Detection method of closed surface fatigue crack

A detection method and technology for fatigue cracks, which can be used in measuring devices, solid analysis using sound waves/ultrasonic waves/infrasonic waves, and material analysis using sound waves/ultrasonic waves/infrasonic waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

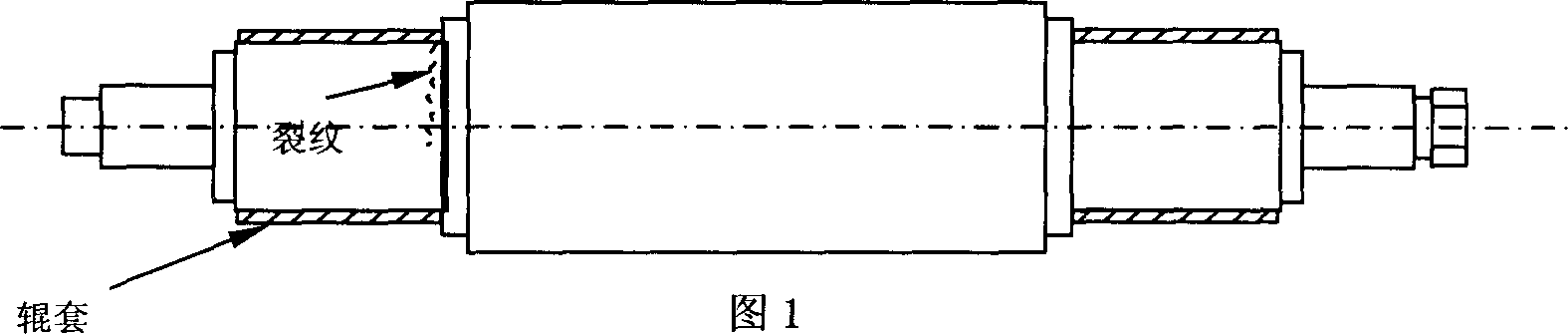

[0010] A method for detecting fatigue cracks on a closed surface, using the ultrasonic pulse reflection method to detect shaft defects by emitting ultrasonic waves from a direction perpendicular to the end face of the roll neck; and receiving detection signals by a probe with a small diffusion angle and good directivity. It can be displayed on the screen of the flaw detector, and the position and equivalent size of the defect can be obtained according to the echo signal. Among them, the instruments used are the latest SS240 and MS340 flaw detectors developed by the British SONATEST company. These two instruments have high precision, and when detecting flaws under high sensitivity conditions, the electric noise of the instrument is extremely low, the waveform signal is stable, and the operation is simple. Probe selection to meet site requirements is another important part. Ultrasonic vibration frequency is much higher than audible sound waves, and is generated by the transduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com