Laser projection system and method

A laser projection and laser projector technology, which is applied to stereo systems, components of TV systems, and optical devices, etc., can solve the problems of unusable mass production of projection templates and limited opportunities to project geometrically accurate projected images, etc. Achieve low cost, improve quality and dimensional accuracy, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

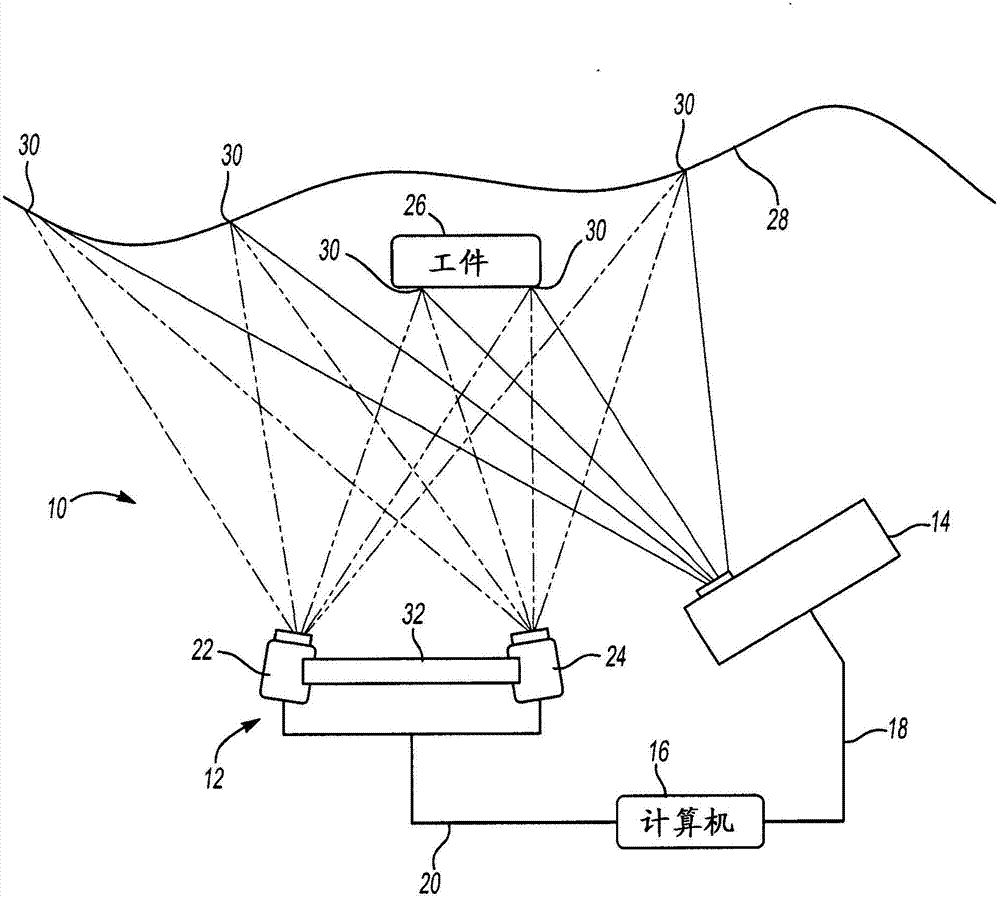

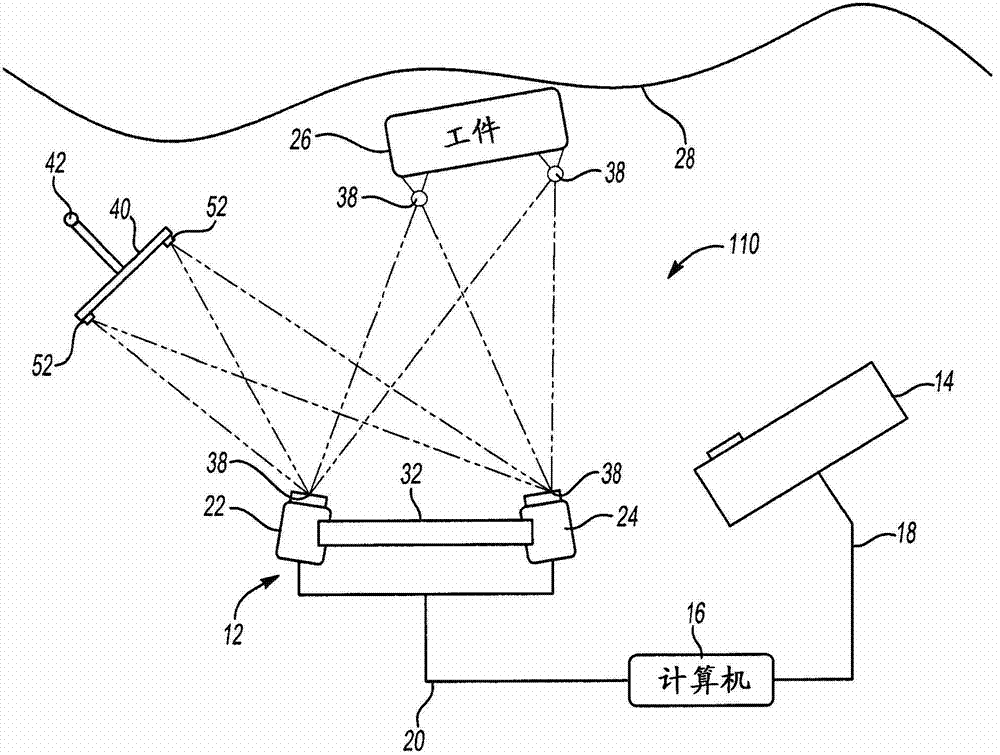

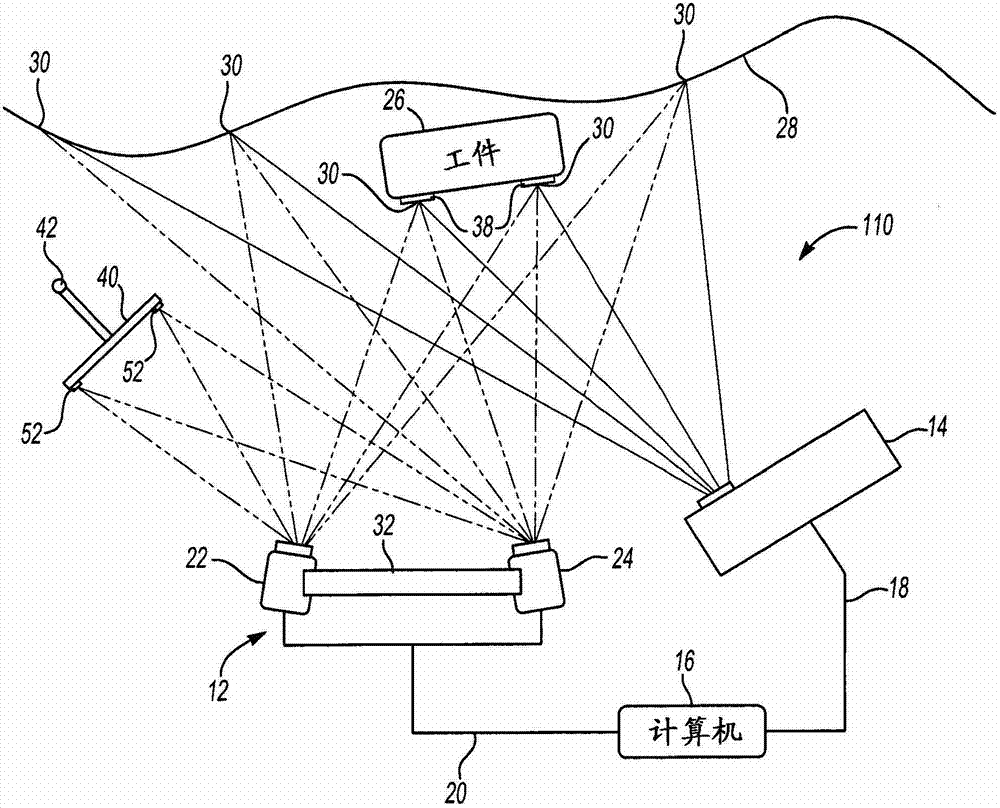

[0015] figure 1 A laser projection system for projecting an image on a workpiece is generally shown at 10 . The laser projection system includes a photogrammetric assembly 12 and a laser projector 14 each in communication via a computer 16 . Computer 16 communicates with laser projector 14 via circuitry 18 and with photogrammetry assembly 12 via circuitry 20 . Although the circuits 18, 20 are shown as hardwired in this example, those skilled in the art will appreciate that radio frequency or equivalent transmissions between the computer 16, photogrammetry assembly 12, and laser projector 14 are also within the scope of the present invention. within range.

[0016] The photogrammetry assembly includes a first camera 22 and, in this embodiment, a second camera 24 . The inventor contemplates that an alternative embodiment may use only the first camera 22, as will be explained below. One type of camera that comes to the mind of the inventor is an industrial camera manufactured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com