Finish machining method for aviation high-speed bearing retainer

A high-speed bearing and aviation technology, which is applied in the field of finishing of bearing cages, can solve the problems that the machining accuracy needs to be improved, and achieve the effect of improving accuracy and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

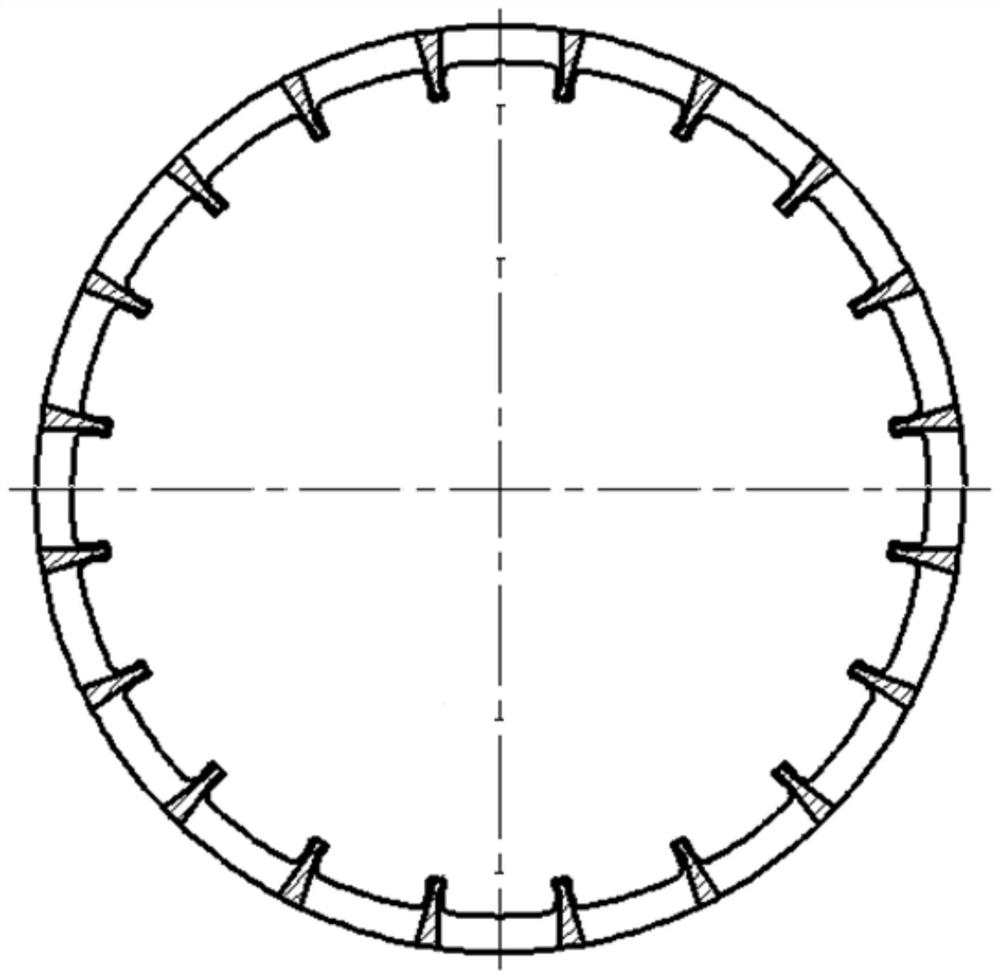

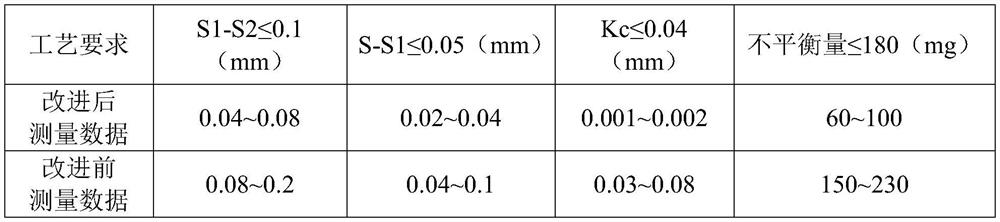

Image

Examples

specific Embodiment approach 1

[0036] Specific implementation mode 1: A method for finishing the cage of an aviation high-speed bearing, specifically according to the following steps:

[0037] 1. Rough turning of the rough billet to obtain the workpiece;

[0038] 2. Carry out quenching and tempering treatment to the workpiece obtained in step 1;

[0039] 3. The workpiece processed in step 2 is finely turned into shape;

[0040] 4. The workpiece processed in step 3 is subjected to equal grinding and two-plane processing;

[0041] 5. Grind the outer diameter of the workpiece processed in step 4, and control the reserved final grinding outer diameter grinding amount of 0.05-0.07mm;

[0042] 6. Grinding the inner diameter of the workpiece processed in step 5;

[0043] 7. Perform surface nitriding treatment on the workpiece after step 6, and control the nitriding depth to 0.18-0.3mm;

[0044] 8. The workpiece processed in step 7 is subjected to the final equal grinding and two-plane treatment;

[0045] 9. P...

specific Embodiment approach 2

[0053] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the rough billet is made of 40CrNiMoA alloy quenched and tempered steel. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0054]Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that: in step 2, the quenching and tempering treatment process is first quenching treatment: control the preheating temperature to 585-595 °C, and the preheating time to 45-51 minutes , the final heating temperature is 830-840°C, and the preheating time is 45-51min; then tempering treatment: the control temperature is 605-610°C°, the processing time is 120-130min, and the hardness of the workpiece after treatment reaches 29-34HRC. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com