Oil applying device for fiber production and controller method

A control method and fiber technology, which can be applied to the configuration of equipment for processing textile materials, spraying/jetting textile material processing, processing textile material containers, etc. Avoids excessive oiling of fibers, shortens service life, and ensures sufficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

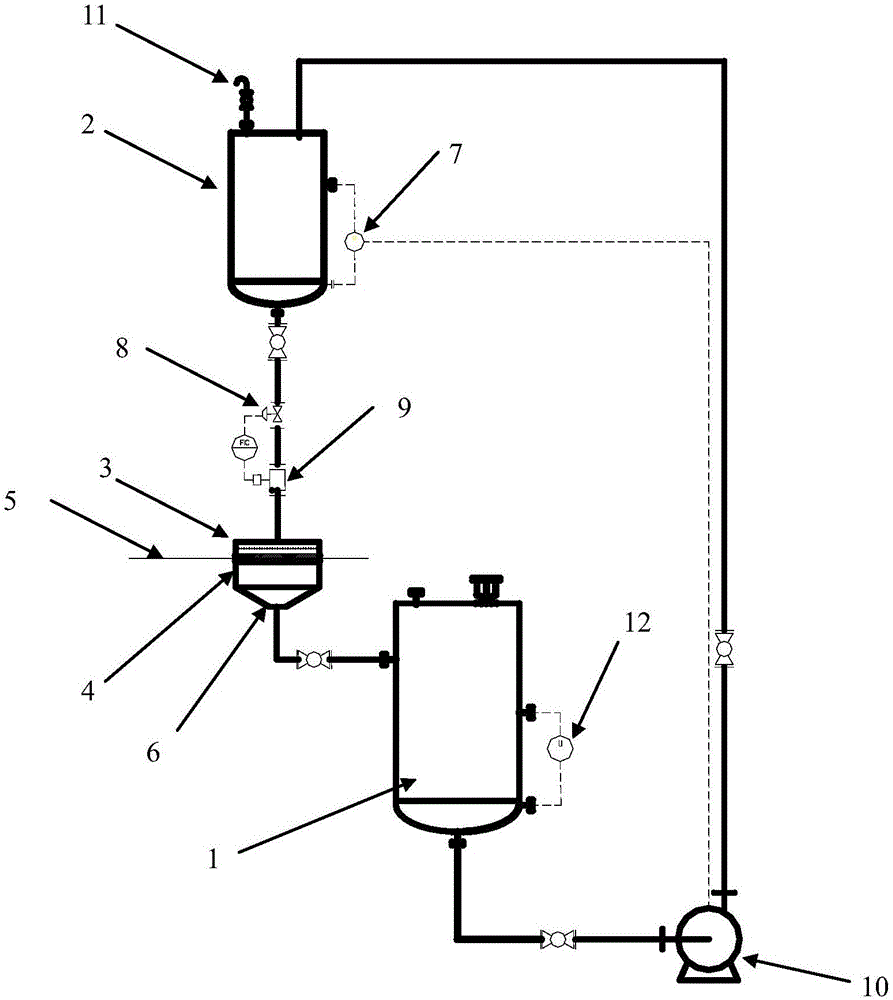

[0044] Such as figure 1 As shown, the present invention provides an oiling device for fiber production, including an oil storage tank 1, a high-level liquid storage device 2, a spraying device 3 and a delivery pump 10, and the oil storage tank 1 and the high-level liquid storage The device 2 is connected through a pipeline, and a delivery pump 10 is arranged on the pipeline; the high-level liquid storage device 2 is arranged higher than the spraying device 3, and is connected with the spraying device 3 through an output pipeline.

[0045] The oiling device for fiber production in this embodiment includes an oil storage tank, a high-level liquid storage device, a spraying device and a delivery pump. Among them, the oil storage tank is used to store oil, and the high-level liquid storage device is installed at a position higher than the spraying device, which is used for temporary storage of oil, and can use the gravity of the oil itself to make the oil flow into the spraying de...

Embodiment 2

[0058] Such as figure 1 As shown, the present embodiment is a further limitation of Embodiment 1. The oiling device of the present embodiment also includes an adsorption device 4, and the adsorption device 4 is installed at the lower end of the ejection device 3. Forming a tow channel between them.

[0059] The oil agent sprayed out by the spraying device oils the fiber tow, and the upper layer oiling method can be adopted, and the oiling is sufficient and uniform, and the addition of the adsorption device can also avoid excessive oiling.

[0060] The ejection device and the adsorption device are arranged up and down, and the ejection device is installed on the upper end of the adsorption device, so that a channel of fiber tow is formed between the two, which is referred to as the tow channel. The spraying device at the upper end can spray the oil agent, and the adsorption device at the lower end can absorb the oil agent evenly and dispersedly in a large amount. When the fibe...

Embodiment 3

[0070]This embodiment is a further limitation of Embodiment 1. The spraying device 3 is provided with a number of oil spray holes, and one end of the spraying device for spraying oil is a pinhole plate.

[0071] The ejection device is generally a fuel injection nozzle or a fuel injection pipe with a large aperture. The fuel injection will affect the tension of the tow, and the friction between the tow and the outside will increase, and it is prone to broken wires and increased hairs. The ejection device in this embodiment is a pinhole plate, which is composed of multiple sets of aperture plates with a diameter of 0.1-1 mm, and the outer diameter of the holes of the pinhole plate is 0.1-1 mm apart.

[0072] The oil agent is sprayed out through the pinhole plate, and the sprayed oil agent is more slender, even a spray of oil agent, more dispersed and more uniform, and the oiling of the fiber tow is more uniform and sufficient, and the oiling efficiency is high. At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com