Method and apparatus for processing positive displacement drill bearing

A technology of screw drilling tools and bearings, applied in the direction of feeding devices, manufacturing tools, metal processing equipment, etc., can solve the problems of accelerated tool damage, deep pit curling on the surface, large tool turning area, etc., and achieve enhanced layer density Increased height, uniform subgrain structure refinement, and continuous and complete metal streamlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

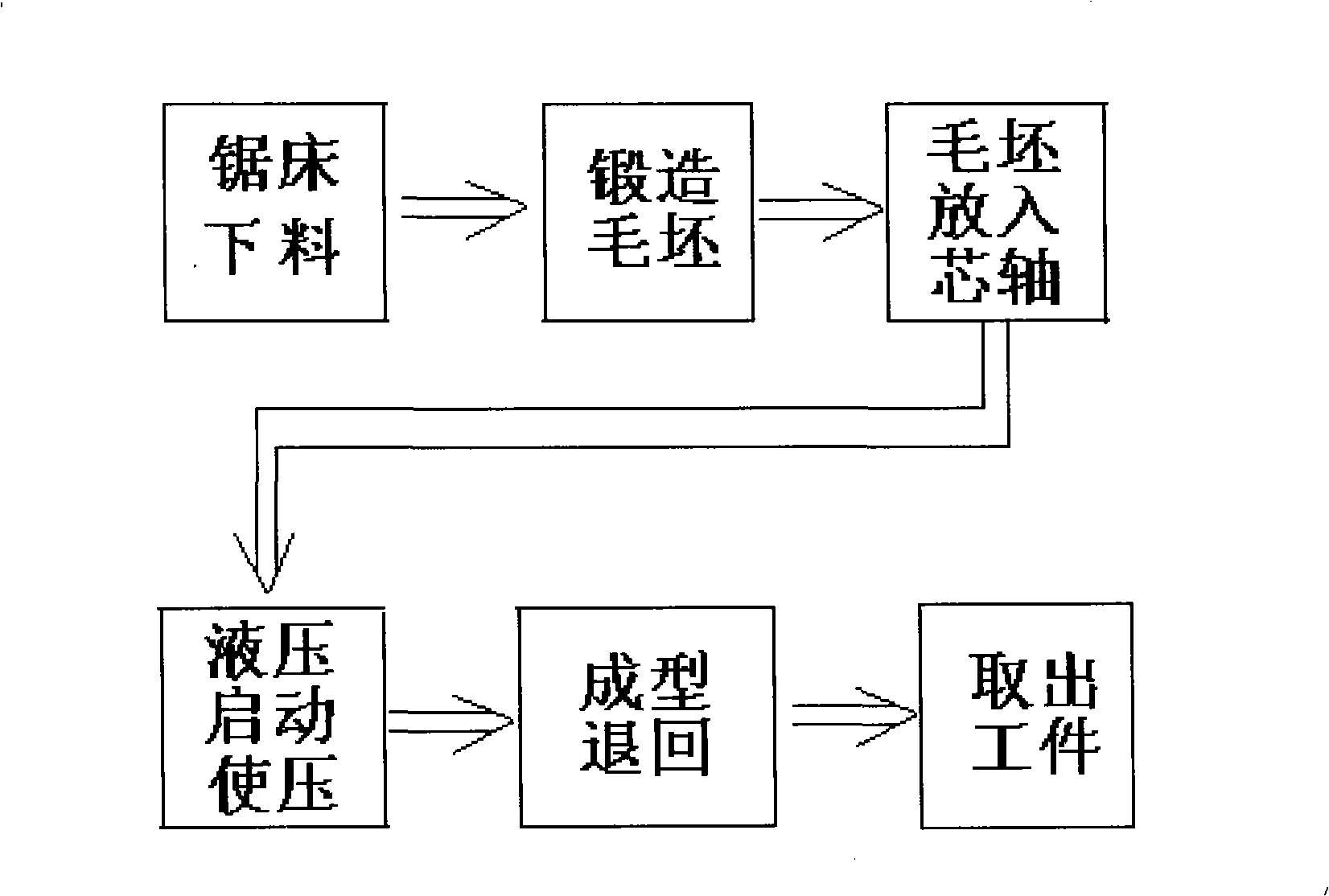

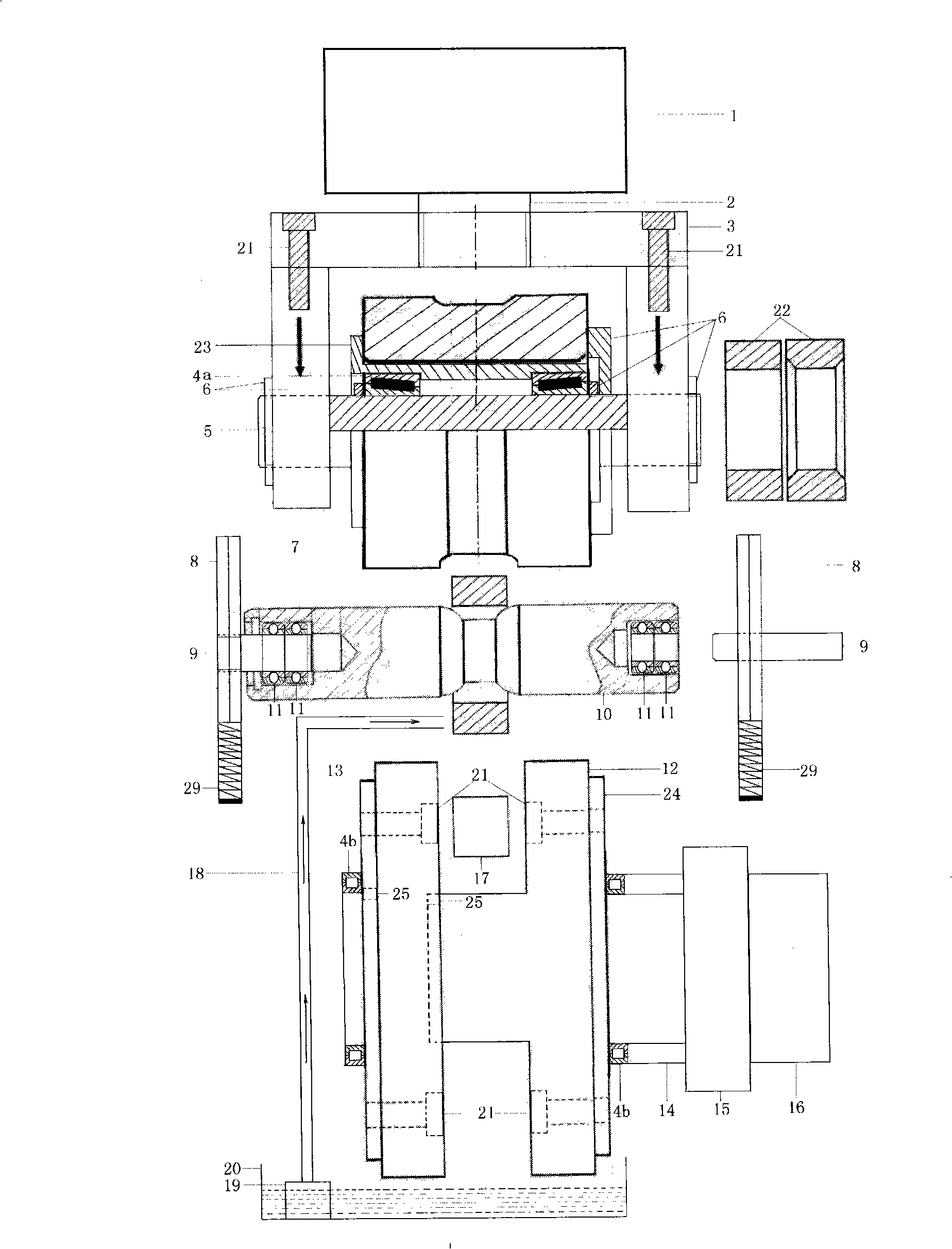

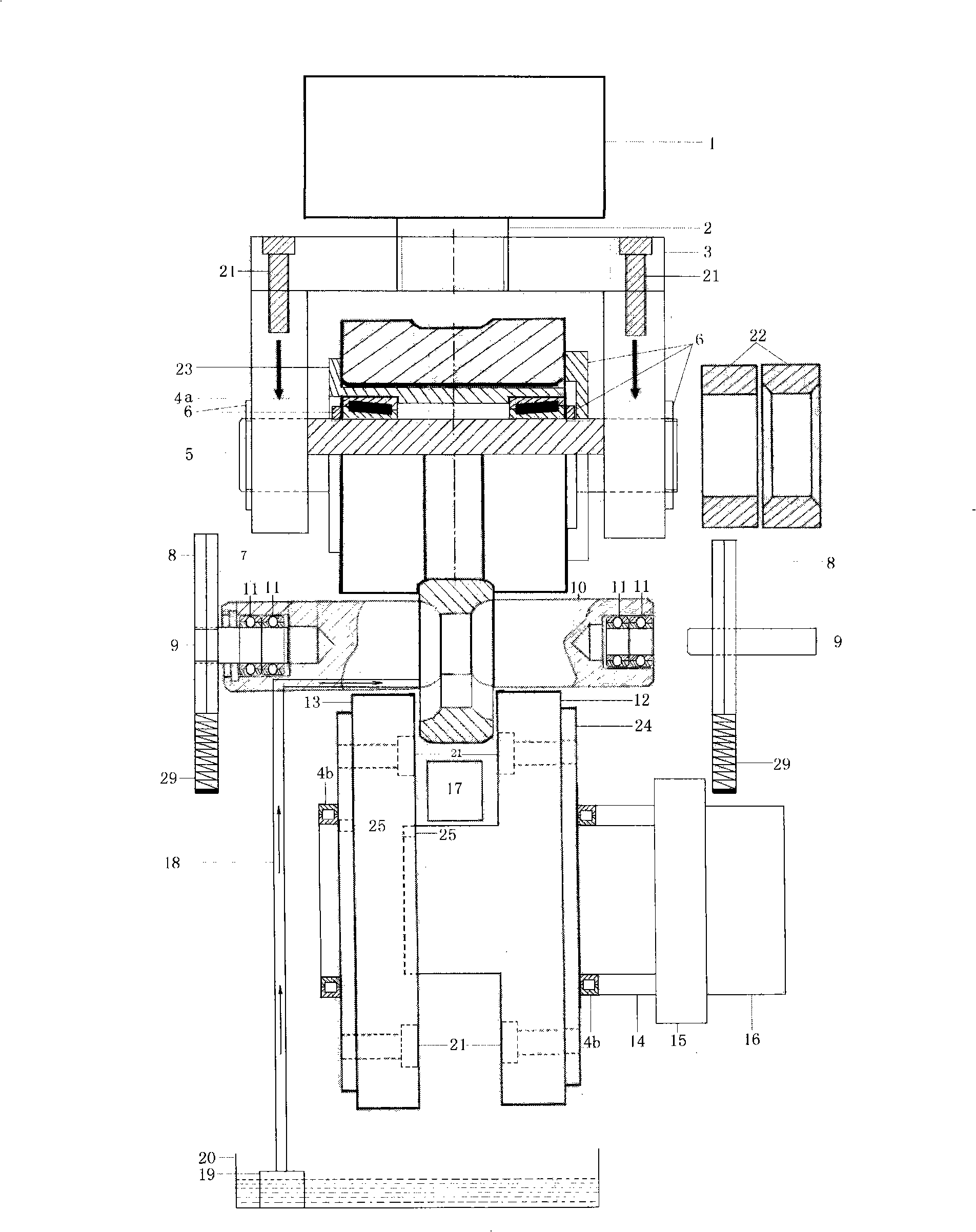

[0041] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8 show: a method for processing screw drilling tool bearings is to adopt cold rolling process to process screw drilling tool bearings, and the steps are as follows:

[0042] 1) Processing the blank of the outer sleeve or the inner sleeve of the bearing: use 55SiMoVA round steel with strong plasticity, with a diameter of Φ60mm-Φ140mm; calculate the length of the round steel according to the model of the drilling tool bearing, cut it into small pieces with a sawing machine, and then place it Heat it in the furnace to about 500-700 degrees, then take it out and forge it into a ring shape with an air hammer, and then use a hole reaming machine to expand the height and diameter of the inner circle and outer circle to the predetermined size of the bearing outer shell blank (22a) or bearing inner Cover blank 22b); The outer diameter of the outer jacket and the outer diameter of the inner sleeve of the same model are 8%-30% smaller tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com