A rotor tilting mechanism and a belt type sealing mechanism for the rotor tilting mechanism

A technology of a rotor tilting and sealing mechanism, which is applied in the aviation field, can solve the problems of difficulty in sealing, cannot ensure the reliability of liquid lubrication and sealing, and achieves the effect of reducing the structure and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

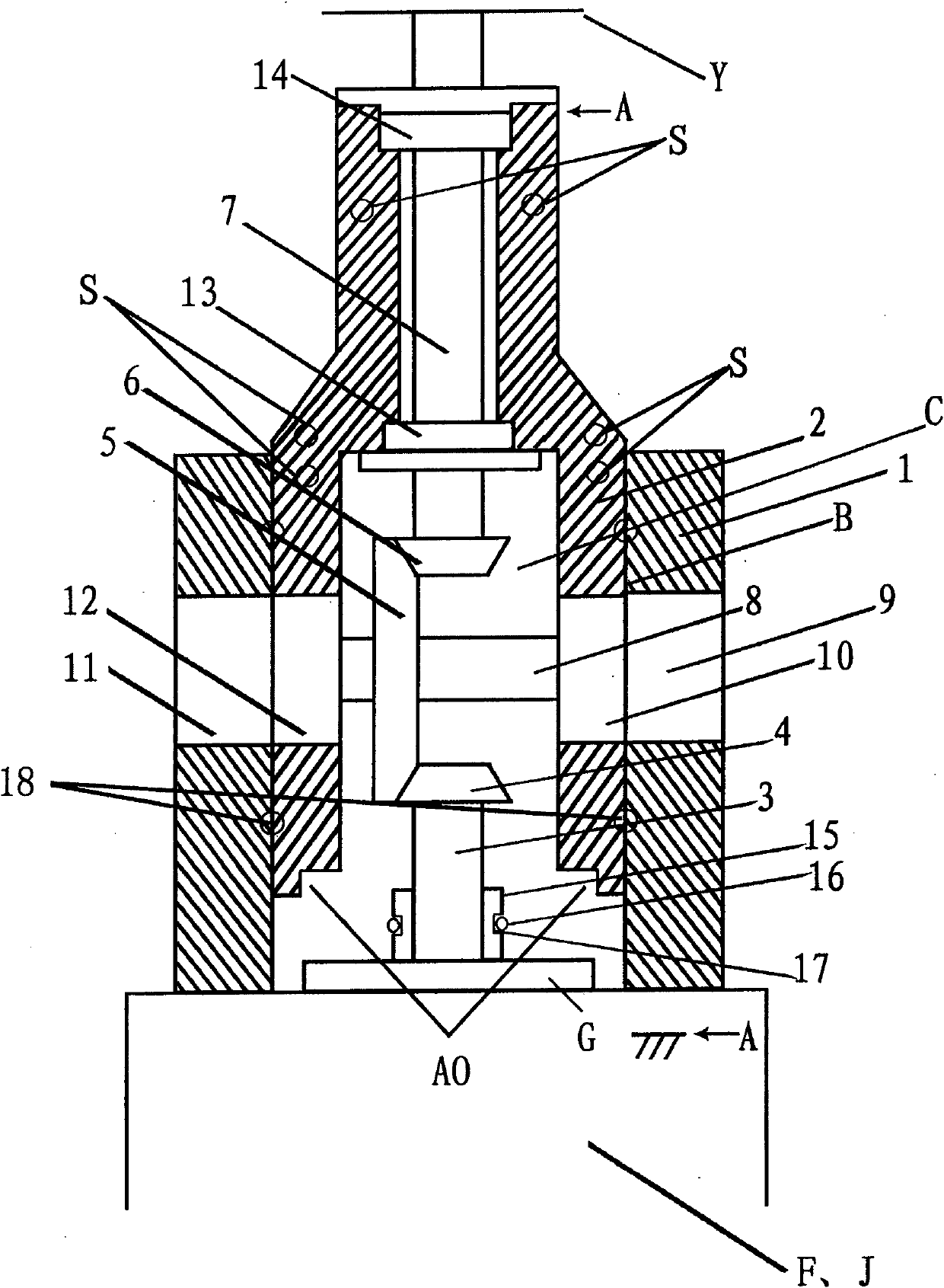

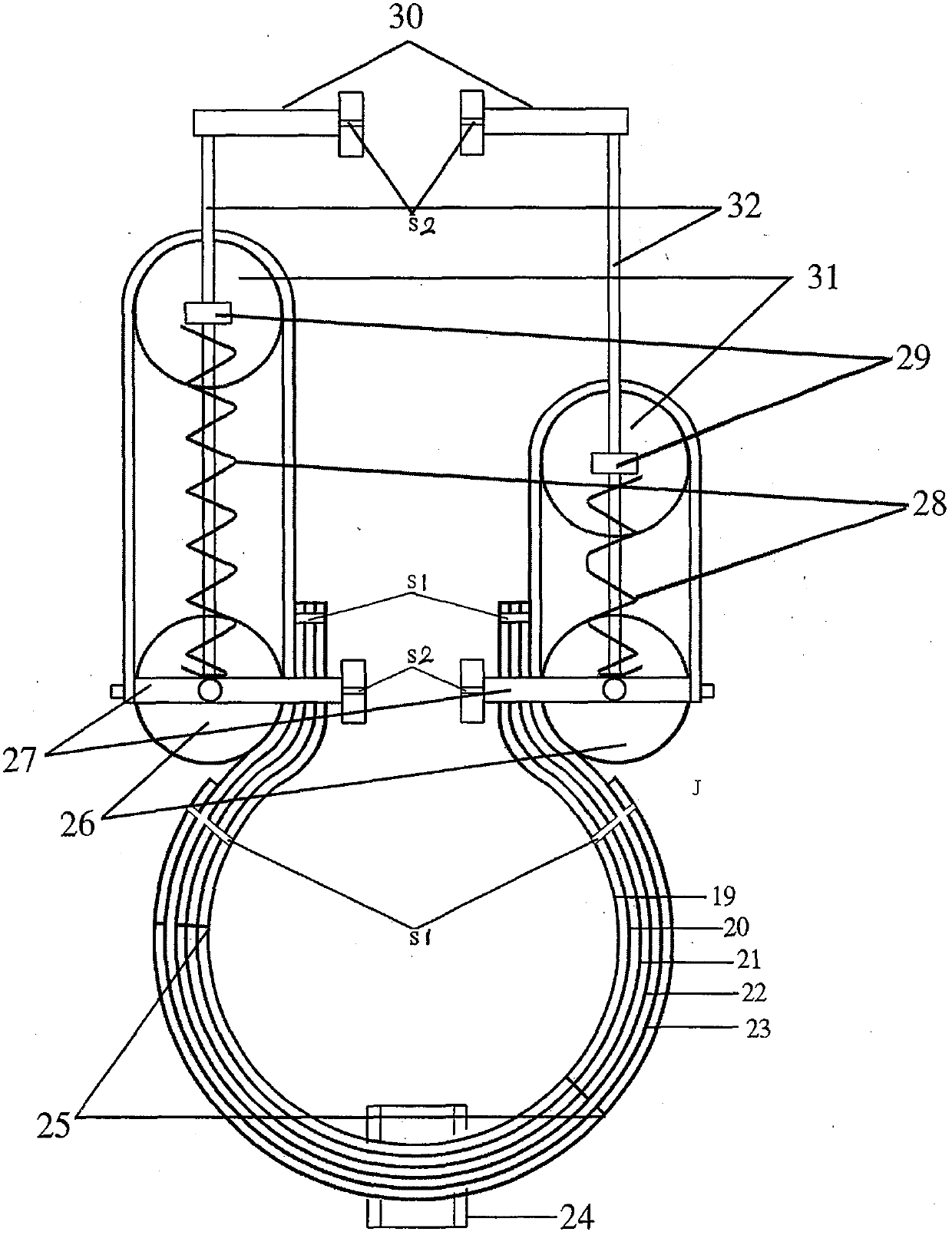

[0019] A tilting mechanism: engine FJ, rotor Y, the engine FJ is connected to the bottom of the support 1, and the support 1 is respectively connected to the outer surfaces of the left and right sides of the lower end of the tilting arm 2, and the tilting arm 2 is connected to the rotor Y, and between the inner sides of the left and right sides of the lower end of the tilting arm 2 is an arc-shaped gearbox C, and the arc-shaped end surface of the arc-shaped gearbox C is wrapped and connected by a belt-type sealing mechanism.

[0020] Said arc-shaped gearbox C is equipped with a cross shaft 8, said cross shaft 8 is provided with power transition bevel gear 5, bearing one 9, bearing two 10, bearing three 11, bearing four 12, wherein cross shaft 8 Respectively through the bearing three 11 and bearing one 9 and the support 1 on the left and right sides of the lower end of the tilting arm 2, and also through the bearing four 12 and bearing two 10 respectively connected with the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com