Stretch-bending molding process of angle steel component of vehicle body

A stretch-bending and angle-steel technology, applied in the field of metal stretch-bending, can solve the problems affecting the forming quality of stretch-bending parts, the manufacturing accuracy of the car body, and the difficulty in controlling the dimensional accuracy of the bending parts, so as to ensure the forming quality, improve the forming accuracy, and realize the The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

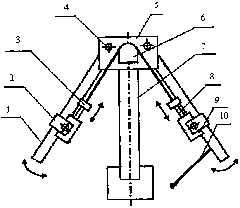

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

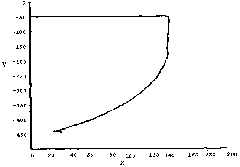

[0035] Based on the swivel-type stretch-bending worktable, the loading sequence of stretching-bending-compensation-stretching is adopted, and the loading mode is controlled by selecting the force and displacement synergistically. Apply a pulling force of 1.25N before bending 0 , remains unchanged during bending, after which 1.5N is applied 0 supplementary tension.

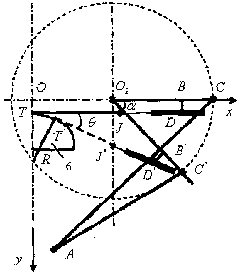

[0036] (1) Determination of the springback of the length of the multi-curvature profile

[0037] Considering the springback, the relationship between the radius of curvature of the mold and the design radius of the part and the springback radius can be expressed as

[0038] R mi =R di -ΔR i (1)

[0039] where R mi is the radius of curvature of the mold, R di Design radius of curvature for the innermost layer of the profile, ΔR i is the rebound radius of curvature.

[0040] ΔR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com