Stress intensity factor-based Method for estimating fatigue damage degree of subsurface of bearing roller path

A technology of stress intensity factor and fatigue damage, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high test cost and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

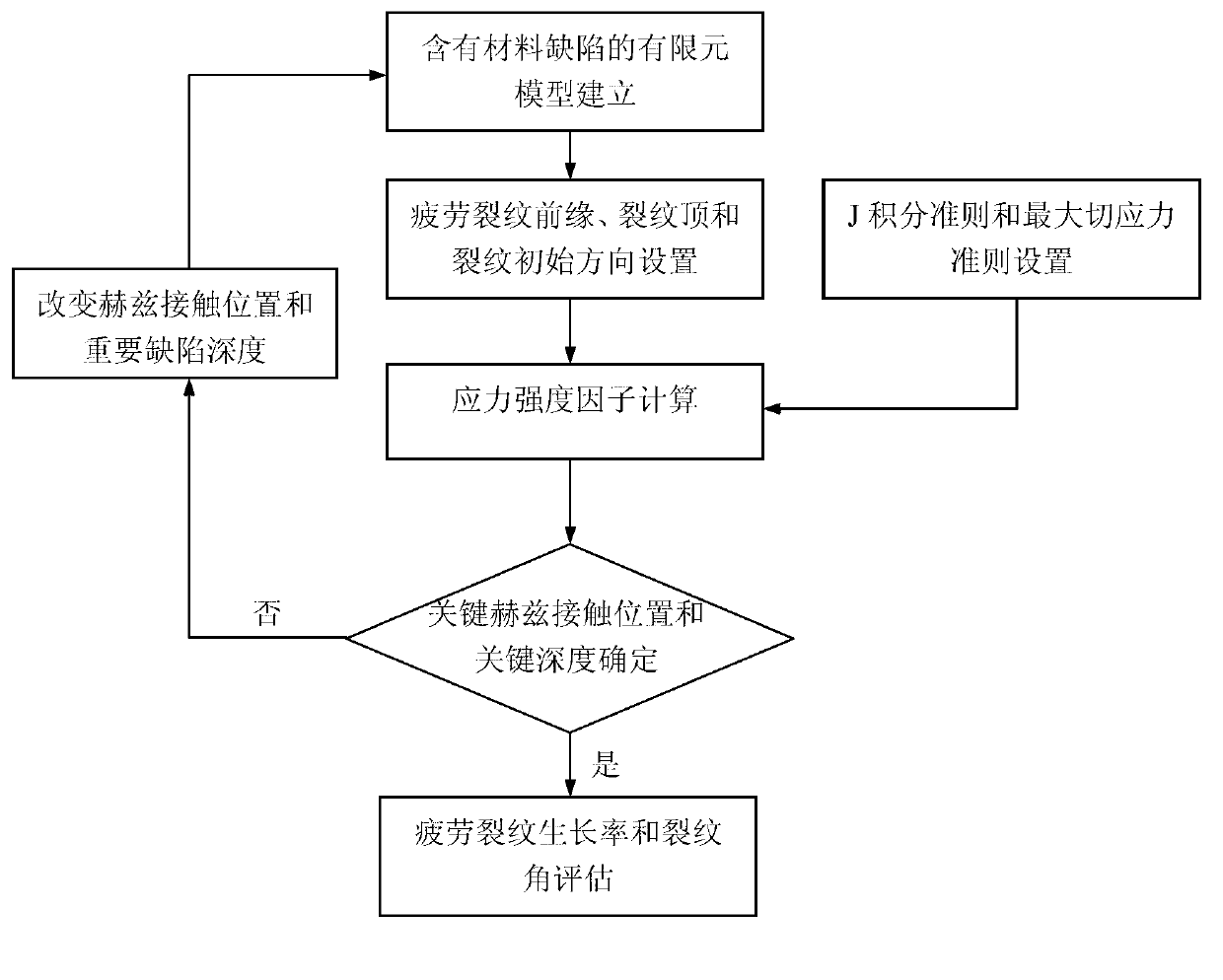

[0040] Such as figure 1 As shown, the method for evaluating the fatigue damage degree of the subsurface of the bearing raceway based on the stress intensity factor of the present invention includes the following steps:

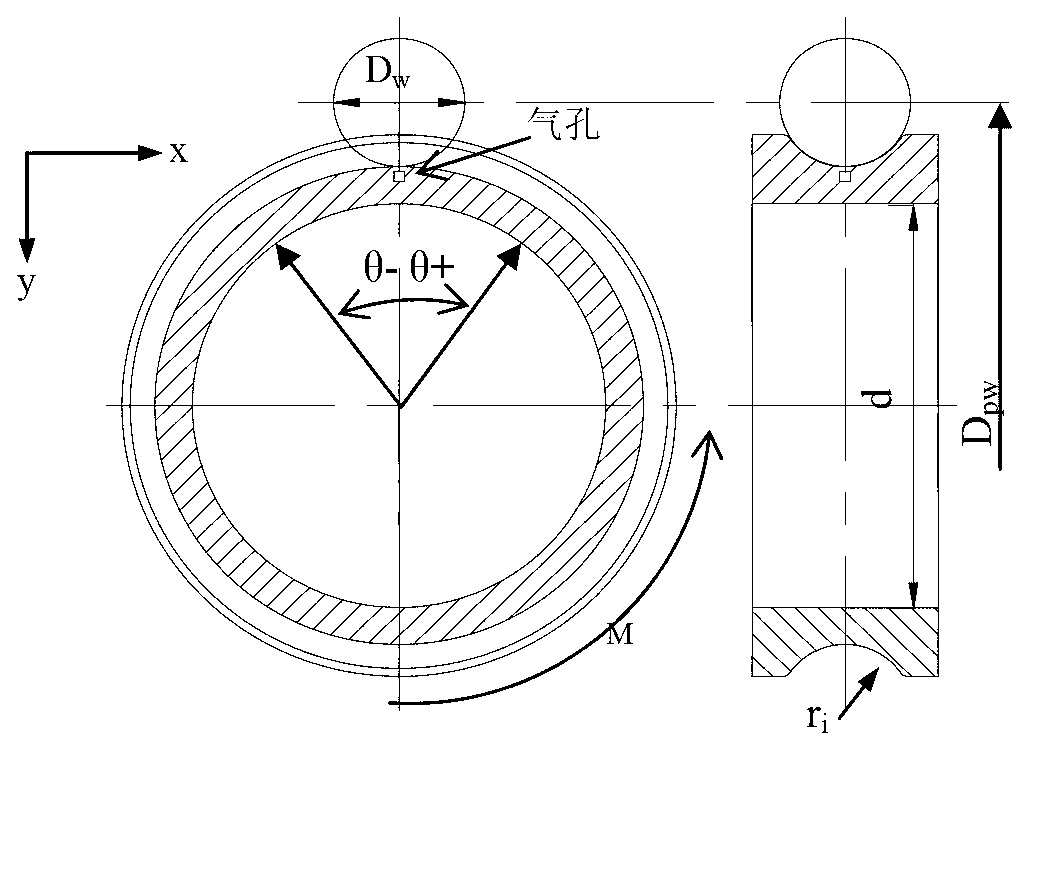

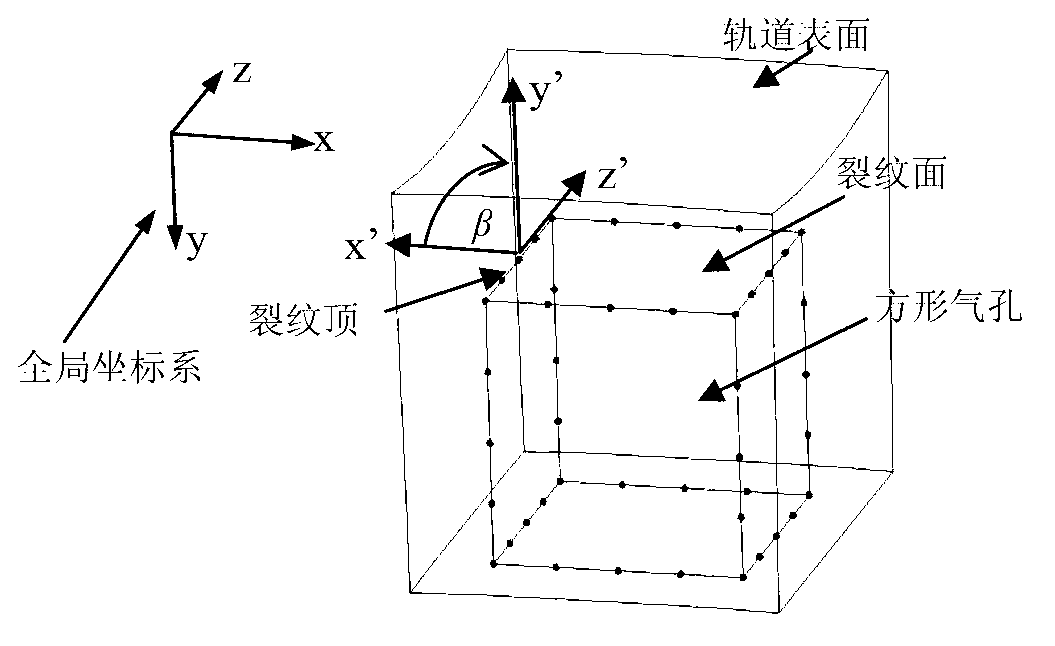

[0041] S1. Establish a bearing model with material defects. In this example, it is a 6208 deep groove ball bearing. The bearing material is GCr15. The bearing inner ring with material defects is as follows figure 2 As shown, the material defect is a square air hole, which is arranged on the subsurface of the raceway, and the subsurface of the raceway refers to the area about several hundred microns deep below the surface of the raceway. The bearing model is divided into meshes, and the crack initiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com