Patents

Literature

148results about How to "Improve oiling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

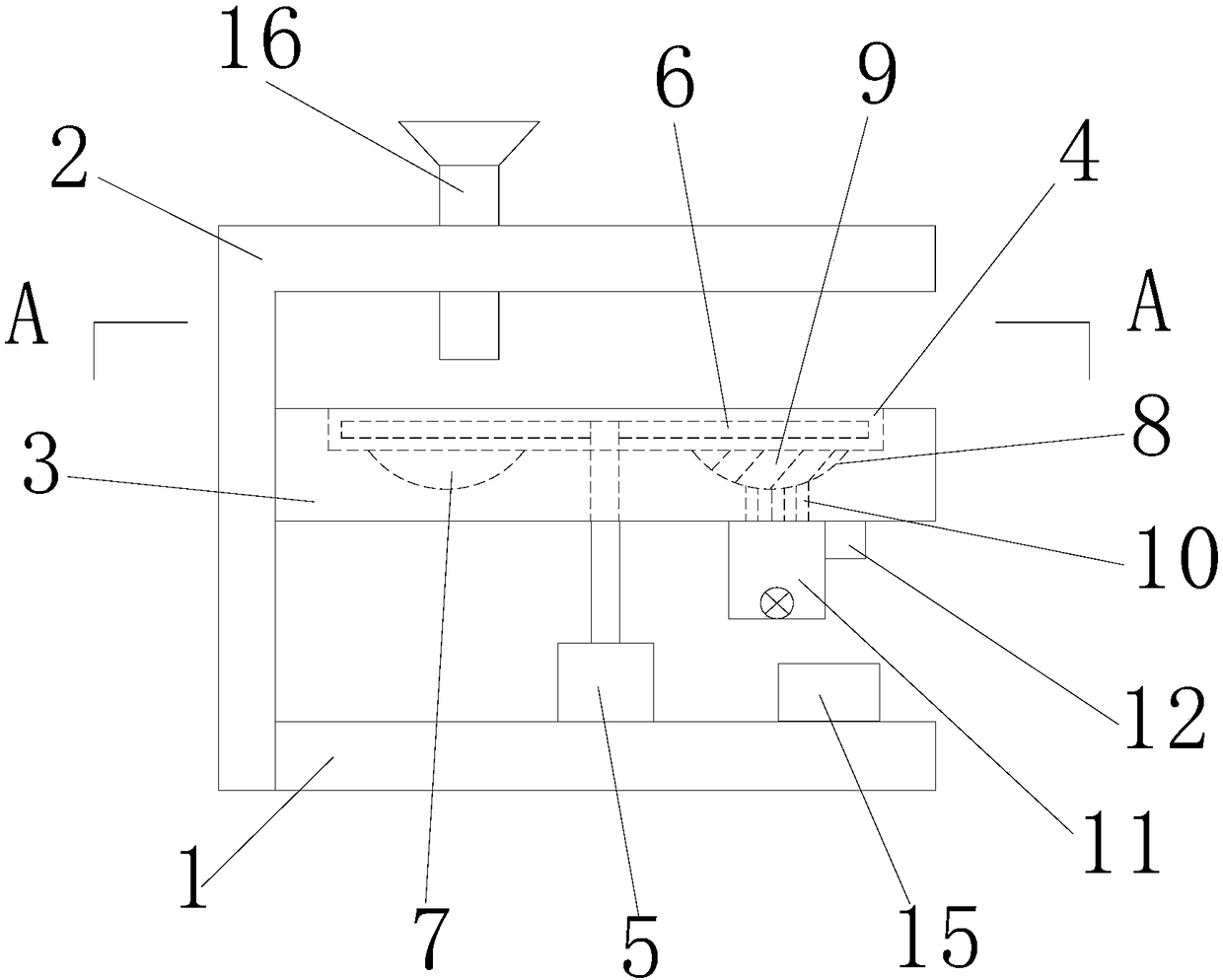

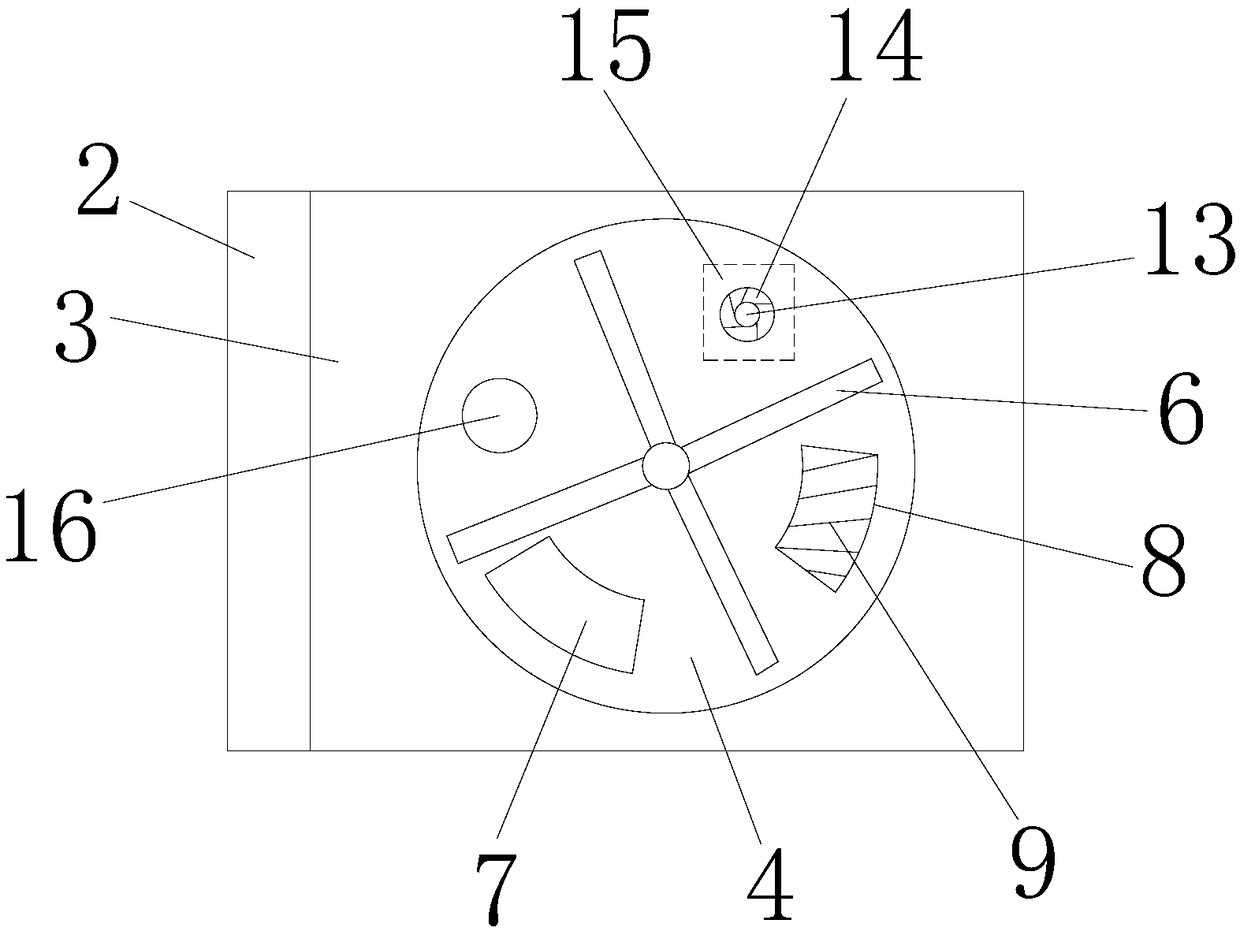

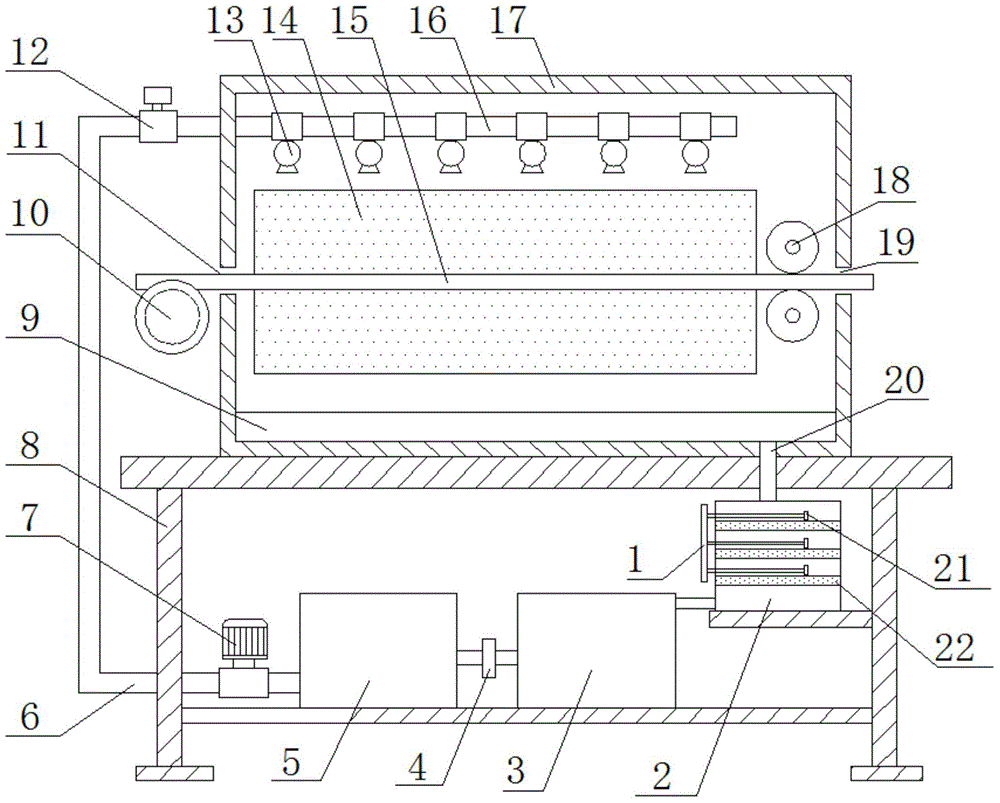

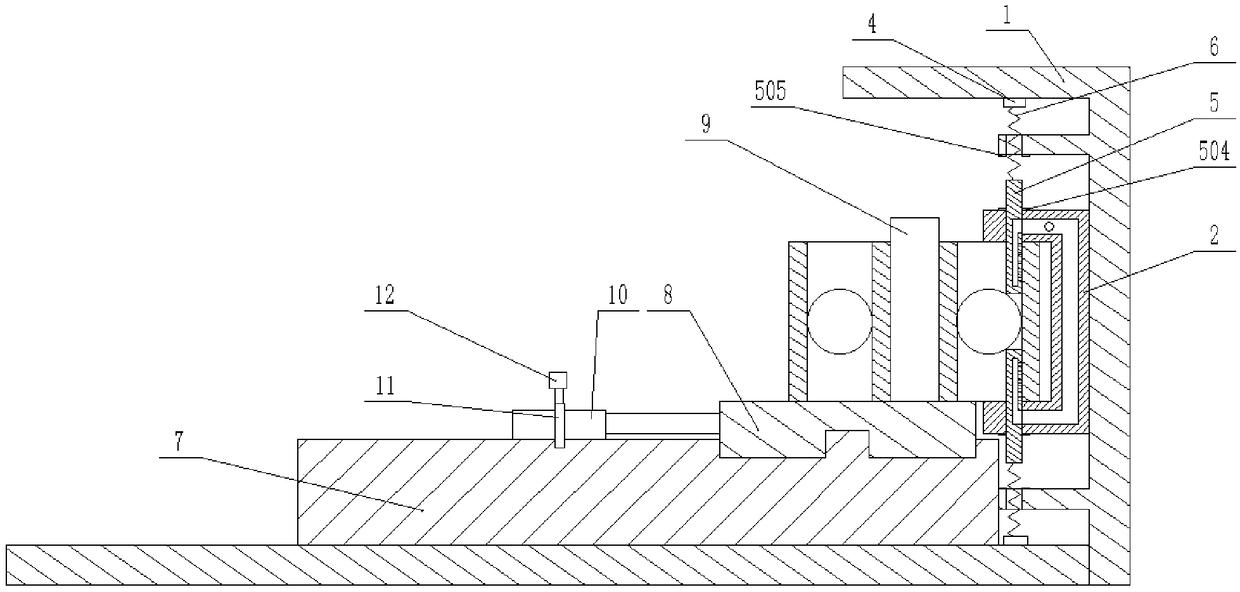

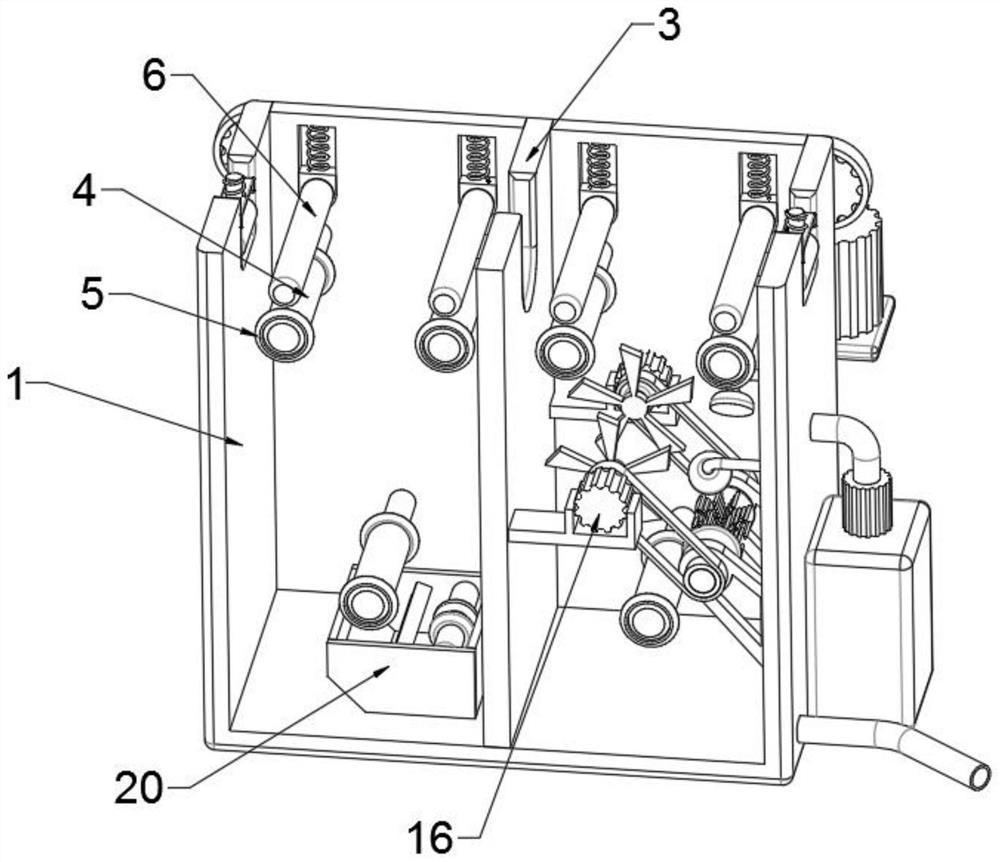

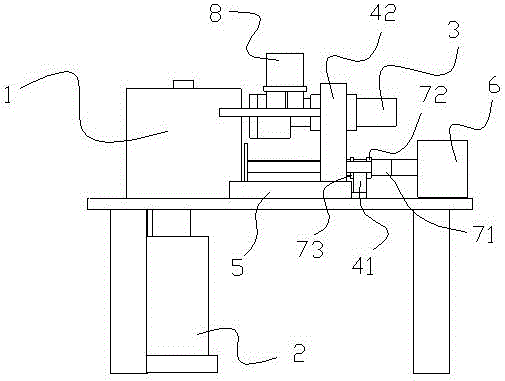

Automatic oil coating device for bearings

InactiveCN108176533AImprove oiling effectStable supportLiquid spraying apparatusEngineeringMaterial storage

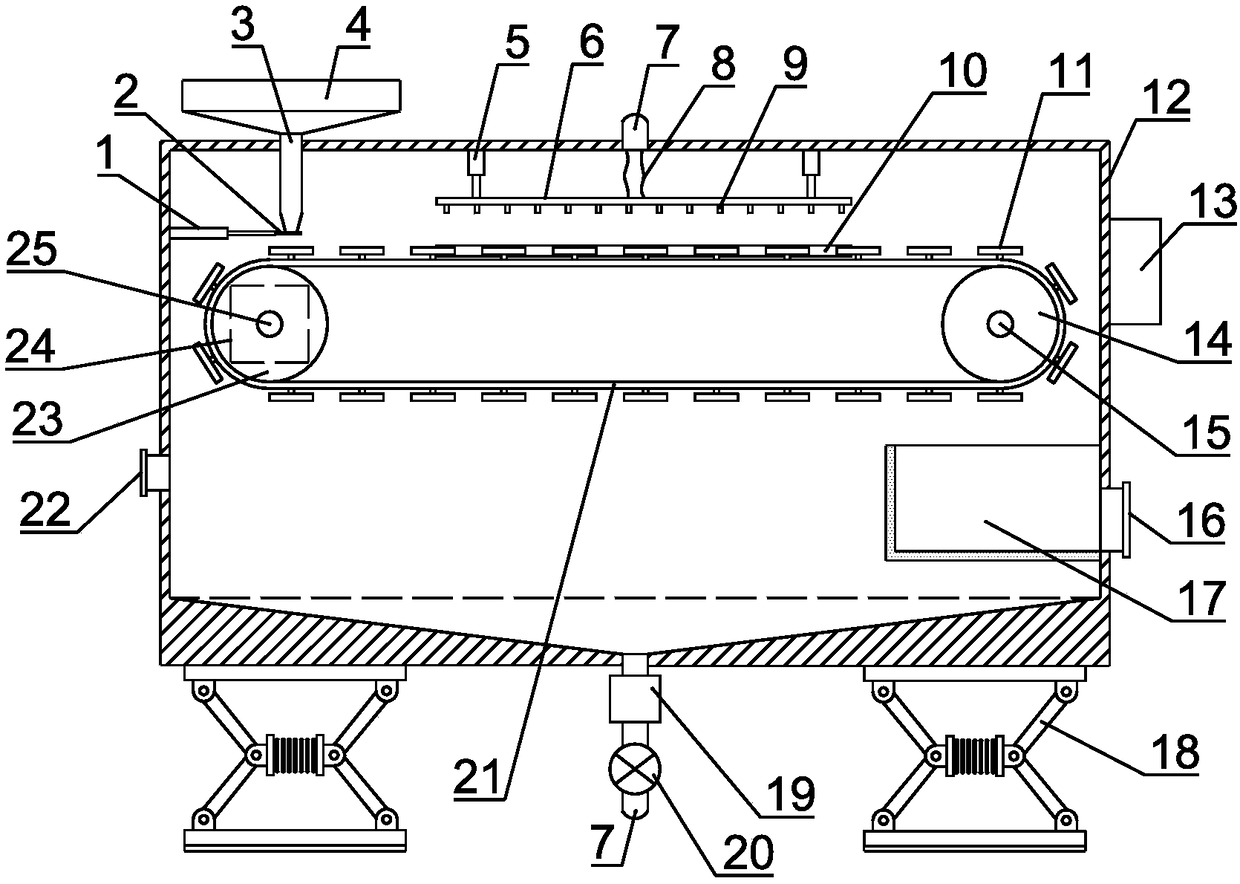

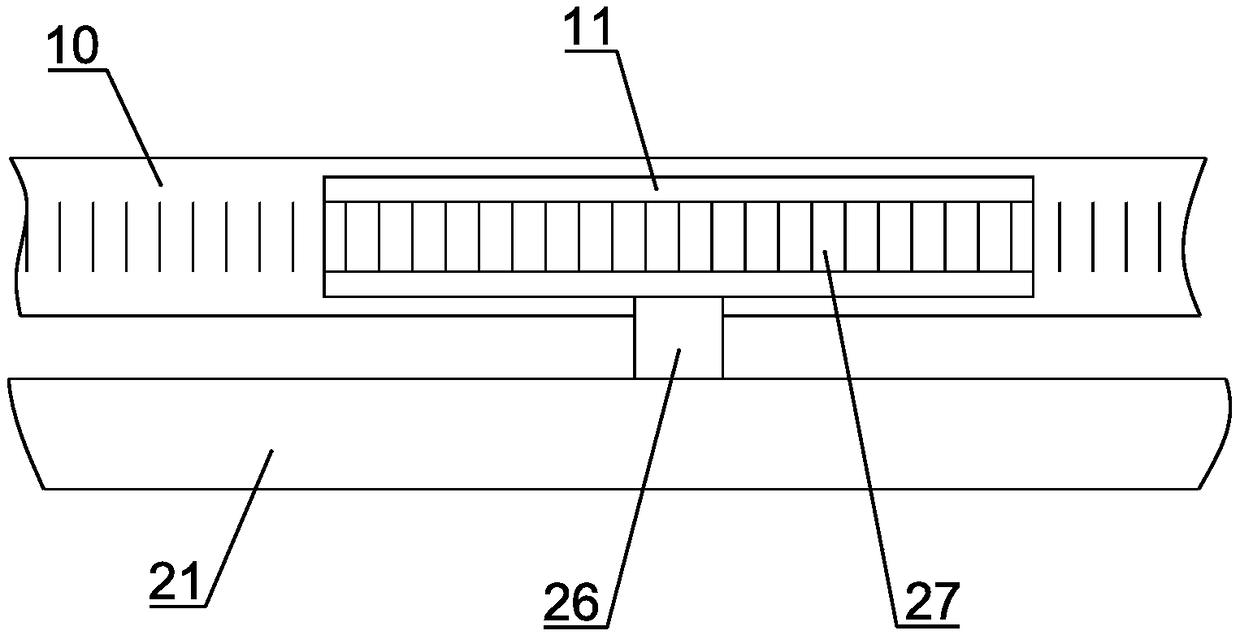

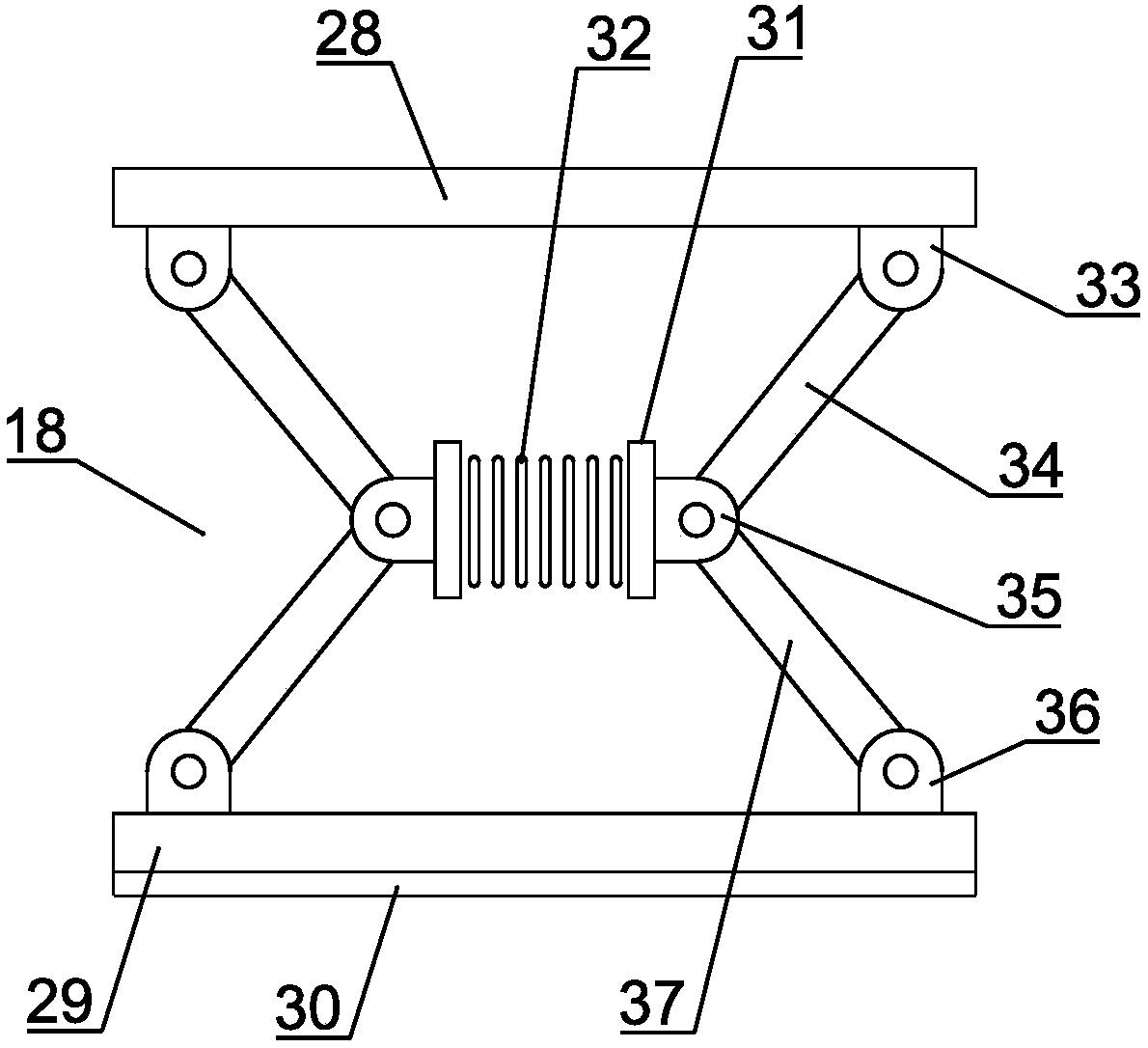

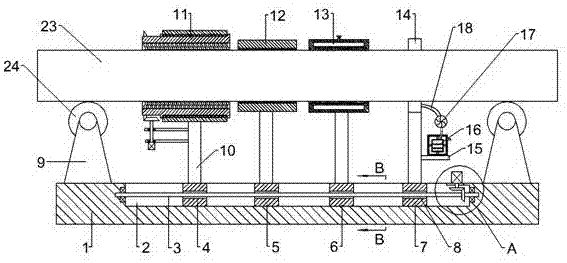

The invention discloses an automatic oil coating device for bearings. The automatic oil coating device comprises a box body, wherein the inner side of the box body is provided with a conveyor belt; aplurality of loading trays are mounted on the conveyor belt, and the outer circles of the loading trays are further provided with gear rings; racks meshed with the gear rings are arranged on the innerwall of the rear side of the box body; the middle of the bottom of the box body is connected with an oil delivery pipe; a high-precision filter and an oil pump are separately mounted on the oil delivery pipe; a cross pipe is further arranged at the upper part of the inner side of the box body, a plurality of oil sprayers are mounted at the lower side of the cross pipe, and second electric push rods are arranged at the two ends of the upper side of the cross pipe; and the oil delivery pipe also communicates with the cross pipe through a hose, a material storage tank is arranged below the rightend of the conveyor belt, and the bottom of the box body is provided with a plurality of damping supports. The automatic oil coating device is novel in structure, great in stability, small in workingnoise, great in bearing oil coating effect, high in automation degree and favorable to popularization.

Owner:HANGZHOU HEAVY STEEL PIPE

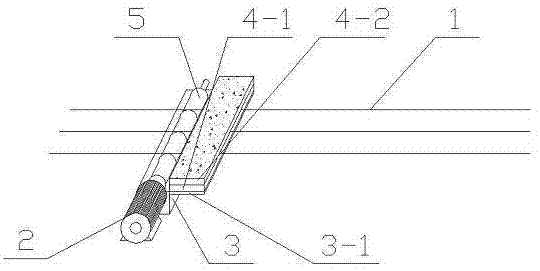

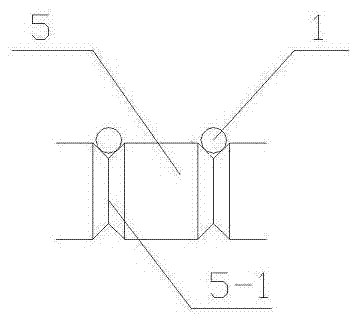

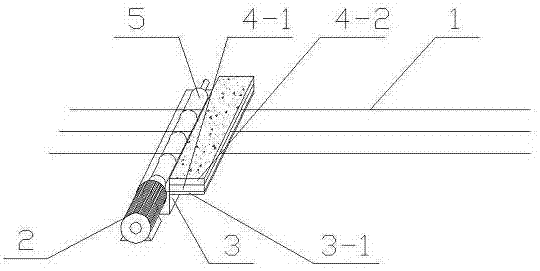

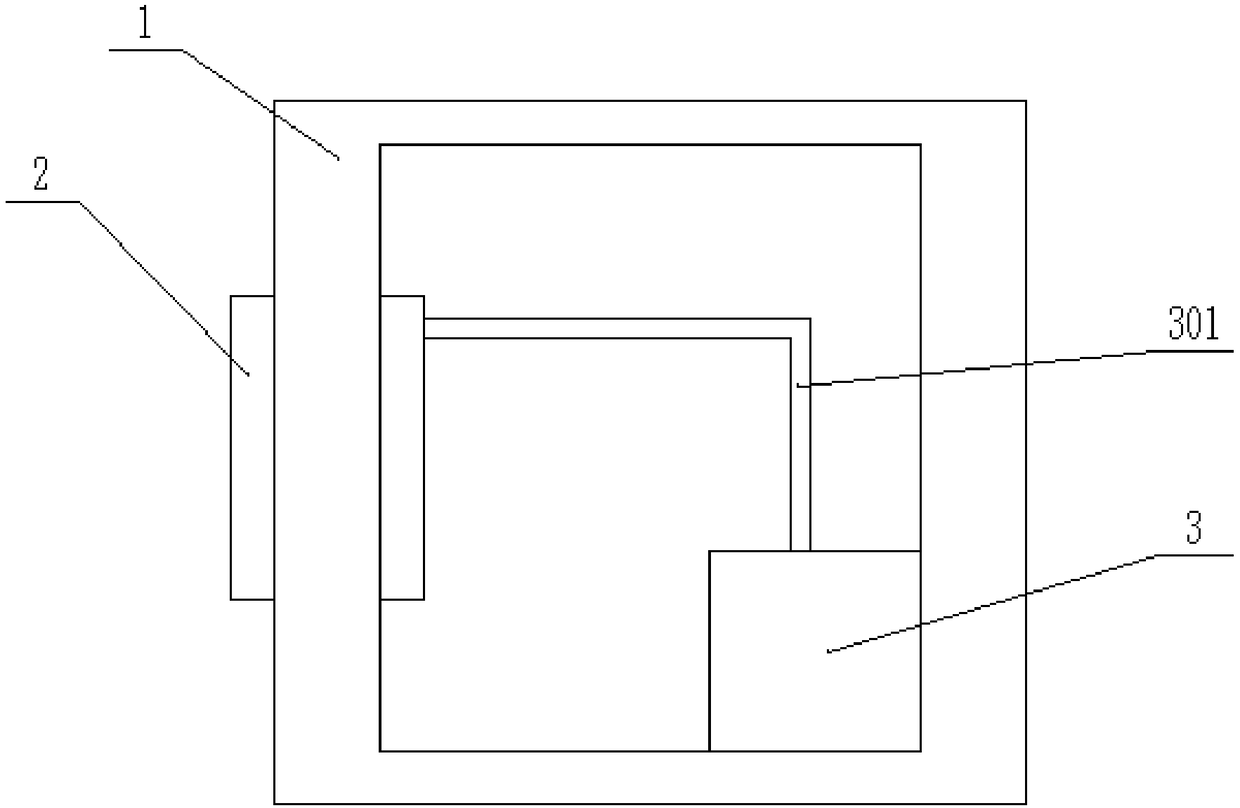

Integral equipment for surface maintenance of building pipelines

ActiveCN107288333AImprove rust removal efficiencyImprove oiling effectScaffold accessoriesBevel gearCoating

The invention provides integral equipment for surface maintenance of building pipelines. The equipment includes a base, both ends of the base are fixedly connected with a supporting base separately, the supporting bases are rotatably connected with supporting rollers, and a pipeline is erected between the two supporting rollers, wherein the base is provided with a mobile device which comprises a mobile groove with an opening facing upwards; the mobile groove is internally provided with a first mobile block, a second mobile block, a third mobile block and a fourth mobile block which are sequentially arranged from left to right; threaded through holes are formed in the first mobile block, the second mobile block, the third mobile block and the fourth mobile block; the threaded through holes are all internally in threaded connection with a threaded rod, both ends of the threaded rod are rotatably connected with the two ends of the mobile groove, and the right portion of the threaded rod is fixedly connected with a first bevel gear. The integral equipment for the surface maintenance of the building pipelines has the advantages of having an integrated function of rust cleaning, polishing, coating and drying, improving maintenance efficiency of the pipelines to a great degree, and having a certain value of popularization and application.

Owner:滨州市科创孵化器有限公司

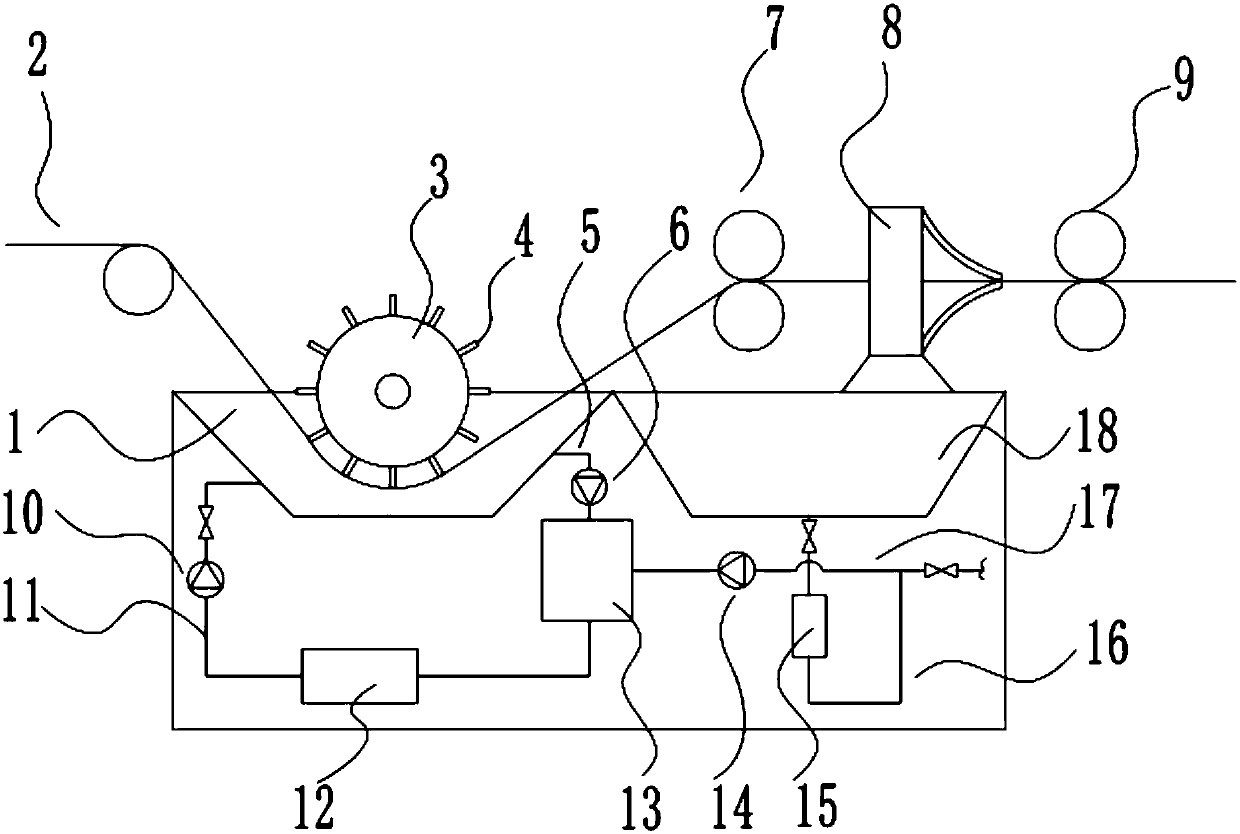

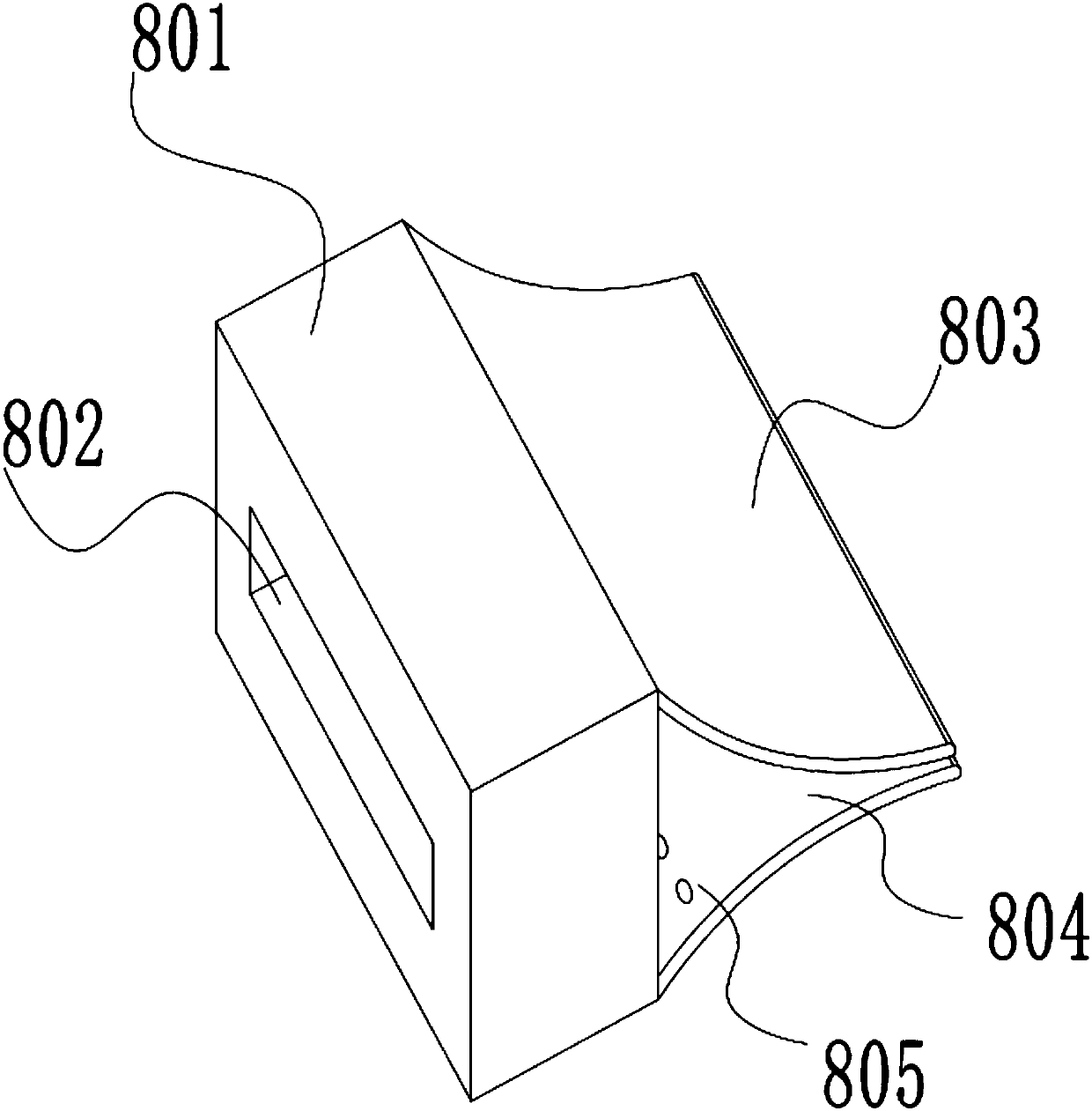

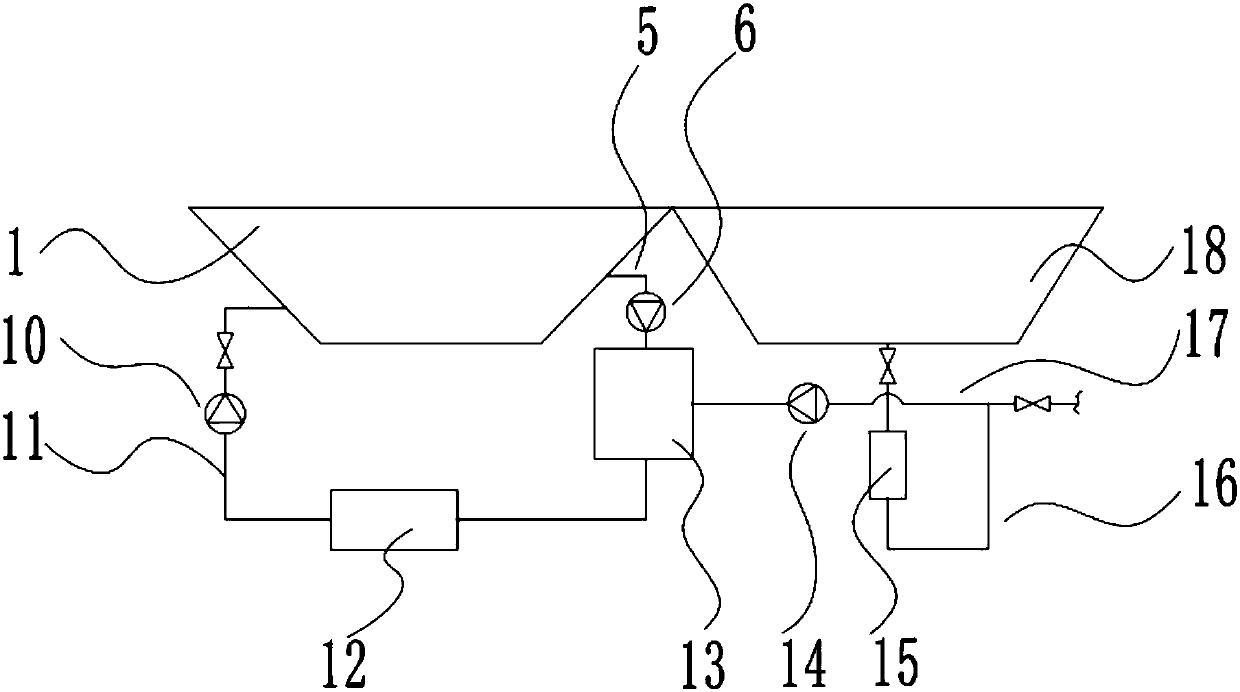

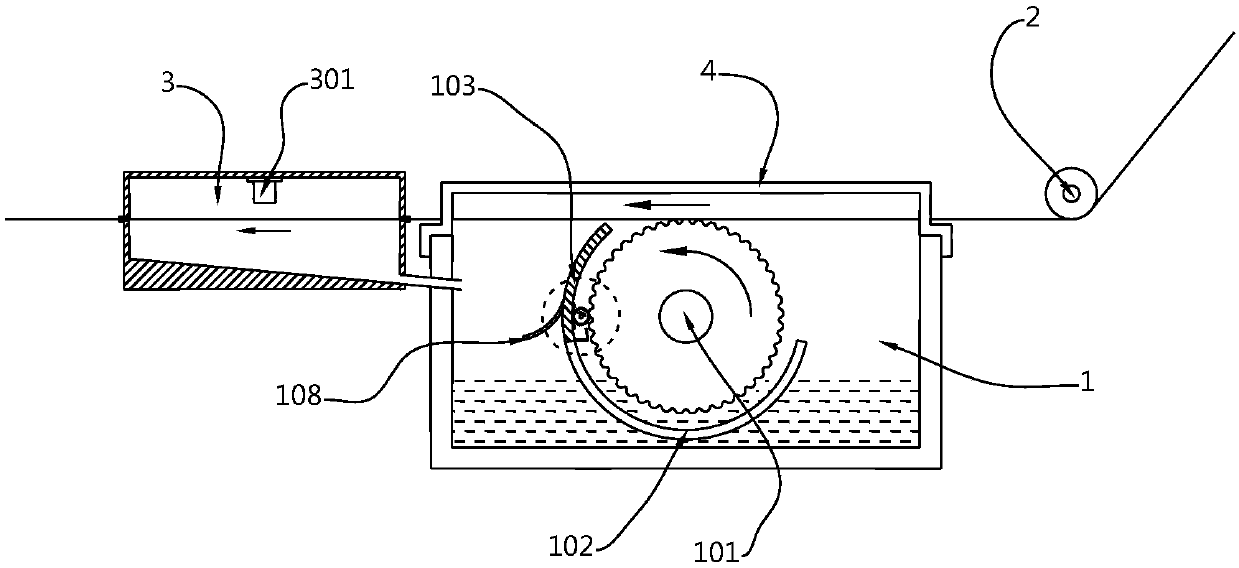

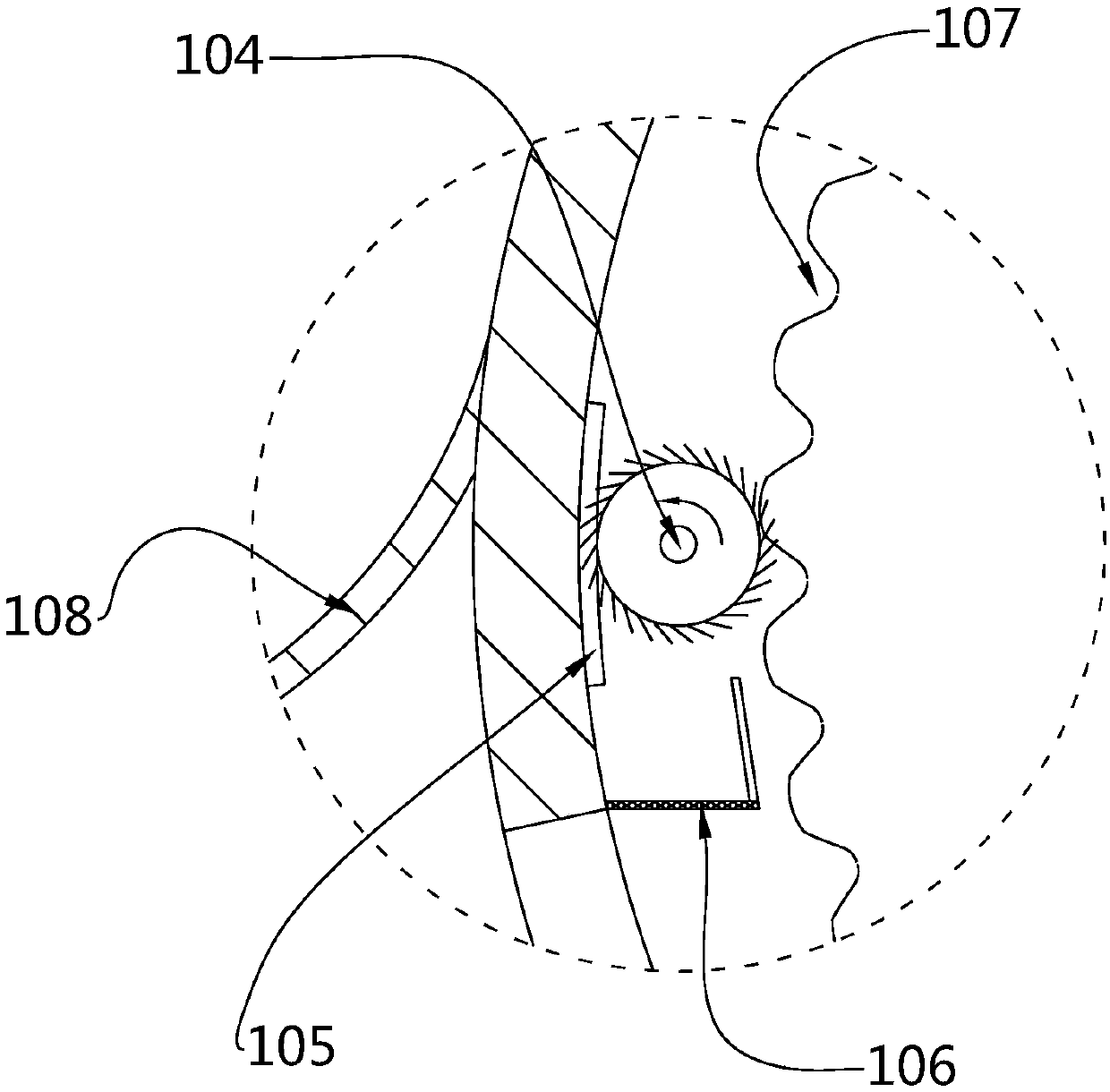

Efficient bituminous waterproof coiled material oiling device

InactiveCN107597496AEasy accessGuaranteed temperatureLiquid surface applicatorsCoatingsFuel tankFeeding pumps

The invention discloses an efficient bituminous waterproof coiled material oiling device which comprises an oiling pool, a coiled material base cloth, an oiling roller and an oil scraper device. The oiling roller is installed in the oiling pool, the surface of the oiling roller is evenly provided with multiple oiling plates, the two sides of the oiling pool are connected with an oil return tank through an oil return pipe and an oil feeding pipe correspondingly, the oil feeding pipe is further provided with a heating device for heating oil liquid, the oil return pipe and the oil feeding pipe are further provided with an oil return pump and an oil feeding pump correspondingly, one side of the oiling pool is provided with the oil scraper device, and the two sides of the oil scraper device areprovided with first pair pressing rollers and second pair pressing rollers for guiding the movement of the coiled material base cloth. The efficient bituminous waterproof coiled material oiling device has the beneficial effects that a gap can be formed between the coiled material base cloth and the oiling roller through the design of the oiling plates, both the two faces of the coiled material base cloth can make good contact with oil liquid, and the oiling effect is improved. Oil liquid scraped away can be recycled, reuse of resources is achieved, and the production cost is saved.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

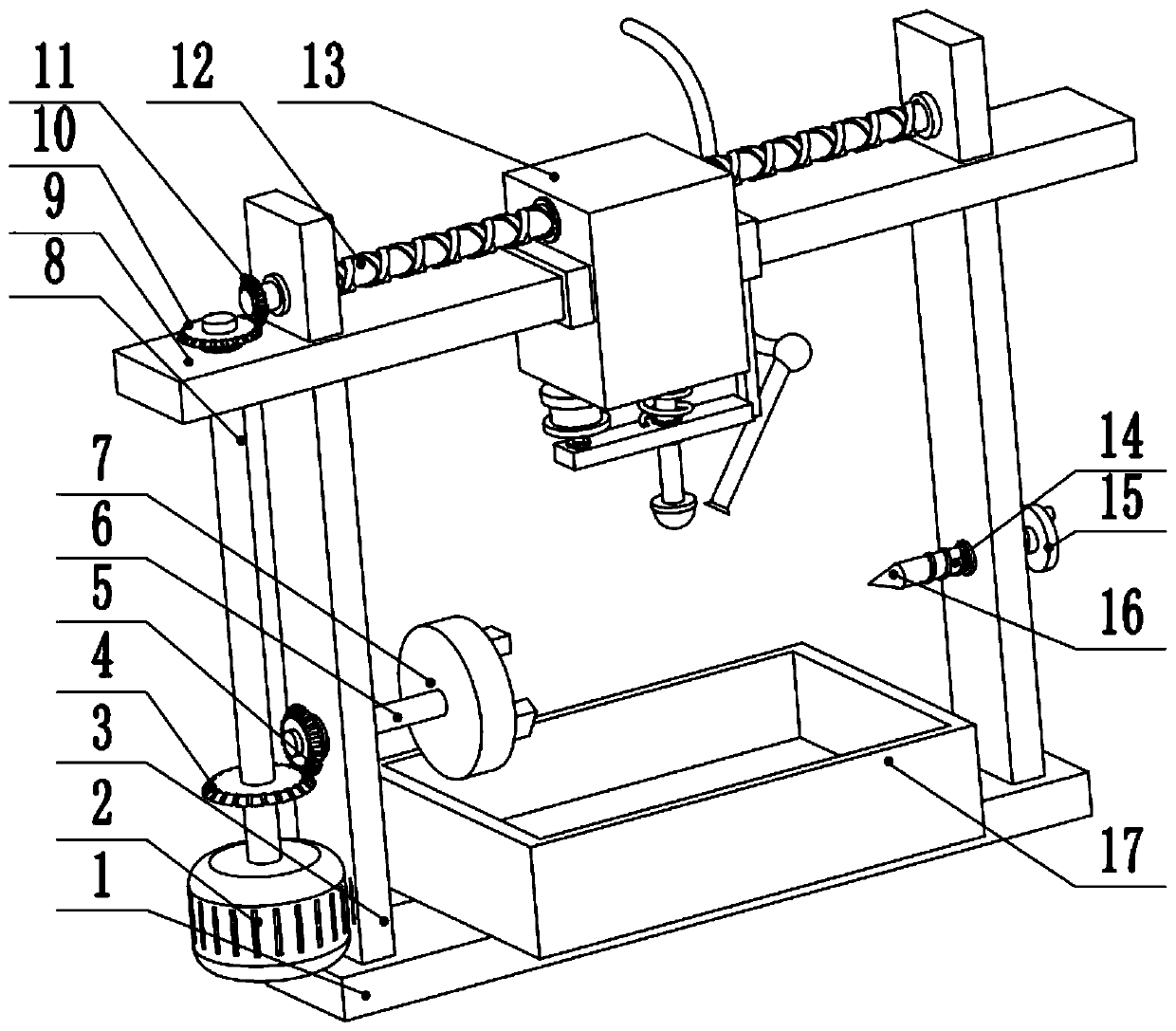

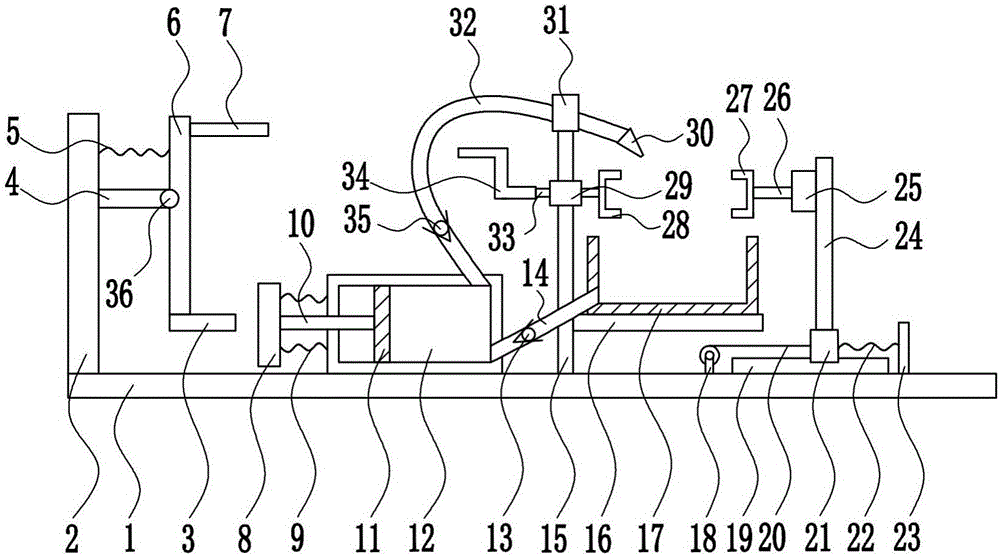

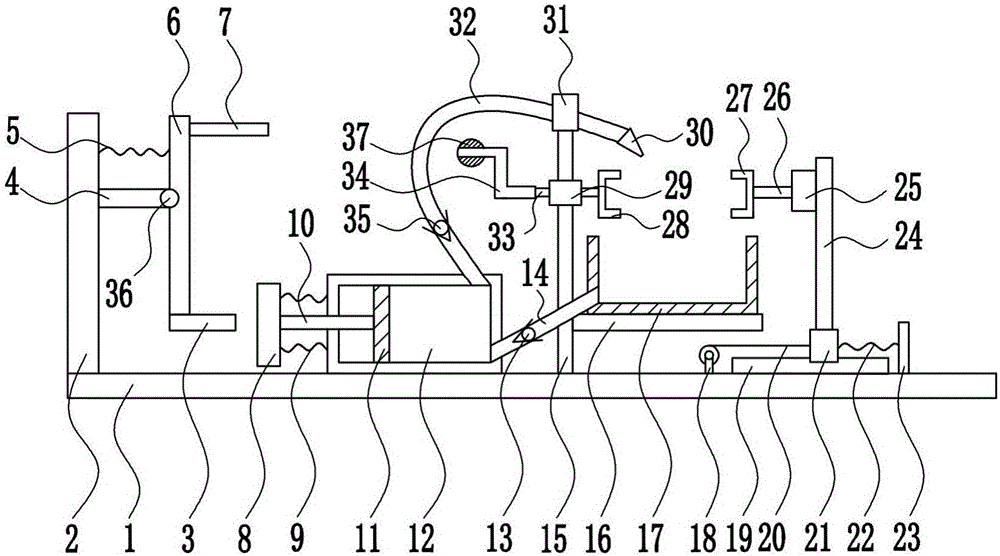

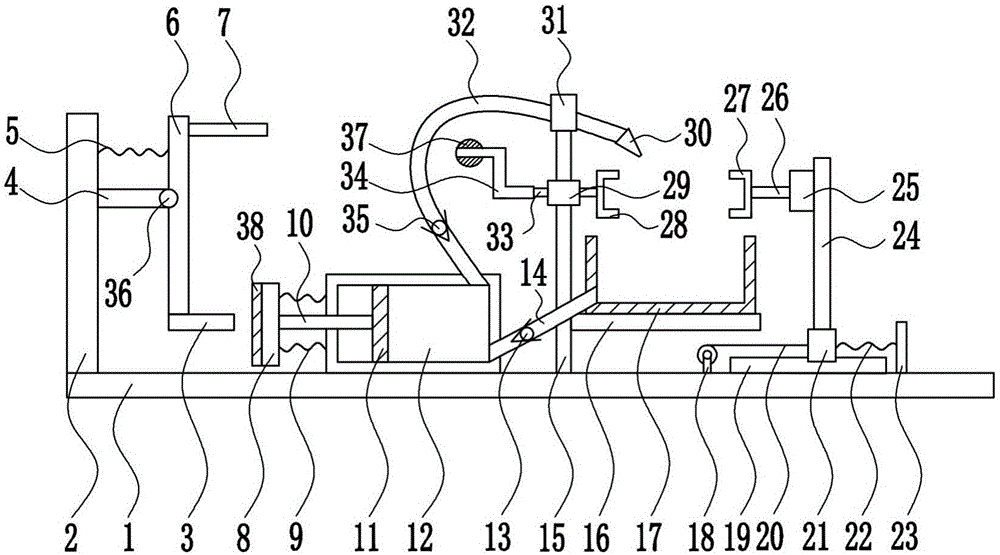

Automatic oiling device for automobile brake component assembling

The invention relates to the technical field of automobile assembling, and discloses an automatic oiling device for automobile brake component assembling. The device comprises a bottom plate, side plates are arranged on the left side and the right side of the bottom plate, the upper parts of the side plates are fixedly connected with a top plate, a driving motor is arranged at the bottom of the side plate on the left side, an output shaft of the driving motor is fixedly connected with a rotating shaft, a first bevel gear is arranged at the lower part of the rotating shaft, the first bevel gearis in meshed connection with a second bevel gear, the second bevel gear is fixedly connected with the left end of a rotating rod, the right end of the rotating rod is provided with a fixed seat, theupper part of the rotating shaft is provided with a third bevel gear, the third bevel gear is in meshed connection with a fourth bevel gear, the fourth bevel gear is fixedly connected with the left end of a lead screw, and the middle of the lead screw is in threaded connection with a sliding seat. The automatic oiling device is suitable for automobile brake component assembling, a workpiece is driven to rotate through the rotating seat, so that a brush head which moves left and right is driven for oiling the surface of the workpiece, the oiling effect is better, and the oil layer on the surface of the workpiece is more uniform.

Owner:WEST ANHUI UNIV

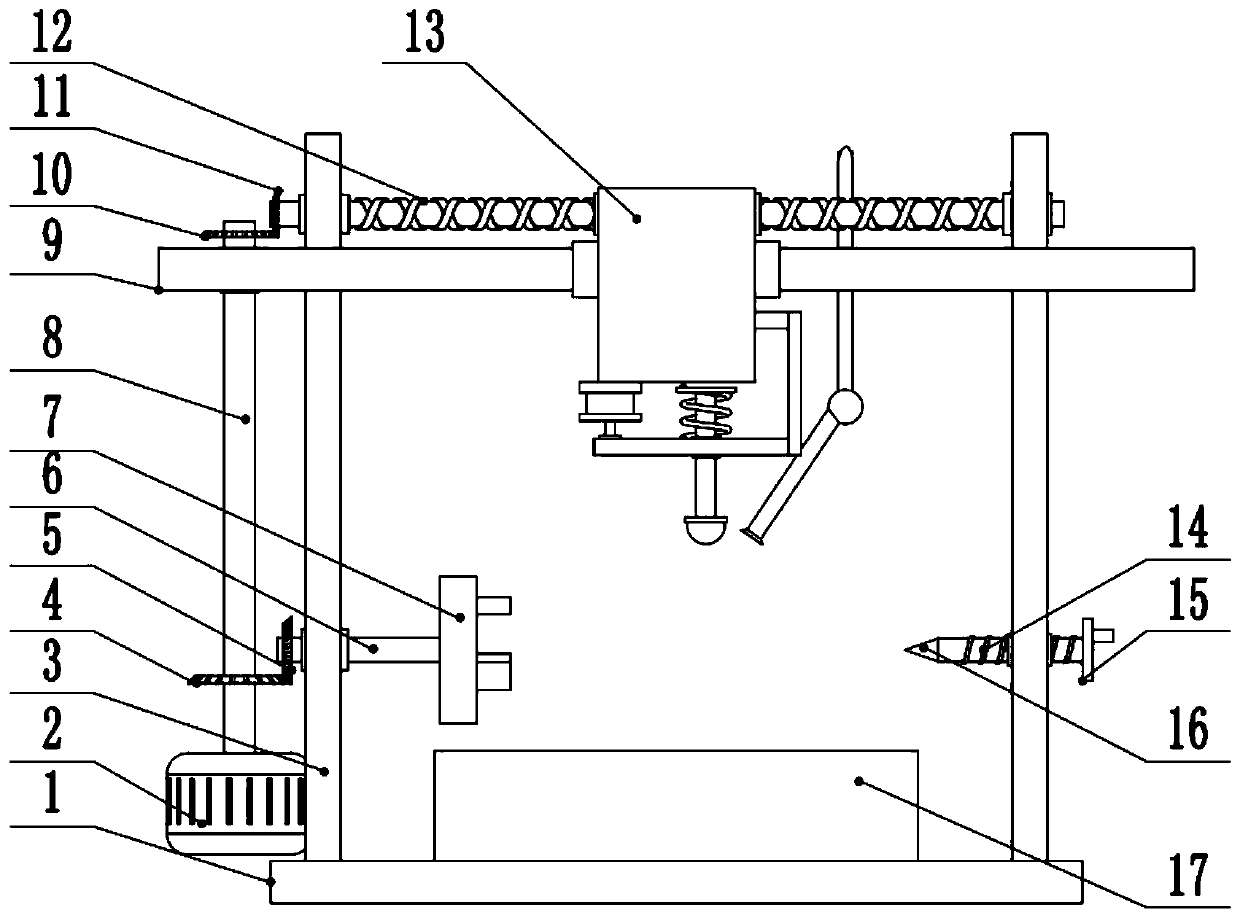

Oil coating lubricating equipment for driverless automobile parts

ActiveCN106481957AEasy maintenanceShorten maintenance timeVehicle componentsEngine lubricationMachine maintenanceCheck valve

The invention relates to oil coating lubricating equipment for automobile parts, in particular to oil coating lubricating equipment for driverless automobile parts. A technical problem to be solved by the invention is to provide the oil coating lubricating equipment for the driverless automobile parts, which is even in oil coating, high in oil coating speed and convenient to operate. In order to solve the technical problem, the oil coating lubricating equipment for the driverless automobile parts, provided by the invention, comprises a bottom plate, a left frame, a collision block, a linkage rod, a first spring, a swinging rod, a pushing rod, a first baffle, a second spring, a connecting rod, a piston, a cylinder body and a first check valve, wherein the left frame is welded at the leftmost side of the top of the bottom plate, the linkage rod is welded at the upper part of the right side of the left frame, and the right end of the linkage rod is connected with the swinging rod through a hinge component. The oil coating lubricating equipment realizes the effects of even oil coating, high oil coating speed and convenient operation. The device can reduce machine maintenance time, can save a large quantity of labor, and is great in oil coating effect.

Owner:海汇汽车制造有限公司 +1

Chain production process

ActiveCN110055543AGuaranteed uniformityImprove oiling effectCharge manipulationSolid state diffusion coatingSurface fatigueHardness

The invention discloses a chain production process. The chain production process includes the steps that a, heat treatment is carried out, in heat treatment equipment, various auxiliary media are adopted under the high temperature to improve the organization structure of parts and improve the performance of various articles; b, carburization is carried out, the parts are placed in the heat treatment equipment to be heated and kept warm, and then carbon containing media are introduced to infiltrate the carbon into the surfaces of the parts so as to improve the hardness and abrasion resistance of a chain; c, quenching is conducted; d, tempering is conducted; e, blacking is conducted; f, bluing is conducted; g, shot blasting is conducted, and according to the requirements, steel shots with the required diameters are sprayed on the surfaces of the parts to form uniform small pits, so that the surface fatigue strength of the chain is improved; h, phosphorization is conducted, the parts areimmersed in phosphating liquid with a certain temperature to form a phosphating layer on the surface of each part, the surface colors of the parts can appear black or gray, the beauty of the chain isimproved, and the purpose of corrosion resistance is achieved at the same time; i, oiling is conducted, after the chain is put into oil immersion equipment, the oil is applied to the surface of the chain to prevent rust and the chain is more shiny; and j, inspection and warehousing are conducted.

Owner:浙江省浦江三联链条有限公司

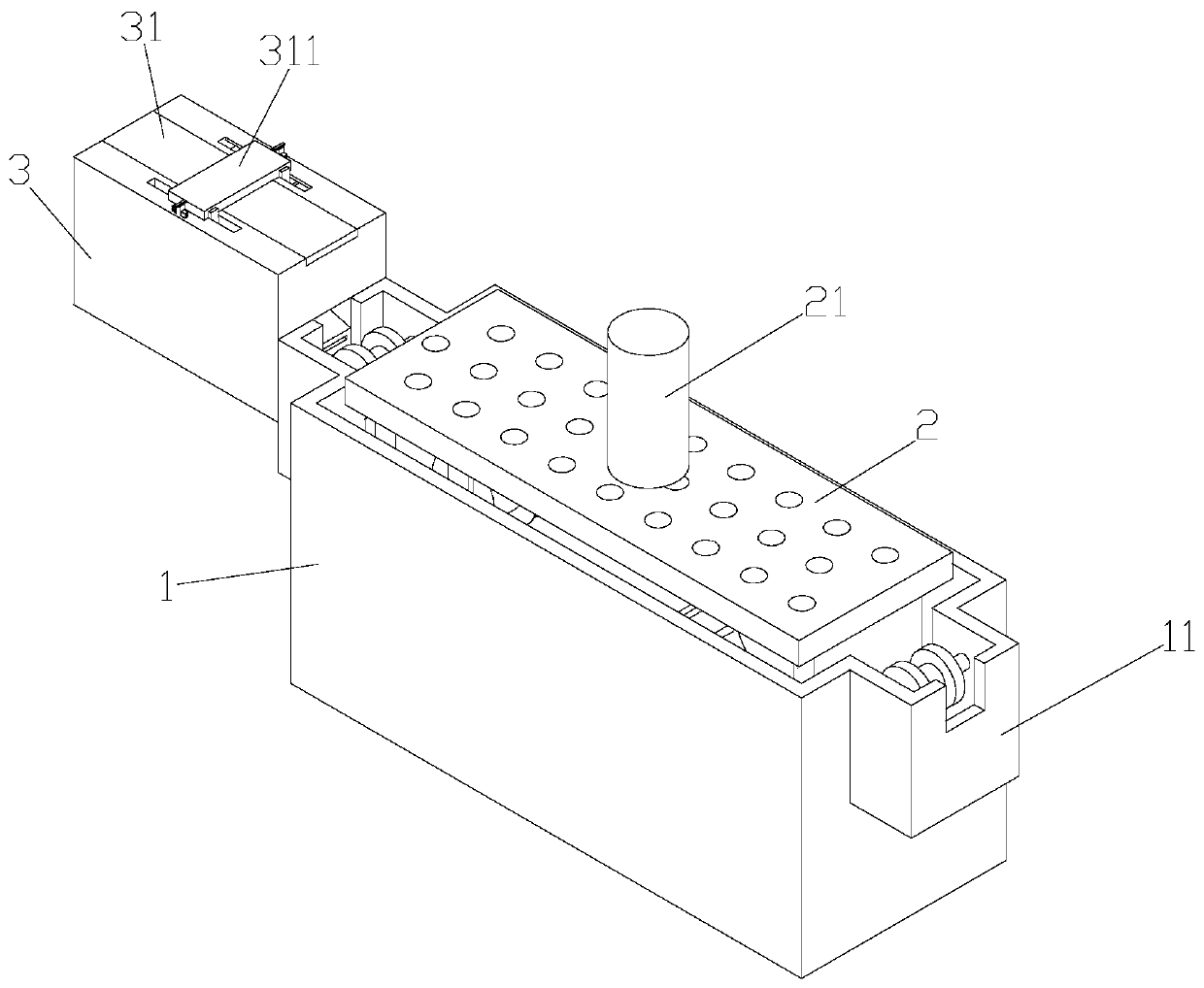

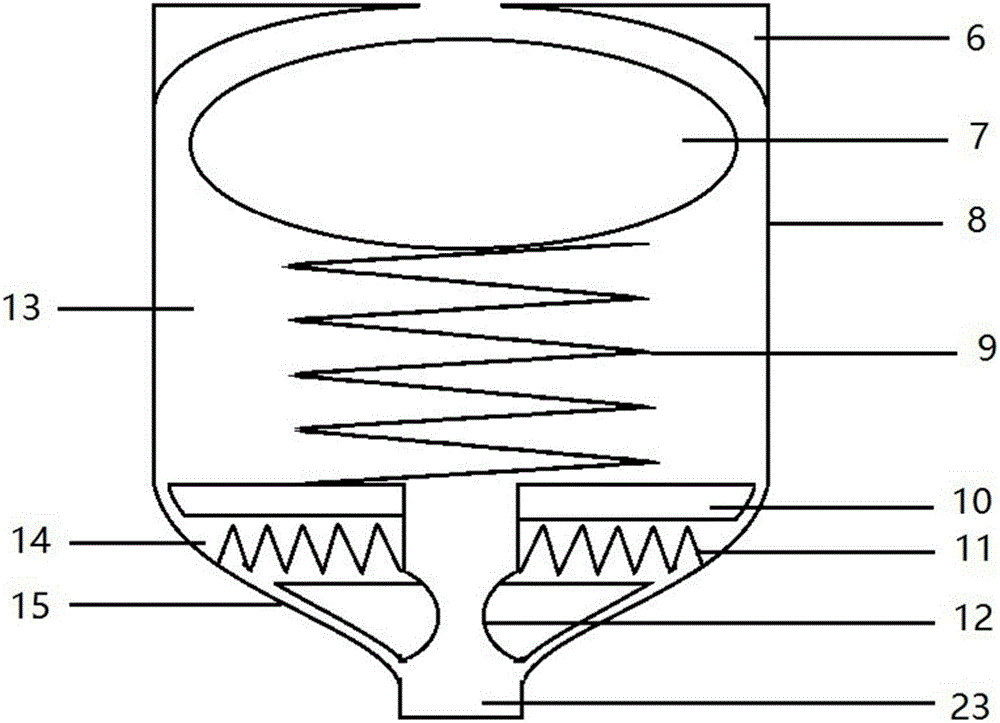

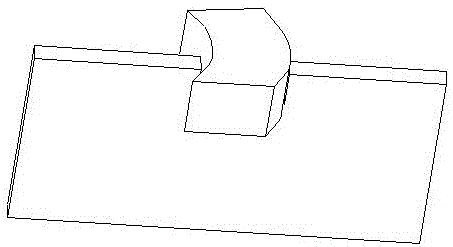

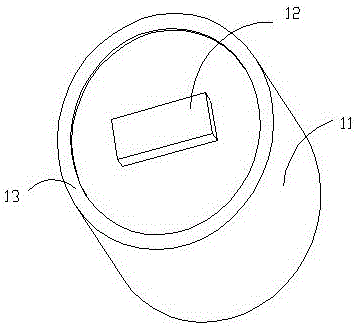

Quick oiling equipment for bearing

InactiveCN108126863AFast oilOiling is efficient and fastLiquid surface applicatorsCoatingsFuel tankEngineering

The invention discloses quick oiling equipment for a bearing. The quick oiling equipment comprises a base, a rack, a mounting plate, a sink tank, a motor, poke rods, an oil storage tank, an oil suction tank, a sponge mat, an oil outlet, an oil storage box, an aspirator pump, a discharge port, a sponge layer, a material receiving box and a discharging hopper, wherein the rack is fixedly arranged atone end of the base; the horizontally arranged mounting plate is fixedly arranged on the lateral part of the rack; the round sink tank is formed in the upper part of the mounting plate; a motor, theoutput shaft of which is vertically arranged upward, is fixedly arranged right below the sink tank on the upper portion of the base; the output shaft of the motor penetrates through the center of circle of the sink tank and extends to the upper side of the sink tank; and the plurality of uniformly distributed poke rods are fixedly arranged on the lateral part of the upper end of the output shaft of the motor radially. Compared with the prior art, the quick oiling equipment disclosed by the invention can oil the bearing efficiently and quickly, so that the oiling efficiency and effect of the bearing are enhanced, the processing environment is prevented from being polluted by residual lubricating oil effectively, and the labor intensity of workers is reduced.

Owner:XINCHANG SANYUAN BEARING CO LTD

Oiling device for textile elasticizer

The invention discloses an oiling device for a textile elasticizer. The oiling device comprises an oil tank, a guide roller is arranged on one side of the oil tank, an oil recovery tank is connected with the other side of the oil tank through a pipeline, an oiling roller is arranged in the oil tank, an arc-shaped filter screen is arranged under the oiling roller, an extended arc-shaped baffle is arranged at one end, close to the oil recovery tank, of the arc-shaped filter screen, a brusher roller is arranged between the arc-shaped baffle and the oiling roller, a yarn cleaning board is arrangedon the arc-shaped baffle opposite to the brusher roller, a yarn collecting tank connected with the arc-shaped baffle is formed under the brusher roller, and a filter hole is formed in the bottom of the yarn collecting tank; a pneumatic vibrator is arranged in the oil recovery tank, and the bottom of the oil recovery tank is an inclined surface. The oiling device disclosed by the invention has theadvantages of being incapable of polluting a working environment in a textile workshop, high in oiling roller cleanness and good in oiled silk yarn in quantity.

Owner:湖州裕帛纺织有限公司

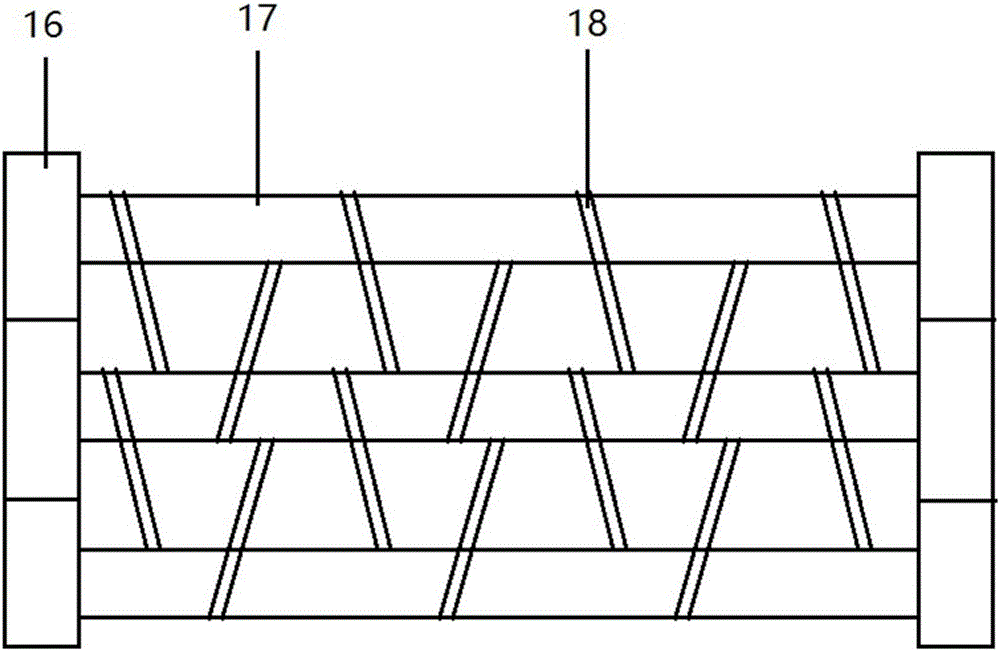

Keel-machine cyclic oiling apparatus

InactiveCN105436014AImprove recycling ratesAvoid wastingLiquid surface applicatorsCoatingsKeelFuel tank

A disclosed keel-machine cyclic oiling apparatus comprises a filtering purification box, an oil recovery box, an oil proportioning box, a circulating pump, a frame, an oil-storing cotton layer, a keel shell plate, an oil jet pipe, an oiling box and an oil brushing roller; and the upper end of the frame is fixedly connected with the oiling box, the oiling box is inside provided with the oil-storing cotton layer, the keel shell plate is arranged in the middle of the oil-storing cotton layer, the oiling box is provided with a material inlet and a material outlet respectively close to two ends of the keel shell plate, the input end of the material inlet is provided with a support roller, and the oil brushing roller is arranged between the material outlet and the oil-storing cotton layer. According to the keel-machine cyclic oiling apparatus, the oil recovery box, the oil proportioning box and the circulating pump are employed for realizing recovery and utilization of oil, the oil cyclic utilization rate is improved and production cost is reduced. The oil brushing roller removes superfluous oil on the keel shell plate and enables oil to be relatively uniformly distributed, oil waste is avoided, and oiling effect and quality are improved.

Owner:TIANJIN FUDACHANG TECH

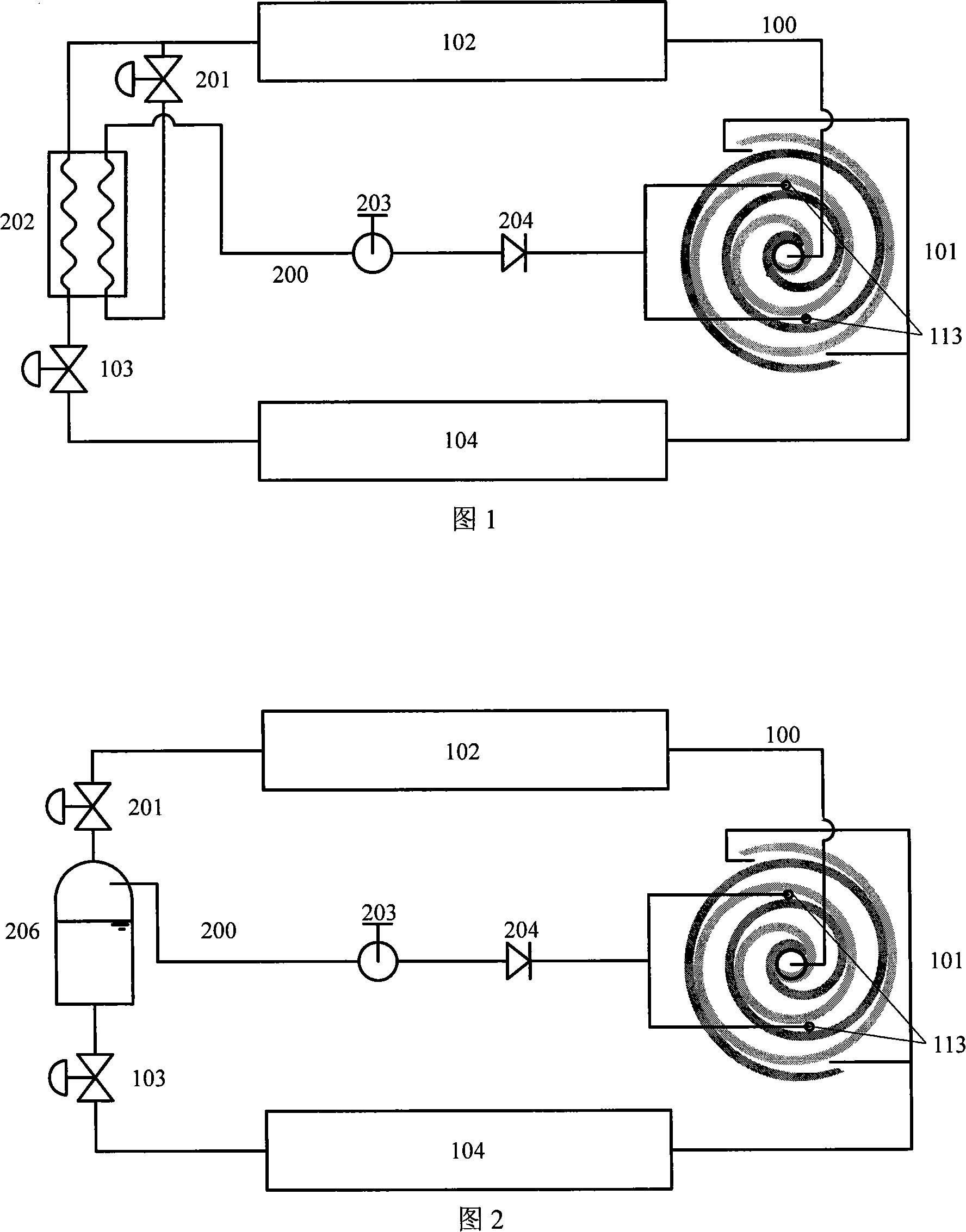

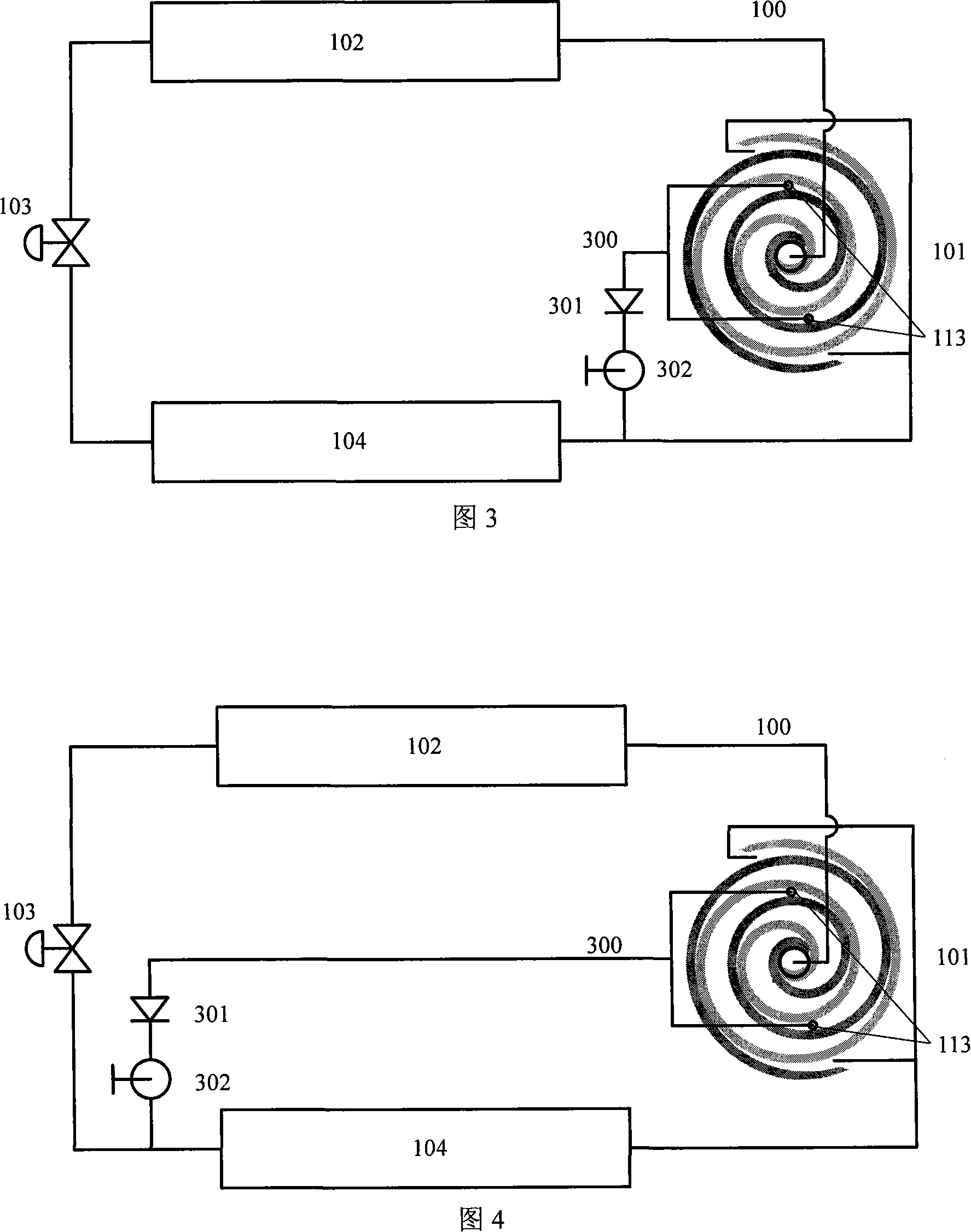

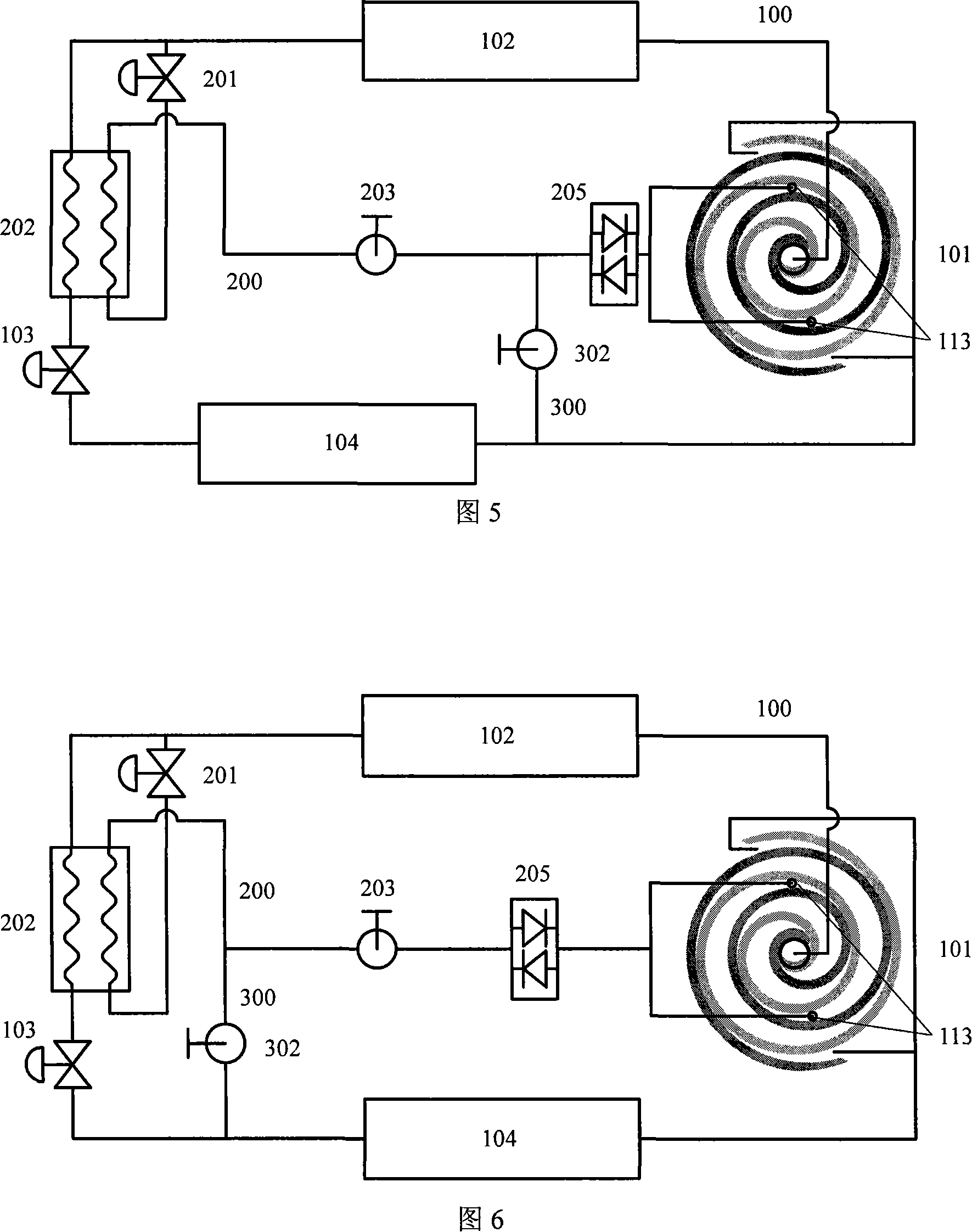

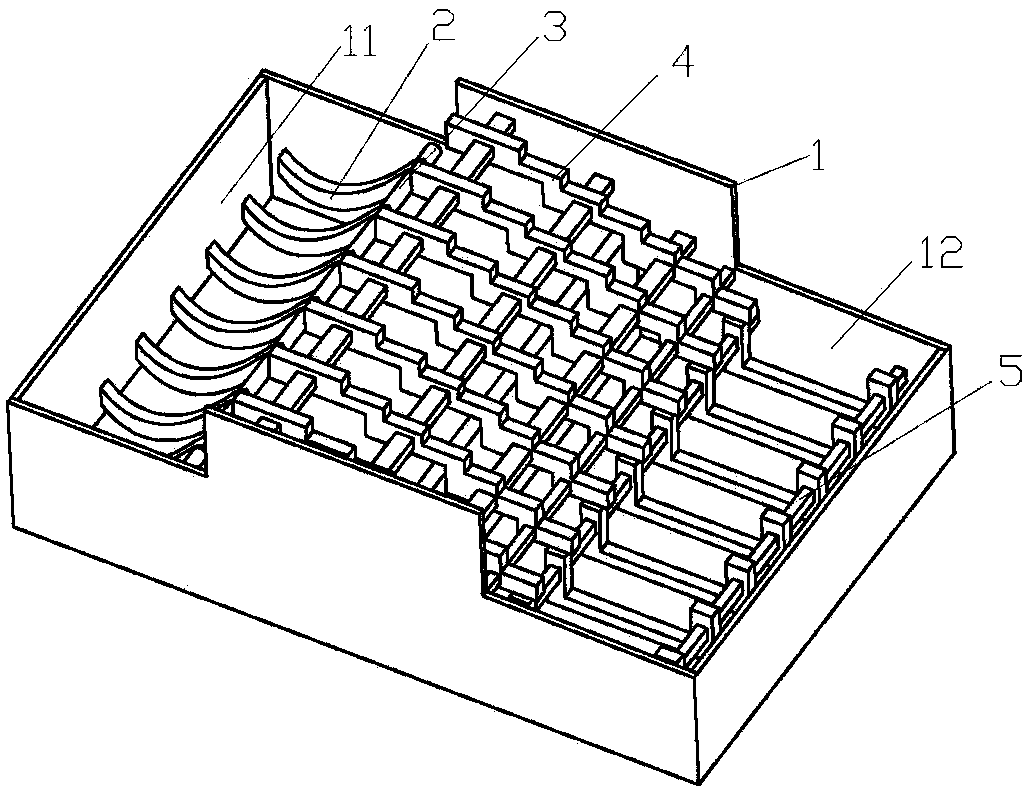

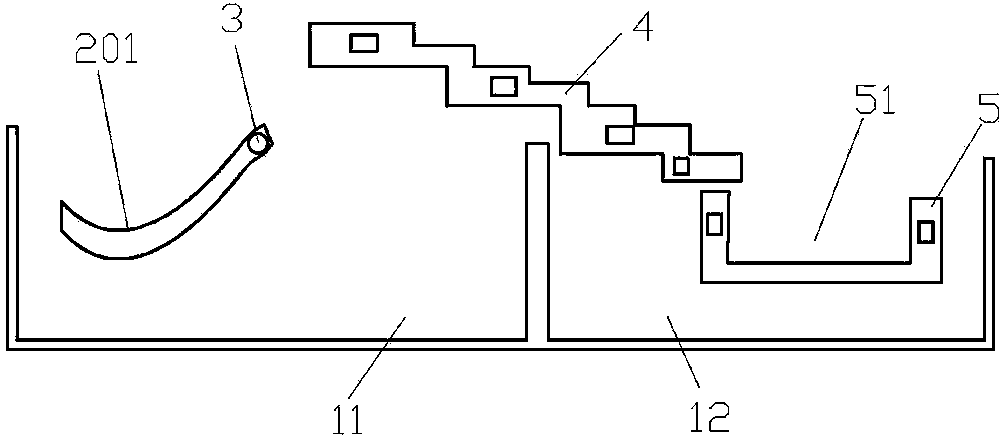

Capacity adjustable cyclone compressor refrigeration system

InactiveCN101140111ASimplify Manufacturing ComplexitySimplify Control ComplexityCompression machines using turbinesRefrigeration componentsCycloneEngineering

The invention relates to a refrigerating system with a capacity-adjusting scroll compressor. The invention adjusts the fit between the compressor and the operating condition through the leakage of a refrigerant of the compression middle section of the compressor to the low pressure side and the injection of the refrigerant of the high pressure side to the compression middle section of the compressor, which can effectively change the efficiency of the compressor and the capacity and performance of the system to result in that the refrigerating system with the scroll compressor can efficiently works within the large range of operating conditions and can effectively adjust the capacity of the system to make the capacity inosculated with the changeable refrigerating or heating requirements in order to improve the applicability of the system and the energy efficiency of the system under varied operating conditions of the large range. The invention can be used in the refrigerating or heating pump system with the scroll compressor in the air conditioning refrigerating field.

Owner:TSINGHUA UNIV

Efficient environmental-friendly oil tank for steel tube production

ActiveCN103372526AStable structureImprove oiling efficiencyLiquid surface applicatorsCoatingsEnvironmental engineeringPipe

The invention relates to the field of equipment for pipe production, and particularly an efficient environmental-friendly oil tank for pipe production. The oil tank comprises a tank body; the tank body comprises an oil storage tank and a collecting tank; the oil storage tank is provided with a row of bearing rods capable of bearing steel tubes; the bearing rods are fixed on a rotating shaft allowing bearing rods to convey the steel tubes to the direction of the collecting tank; and the upper part of the tank body is also provided with a row of transition oil filter frames cooperating with the bearing rods; and the collecting tank is provided with a row of collection frames cooperating with the transition oil filter frames. The efficient environmental-friendly oil tank for pipe production has the advantages of simple structure, high oil painting efficiency and environmental-friendliness.

Owner:ANJI PENGDA STEEL PIPE

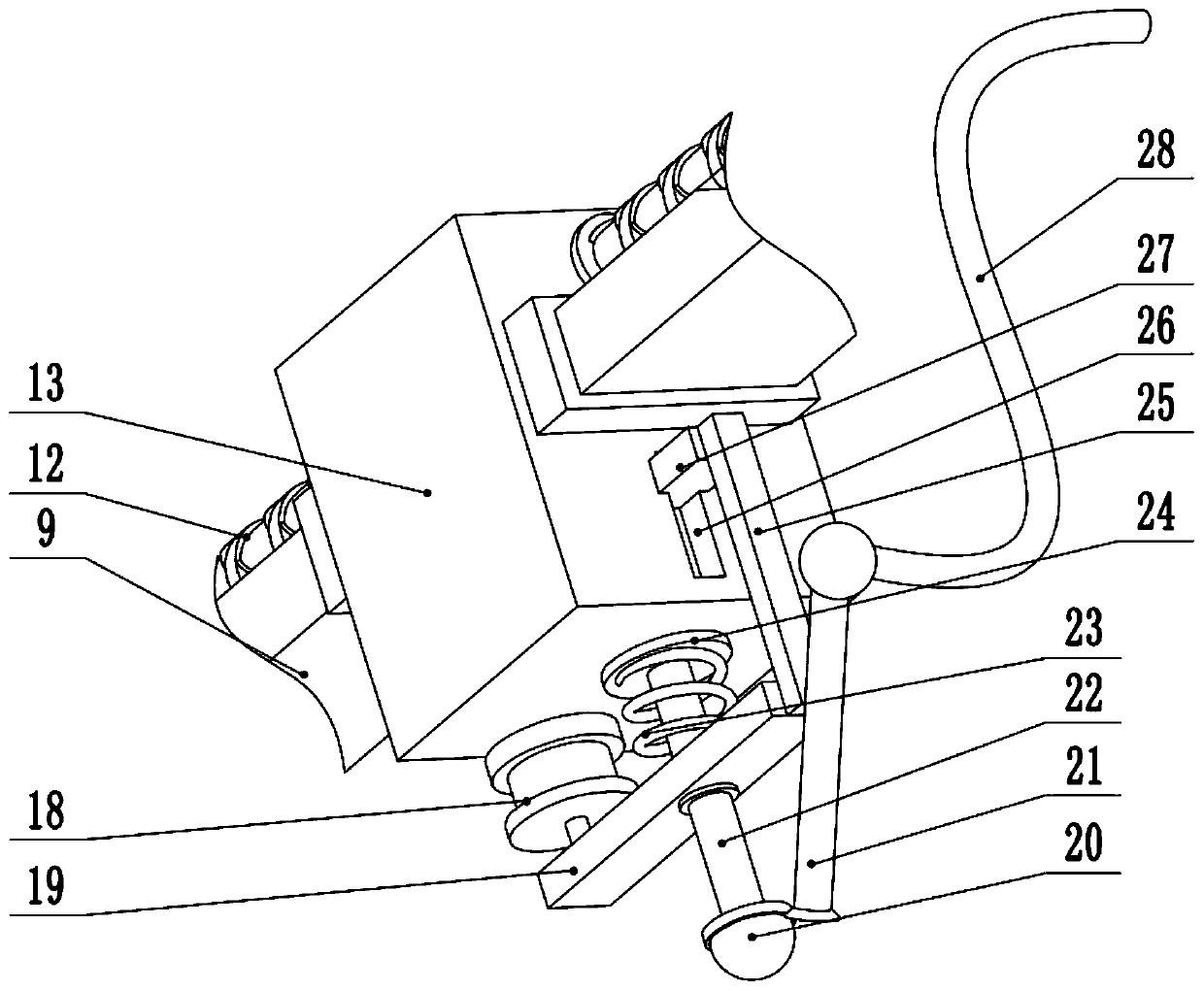

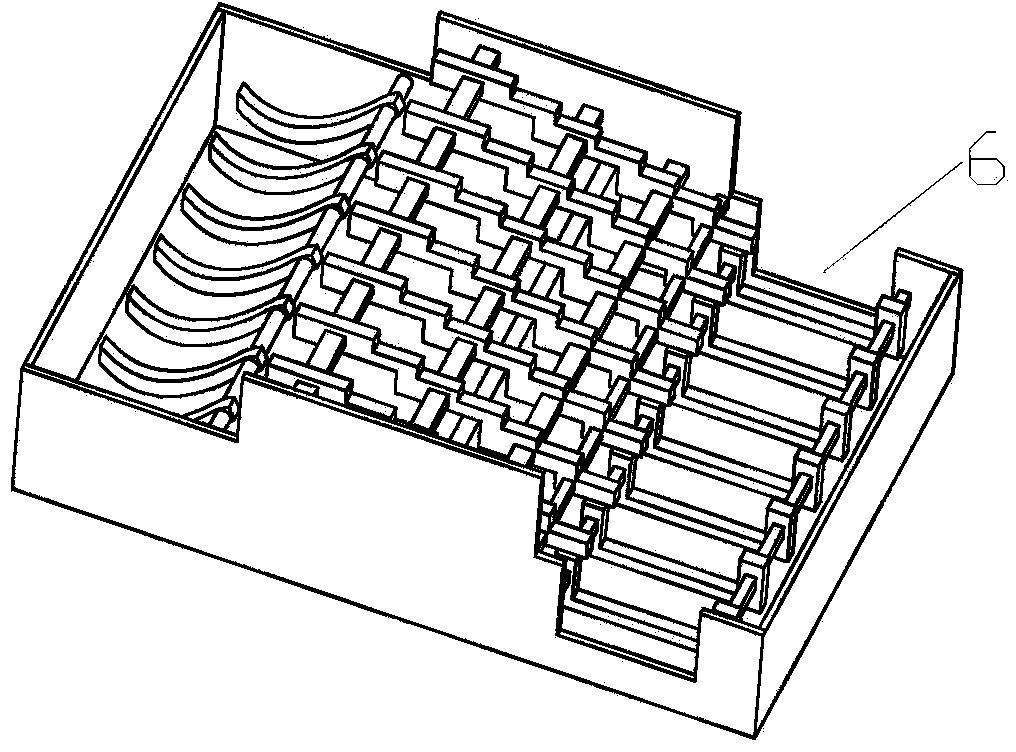

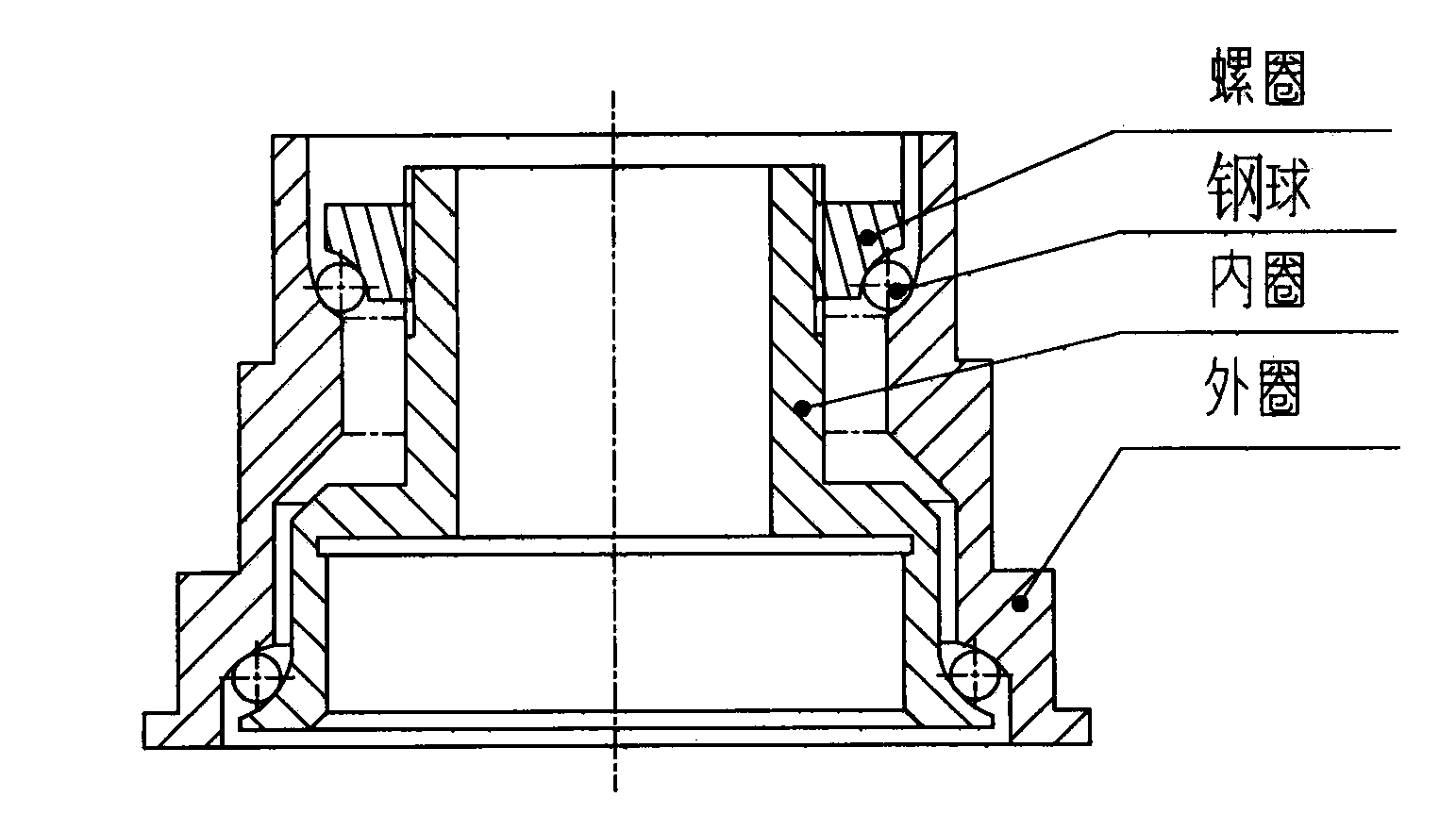

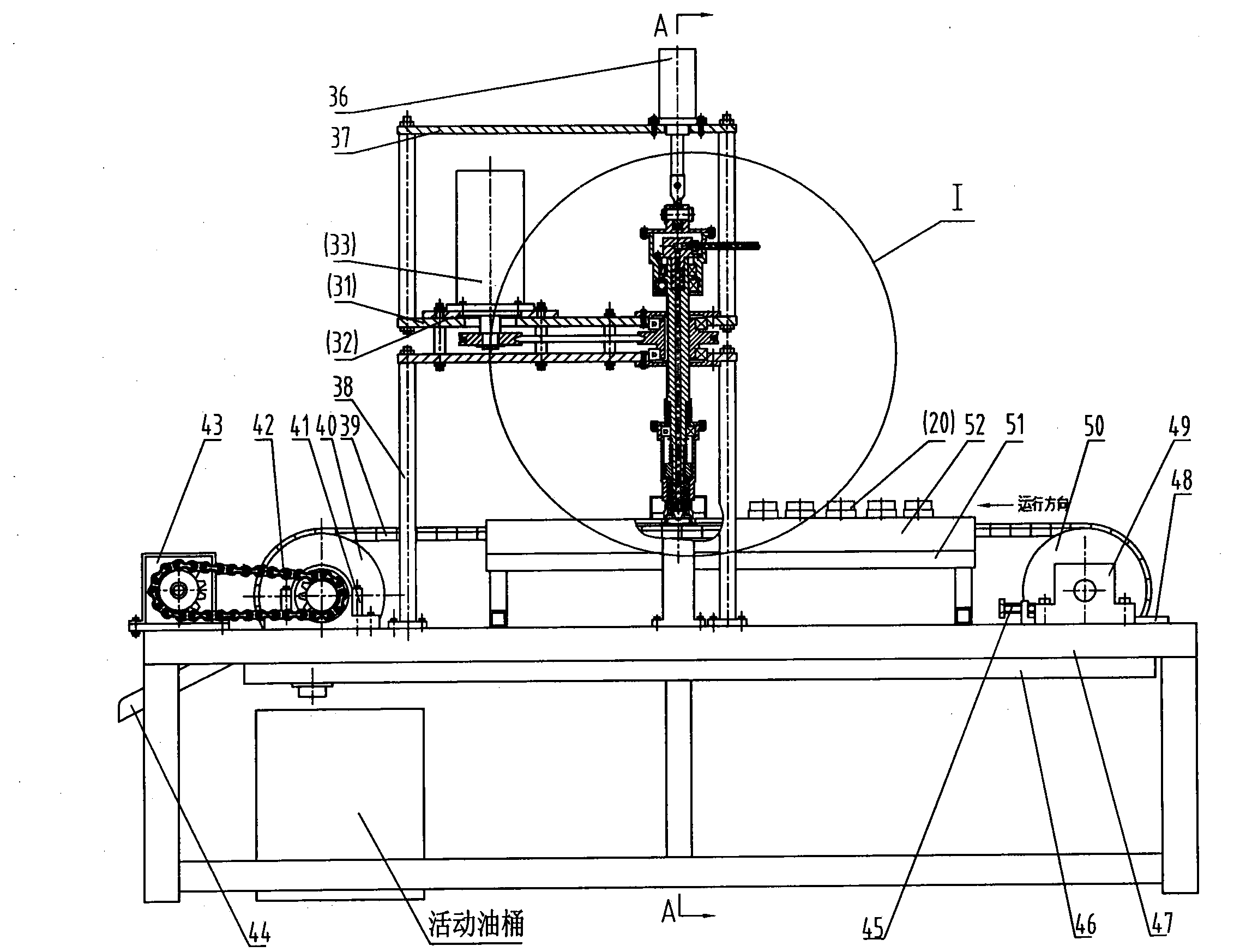

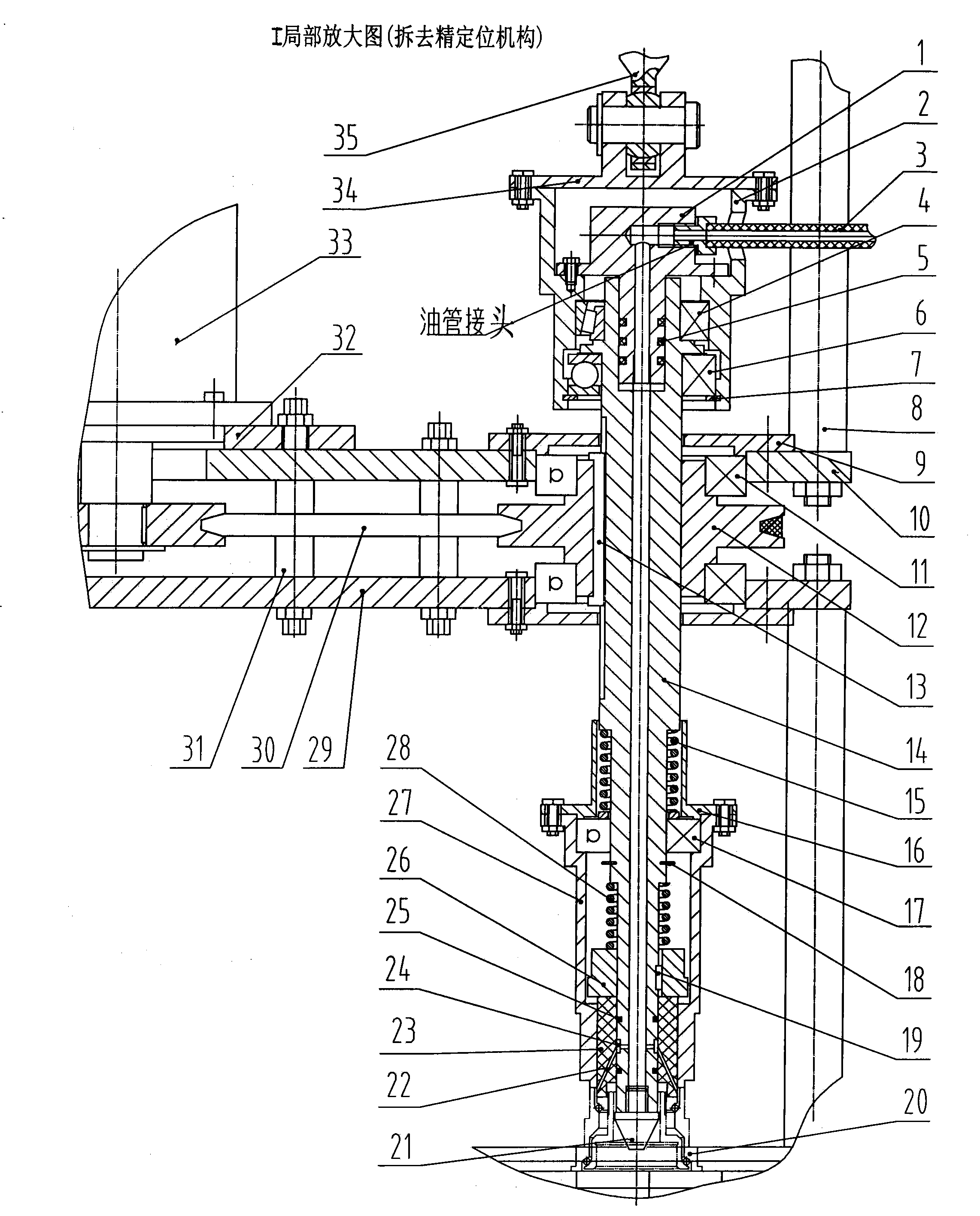

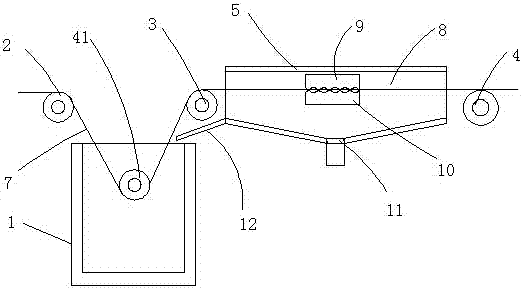

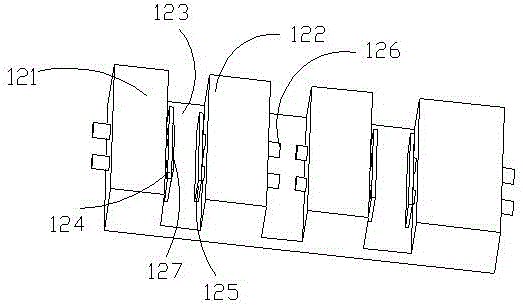

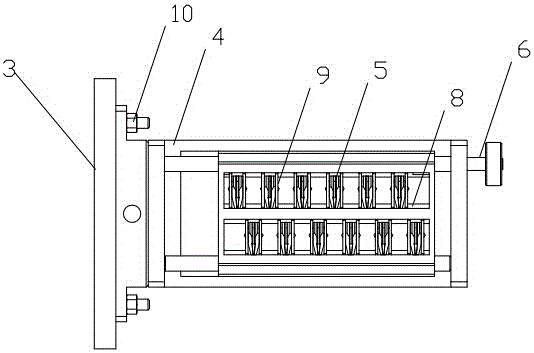

Multi-level flywheel body oiling machine

The invention discloses a multi-level flywheel body oiling machine and relates to bicycle flywheel manufacturing equipment. The multi-level flywheel body oiling machine mainly comprises a machine frame, a conveying belt mechanism, a locating mechanism and an oiling rod part. A supporting strip is fixedly arranged on the lower side of a conveying belt working face. Limiting plates are fixedly arranged on the two sides of the conveying belt working face. Precision locating is carried out through an air cylinder, a workpiece fork and a stopping block combination piece. A large spring, a bearing end cover, a bearing, a blocking ring, a small spring, a transmission block, a pressing injection head and an outer sleeve are arranged on the lower portion of the oiling rod in sequence. The air cylinder drives the oiling rod part through the knuckle bearing to achieve up-down moving. A motor is used for driving through a V-shaped belt and a sliding key to achieve rotating moving of the oiling rod part. During working, a flywheel body moves forward in an intermittence mode on a conveying belt, the oiling rod part moves correspondingly, and hydraulic oil enters a flywheel body inner cavity through an upper end cover, an oiling rod and an inner hole of the pressing injection head to achieve oiling. The multi-level flywheel body oiling machine is good in oiling effect and high in speed, and the problem that currently, no such equipment exists is solved.

Owner:YANCHENG INST OF TECH

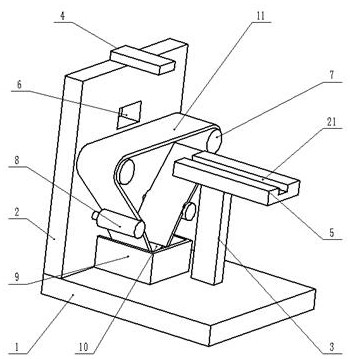

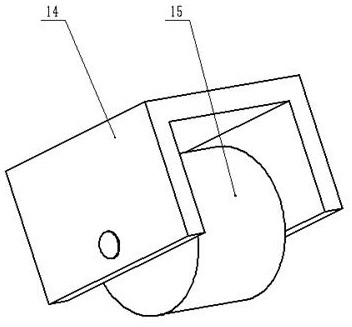

Mechanism for coating oil on enameled wire by using liquid paraffin

InactiveCN102364610AImprove oiling effectUniform rotation speedCable/conductor manufactureOil canElectric machine

The invention discloses a mechanism for coating oil on an enameled wire by using liquid paraffin. The mechanism is arranged on a main body of a processing mechanism and comprises a motor, an oil groove, a felt and a rotary roller, wherein the rotary roller is arranged on the oil groove; the motor is arranged on one side of the oil groove and connected with the rotary roller to control the rotary roller to rotate; a roller groove which corresponds to the enameled wire to be subjected to oil coating is formed on the rotary roller; the roller groove makes a circle on the rotary roller; the enameled wire to be subjected to oil coating passes through the roller groove of the rotary roller; liquid lubricating oil is arranged in the oil groove; the rotary roller is immersed in the liquid lubricating oil; a protruded bracket is arranged in the front of the oil groove; the felt is placed on the protruded bracket of the oil groove; the felt comprises a lower felt and an upper felt; and the enameled wire to be subjected to oil coating passes between the lower felt and the upper felt. By designing the mechanism for coating the oil on the enameled wire by using the liquid paraffin, the enameled wire can be subjected to oil coating by using the liquid paraffin, so that the oil can be more uniformly coated on the enameled wire.

Owner:SUZHOU XINDI ELECTRICAL

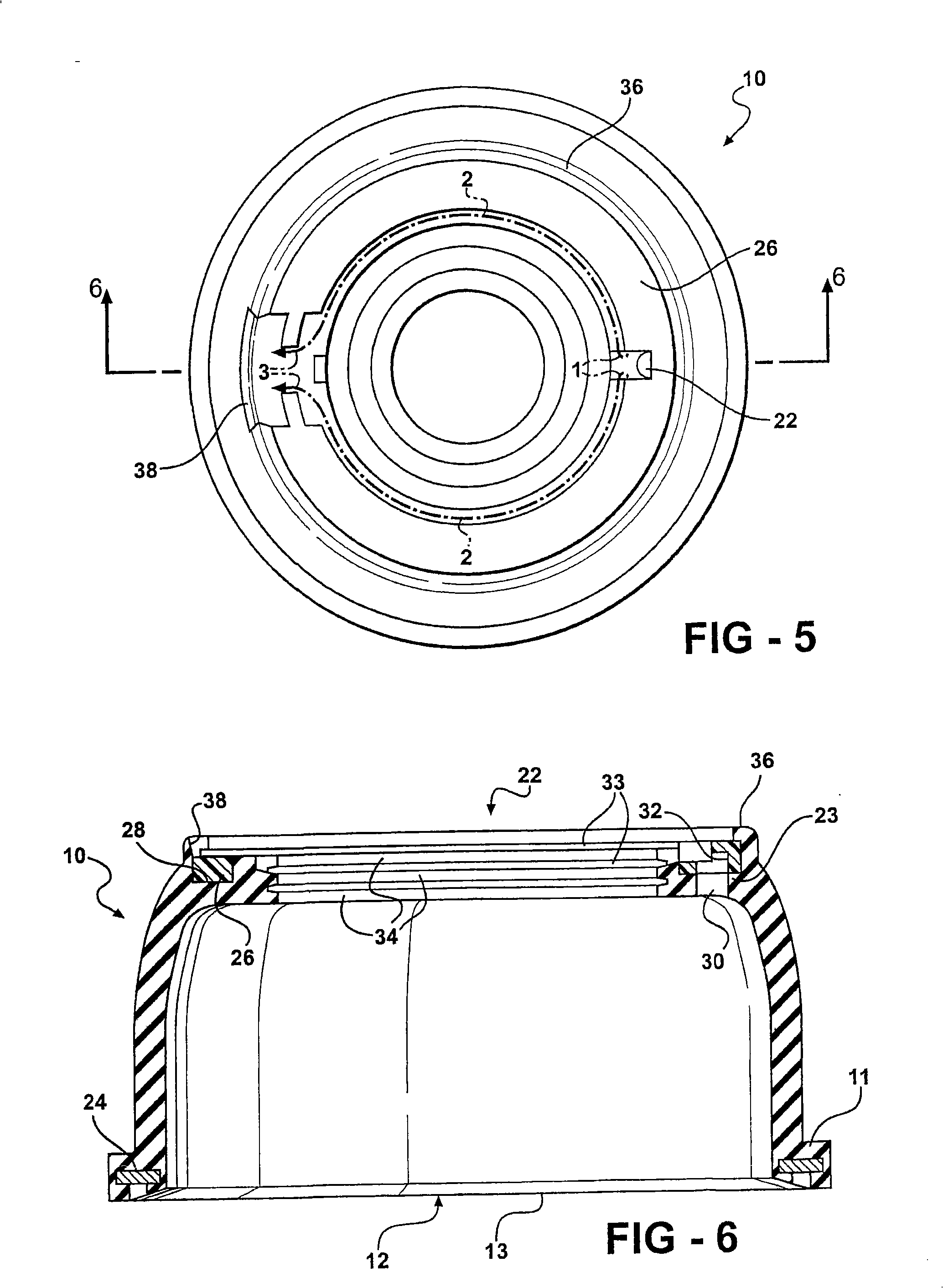

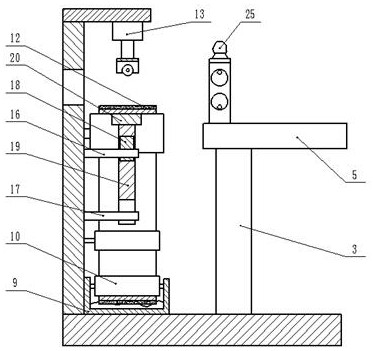

Bearing lubricating device

InactiveCN108246562AImprove oiling effectEnsure normal power onLiquid surface applicatorsBearing componentsLubricationFuel tank

The invention belongs to the field of machine repair, and particularly relates to a bearing lubricating device. The bearing lubricating device comprises a machine frame, a lubricating portion and a rotary portion. A sliding rail is arranged on the machine frame. The lubricating portion comprises a supporting seat, an oil tank and two or more oiling units symmetrically arranged relative to the axisof the supporting seat, a first flow guide hole is formed in the supporting seat, and the oil tank is provided with an oil inlet pipe communicating with the first flow guide hole. Each oiling unit comprises an electromagnet fixed to the machine frame, an oiling bar connected with the machine frame in a sliding mode and a sliding hole formed in the supporting seat, wherein a tension spring is fixed between one end of the oiling bar and the electromagnet, the other end of the oiling bar extends into the sliding hole, an oil outlet and a second flow guide hole capable of communicating with the first flow guide hole are formed in the oiling bar, and the oil outlet communicates with the second flow guide hole. The rotary portion comprises a moving table, a rotary table and a rotary wheel, themoving table can slide on the sliding rail, the rotary table is rotationally connected with the moving table, a positioning shaft is arranged on the rotary table, and the rotary wheel and the rotary table are in belt transmission. By means of the scheme, the problem of non-uniform lubrication in the prior art is solved.

Owner:重庆婉婷科技发展有限公司

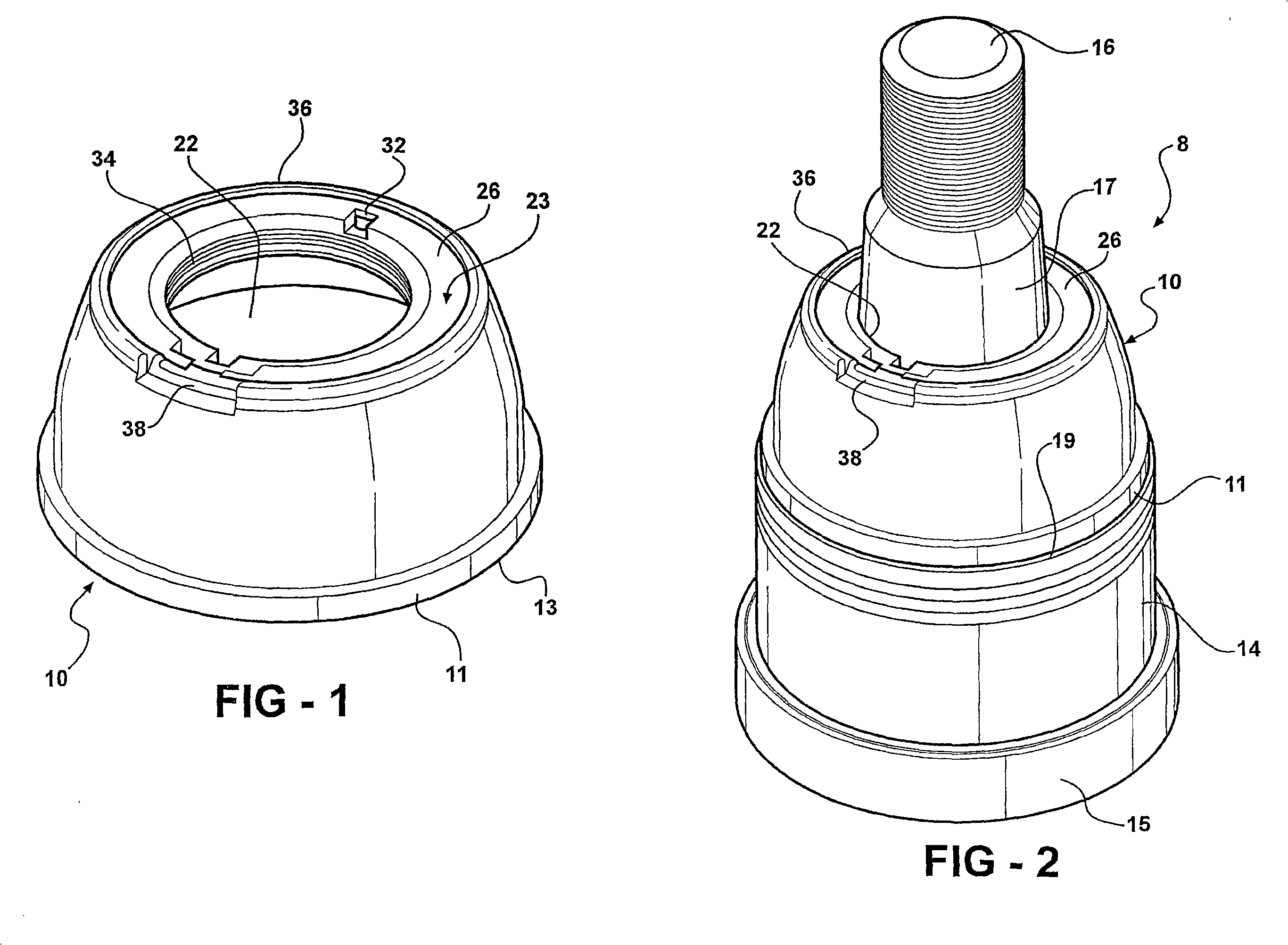

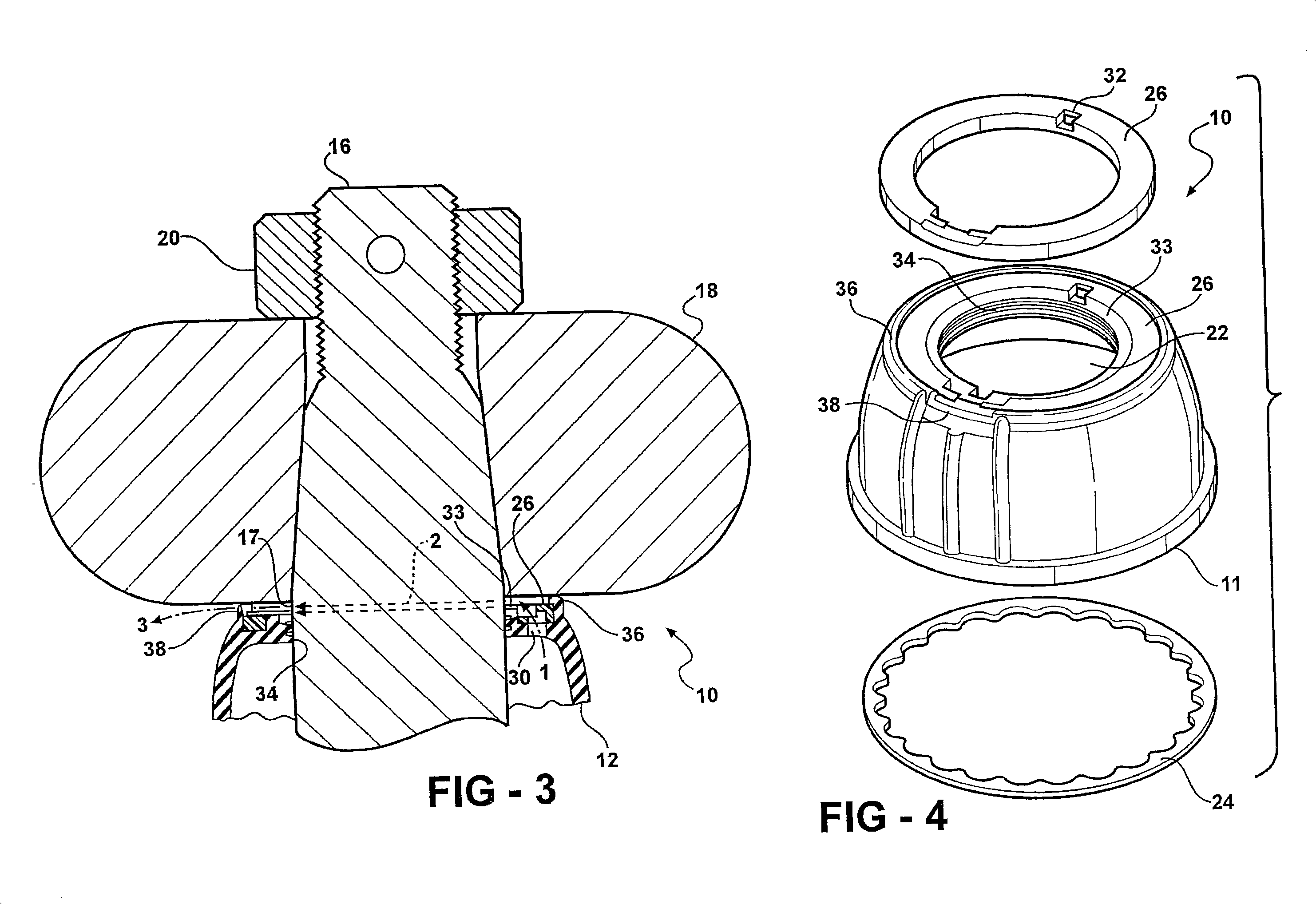

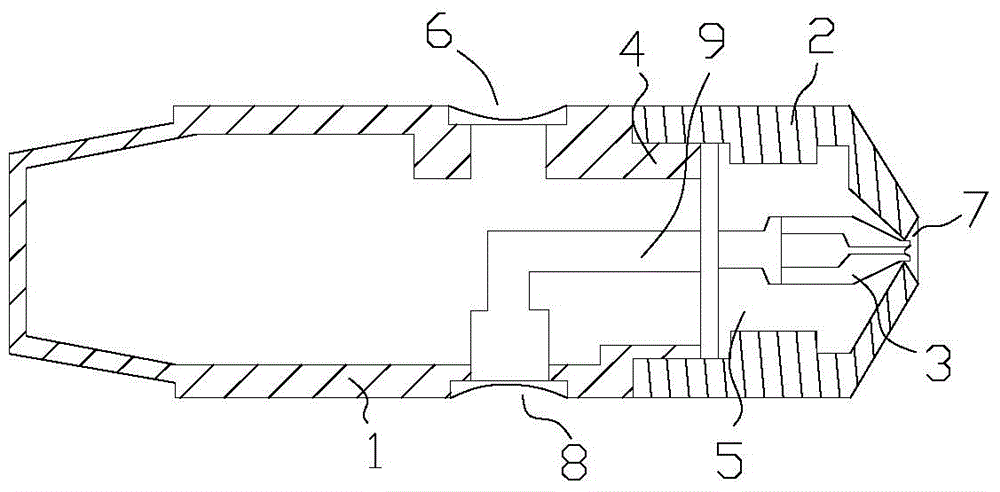

Dust boot with grease channel

ActiveCN101297139AImprove oiling effectImprove featuresYielding couplingBellowsLubricationMechanical engineering

A dust boot with enhanced protection from contaminants and improved lubrication characteristic includes a dust boot body having a housing opening on one end and on an opposing end a stud opening in an upper boot wall. The boot also includes a wiping lip located on an inner face of the upper boot wall in the stud opening, a grease channel on an outer surface of the upper boot wall bounded circumferentially by a rim seal, an offset opening hole through the upper boot wall into the grease channel which is offset from the wiping lip, and a flexible flap portion of said rim seal which is spaced away from said offset opening hole. The dust boot may also include an insert made from a plastic such as nylon housed in the upper boot wall such that the offset opening hole extends through the insert.

Owner:TENNECO LTD

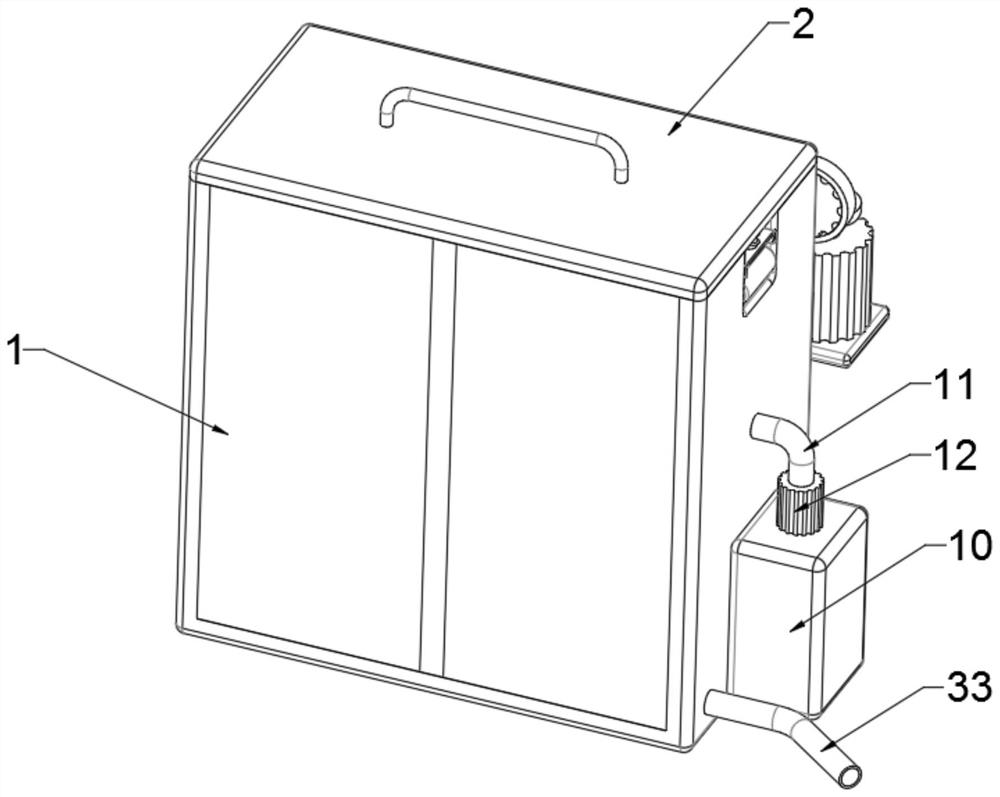

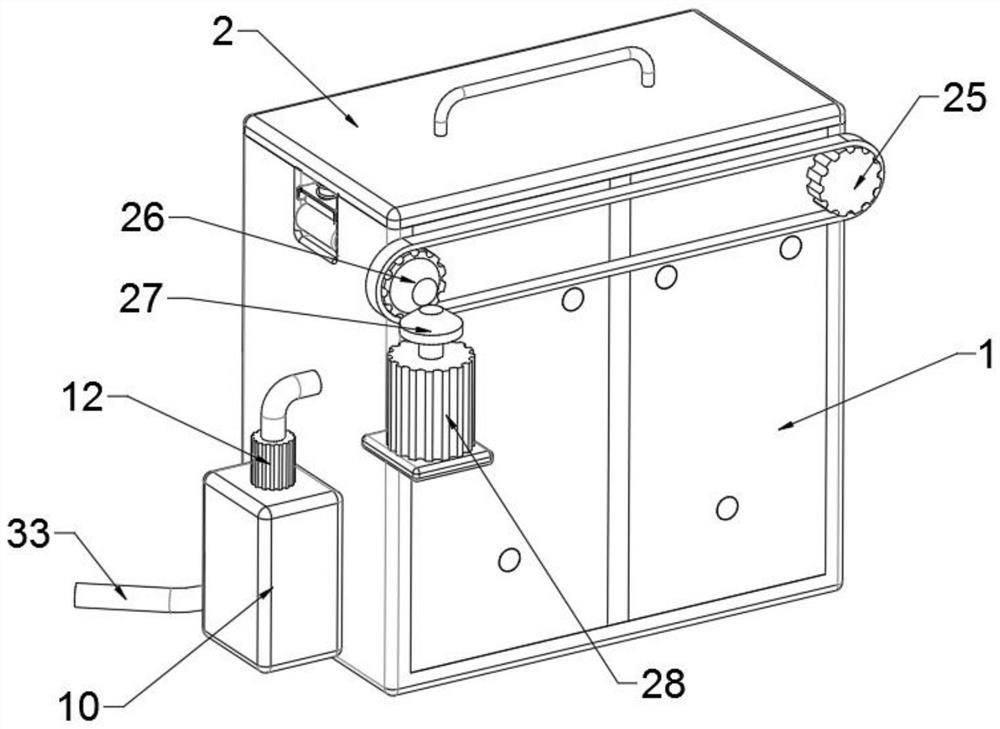

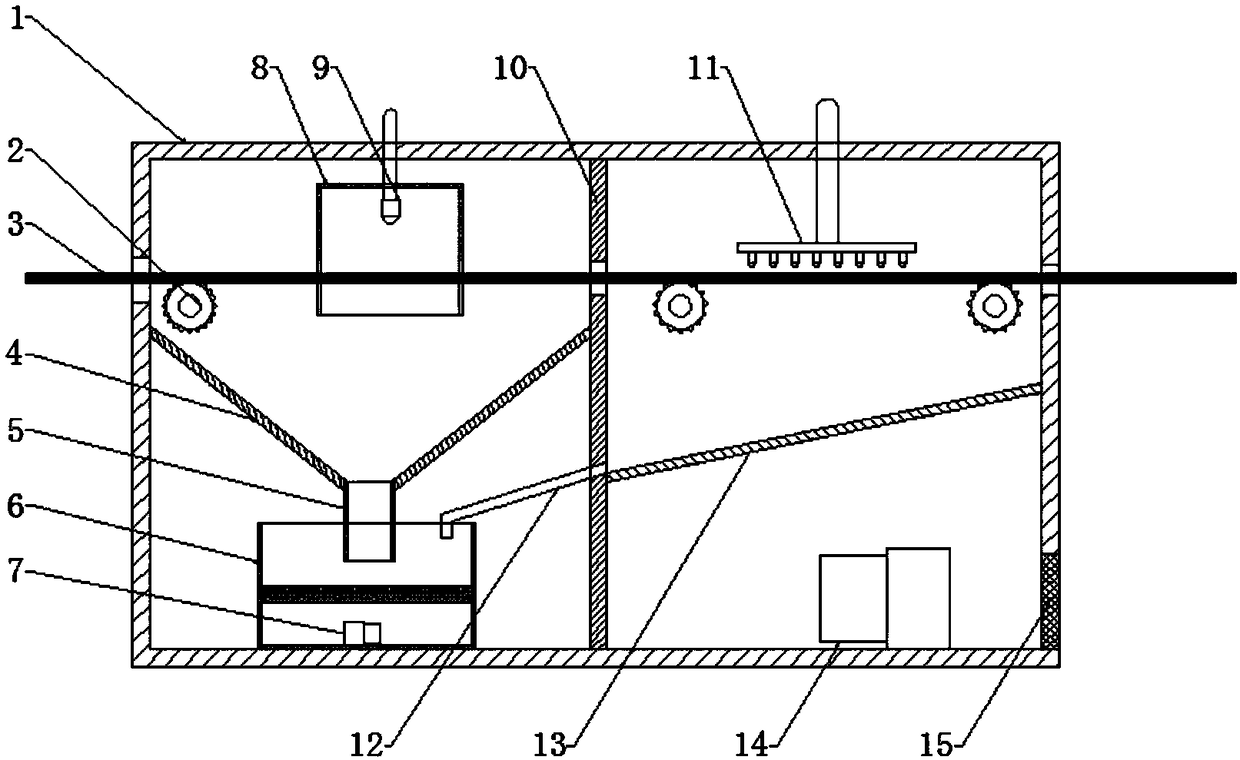

Oiling maintenance device of bearing steel cables for building construction

PendingCN111804525AReduce surface dirtReduce contaminationLiquid surface applicatorsDrying gas arrangementsArchitectural engineeringBuilding construction

The invention relates to the technical field of building construction, and specifically relates to an oiling maintenance device of bearing steel cables for building construction. The oiling maintenance device comprises a maintenance box body, wherein an opening is formed in the upper end surface of the maintenance box body, the position of the opening is matched with a box cover, a partition is vertically arranged in the maintenance box body, the maintenance box body is divided into a cleaning cavity and an oiling cavity by the partition, a through groove for steel cables to pass through is formed in the upper end surface of the partition, two steel cable limiting assemblies are symmetrically arranged in the cleaning cavity and the oiling cavity, a cleaning assembly which is used for cleaning the steel cables is arranged in the cleaning cavity, an oiling assembly which is used for oiling the steel cables is arranged in the oiling cavity, and control assemblies are arranged in two inletand outlet grooves. The oiling maintenance device can be used for oiling maintenance of the steel cables, the steel cables are efficiently cleaned and blow-dried before the oiling operation is performed, then the all-around oiling operation is performed, the overall maintenance effect is high, additionally, the operation is convenient, and the steel cables do not need to be removed.

Owner:王小玲

Workpiece oiling device

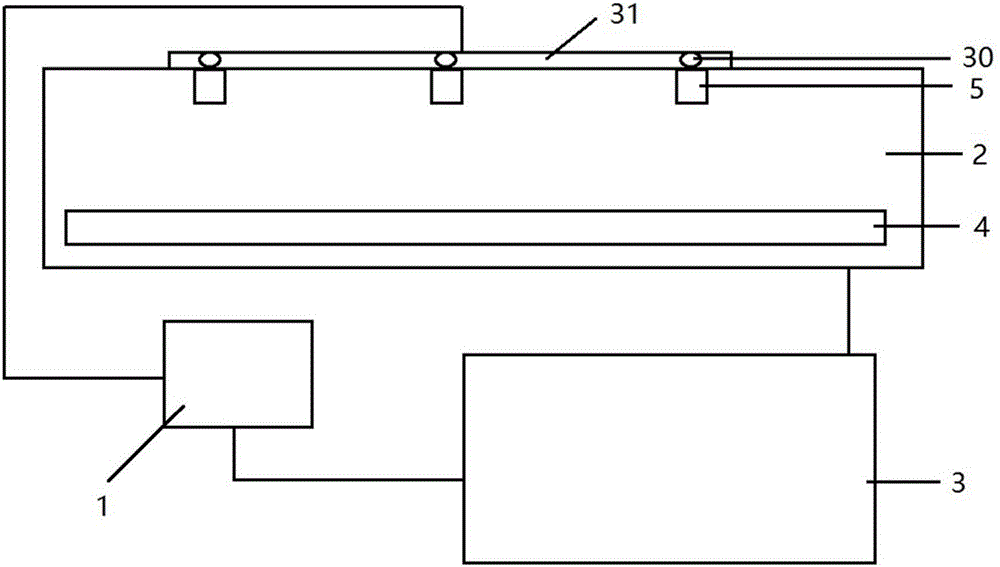

ActiveCN106179834AMeet oiling needsImprove oiling effectLiquid surface applicatorsSpray nozzlesFuel tankEngineering

The invention discloses a workpiece oiling device. The workpiece oiling device comprises an oil extraction pump, an oil tank, an oil spraying tank, a spraying head device and a conveying belt. One end of the oil extraction pump is connected with the oil tank, and the other end of the oil extraction pump is connected with the spraying head device; the spraying head device is installed above the oil spraying tank, and the conveying belt is installed in the oil spraying tank and arranged below the oil spraying tank; and the spraying head device comprises a concentrator and a plurality of atomizing spray heads, the atomizing spray heads are all connected with the concentrator, the concentrator is connected with the oil extraction pump, a filtering device is arranged in the oil tank, and the oil tank is connected with the oil spraying tank. The workpiece oiling device has the beneficial effects that the oiling effect is good, oil can be recycled and reused, the atomization effect is adjustable, convenience is brought to later-period maintenance, operation is convenient, the oiling requirements of different workpieces are met, the production cost is low, the labor intensity is low, and the working efficiency is high.

Owner:浙江安统汽车部件有限公司

Fast oil applying device for chain

InactiveCN107143741ASimple structureEasy to operateChain elementsLubrication elementsOil canFuel tank

Owner:SUZHOU SHUNGE INTELLIGENT TECH

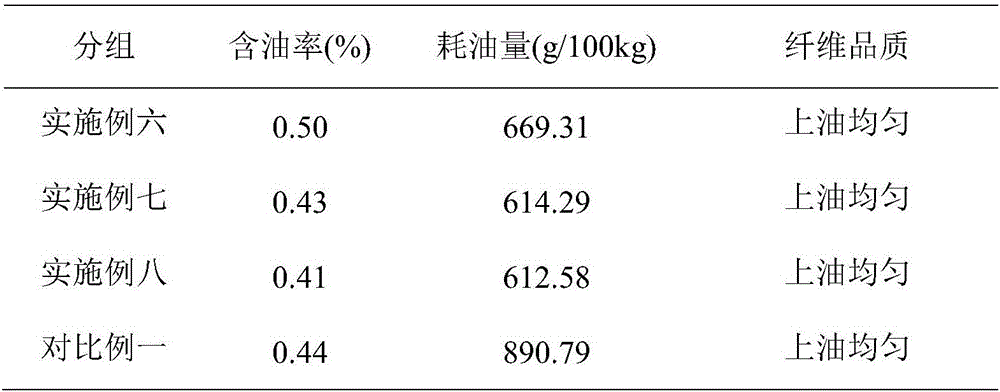

Production process of anti-wicking polyester filament yarns

InactiveCN111607968AImprove mechanical propertiesGood flame retardant and antistatic effectElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolymer scienceSpinning

The invention provides a production process of anti-wicking polyester filament yarns. The production process comprises the following steps that (1), a mixture is taken to be added into a stirrer and stirred at a rotating speed of 600-800 rpm for 10-15 minutes to obtain a flame-retardant and antistatic polyester mixture; (2) the flame-retardant and antistatic polyester mixture is sent into a twin-screw extruder for heating and melting, and a melt is obtained at the extrusion temperature of 280-300 DEG C; (3) the fully melted melt is introduced into a spinning box for metering and filtering, andthe spinning is conducted through a spinning assembly to form a tow; (4), the tow is formed by side blowing cooling air; (5) the tow passes through a spinning finish solution on an oil wheel; (6) stretching and heat setting are conducted through each pair of Roller rollers; (7) an anti-wicking agent is applied; and (8) the anti-wicking polyester filament yarns are obtained by directly winding thetow. The polyester filament yarns prepared by the production process has excellent mechanical properties, the flame-retardant and antistatic polyester mixture is adopted for raw materials, so that the polyester filament yarns have good flame retardant and antistatic properties, the special spinning finish is adopted, oil applying effect is good, and the antistatic ability is high.

Owner:江苏万邦特种纺织发展有限公司

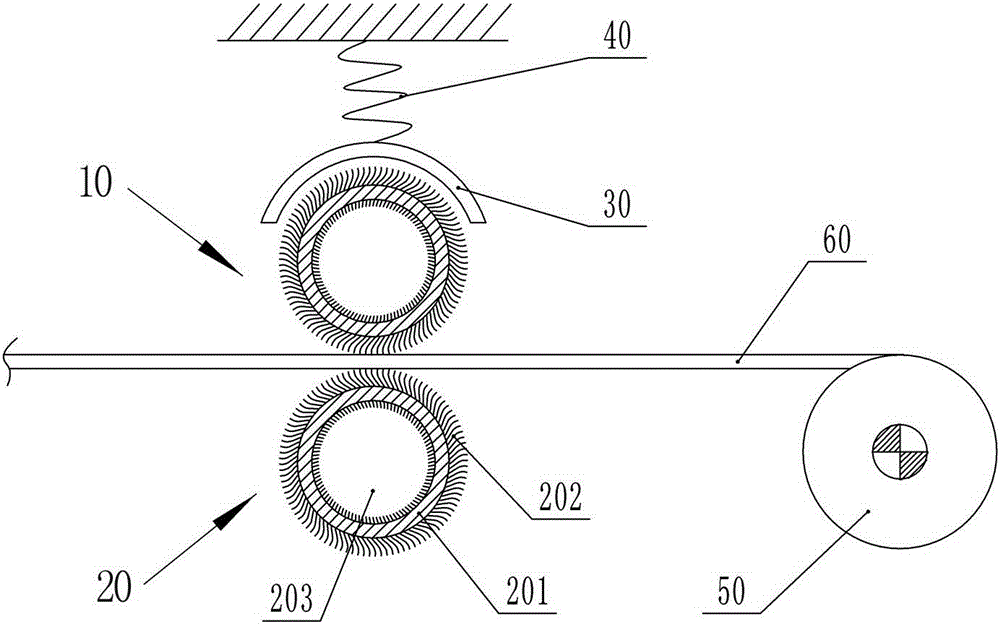

Oil coating structure of calendaring machine

InactiveCN105289916APlay a buffer roleAvoid deformationLiquid surface applicatorsCoatingsPlastic filmSilicone oil

The invention belongs to the field of calendaring, and specifically discloses an oil coating structure of a calendaring machine. The oil coating structure of the calendaring machine comprises an elastic part, a bearing bush and two brush rollers, wherein the two brush rollers are oppositely arranged and rotatably connected to a rack; each brush roller comprises a rotating roller and brush hair; a material storing chamber and a feeding door are arranged on each rotating roller; the hair is inserted into the corresponding material storing chamber and fixed to the surface of the corresponding rotating roller; the bearing bush is in match with the corresponding brush roller; one end of the elastic part is connected to the bearing bush while the other end of the elastic part is connected to the rack. Compared with a traditional plastic calendaring machine, the calendaring machine has the advantages that the oil coating structure can uniformly coat silicone oil on the surface of a plastic film through the rolling contact of the brush rollers and the plastic film, a spray head is not used, and non-uniform oil spraying can be avoided, so that the anti-static electricity capacity of the calendaring machine can be greatly improved.

Owner:CHONGQING TENGTONG IND DESIGN

Spraying type oiling device for chemical fiber production

InactiveCN109082717AEasy to moveConvenient for secondary spraying and oiling workFilament manufactureFilament/thread formingFiberResource utilization

The invention discloses a spraying type oiling device for chemical fiber production. The spraying type oiling device comprises a spraying chamber, an oiling assembly is installed in the spraying chamber, and a first smearing assembly is installed on one side of the oiling assembly. The spraying type oiling device is scientific and reasonable in structure and safe and convenient to use. By arranging the oiling assembly, under the effect of a feeding wheel and a first receiving wheel, chemical fibers can be conveniently driven to move for first spraying oiling, under the effect of a second receiving wheel, a guiding tube and a discharging wheel, the chemical fibers can be conveniently guided for second spraying oiling, the chemical fibers are comprehensively oiled, and the oiling effect is improved. By arranging the first smearing assembly, under the effect of a second driven gear and a rotating tube, the chemical fibers can be conveniently rotatably smeared, and non-uniform chemical fiber oiling is avoided; under the effect of a power gear, a connecting shaft, a first driven gear and a reversing gear, the rotating tube can be conveniently synchronously driven to rotate through rotation of a power shaft, and thus the resource utilization rate is increased.

Owner:长兴一盛纺织有限公司

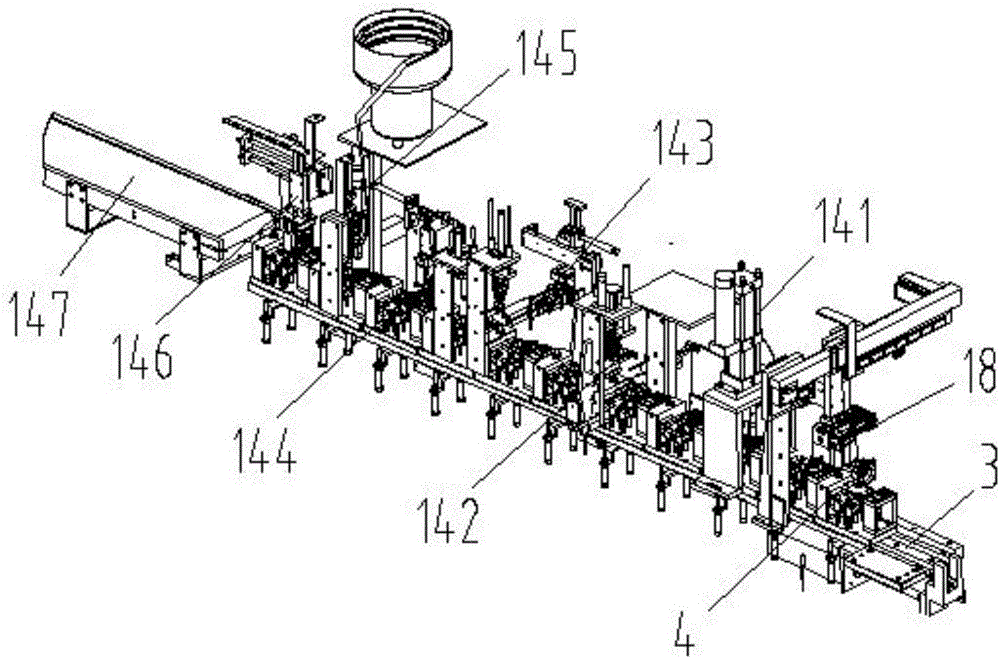

Piston processing method

The invention discloses a piston processing method which comprises the following steps of material selecting and smelting; pouring; thermal treatment; metal processing: carrying out neck ring turning, pinhole base hole processing and oil coating in sequence, wherein a neck ring turning device is adopted to carry out neck ring turning on a piston, a pinhole base hole processing device is adopted to carry out pinhole base hole drilling on the piston, and an automatic oil coating mechanism is adopted to carry out oil coating on the piston; and roundness test: adopting a piston roundness test device to test surface roundness of the piston. The piston processing method disclosed by the invention has the advantage of being high in strength and modulus, stable and precise in neck ring turning, stable in clamping, uniform in oil coating, high in oil coating efficiency, free of manual handheld measuring and wide in measuring position selectivity, and being capable of reducing tool abrasion, avoiding occurrence of oval holes during drilling, improving product quality, reducing a rejection rate and realizing simultaneously measuring roundness of the skirt part and the top part of the piston.

Owner:ANHUI HIGH TECH POWER TECH

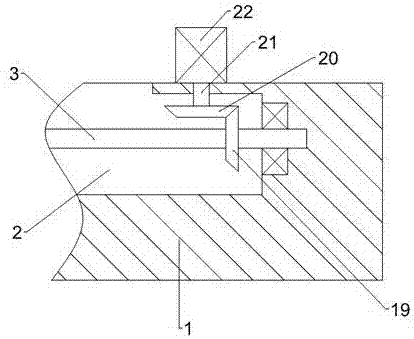

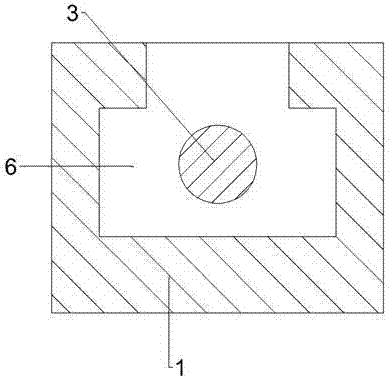

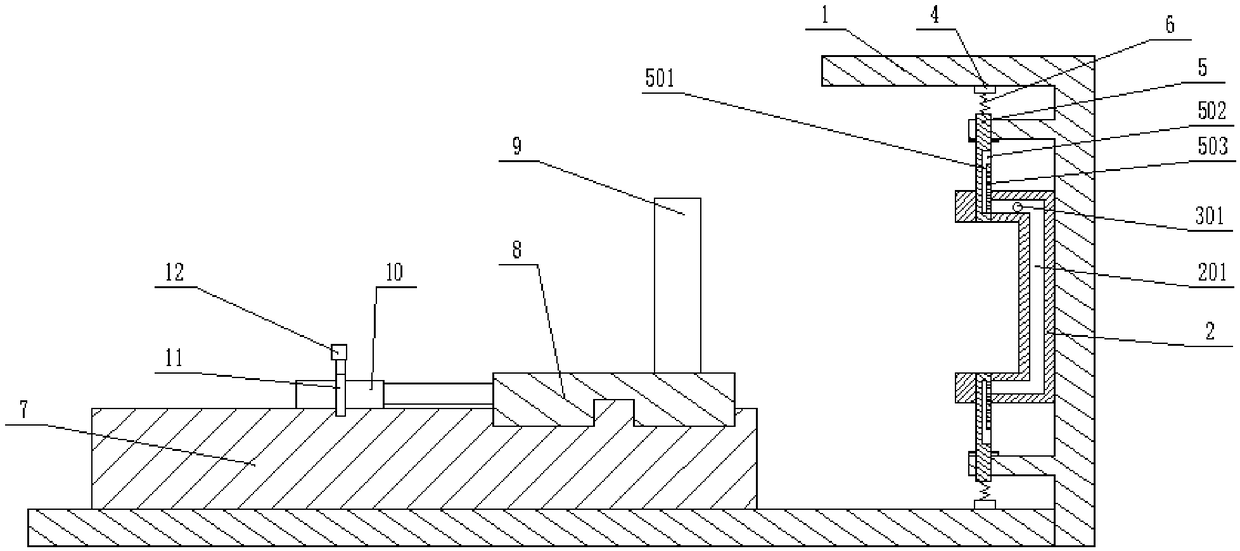

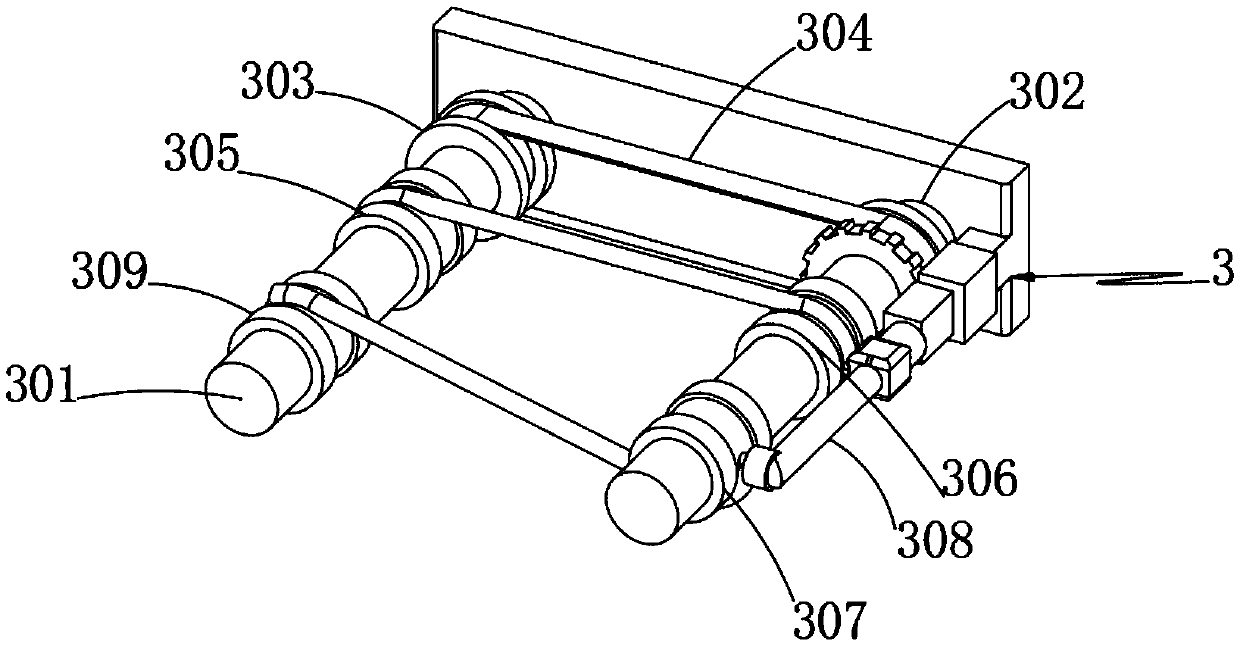

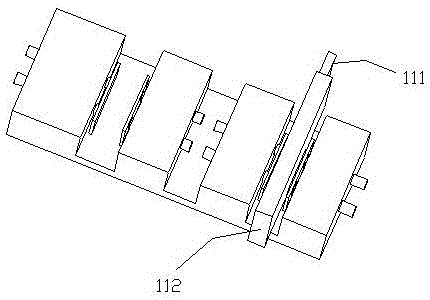

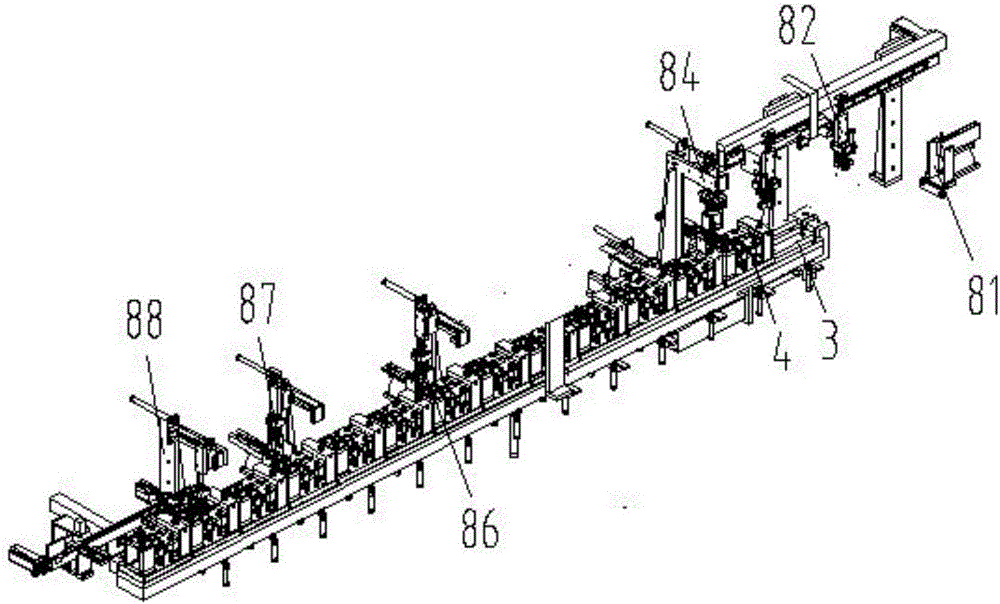

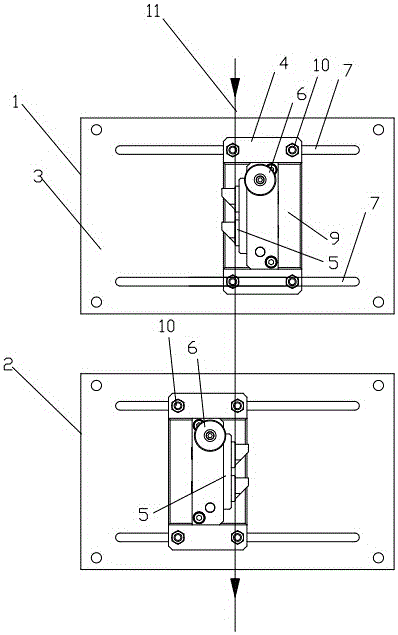

Automatic piston oiling mechanism and method

InactiveCN106540845AShorten the timeImprove oiling efficiencyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an automatic piston oiling mechanism. The automatic piston oiling mechanism comprises a positioning installation base, a motor, a brush, a holding rack assembly, guide rails and an air cylinder, wherein the motor is arranged at the bottom of the positioning installation base, and an output shaft of the motor is connected with the positioning installation base; the positioning installation base is used for storing a piston to be oiled; the holding rack assembly is used for clamping the brush and is in sliding fit with the guide rails; the oil brushing end of the brush can be attached to the surface of the piston to be oiled; and the piston rod end of the air cylinder is connected with the clamping rack assembly so that the clamping rack assembly can be driven to move close to or away from the positioning installation base along the guide rails. The invention further discloses an automatic piston oiling method. The automatic piston oiling mechanism and method have the advantages that the piston is installed stably and firmly, oiling is even, and the oiling efficiency is high.

Owner:ANHUI HIGH TECH POWER TECH

Atomizing nozzle for bearing cleaning line

InactiveCN104998777ASimple structureEasy to adjustSpray nozzlesLiquid spraying apparatusAir channelNozzle

The invention discloses an atomizing nozzle for a bearing cleaning line. The atomizing nozzle comprises a nozzle core, a nozzle casing and an air tap. A threaded base is arranged at the front end of the nozzle core. The nozzle casing is movably connected to the threaded base in a threaded mode, and a liquid mixing cavity is formed in the nozzle casing. The nozzle casing is provided with a horn-shaped nozzle hole. The nozzle core is provided with a liquid inlet hole and an air inlet hole. The liquid inlet hole is communicated with the liquid mixing cavity. The air inlet hole extends into the liquid mixing cavity through an air channel. The air tap is installed at the tail end of the air channel and arranged in the nozzle hole. The front end of the air tap is constructed to be in the shape of a horn matched with the nozzle hole. The atomizing nozzle for the bearing cleaning line is simple in structure; and the flow of the nozzle can be adjusted conveniently, the flow magnitude of the nozzle can be changed in the using process according to practical situations of workpieces. Thus, the using requirements of different workpieces are met so that a better oiling effect can be achieved.

Owner:WUHU HAILIAN MACHINERY INSTALLATION

Chain oiling device

The invention discloses a chain oiling device which comprises a tank, chain wheels, a chain, an oil pump, an air pump and a motor. The multiple chain wheels are arranged on the inner side of the tankfrom left to right; the chain sequentially bypasses the multiple chain wheels; a clapboard is arranged on the inner side of the tank; the inner side of the tank is divided into a left cavity and a right cavity through the clapboard; a mist spray cover is arranged at the position, located on the upper part of the chain, in the cavity on the left side; and oil mist nozzles are arranged on the innerside of the mist spray cover. Through arranging the oil mist nozzles, misty oil is sprayed for oiling the chain in all dimensions, so that an oiling effect is better, the excessive oiling is avoided,and the production cost is reduced; through arranging the mist spray cover, the oil mist activity range is limited, so that concentrated mist spraying is realized, and the oiling efficiency is improved; and meanwhile, through arranging a spray pipe and the multiple nozzles arranged on the spray pipe, redundant oil on the chain can be cleared through high-pressure gas and is recovered into an oil tank through an oil return plate and an oil return pipe, so that the occurrence of the phenomena of environment pollution and resource waste occurred since the redundant oil is carried out by the chainis avoided.

Owner:浙江德立坤链传动有限公司

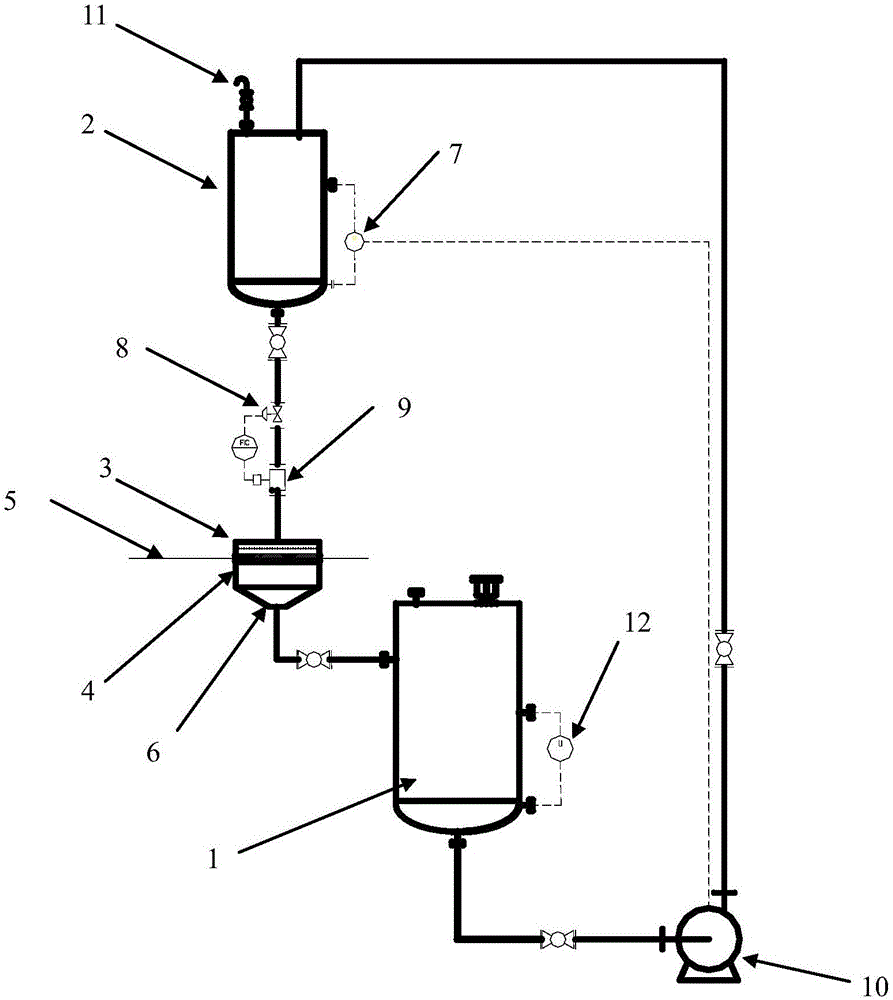

Oil applying device for fiber production and controller method

ActiveCN106637752AAccurately control the dosageWith temporary storage functionTextile treatment containersTextile treatment machine arrangementsFiber bundlePetroleum engineering

The invention discloses an oil applying device for fiber production. The oil applying device comprises an oil storing box, a high-position liquid storing device, an ejecting device and a delivery pump; the oil storing box is connected with the high-position liquid storing device through a pipeline, and the delivery pump is arranged on the pipeline; the set position of the high-position liquid storing device is higher than that of the ejecting device, and the high-position liquid storing device is connected with the ejecting device through an output pipeline. According to the oil applying device and a control method, oil is applied to fiber bundles through the device, the oil applying uniformity is good, and the oil applying rate is high; in addition, the delivery pump can intermittently run, and energy saving and consumption reducing can be achieved; meanwhile, the oil flow can be easily controlled, and oil is saved.

Owner:CHINESE TEXTILE ACAD

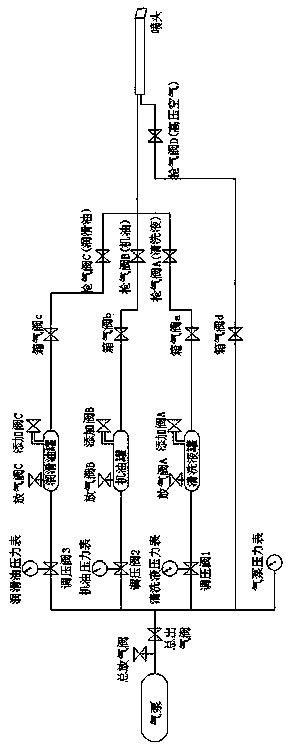

High-pressure cleaning oiling system and oiling method

PendingCN108311444AEasy to operateStrong controllabilityDrying gas arrangementsCleaning using liquidsControllabilityHigh pressure

The invention provides a high-pressure cleaning oiling system. The high-pressure cleaning oiling system comprises a cleaning oiling system. The cleaning oiling system comprises a cleaning system, an air drying system, an injecting system and an air pump pressure gauge; the left end of the cleaning oiling system is connected with an air supplying device in series and the right end of the cleaning oiling system is connected with an injecting head in series; a main deflation valve and a main air outlet valve is sequentially connected between the air supplying device and the cleaning oiling systemin series. The invention further comprises a high-pressure cleaning oiling method of the high-pressure cleaning oiling system. The method mainly comprises steps of cleaning, air drying and oiling. The system is easy and convenient to operate, strong in controllability, good in cleaning effect, good in oiling effect and capable of realizing the complete coverage of lubricating oil.

Owner:STATE GRID CORP OF CHINA +1

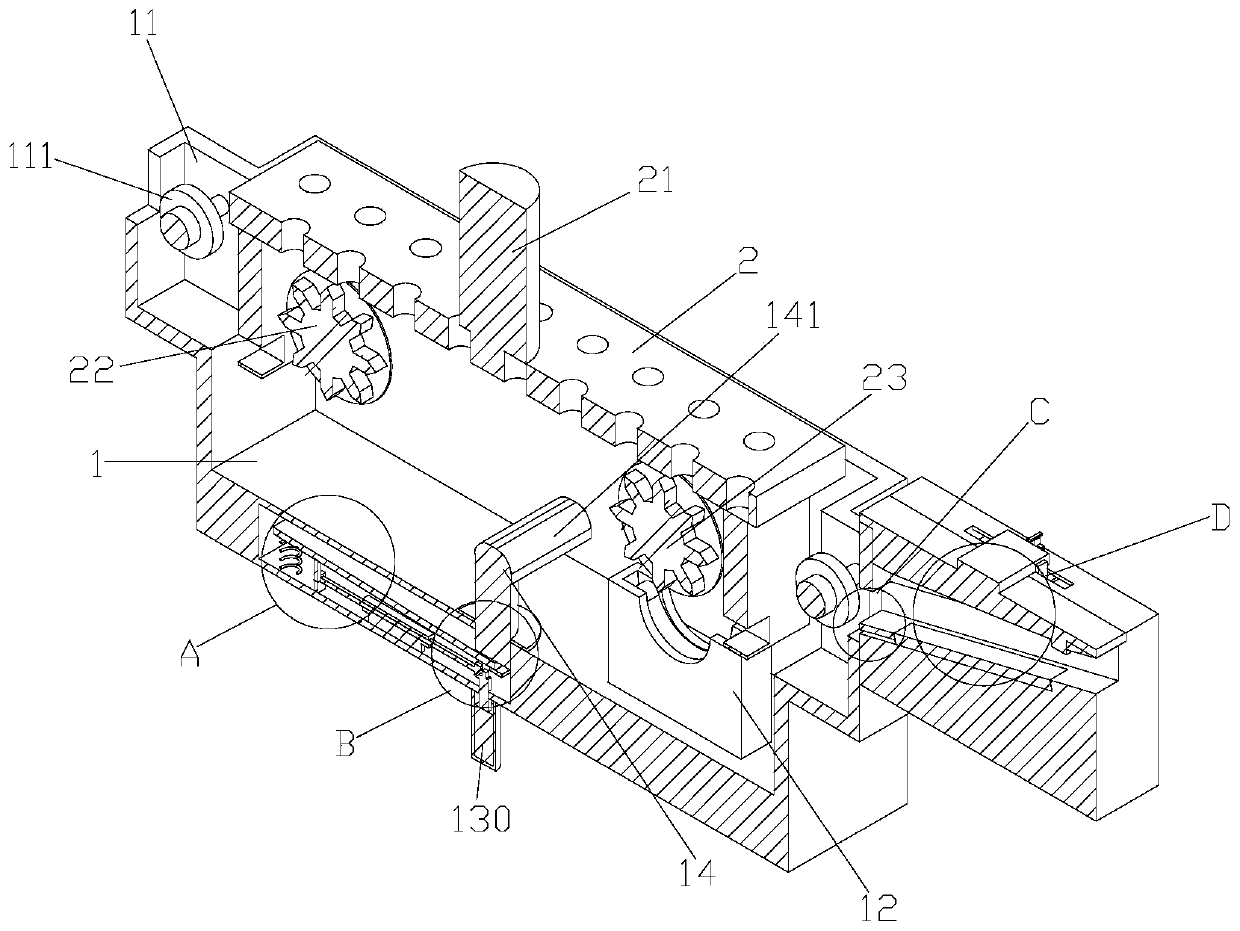

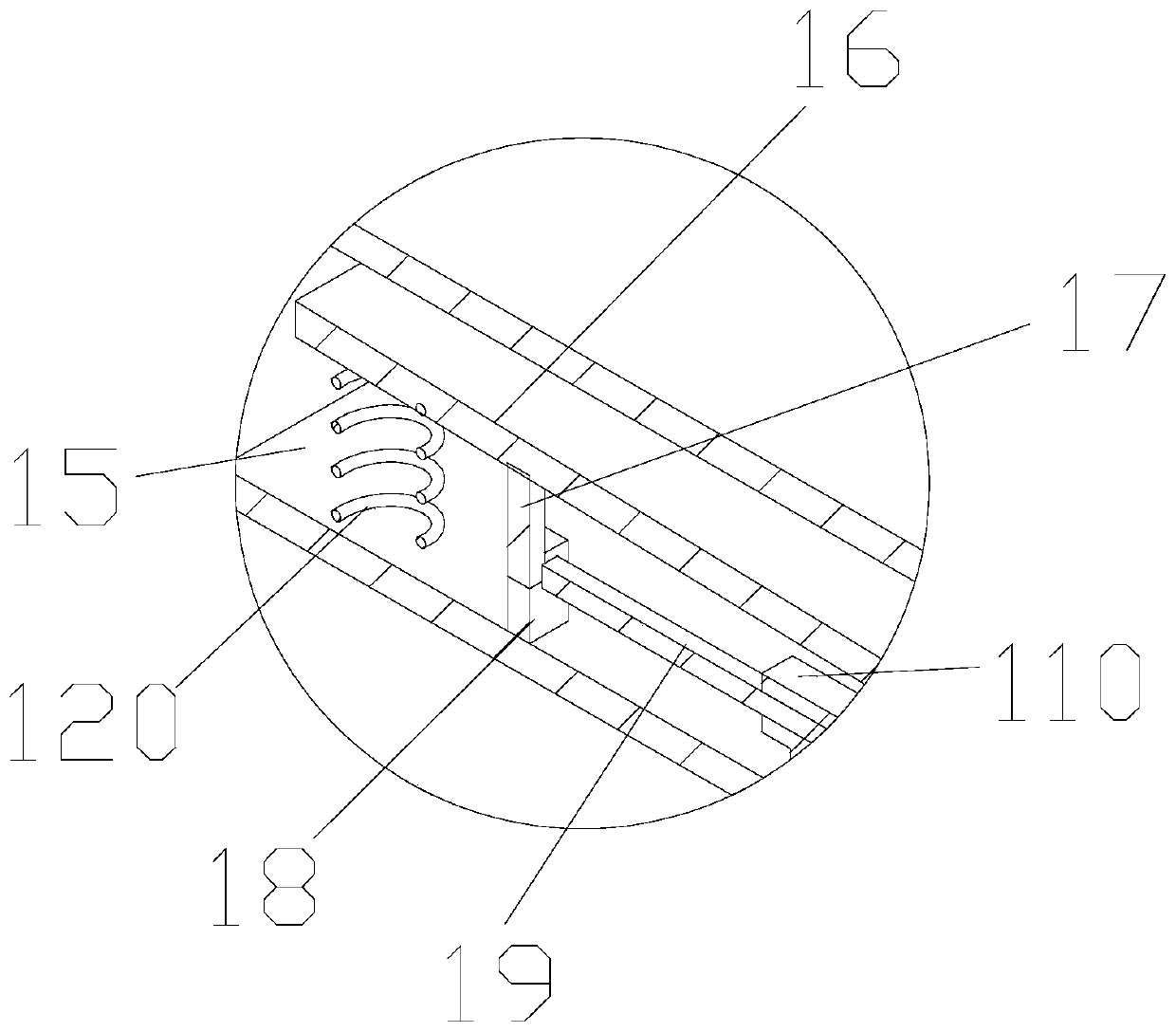

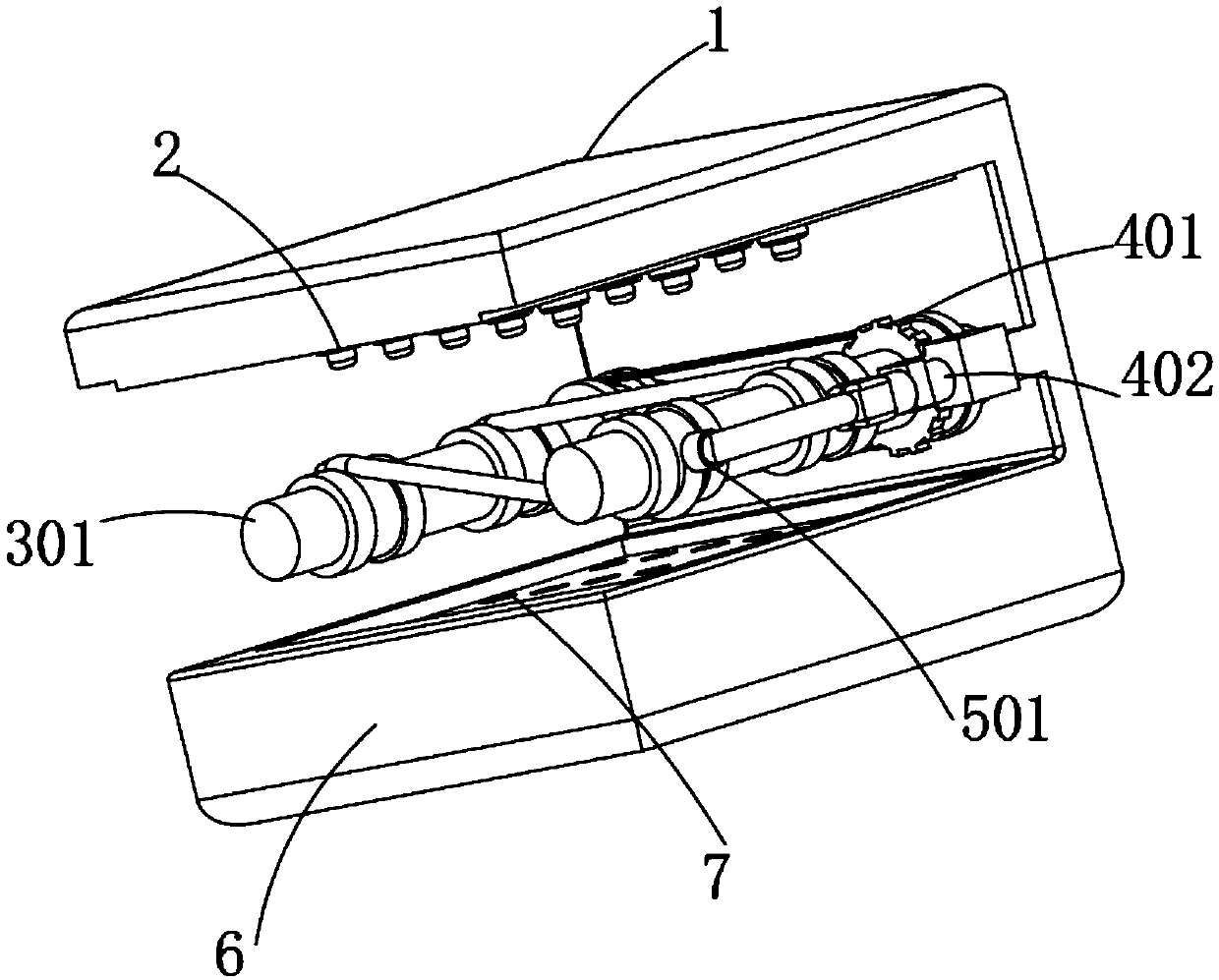

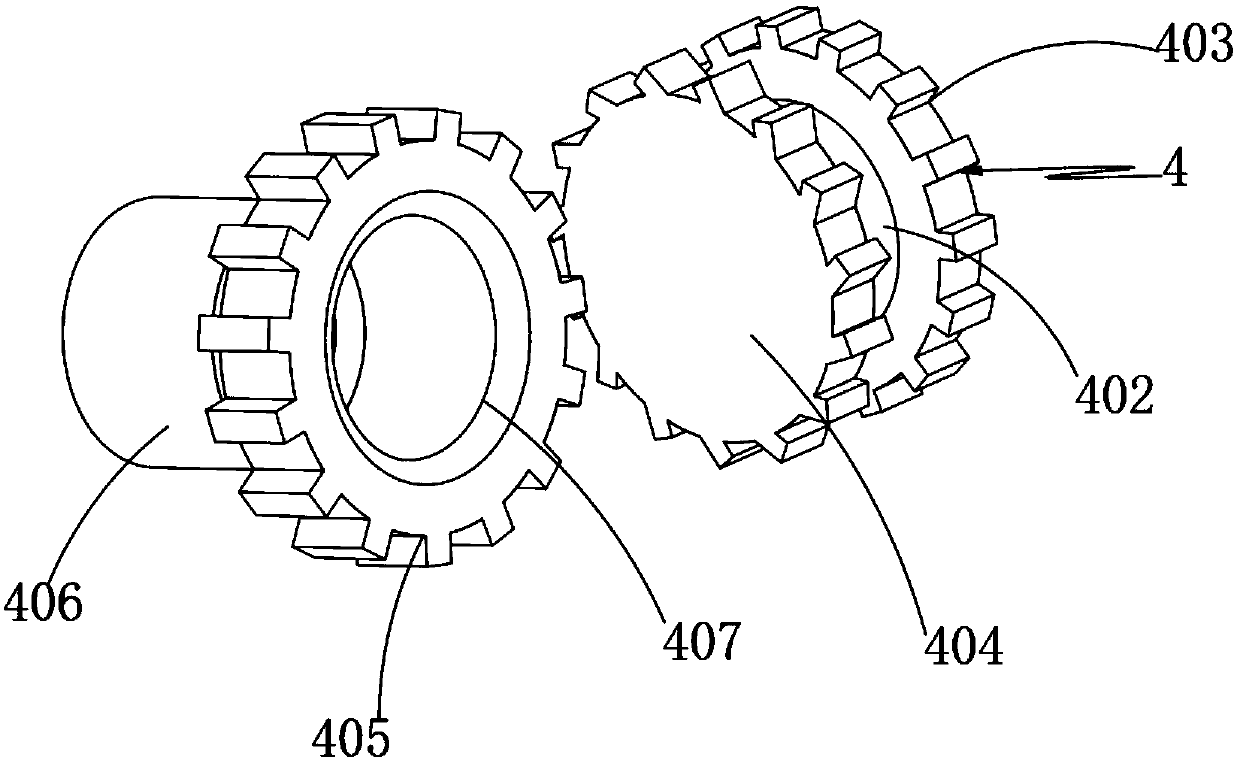

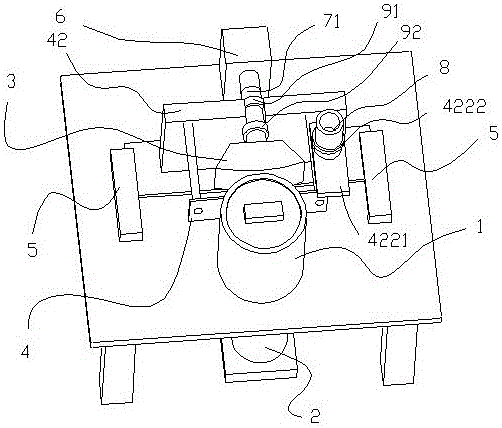

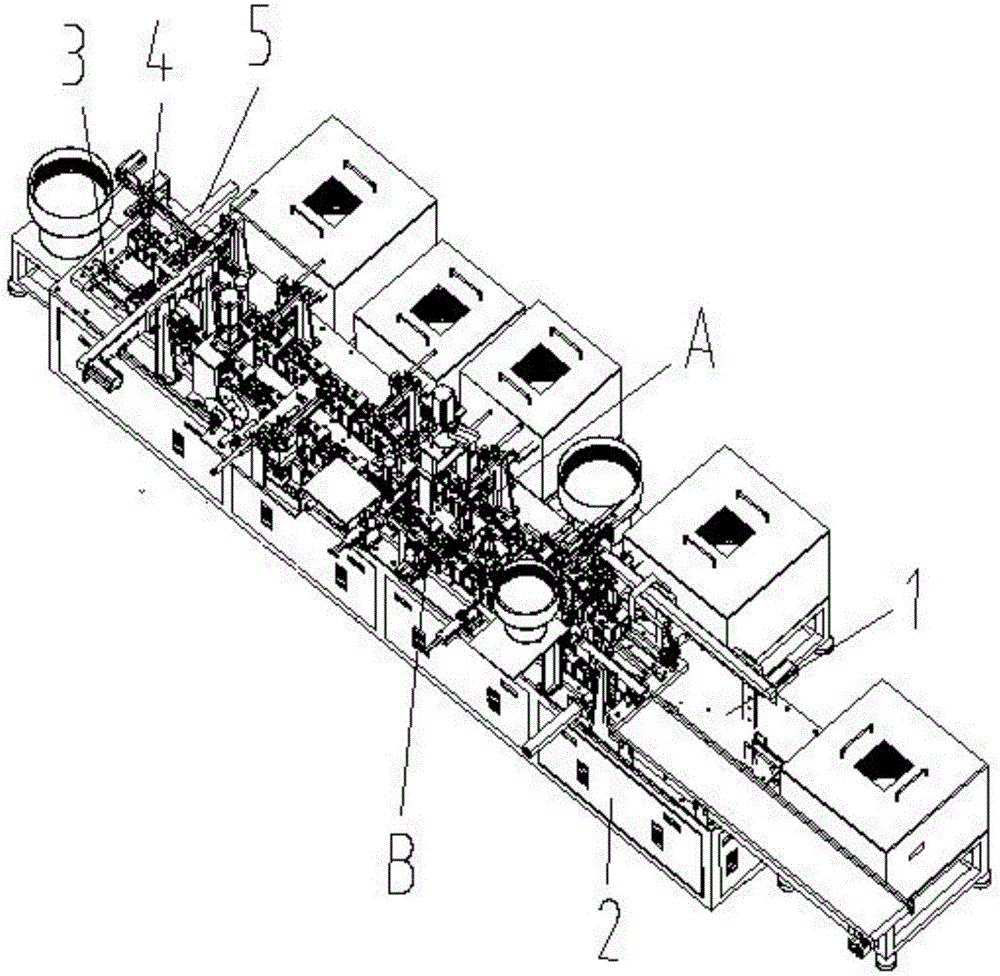

Integrated assembling mechanism of box oil injector

ActiveCN106514241AMesh precisionImprove assembly efficiencyAssembly machinesMatched controlEngineering

The invention relates to an integrated assembling mechanism of a box oil injector. The integrated assembling mechanism of the box oil injector comprises a rack and a matched control box, wherein two conveying devices are arranged on the rack; a conveying carrier is arranged on each conveying device; a transposition cylinder arranged on the rack is switched on the two conveying devices; each conveying carrier comprises a conveying carrying seat; an assembling carrier is arranged in the middle of each conveying carrying seat; a gear shaft placing carrier and a cover plate placing carrier are respectively arranged on two sides of each conveying carrying seat; the conveying device on the rear side is matched with a gear shaft feeding manipulator, a cover plate feeding device, a gear shaft feeding device, a gear feeding device and a copper cover feeding device; and the upper part of the conveying device on the front side is matched with a box transferring device, a copper cover riveting device, a gear shaft oil injection device, a gear shaft assembling device, a cover plate assembling device, a bolt locking device and a discharging manipulator. By the integrated assembling mechanism of the box oil injector, a gear shaft can be accurately engaged with a gear during followed-up assembling, integrated automatic accurate assembling is realized, and the assembling efficiency and the yield are greatly improved.

Owner:安徽长吉汽车科技有限公司

Middle core wire oiling device for wire and cable production

ActiveCN112435803AGuaranteed reflowReduce wasteClimate change adaptationCable/conductor manufactureDrive shaftStructural engineering

The invention discloses a middle core wire oiling device for wire and cable production, and relates to the technical field of wire and cable production equipment, the middle core wire oiling device comprises a bottom plate, a vertical plate and a support plate, the vertical plate is fixedly connected to the left end of the bottom plate, and the upper end of the vertical plate is fixedly welded with a transverse plate and fixedly connected to the bottom plate; a guide plate is fixedly connected to the upper end of the support plate; and the vertical plate is provided with a wire inlet, the right side of the vertical plate is rotationally connected with main belt rollers which are symmetrical front and back, and auxiliary belt rollers are arranged below the main belt rollers. Compared with the prior art, the oiling device has the beneficial effects that through rotation of the driving shaft of the lead mechanism, the driving lever intermittently keeps the conveying belt at different positions under the action of the eccentric wheel to oil a central core wire, the oil immersion roller enables the conveying belt and the oil cloth to be stained with oil in the opening box, and meanwhile, the auxiliary belt rollers on the two sides play a role in extrusion; and by means of the mode, oiling is even, waste of oil is effectively reduced, and production cost is saved.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV

A para-aramid fiber double surface oiling device

ActiveCN104963010BAvoid the problem of large differences in oiling quantityOil infiltrationFilament/thread formingFiber bundleEngineering

The invention relates to a chemical fiber oiling device, in particular to a double-faced oiling device for para-aramid fibers. The double-faced oiling device for the para-aramid fibers comprises a first oiling mechanism and a second oiling mechanism which are vertically arranged from top to bottom, and the first oiling mechanism and the second oiling mechanism each comprises a fixing plate, an oil nozzle fixing seat, oil nozzles and a guide rod; the fixing plates are connected with the oil nozzle fixing seats through fixing plate sliding rails, the oil nozzle fixing seats are provided with the guide rods, oil nozzle sliding rails are arranged on the guide rods, and the oil nozzle sliding rails are provided with multiple oil nozzle fixing blocks. According to the double-faced oiling device for the para-aramid fibers, it can be guaranteed that fiber bundles are located at oil outlets of the oil nozzles by adjusting the positions of the nozzles and relevant structures, and therefore oiling agents can be fully infiltrated on the fiber bundles; in addition, a frequency converter and a metering oil pump are supplemented to control the oiling amount, therefore, it can be guaranteed that the oiling amount of each fiber bundle is unified, and the problem that the differences of the oiling amount of the fiber bundles are large can be prevented from occurring.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com