is vertically arranged on the lower side of the platform board 8; a moving chute is correspondingly arranged on the opposite inner side of the two vertical side boards 1; Installed on the platform board 8; the flip frame includes two strip panels 12, a central axis 27 and four steel mesh clamping units for clamping food; the central axis 27 is fixed laterally between the two strip panels 12 , and the two strip panels 12 are parallel to each other, the installation point of the central axis 27 is located at the inner center of the strip panel 12; a support shaft 13 is horizontally arranged at the outer center of the two strip panels 12; There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com