Chain production process

A production process and chain technology, which is applied in metal material coating process, manufacturing tools, lighting and heating equipment, etc. The effect of improving oiling efficiency, improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

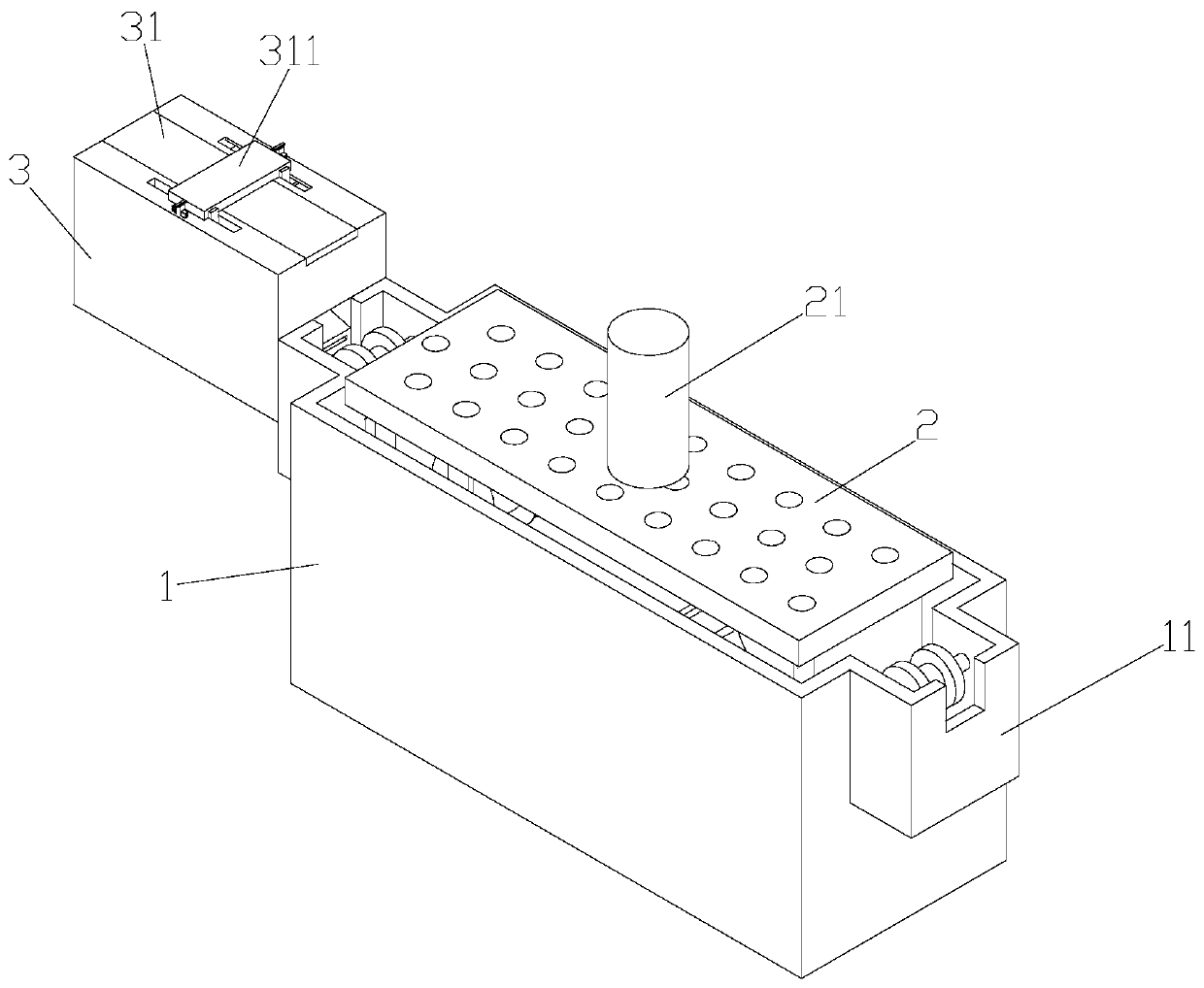

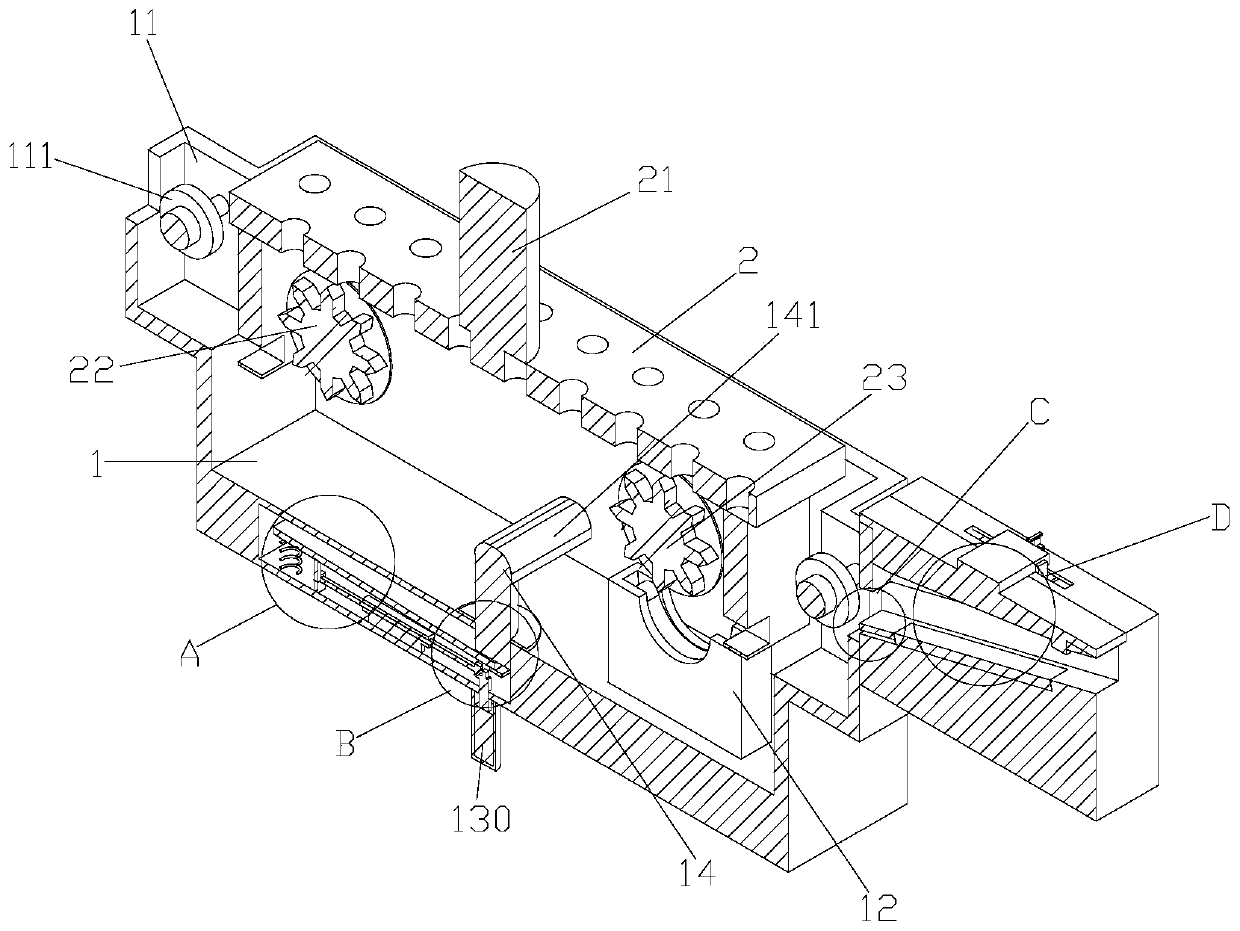

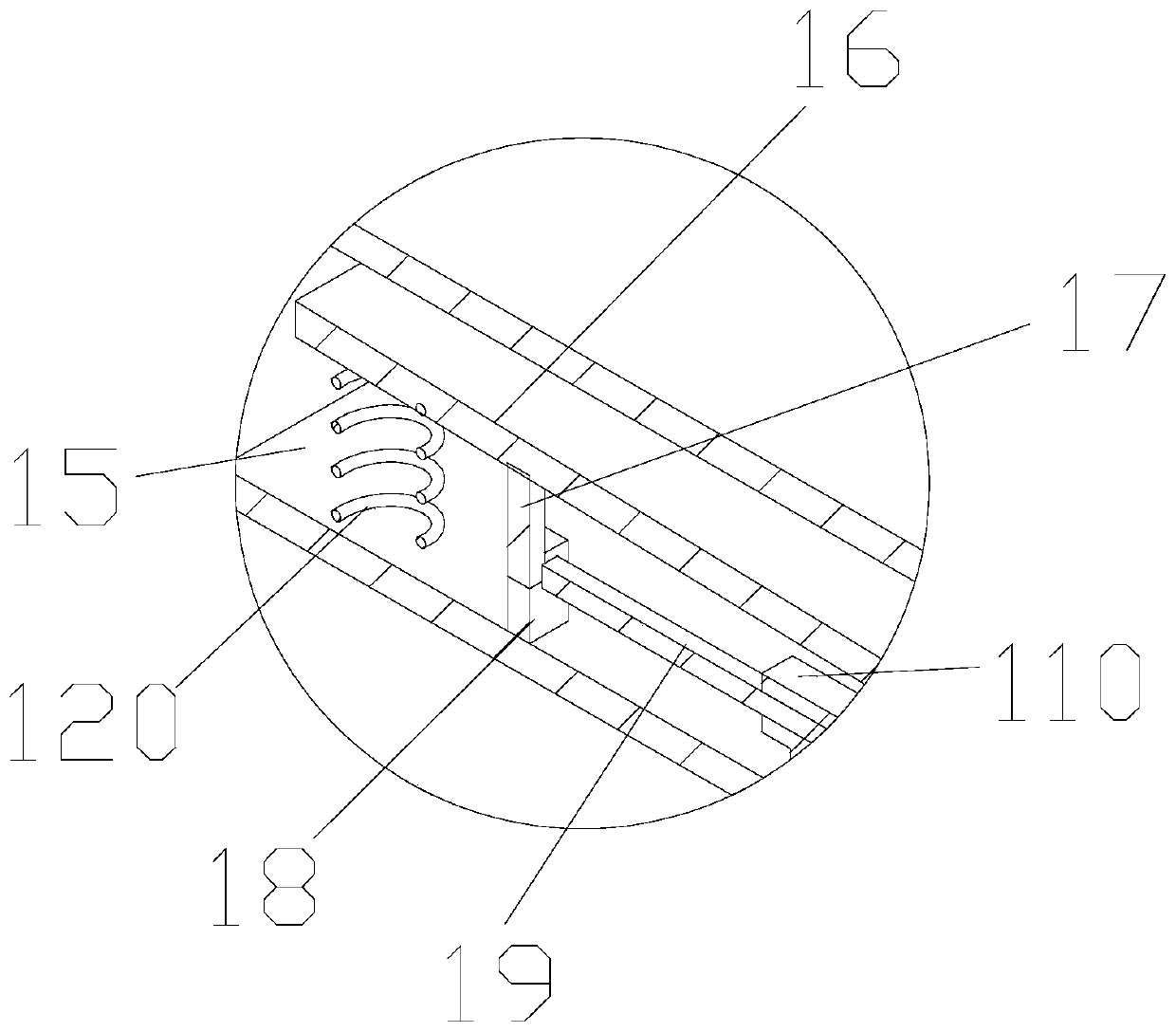

Embodiment 1

[0041] A chain production process, including: a. Heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. Carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after heat...

Embodiment 2

[0057] A chain production process, including: a. Heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. Carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after heat...

Embodiment 3

[0059] A chain production process, including: a. Heat treatment: in heat treatment equipment, various auxiliary media are used at high temperature to improve the structure of parts and improve the performance of various items; b. Carburizing: place parts in heat treatment equipment Heating and keeping warm, and then passing through carbon-containing medium to infiltrate carbon into the surface of the parts to improve the hardness and wear resistance of the chain; c. Quenching: the parts are heated in the heat treatment equipment and kept warm, and then cooled in different media according to requirements, so that Improve the hardness of the parts; d. Tempering: the quenched parts are heated at a specific temperature in the heat treatment equipment, and then cooled after being kept warm; e. Blackening: the principle of polymer organic polymerization is adopted, and the residual heat of tempering during the heat treatment process is used Blackening of the film; f, blue: after heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com