Hand-push type straw crop harvester

A harvester, hand-push technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inaccessibility of machinery, slow harvesting speed, and inability of farmers to use machinery and machinery, so as to achieve direct structure and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

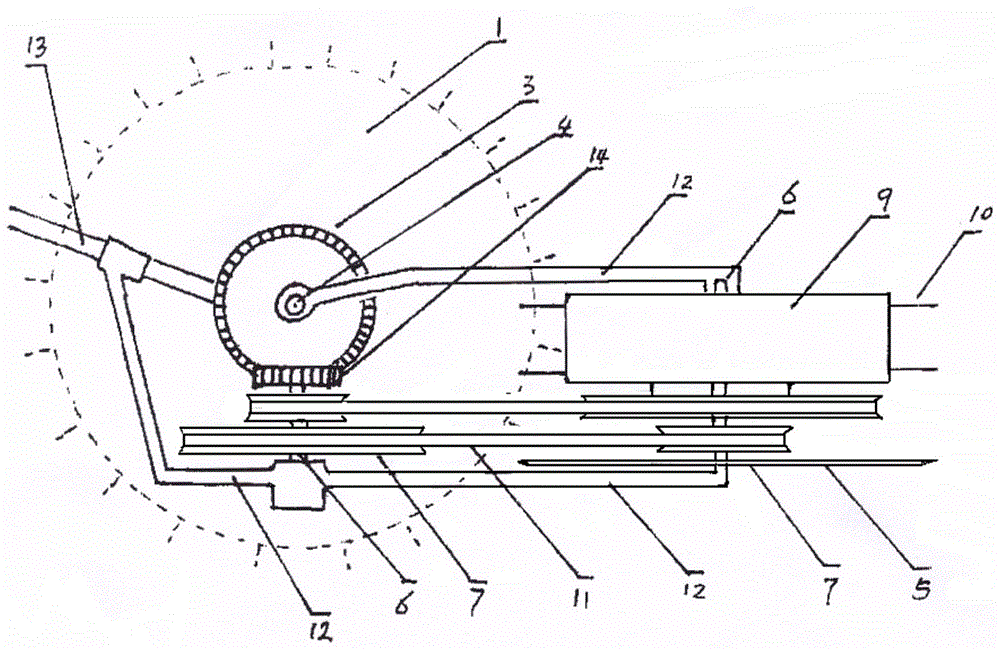

[0013] Below in conjunction with accompanying drawing and embodiment human power mower is further described.

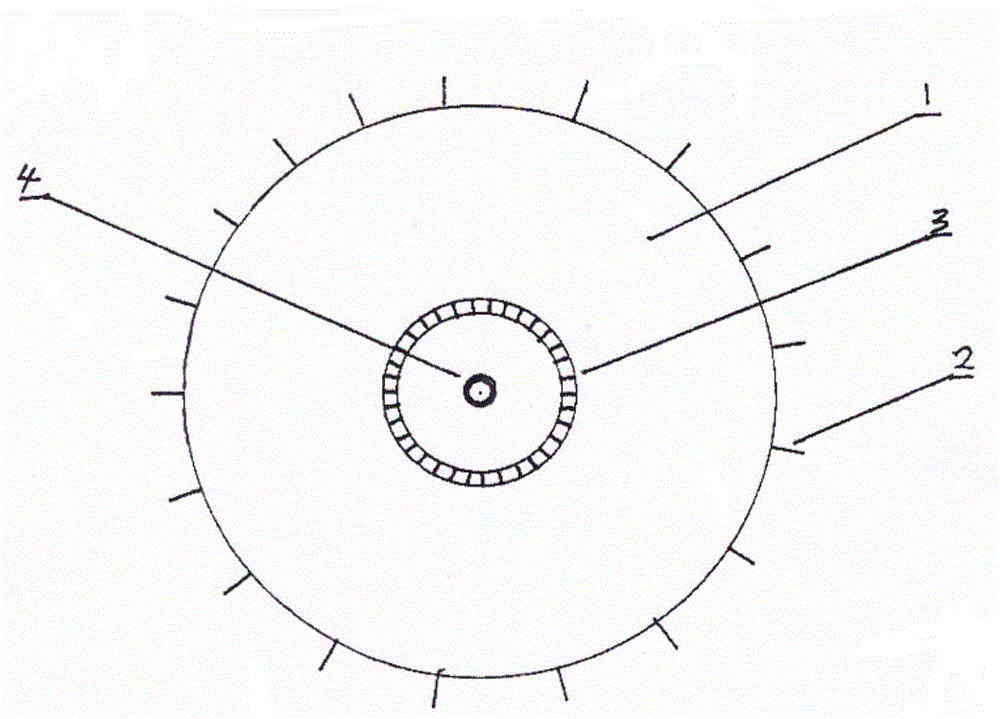

[0014] figure 1 It is a circular plan view of a non-slip traveling wheel of a hand-push straw crop harvester and the gears connected in parallel with it. The circumference of the anti-skid walking wheel (1) in the figure is inserted with a lot of anti-skid rods (2), and these anti-skid rods (2) can be inserted into the soil due to gravity when the hand-push straw harvester is walking to make the road wheel and the ground No slippage occurs. Parallel with the anti-skid road wheel (1) is a gear (9) vertical to the ground, and it is fixed on the connecting shaft (4) in parallel with the anti-skid road wheel (1), and the vertical gear (3) is vertical when the anti-skid road wheel (1) walks ) also rotates coaxially.

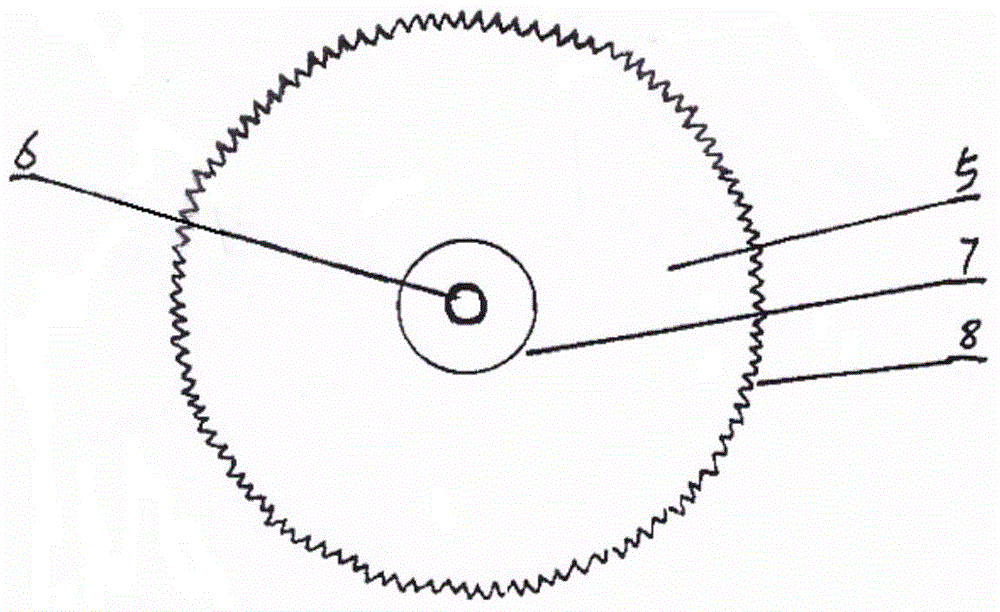

[0015] figure 2 It is a circular plan view of the low cutting wheel (5) of the hand-push straw harvester. The circumference of the low position cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com