Patents

Literature

84 results about "Surface fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

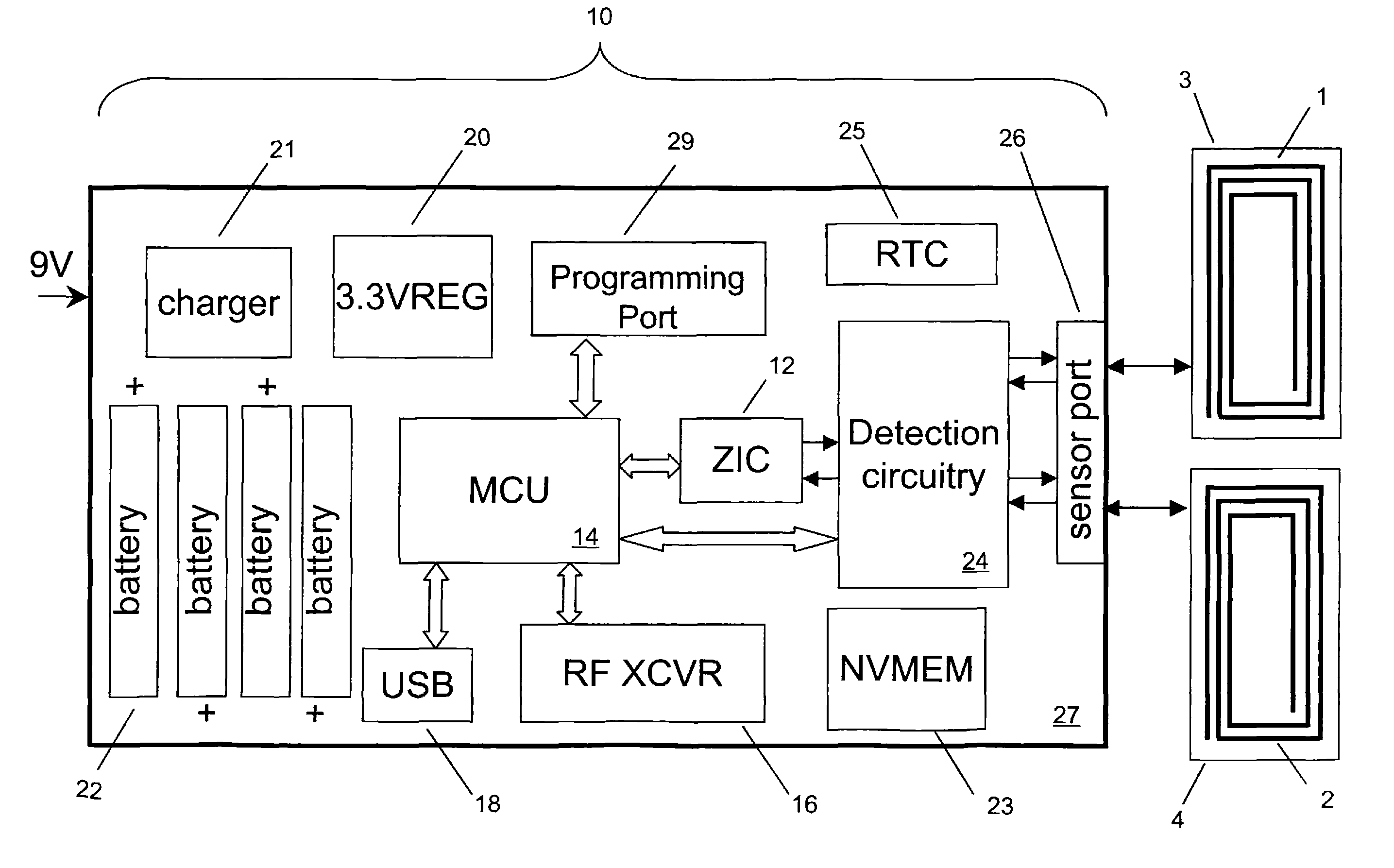

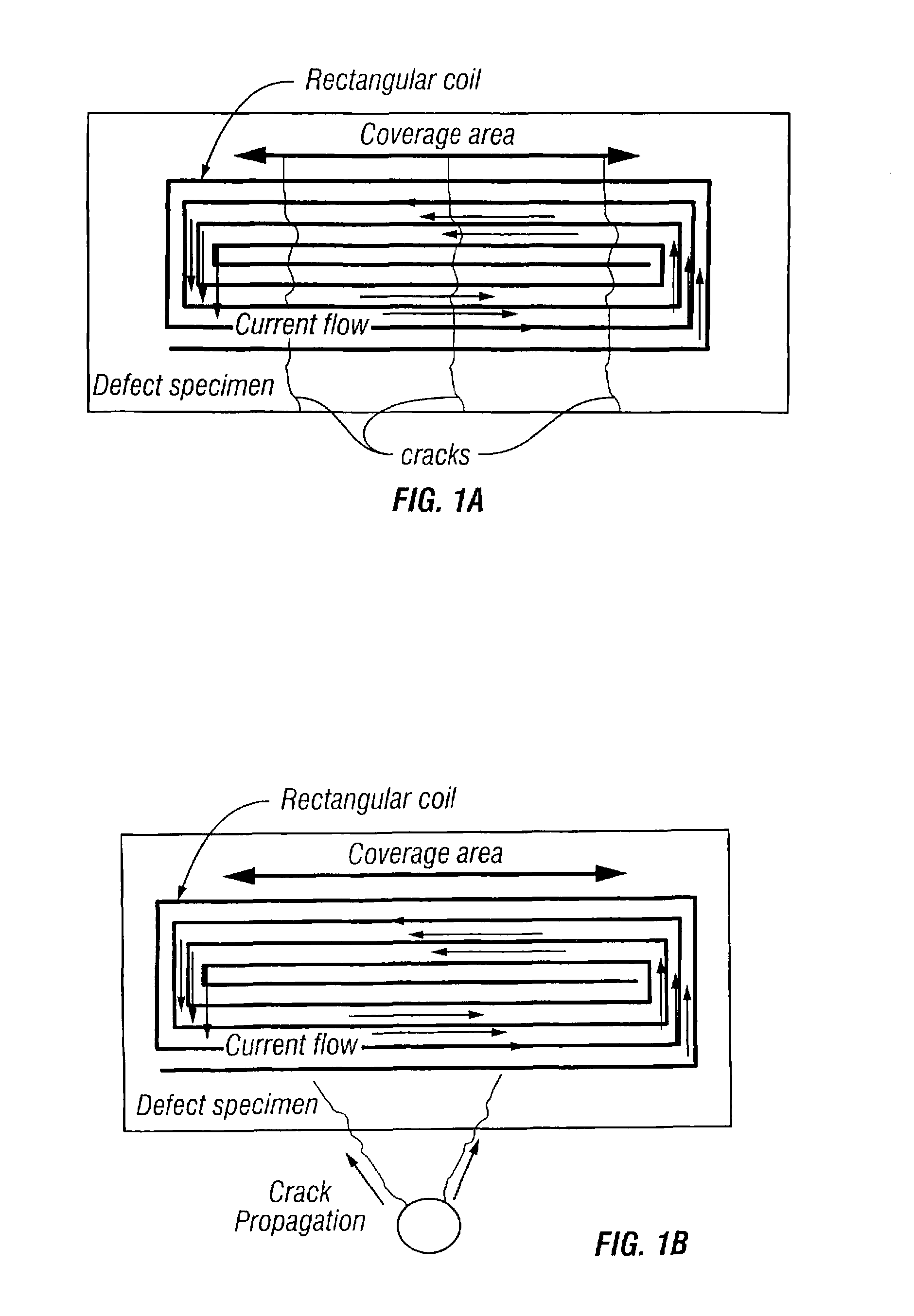

Mountable eddy current sensor for in-situ remote detection of surface and sub-surface fatigue cracks

A wireless, integrated, mountable, portable, battery-operated, non-contact eddy current sensor that provides similar accuracy to 1970's laboratory scale equipment (e.g., a Hewlett-Packard GP4194A Impedance Analyzer) at a fraction of the size and cost.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

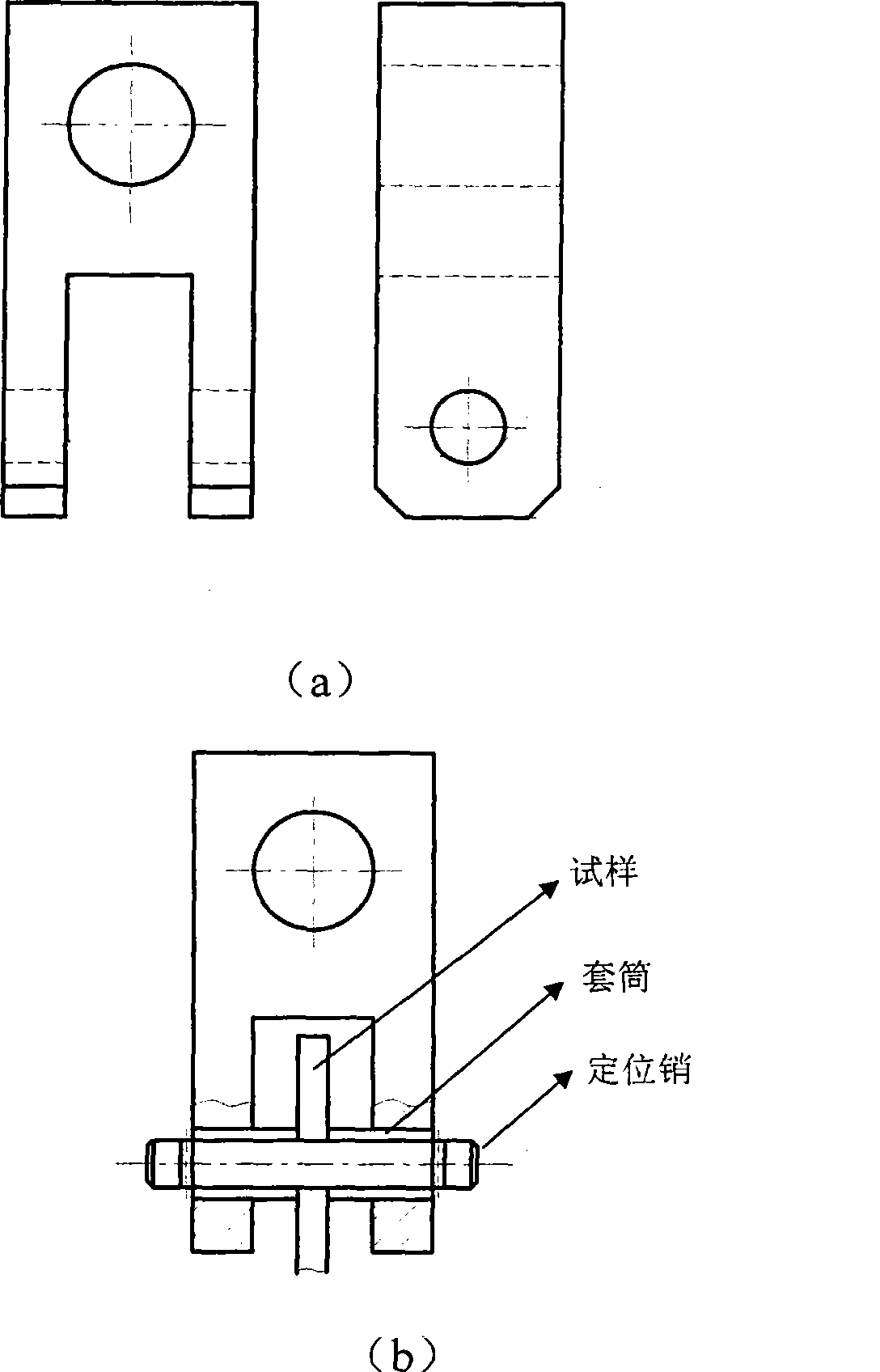

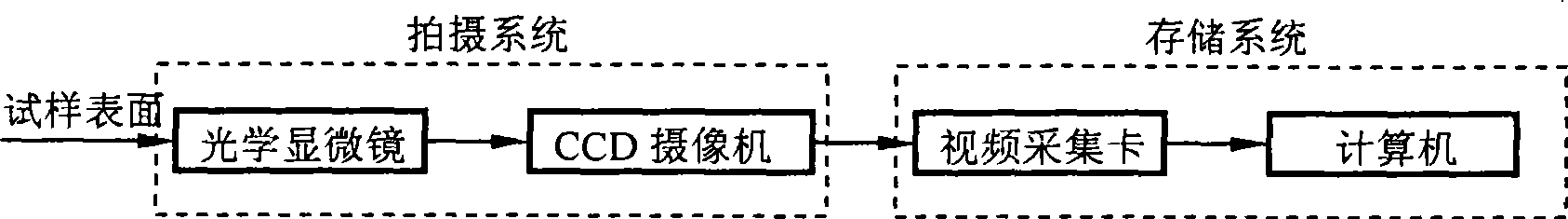

Surface fatigue crack detecting method based on CCD image characteristic

InactiveCN101413901AImprove reliabilityLow costOptically investigating flaws/contaminationSurface fatigueImaging processing

The invention discloses a method used for detecting surface fatigue crack with CCD image characteristic, aiming at the defects that the existing fatigue crack detection method has low precision, needs the contact with the samples, needs expensive equipment and is troublesome to execute, and the like. The method utilizes the MATLAB image processing technology to research the characteristic parameters (length and width) used for characterizing the surface fatigue crack extension, compares two characterization methods, and validates the precision of the method used for detecting the surface fatigue crack images. The method has the advantages of high precision, non-contact type, simple equipment, easy execution, and the like, can realize the intellectualized malfunction diagnosis, and provides guiding suggestions for practical production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Laser nanometer cermet alloying process for surface of metallurgic hot roller

InactiveCN1932079AImprove thermal stabilityHigh strengthRollsMetallic material coating processesCeramic coatingCo2 laser

The laser nanometer cermet alloying process for surface of metallurgical hot roller includes the following steps: 1. machining the roller to eliminate surface fatigue layer to obtain required size and shape, grinding the surface to be laser treated, eliminate dirt and cleaning properly; 2. mixing phenolic resin adhesive and nanometer carbide ceramic paint homogeneously and coating the mixture to the surface of the roller in the thickness of 0.01-0.05 mm before air drying; and 3. scanning the nanometer ceramic coating on the surface of the roller fast with high power CO2 laser in the technological parameters of laser power 1,000-10,000 W, scanning speed of 1.5-20 m / min, lapping rate of 15-35 % and light spot diameter of 0.6-5 mm. The present invention has optimized technological parameters, and can result in solid solution reinforcing and dispersion reinforcing effect, raise the heat stability of the alloy layer, and raise the strength, plasticity and toughness of the alloy layer.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Technique for restoring precision of stepped cushion of rolling mill by adopting laser cladding technology

ActiveCN109468634ASimple and fast operationReduce labor intensityMetallic material coating processesSurface fatigueOptoelectronics

The invention belongs to the field of laser repairing and particularly relates to a technique for restoring the precision of a stepped cushion of a rolling mill by adopting a laser cladding technology. The technique is specifically implemented by the following steps of: surface derusting, detection before repair, processing for removing surface fatigue layers, detection after processing, determination of a laser cladding process (including technological parameters and alloy powder constituents), detection after laser cladding, rough and fine machining, and detection after repair; the techniqueis simple and convenient to operate, greatly alleviates the labor intensity, has the characteristics of restoring the dimensional precision of the original design and improving the corrosion resistance and the wear resistance of the surface, improves the overall use efficiency, has quite small influences on the surface and prevents relatively large deformation; after being machined by a grindingmachine, the surface is smooth, uniform and high in glossiness; after repairing, a product is tracked and detected; the dimensional precision of the stepped cushion can be restored after laser cladding; the running cost is low; the surface is free of detection flaws and cracks after being machined; the product can meet the requirements of normal use; and the service life of the product is prolonged by at least three times.

Owner:SHENYANG DALU LASER TECH

Boat diesel oil generator tank cover repair process method

InactiveCN101204766AImprove surface propertiesExtended service lifeMetallic material coating processesLaser beam welding apparatusSurface fatigueEngineering

The invention provides a technique for repairing an oil electric engine cylinder sleeve for ship, which is characterized in that the invention comprises the following working procedures: 1 detecting and cleaning the cylinder sleeve: carrying out a jump detection and a dimension detection on the cylinder sleeve on a lathe, confirming a hurt part, carrying out mechanical cleaning on the machine type of the hurt part and carrying out detection of removing a surface fatigue layer; 2 laser cladding repairing on the hurt part: the parameters during an operation process are: a laser power of 6200 to 8000W, a facula diameter of 2 to 6mm and a facula moving speed of 100 to 150mm / s; 3 machinery processing to resume the shape of the cylinder sleeve: carrying out machinery processing to resume the original designed dimension state on a boring lathe and a boring lathe. The technique for repairing an oil electric engine cylinder sleeve for ship provided by the invention has the advantages of high suitability, simple and convenient operation, small temperature distortion, uniform welding structure, realizing automatic operation with little residual stress; the invention requires no restoration heat treatment.

Owner:SHENYANG DALU LASER TECH

Method for repairing roller sleeve of continuous casting roller

InactiveCN102728993AExtended service lifeReduce consumptionWelding/cutting media/materialsSoldering mediaHigh power lasersAlloy

The invention discloses a method for repairing a roller sleeve of a continuous casting roller. The method comprises the following steps of: preliminarily checking the roller sleeve; measuring the size of each part of the roller sleeve, removing a fatigue layer on the surface of the roller sleeve, and performing magnetic particle inspection and ultrasonic flaw detection; preparing Ni45 and WC alloy powder by adopting a mechanical mixing method, preheating the roller sleeve, coating the alloy powder on the surface of the roller sleeve by adopting a coaxial powder feeding method and scanning with a high-power CO2 laser device, thermally treating the whole roller sleeve, and slowly cooling together with a furnace; and performing rough machining and precision machining on the roller sleeve of the continuous casting roller meeting the requirements by using a lathe. Compared with the prior art, the method has the advantages that the service life of the roller sleeve is prolonged; consumption is reduced; the roller sleeve is high in abrasion resistance and heat resistance; and the method is simple, strong in controllability and low in cost, and saves the alloy material.

Owner:YANSHAN UNIV

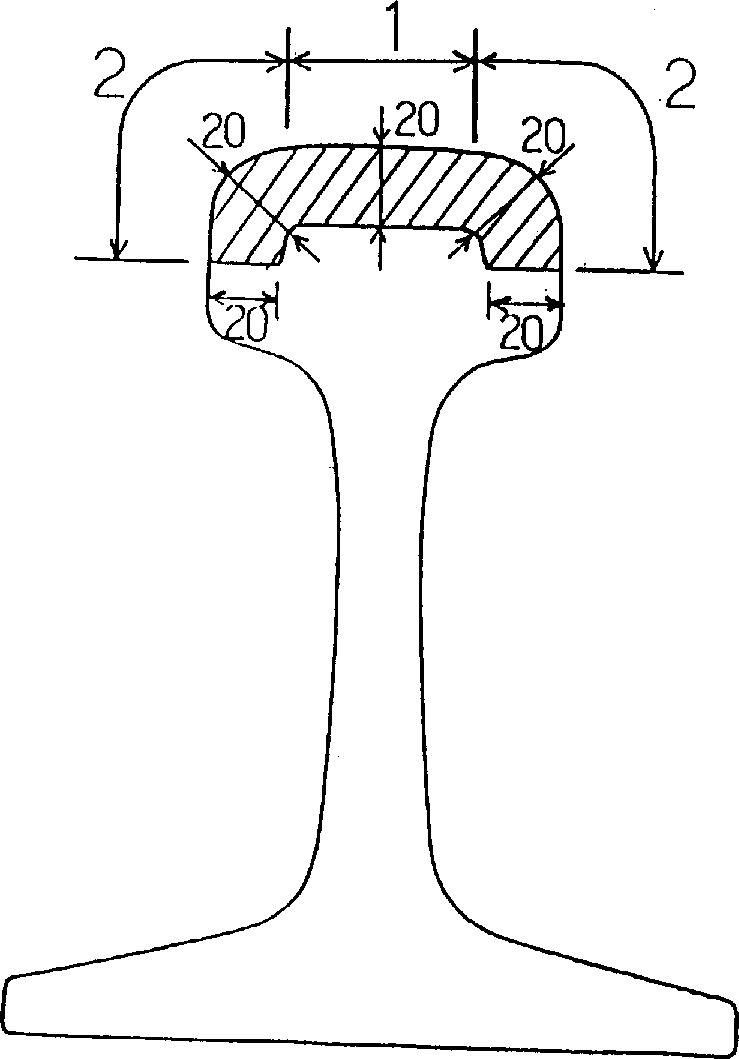

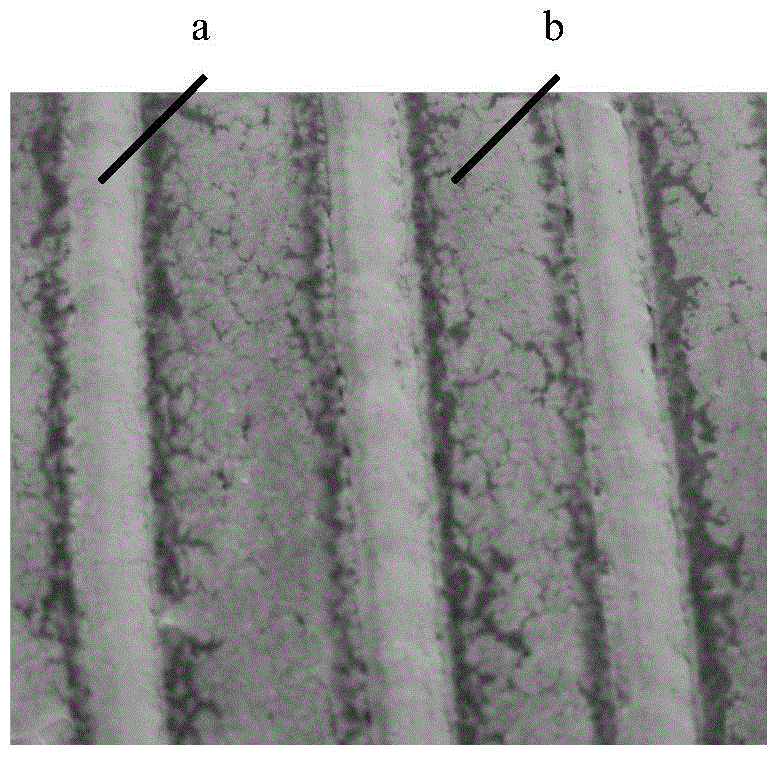

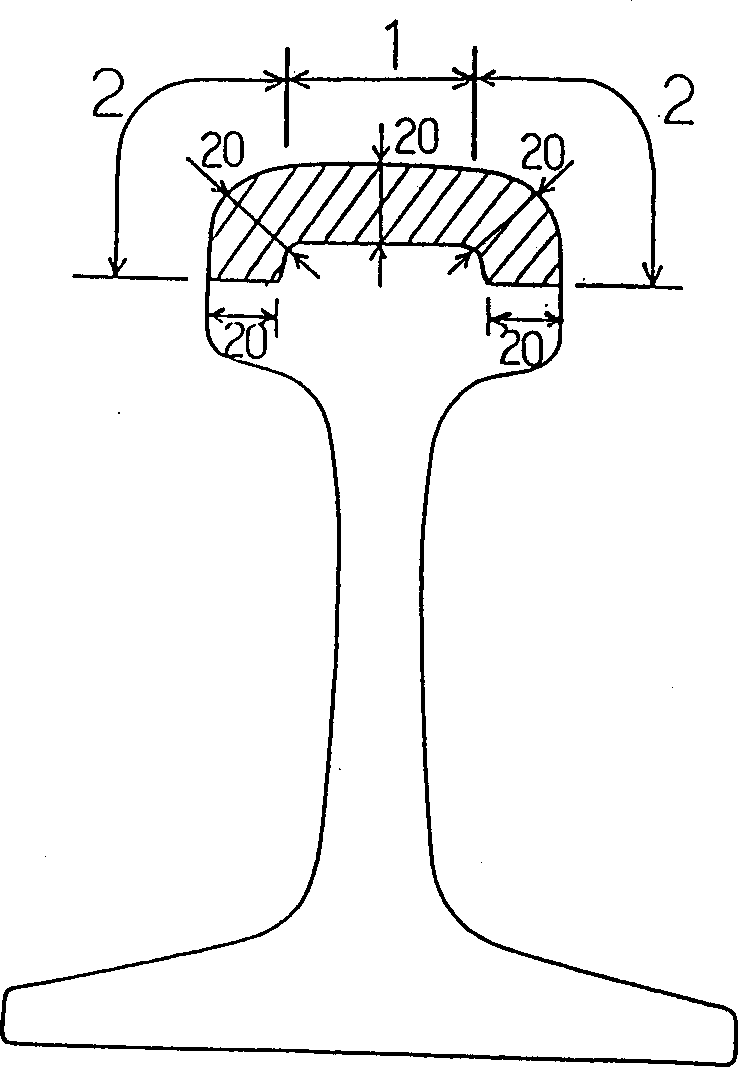

Bainite type rail excellent in surface fatigue damage resistance and wear resistance

High-strength bainitic steel rails have improved resistances to surface fatigue failures and wear required of the head of rails for heavy-load service railroads. The high-strength bainitic steels rails having excellent resistances to surface fatigue failures and wear contain constituents of specific ranges and consisting of bainitic structures at least in part are characterized in that the total area occupied by carbides whose longer axes are 100 to 1000 nm in a given cross section of said bainitic structures accounts for 10 to 50 percent thereof.

Owner:NIPPON STEEL CORP

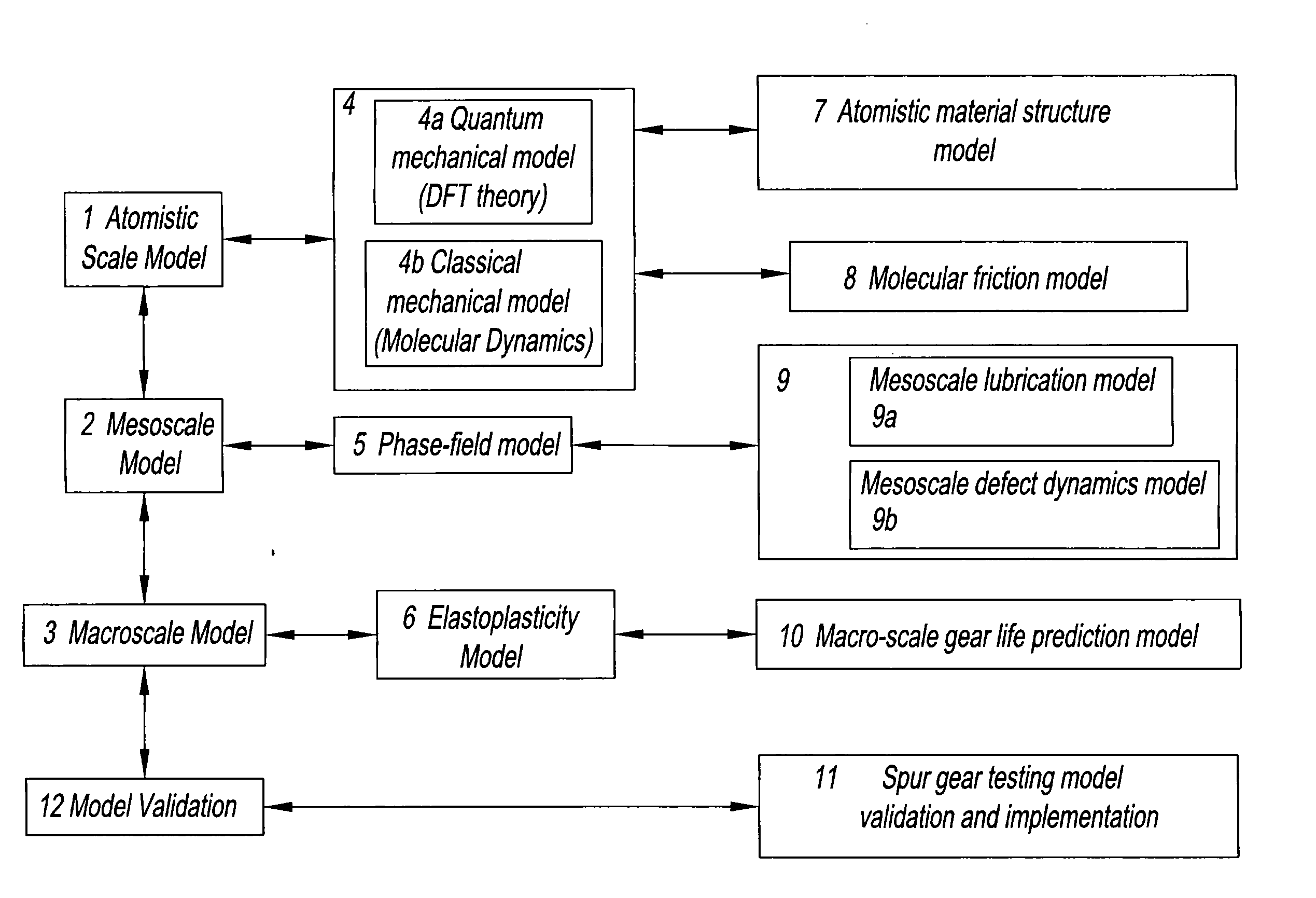

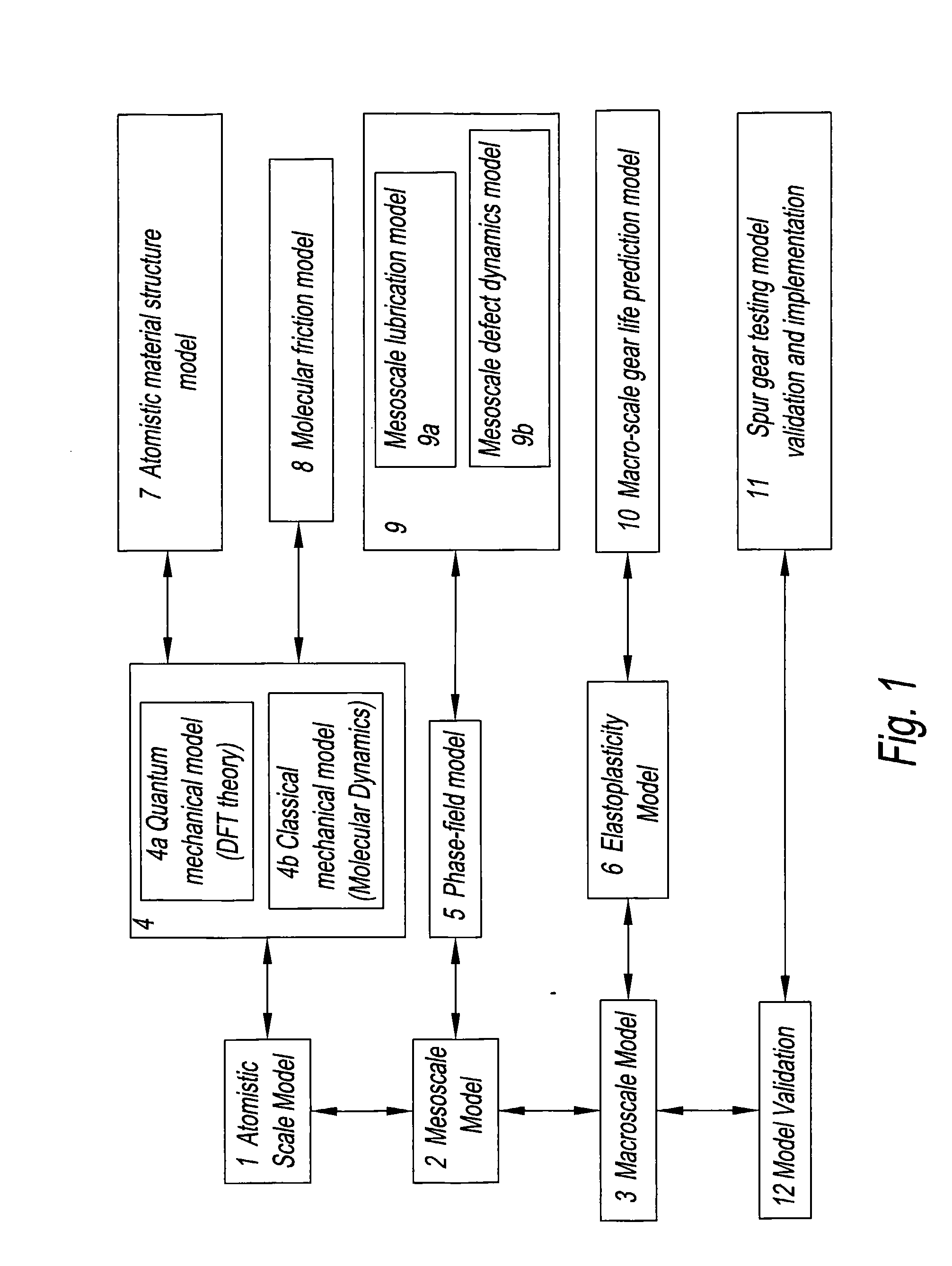

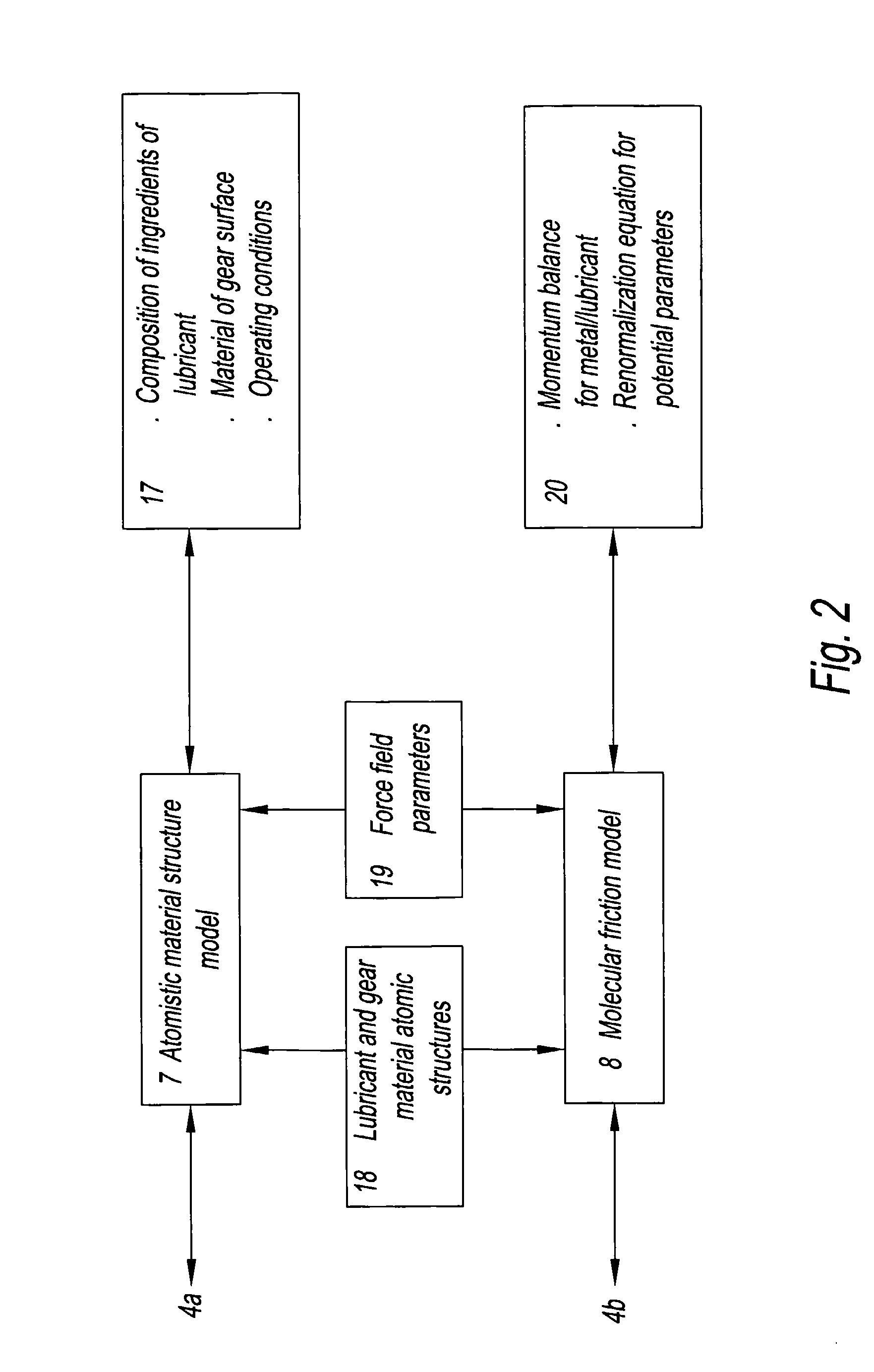

Systems and Methods for Modeling Surface Properties of a Mechanical Component

There is a method for modeling the surface fatigue life of a mechanical component. The method has the following steps: a) modeling the surface fatigue life of the mechanical component on an atomistic scale to form an atomistic model, b) modeling the surface fatigue life of the mechanical component on a mesoscale to form a mesoscale model, c) modeling the surface fatigue life of the mechanical component on a macroscale to form a macroscale model, and d) testing the surface fatigue life of the mechanical component. Feedback from the macroscale model is employed at least once to validate the atomistic model. Feedback from the macroscale model is employed at least once to validate the mesoscale model. Feedback from the testing is employed at least once to validate the macroscale model. There is also an interactive, multiscale model for prediction surface fatigue life or degradation rate for a mechanical component.

Owner:UNITED TECH CORP

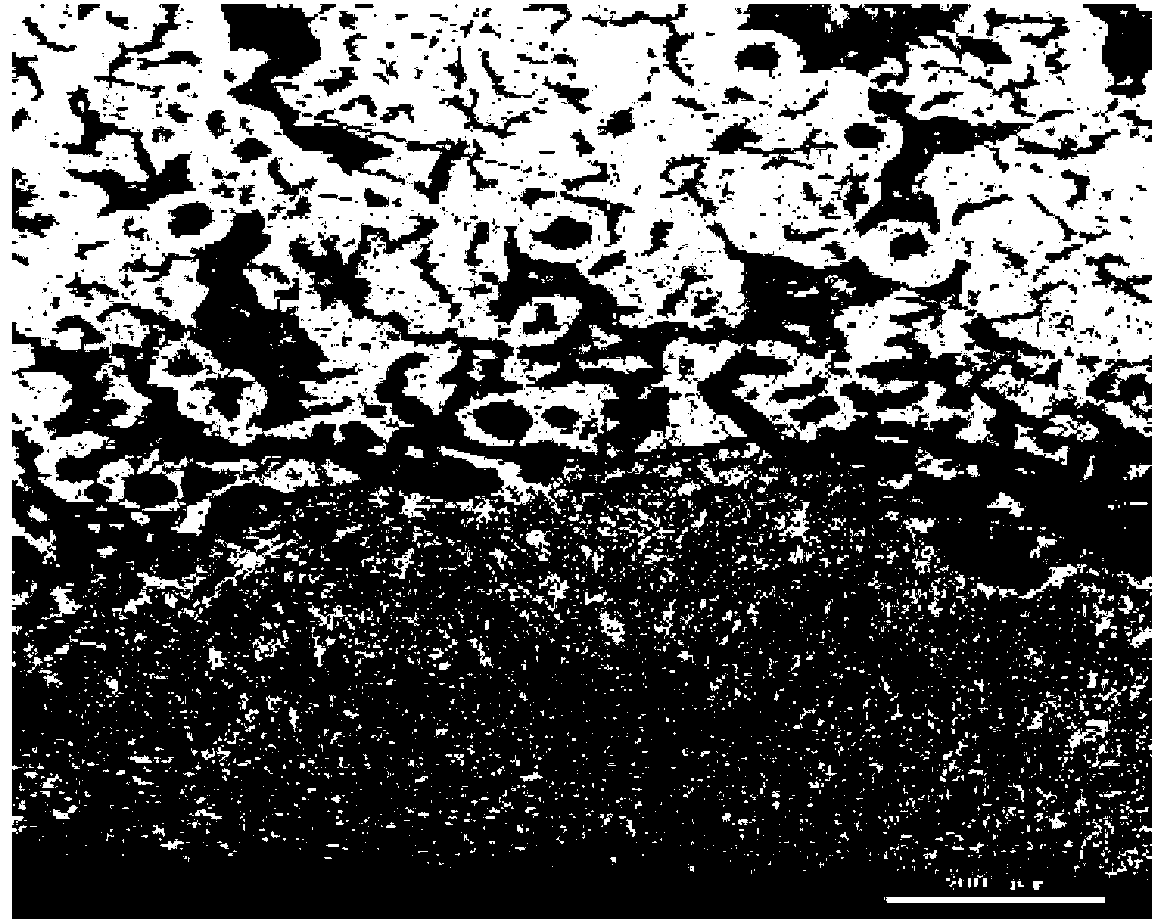

Laser rapid repairing method for high chromium cast steel roller surface layer fatigue micro cracks

InactiveCN104148806AHigh surface finishHigh and uniform hardnessLaser beam welding apparatusShielding gasHigh-temperature corrosion

The invention relates to a laser rapid repairing method for high chromium cast steel roller surface layer fatigue micro cracks. The laser rapid repairing method is used for rapidly conducting laser repairing on high chromium cast steel roller surface layer fatigue micro cracks in order to obtain a corrosion-resistant and high-temperature-corrosion-resistant surface reinforced layer. The laser rapid repairing method is characterized by comprising the steps that (1) surface preprocessing is carried out a high chromium cast steel sample with surface fatigue micro cracks, the high chromium cast steel sample is preheated to 150 DEG C, and the temperature is kept for 1.5 h; (2) the diameter of a laser spot is 3-5.5 mm, the power is 1800-2700 W, the scanning speed is 300-1500 mm / min, the overlap rate is 16.7-50 %, and argon is used as protective gas; (3) two times of tempering at 560 DEG C are carried out after laser processing, and the temperature keeping time is 1 h every time; (4) the initial point and the finishing point in the laser fusing process do not fall on a workpiece. The laser rapid repairing method can fuse high chromium cast steel roller surface layer fatigue micro cracks, a laser fusing layer and a base body are combined in a metallurgy mode, the thickness is 0.4-0.7 mm, the hardness is improved to HV672, the corrosion resistance is improved by three times compared with the base body, and the high temperature abrasion resistance at 560 DEG C and 650 DEG C is obviously improved compared with the base body.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

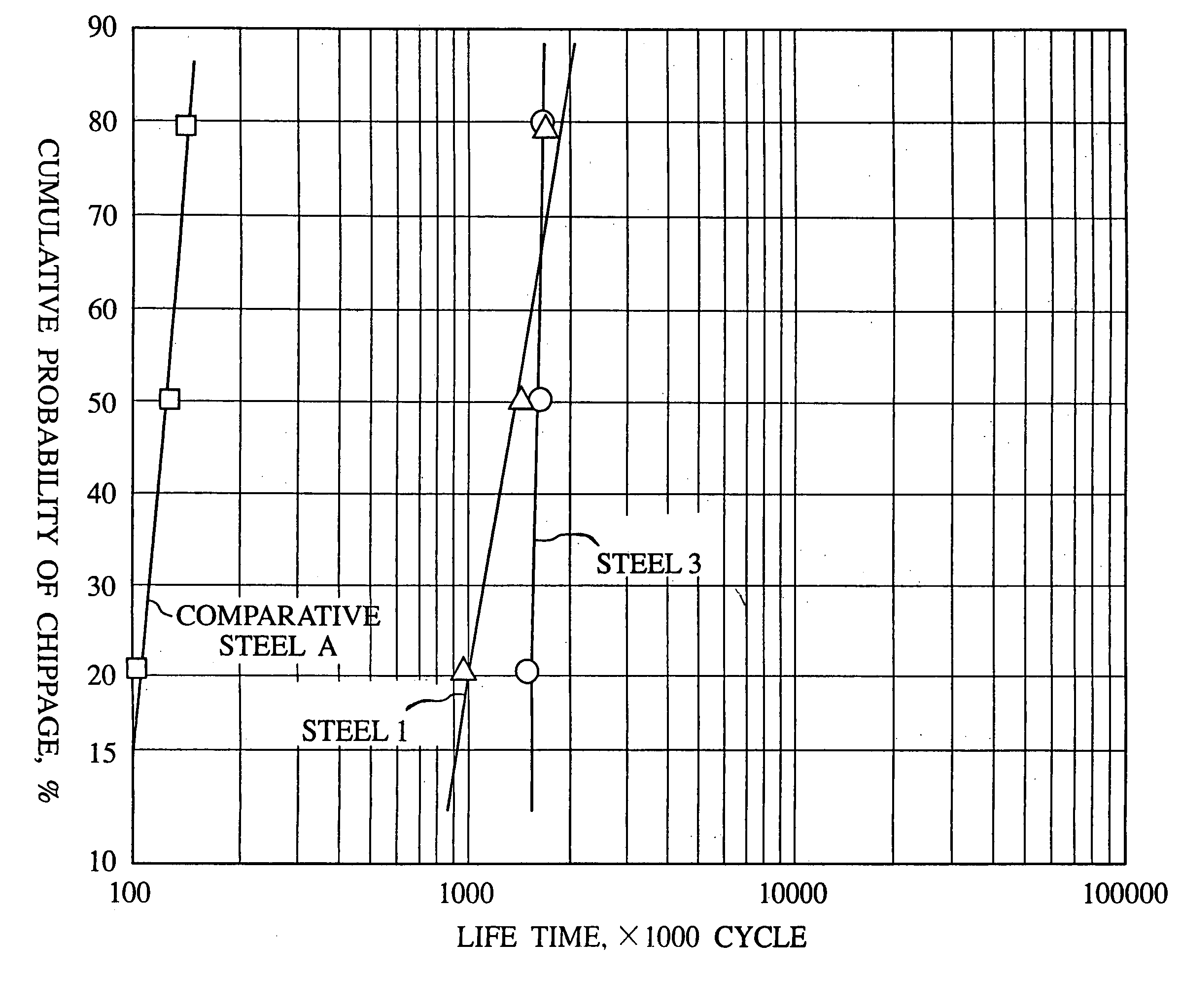

High-strength race and method of producing the same

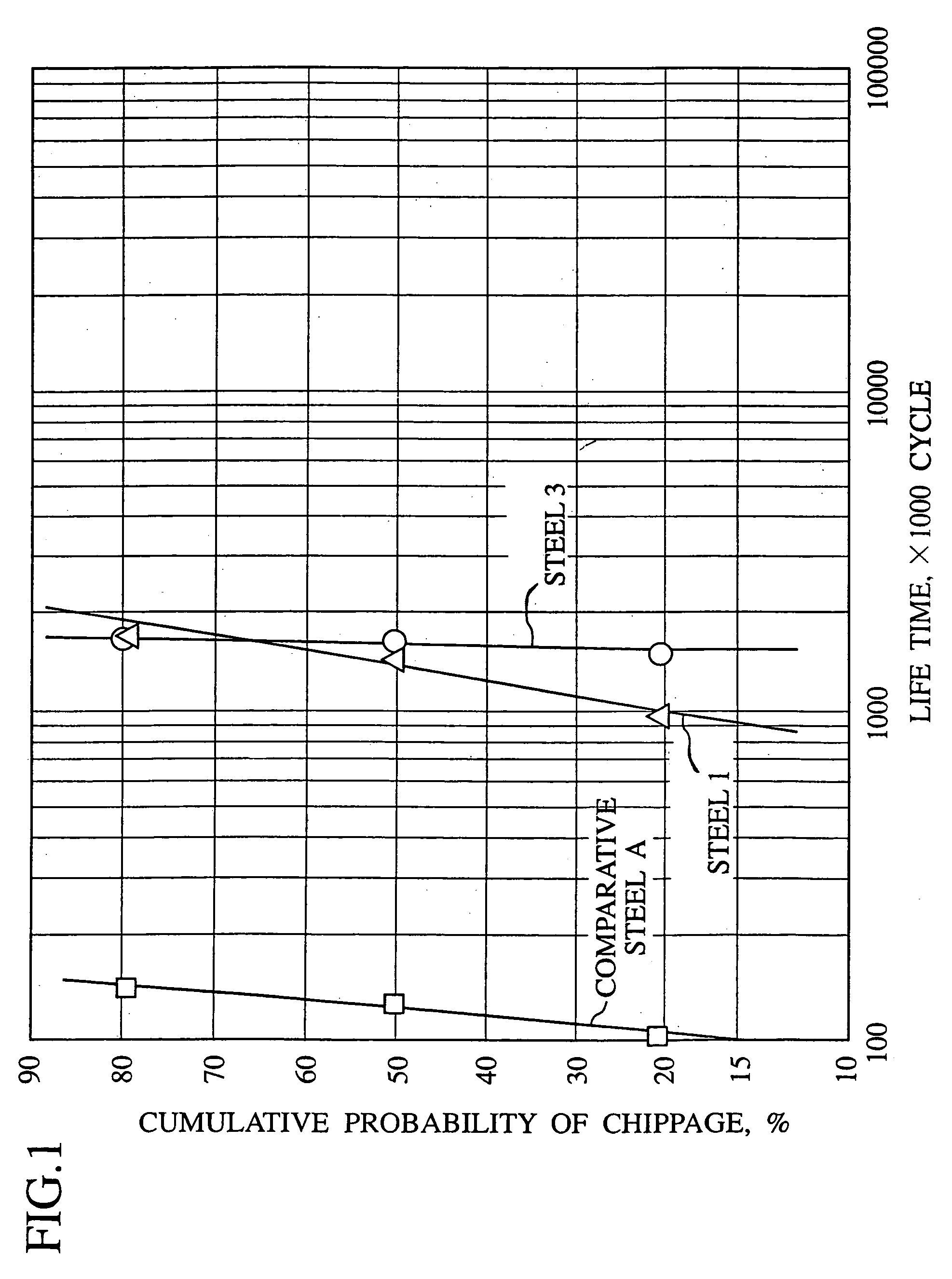

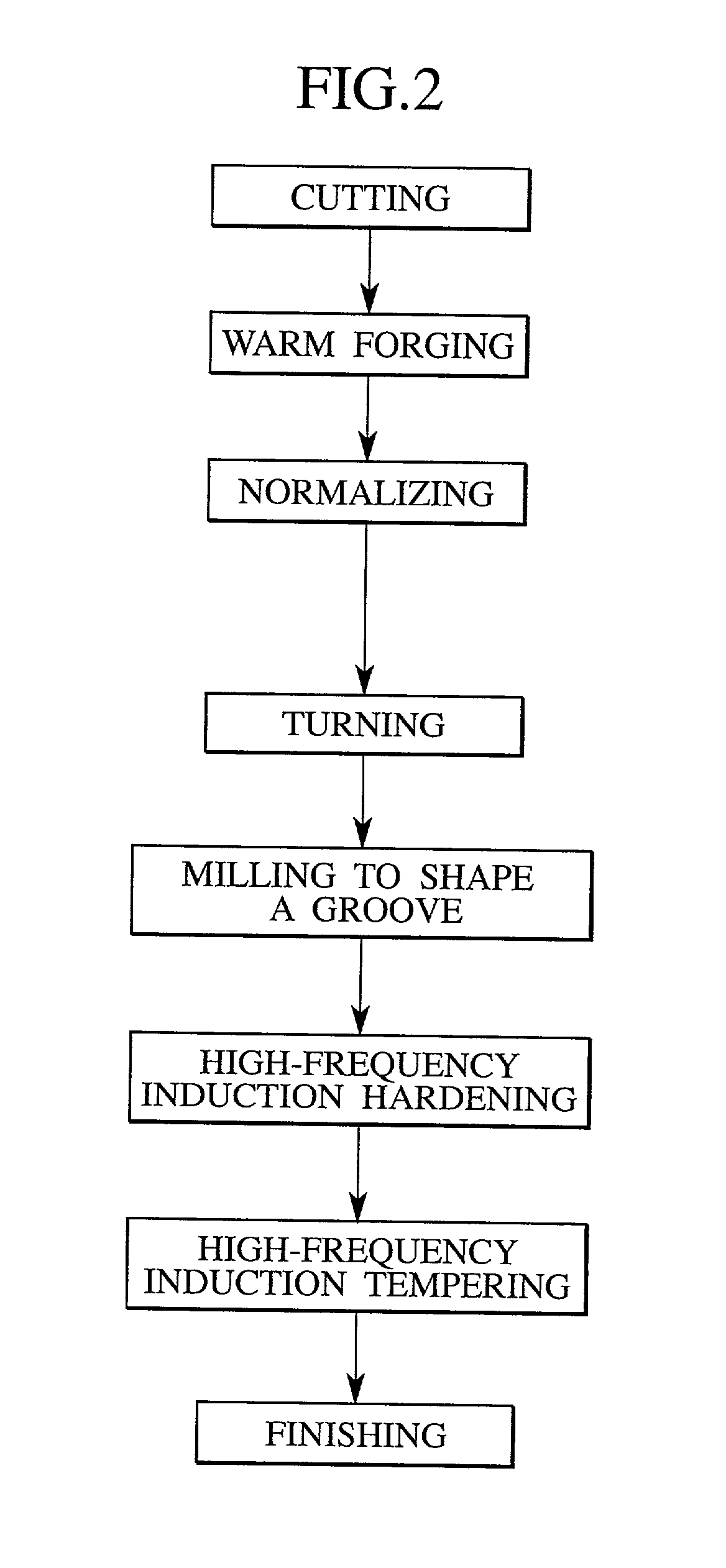

InactiveUS7083688B2High hardnessImprove fatigue performanceBearing componentsFurnace typesSurface fatigueHardness

The high-strength race of the present invention comprises using A steel for a high-strength race comprising the following elements in percentage by weight: C: 0.30 to 0.60%, Si: 0.30 to 1.30%, Mn: 0.5 to 1.5%, B: 0.0050% or less, Cr: 0.1 to 0.5%, Mo: 0.1 to 0.5%, Si+Mo: 0.5 to 1.4%, Ni: 0.02 to 1.0%, the balance of Fe and unavoidable impurities, performing induction hardening to make the race have a surface hardness of 58 HRC or more and further a surface hardness of 52 HRC or more even after the surface is tempered at 300° C. The high-strength race is superior in rotating fatigue properties, anti-surface fatigue strength and productivity by a combination of composition control and induction hardening.

Owner:NISSAN MOTOR CO LTD

Method for restoring inner bore of gear coupling

InactiveCN102747364AExtended service lifeImprove wear resistanceMetallic material coating processesLaser coatingHigh power lasers

A method for restoring the inner bore of a gear coupling is disclosed. Dimensions of all parts of the gear coupling are measured to check whether all the dimensions satisfy laser coating restoration standards, the surface fatigue layer of the inner bore of the gear coupling is removed, Ni55 and nanometer WC powder which are prepared in proportion are fully mixed in a mechanical powder mixer through adopting a mechanical mixing method, the Ni55 and the nanometer WC powder are coated on the surface of the inner bore of the gear coupling through adopting a coaxial powder sending method and through scanning by adopting a large-power CO2 laser, and the gear coupling undergoes heat treatment and then is slowly cooled with a furnace; and the inner bore of the cooled gear coupling is machined to obtain the gear coupling with the dimensions and the surface process which satisfy requirements, the gear coupling undergoes processing precision detection, and finally the gear coupling is packaged. Compared with the prior art, the method disclosed in the invention has the advantages of continuous use, better performances and long service life of the gear coupling, simple technology, strong controllability, less energy consumption and the like.

Owner:YANSHAN UNIV

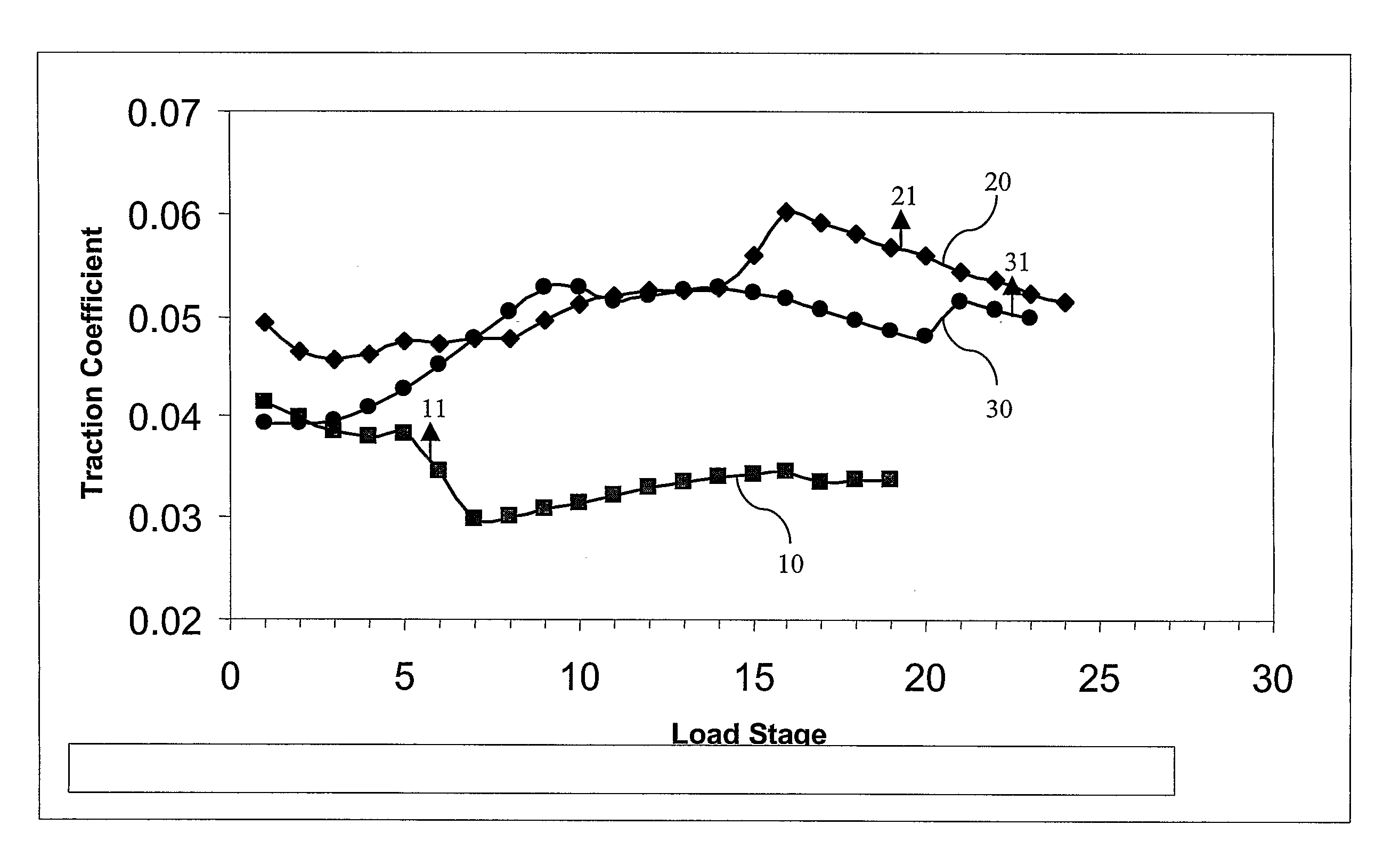

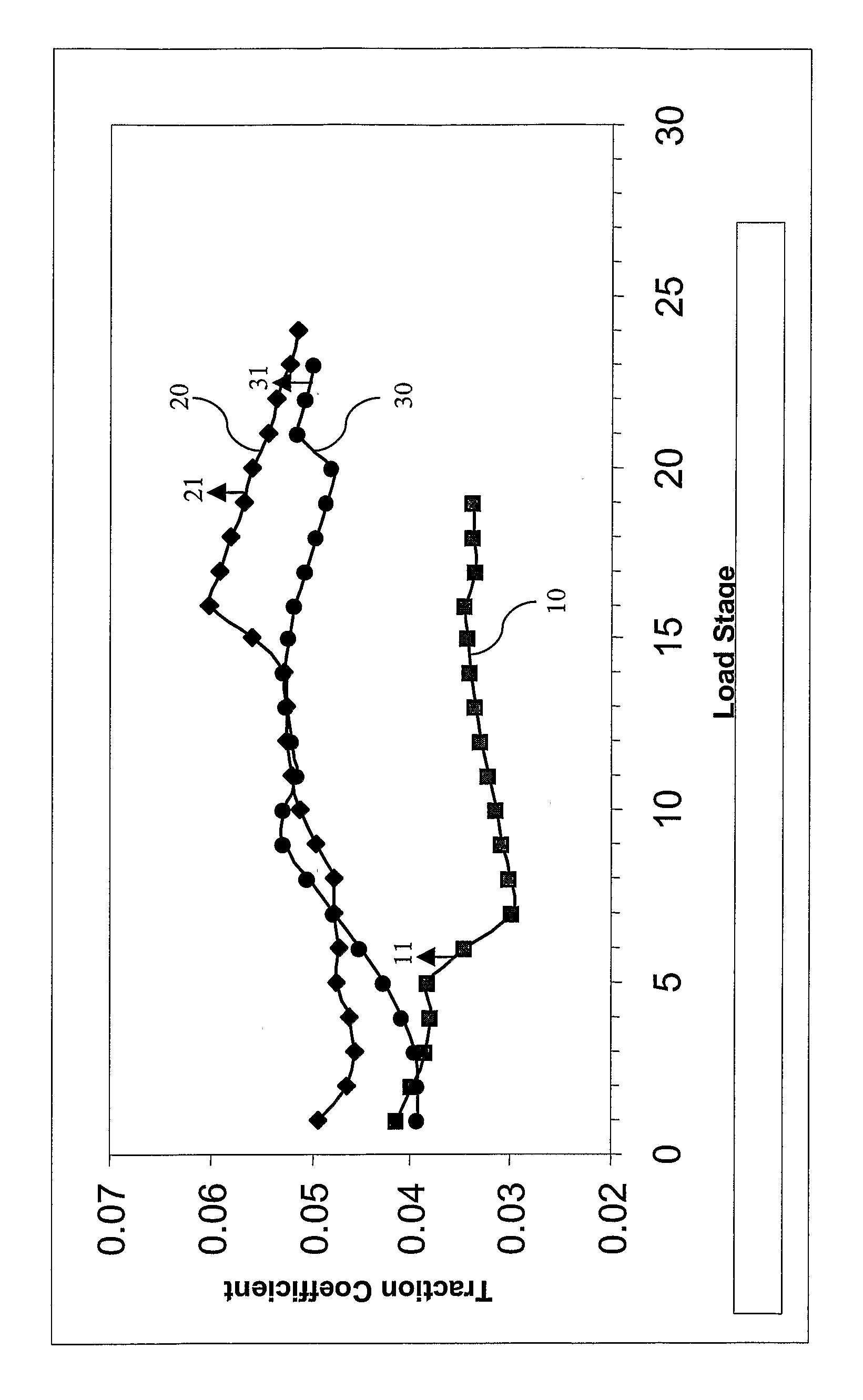

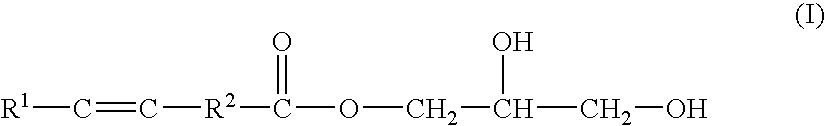

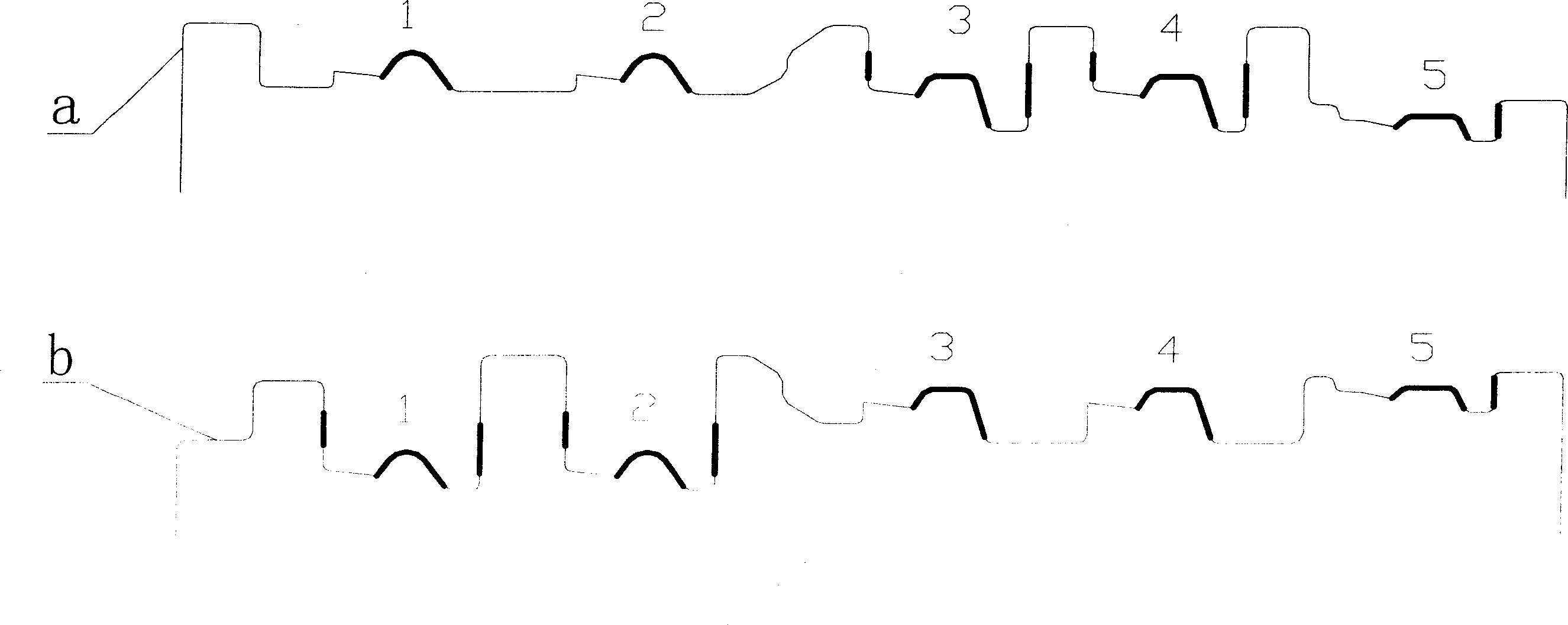

Lubricants Containing Multifunctional Additive Packages Therein for Improving Load-Carrying Capacity, Increasing Surface Fatigue Life and Reducing Friction

InactiveUS20090011964A1Improved performance characteristicsImprove performanceAdditivesSurface fatigueLife time

Owner:UNITED TECH CORP

Laser surface intensified technique for roller of rolling section bar

InactiveCN101003847AEasy to masterSimple and fast operationRollsMetal rolling arrangementsLaser processingSurface fatigue

This invention discloses a process for laser surface enhancement of roller for rolling profiles. The process comprises: processing the roller by turning to remove the surface fatigue layer, inspecting damage, pretreating the surface, loading into a laser processing machine tool, uniformly spraying light-absorption material onto the roller body by a spray gun to completely coate the sites to be processed, drying the light-absorption material, and performing enhancement treatment by selecting laser intensity indexes. The enhancing layer of the treated roller has a thickness of 0.8-1.5 mm, and hardness in HRC 47-53 range. The enhancing layer does not produce any crack. The treated roller does not deform, and the surface roughness can satisfy machining requirements. The treated roller has good toughness and good anti-fatigue ability.

Owner:攀枝花钢城集团有限公司协力分公司

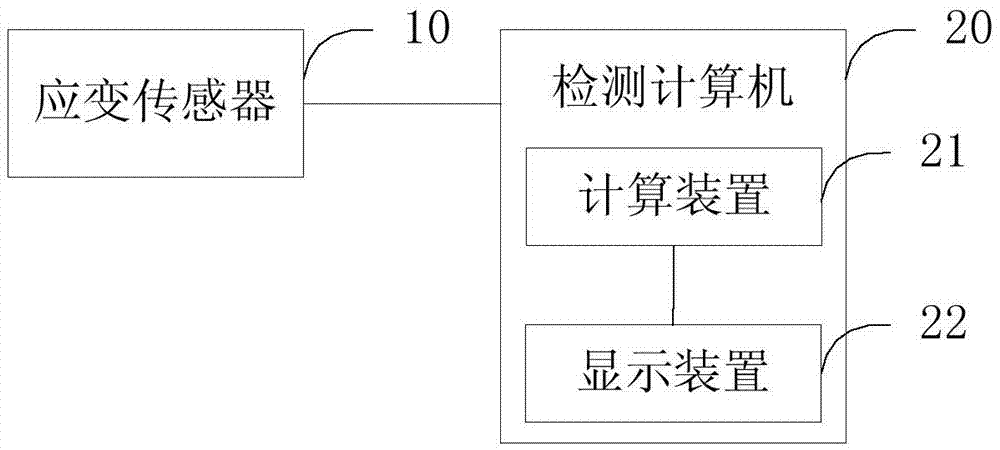

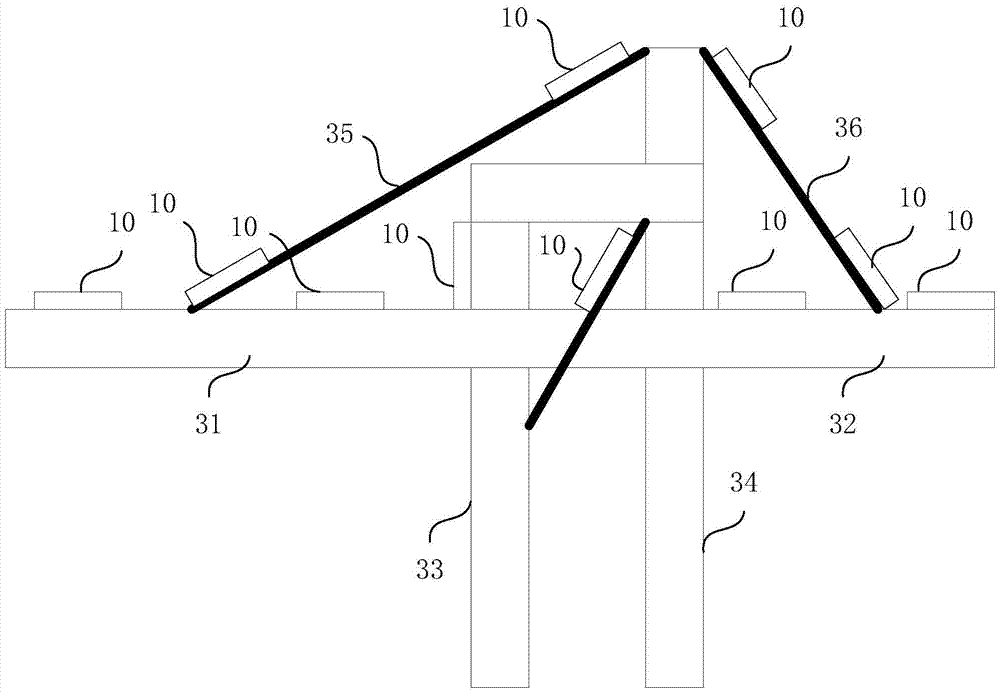

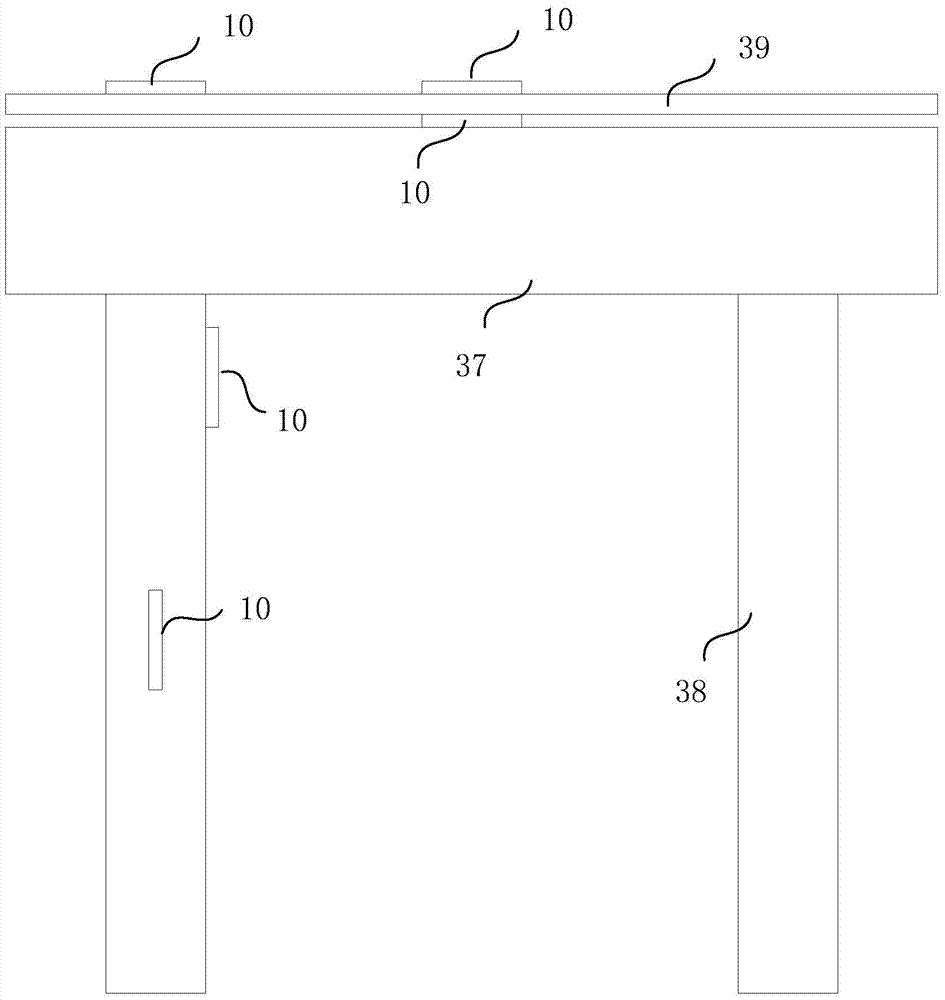

Metal structure fatigue detecting system and method for off-shored crane

InactiveCN105438985AGuaranteed detection effectGuaranteed failure warningSafety gearSurface fatigueDisplay device

The invention discloses a metal surface fatigue detecting system and a metal surface fatigue detecting method for an off-shored crane. The detecting system comprises a plurality of strain sensors and a detecting computer, wherein the plurality of strain sensors are arranged at a plurality of preset positions of the off-shored crane to detect stress data of each preset position of the off-shored crane under different working conditions; the detecting computer comprises a computing device and a display device; the display device is connected to the plurality of the strain sensors to receive the stress data for generating a variation image of the stress data and judging fatigue degree according to a preset model; and the display device is connected to the computing device for displaying the variation image and the judged results of the fatigue degree. According to the scheme, the off-shored crane realizes real-time detection display of the stress data, and guarantees fatigue degree detection and fault early warning in an operation process of the off-shored crane.

Owner:GUANGZHOU SPECIAL MECHANICAL & ELECTRICAL EQUIP INSPECTION & RES INST

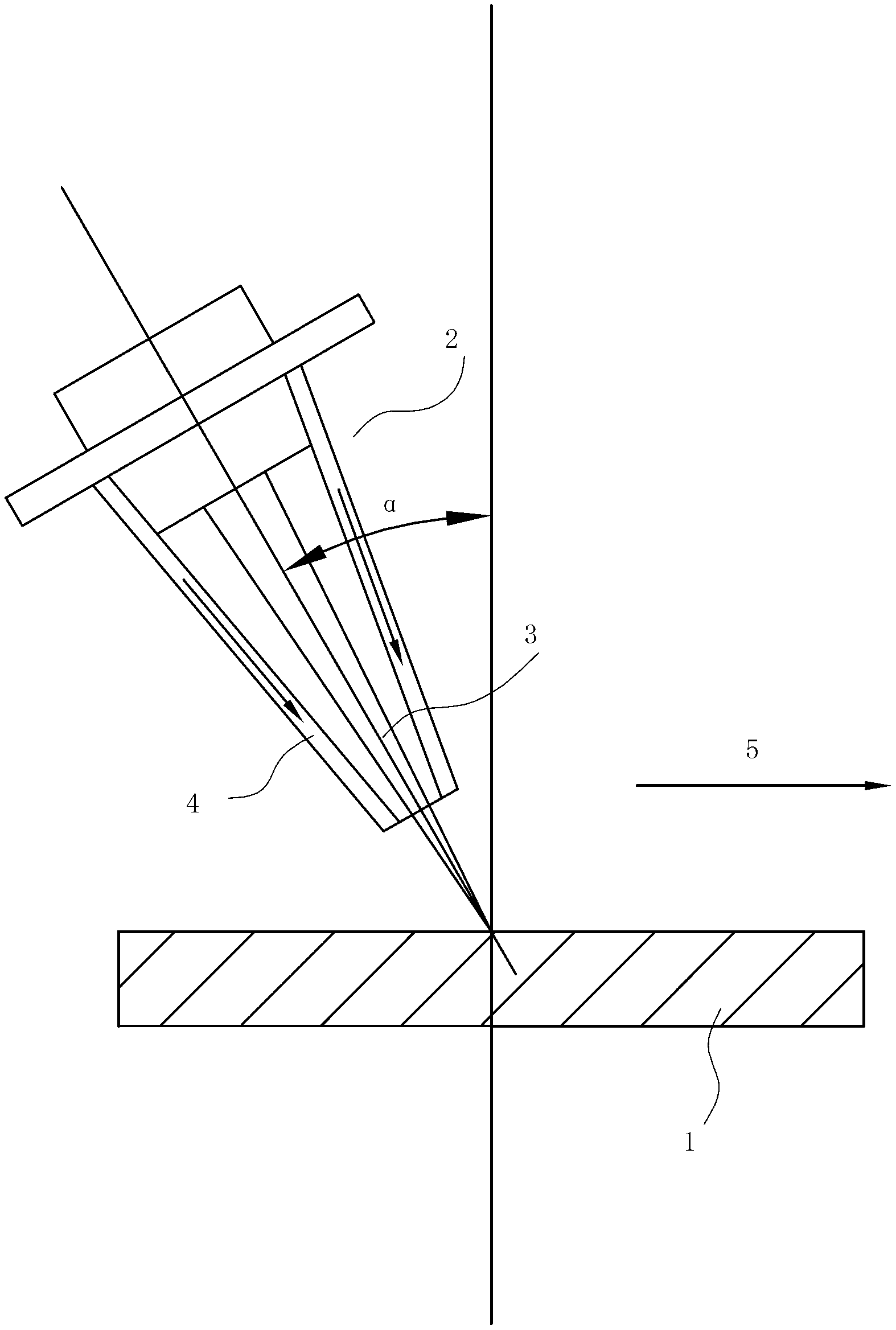

Laser melting quenching process capable of greatly increasing RuT300 surface hardness

The invention relates to a laser melting quenching process capable of greatly increasing the RuT300 surface hardness. The laser melting quenching process is characterized by comprising the following steps of carrying out flattening treatment and surface pretreatment on the surface of a to-be-treated RuT300 workpiece, setting the included angle of the transmitting direction of a laser beam and the normal of the treated surface of the workpiece at 0-45 DEG, carrying out laser melting quenching and carrying out liquid penetrant test immediately after the workpiece is cooled to the room temperature after the laser melting quenching. Compared with the prior art, the process disclosed by the invention has advantages that the operation is simple, the efficiency is high and the corresponding surface blackening treatment is not needed, so that the processing efficiency is increased; the workpiece deformation is little, so that the application of high-precision parts or dies can be satisfied; and the repeatability is good, the crater crack problem is well solved and a laser quenching zone with no crack or air hole on the surface is obtained, so that the surface fatigue resistance of the parts can be greatly increased and the service life of the parts is prolonged.

Owner:北方材料科学与工程研究院有限公司 +1

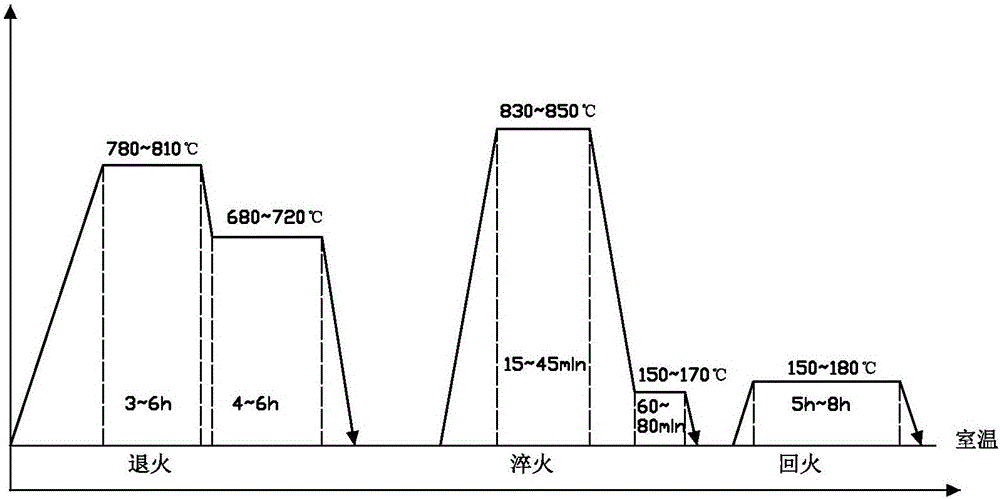

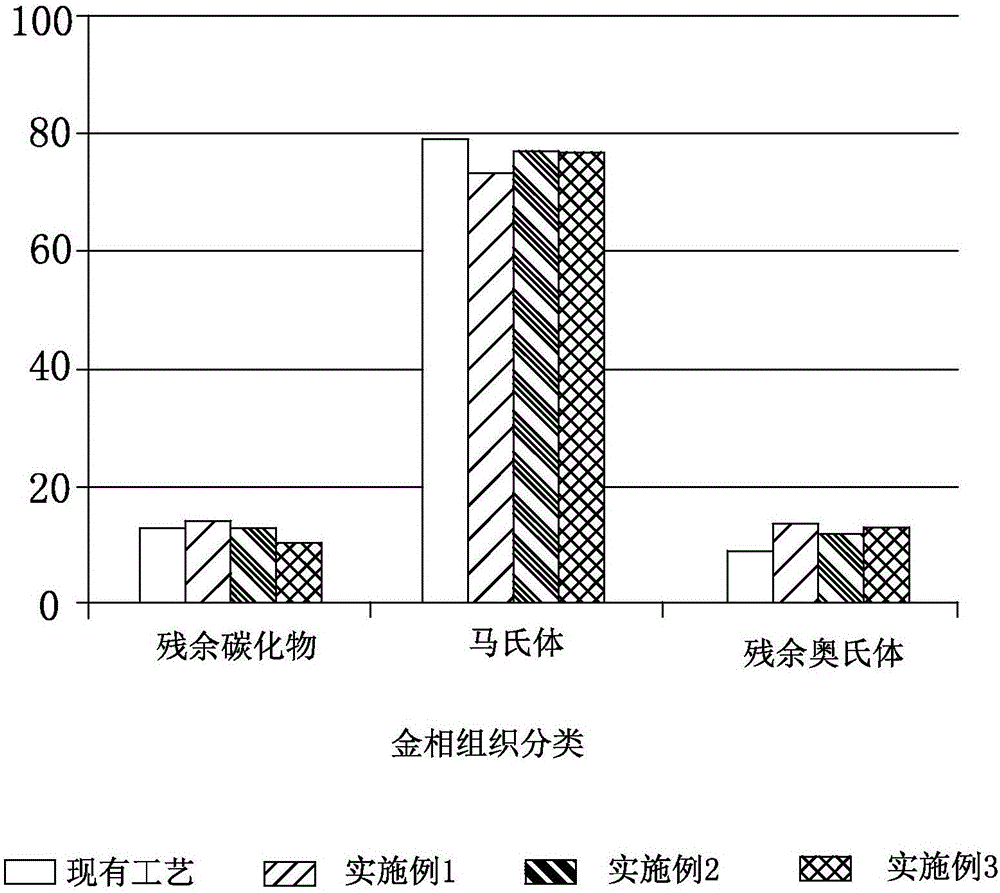

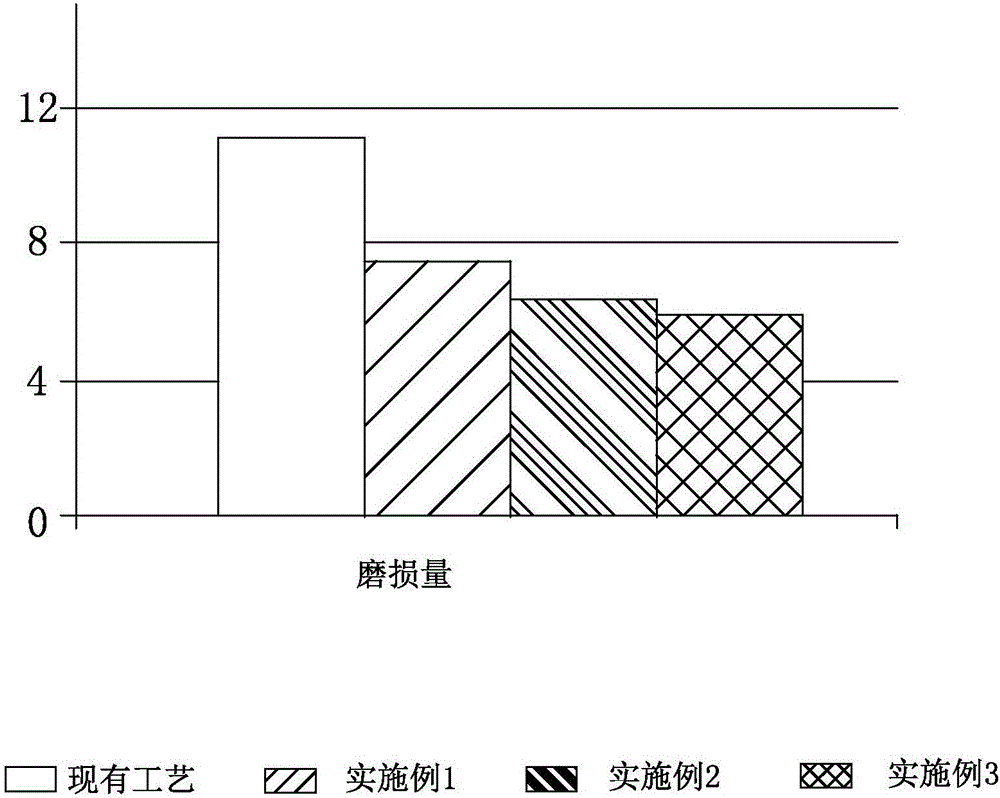

Heat treatment technology for bearing ferrule

InactiveCN106222375AImprove stabilityRelieve stress concentrationFurnace typesHeat treatment furnacesMartensite transformationSurface fatigue

The invention relates to a heat treatment technology for a bearing ferrule. The heat treatment technology comprises the following steps: carrying out spheroidizing annealing on the bearing ferrule firstly, rising the temperature in a furnace to 780-810 DEG C, keeping the temperature for 3-6h, annealing the bearing ferrule, then keeping the temperature for 4-6h at the temperature of 680-720 DEG C, furnace cooling the bearing ferrule to 600-650 DEG C at the cooling speed of 20-40 DEG C / h, and tapping and air cooling the bearing ferrule; then quenching the bearing ferrule, adopting the temperature of 830-850 DEG C, keeping the temperature for 15-45min, carrying out a salt bath on the bearing ferrule at the temperature of 150-170 DEG C, carrying out isothermal holding for 60-80min, and then taking out the bearing ferrule, and air cooling the bearing ferrule to the room temperature; and finally, carrying out tempering on the bearing ferrule, air cooling the bearing ferrule to the room temperature, and carrying out tempering for 5-8h at the temperature of 150-180 DEG C. According to the heat treatment technology, the content of retained austenite in the bearing ferrule can be stabilized between 10-15 percent, so that the stability of the retained austenite is greatly strengthened; the retained austenite on the surface of a bearing can carry out inducible martensitic transformation in the very short using process from the start, so that the heat treatment technology has the advantages of good size stability, good abrasion resistance and good surface fatigue strength.

Owner:C&U CO LTD +2

Carburized component and manufacturing method thereof

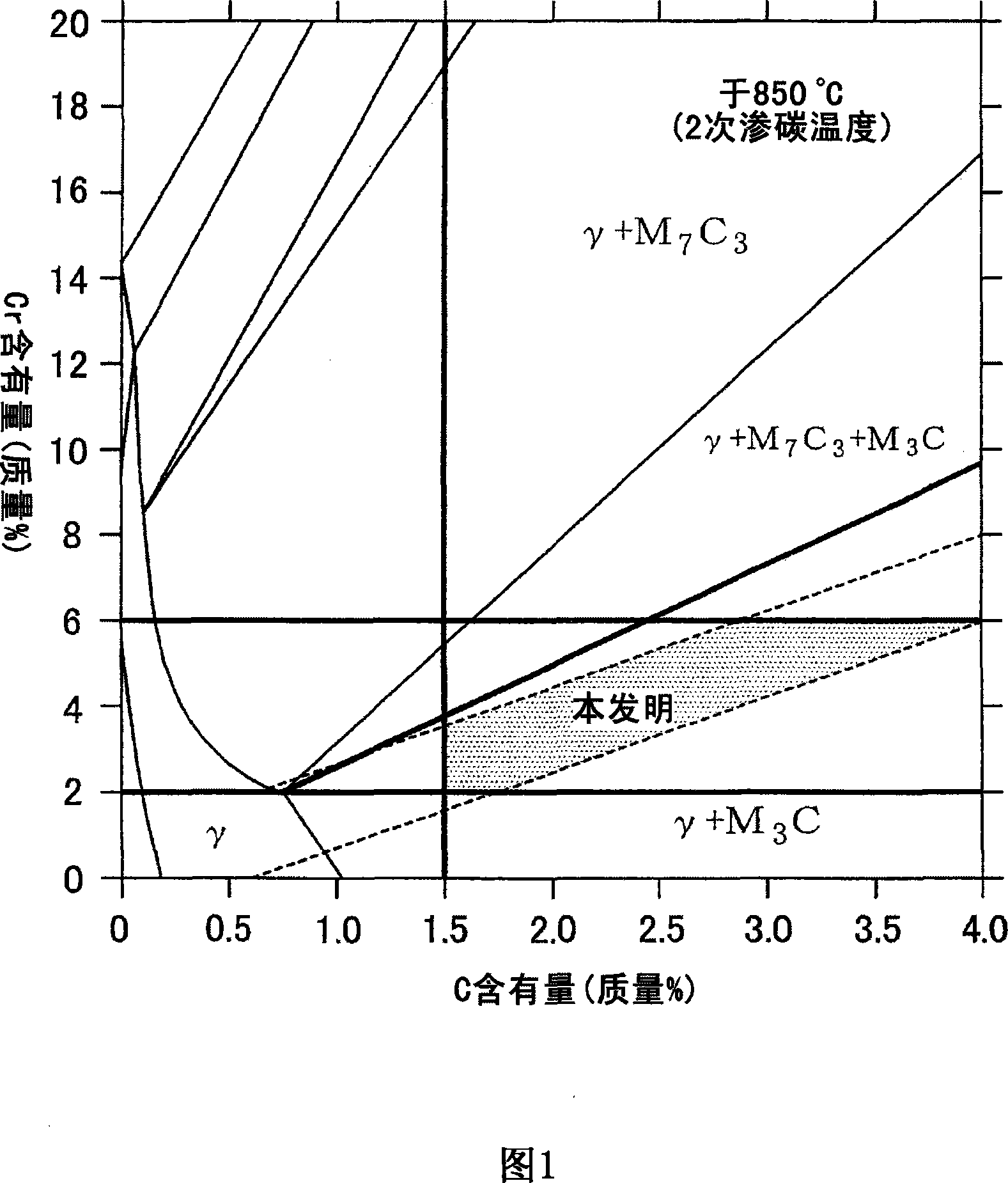

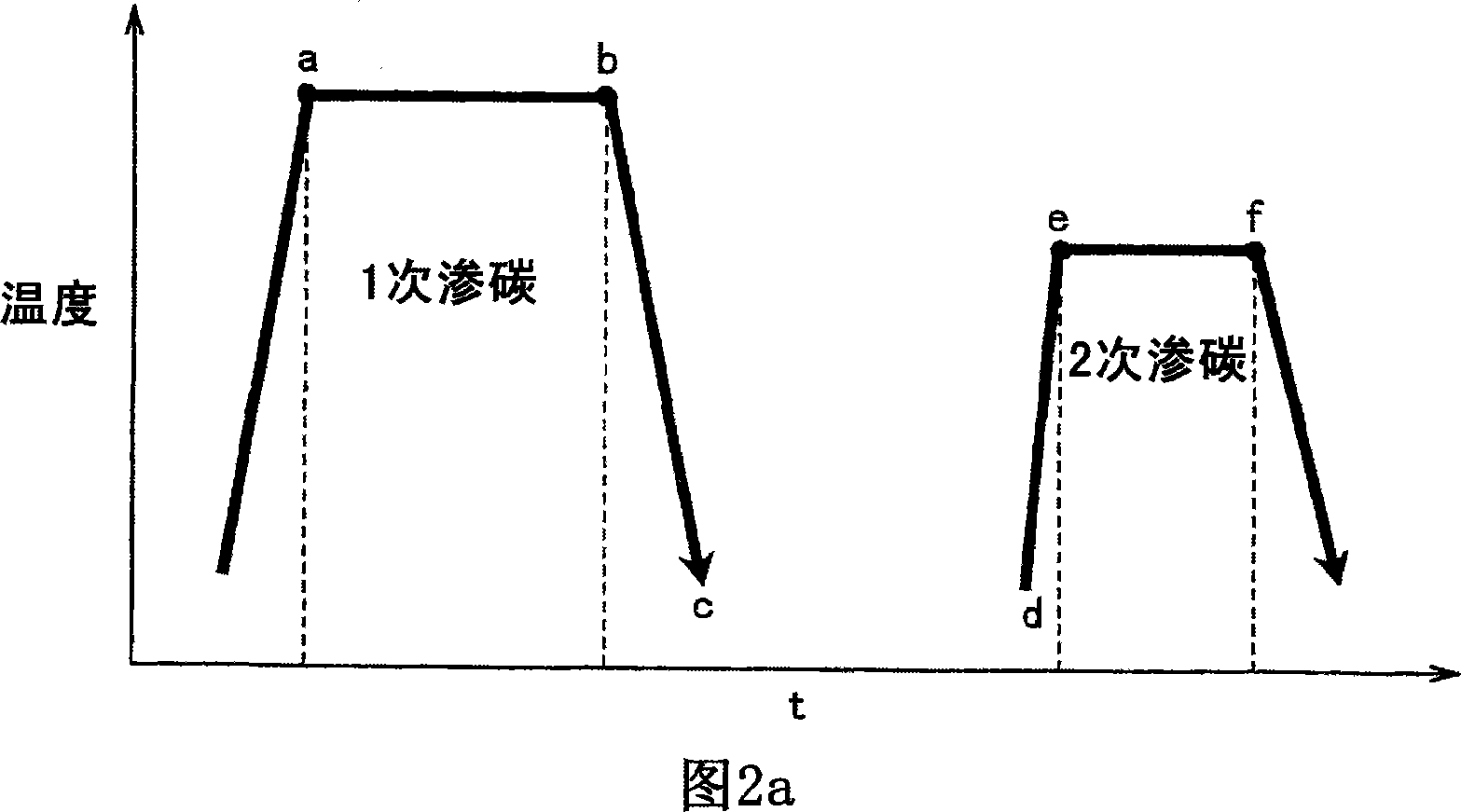

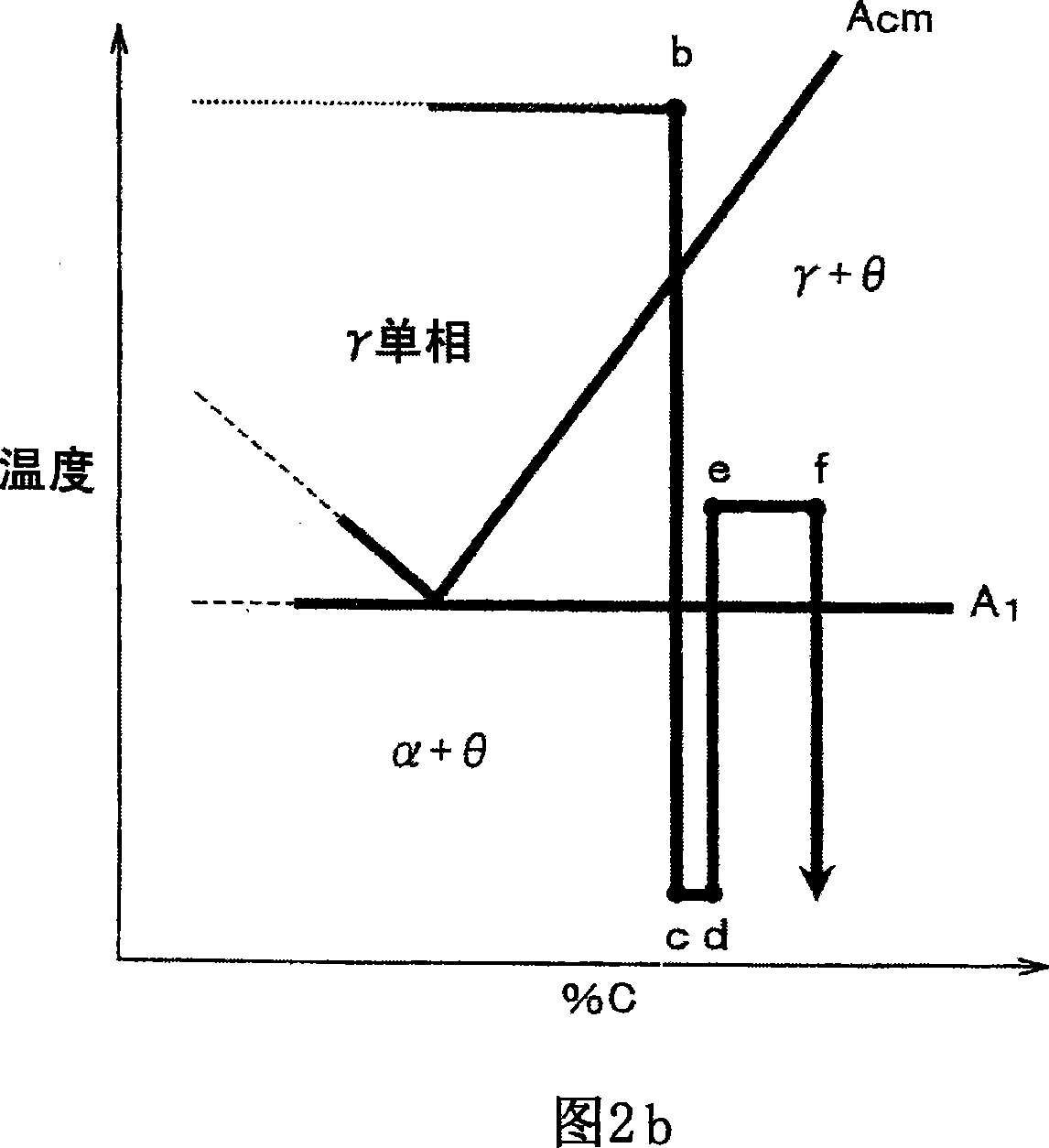

The carburized component of the present inventions is characterized by having a base metal containing: C: 0.10% to 0.40%; Si: 0.05% to 0.8%; Mn: 0.35% to 1.2%; Cr: 2.0% to 6.0%; and remnant including Fe and inevitable impurities, having a carburized layer formed on a surface layer portion of said base metal, having a grain boundary oxidized layer depth of 1[mu]m or less on a surface thereof and an average C concentration SC of 1. 5% to 4. 0% at 25[mu]m deep from the surface, and adjusted so as to satisfy: 1.76SC-1.06 C22C 38 / 18 B32B 15 / 01 C23C 8 / 22 C22C 38 / 24 C22C 38 / 26 C21D 7 / 06 4 15 1 2007 / 4 / 20 101058864 2007 / 10 / 24 000000000 Daido Steel Co., Ltd. Japan Hattori Atsushi Kano Takashi lougao chao 32200 The Patent Agency of the South-East University No.2 Sipailou, the City of Nanjing, Jiangsu Province 210018 Japan 2006 / 4 / 20 2006-116308 Japan 2007 / 2 / 16 2007-035632

Owner:DAIDO STEEL CO LTD

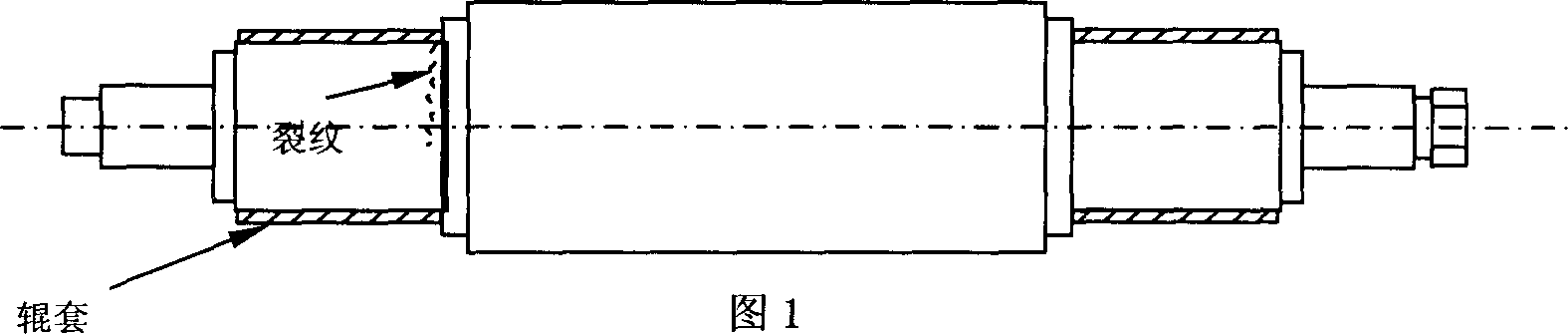

Detection method of closed surface fatigue crack

A method for detecting fatigue crack of closed surface includes emitting ultrasonic wave towards end surface vertical to roller neck to carry out detection on defects of shafts, using probe with small diffusion angle and excellent directional property to receive detection signal and displaying it on screen of crack detector, obtaining position and equivalent size of defect according to echo signal.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Chain production process

ActiveCN110055543AGuaranteed uniformityImprove oiling effectCharge manipulationSolid state diffusion coatingSurface fatigueHardness

The invention discloses a chain production process. The chain production process includes the steps that a, heat treatment is carried out, in heat treatment equipment, various auxiliary media are adopted under the high temperature to improve the organization structure of parts and improve the performance of various articles; b, carburization is carried out, the parts are placed in the heat treatment equipment to be heated and kept warm, and then carbon containing media are introduced to infiltrate the carbon into the surfaces of the parts so as to improve the hardness and abrasion resistance of a chain; c, quenching is conducted; d, tempering is conducted; e, blacking is conducted; f, bluing is conducted; g, shot blasting is conducted, and according to the requirements, steel shots with the required diameters are sprayed on the surfaces of the parts to form uniform small pits, so that the surface fatigue strength of the chain is improved; h, phosphorization is conducted, the parts areimmersed in phosphating liquid with a certain temperature to form a phosphating layer on the surface of each part, the surface colors of the parts can appear black or gray, the beauty of the chain isimproved, and the purpose of corrosion resistance is achieved at the same time; i, oiling is conducted, after the chain is put into oil immersion equipment, the oil is applied to the surface of the chain to prevent rust and the chain is more shiny; and j, inspection and warehousing are conducted.

Owner:浙江省浦江三联链条有限公司

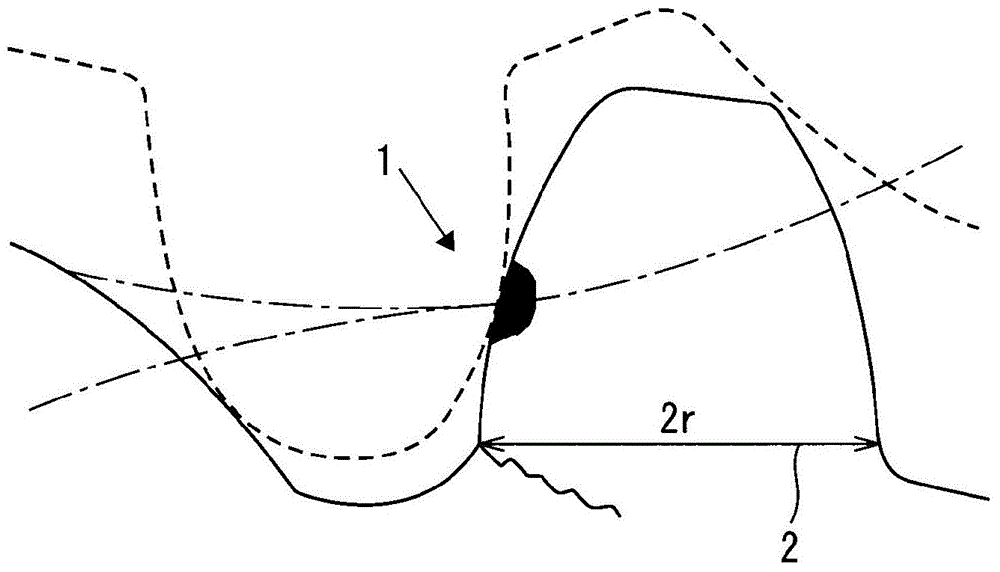

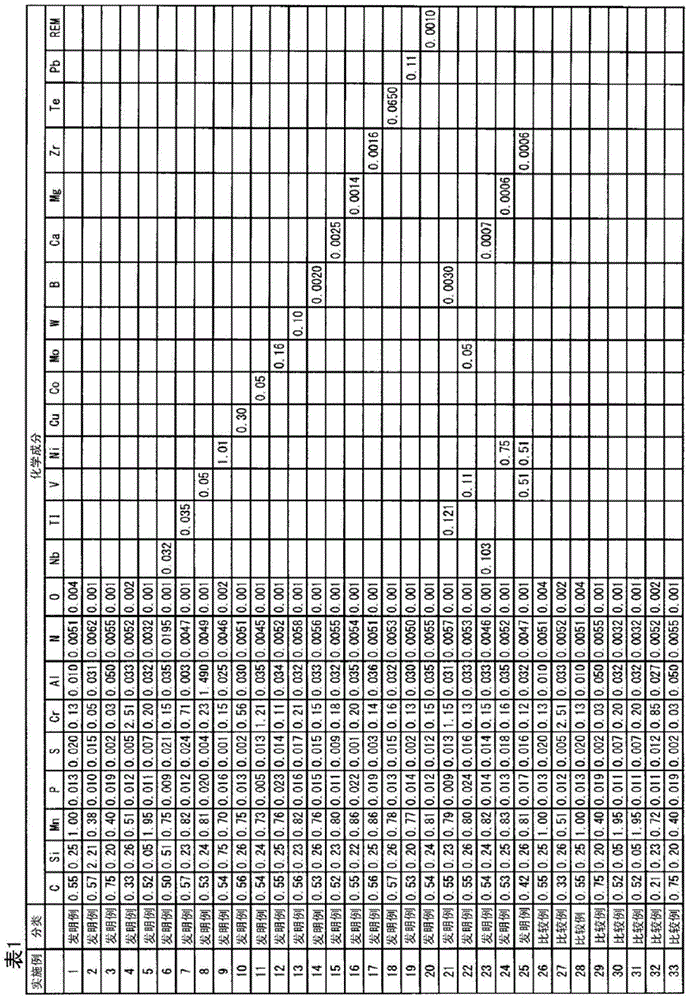

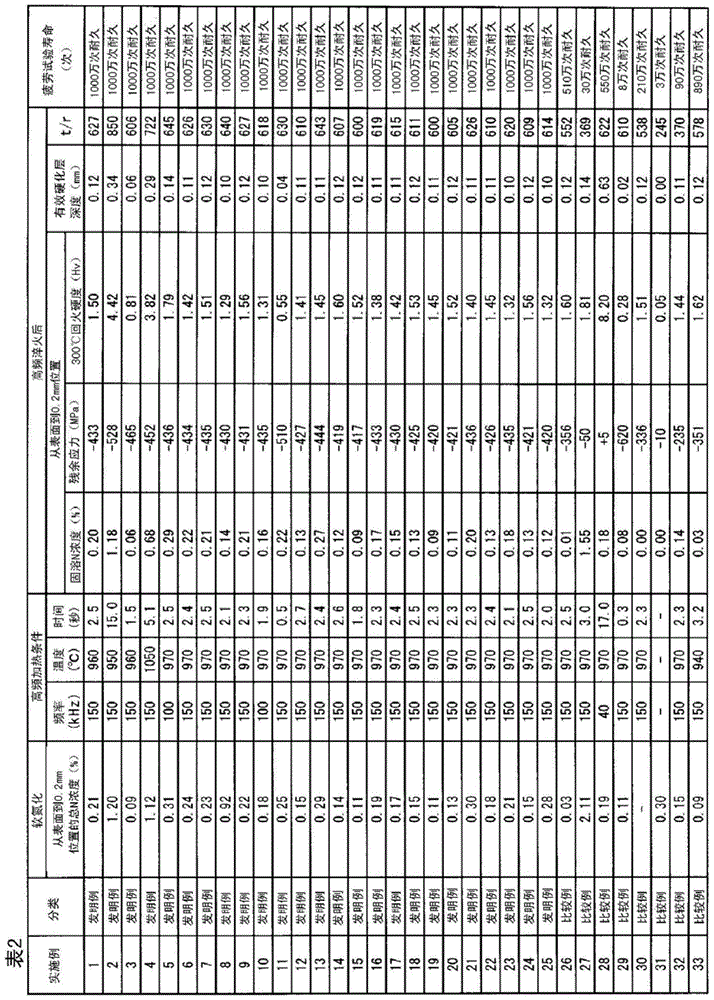

Soft-nitrided induction-quenched steel component

InactiveCN104981556AHigh compressive residual stressExcellent compressive residual stressSolid state diffusion coatingIncreasing energy efficiencyChemical compositionSurface fatigue

A soft-nitrided induction-quenched steel component having excellent surface fatigue strength, characterized in having a predetermined chemical composition, a solid solution N concentration of 0.05 to 1.5% to a depth of 0.2 mm from the surface, a Vickers hardness of Hv 600 or higher to a depth of 0.2 mm from the surface following tempering at 300°C, an effective hardening layer depth (t) of 0.5 mm or more, and a ratio t / r ≰ 0.35, where r (mm) is the radius or half the thickness of a location liable to be damaged.

Owner:NIPPON STEEL CORP

Chain processing technology

ActiveCN110079654AImprove uniformityReduce manufacturing costLiquid surface applicatorsSolid state diffusion coatingSurface fatigueHardness

The invention discloses a chain processing technology. The technology includes the following steps that a, heat treatment is performed; b, carburization is performed as follows: parts are placed in heat treatment equipment to be heated and subjected to heat preservation, then a carbon-containing medium is introduced, carbon permeates the surfaces of the parts, and thus the hardness and wear resistance of chains are improved; c, quenching is performed; d, tempering is performed; e, blackening is performed as follows: according to the high-polymer organic polymerization principle, film forming and blackening are performed by the aid of tempering waste heat in the process of the heat treatment technology; f, bluing is performed as follows: the parts are cooled and saponified by the aid of a chemical aqueous solution after being heated to the specific temperature, so that the surfaces of the parts are blue; g, shot blasting is performed as follows: steel shots in the required diameter areblasted to the surfaces of the parts as required, uniform small pits are formed, and thus the surface fatigue strength of the chains is enhanced; h, surface treatment is performed as follows: the chains are placed in impregnating equipment and are immersed in paint, and the surfaces of the chains are coated with the paint; and i, drying is performed as follows: the chains are conveyed into a drying chamber to dry the paint on the chains, and chain finished products are obtained.

Owner:佛山市南海岱阳机械有限公司

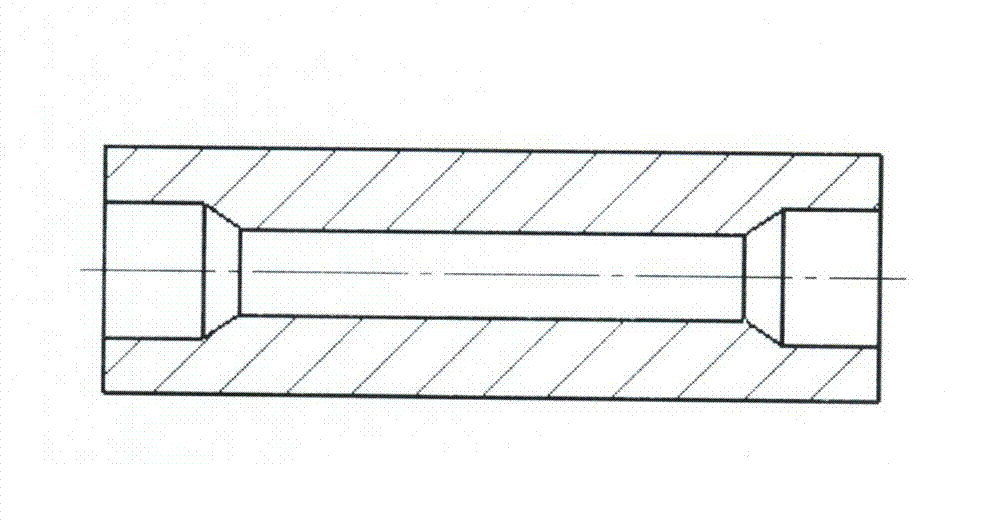

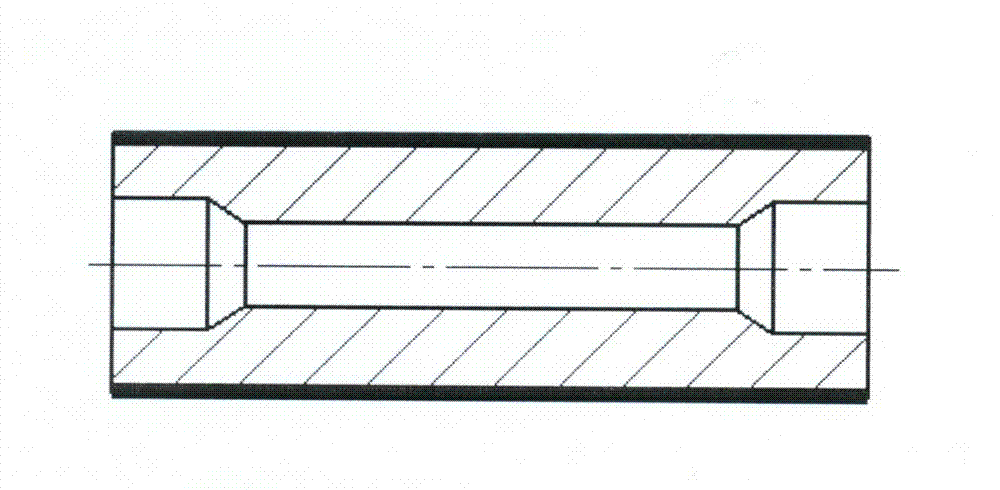

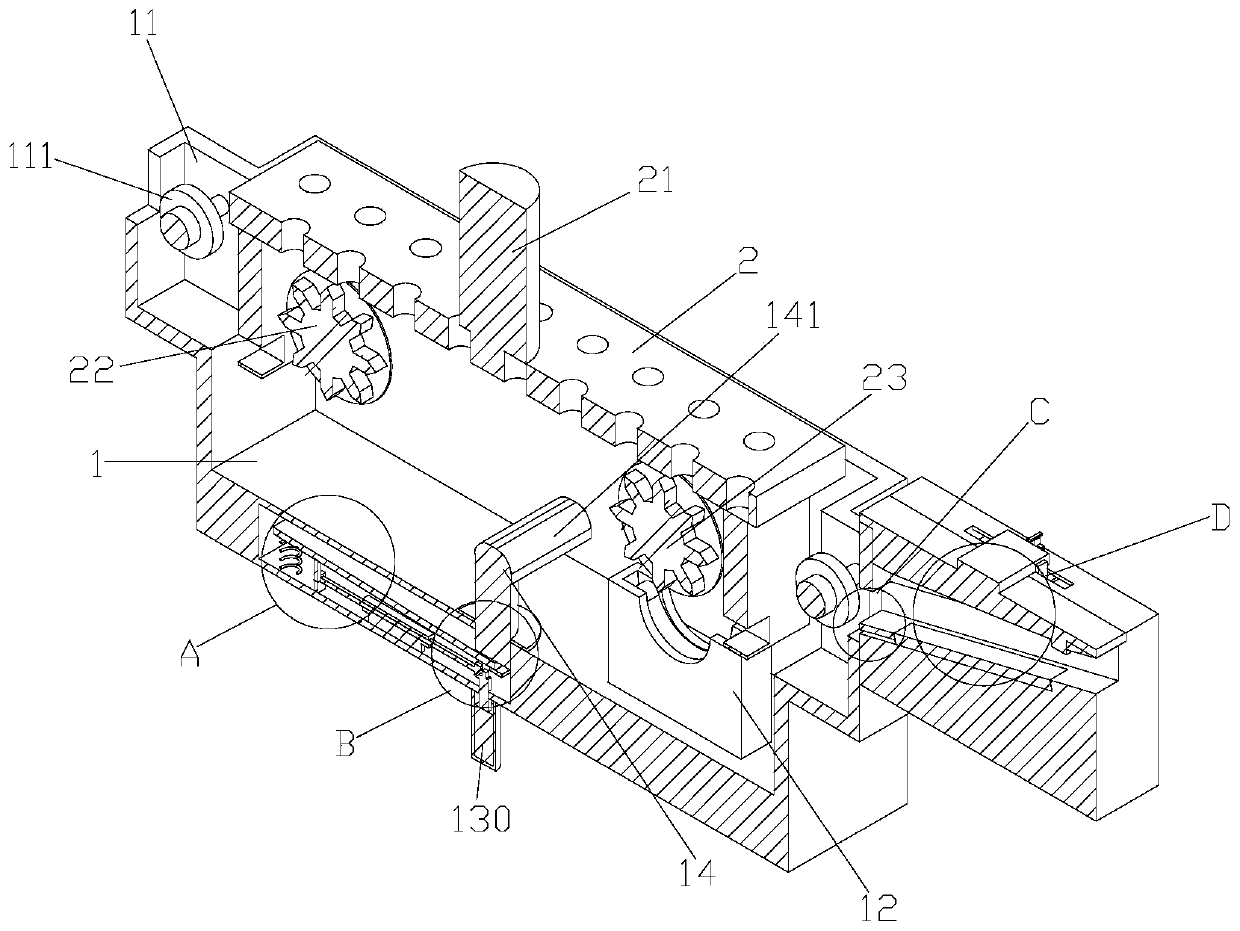

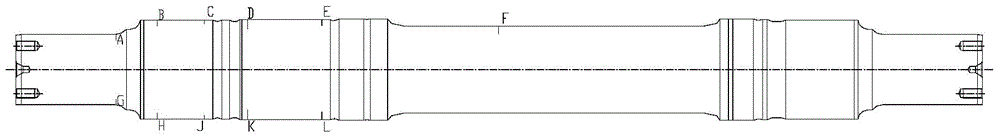

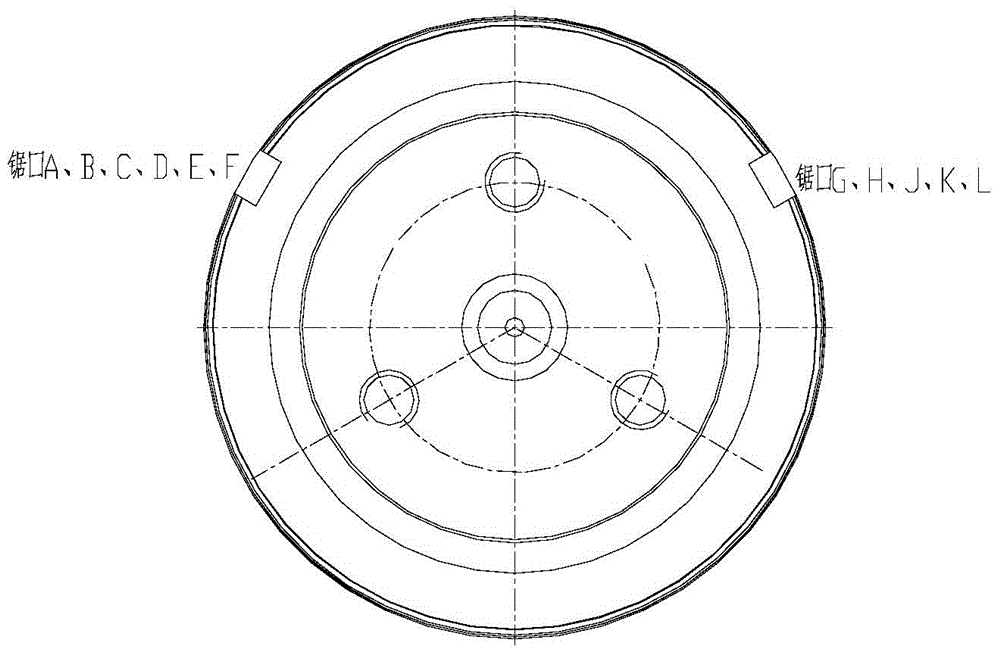

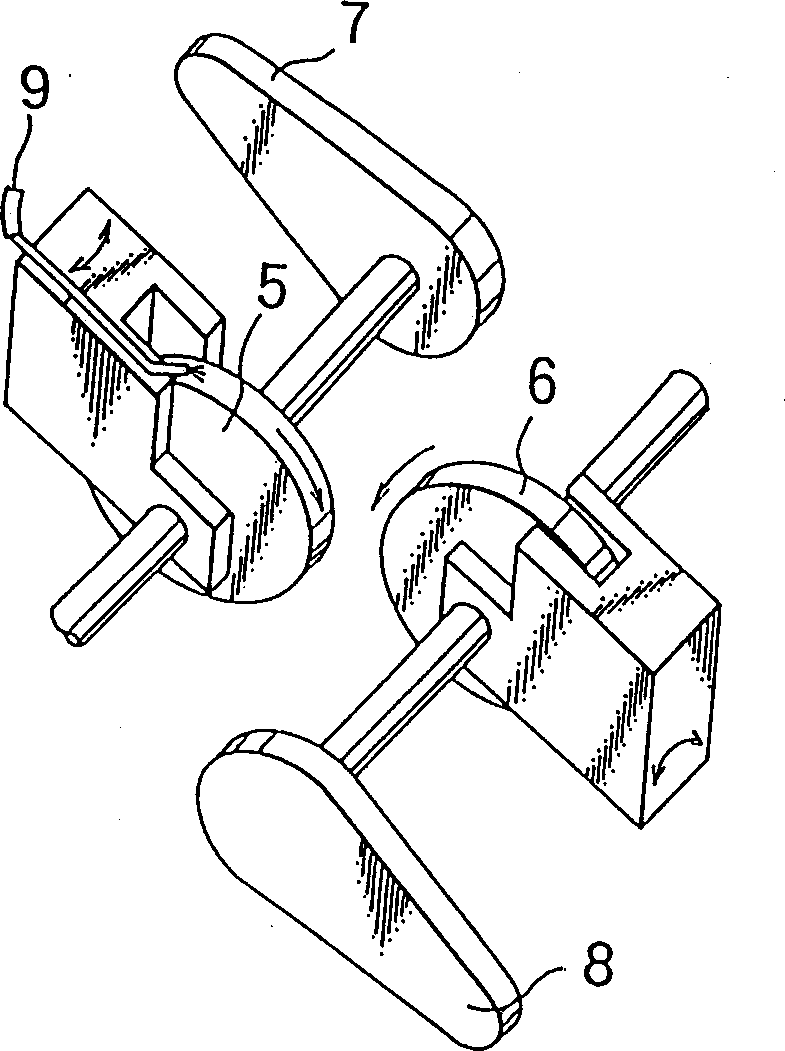

Method and apparatus for processing positive displacement drill bearing

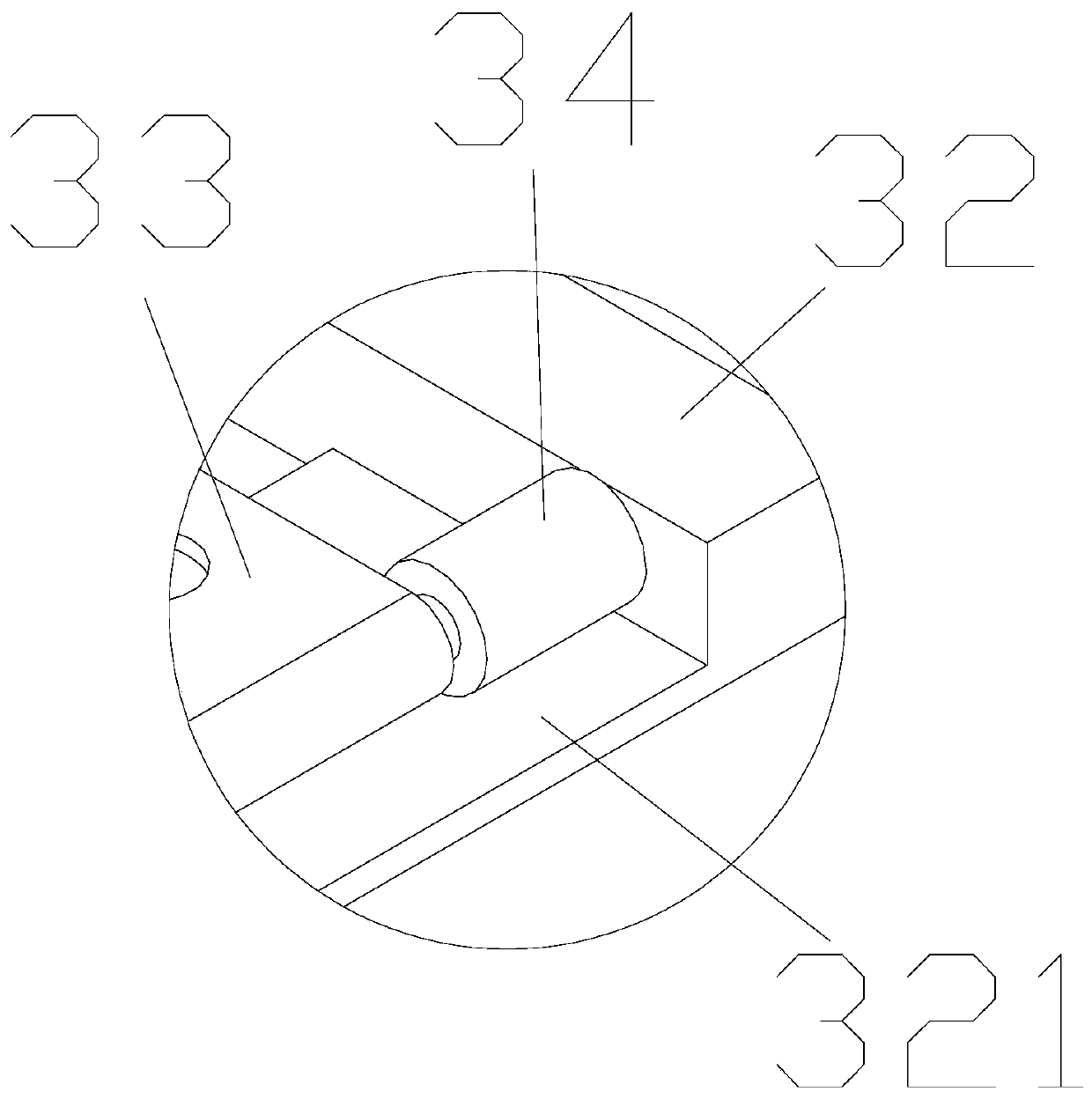

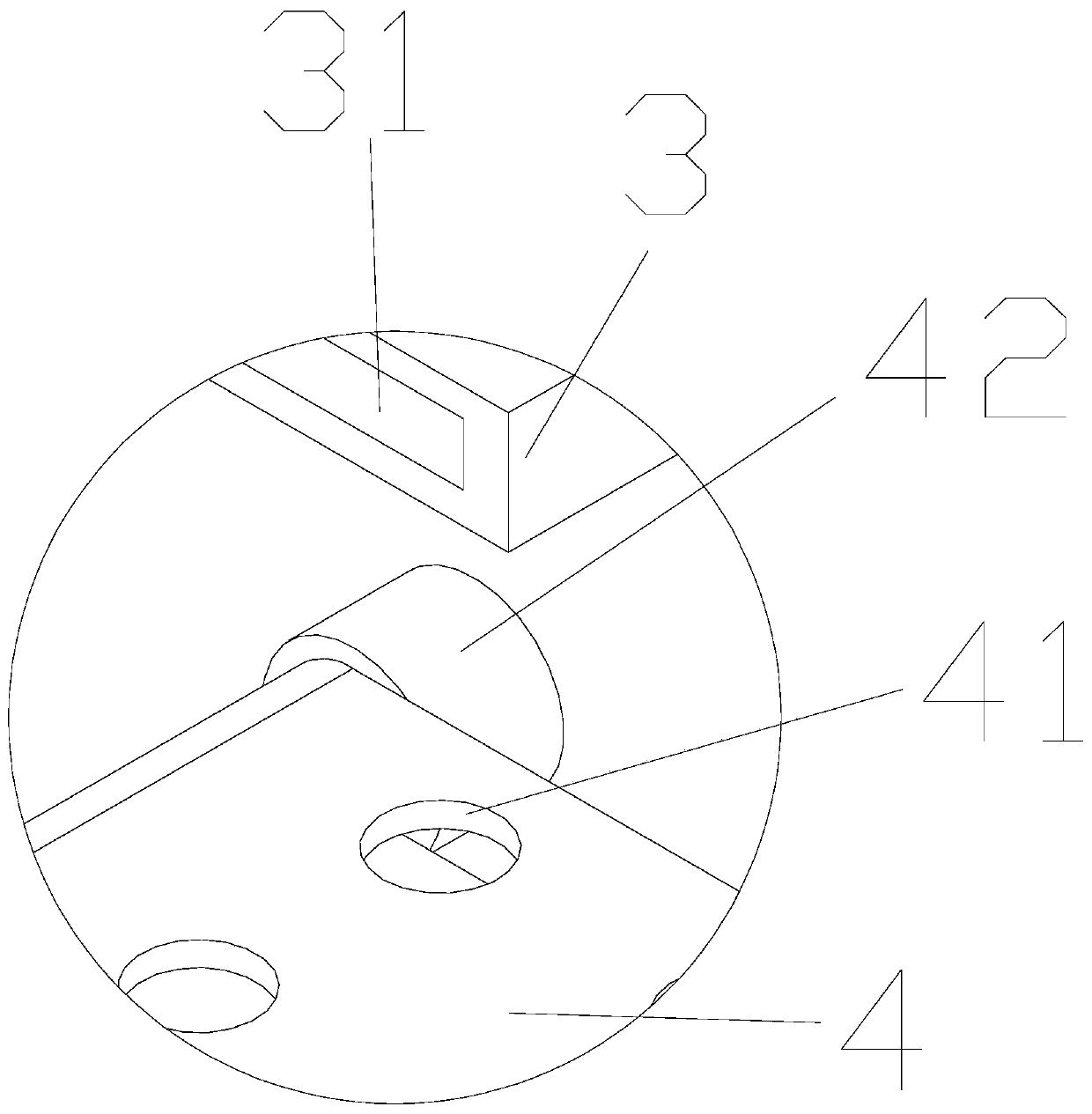

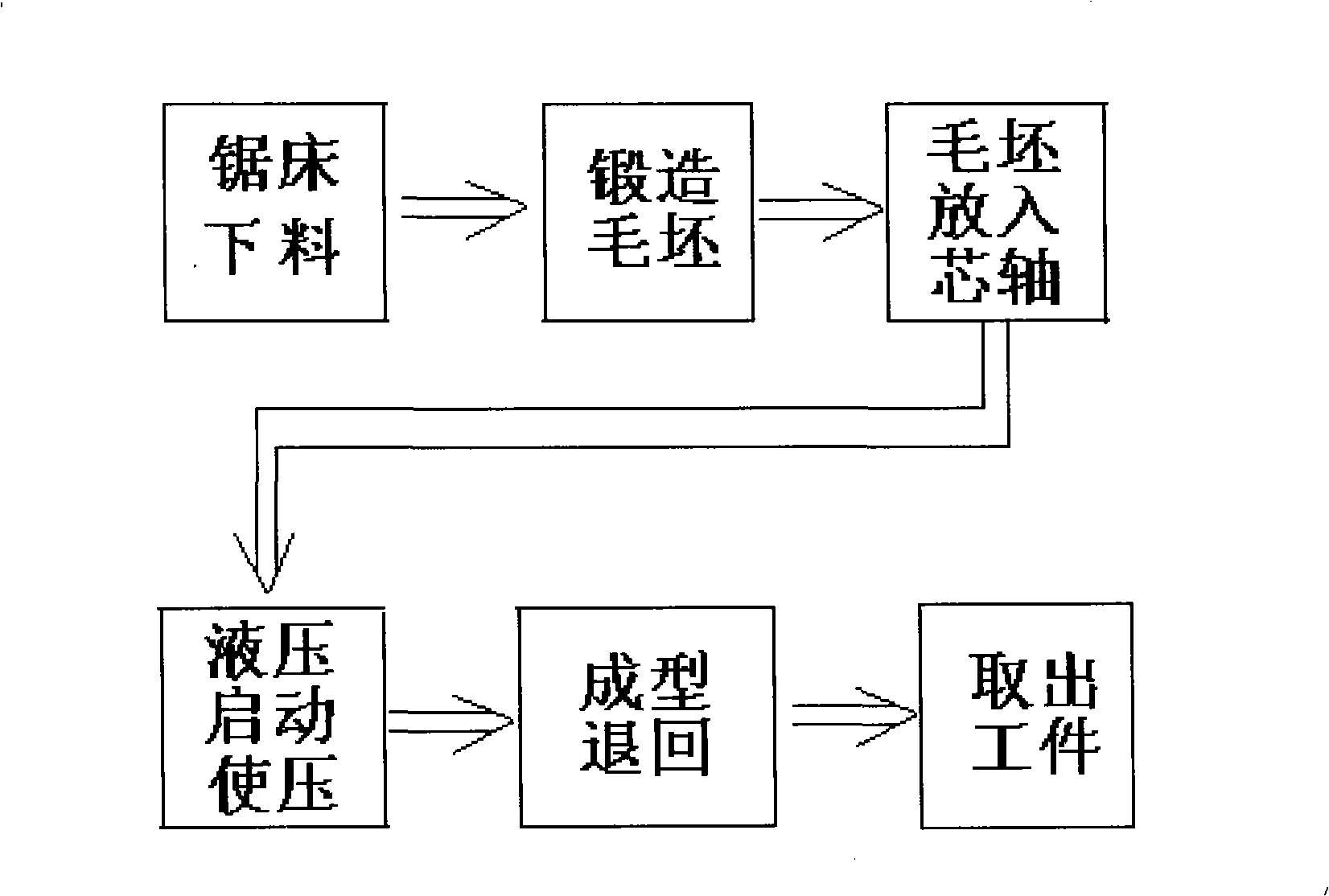

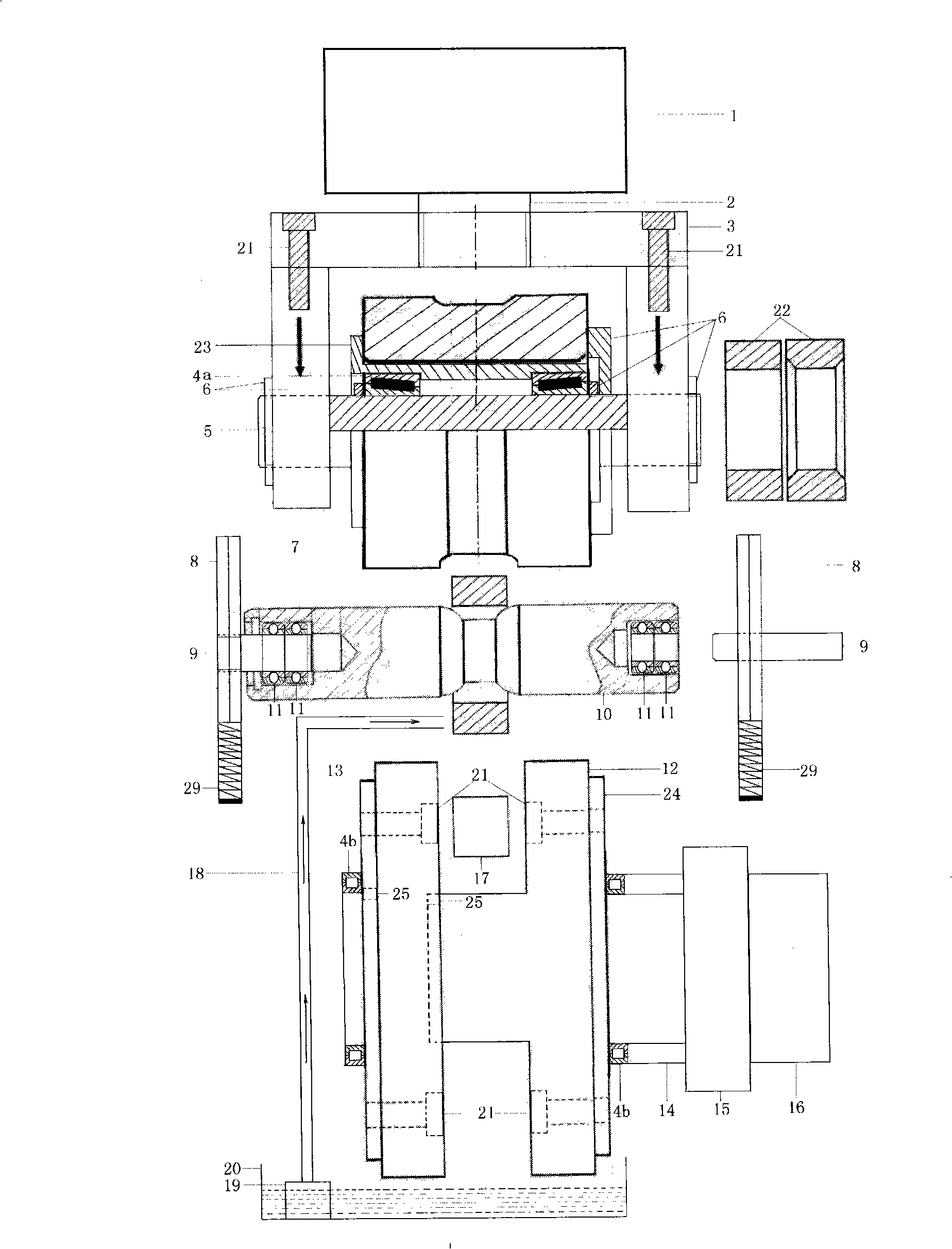

InactiveCN101293316AImprove surface fatigue strengthReduce sensitivityMetal-working feeding devicesEngine componentsSurface fatigueDrive wheel

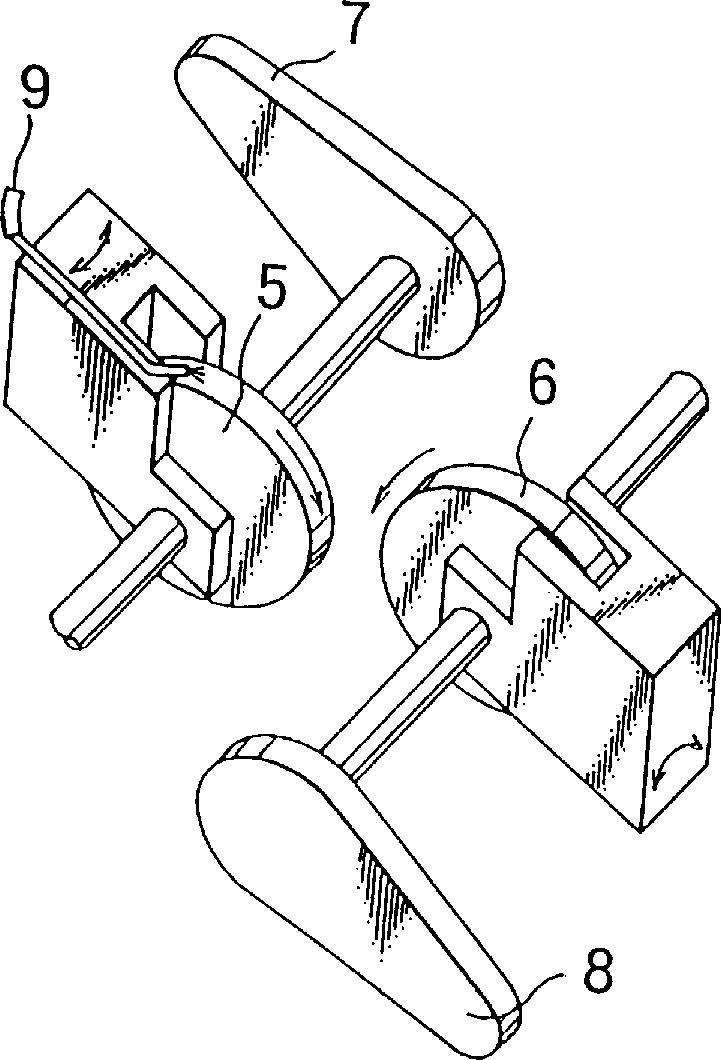

The invention discloses a method and a device for processing a bearing of a screw drill. The method adopts cold-rolling technique to process, firstly, an external sleeve blank or an internal sleeve blank of the bearing are processed; then the bearing of the screw drill is coldly rolled; a hydraulic oil cylinder (1) pushes a rolling wheel (7) to move downwards to be contacted with the bearing blank arranged on a rolling core roller (10) by pressurizing, thus lead the rolling wheel (7) to be parallel with the central shaft of the rolling core roller (10) and lead the rolling core roller to be contacted with the drive wheel (12) of a rotating mechanism; a coupler (14) connected with a motor (16) by a reducer drives the drive wheel and a driven wheel (13) to lead the rolling core roller to rotate; the rolling wheel (7) continuously puts pressure on the bearing blank until the bearing blank is deformed to achieve workpiece shaping standard. The invention can remarkably improve the surface fatigue intensity of a part, can eliminate a lathe machining process and can lead the utilization rate of materials to be improved from the former 45 percent to over 75 percent, which leads the power consumption of the device to be greatly reduced.

Owner:李元甲

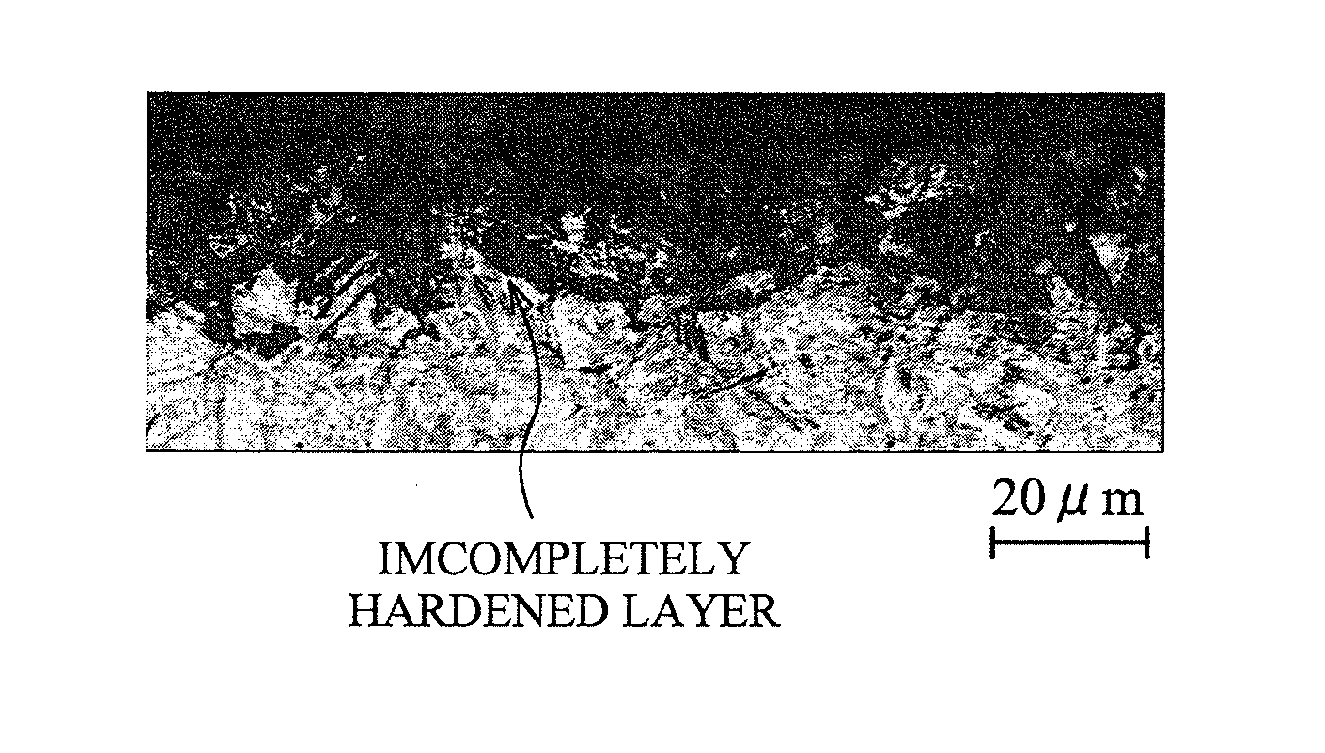

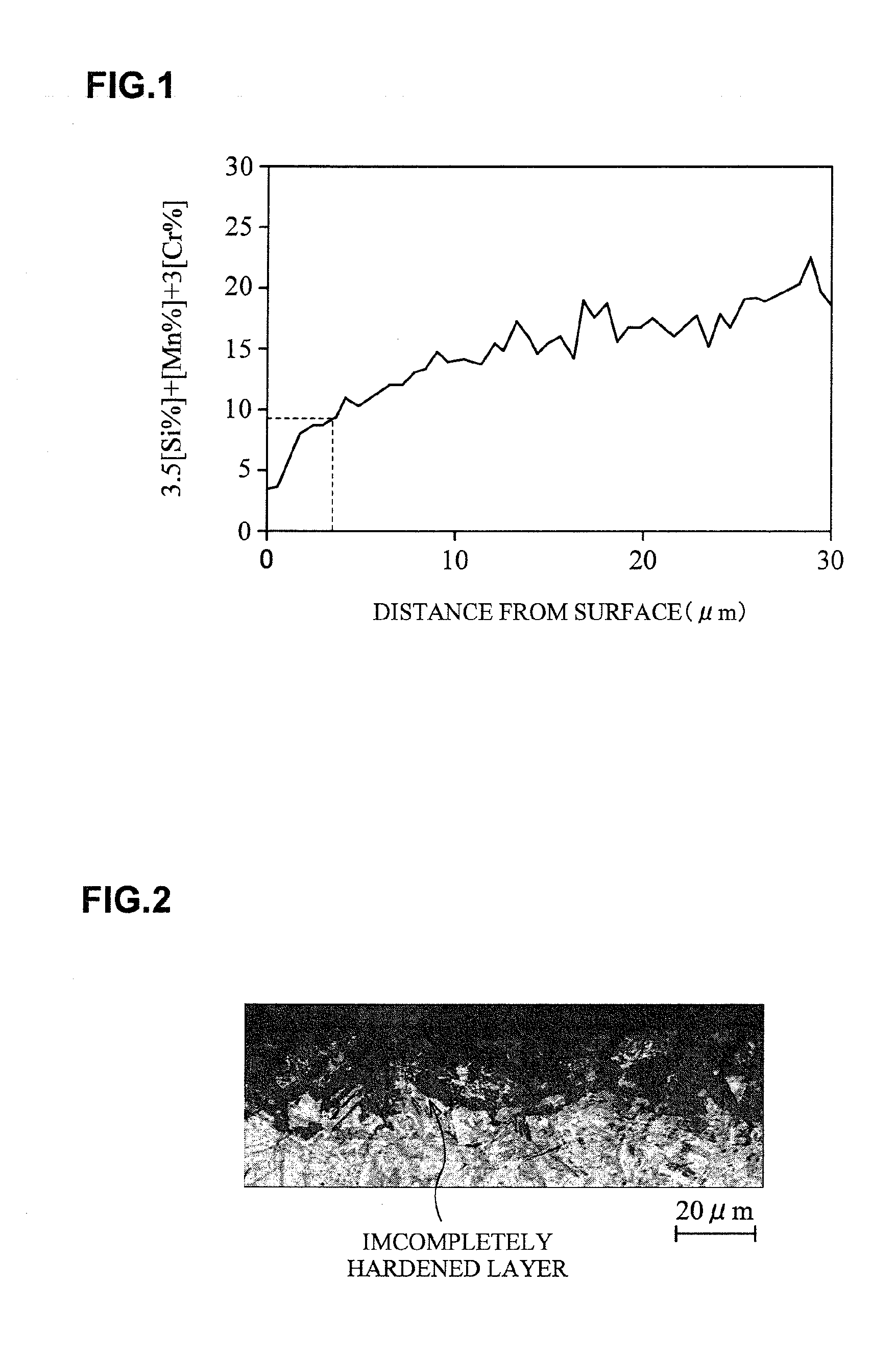

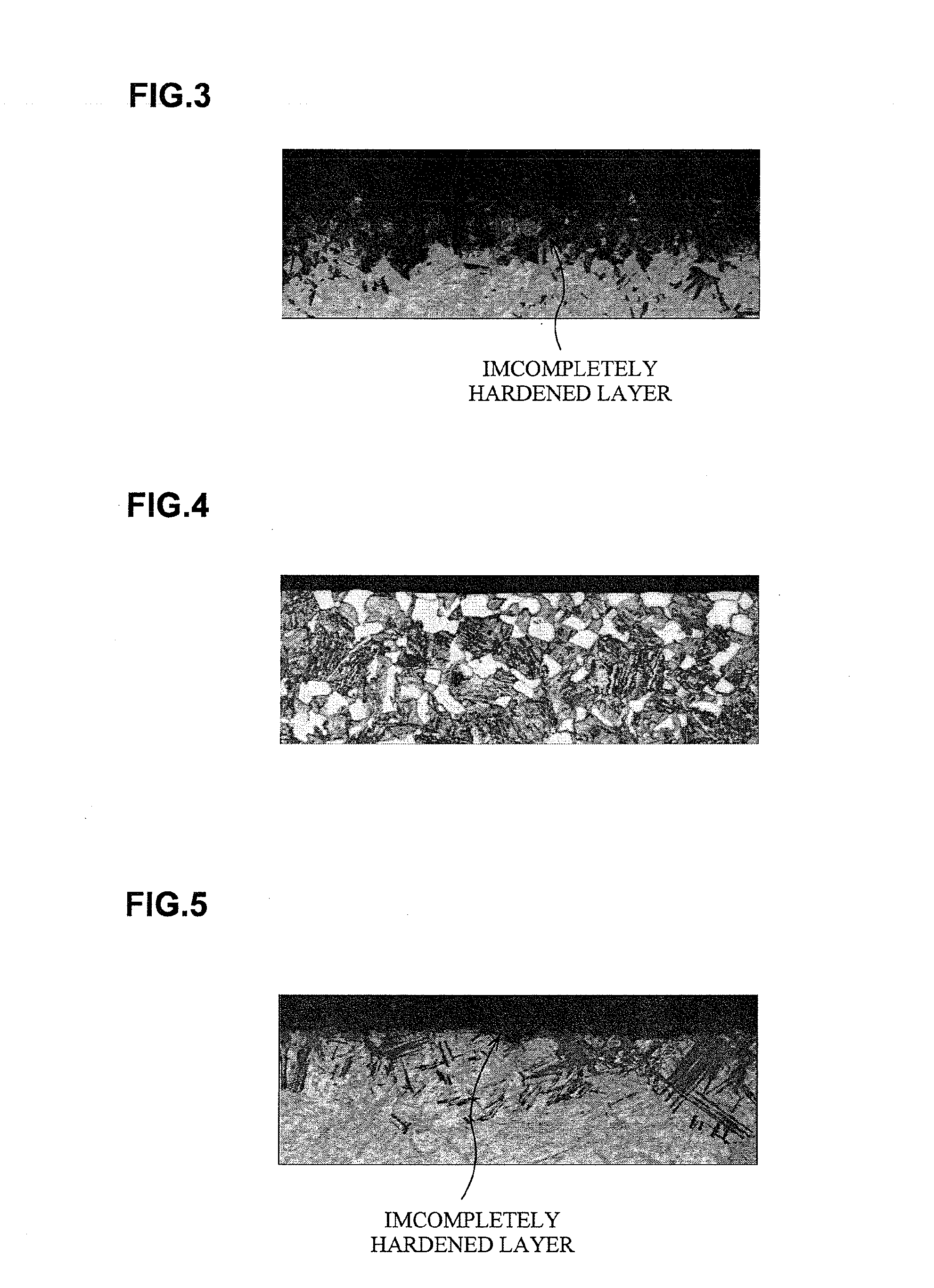

Gas-carburized steel part excellent in surface fatigue strength, steel product for gas carburizing, and manufacturing method of gas-carburized steel part

ActiveUS20120312425A1Improve surface fatigue strengthAvoid resistanceSolid state diffusion coatingFurnace typesSurface fatigueAlloy

The present invention provides a steel product for gas carburizing used for manufacturing a carburized steel part. In the above steel product for gas carburizing, a composition of a base metal contains, in mass %, C: 0.1 to 0.4%, Si: exceeding 1.2 to 4.0%, Mn: 0.2 to 3.0%, Cr: 0.5 to 5.0%, Al: 0.005 to 0.1%, S: 0.001 to 0.3%, N: 0.003 to 0.03%, and O: limited to 0.0050% or less, and P: limited to 0.025% or less, and when the contents of Si, Mn, and Cr (mass %) are set to [Si %], [Mn %], and [Cr %], Expression (1) below is satisfied, and an alloy shortage layer satisfying Expression (2) below exists in a range from its surface to 2 to 50 μm in depth.32≧3.5[Si %]+[Mn %]+3[Cr %]>9 (1)3.5[Si %]+[Mn %]+3[Cr %]≦9 (2)

Owner:NIPPON STEEL CORP

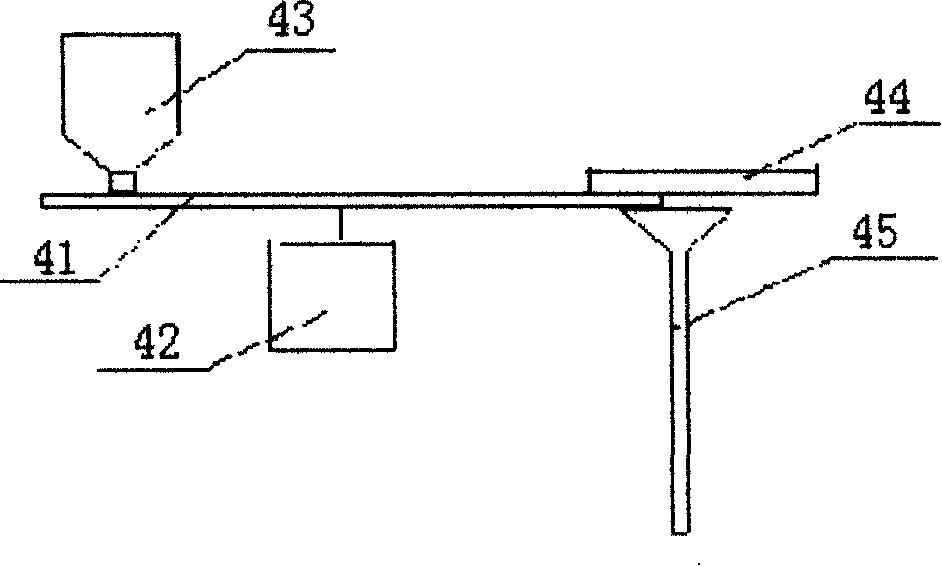

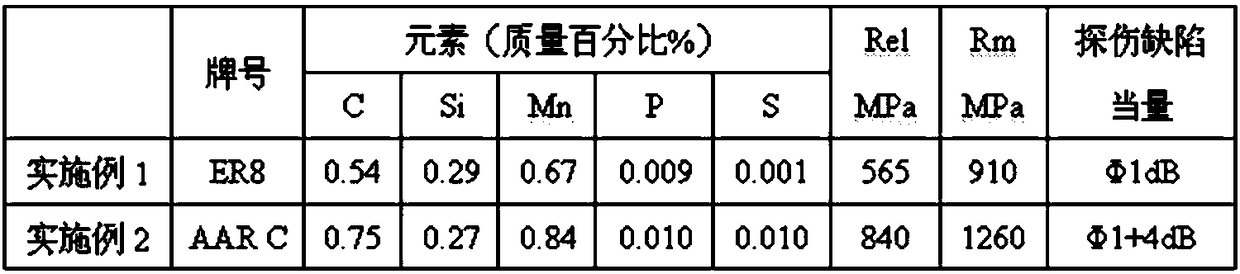

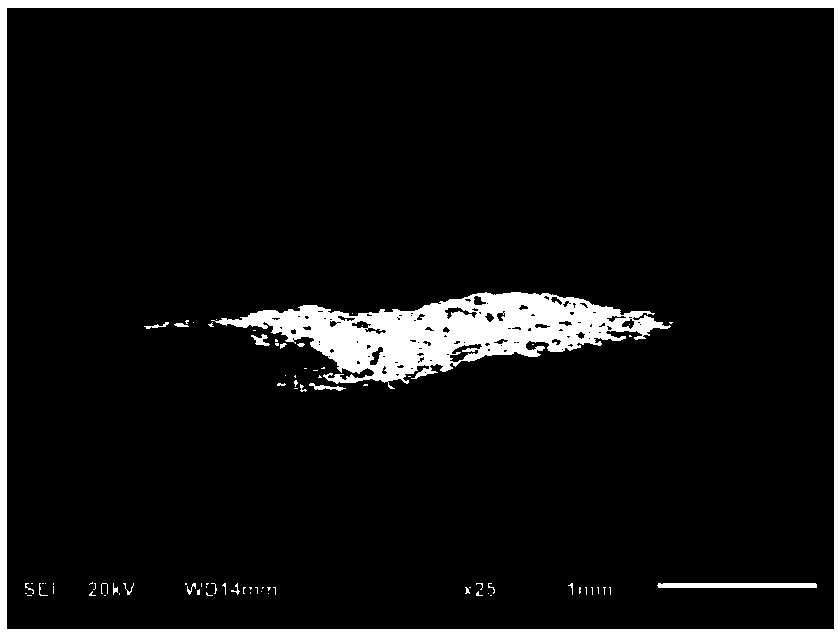

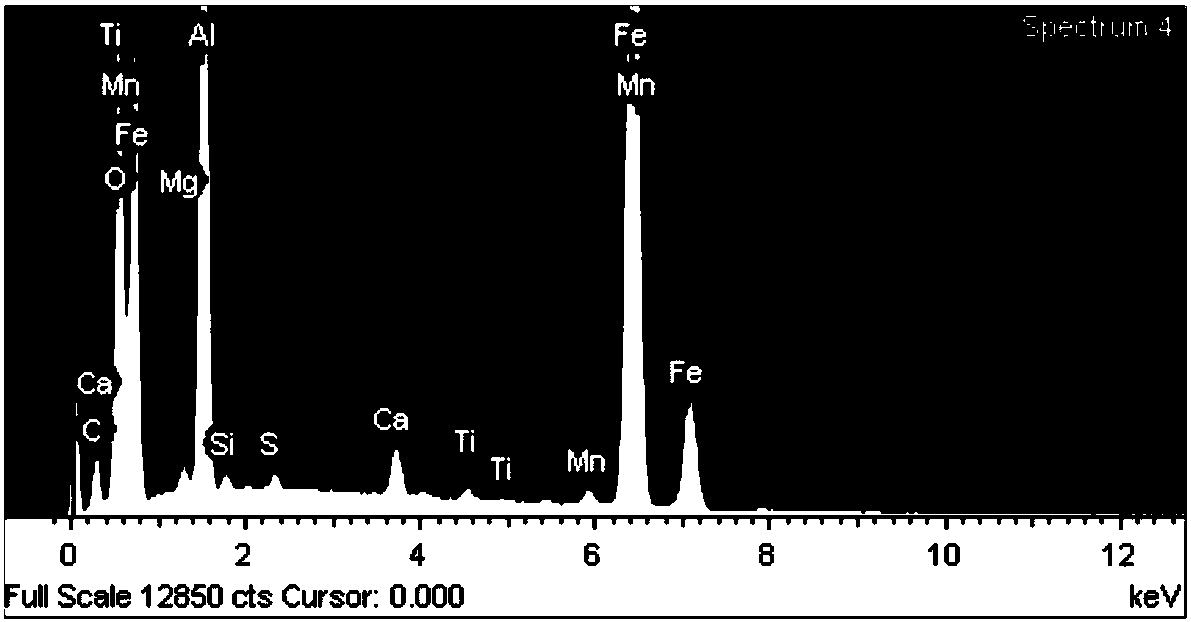

Method for ultrasonic inclusion detection of train wheels

InactiveCN108088904AQuality improvementSimple stepsAnalysing solids using sonic/ultrasonic/infrasonic wavesSurface fatigueEngineering

The invention provides a method for ultrasonic inclusion detection of train wheels. The method is applied to the technical fields of train wheel manufacturing and performance detecting processes. Themethod comprises the following steps: (1) performing ultrasonic flaw detection on a rim inner side surface and a rim tread of a train wheel, and determining that a detection surface with a strong defect reflection signal is parallel to a length direction of an inclusion; (2) cutting a cross section sample of a rim which contains the inclusion, and taking a sample square rod by linear cutting, wherein the inclusion exists in the middle of the sample square rod; (3) by taking the sample square rod as a sample, performing micro-particle shot blasting on the sample; and (4) applying a stair load fatigue test on the sample, wherein an initial load is lower than a fatigue limit of surface fatigue, and under a load load, ensuring that a fatigue crack cracks and expands from the inclusion. The method provided by the invention can completely display the full view of the inclusion which is discovered by ultrasonic flaw detection and can accurately measure the size of a defect.

Owner:MAANSHAN IRON & STEEL CO LTD

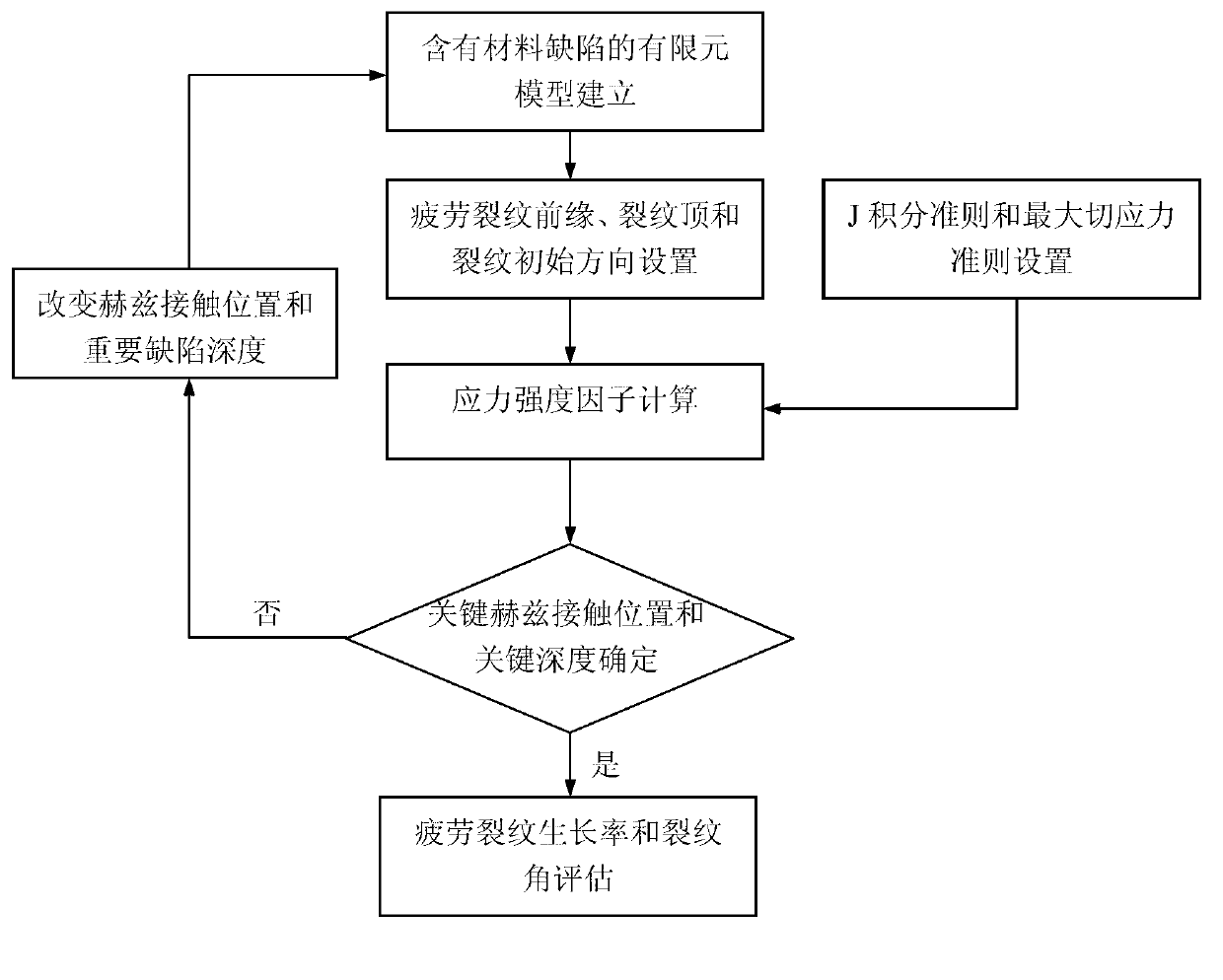

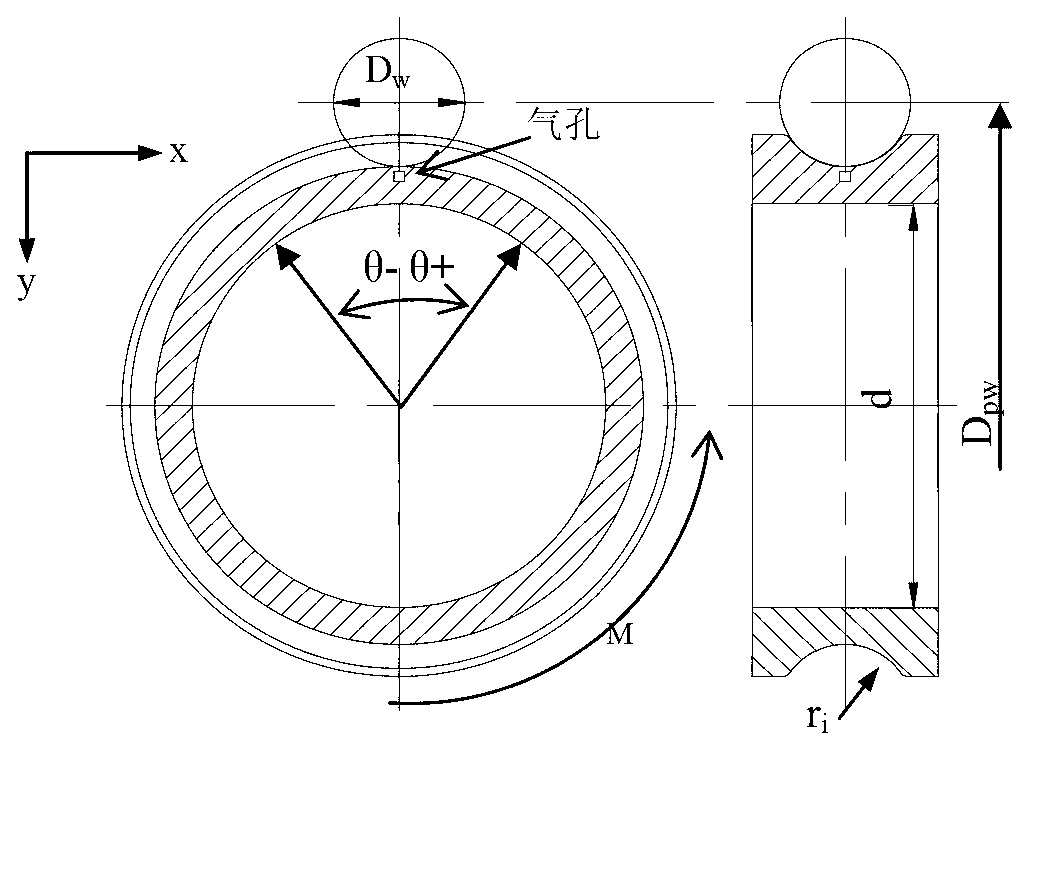

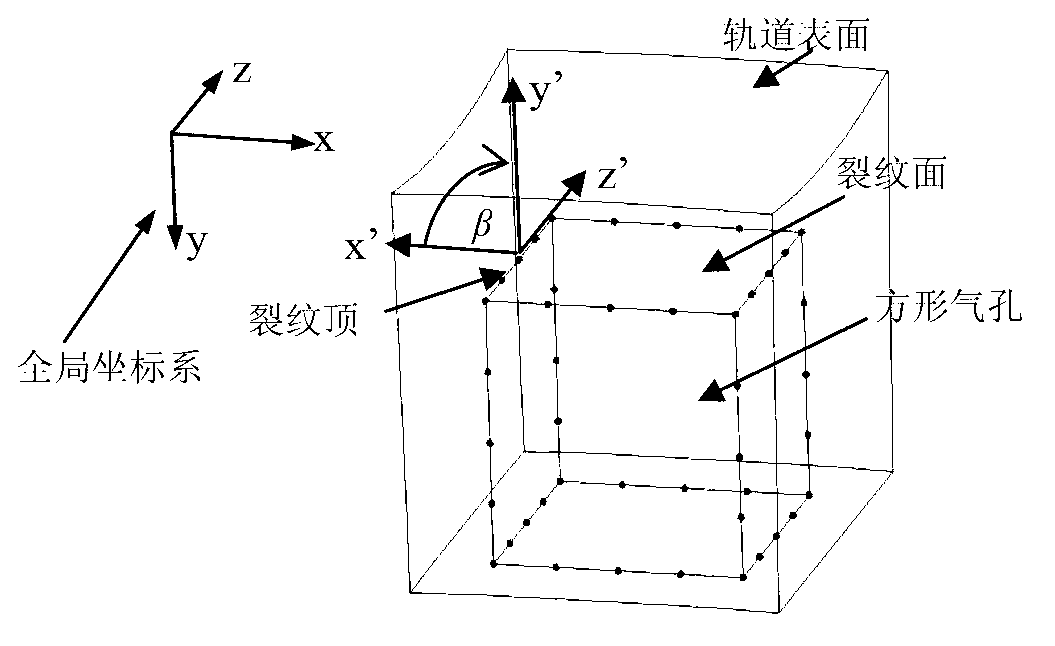

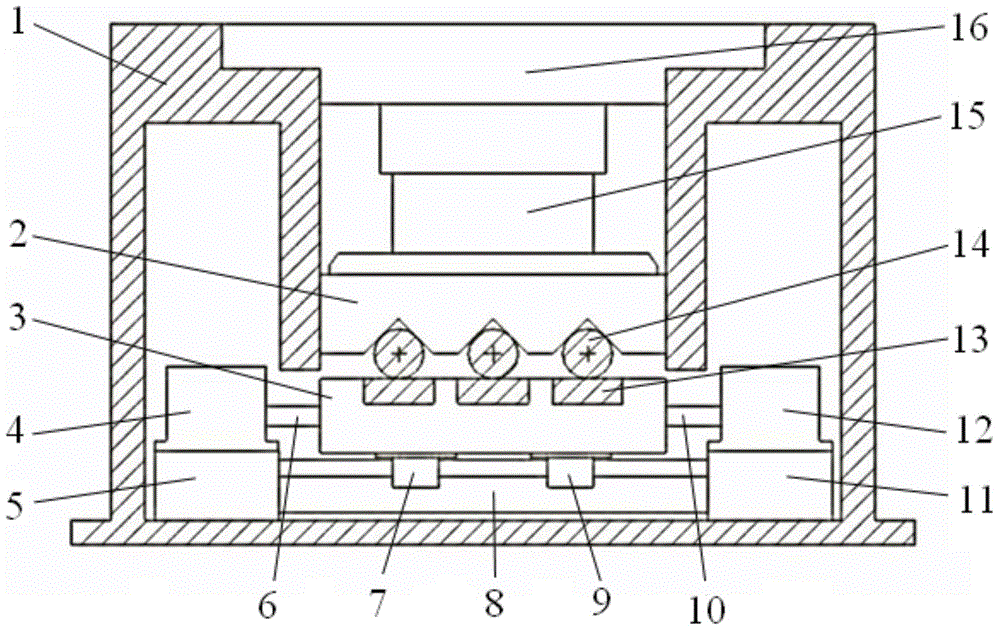

Stress intensity factor-based Method for estimating fatigue damage degree of subsurface of bearing roller path

The invention relates to a stress intensity factor-based method for estimating the fatigue damage degree of a subsurface of a bearing roller path. The method comprises the following steps of: S1. constructing a bearing model containing a material defect, and dividing a grid; S2. calculating a crack top stress intensity factor; S3. calculating an equivalent stress intensity factor; S4. determining a key hertz contact position; S5. determining a key depth of the material defect on the subsurface of the roller path; S6. determining KI (gamma), KII (gamma) and KIII (gamma) and the equivalent stress intensity factor Keff when H is equal to H0 and theta is equal to theta0; and S7. determining the crack growth rate or the crack growth angle. The method has the advantages of high efficiency, low cost, high practicability and the like based on a finite element analysis method; furthermore, by the method, the consumed time is short; the method can be combined with a test method, and a test can be instructed; and the test cost can be saved.

Owner:WUHAN UNIV OF TECH

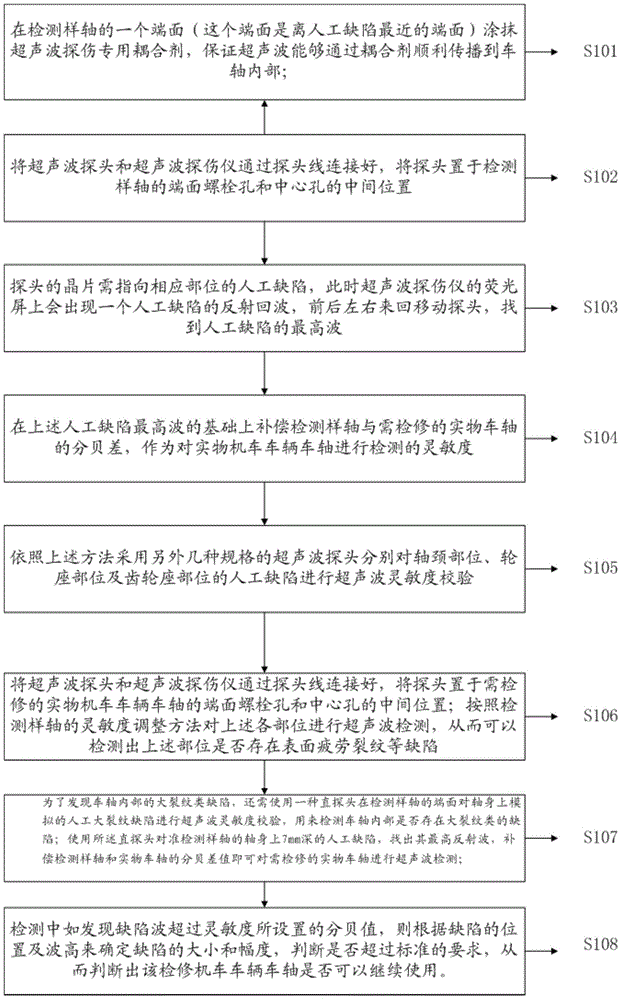

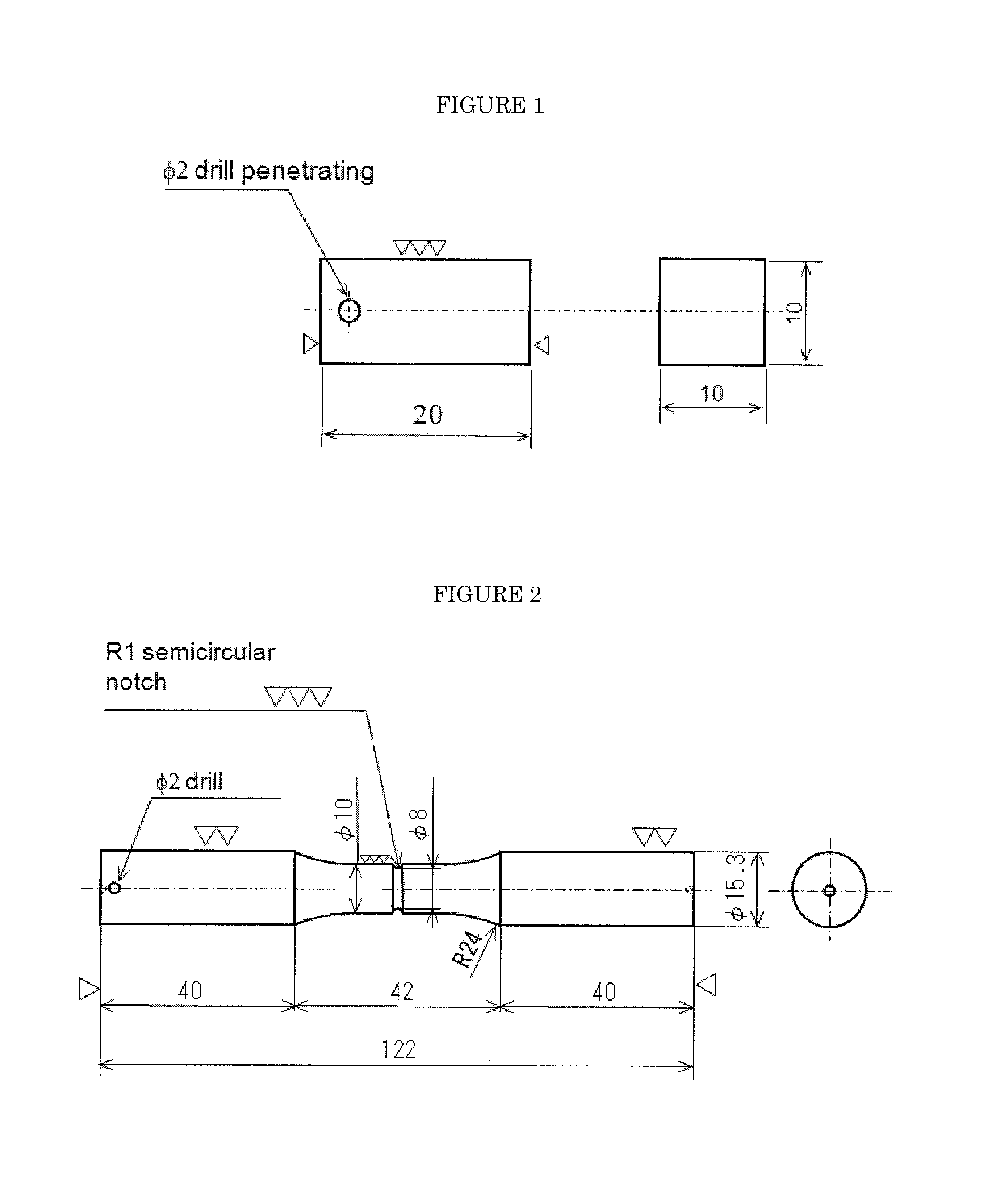

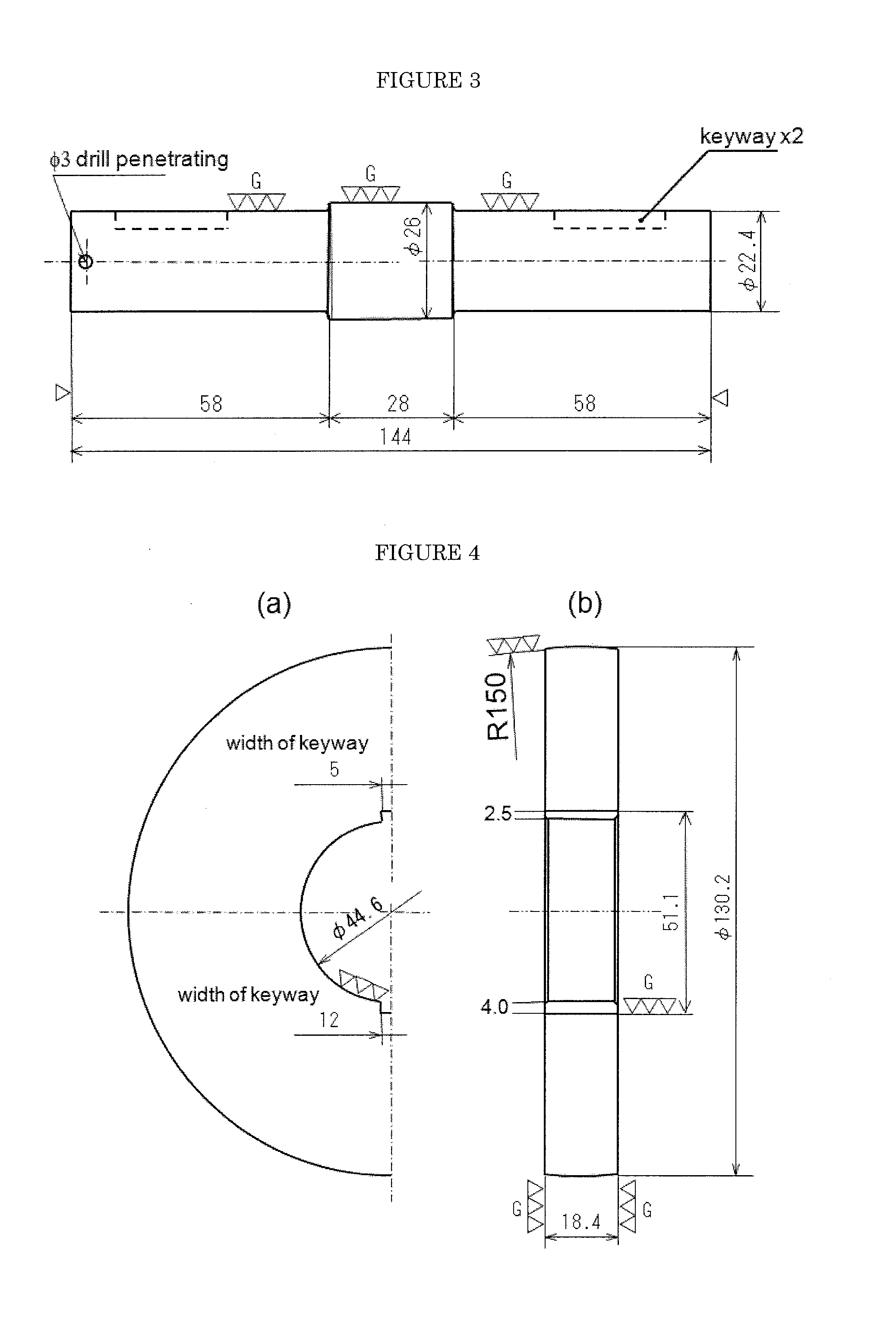

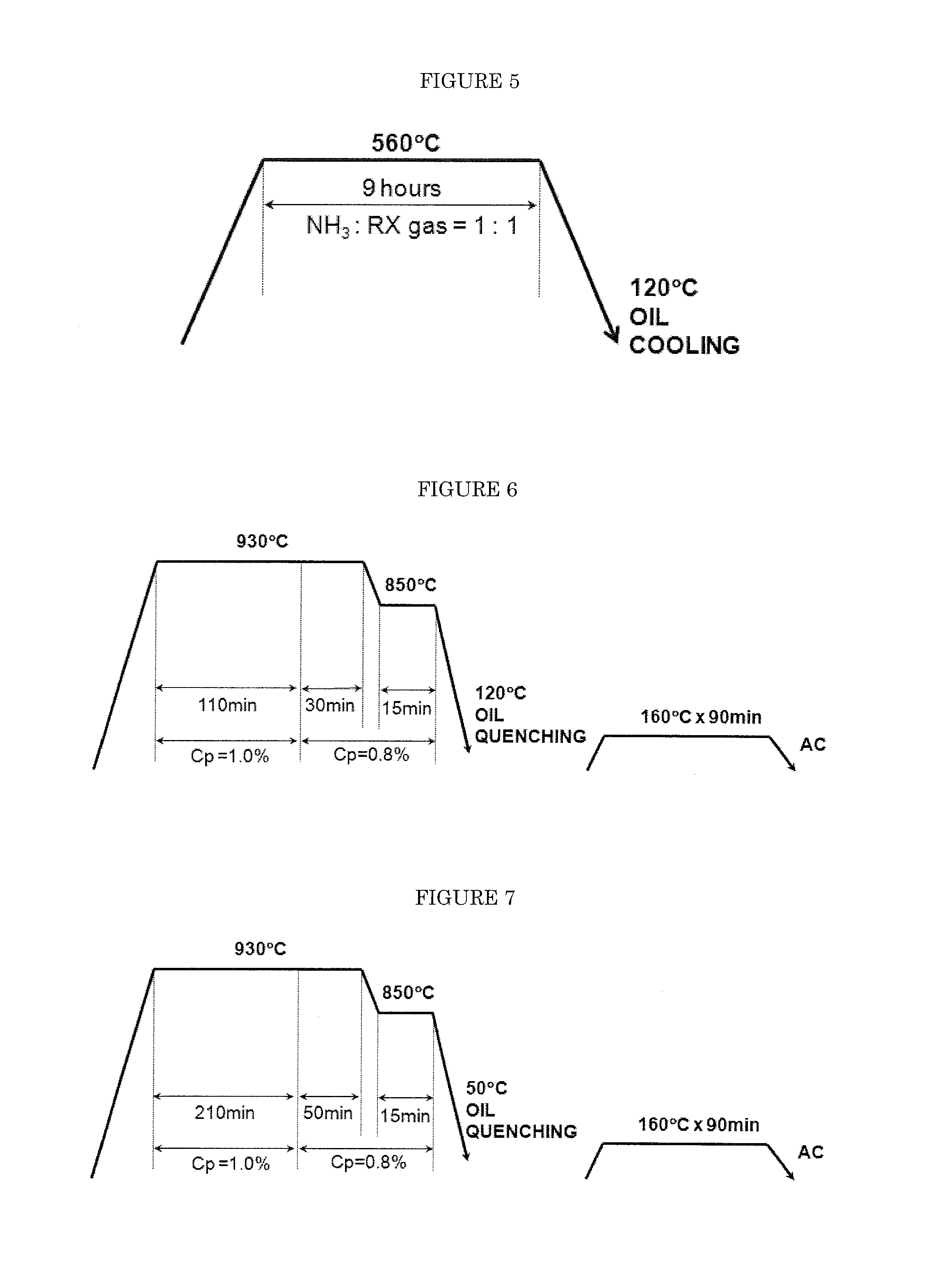

Method and device for detecting sample axle through ultrasonic

ActiveCN105092702AAnalysing solids using sonic/ultrasonic/infrasonic wavesSurface fatigueUltrasonic technology

The invention relates to a method and device for detecting a sample axle through ultrasonic. The method comprises the steps that by means of a detected sample axle, a sensitivity compensation value which is discrepant with an axle of a physical locomotive vehicle to be maintained is obtained, correction is conducted on an ultrasonic fault detector, and the situation that defects of fatigue cracks of a wheel seat part, an axle journal part and a gear seat part of the axle of the locomotive vehicle can be rapidly and accurately detected by adopting an ultrasonic technology under the condition that a wheel set of a locomotive under repairing is not disassembled is achieved. When the axles of a large number of locomotive vehicles under repairing need to be detected on the surface fatigue cracks through the ultrasonic technology, the axles of the locomotive vehicles under repairing can be detected correspondingly on the premise of not being disassembled. By means of the method for detecting the sample axle through the ultrasonic, the detection result is accurate and reliable, detection can be achieved without disassembling the wheel set, therefore, the detection efficiency is greatly improved, and meanwhile the detection cost is reduced.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Steel for nitriding and nitrided component

InactiveUS20140034194A1Easy to implementHigh bending fatigue strengthSolid state diffusion coatingFurnace typesChemical compositionSurface fatigue

A steel for nitriding having a chemical composition consisting of, by mass percent, C: 0.07-0.14%, Si: 0.10-0.30%, Mn: 0.4-1.0%, S: 0.005-0.030%, Cr: 1.0-1.5%, Mo: ≦0.05% (including 0%), Al: 0.010% or more to less than 0.10%, V: 0.10-0.25%, optionally at least one element selected from Cu: ≦0.30% and Ni: ≦0.25% [0.61Mn+1.11Cr+0.35Mo+0.47≦2.30], and the balance of Fe and impurities. P, N, Ti and O among the impurities are P: ≦0.030%, N: ≦0.008%, Ti: ≦0.005%, and O: ≦0.0030%. The steel is easily subjected to cutting before nitriding and suitable for use as an automobile ring gear. The nitrided component having a surface hardness of 650-900 HV, core hardness being ≧150 HV, and effective case depth of ≧0.15 mm has excellent bending fatigue strength and surface fatigue strength although the content of Mo is as low as ≦0.05% and has a small amount of expansion caused by nitriding.

Owner:NIPPON STEEL CORP +1

Flexible film laser cladding reinforcing method of die-casting die

ActiveCN110042390AImprove performanceExtend your lifeMetallic material coating processesSurface fatigueDie casting

The invention discloses a flexible film laser cladding reinforcing method of a die-casting die. The method includes the steps that the die-casting die is detected comprehensively, and the abrasion loss of the die is determined; a surface fatigue wear layer is removed, and machining surface impurities are removed; alloy powder is prepared, the alloy powder is prearranged on the surface of the to-be-clad die-casting die, a prearranged flexible film is scanned through a laser, and a wearproof laser cladding layer is prepared; and the surface of the cladding layer is nondestructively detected, andthe cladding layer is ground and polished. By means of the method, the utilization rate of the powder in the cladding process is increased, it is guaranteed that the powder is uniformly conveyed, thereinforcing cost is reduced, and the service life of the repaired die-casting die is prolonged by one time or above compared with a conventional repairing method.

Owner:YANSHAN UNIV

Bainite type rail excellent in surface fatigue damage resistance and wear resistance

High-strength bainitic steel rails have improved resistances to surface fatigue failures and wear required of the head of rails for heavy-load service railroads. The high-strength bainitic steels rails having excellent resistances to surface fatigue failures and wear contain constituents of specific ranges and consisting of bainitic structures at least in part are characterized in that the total area occupied by carbides whose longer axes are 100 to 1000 nm in a given cross section of said bainitic structures accounts for 10 to 50 percent thereof.

Owner:NIPPON STEEL CORP

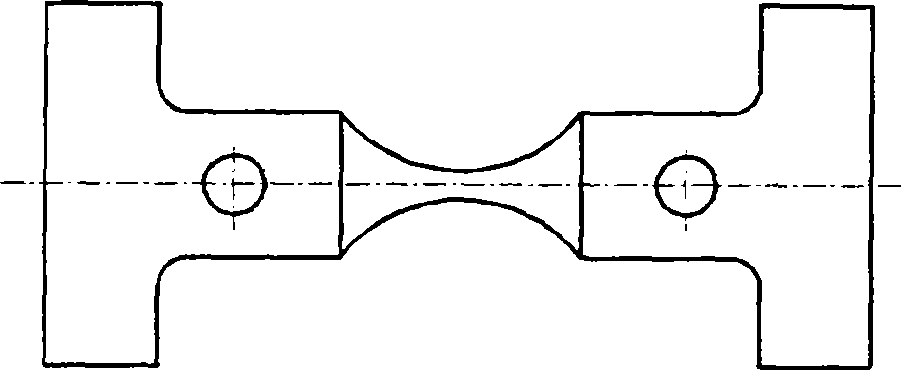

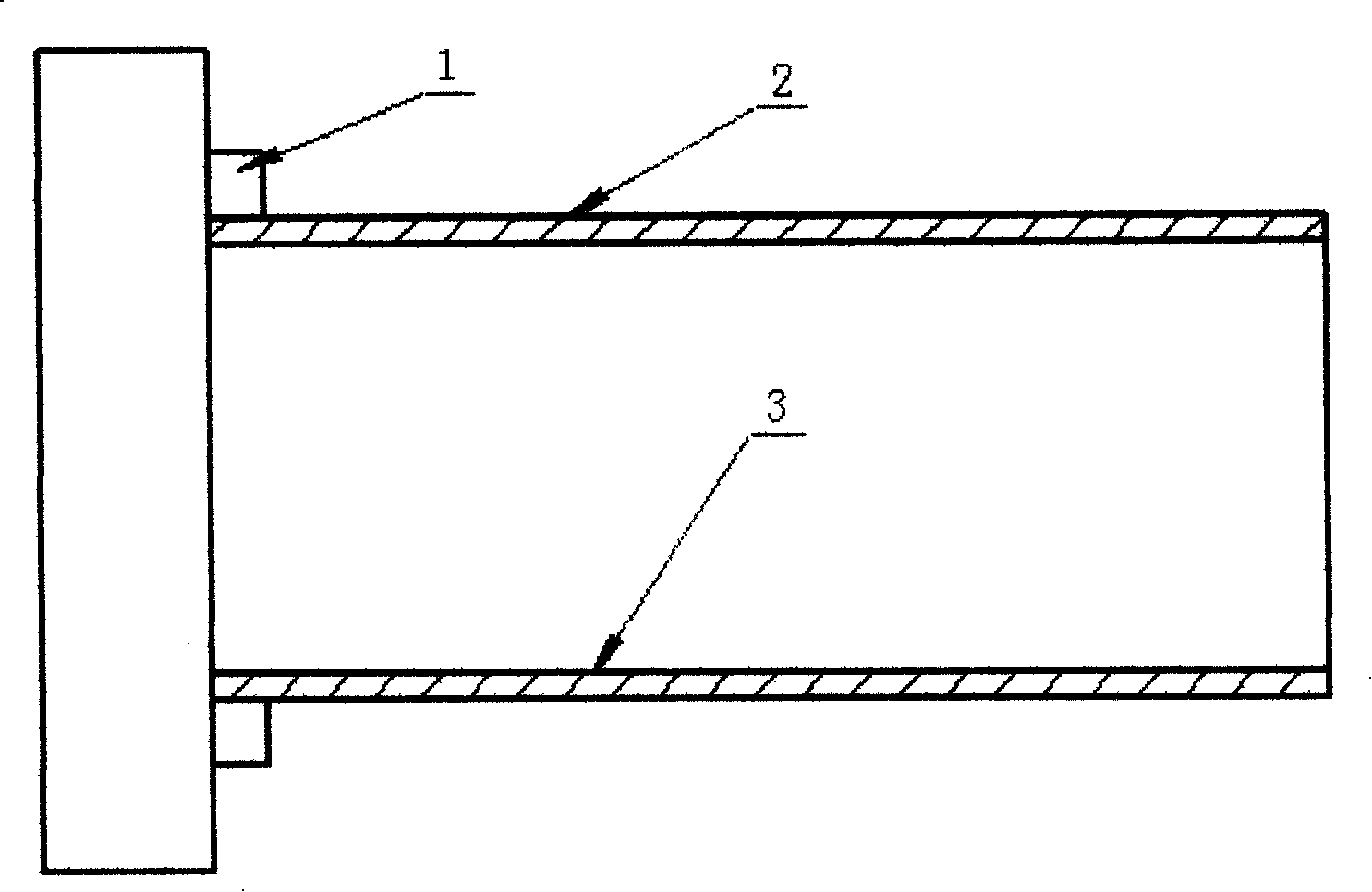

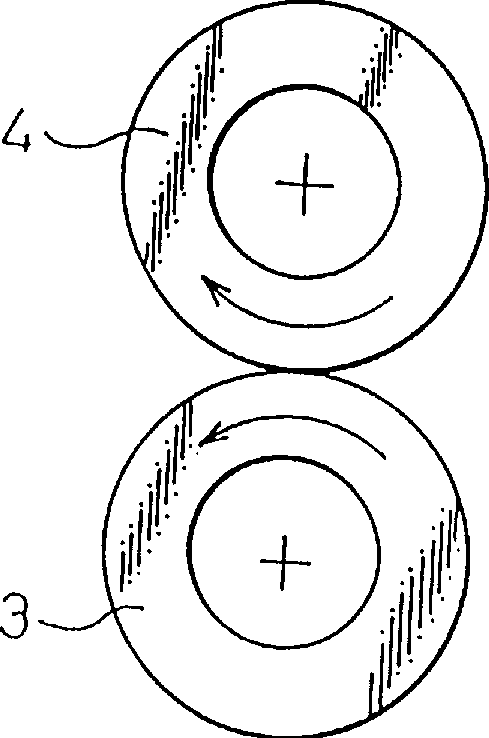

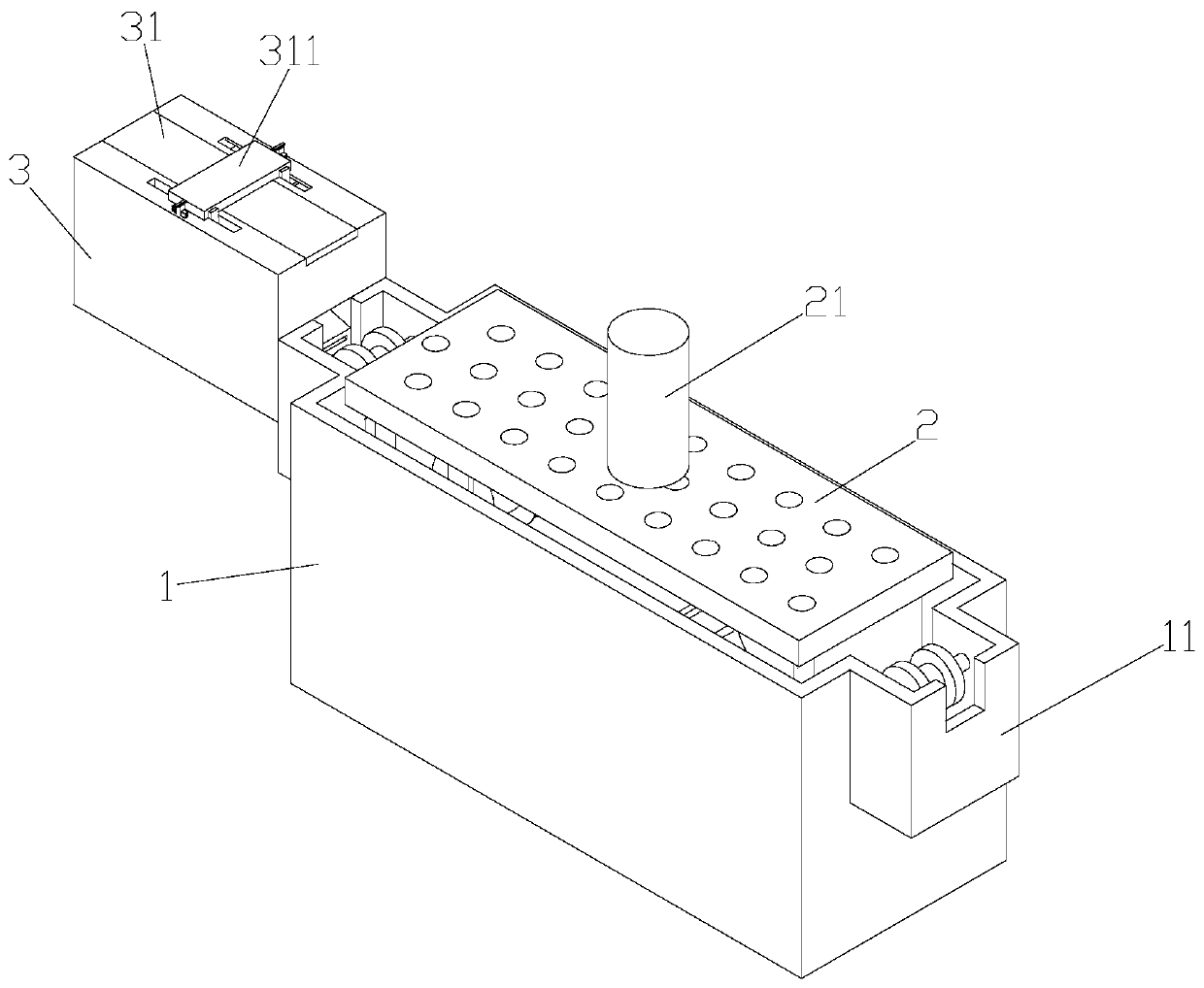

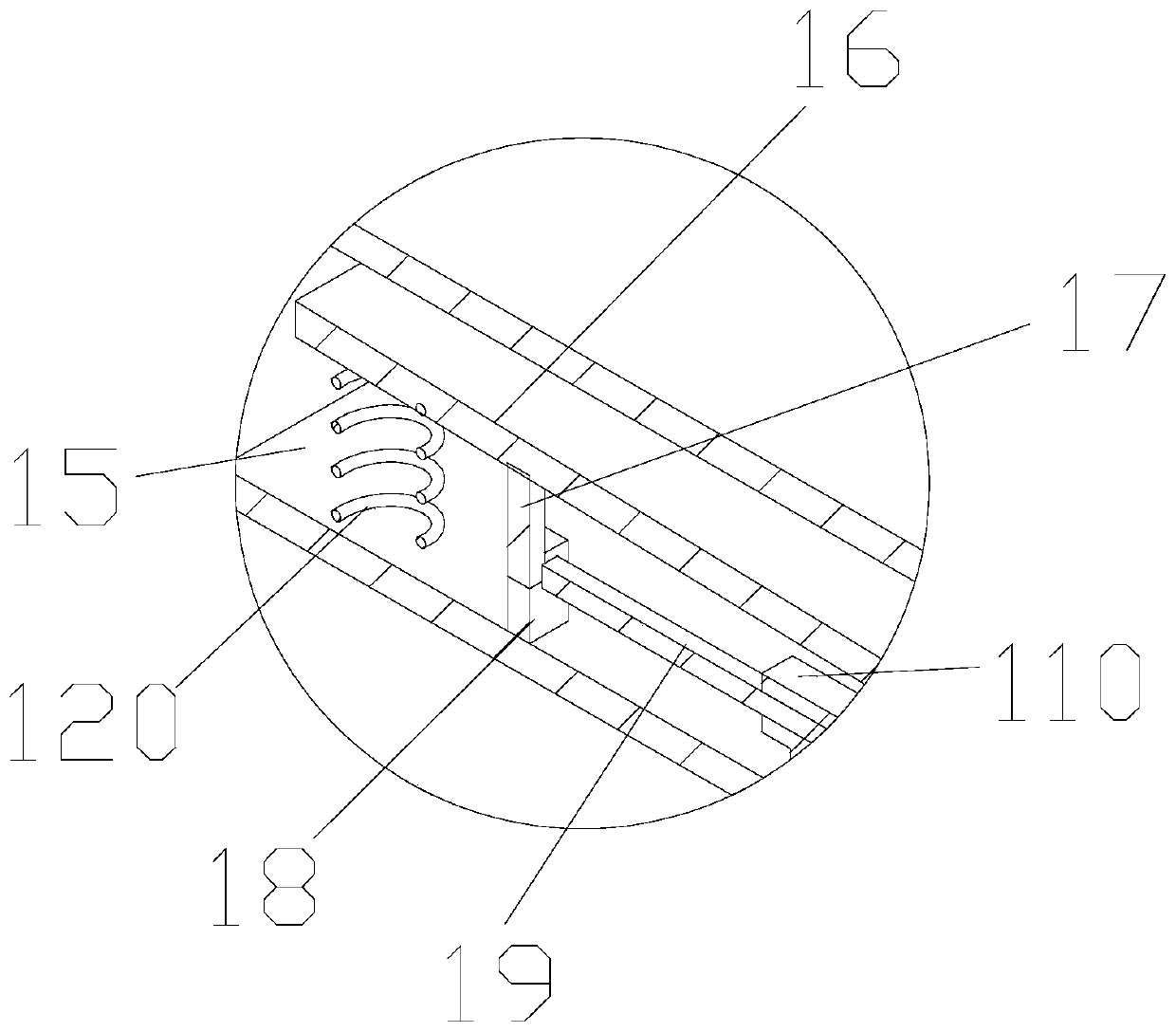

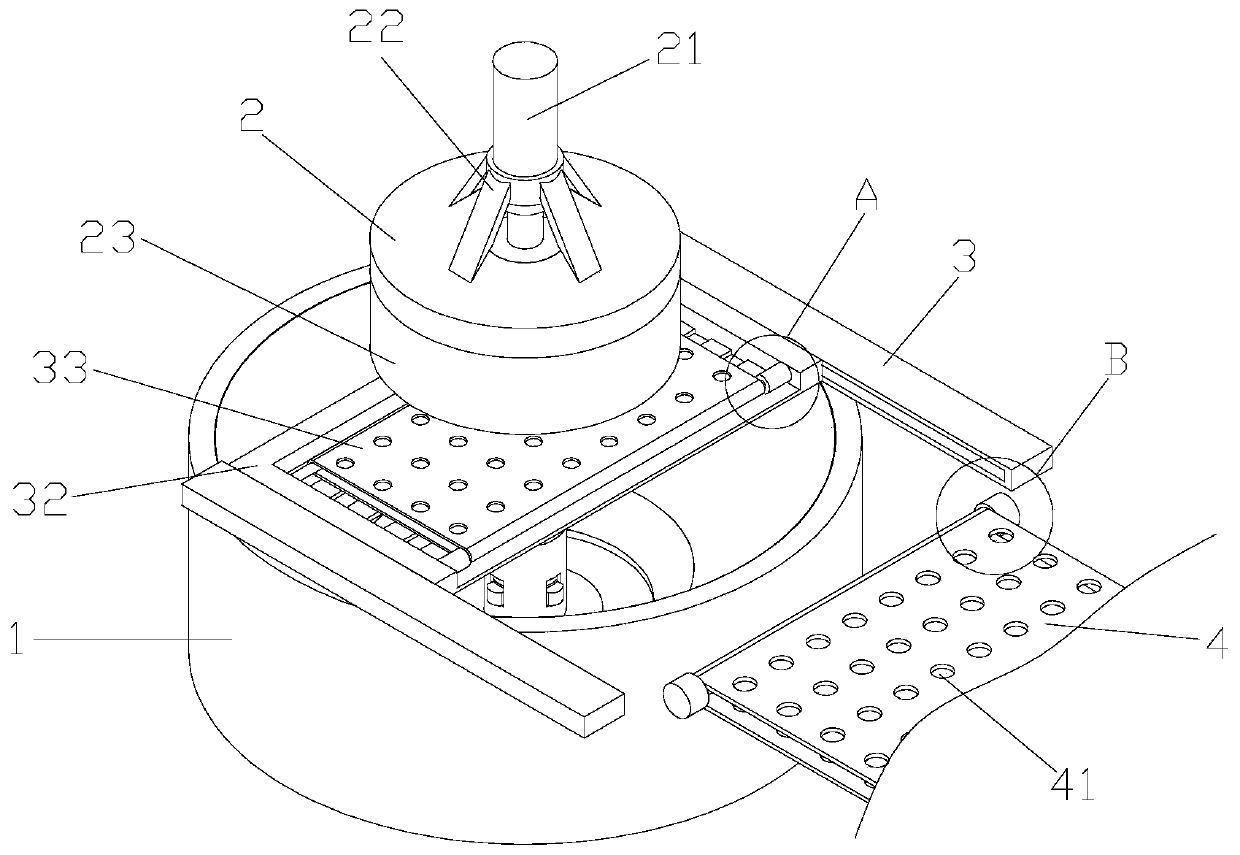

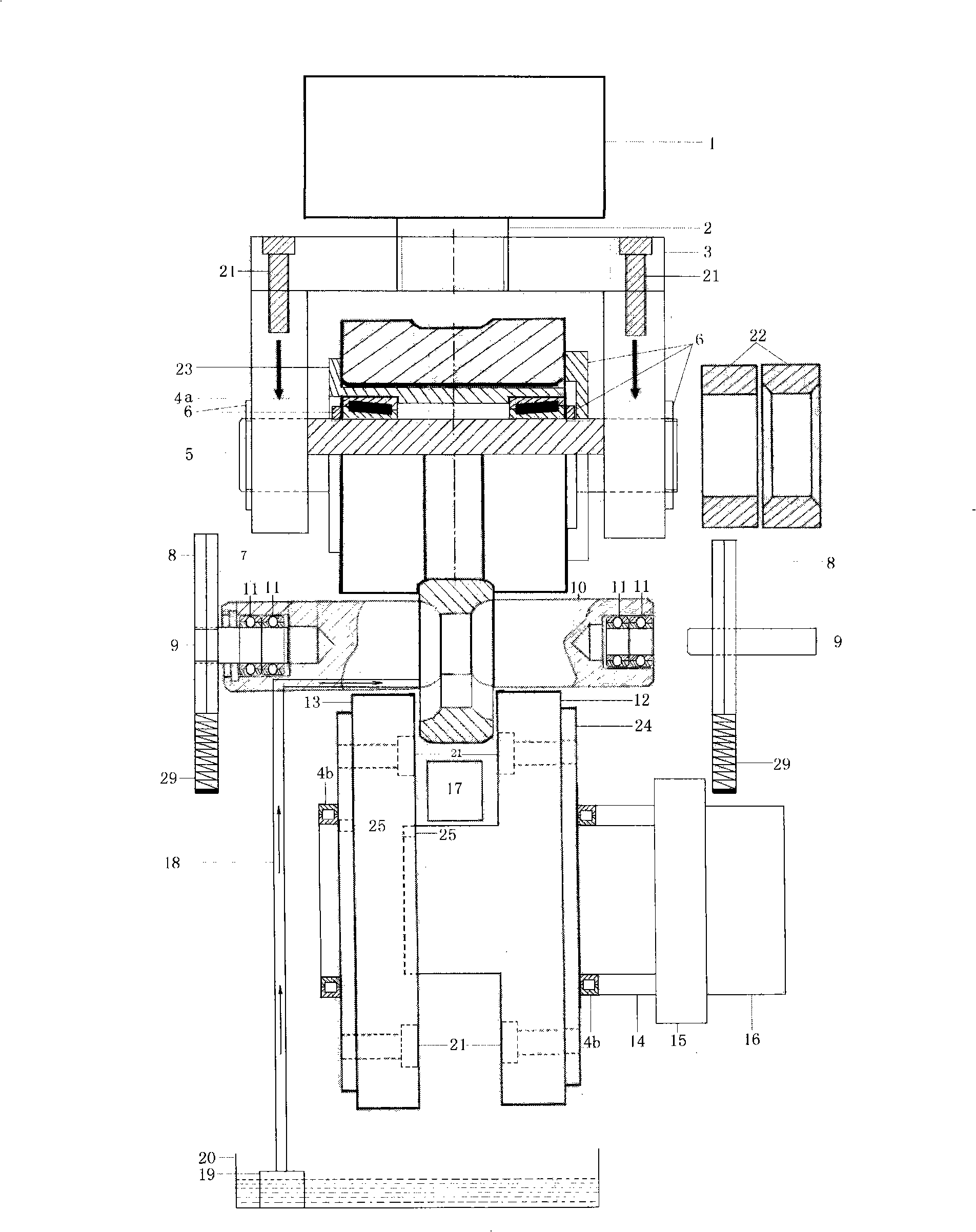

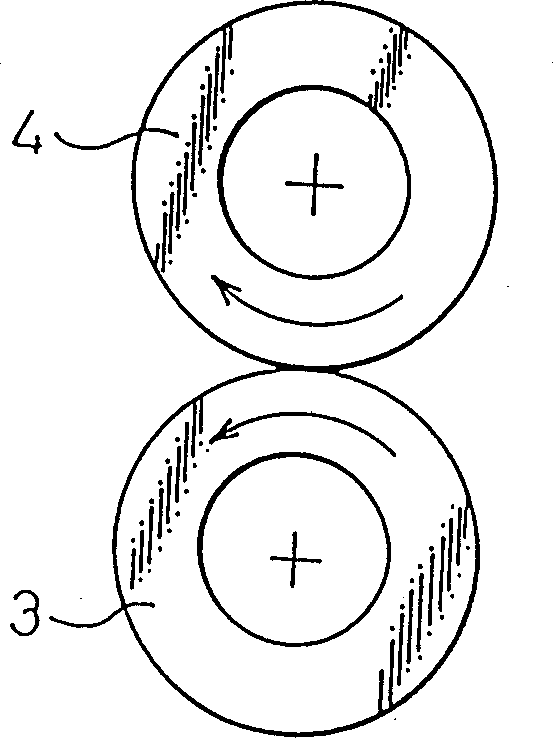

Rolling contact fatigue testing machine

InactiveCN105571862AStructure directlySimple structureMachine bearings testingFatigue testingSurface fatigue

The invention relates to a rolling contact fatigue testing machine, and the machine is mainly used to carry out rapid fatigue test on rolling contact in the plane strain state. The fatigue testing machine can effectively simulate fatigue of a component with plane-strain rolling contact feature and evaluate and select processing parameters for forming the rolling contact surface, and is thus an ideal testing machine to research on the surface fatigue failure mechanism of materials. The fatigue testing machine is composed of a frame body, a linear guide rail, a sliding platform, linear motors, a loading platform and a loading mechanism, multiple strip-shaped samples can be placed on the sliding platform on the linear guide rail, and one or multiple cylindrical rolling bodies is / are arranged in the lower portion of the loading platform correspondingly. During test, the loading mechanism enables the samples make contact with the rolling bodies in certain pressure, the linear motors drive the sliding platform to make reciprocating movement in certain amplitude, and the fatigue condition of the samples can be observed after certain period.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com