Rolling contact fatigue testing machine

A technology of rolling contact fatigue and testing machine, which is applied in the direction of mechanical bearing testing, etc. It can solve the problems of unsuitable fatigue performance state, unsuitable for rolling contact fatigue failure, unable to quickly evaluate and select, etc., and achieve the effect of direct structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

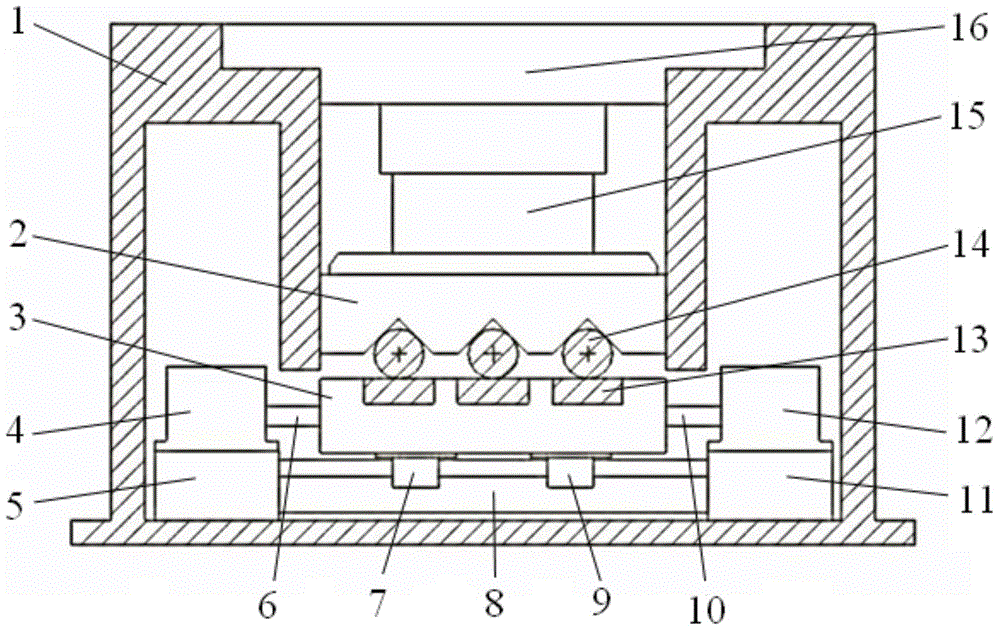

[0027] A rolling contact fatigue testing machine whose structure is as follows figure 1 As shown, it mainly includes a frame body 1, a loading platform 2, a sliding platform 3, a linear motor 4, a linear guide 8, a linear motor 12, a loading mechanism 15, a loading mechanism 16, and the like. The frame body 1 mainly plays the role of stability and structural support. It wraps other parts of the experimental machine inside. Due to the force and vibration, it should be firmly connected to the desktop during use. The bottom of the frame body 1 is horizontally fixed with a linear guide 8 and a matching sliding block 7, a sliding block 9; the sliding platform 3 is fixed on the sliding block 7, the sliding block 9 and slides horizontally along the linear guide 8; the sliding block 7, the sliding block 9 Via the connecting rod 6, the connecting rod 10 is connected with the linear motor 4 and the linear motor 12. The linear motor 4 and the linear motor 12 are respectively fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com