A device suitable for high-efficiency finishing of the inner surface of a non-magnetic workpiece

An inner surface, non-magnetic technology, applied in machine tools suitable for grinding workpiece edges, surface polishing machine tools, manufacturing tools, etc., can solve skin and eye injuries, waste liquid is difficult to handle, metal corrosion, etc. problems, to achieve the effect of good versatility, high processing efficiency and small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

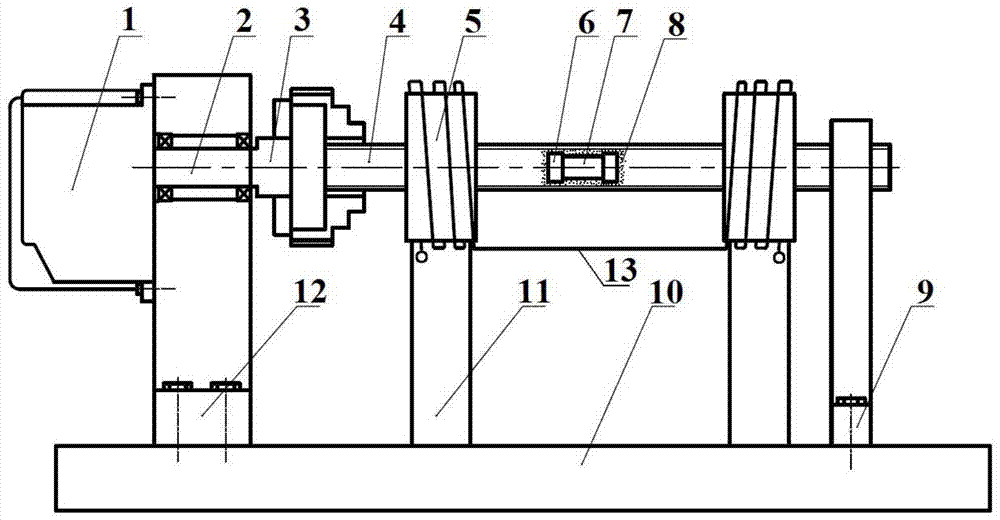

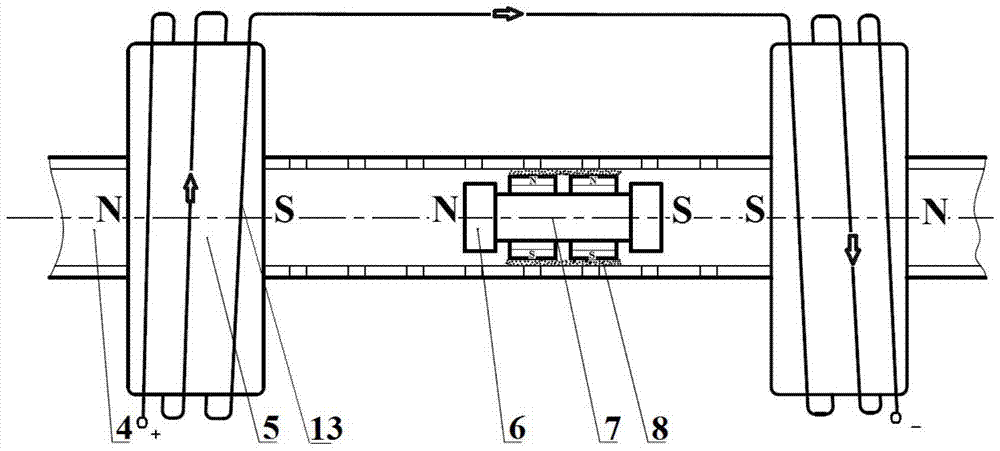

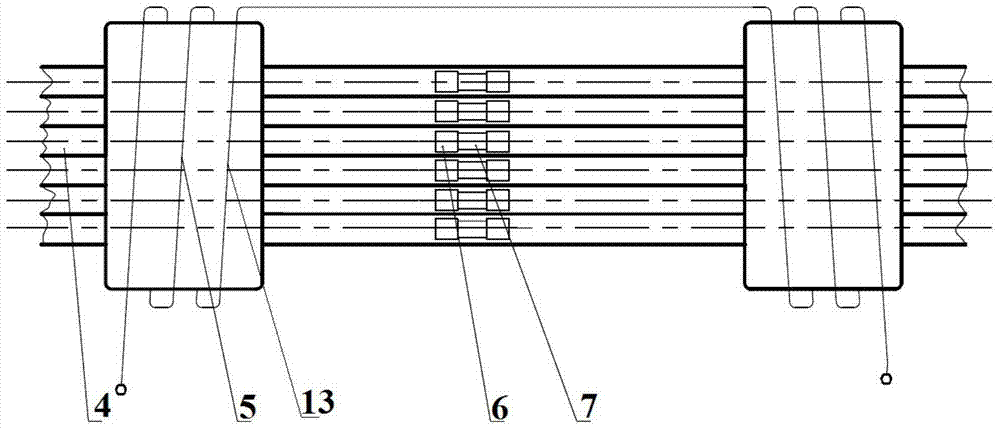

[0025] as attached figure 1 As shown, a magnetic grinding device suitable for smoothing the inner surface of a non-magnetic workpiece, the device consists of a spindle motor 1, a spindle 2, a chuck 3, a workpiece 4, a coil 5, a magnetic pole 6, a magnetizer 7, a magnetic abrasive 8, Tailstock 9, base 10, spacer 11, support 12 and enameled wire 13 constitute, described main shaft motor 1 and main shaft 2 are fixed on the support 12, and main shaft motor 1 is connected with workpiece 4 through main shaft 2, chuck 3, and workpiece 4. The tail part is supported by the tailstock 9; the enameled wire 13 is wound into two coils 5, the two coils 5 wrap the workpiece 4, and a single-phase alternating current is passed through, and the two coils 5 are supported and fixed by two spacers 11; There are two magnetic poles 6, and the two magnetic poles 6 are connected by a magnetizer 7, put into the inside of the workpiece 4, and fill in the magnetic abrasive 8 and grinding liquid; the pad 1...

Embodiment 2

[0027] Such as figure 1 and figure 2 As shown, take the processing of the inner wall of porous pipes as an example.

[0028] A magnetic grinding device suitable for smoothing the inner surface of a non-magnetic workpiece, the device consists of a spindle motor 1, a spindle 2, a chuck 3, a workpiece 4, a coil 5, a magnetic pole 6, a magnetizer 7, a magnetic abrasive 8, and a tailstock 9 , a base 10, a spacer 11, a support 12 and an enameled wire 13, the spindle motor 1 and the spindle 2 are fixed on the support 12, the spindle motor 1 is connected to the workpiece 4 through the spindle 2, the chuck 3, and the tail of the workpiece 4 is formed by The tailstock 9 is supported; the enameled wire 13 is wound into two coils 5, the two coils 5 wrap the workpiece 4, and pass through a single-phase alternating current, and the two coils 5 are supported and fixed by two spacers 11; the magnetic poles 6 Two magnetic poles 6 are connected by a magnetizer 7, put into the inside of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com