Efficient environmental-friendly oil tank for steel tube production

A steel pipe, environmental protection technology, applied in the direction of the surface coating liquid device, coating, etc., can solve the problems of poor oil coating effect, environmental protection, oil pollution discharge, etc., to achieve good oil coating effect, comprehensive design, structural solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

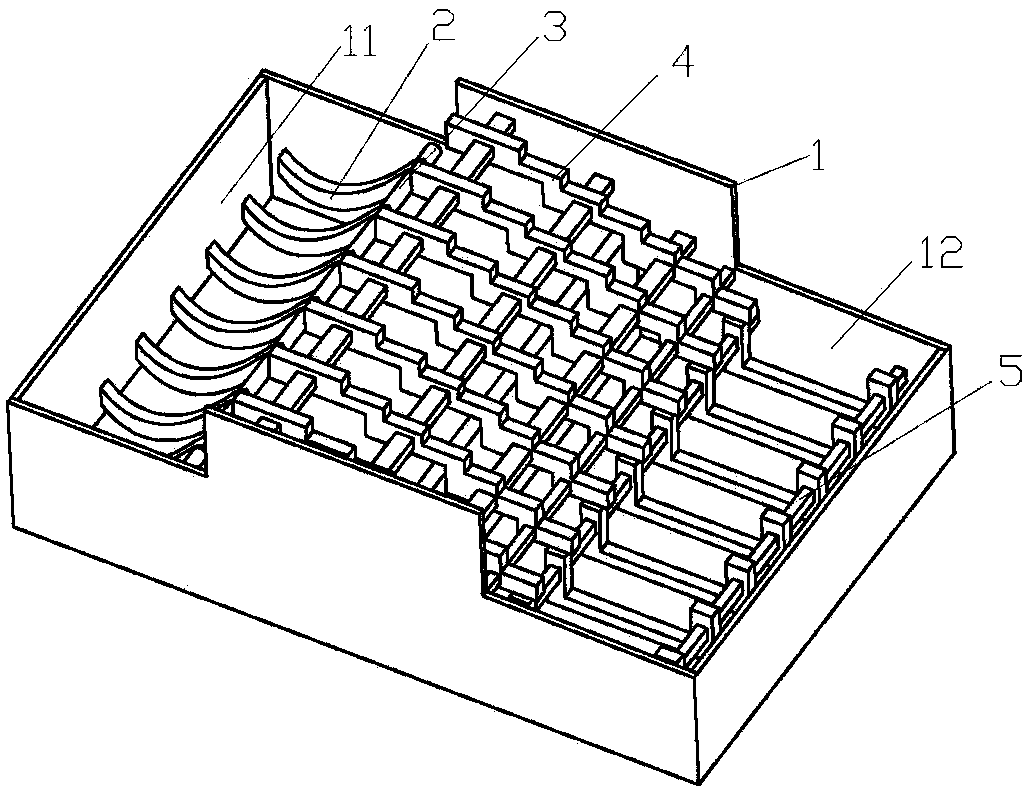

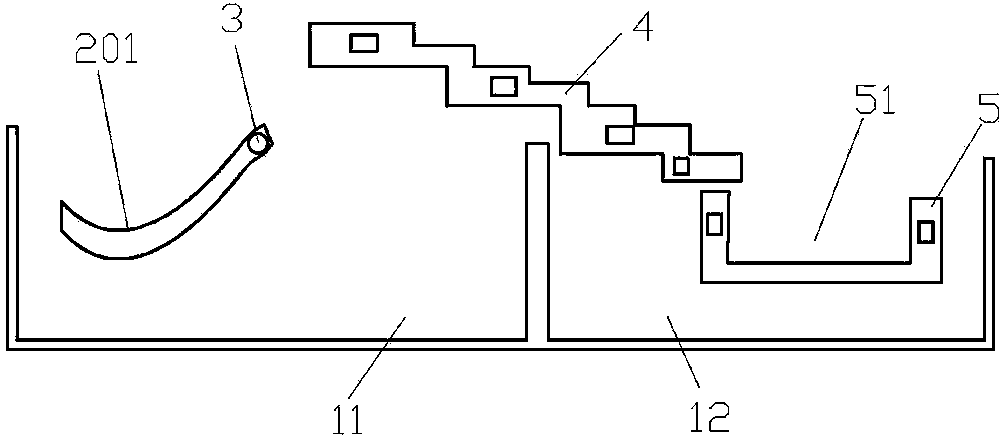

[0017] Example 1, such as figure 1 , 2 As shown, an efficient and environment-friendly oil tank for the production of steel pipes includes a tank body 1, the tank body 1 includes an oil storage tank 11 and a collection tank 12, the oil storage tank 11 is provided with a row of bearing rods 2 capable of carrying steel pipes, and the bearing rods 2 has an arc-shaped concave portion 201, the bearing rod 2 is fixed on a rotating shaft 3 that can transport the steel pipe to the collection tank 12, the rotating shaft 3 passes through the tank body 1, hangs in the tank body 1, and passes through the external The motor or cylinder realizes the rotation. The upper part of the tank body 1 is also provided with a row of transition oil filter racks 4 that cooperate with the bearing rod 2. The transition oil filter racks 4 are in a stepped structure from the oil storage tank 11 to the collection tank 12 and downwards. , the transition oil filter rack 4 is suspended in the tank body 1 ...

Embodiment 2

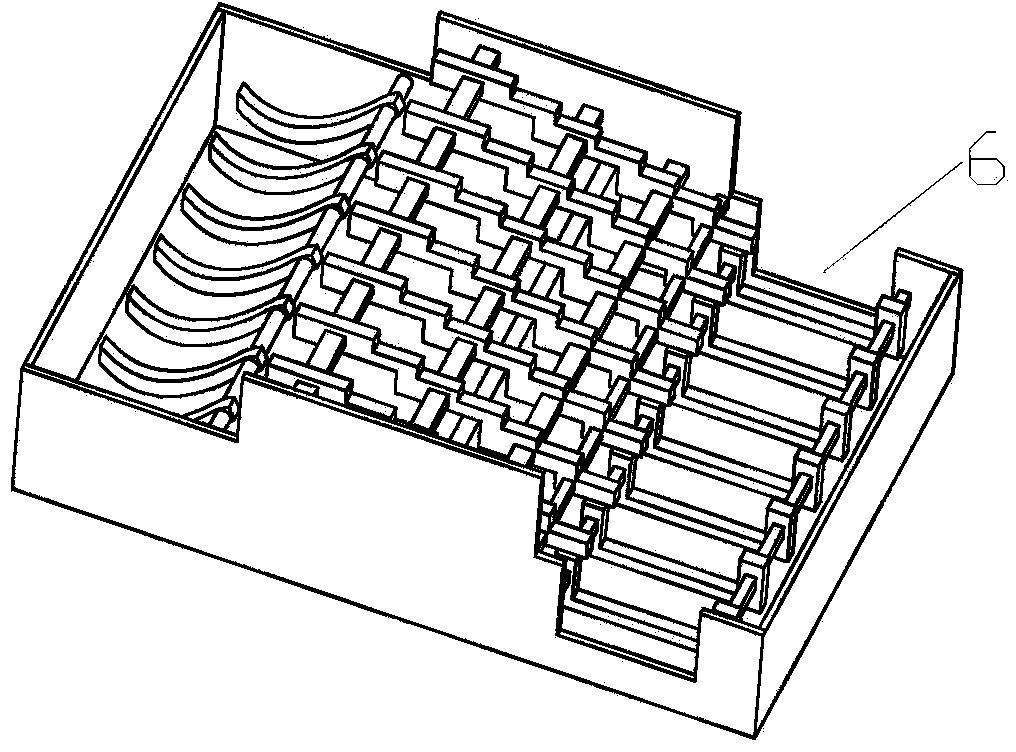

[0018] Example 2, such as image 3 As shown, the difference between it and Embodiment 1 is that the collection frame 5 has a collection frame 51, and the collection tank 12 has a through hole 6 on the tank wall facing the collection frame 51.

Embodiment 3

[0019] Embodiment 3 differs from Embodiment 2 in that: the collection tank 12 is connected with an oil return pipe for returning the oil to the oil storage tank 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com