Spraying type oiling device for chemical fiber production

A chemical fiber and spraying technology, applied in the field of chemical fiber, can solve the problems of oiling blind spots between chemical fiber and contact objects, uneven oiling of chemical fiber, and low quality of finished products, so as to avoid uneven oiling and improve oiling effect, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

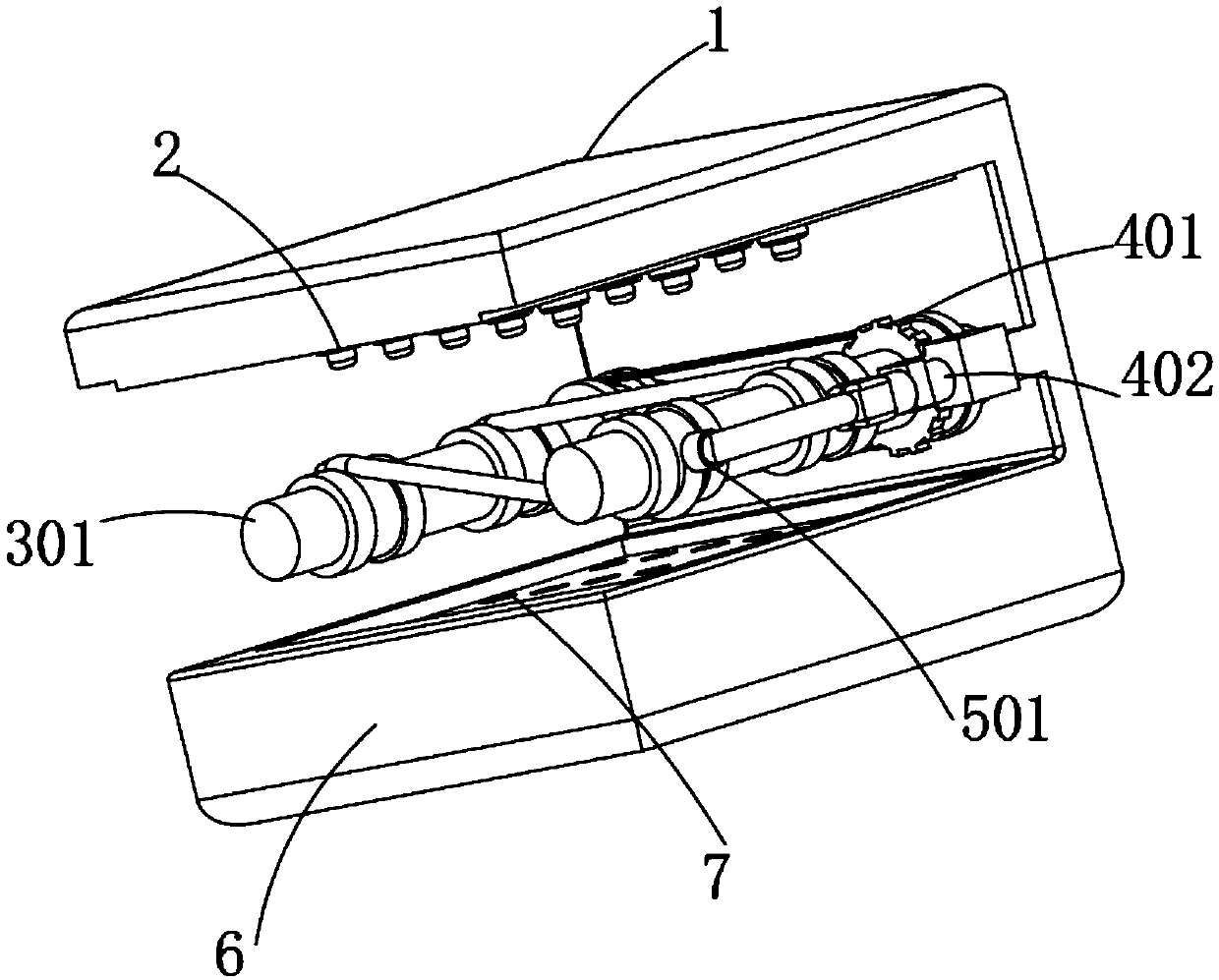

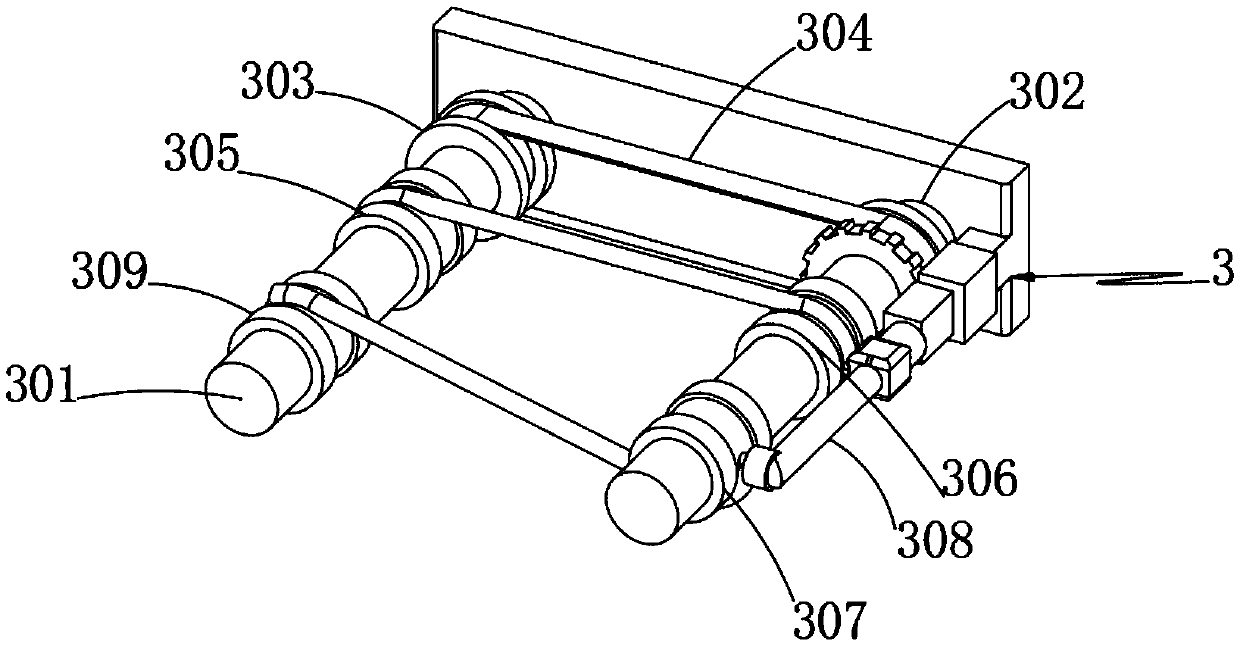

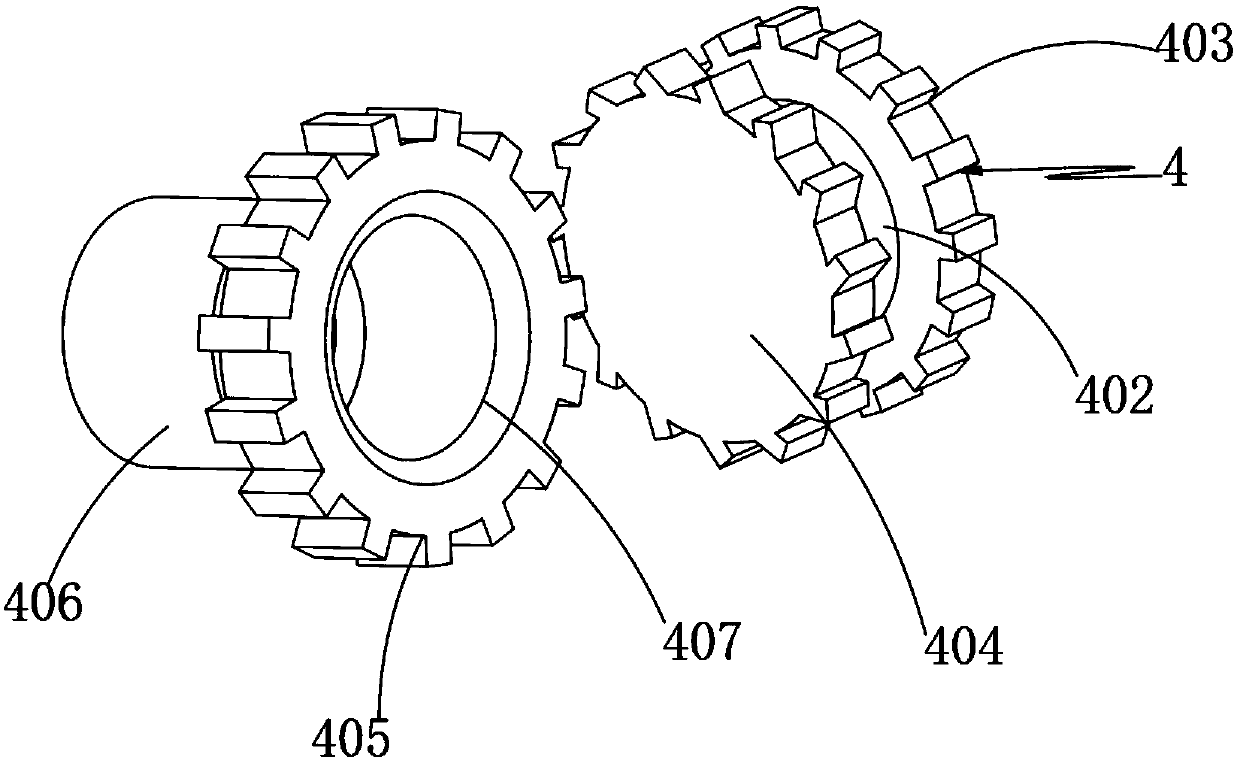

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a spray type oiling device for chemical fiber production, including a spray chamber 1, a nozzle 2 is evenly installed on the top of the spray chamber 1, and an oiling device is installed on the bottom of the nozzle 2. Assembly 3, the oiling assembly 3 includes a first rotating roller 301, a second rotating roller 302, a power shaft 303, a linkage belt 304, a feed wheel 305, a first receiving wheel 306, a second receiving wheel 307, a guide pipe 308 and an outlet Material wheel 309, a first rotating roller 301 is installed on one side of the spray chamber 1, a second ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com