Patents

Literature

550results about How to "Improve finishing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual prop processing method and apparatus, electronic device and storage medium

ActiveCN108459811AImprove screening efficiencyImprove finishing efficiencyVideo gamesInput/output processes for data processingGraphicsGraphical user interface

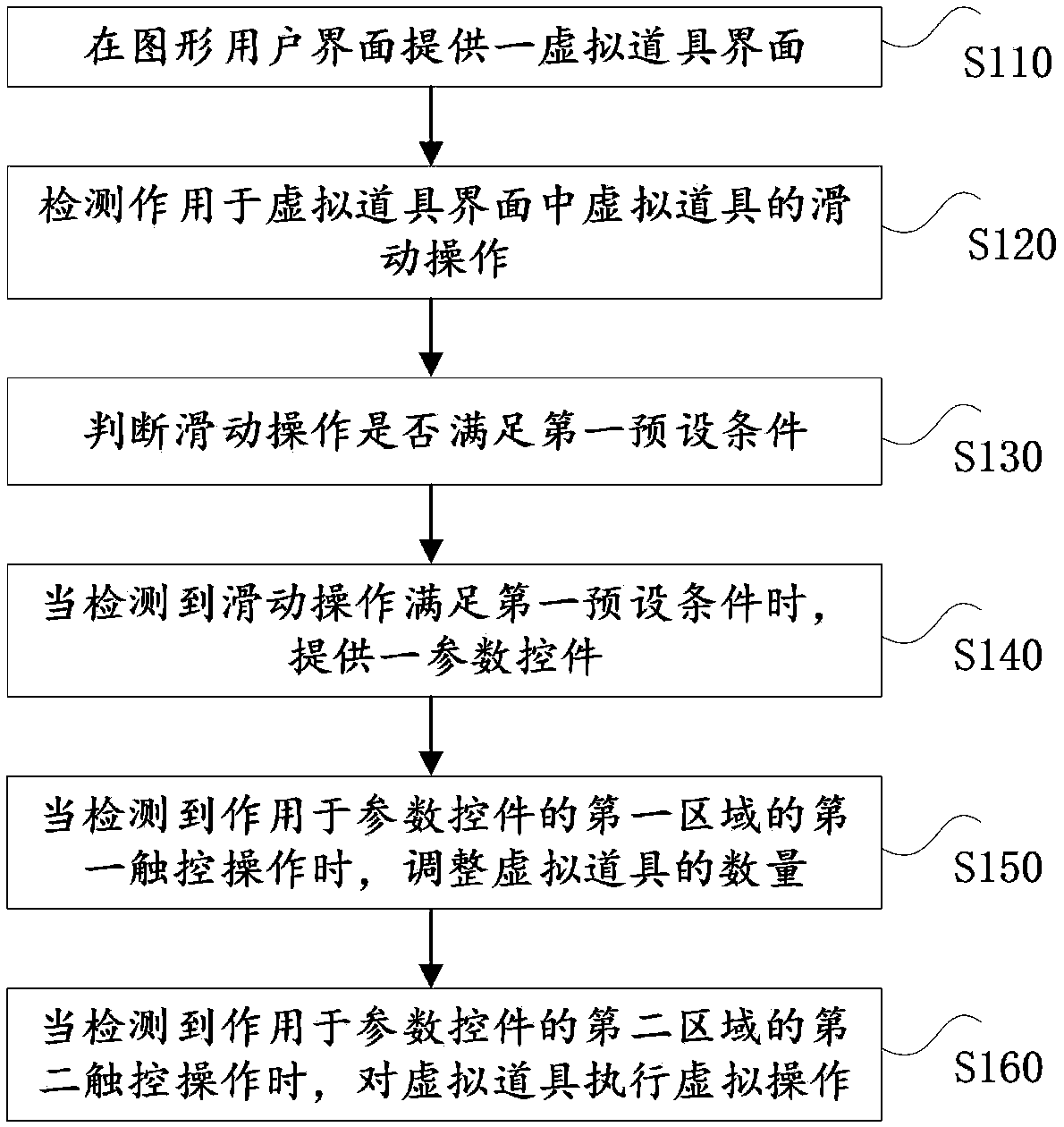

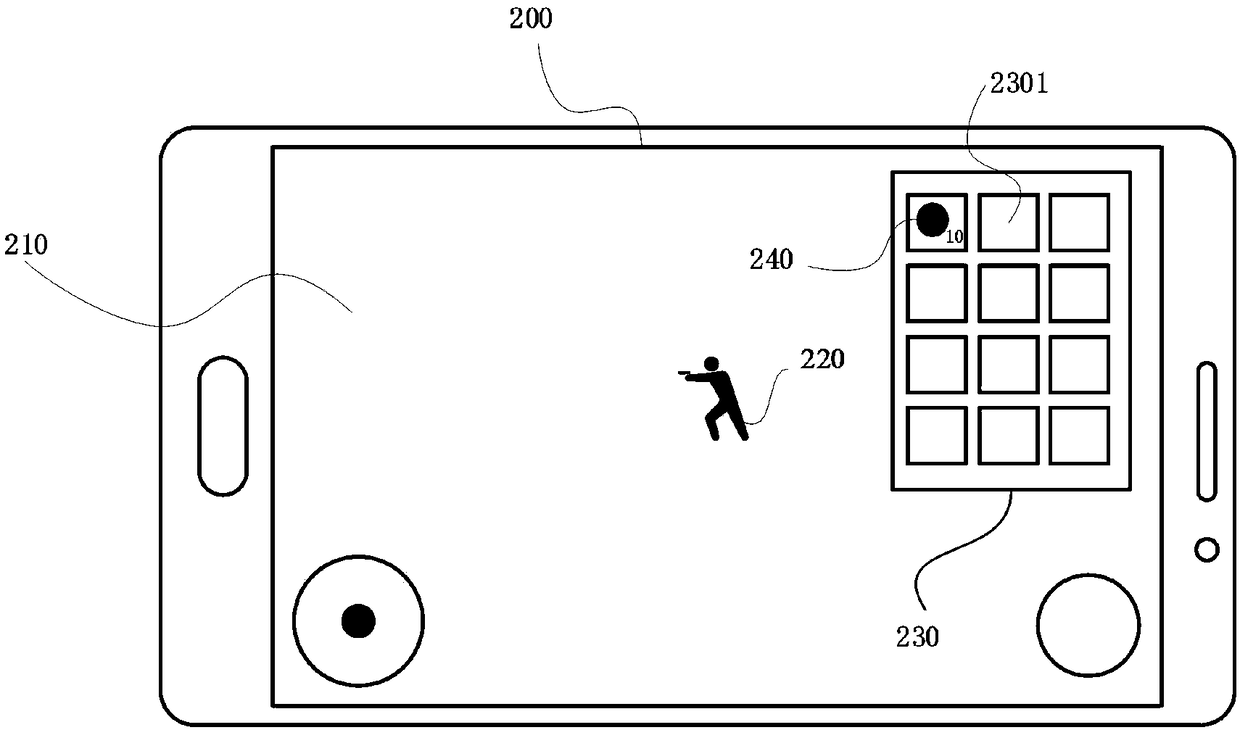

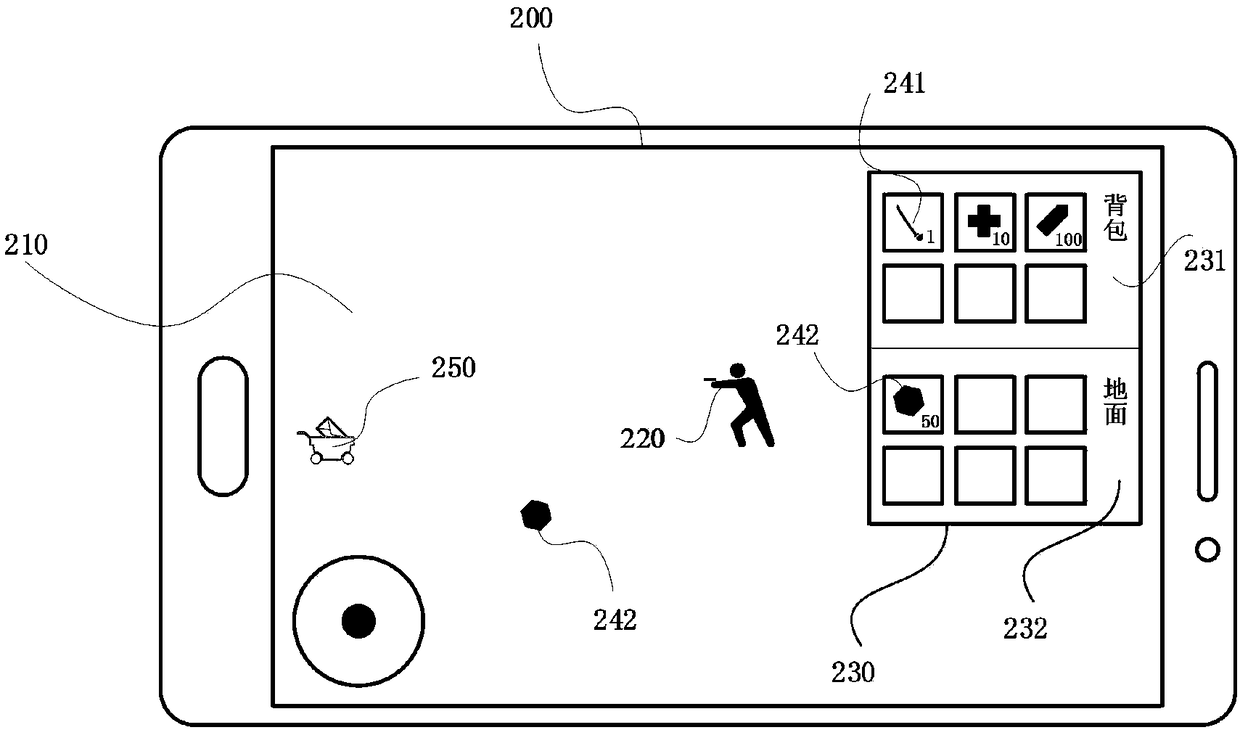

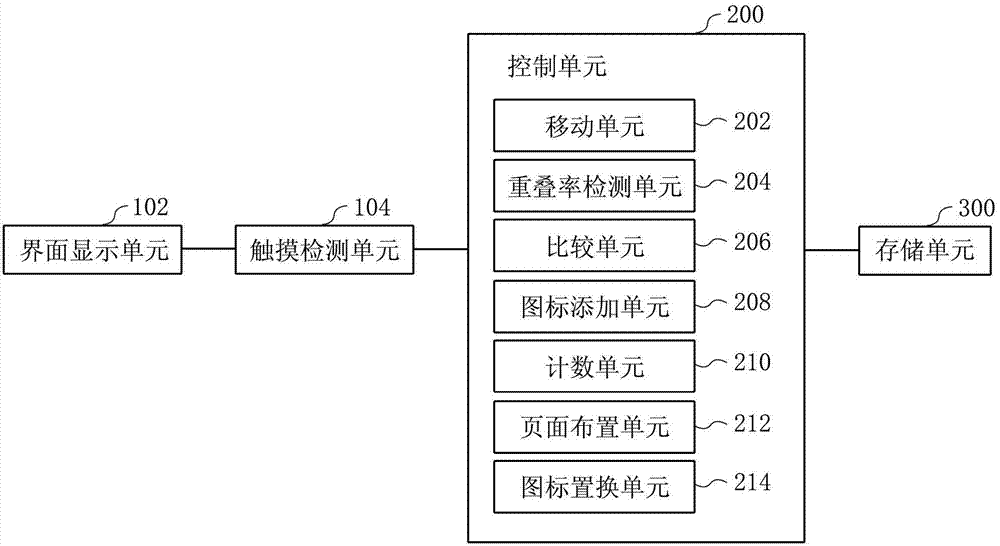

The invention discloses a virtual prop processing method and apparatus, an electronic device and a storage medium. The method comprises the steps of providing a virtual prop interface in a graphic user interface, wherein the virtual prop interface comprises virtual props displayed in a preset display mode; detecting sliding operation on the virtual props in the virtual prop interface; judging whether the sliding operation meets a first preset condition or not; when it is detected that the sliding operation meets the first preset condition, providing a parameter control, wherein the parameter control is used for adjusting the quantity of the virtual props; and after the quantity of the virtual props is adjusted, executing virtual operation on the virtual props. The technical problem of lowvirtual prop screening and arrangement efficiency in an interactive mode of a mobile terminal is solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

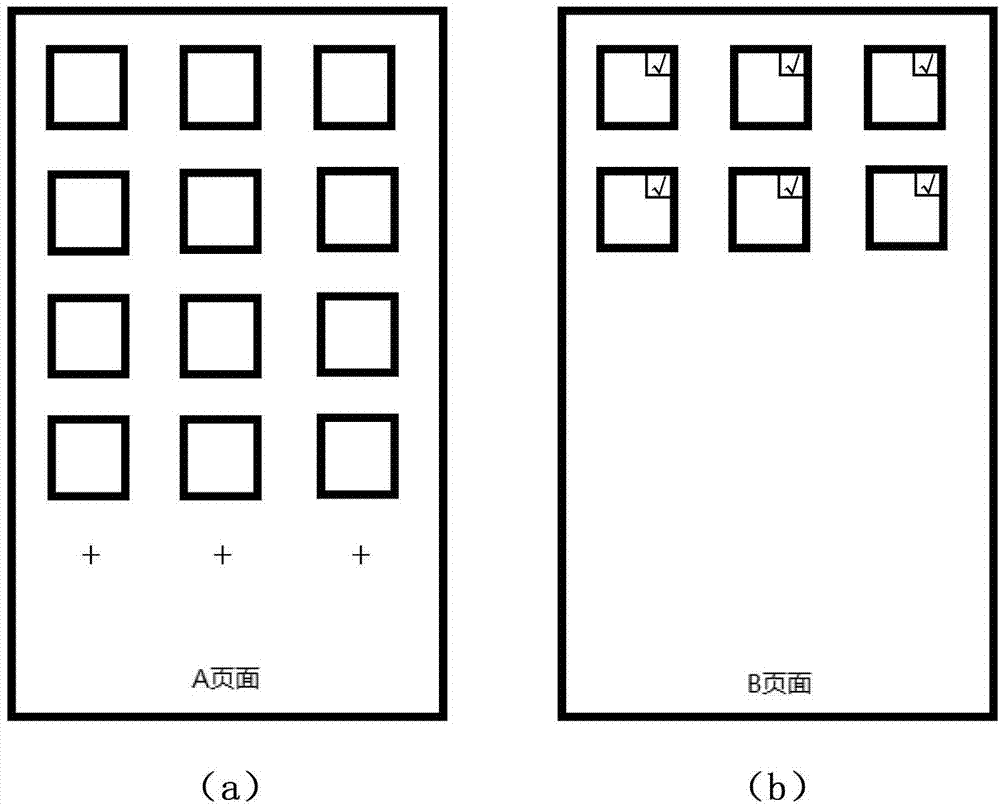

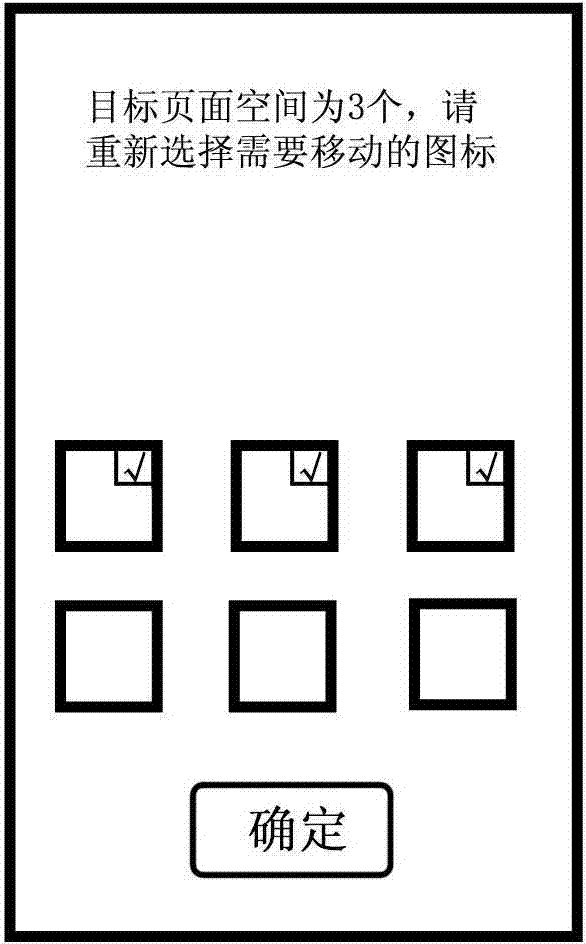

Icon moving method and portable touch terminal using same

InactiveCN103500050AImprove finishing efficiencyInput/output processes for data processingThumbnailOverlap ratio

Owner:SAMSUNG TIANJIN MOBILE DEV CENT +1

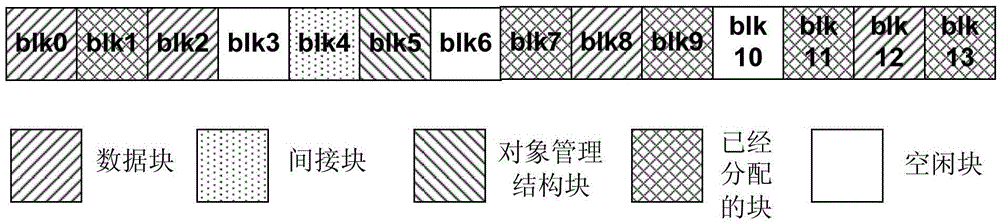

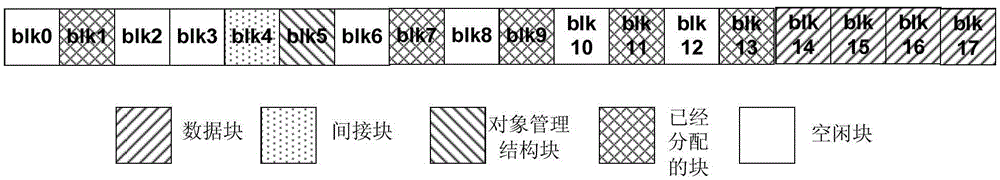

Disk defragmentation method, disk defragmentation device and host

ActiveCN105589812AImprove finishing efficiencyInput/output to record carriersMemory adressing/allocation/relocationDisk arraySpace management

The embodiment of the invention provides a disk defragmentation method, a disk defragmentation device and a host. The method comprises the following steps: judging the fragmentation degree of a first disk area according to a first space management object; if determining that the fragmentation degree of the first disk area reaches the preset fragmentation degree, writing a data block of each object corresponding to a defragmentation sub-area into a continuous disk space according to the first space management object, and writing metadata, which is generated when the data block of each object is written in the continuous disk space, in the continuous space, wherein the defragmentation sub-area is smaller or equal to the first disk area; and releasing the defragmentation sub-area. Visibly, a section of continuous idle space in the first disk area can be obtained after the defragmentation sub-area is subjected to disk defragmentation according to space management information; and thus, the disk defragmentation efficiency is increased.

Owner:CHENGDU HUAWEI TECH

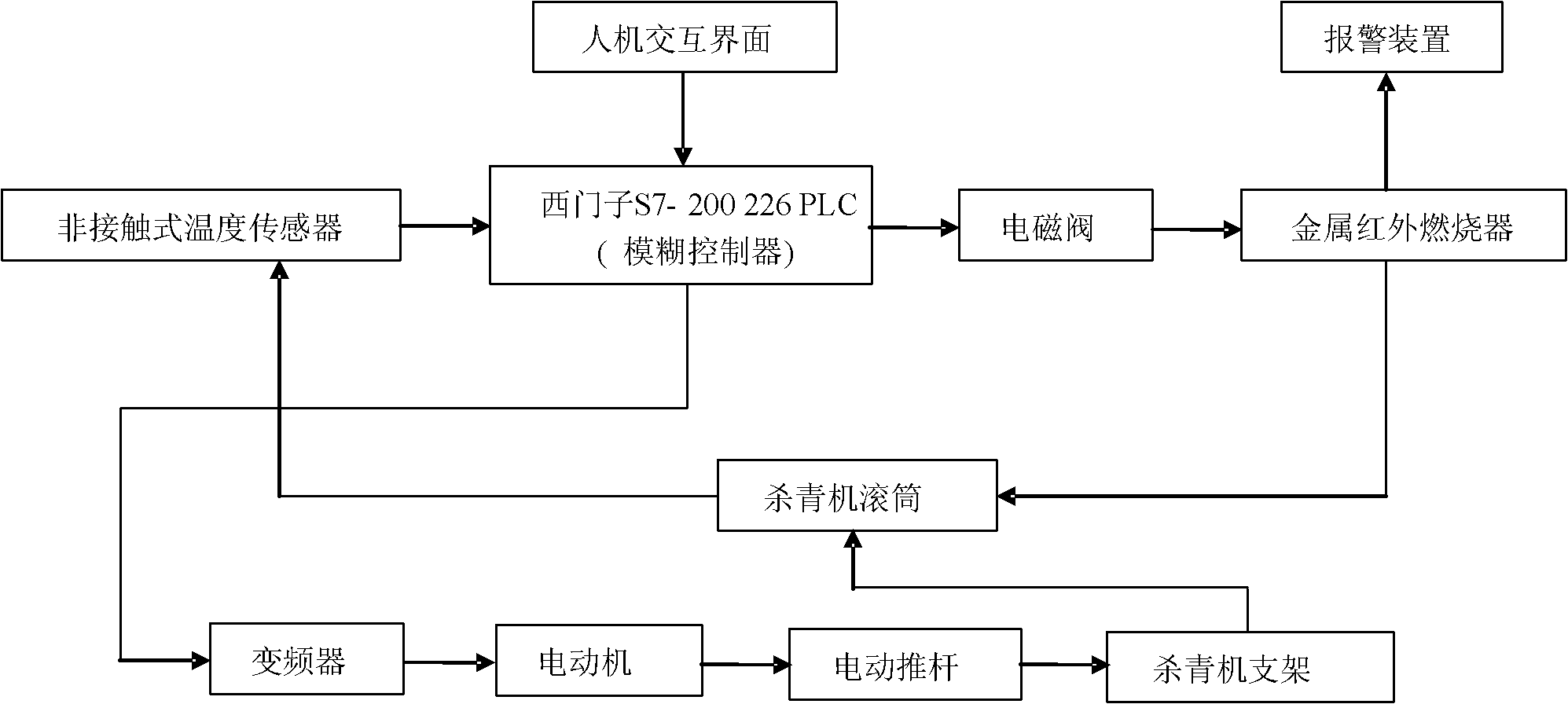

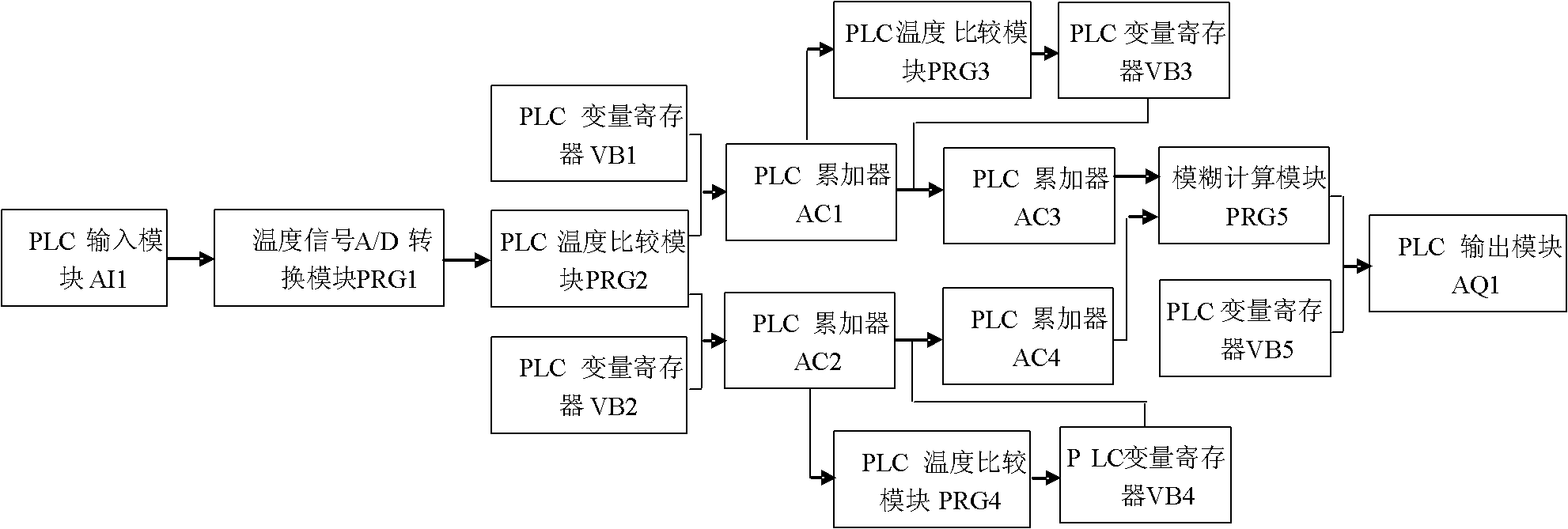

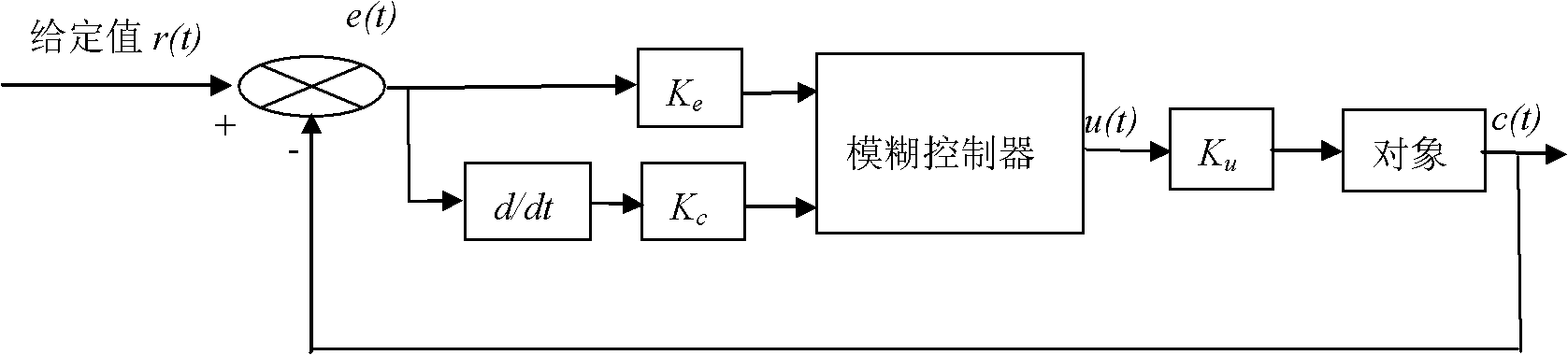

Tea green-removing machine and fuzzy control method thereof

ActiveCN101990960AControl the heating temperatureFully heatedPre-extraction tea treatmentCombustorInput control

The invention discloses a tea green-removing machine and a fuzzy control method thereof. The method comprises the following steps of: heating a barrel of the tea green-removing machine by using a combustor, wherein T is a given temperature value, a feedback value Tt is the current temperature value of the outer wall of the barrel of the tea green-removing machine, and temperature difference E is equal to Tt-T, and a temperature difference change rate EC is equal to Tt-Tt-1, the first input quantity of a fuzzy controller is Ke*E, and the second input quantity of the fuzzy controller is KC*EC; the output quantity of the fuzzy controller is U, and the input control quantity of the tea green-removing machine is KU*U, and the Ke, KC and KU represent a temperature difference ratio factor, a temperature difference change ratio factor and a control quantity ratio factor respectively; and the input control quantity KU*U is a voltage signal of an electromagnetic valve, namely the voltage signalloaded in an electromagnetic coil in the electromagnetic valve which is used for controlling the flow of the combustible gas in the combustor. The tea green-removing machine and the fuzzy control method thereof have the advantages that: the implementation is easy; the automation degree is high; and the tea green-removing effect is good.

Owner:CENT SOUTH UNIV

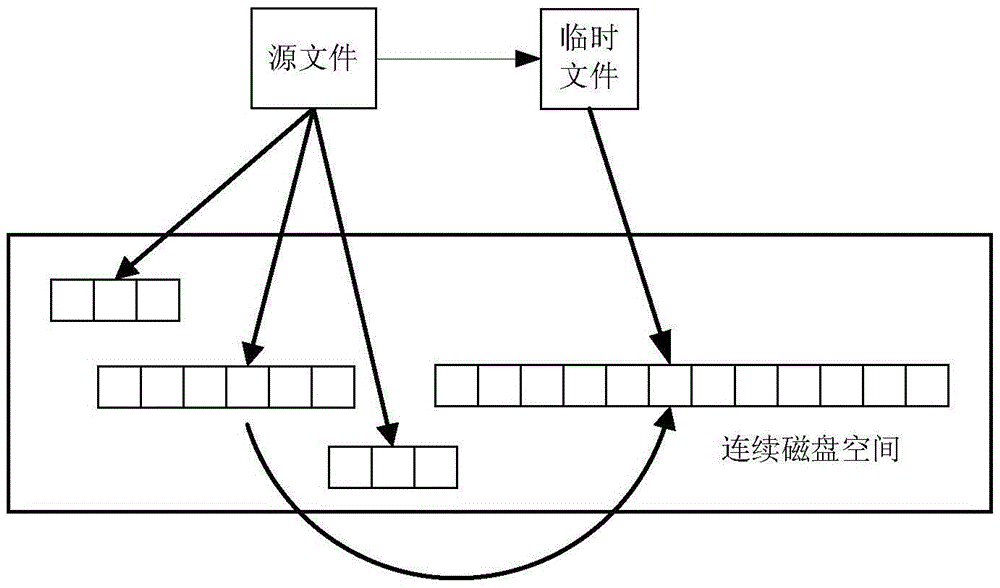

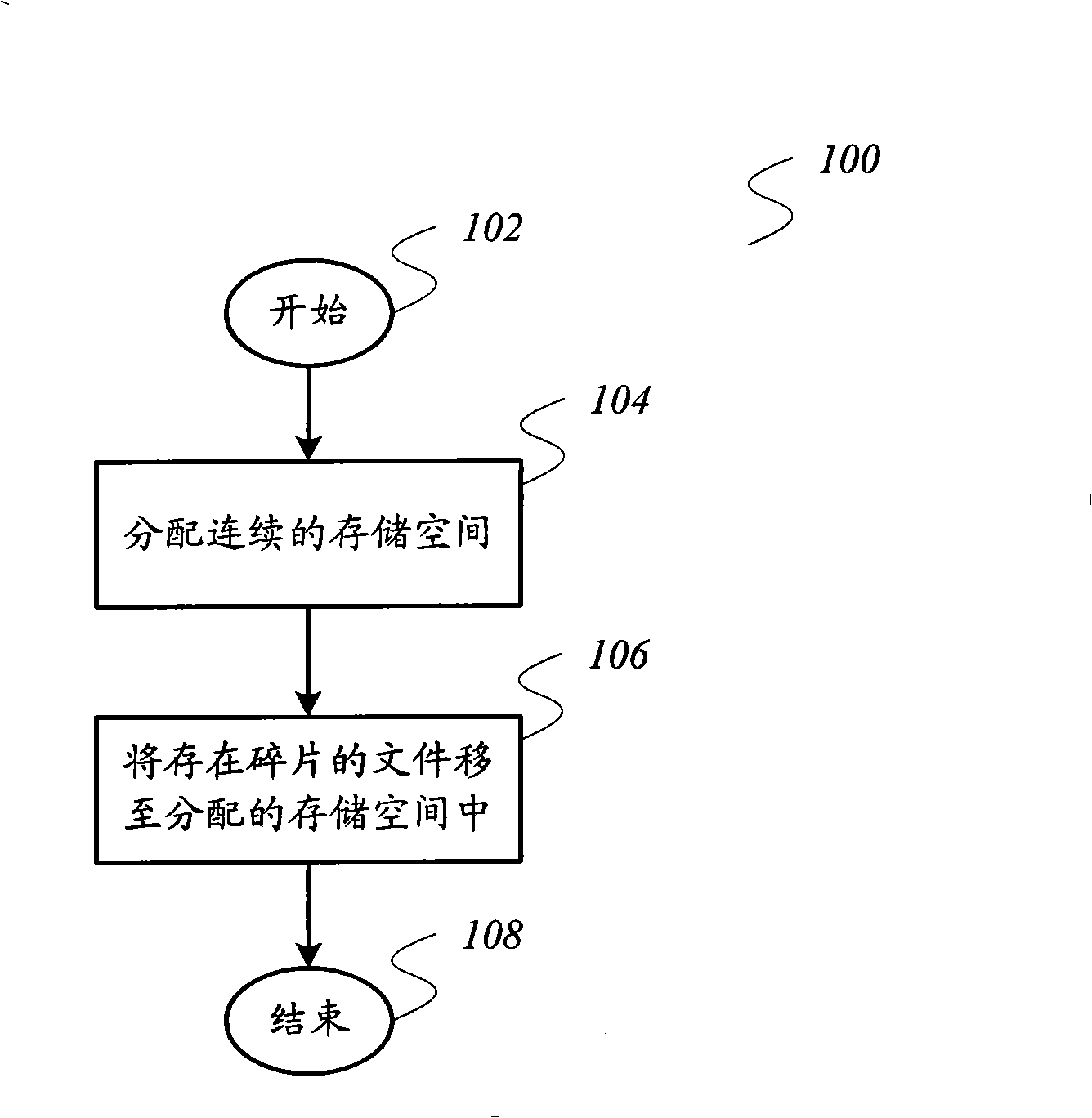

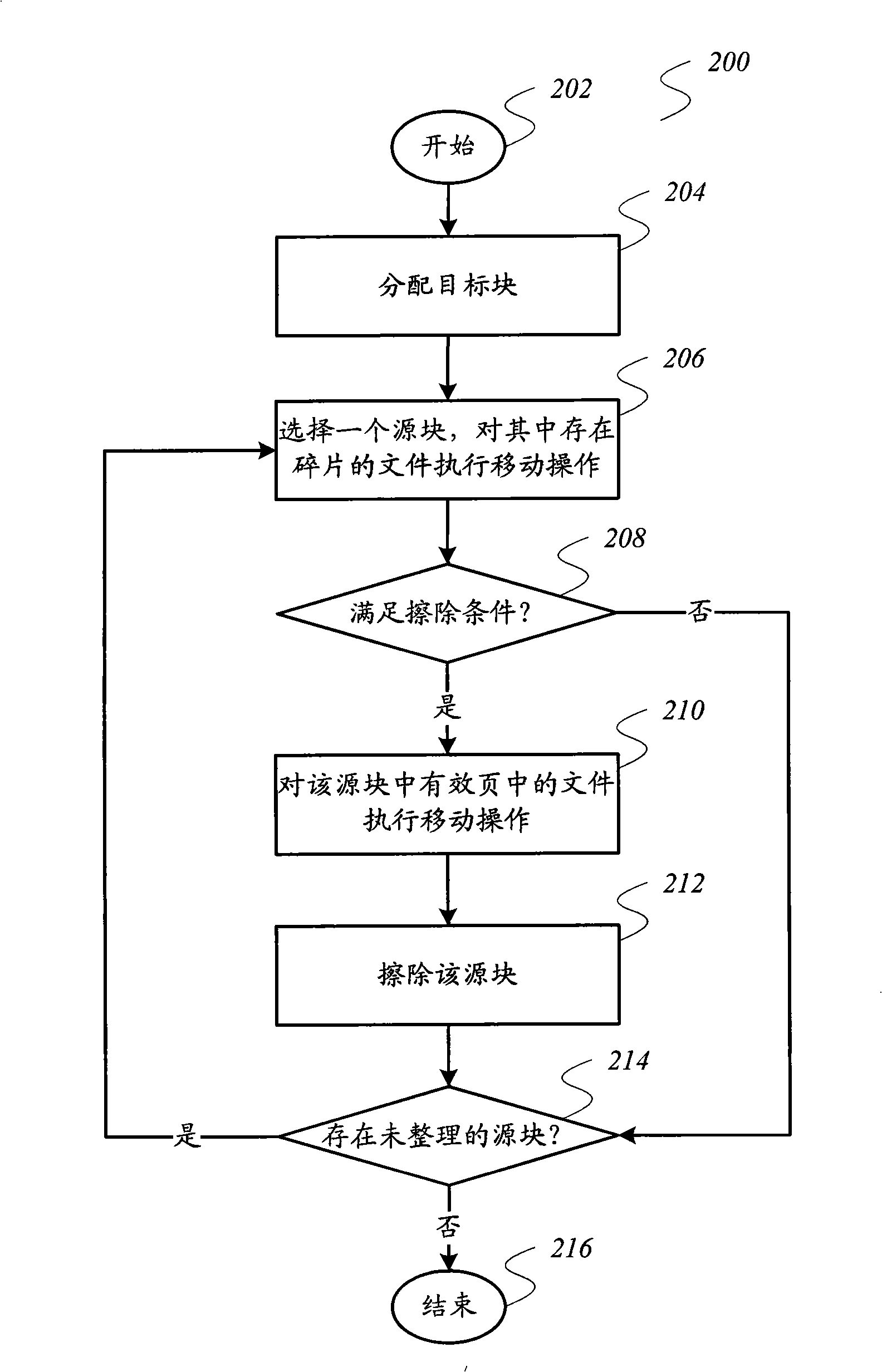

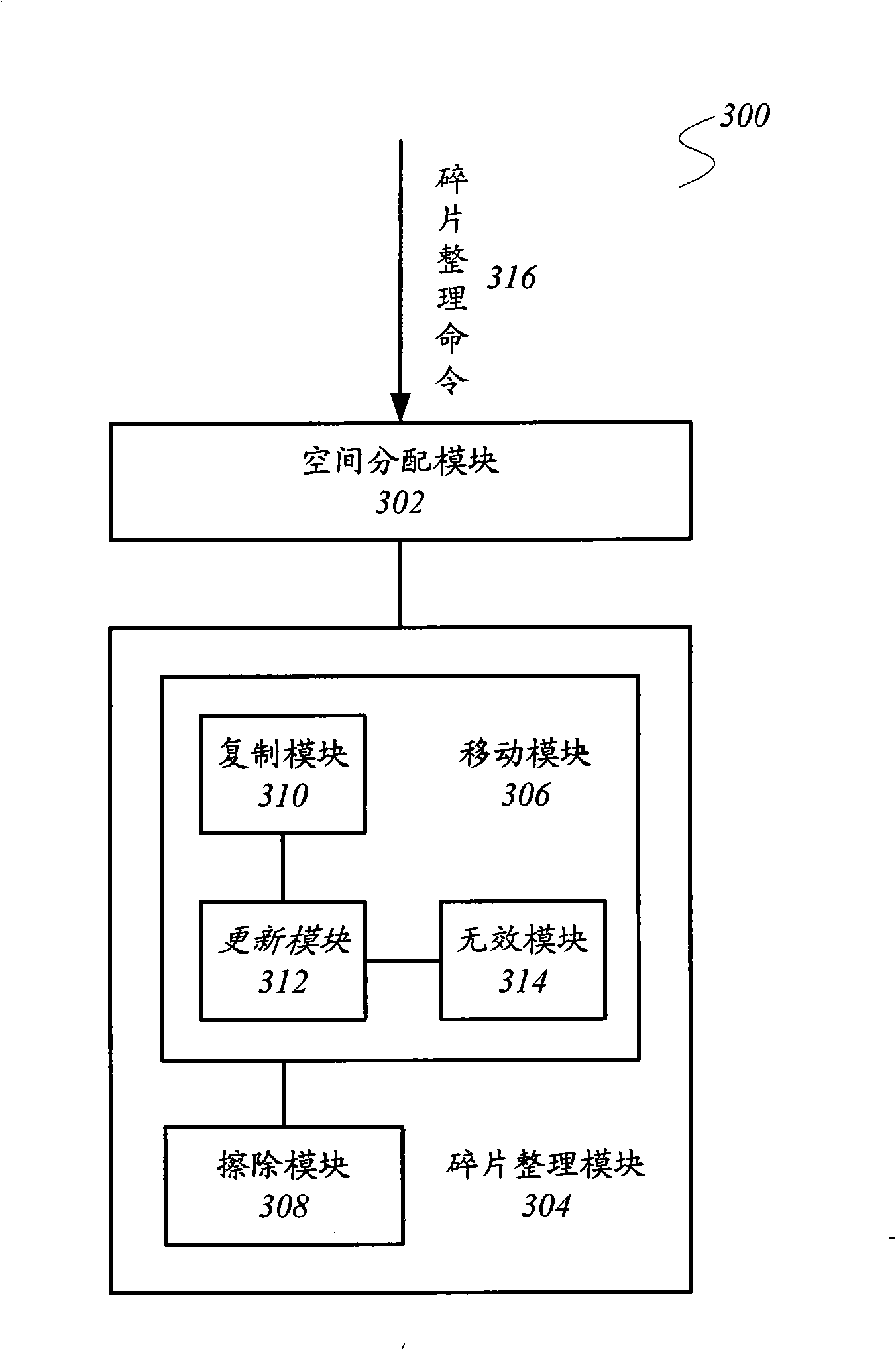

Method and system for arranging file chips

InactiveCN101404028ALow costImprove finishing efficiencySpecial data processing applicationsFile copyingDefragmentation

The invention relates to file fragmentation sorting out, and provides a method for sorting out file fragmentations and a system thereof by aiming at the disadvantages such as high cost of the existing methods for sorting out the file fragmentations of a mobile terminal. The method comprises the step of allocating continuous storage spaces, and the step of transferring files with the fragmentations to the allocated storage space. The invention also provides a system for sorting out the file fragmentations. Fragmented files are stored by an empty block, and no additional memory is needed, thus the total cost can be reduced. The storage addresses of the fragmented files are updated to the addresses in the empty block, which causes the files with the fragmentations to be copied only once, and does not lead to an excessive processing burden. As only the files with the fragmentations are sorted out, the sorting efficiency is higher. Furthermore, an erase operation is performed only when the erase condition is satisfied, thus the performance degradation caused by frequent erasures can be effectively avoided. A threshold can be adjusted according to the number of the empty blocks and the system burden, therefore the process for sorting out the fragmentations can be optimized.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Method for performing crease-resistant finishing on cotton textile fabrics or garments

ActiveCN102926146AFeel goodSoft touchHeating/cooling textile fabricsLiquid/gas/vapor removalEngineeringHigh pressure

The invention relates to a method for performing crease-resistant finishing on cotton textile fabrics or garments. The method comprises the following steps of: putting the cotton textile fabrics or garments into a rotation cage of a potion spraying machine, and uniformly spraying an anti-crease potion onto the cotton textile fabrics or garments by a high pressure nozzle of the potion spraying machine; performing dehydration treatment after fully and uniformly absorbing the anti-crease potion; pressing the pre-dried cotton textile fabrics or garments; putting the preset cotton textile fabrics or garments into a baking oven for high temperature setting; placing the baked cotton textile fabrics or garments in a ventilated and humid environment for naturally restoring the humidity, and then washing the cotton textile fabrics or garments by a washing machine; dehydrating the cotton textile fabrics or garments washed in the above step, and drying the cotton textile fabrics or garments by a dryer; and entirely pressing and packaging.

Owner:GUANGDONG QUNHAO CLOTHING

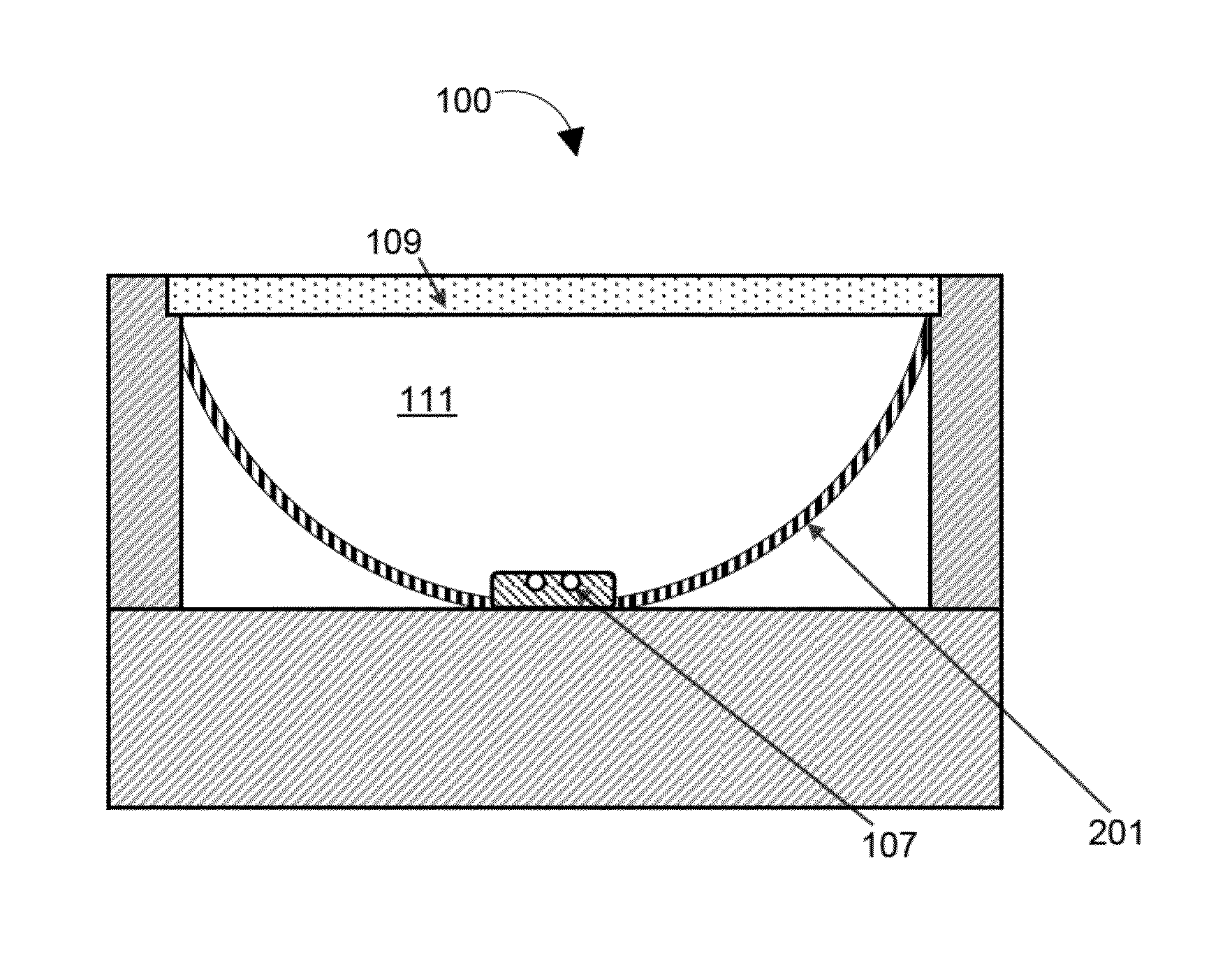

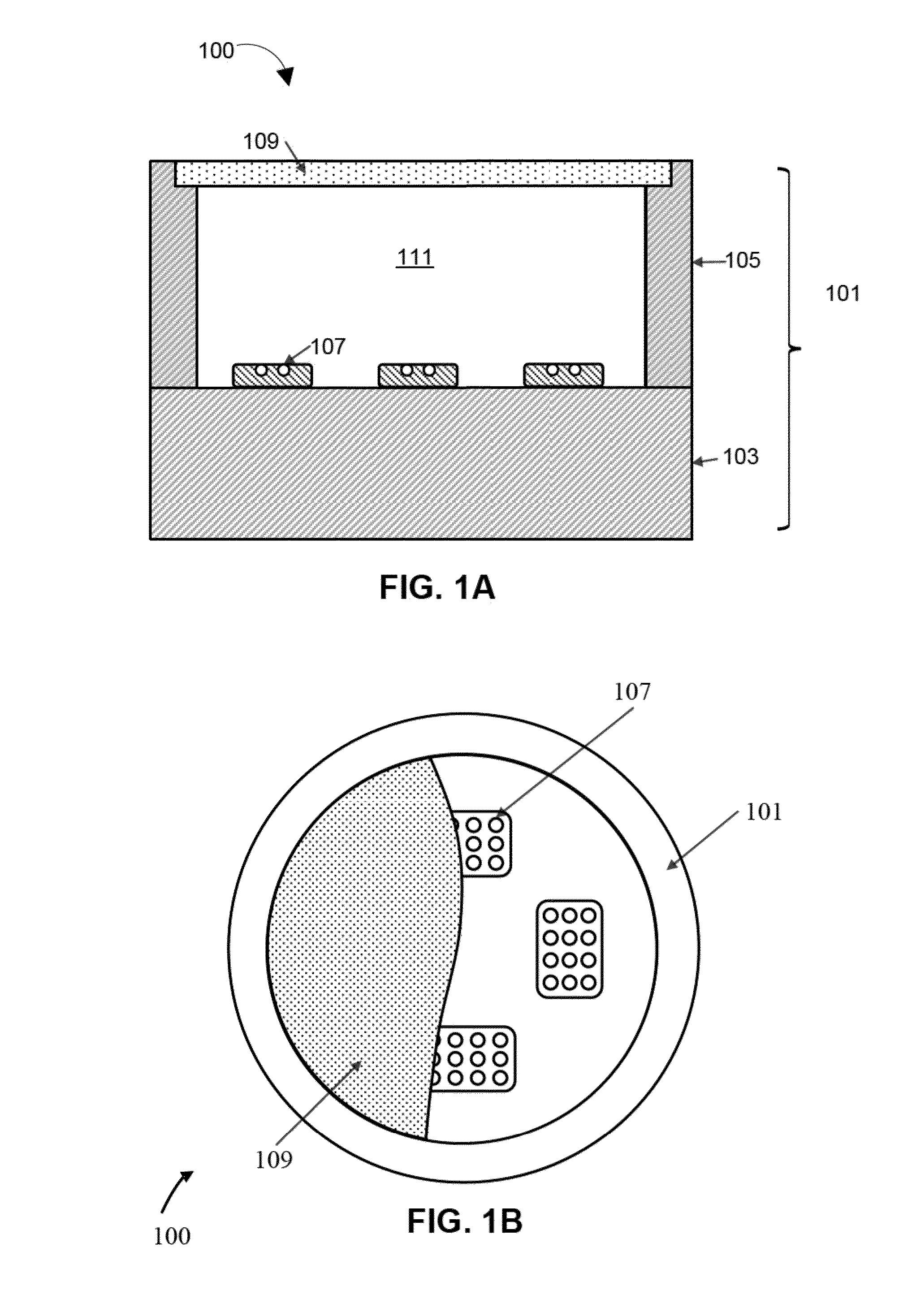

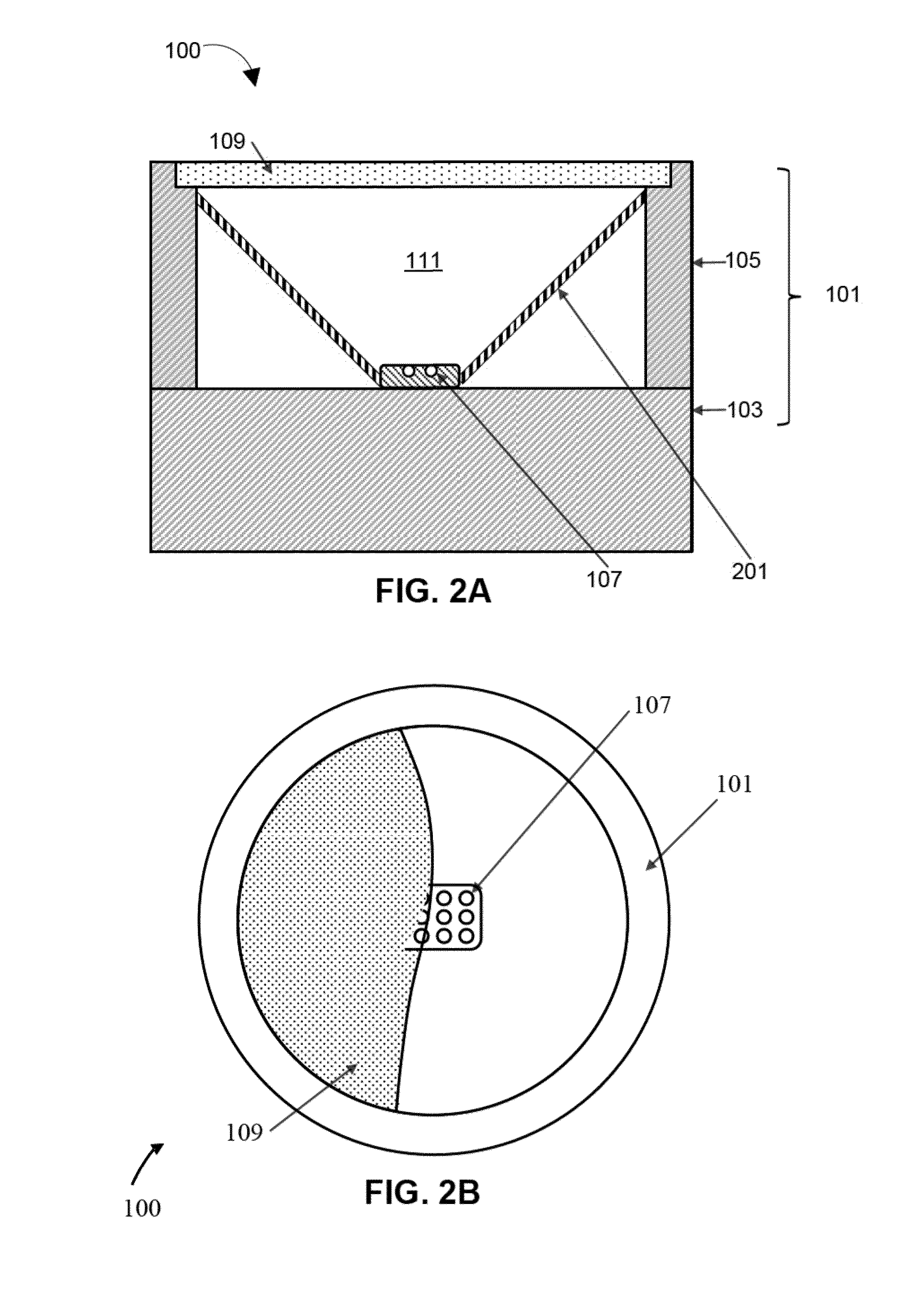

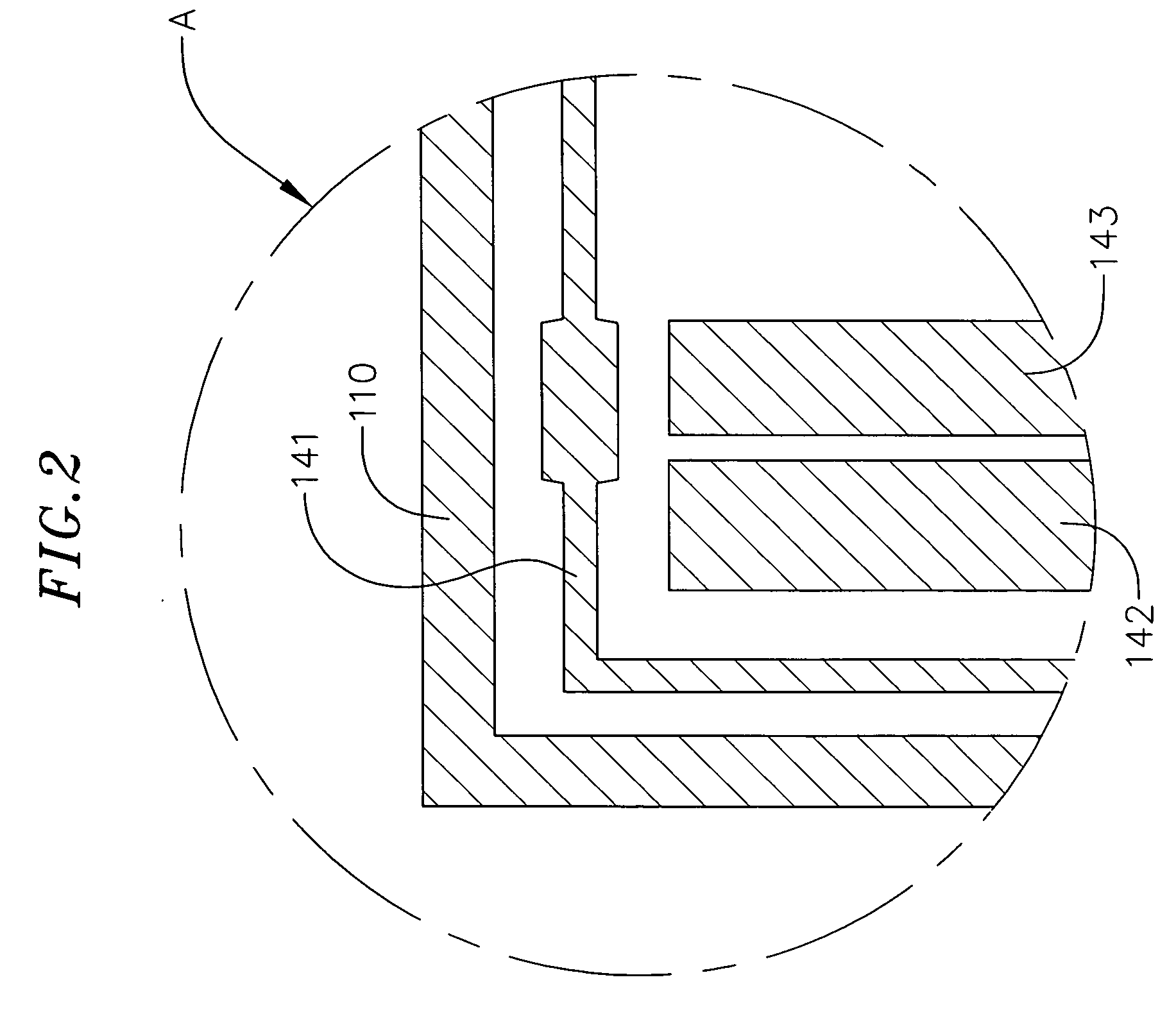

Led-based lighting arrangements

InactiveUS20140103796A1Increase lighting arrangement efficiencyImprove finishing efficiencyPlanar light sourcesDischarge tube luminescnet screensEffect lightWavelength conversion

Embodiments concern various LED-based lighting arrangements, such as for use in downlights or area lights, with increased light efficacy by utilizing a light reflective component to define a light reflective mixing chamber that is substantially frusto-conical, frusto-pyramidal, hemispherical, or paraboloidal. The reflective component may be single-piece component configured to fit within a pre-existing housing and placed between the LEDs and a wavelength conversion component.

Owner:INTEMATIX

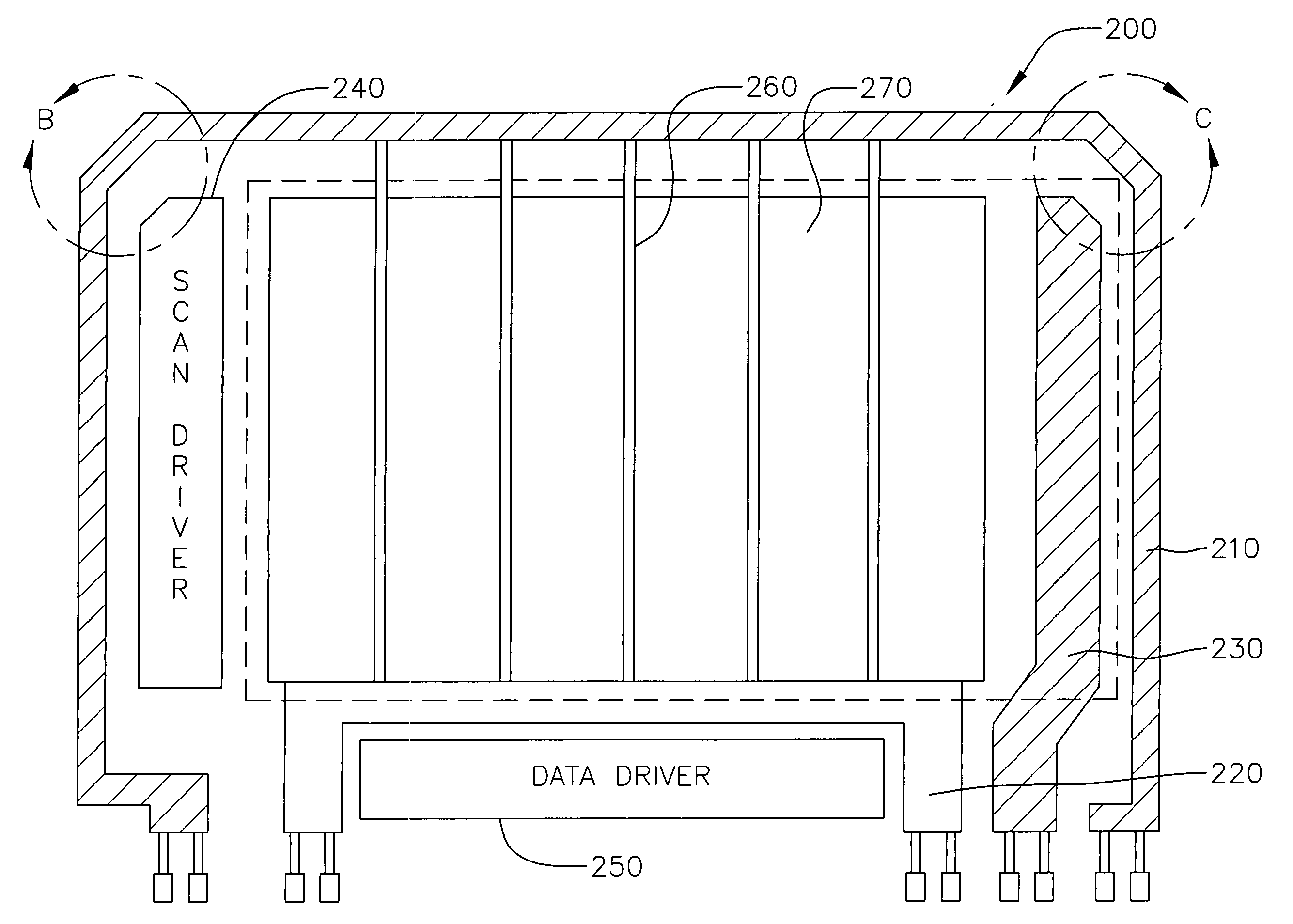

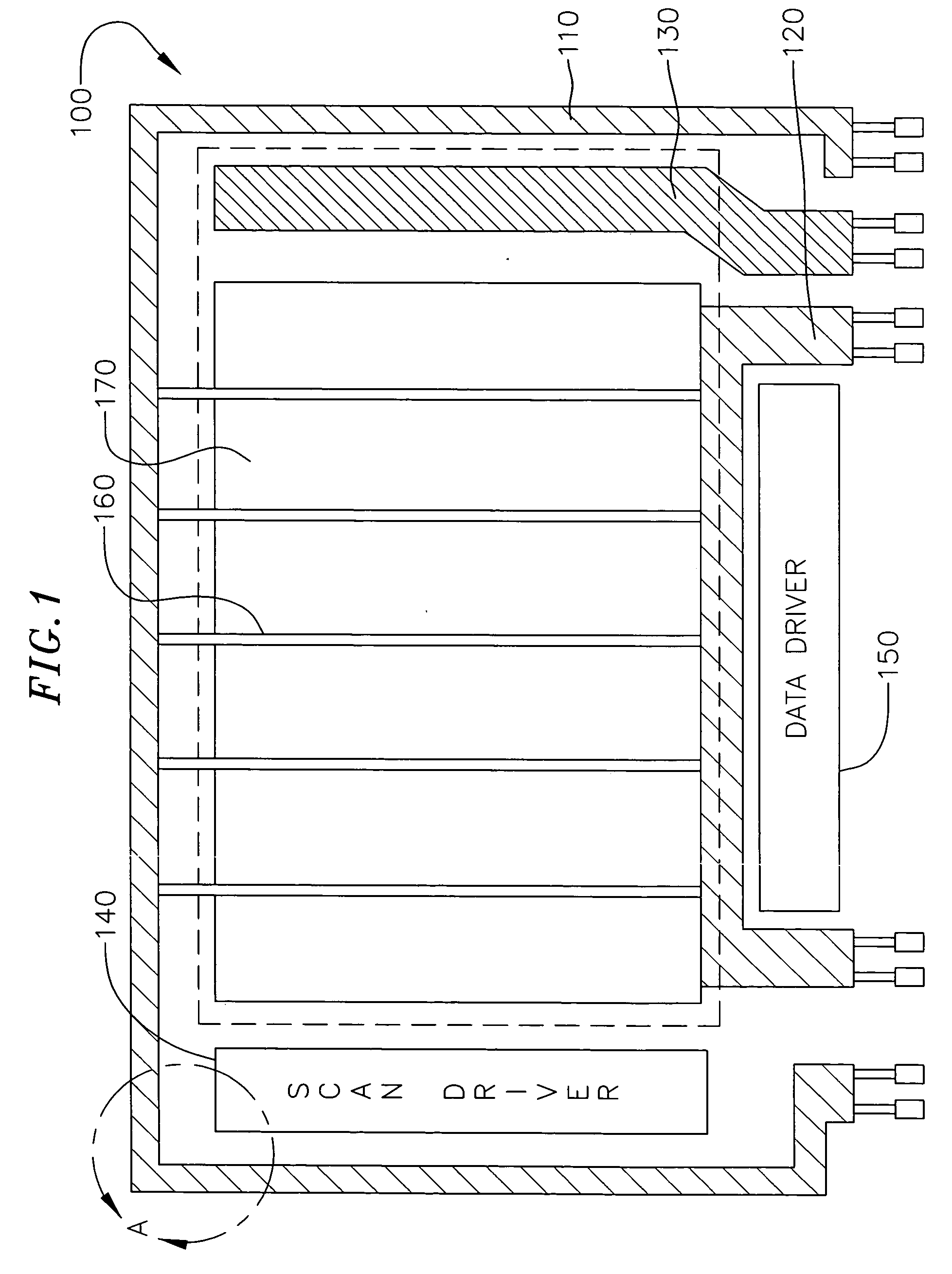

Organic electroluminescent display device

ActiveUS20050078105A1Improve finishing efficiencyRelieving degree of accumulationElectroluminescent light sourcesSolid-state devicesEngineeringOrganic electroluminescence

A display device in which charge damage occurring at wiring near the periphery is prevented or reduced, and wiring is facilitated during manufacturing by controlling an angle of an edge part of the wiring near the periphery. A display device includes a substrate, a pixel region including a plurality of unit pixels formed on the substrate. A power supply voltage line supplies a power supply voltage to the pixel region, and a cathode voltage line supplies a cathode voltage to the pixel region. The power supply voltage line includes an edge part formed in an obtuse angle. The edge part of wiring adjacent to the power supply voltage line may also be formed in an obtuse angle. Further, a cathode voltage line and a scan driver each may include an edge part formed in an obtuse angle. The display device may be an organic electroluminescent display device.

Owner:SAMSUNG DISPLAY CO LTD

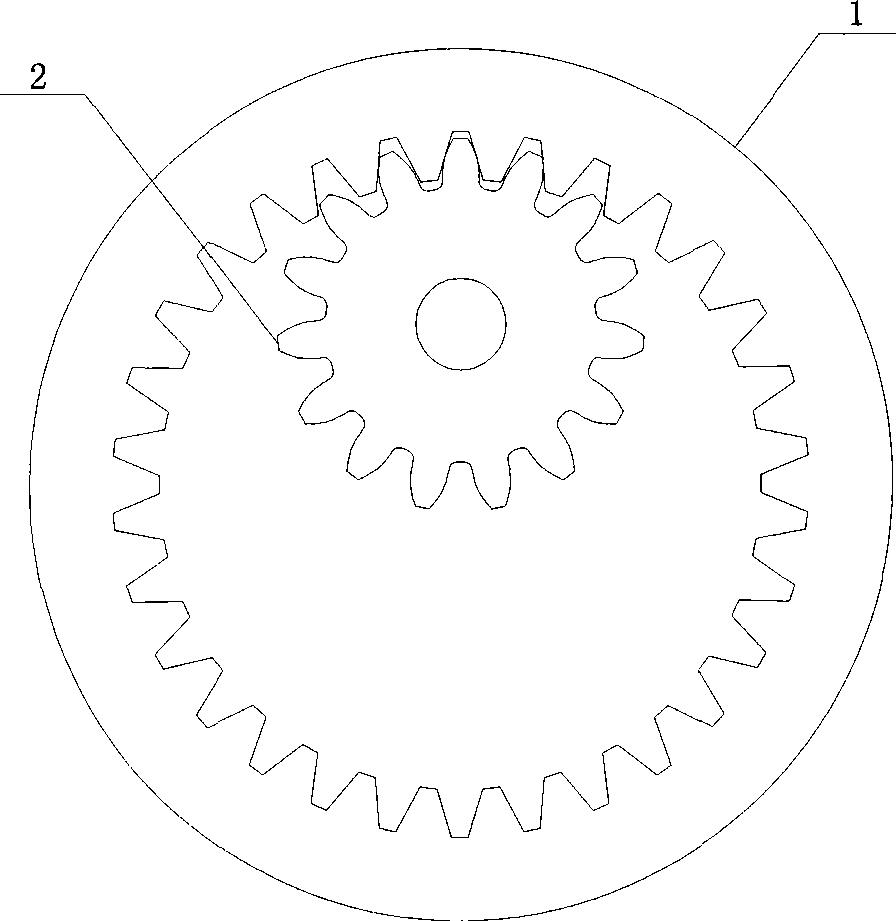

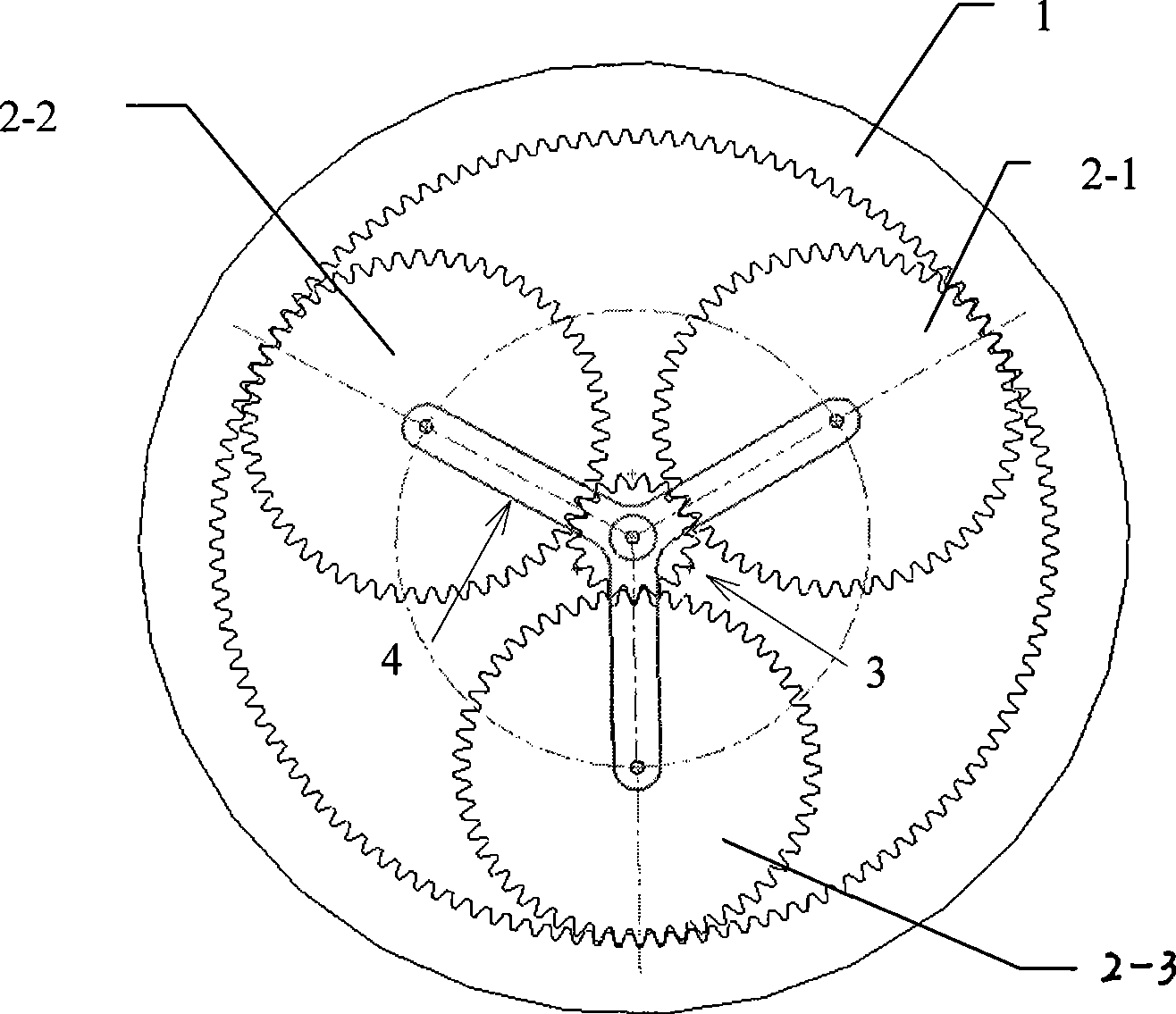

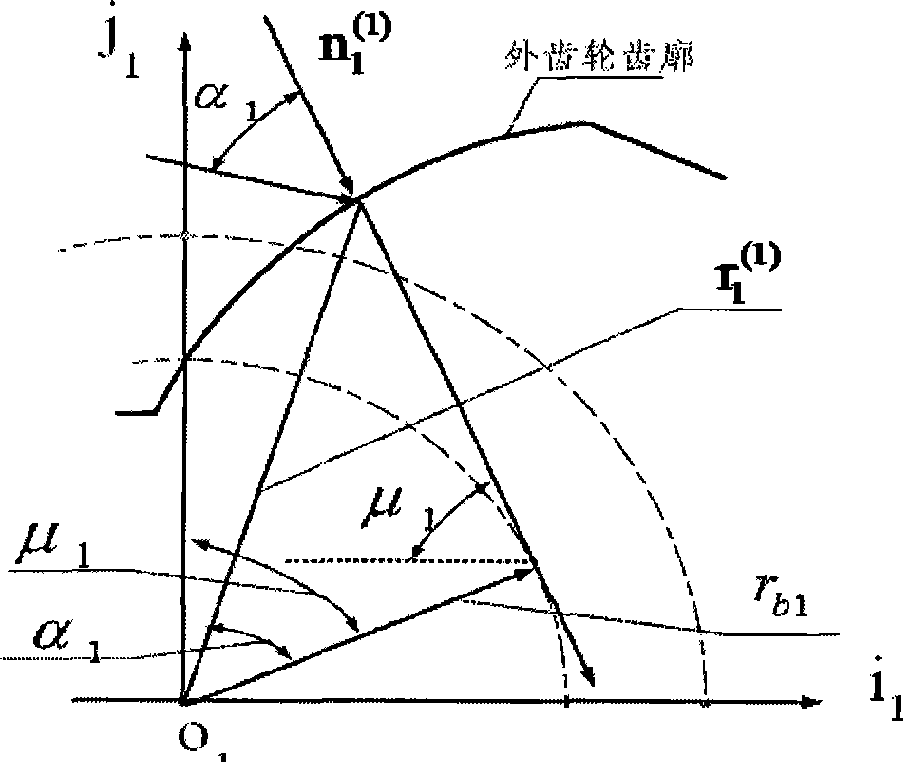

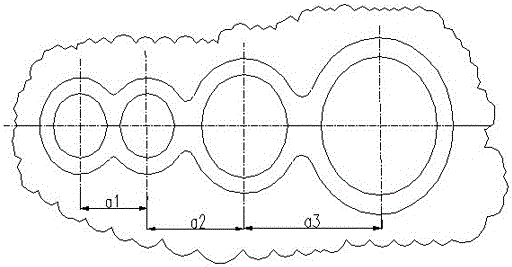

Straight line-involute profile inner-gearing cylindrical gear pair

InactiveCN101476614AImprove manufacturing precisionHigh precisionToothed gearingsPortable liftingGear wheelEngineering

The invention discloses a meshed cylindrical gear pair in a linear-involute tooth profile, which comprises an internal gear and a gear in meshing transmission with the internal gear. The tooth profile of the internal gear is linear, and the tooth profile of the gear in meshing transmission with the internal gear is involute. The tooth profile of the internal gear is changed into a straight line from an involute, grinding teeth can be shaped only by linearly finishing by a grinding wheel, the finishing efficiency is remarkably improved, and the precision can reach grade 4 to 6; and the internal gear adopts low-carbon steel carburization quenching, not only has high tooth surface strength, but also does not need to adjust quality before quenching, and improves the gear shaping processing efficiency greatly, so the meshed cylindrical gear pair radically solves the problems of low processing efficiency of the internal gear, poor precision and low tooth surface hardness, and promotes overall performances of a high-speed heavy duty speed reducer (speed increaser) containing the internal gear pair made in China.

Owner:HENAN UNIV OF SCI & TECH

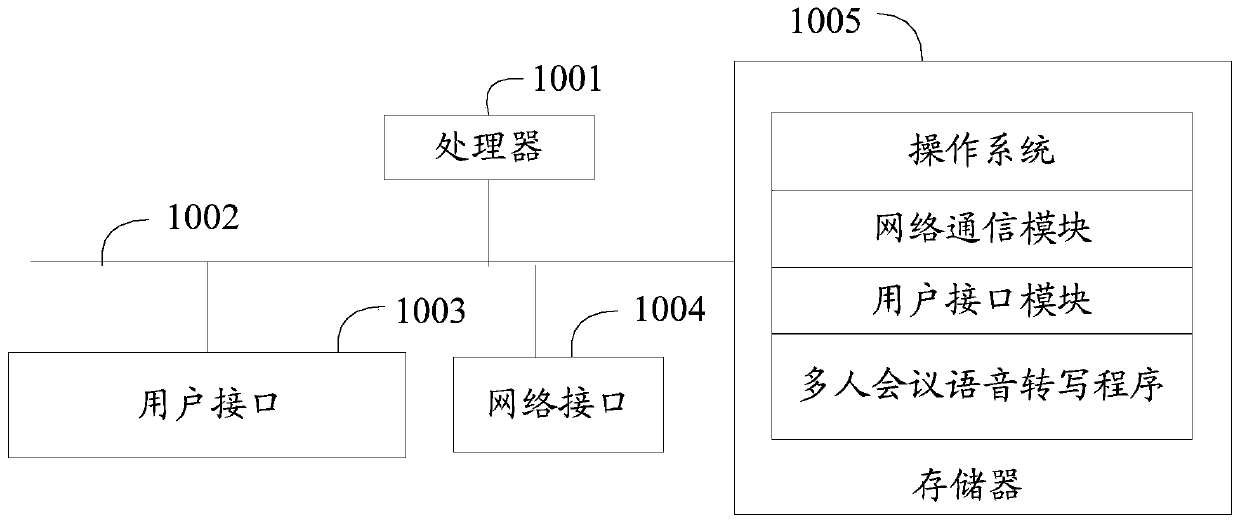

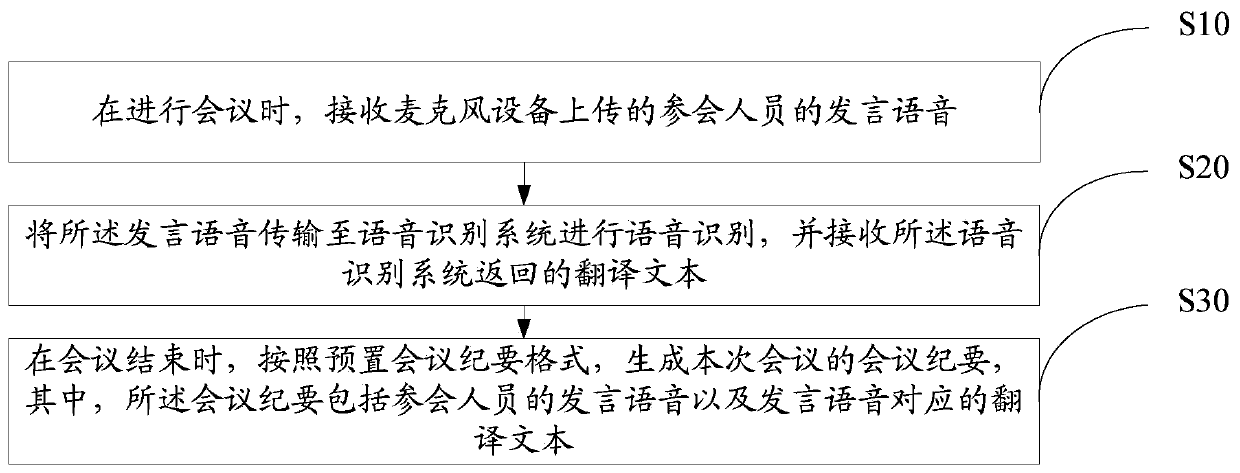

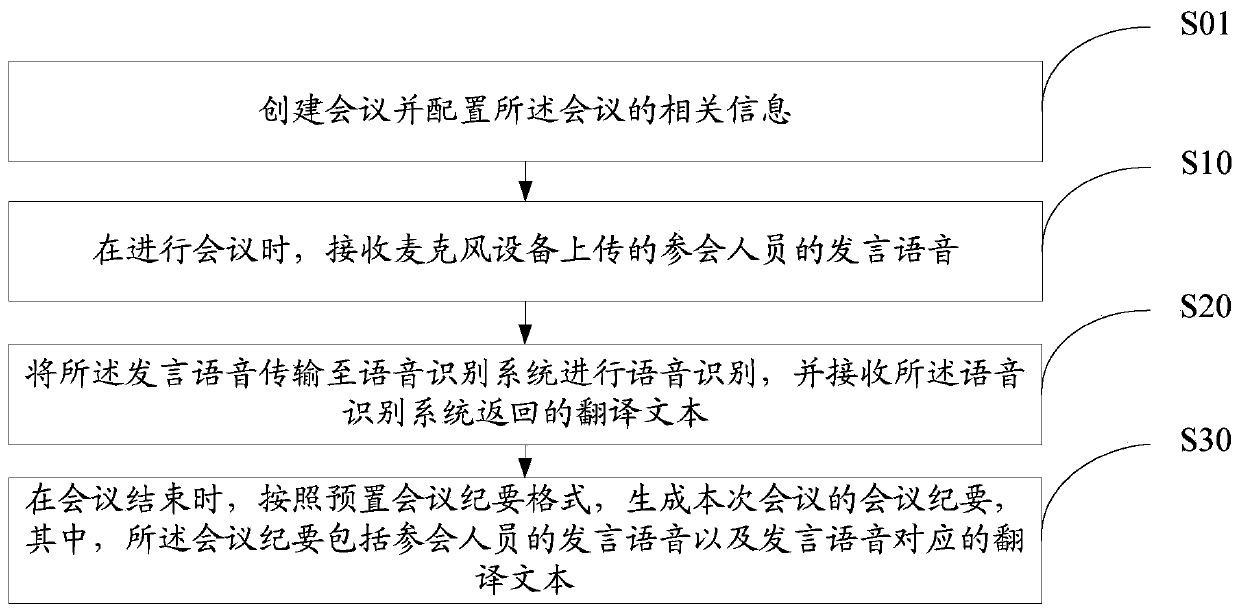

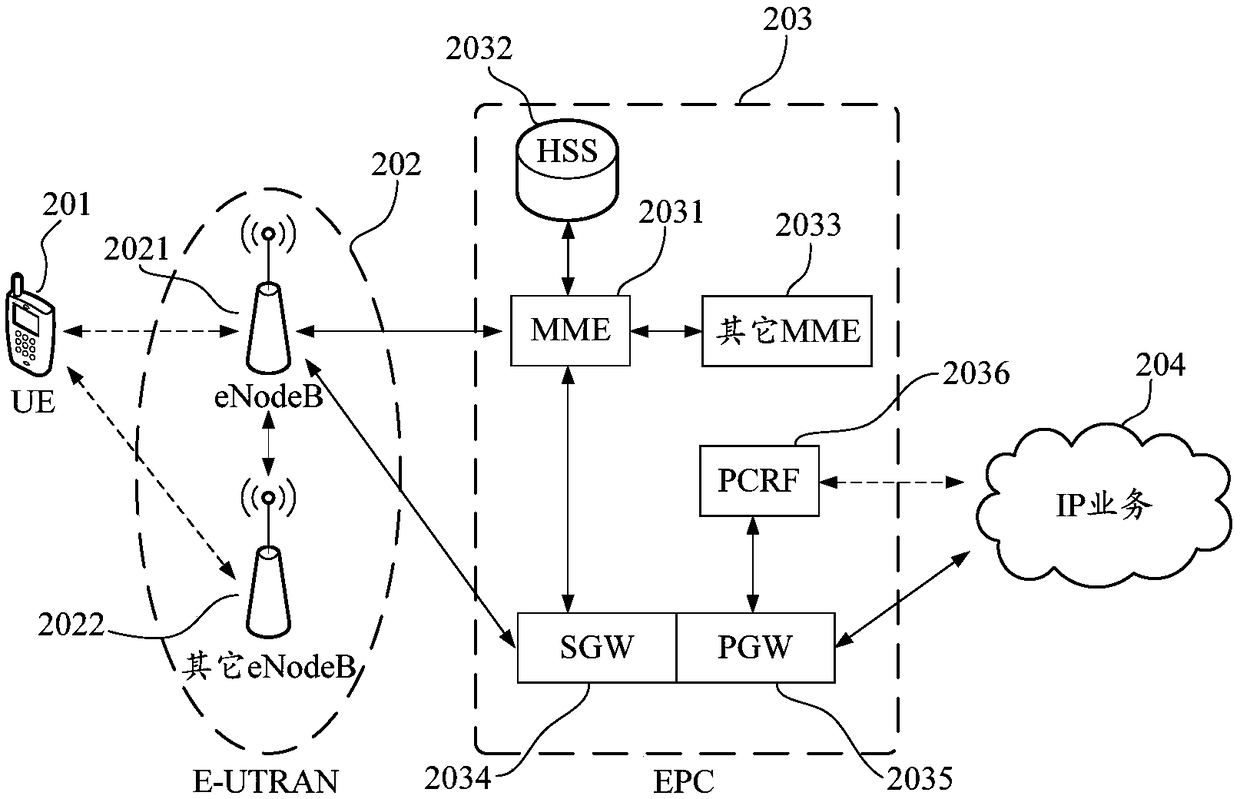

Multi-person conference voice transfer method, device and system, equipment and storage medium

PendingCN110049270AAvoid tedious and time-consumingImprove finishing efficiencySpecial service provision for substationTelevision conference systemsSpeech identificationMicrophone

The invention relates to the technical field of artificial intelligence, and discloses a multi-person conference voice transfer method, which comprises the following steps of: during a conference, receiving a speaking voice of a participant uploaded by microphone equipment; transmitting the speaking speech to a speech recognition system for speech recognition, and receiving a translation text returned by the speech recognition system; and at the end of the conference, generating a conference summary of the current conference according to a preset conference summary format, the conference summary comprising speaking voices of participants and translation texts corresponding to the speaking voices. The invention further discloses a multi-person conference voice transferring device, system and equipment and a computer readable storage medium. According to the invention, tedious and time-consuming manual conference voice arrangement is avoided, the arrangement efficiency of conference summaries is improved, manpower is saved, and the user experience is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

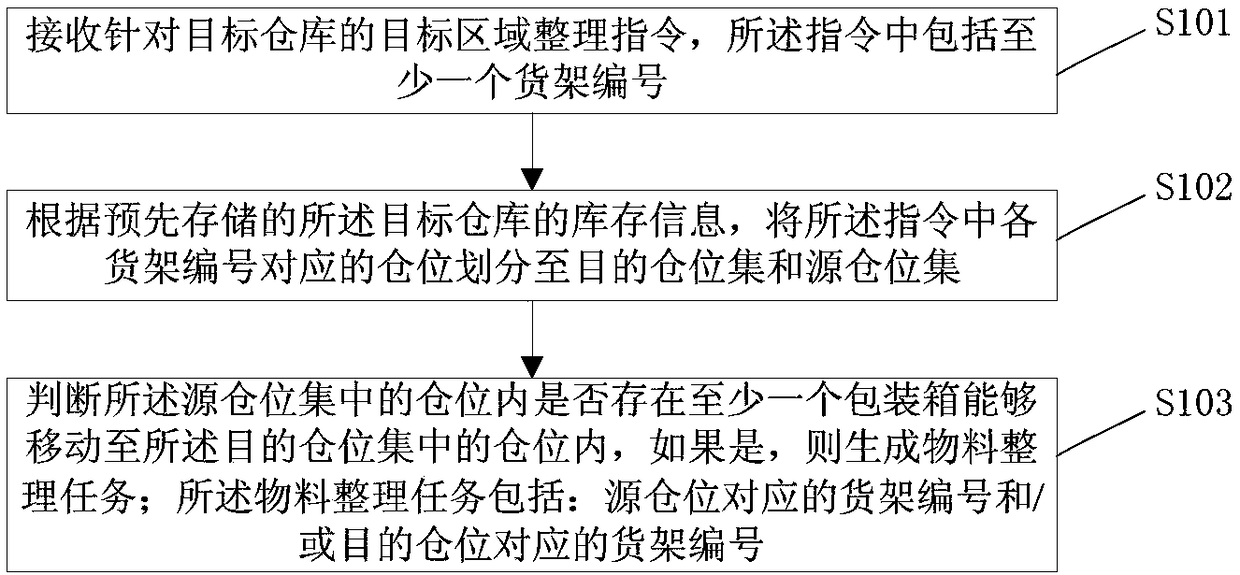

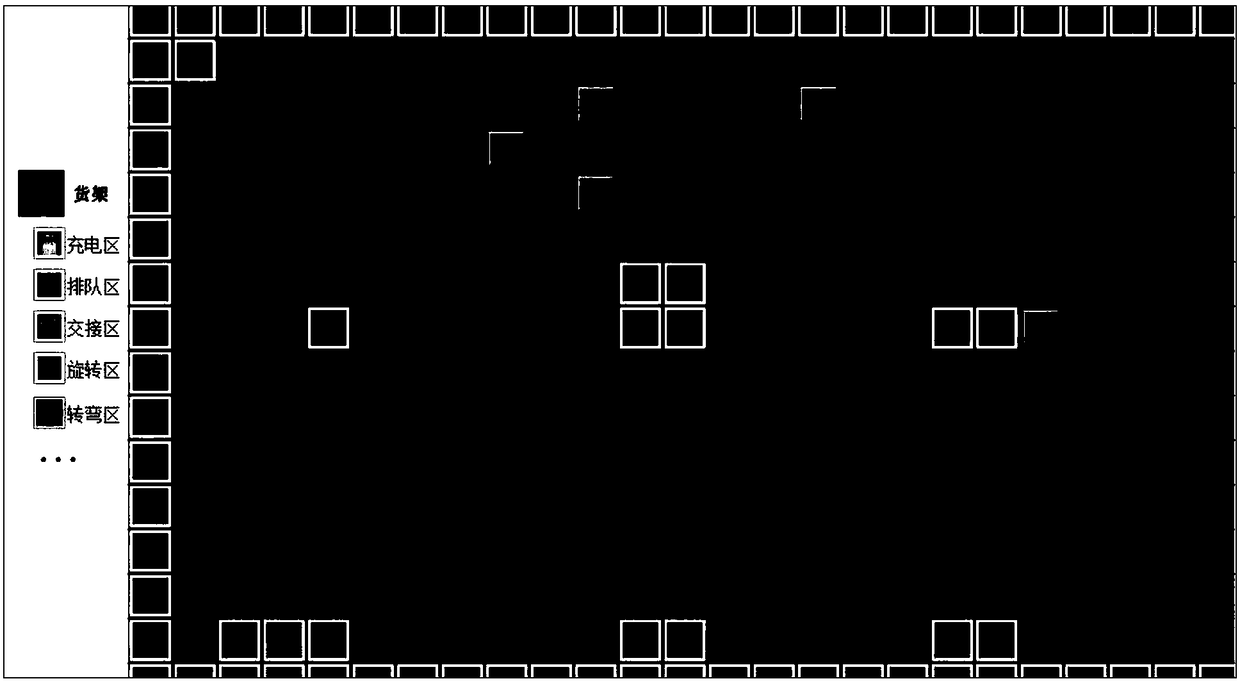

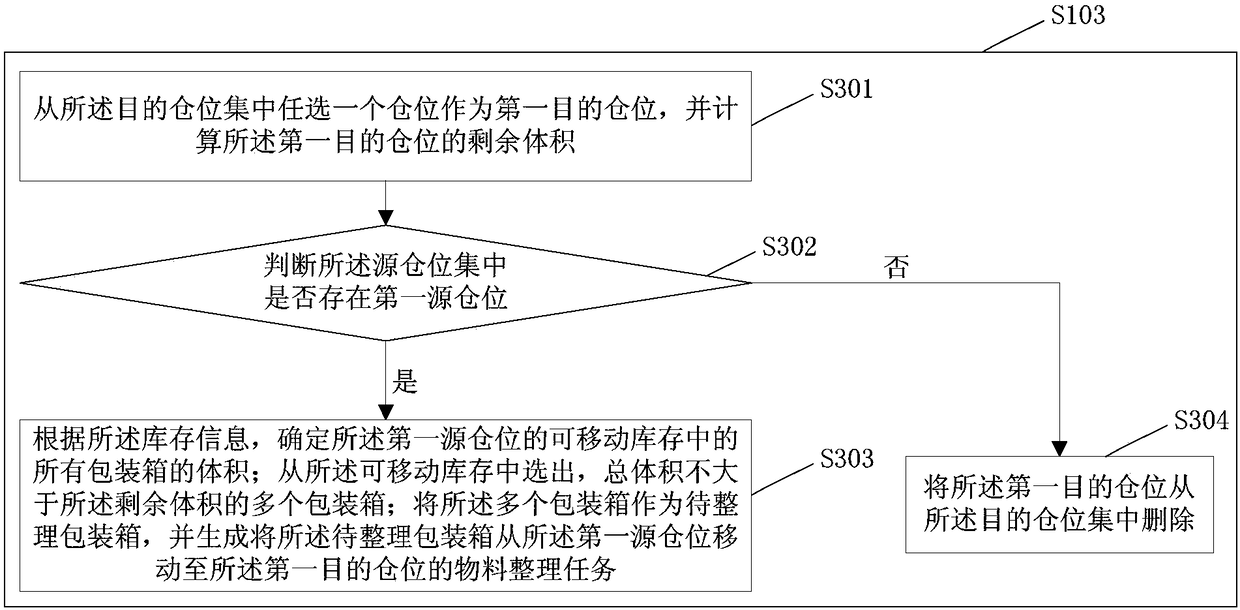

Generation method and device of material arrangement task and material arrangement method and device

PendingCN108229867AImprove production efficiencyImprove finishing efficiencyLogisticsComputer scienceStorage garage

Owner:HANGZHOU HIKROBOT TECH CO LTD

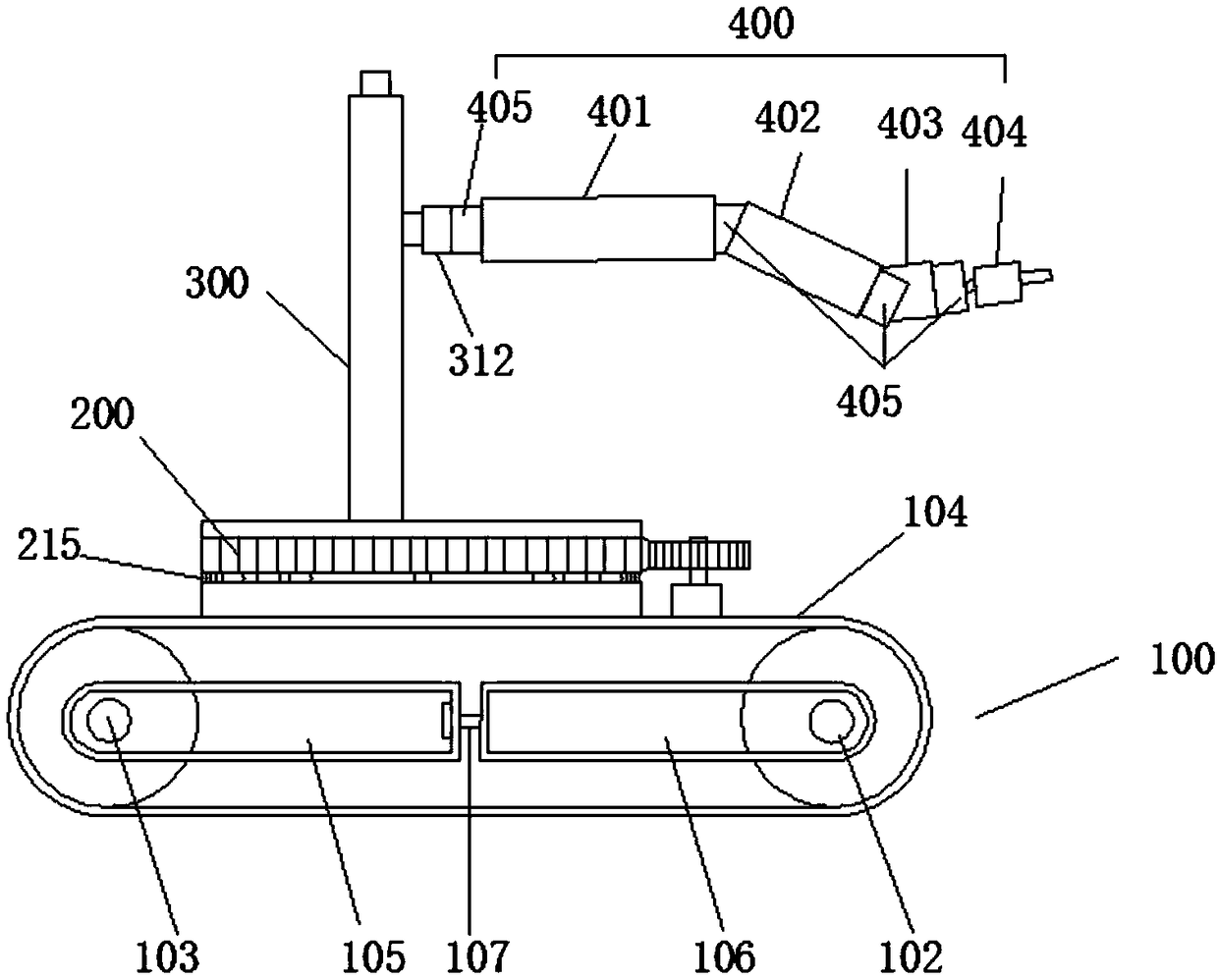

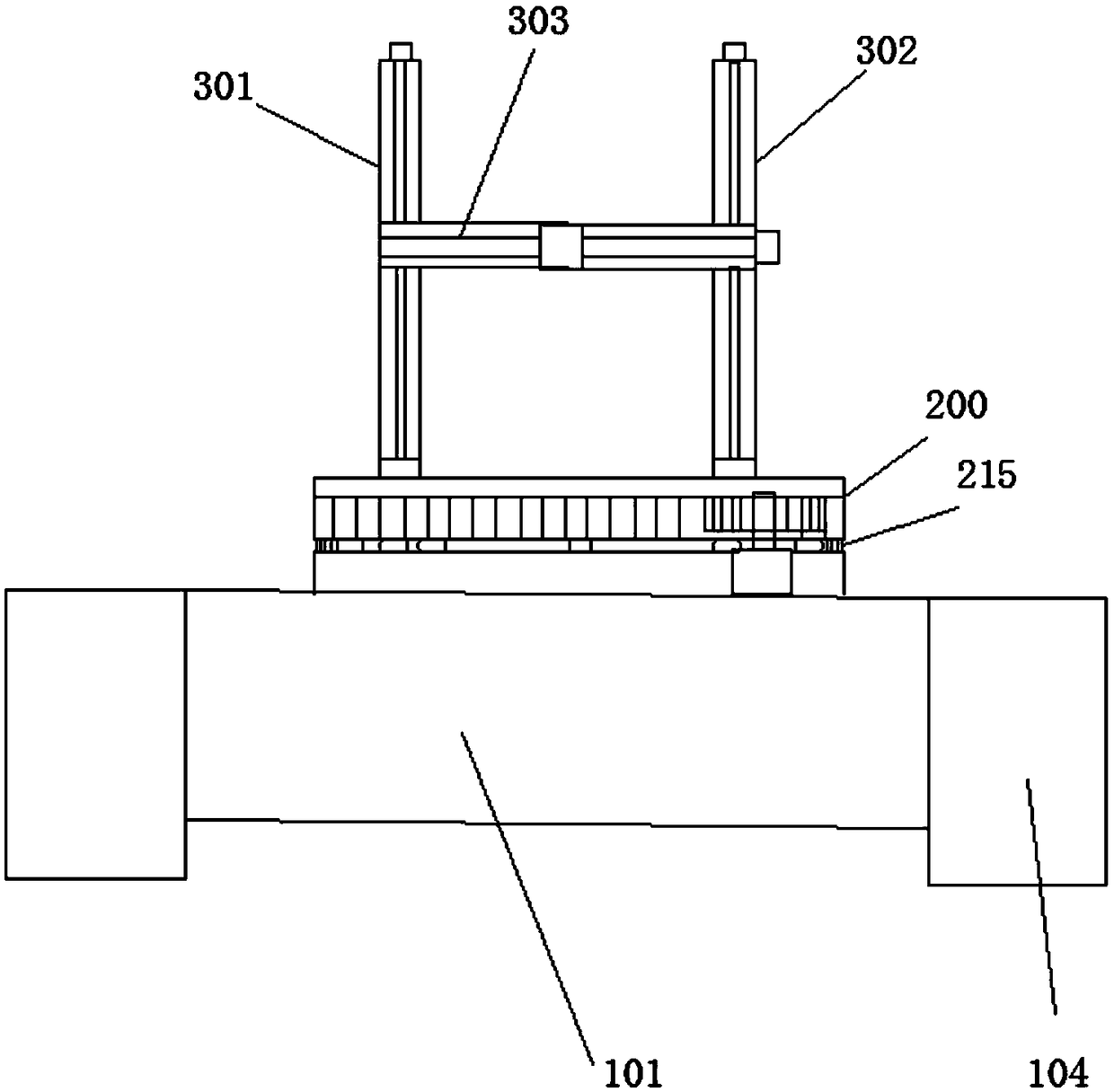

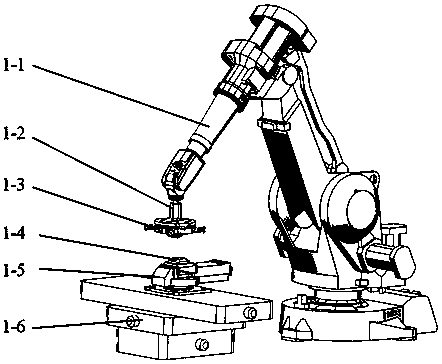

Industrial robot

InactiveCN109015594AImprove weight capacityFully supportedProgramme-controlled manipulatorArmsRobotic armEngineering

The invention provides an industrial robot and belongs to the field of robots. The industrial robot comprises a moving device, a rotating supporting device, a lifting device and a mechanical arm. Therotating supporting device is arranged on the moving device, the lifting device is arranged on the rotating supporting device, and the mechanical arm is connected with the lifting device. The rotatingsupporting device comprises a rotating driving mechanism, a rotating transmission mechanism and a supporting platform. The lifting device comprises a first lifting device body, a second lifting device body and a horizontal moving device. The mechanical arm utilizes a mechanical large arm body, a mechanical small arm body, a wrist joint and a mechanical claw to realize multiple degrees of freedomof movement and realize arranging and carrying of cargos, the cargo arranging efficiency is improved, and a lot of manpower and material resources are saved.

Owner:李友朋 +1

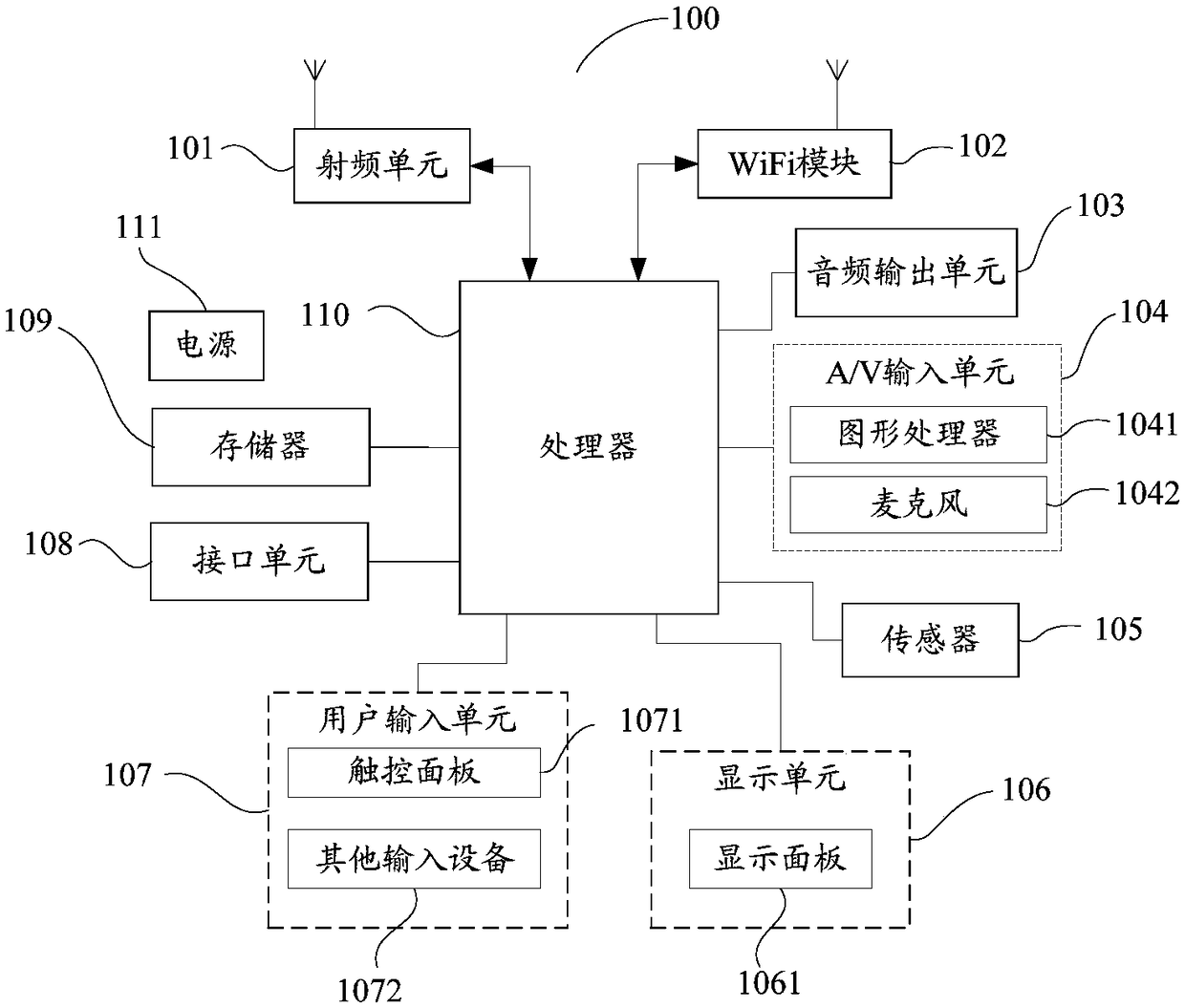

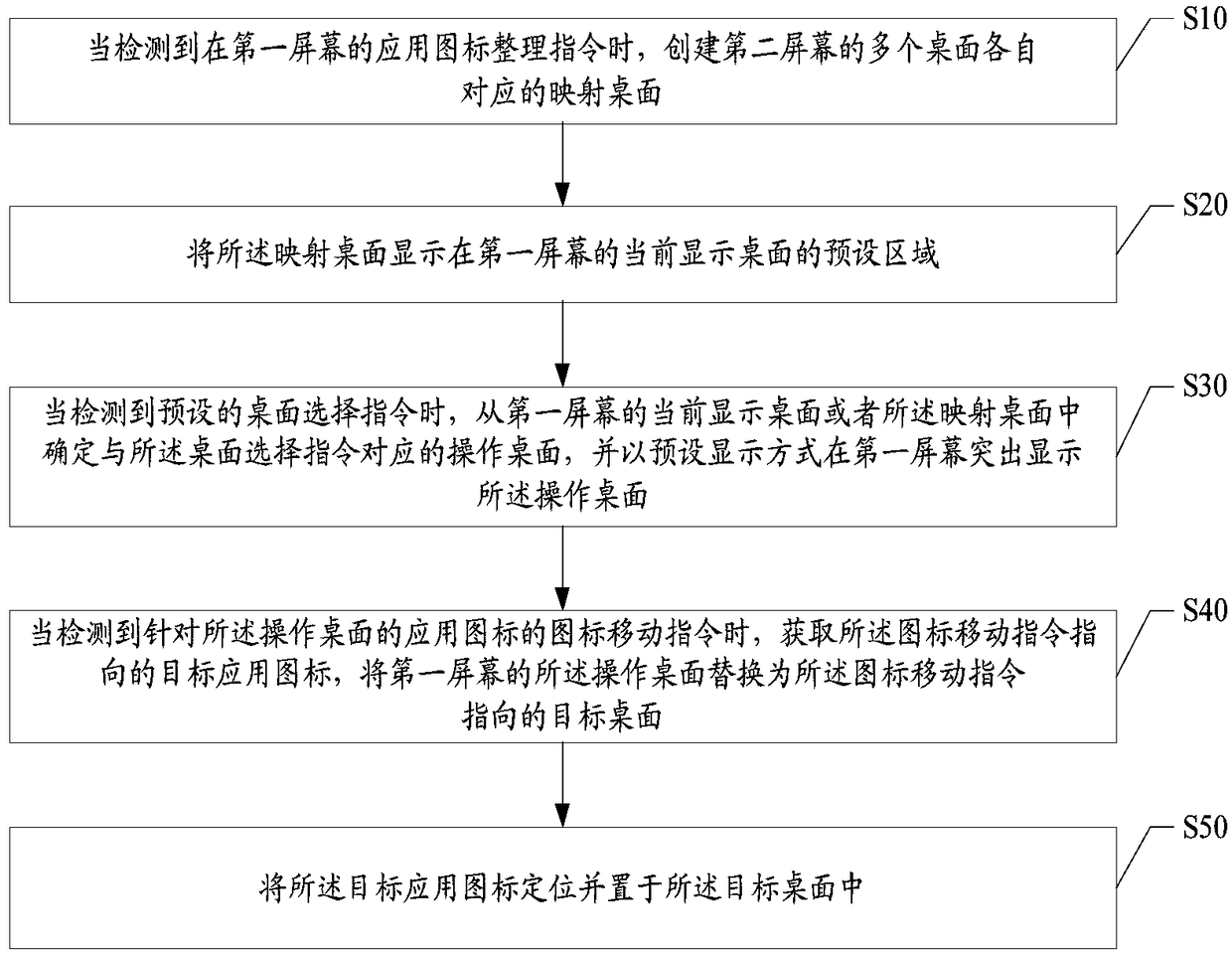

Double-side screen application icon arrangement method, mobile terminal and readable storage medium

InactiveCN109213401AEasy to operateImprove finishing efficiencyInput/output processes for data processingApplication softwareSecond screen

The invention provides a double-sided screen application icon arranging method. The mobile terminal comprises a first screen and a second screen. The mobile terminal comprises the following steps: when an application icon arranging instruction on the first screen is detected, a mapping desktop corresponding to a plurality of desktops of the second screen is created; when a mapping desktop corresponding to a plurality of desktops of the second screen is detected, a mapping desktop corresponding to a plurality of desktops is created. Displaying the mapped desktop in a preset area of the currently displayed desktop of the first screen; when a preset desktop selection instruction is detected, determining an operation desktop corresponding to the desktop selection instruction, and displaying the operation desktop; when an icon moving instruction for an application icon of the operation desktop is detected, obtaining a target application icon pointed to by the icon moving instruction and replacing the operation desktop with a target desktop pointed to by the icon moving instruction; positioning and placing the destination application icon on the destination desktop. The invention also provides a mobile terminal and a readable storage medium. The invention solves the technical problems that the sorting operation of the desktop icon of the application program of the prior double-sidedscreen mobile terminal is tedious and the efficiency is not high.

Owner:南昌努比亚技术有限公司 +1

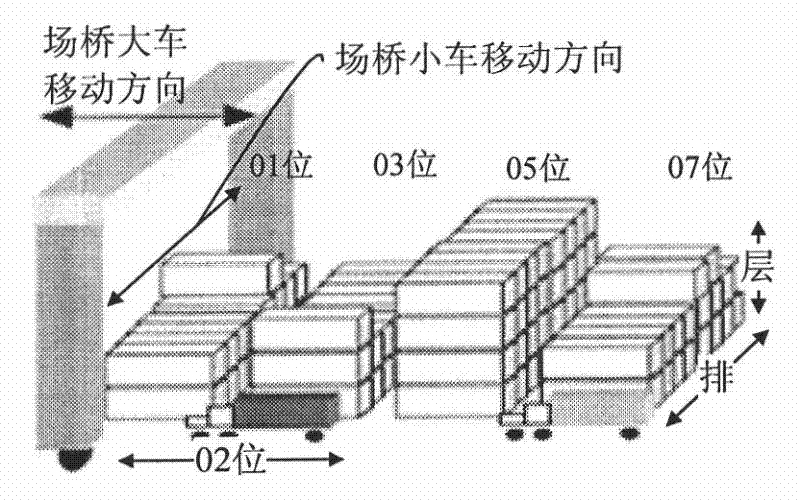

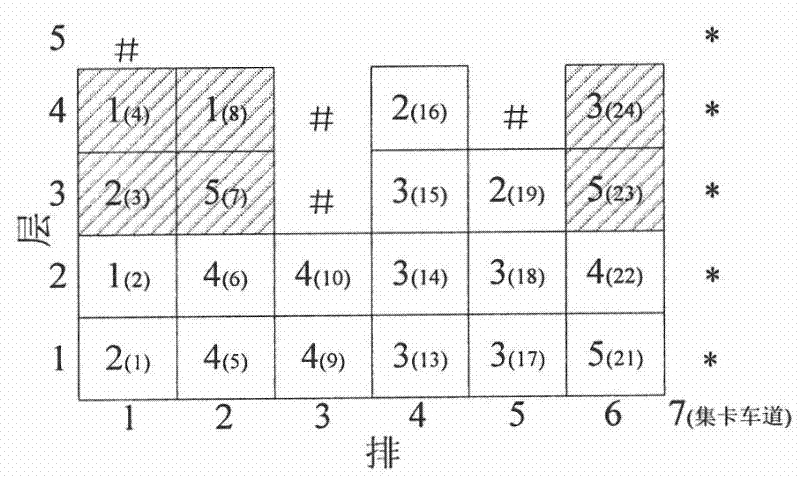

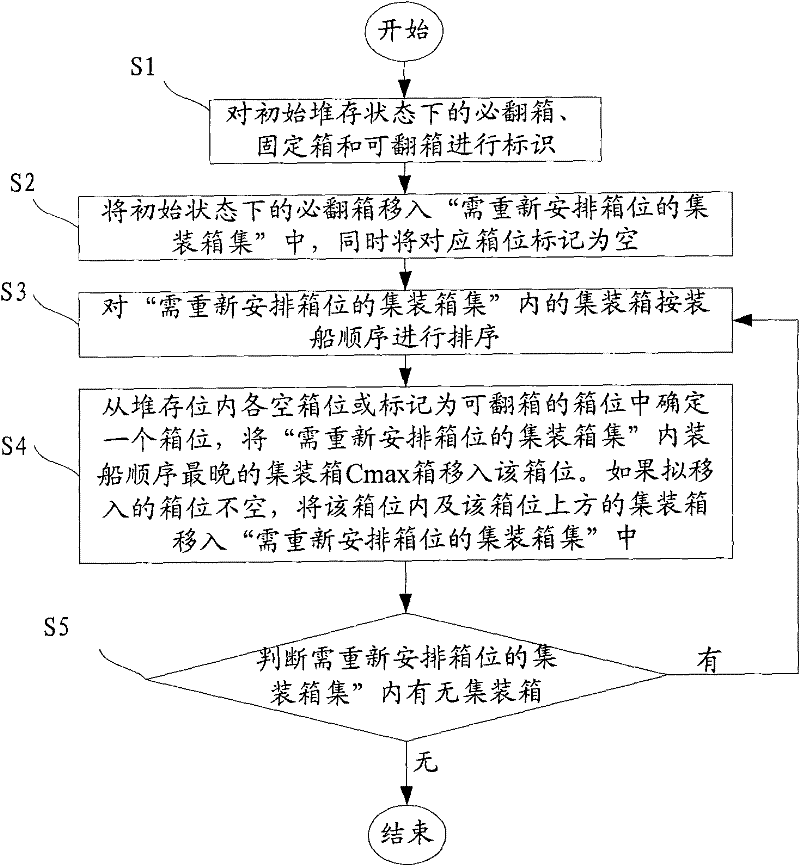

Pre-turning box finishing method of dock export carton of large-scale container before shipping

The invention discloses a pre-turning carton finishing method of a dock export carton of a large-scale container before shipping, which comprises the following steps of: determining a target state of a pre-turning carbon, and marking a fixed carton in an initial stockpiling state according to the target state of the pre-turning carton; carrying out a carton-turning operation to a non-fixed carton in the initial stockpiling state and recording the times of carton-turning according to the control rule of the ineffective turning carton until the carton is unnecessary to turn in the stockpiling position so as to form a plurality of pre-turning carton finishing schemes; and determining the scheme with the least times of effective carton-turning to be a pre-turning carton finishing optimal scheme. The method can realize the intelligence, the optimization and the rapid strategy of the pre-turning carton scheme of the dock export carton of the large-scale container, reduce carton-turning times and improve carton-turning efficiency. With advanced determination of the target state of the pre-turning carton, the marking of the fixed carton in the initial stockpiling state and in the searching process of the carton-turning scheme and control rules of ineffective carton-turning, the pre-turning carton finishing method effectively controls the search space of the scheme and the complexity of calculation and optimizes the carton-turning times. In the method, effectiveness determination and optimal adjustment are also carried out on carton-turning twice or more to optimize the carton-turning times and ensure that the carton-turning efficiency is higher.

Owner:WUHAN UNIV OF TECH

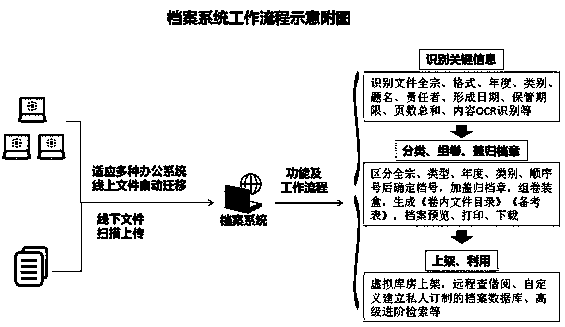

Automatic information filing and sorting system

ActiveCN111597150AImplement automatic handoverSupport online previewCharacter and pattern recognitionOffice automationSoftware engineeringBarcode

The invention discloses an automatic information filing and sorting system. The invention belongs to the field of office automation, the automatic archiving and sorting information system mainly realizes the following functions: the system adapts to various office systems, archived arrangement is carried out on electronic files in the office system; the system strictly complies with the provisionof 5.4. 4: the electronic file can be identified on the archived file in the form of an archived seal generated by the system or in other forms such as a bar code and the like in the 'archived file arrangement rule'; the concept of 'electronic file paper ' is used as a support; a path and an operation method for intelligent archive management are actively explored in order to accelerate and promote digital archive construction, archive digital processing, intelligent archive management and the like, basic theoretical research of archives is enriched and practiced to a certain extent, and the system has unique value for practical exploration of archive subject development.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

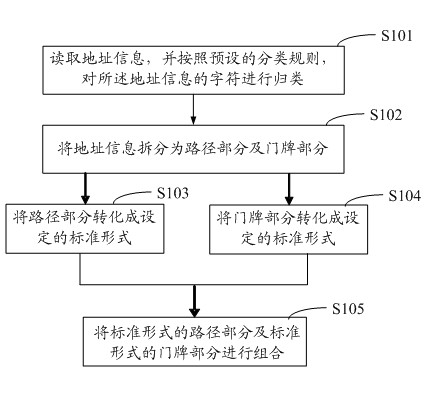

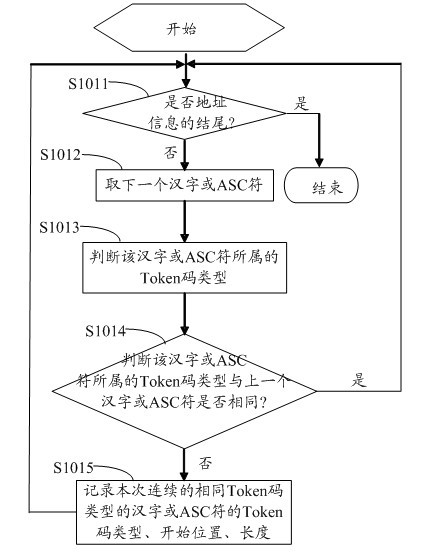

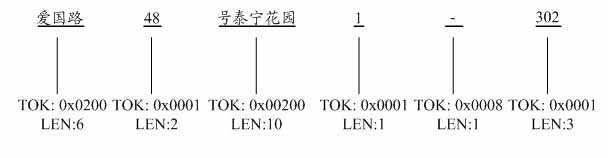

System and method for automatically identifying Chinese address subscribers

InactiveCN102073724AReduce address collation costsImprove finishing efficiencyCharacter and pattern recognitionSpecial data processing applicationsClassification ruleStandardization

The invention is applicable to the postal service field and provides a system and method for automatically identifying Chinese address subscribers. The method comprises the following steps: reading the address information and classifying the characters of the address information according to the preset classification rule; dividing the address information into a path part and a door plate part according to the classification; converting the path part into the set standard form; converting the door plate part into the set standard form; and combining the path part in the standard form with the door plate part in the standard form and outputting the combined parts. In the embodiment of the invention, the address information is classified and the door plate part and the path part are standardized, thus preventing manually classifying the address information which is nonstandard in writing, thereby reducing the address classifying cost and improving the classifying efficiency of the nonstandard address information.

Owner:SHENZHEN ROUTDATA TECH

Thermoelectric Converter and System Comprising a Thermoelectric Converter

InactiveUS20120113594A1Improve efficiencyImprove finishing efficiencyThermal electric motorCooling/ventilation/heating modificationsThermal energyElectricity

An apparatus and process are disclosed that relates to a thermoelectric converter for converting thermal energy into electric energy. The apparatus includes at least one magnetic circuit including magnetic flux; at least one electric coil coupled to the at least one magnetic circuit; a magnetic switch coupled to the at least one magnetic circuit which loads the at least one electric coil with magnetic flux of the at least one magnetic circuit depending on a temperature of the magnetic switch, wherein the magnetic switch has a ferromagnetic state below a critical temperature (Tc) and a paramagnetic state above the critical temperature (Tc).

Owner:IBM CORP

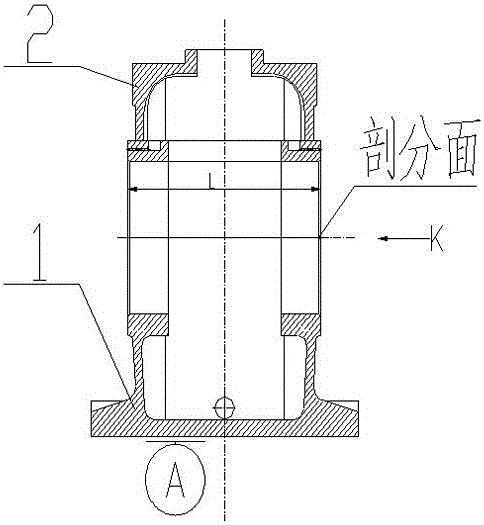

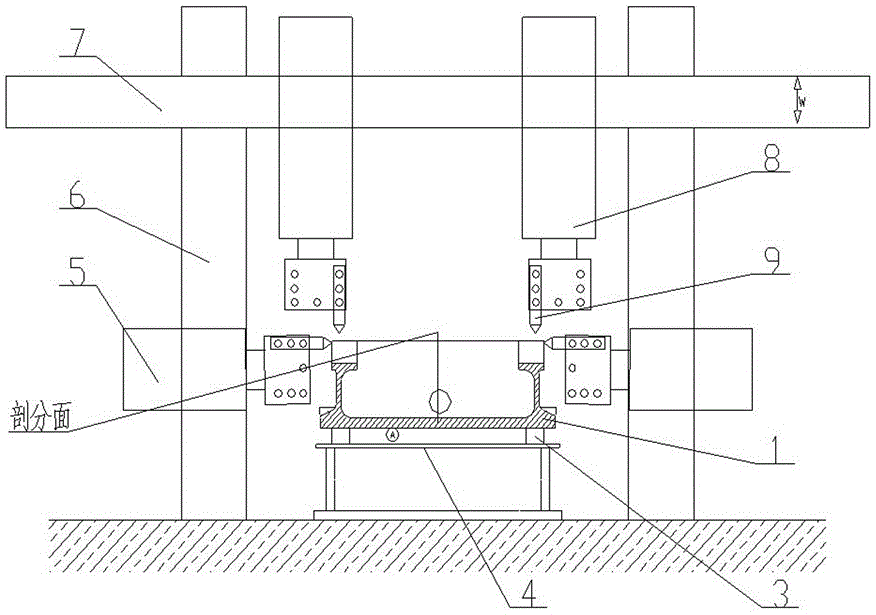

Machining method for improving form and position precision of large gearbox body device

InactiveCN105750601AImprove finishing efficiencyReduce adjustment and deformation errorsMilling equipment detailsOther workshop equipmentEngineeringMachine tool

The invention relates to a machining method for improving the form and position precision of a large gearbox body device. The processing method comprises the following steps: marking out, performing rough machining on the subdivision surface and a semi-axle hole of each separated gearbox body, performing artificial failure, marking out secondarily, carrying out semifinishing on the subdivision surface and the semi-axle hole of each separated gearbox body, performing natural failure, performing finishing on the subdivision surface of each separated gearbox body, assembling a gearbox body device, performing finishing on the axle holes of the gearbox body device, and checking finally. According to the machining method, since semifinishing and finishing of each separated gearbox body and the gearbox device are performed by the same machine tool on the same locating basis, the machining precision is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

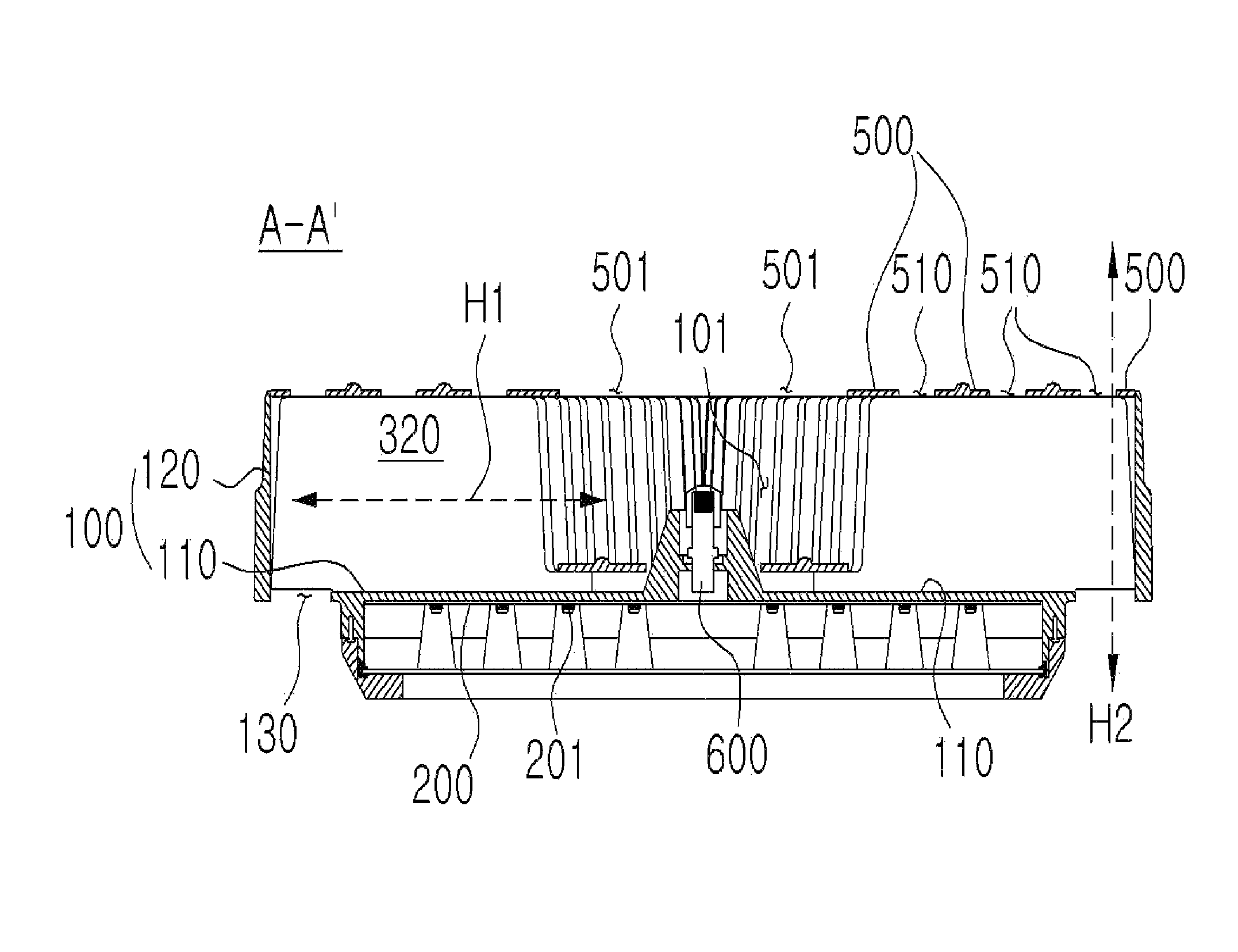

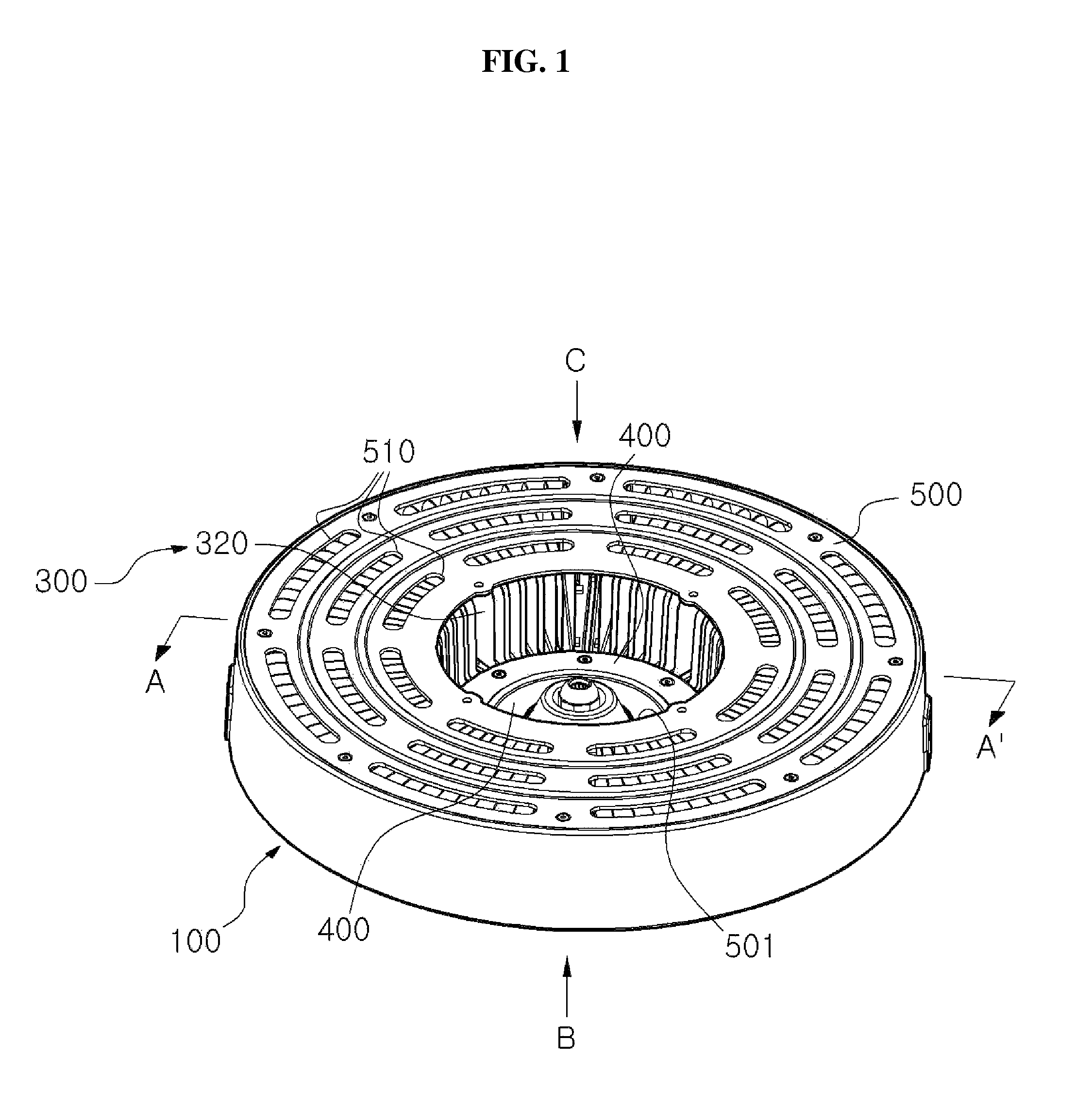

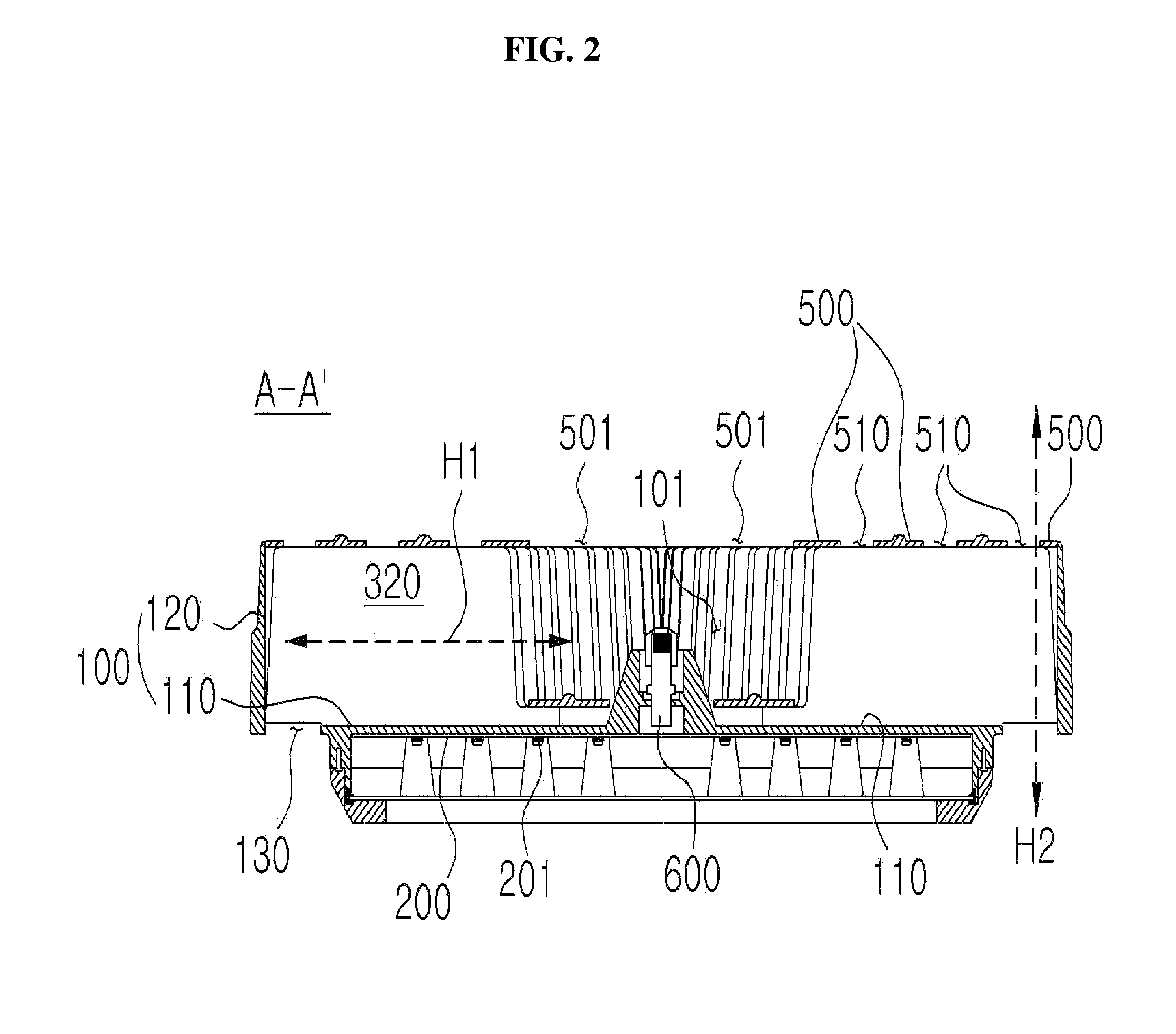

Optical semiconductor lighting apparatus

InactiveUS8585250B1Reduce weightImprove cooling efficiencyPlanar light sourcesLighting support devicesComputer moduleNatural convection

A first heat sinking path formed in a forming direction of a heat sink unit disposed radially in a housing where a light emitting module is mounted. A second heat sinking path is formed along an edge of the light emitting module. By providing a light engine concept in which a light emitting module, an optical member, and a heat sink unit are included and a bottom surface is gradually widened from one side to the other side, an optical semiconductor lighting apparatus can reduce a total weight of a product, can further improve heat dissipation efficiency by inducing natural convection, is simple in the product assembly and installation, and is easy in maintenance, and can provide products with high reliability by increasing the arrangement efficiency of semiconductor optical devices per unit area.

Owner:POSCO LED

Microwave enzyme-deactivating process for green tea

ActiveCN103380829AStop metabolismNot easy to crushPre-extraction tea treatmentGreen teasMicrowave power

The invention discloses a microwave enzyme-deactivating process for green tea. The process comprises the following steps: setting the temperature of a microwave warehouse to be more than 200 DEG C and preheating the microwave warehouse; placing 1.5 to 2 kg of fresh tea leaves into the microwave warehouse, adjusting microwave power to be 1500 to 1800 W, stirring the fresh tea leaves, allowing leaf temperature to rapidly rise to more than 80 DEG C and maintaining the temperature for 5 min; shaking the leaves, throwing the enzyme-deactivated leaves upwardly to allow the leaves to scatter in the air and then to naturally fall into the microwave warehouse and repeatedly throwing the leaves until leaf temperature drops to less than 42 DEG C; adjusting the microwave power to be 2000 to 2200 W and stewing the leaves; and taking the enzyme-deactivated leaves out of the microwave warehouse when water content in the leaves is in a range of 55 to 60%. The process provided by the invention terminates metabolism of the tea leaves, allows substances related to tea quality to maintain optimal, removes grassy smell and retains original tea fragrance of the green tea; the prepared green tea has a good color, almost being dark blue, and has no burnt leaves; moisture in the leaves gradually decreases, the tea is soft and is difficult to triturate during rolling, and the tea naturally curls to form cords.

Owner:绍兴健茗茶业有限公司

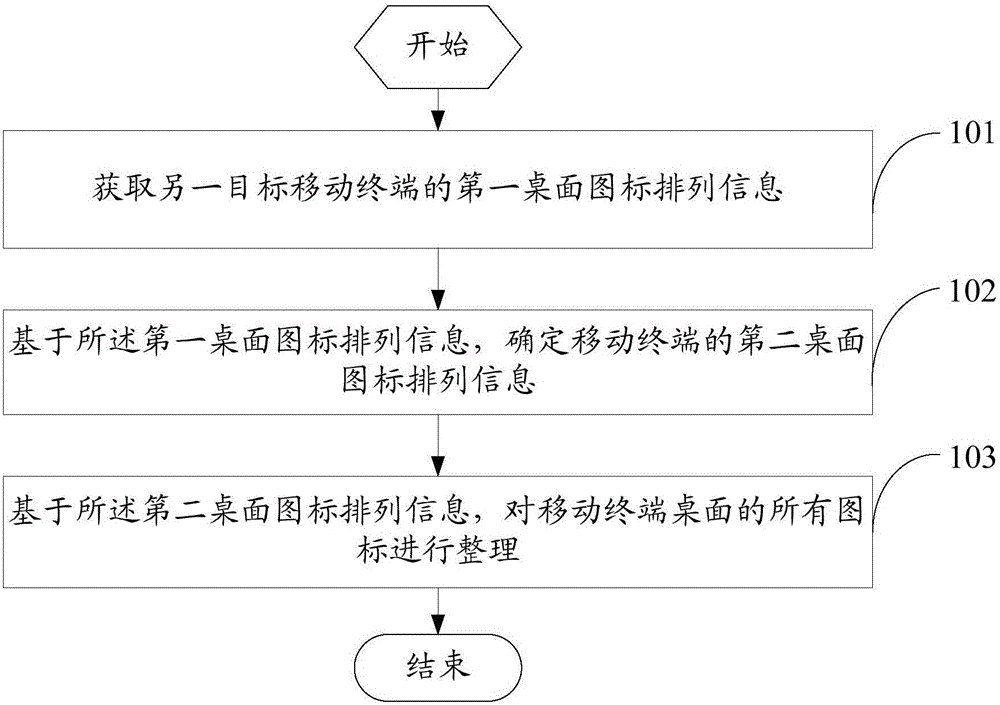

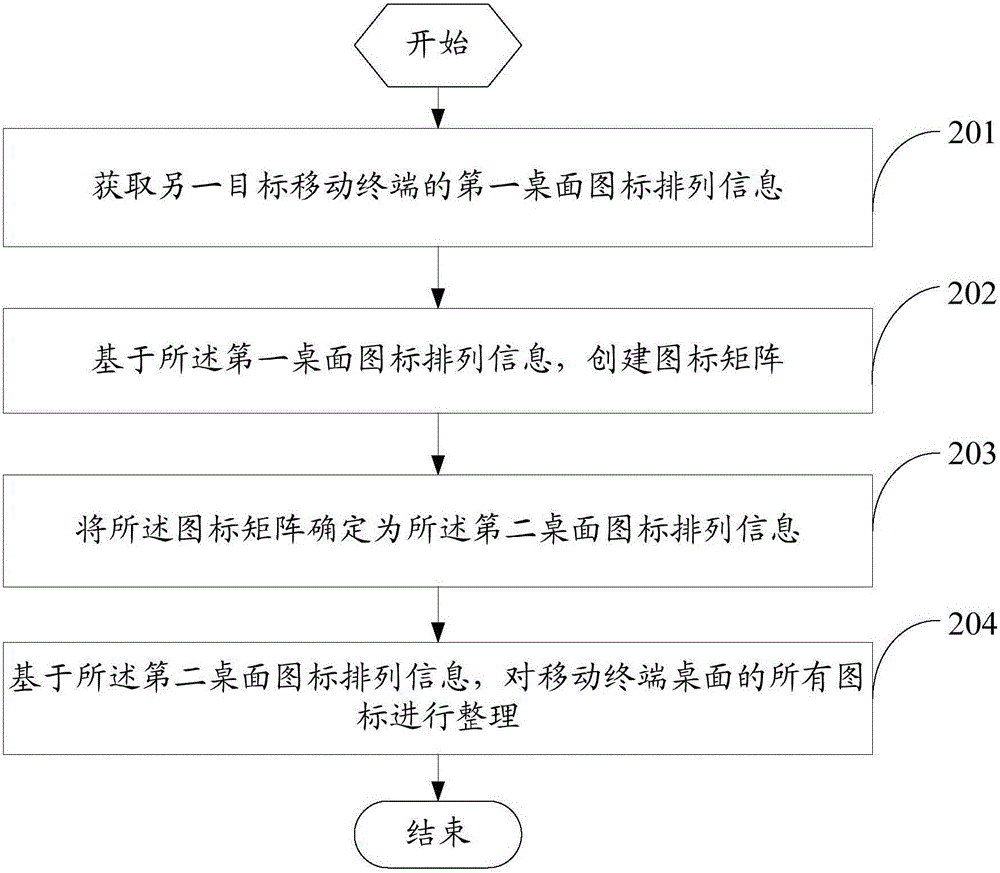

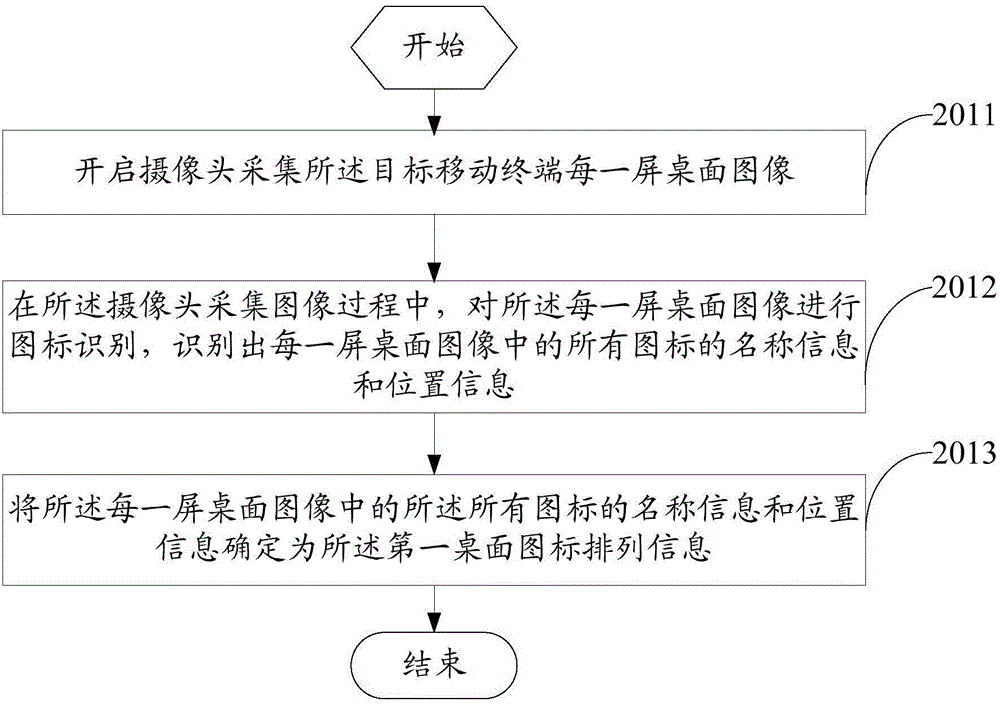

Desktop icon arranging method and mobile terminal

InactiveCN106201196AAvoid cumbersomeImprove finishing efficiencyInput/output processes for data processingOperating systemTime-Consuming

Owner:VIVO MOBILE COMM CO LTD

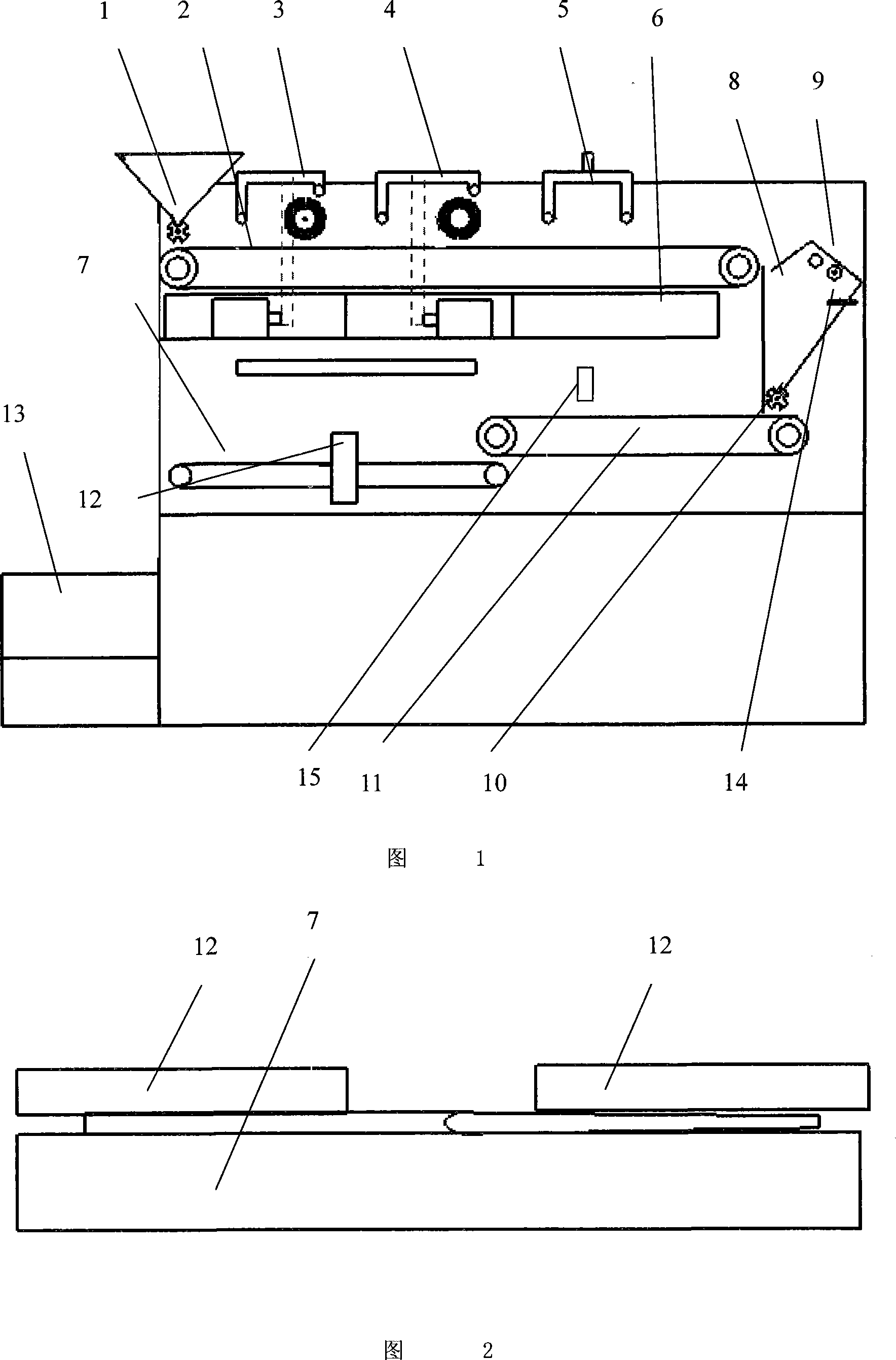

Chopsticks cleaning machine

InactiveCN101143086AImprove finishing efficiencyTableware washing/rinsing machinesEngineeringSmall head

A chopsticks cleaning machine includes a machine frame, a feeding mechanism, a first conveyer belt, a spray rinsing area, a spraying area and a clean water spraying area and also includes a drying and sterilizing mechanism, a rotating and intermitting mechanism, a second conveyer belt and a chopsticks tidying mechanism. An outlet of the first conveyer belt is connected with the drying and sterilizing mechanism, which is connected with the rotating and intermitting mechanism. The drying and sterilizing mechanism includes a chopsticks transferring box, an infrared tube. The second conveyer belt is arranged under the rotating and intermitting mechanism. Two sheets of limiting plates are arranged above the left side and the right side of the second conveyer belt. The space between the two sheets of the limiting plates is a chopsticks crossing area. A chopsticks-collecting box is placed at the outlet of the second conveyer belt. The width of the second conveyer belt is longer than the total length of the chopsticks; the heights of the limiting plates and the second conveyer belt is less than the thickness of the bigger end of the chopsticks and is larger than the thickness of the smaller end of the chopsticks. The invention provides a chopsticks cleaning machine, which can dry and sterilize the chopsticks after cleaning and at the same time has the function of ordering and tidying the bigger ends and the smaller ends of the chopsticks.

Owner:ZHEJIANG UNIV OF TECH

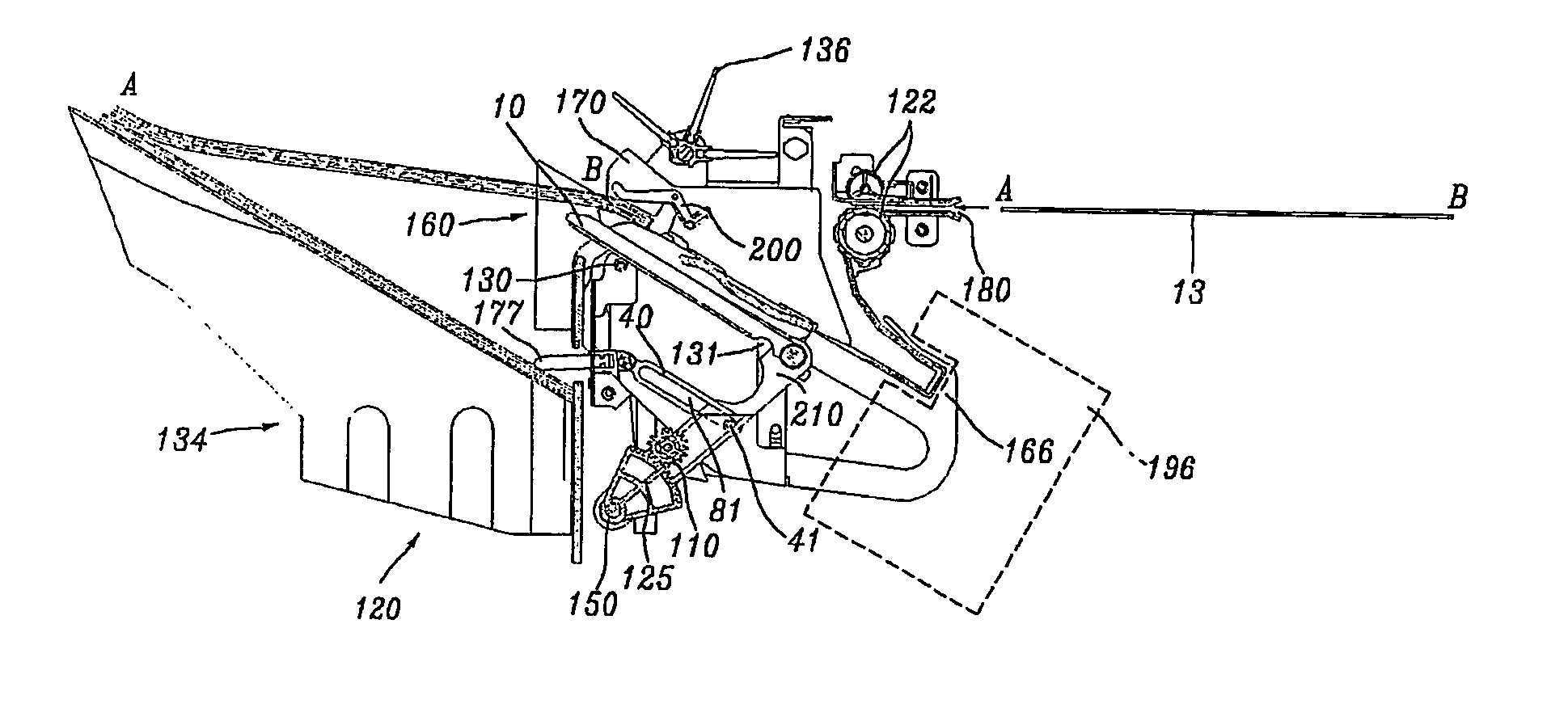

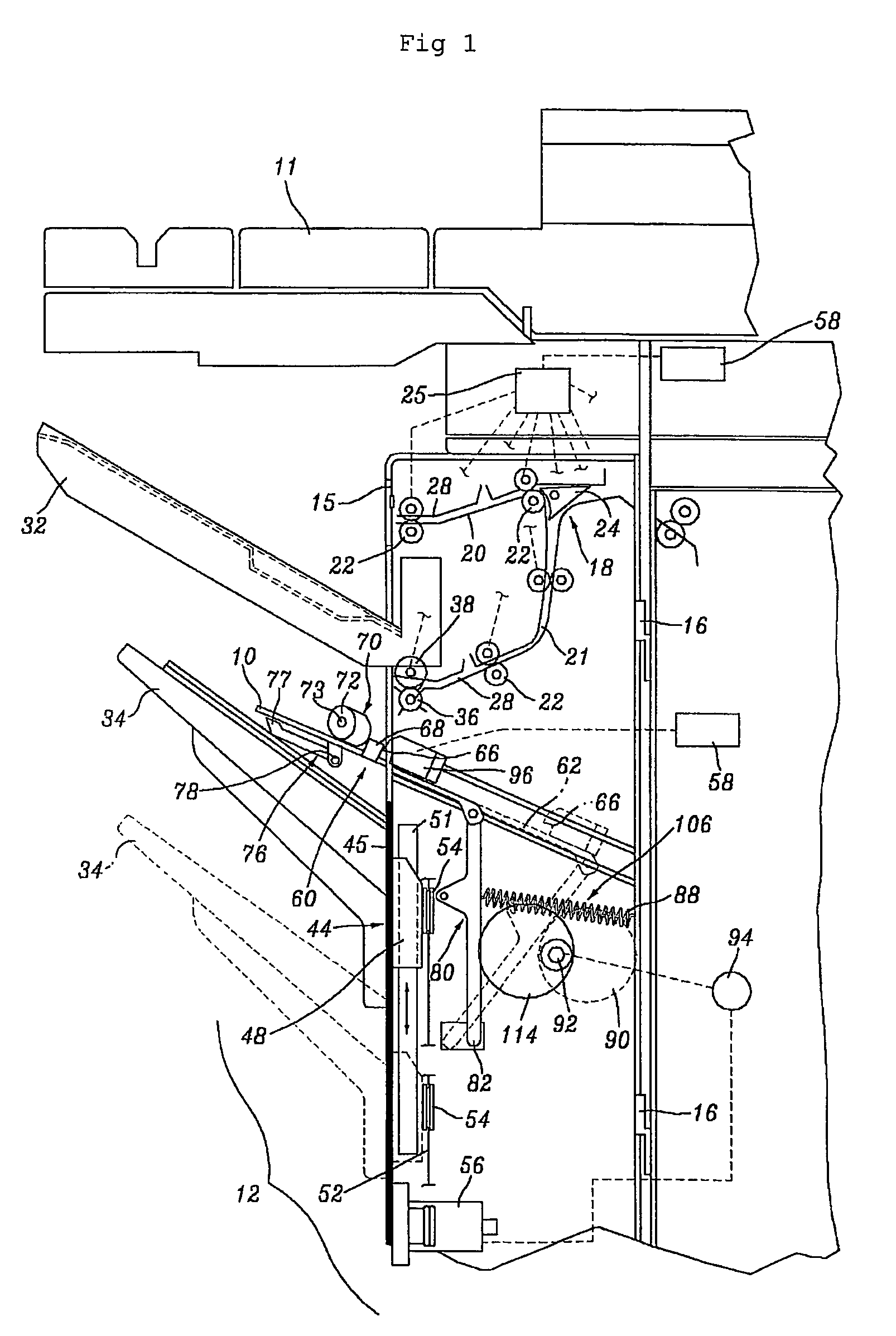

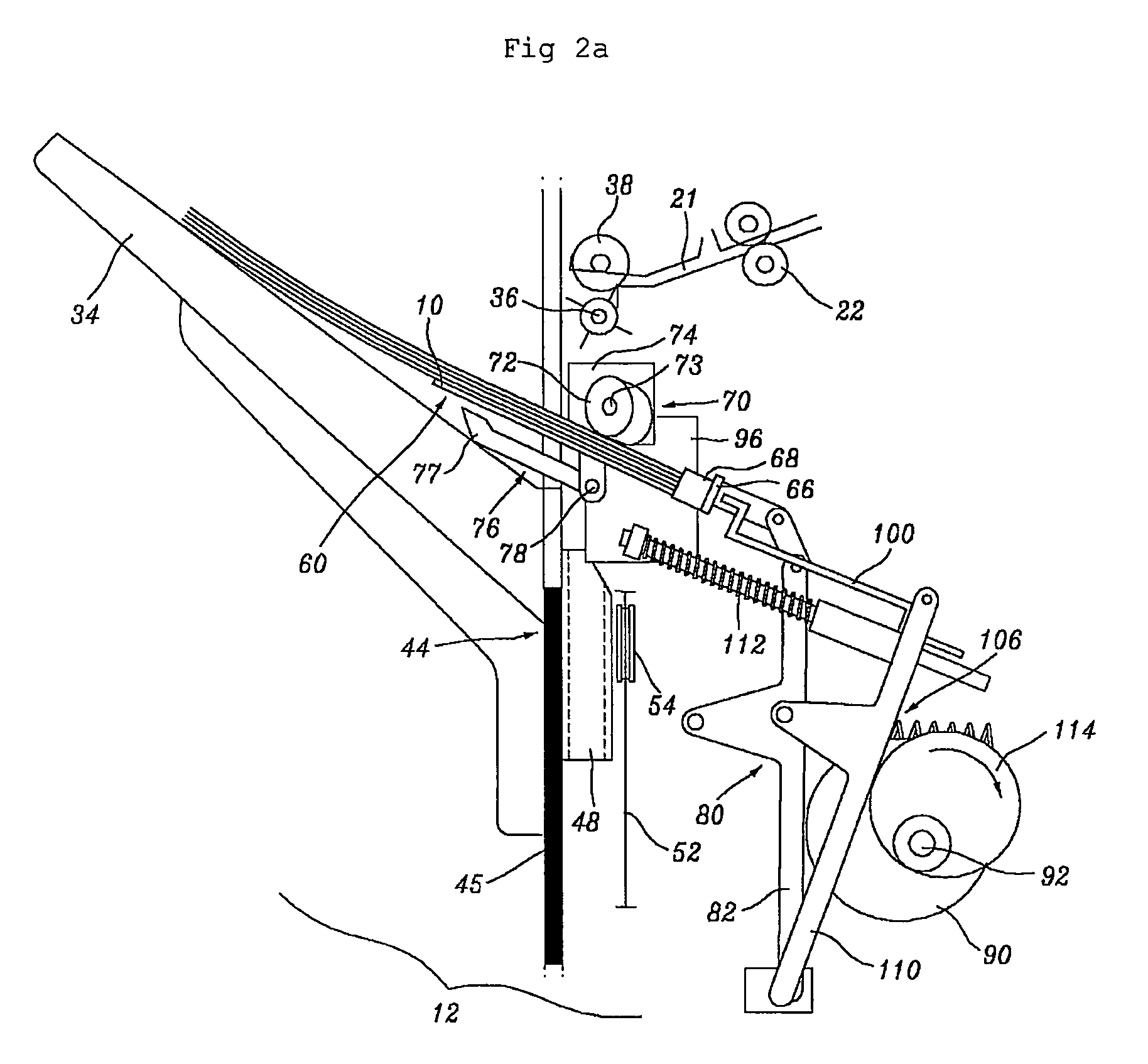

Finishing apparatus in copying machine

InactiveUS7690636B2Smooth bootGood conditionElectrographic process apparatusPile receiversPulp and paper industryStacker

A finishing apparatus in a copying machine is disclosed, which can finish large sized papers without enlarging the size of a tray base. The finishing apparatus includes a jogging assembly 170 aligning papers in left and right directions, a paper contact plate 166 provided with a stapler 196, a paper roller 200 pushing the papers to a paper stacker 134, ends of the papers being positioned in the stapler, a tray base 10 moving in a direction opposite to the paper roller to guide alignment of a set of the papers, and an angle adjusting unit guiding the papers by adjusting a tilt angle of the papers in accordance with the size of the papers.

Owner:GRADCO JAPAN

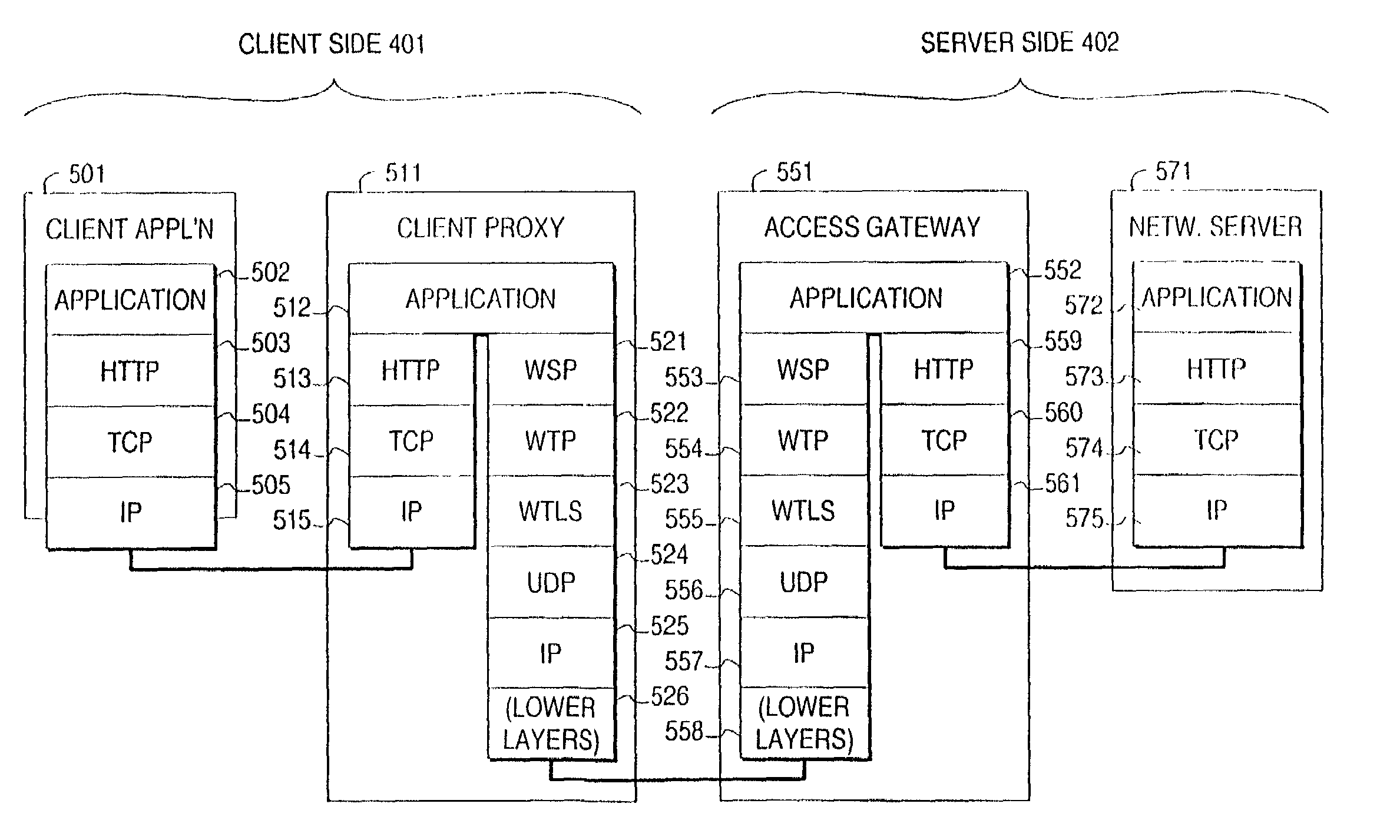

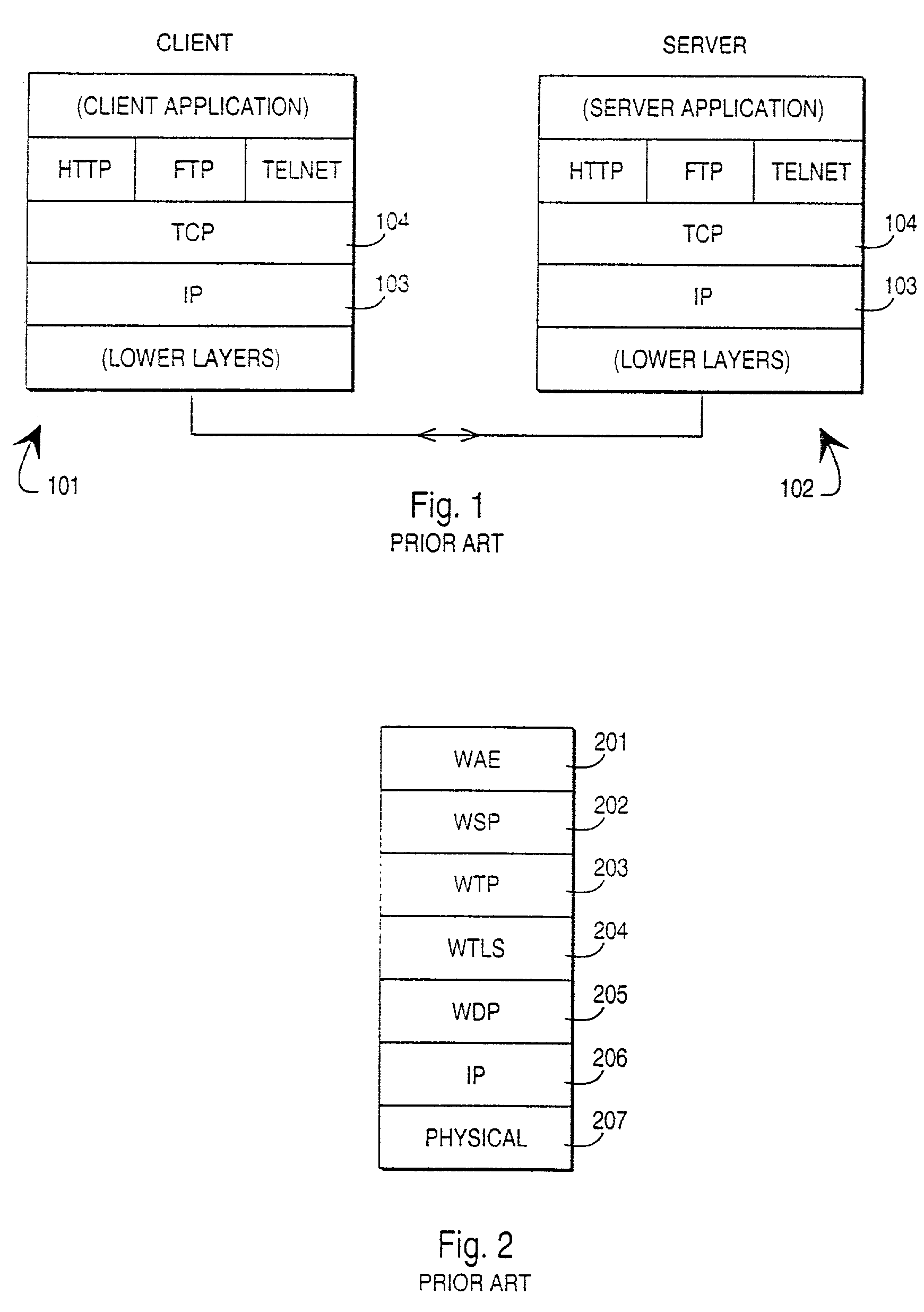

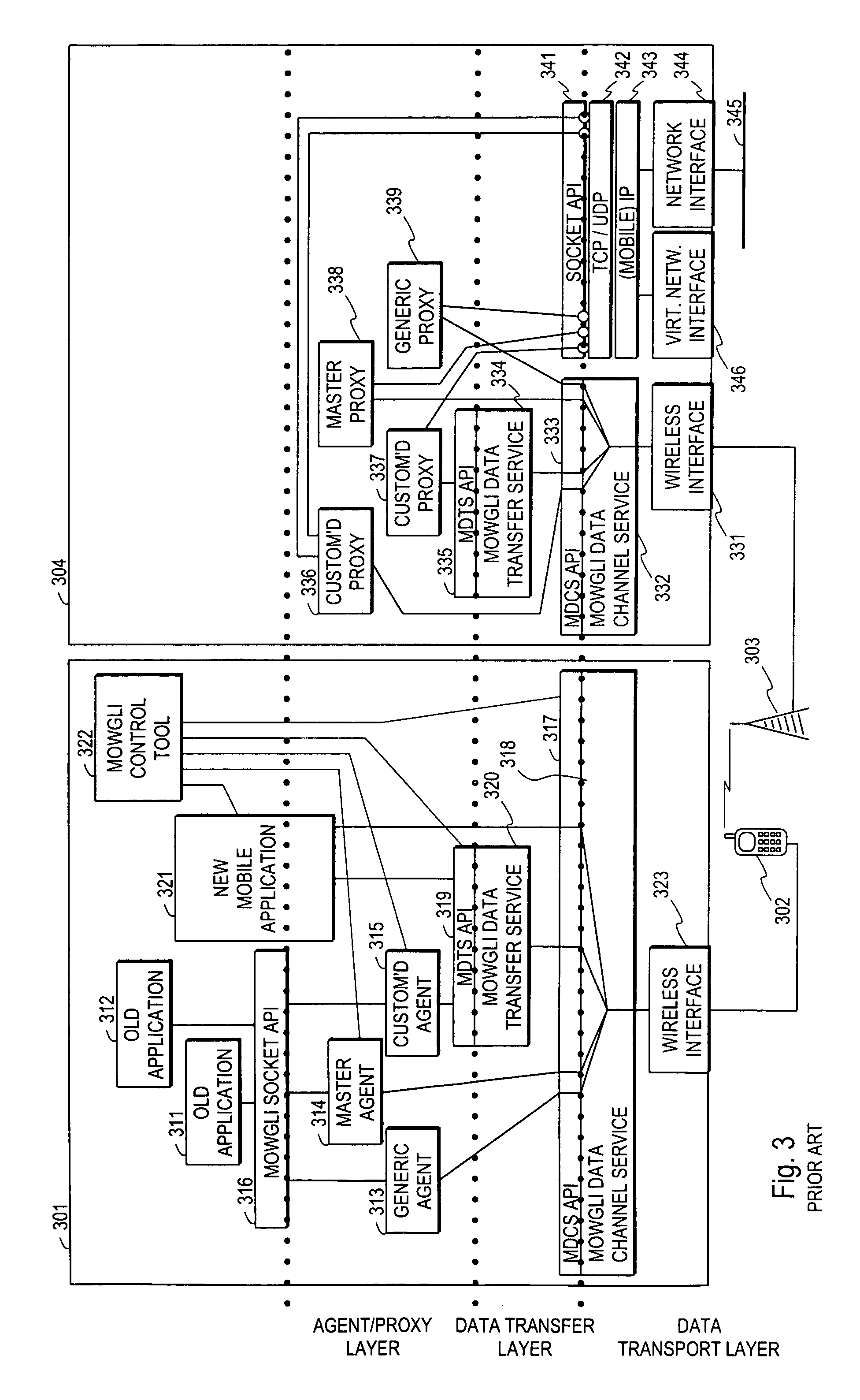

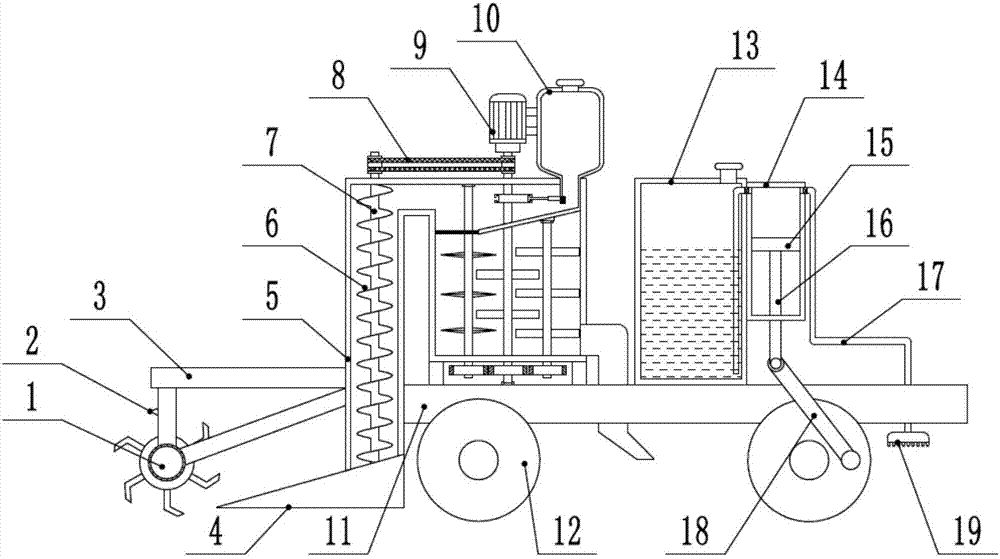

Methods and arrangements for providing efficient information transfer over a limited-speed communications link

ActiveUS7162535B2Efficient and widely usable information transferImprove service levelMultiple digital computer combinationsSecuring communicationDigital dataClient agent

Methods and arrangements are disclosed for transferring digital data over a limited speed communications link between a client side subarrangement (401) and a server side subarrangement (402). Within the client side subarrangement (401), a client application (411, 502) receives and transmits digital data using a first communications protocol stack (412, 503, 504, 505) and, within the server side subarrangement (402), a server application (426, 572) receives and transmits digital data using the first communications protocol stack (425, 573, 574, 575). Digital data is transferred between the client application (411, 502) and the server application (426, 572) through a client proxy (511) within the client side subarrangement (401) and an access gateway (551) within the server side subarrangement (402). Said client proxy (511) performs protocol conversations between the first communications protocol stack (412, 503, 504, 505) and a second communications protocol stack (415, 521, 522, 523, 524, 525, 526) that provides a bandwidth efficiency that is better than a bandwidth efficiency to which the first communications protocol corresponds.

Owner:MAVENIR SYSTEMS

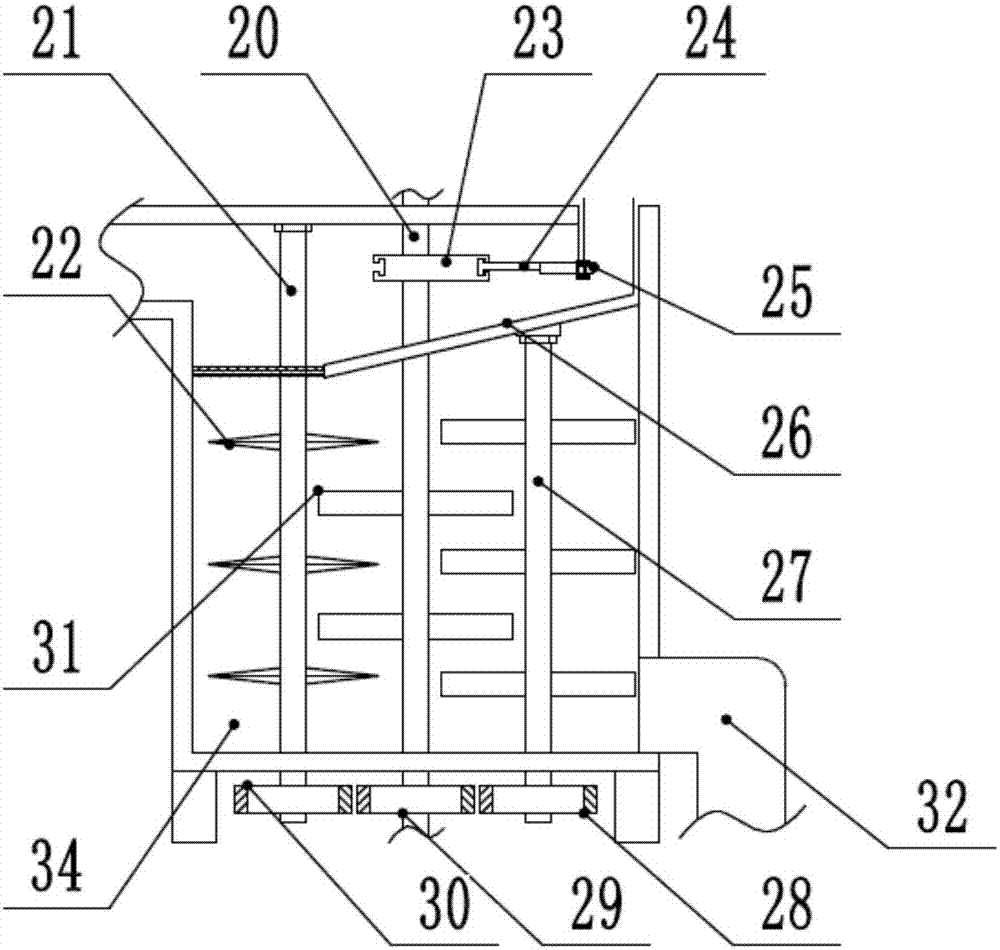

Agricultural traveling soil turning and fertilizing integrated device

InactiveCN107969179AIncrease humidityExtend the mixing timeSpadesWatering devicesAgricultural engineeringUltimate tensile strength

The invention discloses an agricultural traveling soil turning and fertilizing integrated device which comprises a rotary blade, a lifting chamber, a bottom plate, wheels, a water tank, a cylinder body and a mixing chamber, wherein two ends of a rotating shaft of the rotary blade are rotationally connected with a supporting plate by virtue of a supporting rod; a bucket is arranged on the right side of the rotary blade and fixedly arranged at the lower end of the lifting chamber; the mixing chamber is formed in the right side of the lifting chamber; the water tank is arranged on the right sideof the mixing chamber; the right side of the water tank is fixedly connected with the cylinder body; a piston is connected into the cylinder body in a sliding manner; the lower end of the piston is fixedly connected with a push rod; the push rod penetrates through the lower end of the cylinder body and rotationally connected with a connecting rod; and the connecting rod is rotationally connected with an eccentric position of the wheels. The integrated device disclosed by the invention is novel in design, simple in structure and excellent in soil turning effect, and the fertilizer is fully mixed with soil in the soil turning process, so that the fertilization effect is improved, the labor intensity of labor personnel is lowered, and the land rearrangement efficiency is improved.

Owner:黄利伟

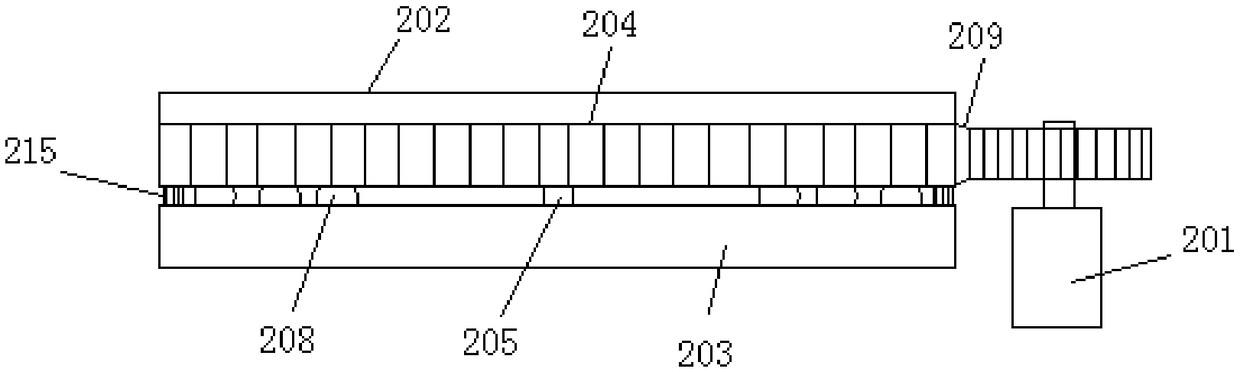

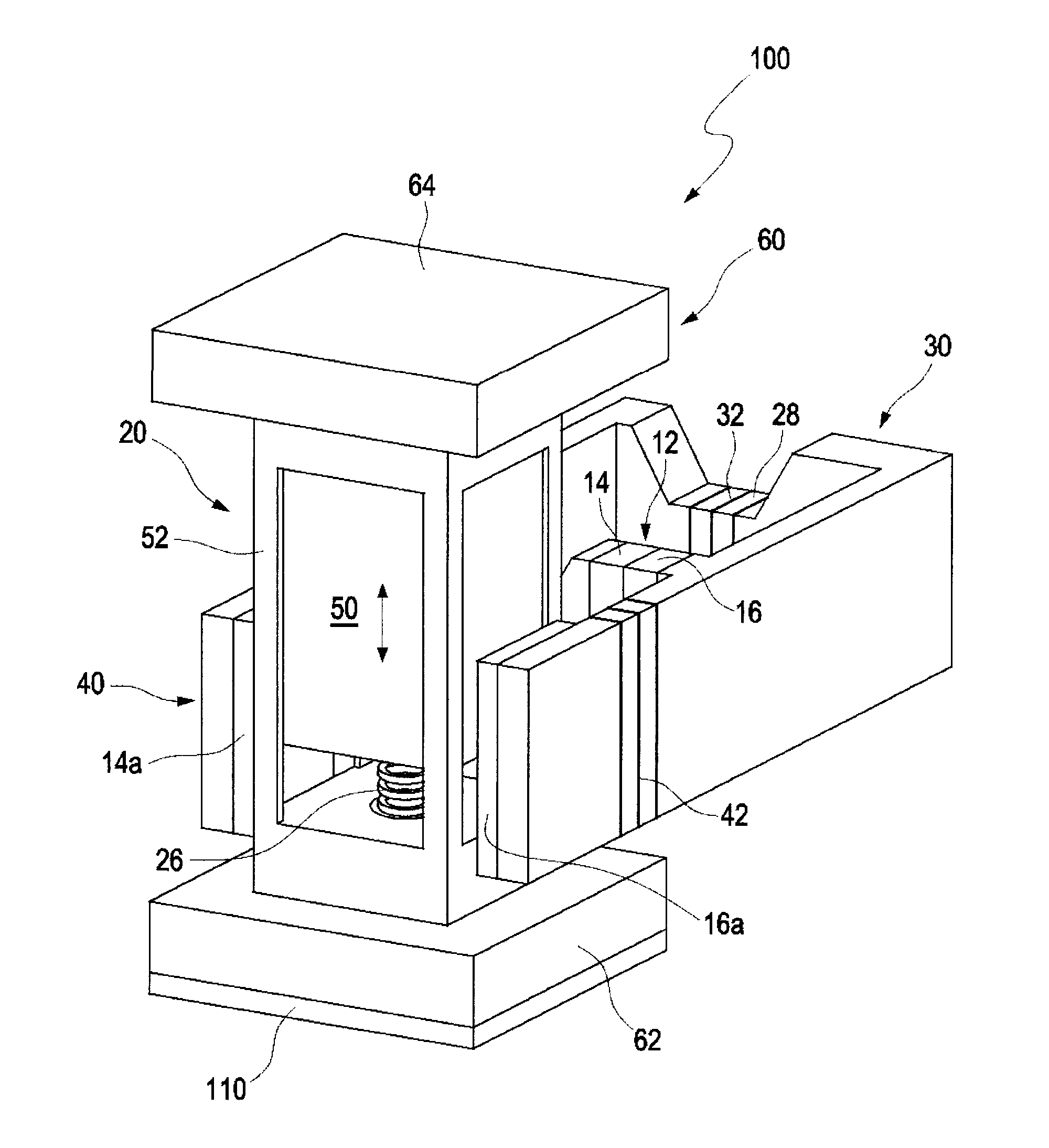

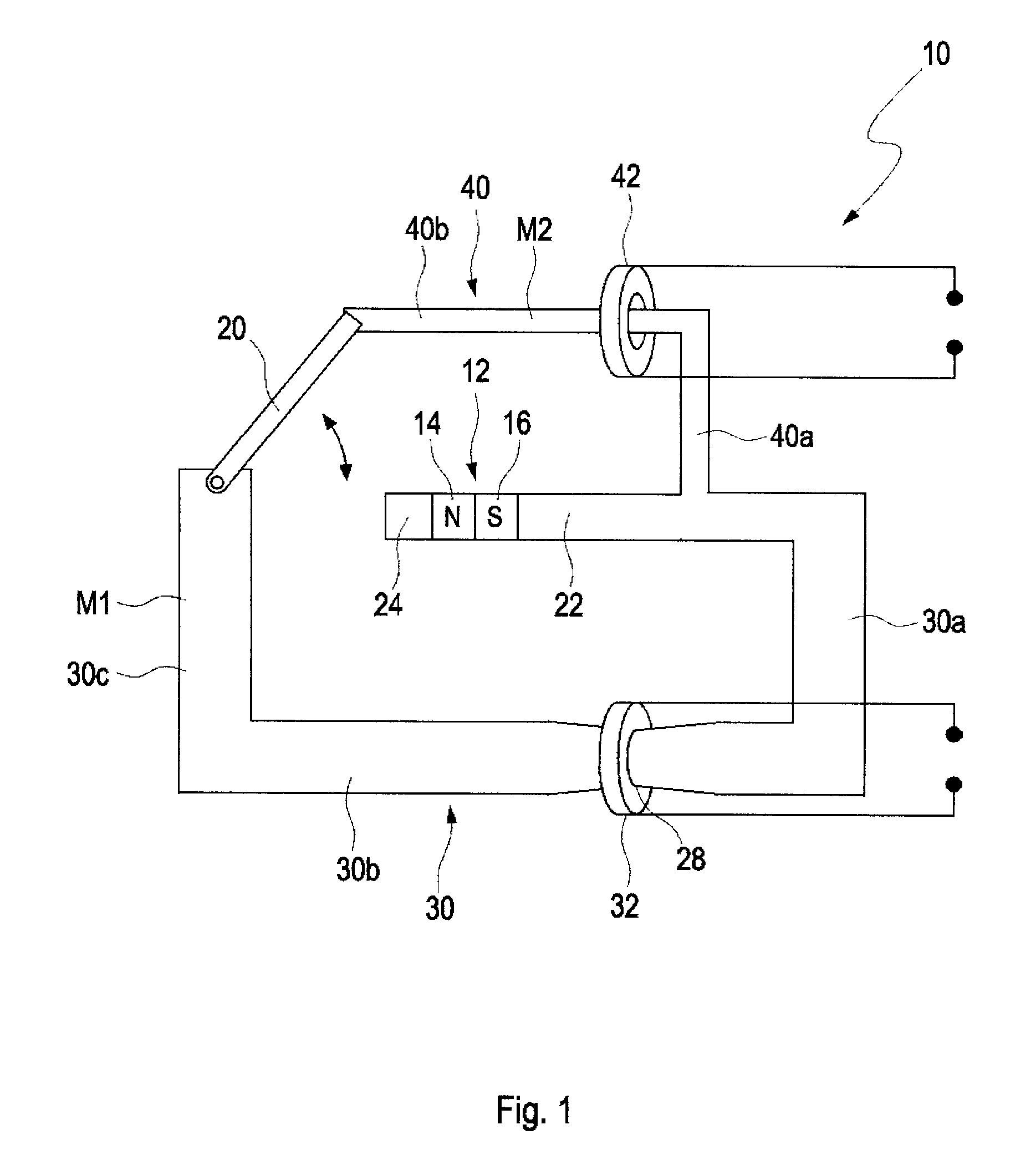

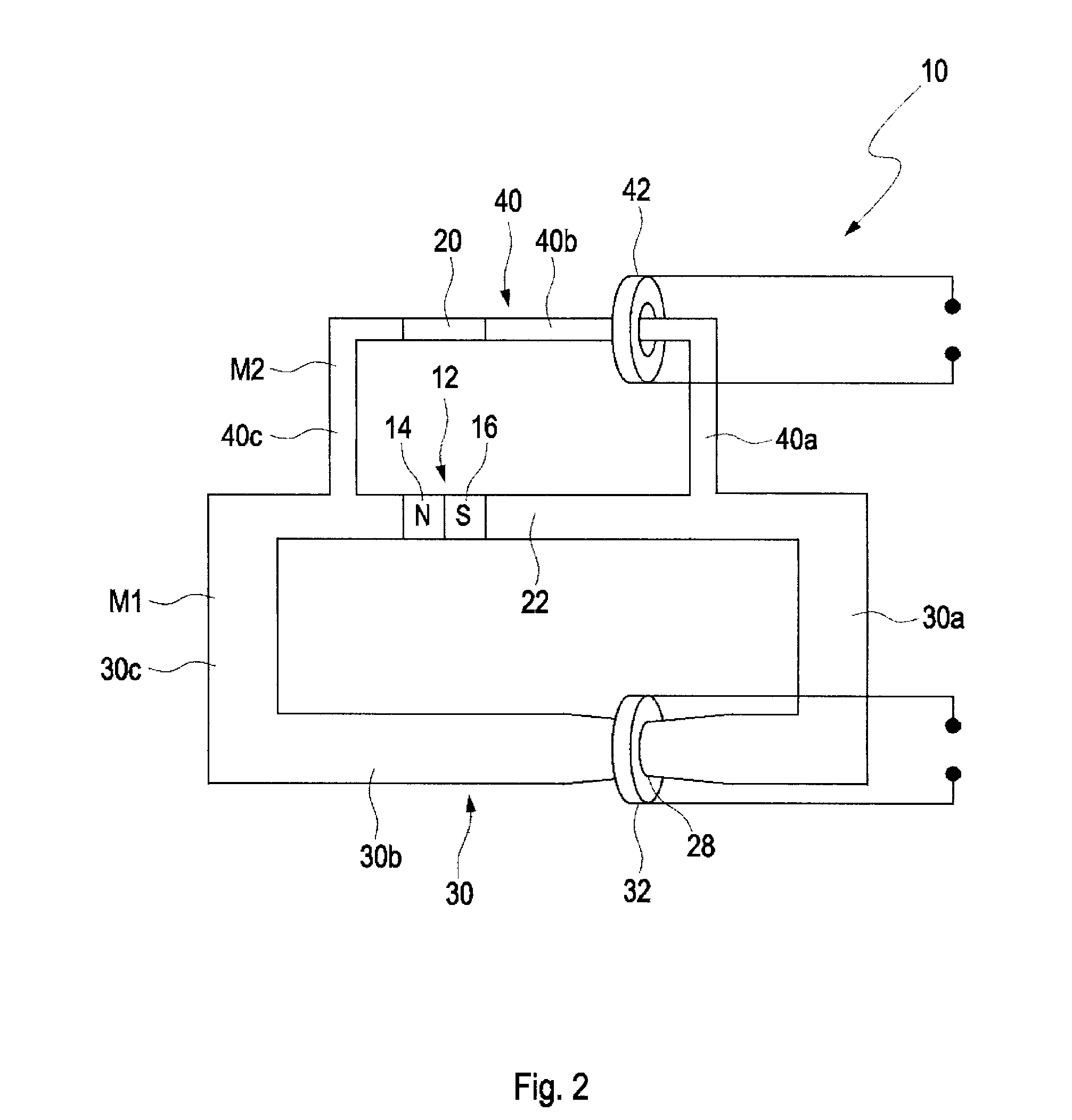

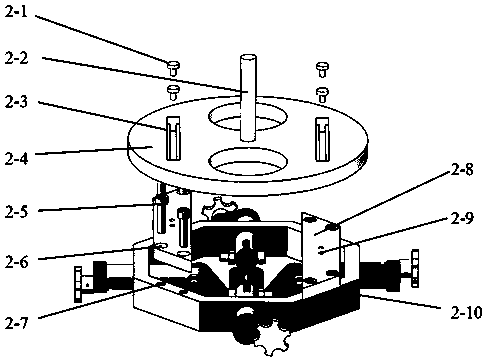

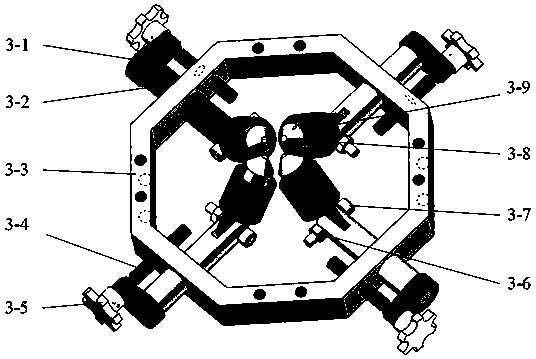

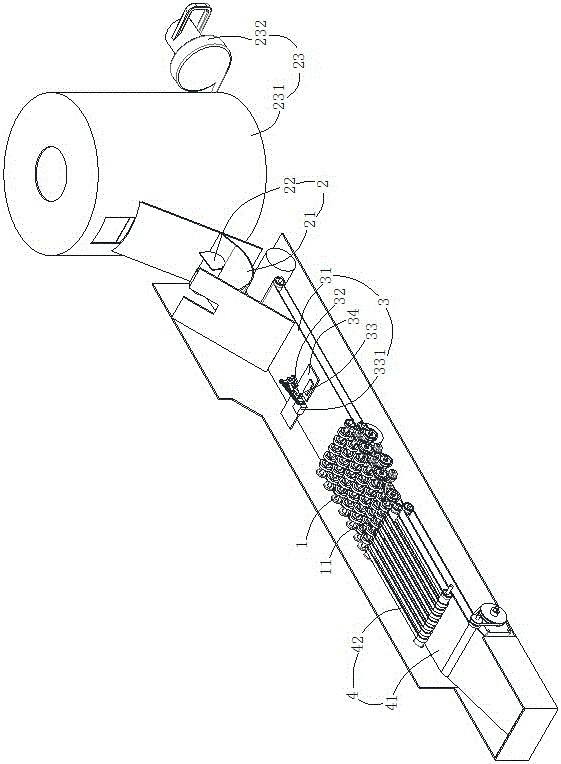

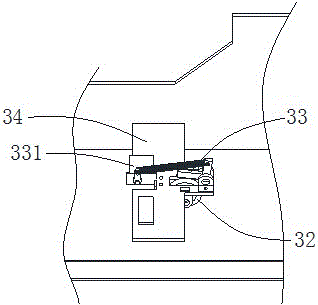

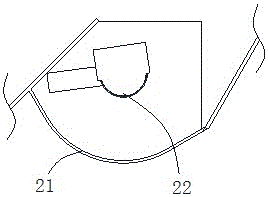

Automated magnetic field-aided finishing machining device and method

ActiveCN108687573ASolve the problem of flexible automation controlImprove processing efficiencyManipulatorGrinding work supportsMagnetic polesMulti degree of freedom

Aiming at achieving the technical aim of efficient high-quality finishing and flexible control over a complex surface, the invention discloses an automated magnetic field-aided finishing machining device and method. The device comprises an industrial robot, an industrial vibrating motor, a novel finishing machining device, a workpiece clamping device and a triaxial precision displacement worktable; the novel finishing machining device comprises a magnetic field generating device, a fixed plate, a connecting plate, guide screws and a connecting rod; the magnetic field generating device comprises linkages, guide rods, a magnet yoke, lead screws, handles, nuts, bolts, four magnetic poles and magnetic pole sleeves; by the industrial robot, multi-degree of freedom flexible regulation is realized, and automated finishing machining on workpieces different in surface profile can be completed; under the vibrating combined action of the industrial vibrating motor, finishing machining efficiencycan be increased; and feature surfaces of different workpieces can be regulated by angles of the magnetic poles of the novel finishing machining device. The device and method are capable of breaking through the limitation of finishing machining on the complex surface by the traditional method, and therefore, efficient high-quality flexible automated finishing machining is realized.

Owner:SHANDONG UNIV OF TECH

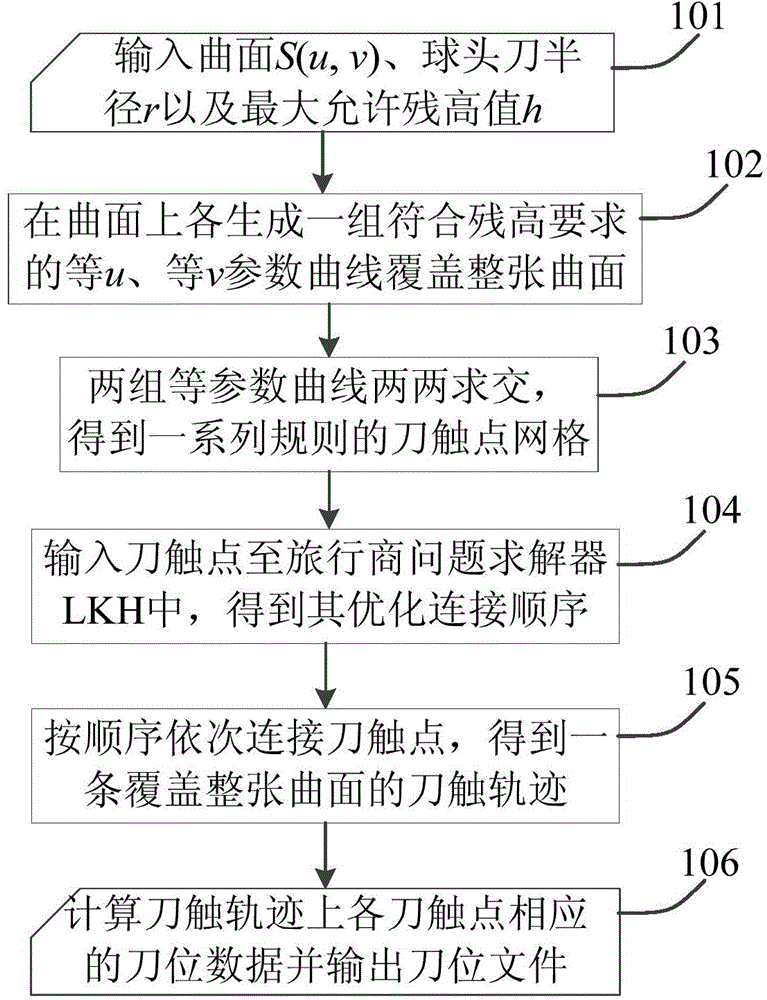

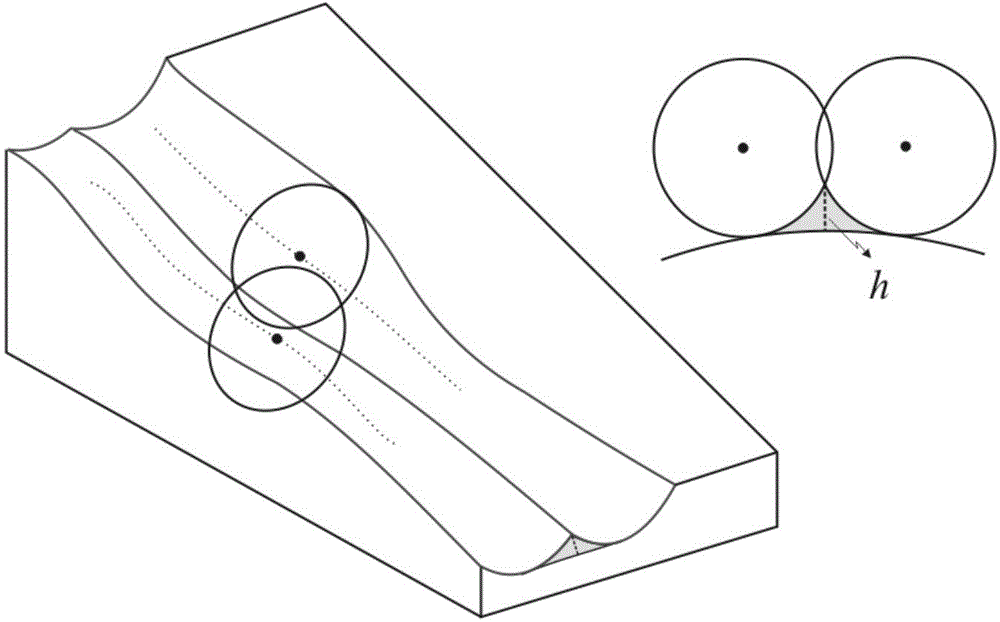

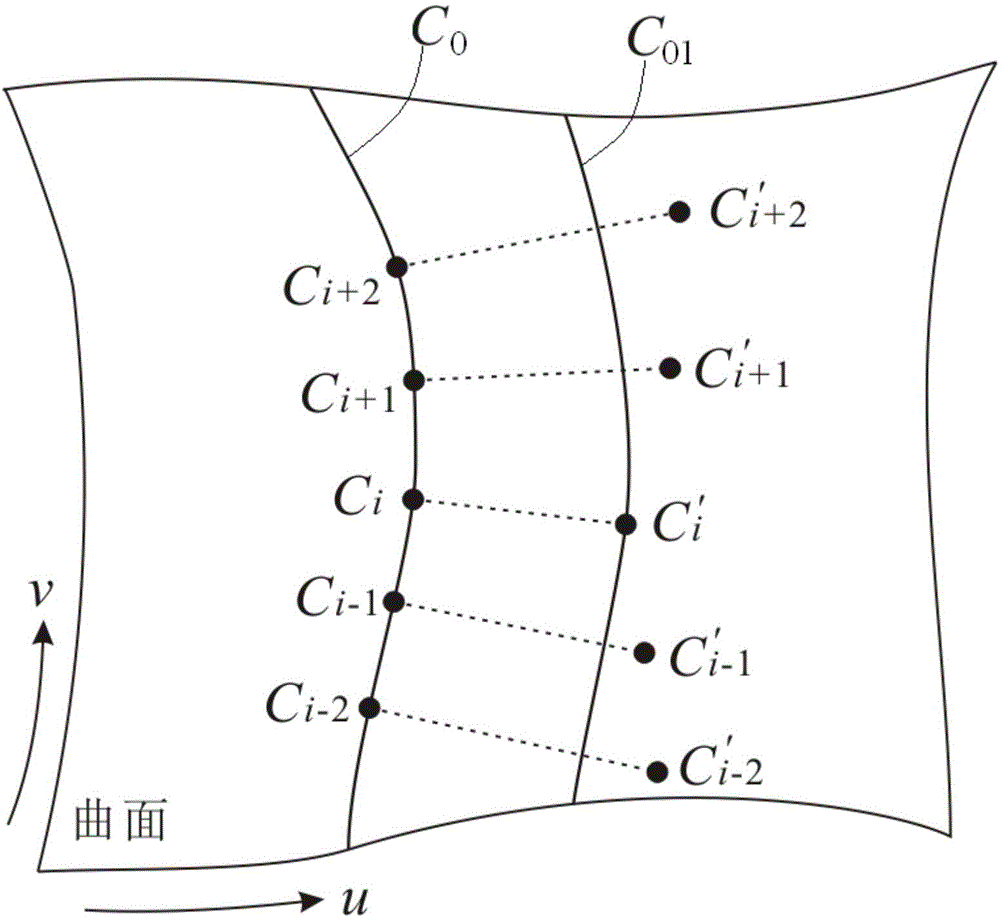

Method for generating curved surface finishing tool path based on traveling salesman problem solver

ActiveCN104063746AImprove finishing efficiencyShorten the total path lengthForecastingOgiveSurface finishing

The invention discloses a method for generating a curved surface finishing tool path based on a traveling salesman problem solver. The method comprises the following steps that a curved surface to be machined S (u,v), the radius r of a ball-head cutter and a maximum permissible residual high value h are input; a set of equal u parameter curves and a set of equal v parameter curves which meet the residual high requirement are generated in the curved surface u direction and the curved surface v direction respectively, and an entire curved surface is covered in the two directions; the two sets of equal parameter curves are subjected to pairwise intersection, and a series regular cutter contact grids are obtained on the curved surface; obtained cutter contact coordinates are input into the traveling salesman problem solver LKH, and the optimized connecting sequence of cutter contacts is obtained; the cutter contacts are sequentially connected according to the sequence, and a cutter contact track covering the entire curved surface is obtained; cutter position points corresponding to the cutter contacts in the cutter contact track are calculated, and a cutter position file is output. The finishing tool path generated by the method is small in path length, few in cutter lifting times, and capable of improving the curved surface finishing efficiency.

Owner:ZHEJIANG UNIV

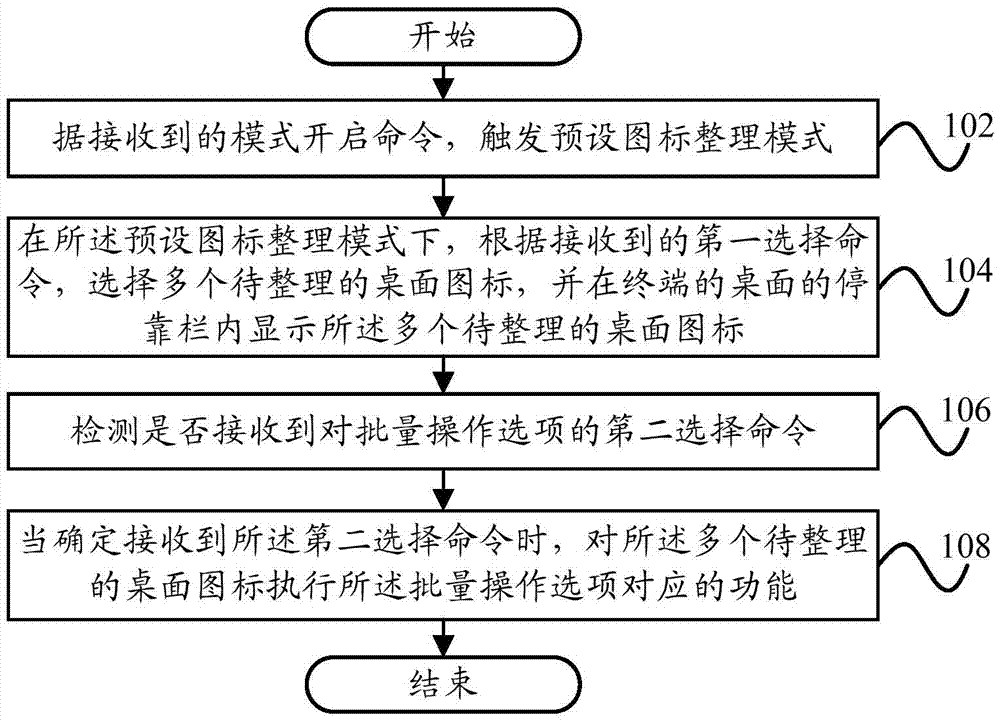

Desktop icon batch settling method and device and terminal

InactiveCN106873843AOrderly and smoothImprove finishing efficiencyExecution for user interfacesInput/output processes for data processingBatch operationComputer terminal

The invention provides a desktop icon batch settling method and device and a terminal. The desktop icon batch settling method includes: according to received pattern opening commands, triggering a preset icon settling pattern; under the preset icon settling patter and according to the first selection command, selecting multiple desktop icons to be settled and displaying the desktop icons to be settled in a dockbar of a desktop of the terminal; detecting whether receiving the second selection command for batch operation items or not, and if yes, executing functions corresponding to the batch operation items on the desktop icons to be settled. With the method, the entire icon settling process is clear and highly indicative, users can be guided to complete settling of the desktop icons orderly and smoothly, settling efficiency of the entire icon settling process is improved, and use experience of the users is improved.

Owner:BEIJING ANYUNSHIJI TECH CO LTD

Library management system based on radio frequency identification device (RFID) technology

InactiveCN103106755ASimplify borrowing and returning proceduresShorten circulation cycleCash registersLibrary cardEngineering

The invention belongs to the technical field of computer application, in particular to a library management system based on a radio frequency identification device (RFID) technology. The library management system based on the RFID technology is composed of a label conversion subsystem, a self-service borrowing-returning subsystem, an intelligent searching subsystem, an automatic checking subsystem and a safety door detection subsystem. The label conversion subsystem is composed of a control main machine and a label conversion device, and achieves switching work of a library electronic label, a frame sign label and a library card electronic label. The library management system based on the RFID technology identifies each book, and applies a book management card to daily management of a library, achieves self-service borrowing and returning, carries out checking and searching rapidly, and is combined with an existing security access control system to form a modernized library management system integrally based on the RFID technology.

Owner:QINGDAO ZHONGKE SOFTWARE

Coin sorting device

InactiveCN105931365AImprove finishing efficiencySimple structureCoin/currency accepting devicesSingle foldEngineering

The invention discloses a coin sorting device. The coin sorting device comprises a rubbing mechanism which is used for rubbing and folding folded banknotes, and a feeding mechanism which is used for feeding single folded banknotes into the rubbing mechanism. The feeding mechanism comprises a banknote feeding bin which is used for temporarily storing the banknotes, and a negative pressure sucker which is used for sucking the single banknotes. A banknote separating device is arranged on one side, which is away from the rubbing mechanism, of the banknote feeding bin. The banknote separating device comprises a vertical feeding bucket and a blowing device. An air inlet which is arranged along the tangential direction is arranged on the side wall, which is close to the lower end, of the feeding bucket. The air outlet of the blowing device is connected with the air inlet through a pipeline. A discharge hole is arranged in the side wall, which is close to the upper end, of the feeding bucket. The feeding end of the banknote feeding bin joins in the discharge hole of the feeding bucket. The coin sorting device provided by the invention has the advantages of simple structure, wide application range, high feeding efficiency, great rubbing effect, high coin sorting efficiency and the like.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com