Straight line-involute profile inner-gearing cylindrical gear pair

A technology of involute teeth and cylindrical gears, used in gear transmissions, belts/chains/gears, components with teeth, etc., can solve uneven wear on the tooth surface, too sensitive manufacturing and installation errors, and low bearing capacity and other problems, to achieve the effect of improving the overall meshing performance, reducing dynamic excitation and reducing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

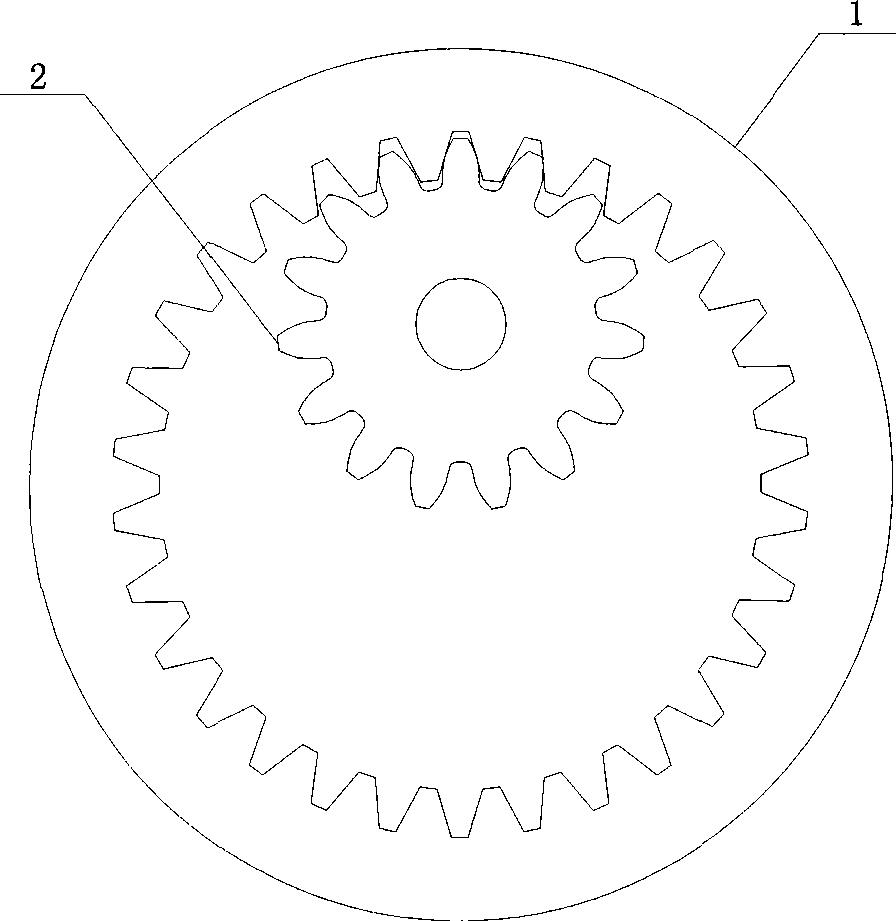

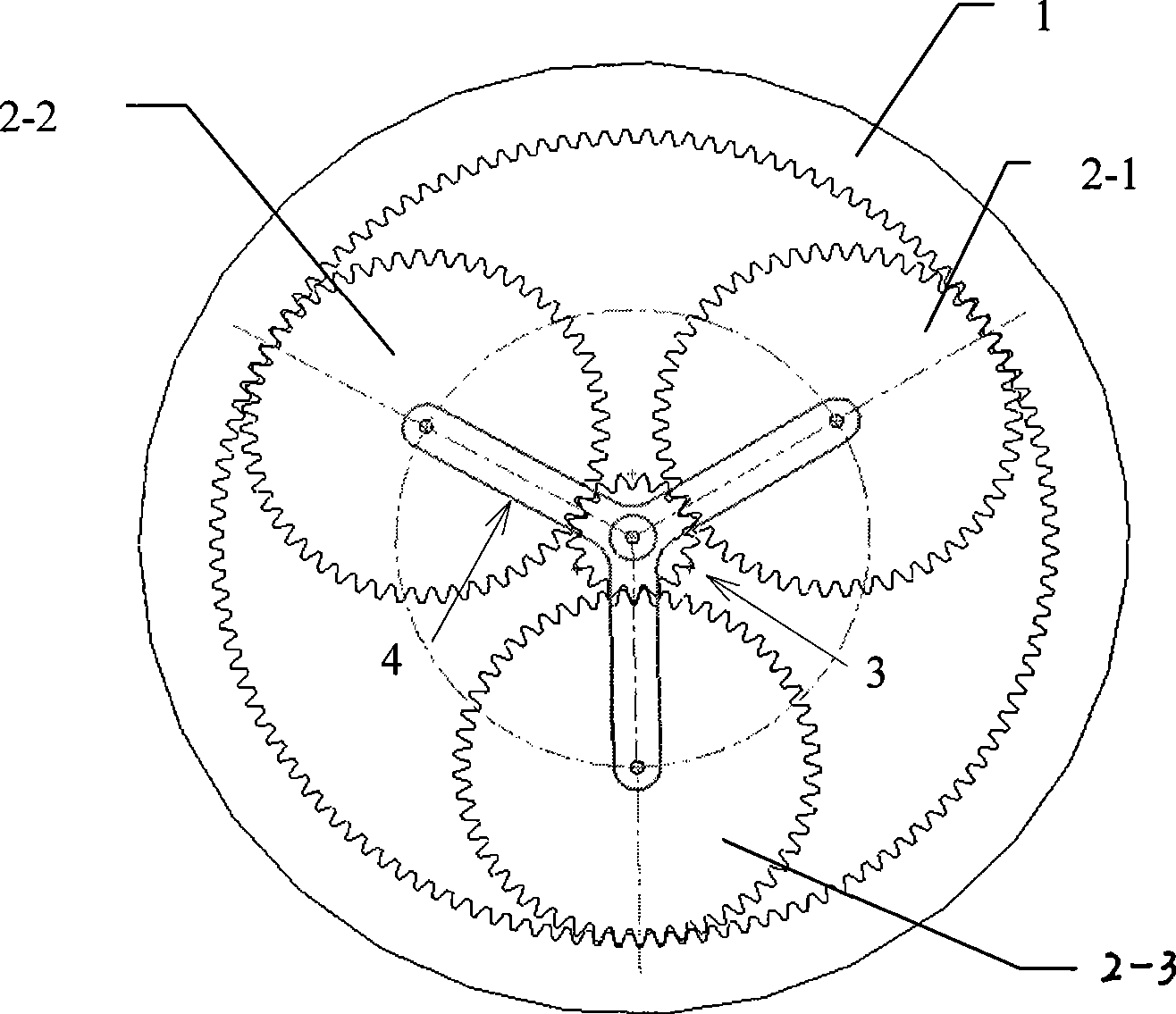

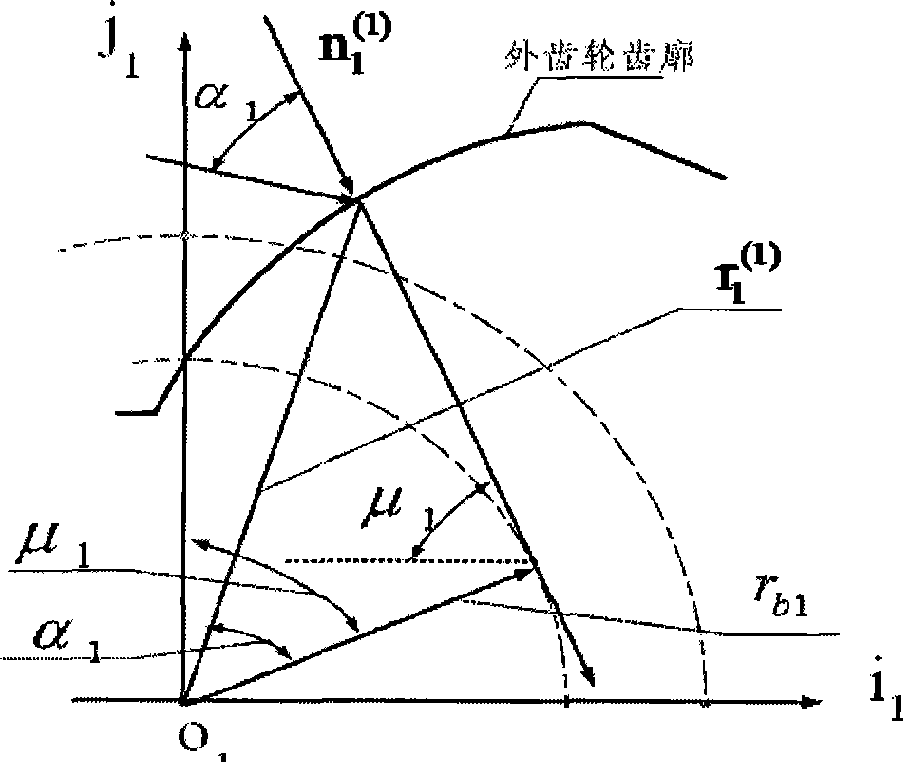

[0046] Such as figure 1 shown, as figure 1 As shown, the linear-involute internal meshing cylindrical gear pair of the present invention includes an internal gear 1 with a linear tooth profile and an involute gear 2 meshing with it for transmission. The internal gear 1 can be a spur gear or a helical gear. The internal gear 1 with a straight tooth profile can mesh with 1 to 6 involute gears, and can be applied to parallel shaft transmission or planetary transmission. Such as figure 2 Shown is a schematic diagram of the structure of the NGW planetary gear train. The internal gear 1 with a linear tooth profile is meshed with three gears 2-1, 2-2, and 2-3 with involute tooth profiles. The three involute tooth profiles The gears 2-1, 2-2, 2-3 are fixed firmly with the sun gear 3 through the planet carrier 4, and are meshed with the sun gear 3 for transmission respectively. The tooth profile of the internal gear 1 is changed to a straight line, and the grinding wheel can be sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com