Semi-finished product of high-frequency quenching component and its manufacturing method

一种高频淬火、制造方法的技术,应用在制造工具、提高能源效率、工艺效率的提高等方向,能够解决经济性下降、不能避免表层部的组织不均匀化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

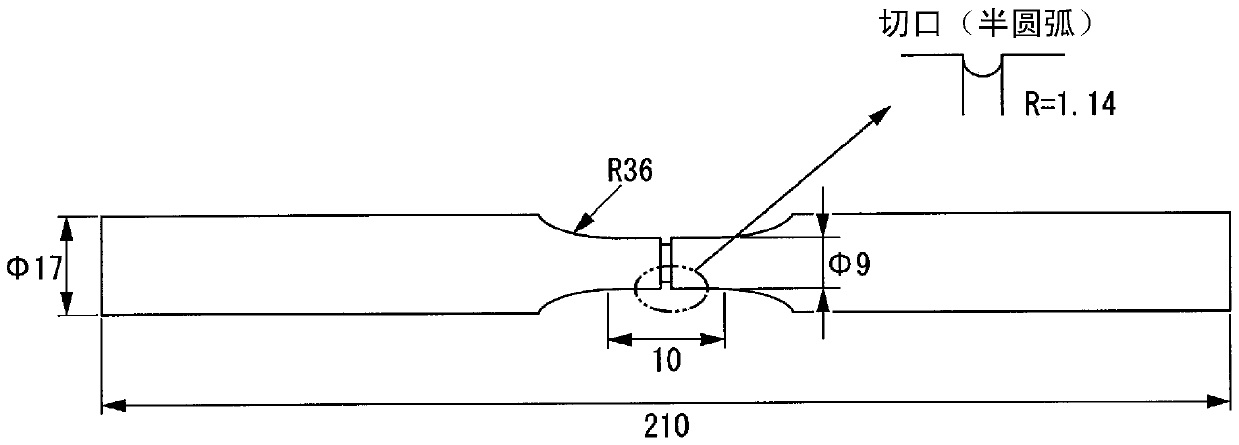

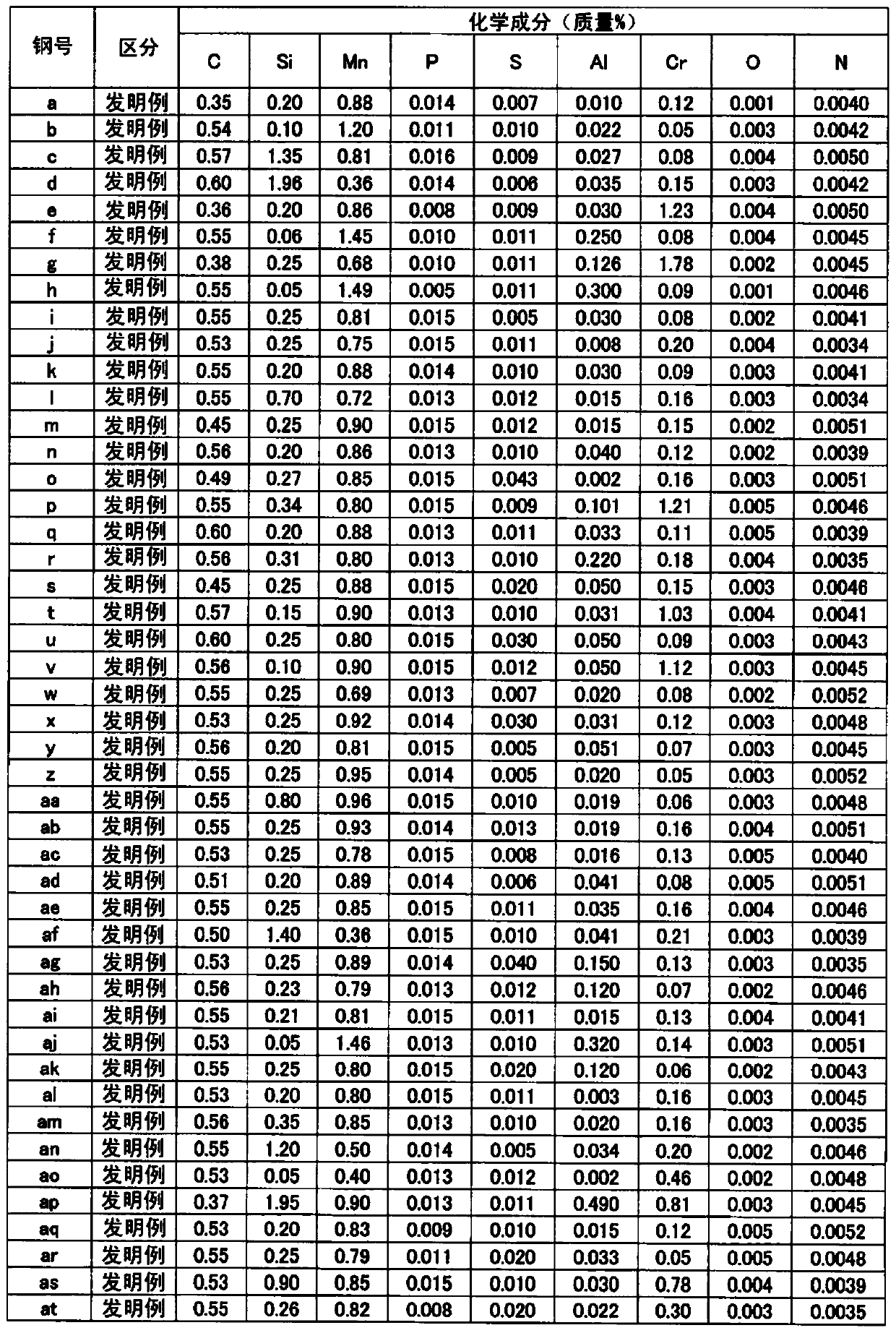

[0127] Hereinafter, the present invention will be specifically described by way of examples. The conditions in the examples are one example of conditions employed to confirm the feasibility and effects of the present invention, and the present invention is not limited to this one example of conditions. In the present invention, various conditions can be adopted within a range in which the object of the present invention can be achieved without departing from the gist of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com