Steel material and component

A steel and core technology, applied in the field of high-frequency quenched parts, can solve the problems of high energy and cost, difficulty in carburizing production line, low carburizing efficiency of large parts, etc., and achieve high surface fatigue strength, cutting excellent effect

Active Publication Date: 2021-08-27

NIPPON STEEL CORP

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in the carburizing treatment, a lot of energy and cost are spent

In addition, the production line of carburizing treatment is difficult

Inefficient carburizing of large components in turn for carburizing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

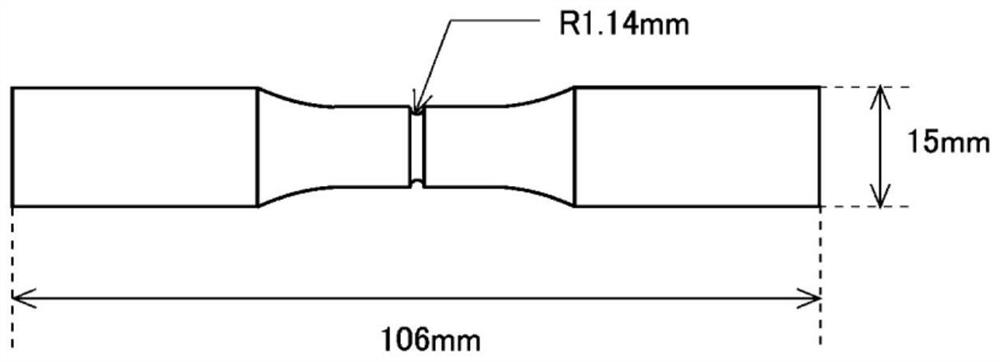

[0337] Specific description will be given below by way of examples. The conditions in the examples are an example of conditions employed to confirm the practicality and effects of the steel material of the present embodiment. Therefore, the steel material of this embodiment is not limited to this example of conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

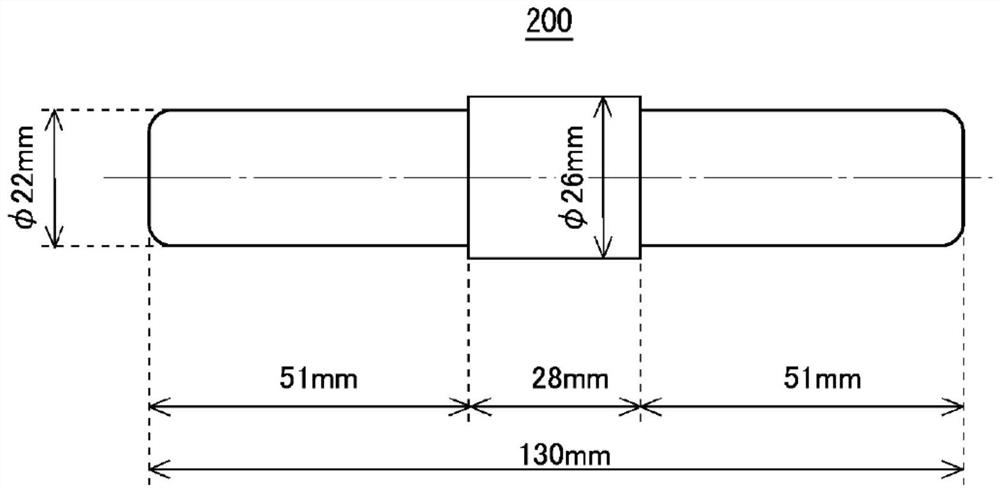

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

Provided is a steel material having excellent machinability and exhibiting, when subjected to induction hardening to form an induction-hardened component, high surface fatigue strength, high-cycle bending fatigue strength, and low-cycle bending fatigue strength. A steel material according to the present disclosure has a chemical composition containing, in terms of mass%, C: 0.40-0.70%, Si: 0.15-2.10%, Mn: 0.30-1.15%, Cr: 0.01 to less than 0.50%, S: 0.005-0.070%, N: 0.0020-0.0200%, Ti: 0.0080-0.2000%, B: 0.0005-0.0050%, Al: 0.005-0.100%, and P: less than 0.050%, with the balance consisting of Fe and impurities. The steel material satisfies formula (1) to formula (5) described in the specification, has a ferrite area ratio of 40% or less, and has a martensite area ratio of 10% or less.

Description

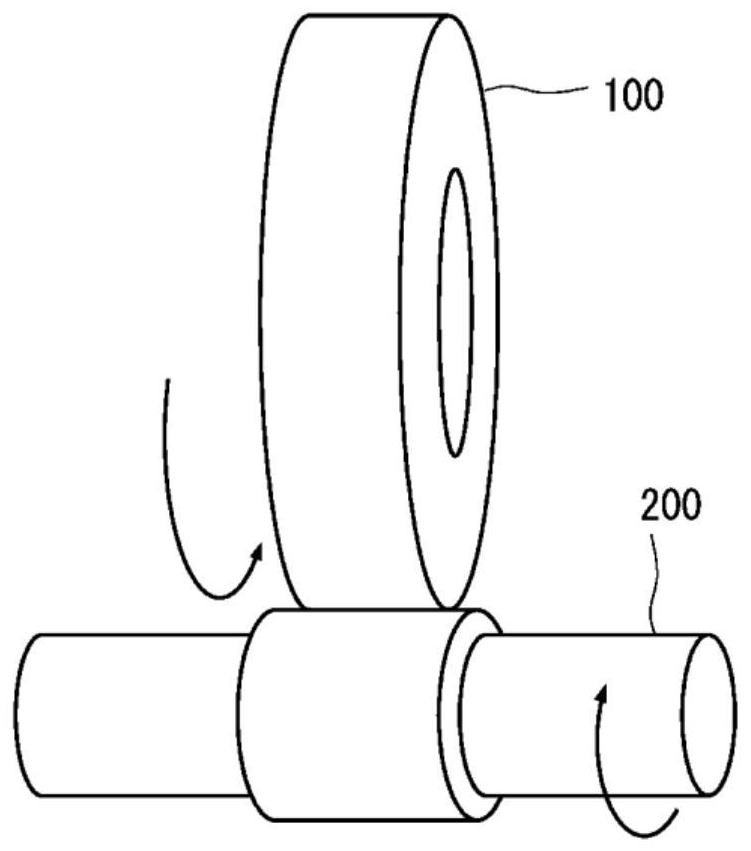

technical field [0001] This disclosure relates to a steel material and a component, and more specifically, to a steel material used as a raw material of an induction hardened component, and to a component obtained by induction hardening the steel material. In this specification, a part subjected to induction hardening is referred to as an "induction hardened part". It should be noted that the induction hardened component does not necessarily need to be subjected to induction hardening treatment on the entire component, and also includes parts that have been subjected to induction hardening treatment only in part. That is to say, in this specification, a part including a part that has been induction hardened (hereinafter referred to as a hardened part) and a part that has not been induction quenched (hereinafter referred to as an unquenched part) is also defined as an "induction hardened part". . It should be noted that, of course, the case where the entire part is induction ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/06C21D9/32C22C38/00C22C38/60

CPCC22C38/00C21D8/06C22C38/60C21D9/32C22C38/28C21D6/004C22C38/12C22C38/04C22C38/32C21D8/005C22C38/002C21D6/008C22C38/16C22C38/40C22C38/02C22C38/001C22C38/005C22C38/06C21D6/005Y02P10/25C21D2211/008

Inventor 宫西庆江头诚

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com