Tilting mechanism and sealing mechanism

A technology of sealing mechanism and tilting mechanism, which is applied in the aviation field, can solve problems such as difficult sealing and inability to ensure the reliability of liquid lubricated sealing, and achieve the effect of reducing structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

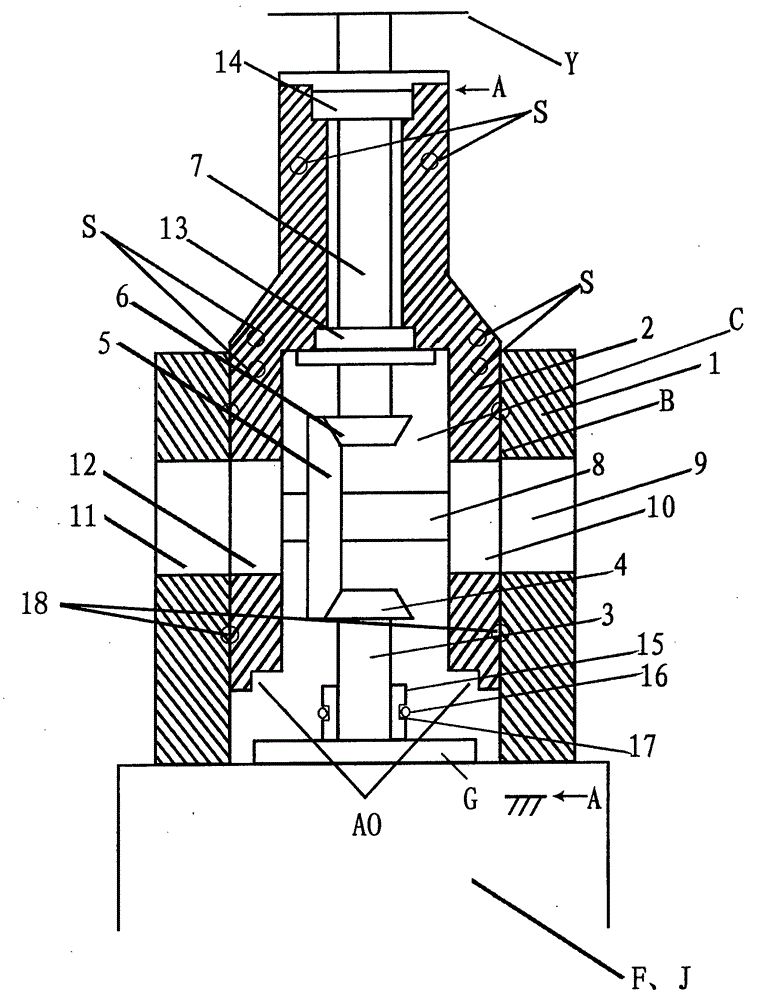

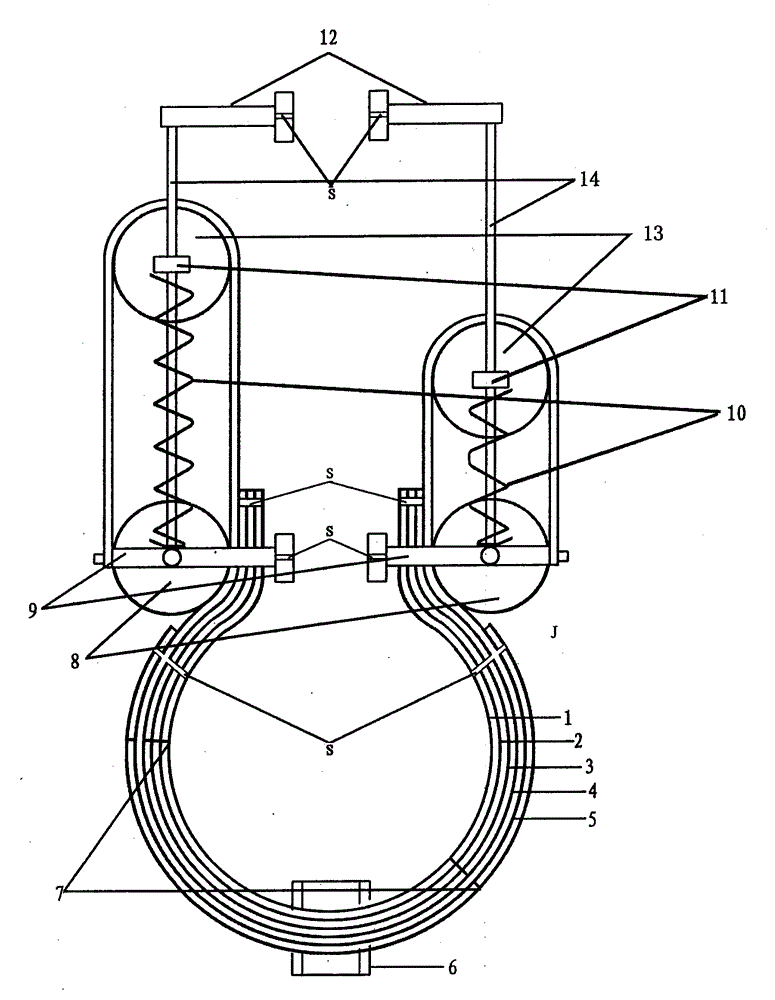

[0025] A tilting mechanism and a sealing mechanism, comprising: an engine FJ and a rotor Y, the engine FJ is connected to a support 1, the support 1 is connected to a tilting arm 2, and the tilting arm 2 is connected to The connection of the support 1 is a gearbox C, and the gearbox C is connected to the sealing mechanism J.

Embodiment 2

[0027] A tilting mechanism and a sealing mechanism described in Embodiment 1, a horizontal shaft 8 is installed in the gearbox C, and a power transition bevel gear 5 and bearings 9, 10, 11 are installed on the horizontal shaft 8 , 12, the power bevel gear 5 below is connected to the power bevel gear 4, the power bevel gear 4 is connected to the engine power shaft 3, the power bevel gear 5 is connected to the power output bevel gear 6, and the The power output bevel gear 6 is connected to the power output shaft 7, the power output shaft 7 is connected to the tilt arm 2 through the bearings 13, 14, and the power output shaft 7 is connected to the rotor Y.

Embodiment 3

[0029] Embodiments 1 and 2, a tilting mechanism and a sealing mechanism, the engine power shaft 3 has a bearing gland G, and the front end of the bearing gland G is in a convex shape 15, and the There is an O-ring groove 17 on the convex shape 15 of the garden, and an O-ring 16 is set in the described sealing groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com