Atomizing nozzle for bearing cleaning line

A technology for cleaning atomizing nozzles and bearings, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., which can solve the problems of unsatisfactory use effect and inability to adjust the spray flow rate, etc., and achieve simple structure, convenient adjustment, and easy oiling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments.

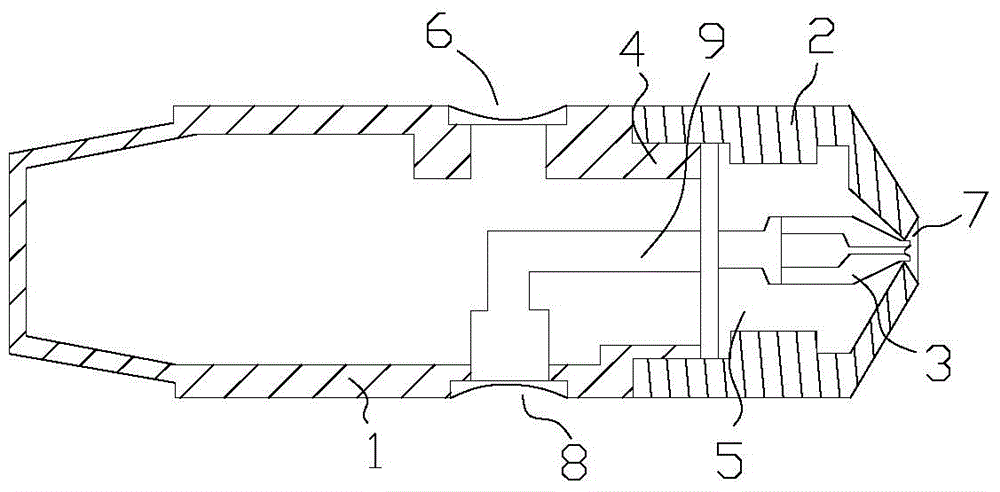

[0012] refer to figure 1 , The atomizing nozzle of the present invention is mainly composed of a nozzle core 1, a nozzle cover 2 and an air nozzle 3. The front end of the nozzle core 1 is provided with a threaded seat 4, and one end of the nozzle cover 2 is configured as a threaded sleeve with internal threads that matches the threaded seat 4. The nozzle cover 2 is screwed on the threaded seat 4 through the threaded sleeve, so that the nozzle can be Core 1 rotates. When the nozzle cover 2 rotates outward relative to the nozzle core 1, the distance between the nozzle cover 2 and the nozzle core 1 becomes larger; when the nozzle cover 2 rotates toward the nozzle core 1 side, the distance between the nozzle cover 2 and the nozzle core 1 shorten.

[0013] The nozzle cover 2 is provided with a liquid mixing chamber 5, specifically, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com