Stainless steel water meter shell and machining method thereof

A stainless steel and water meter technology, applied in metal processing equipment, manufacturing tools, liquid/fluid solid measurement, etc., can solve the problems of high refractoriness, small thermal expansion, high cost, etc., achieve high normal temperature strength and high temperature strength, improve surface treatment, The effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of stainless steel water meter casing, it adopts following method to prepare:

[0036] 1 Model Preparation

[0037] After pre-foaming, the EPS beads are filled in the mold for filling, and made into a water meter shell to make the surface smooth. All dimensional indicators (shape shrinkage, body shrinkage, and machining allowance) all meet the process requirements, and Fully dry and restore, the drying room is 55-65°C, and the pattern is placed for no less than 6 weeks to facilitate casting.

[0038] The particle size of the EPS beads is 0.2-0.3mm, the expansion ratio is preferably ≥ 40, and the filling pressure is 0.4Mpa;

[0039] 2 groups

[0040] Bond the qualified model with 851 strong adhesive. Because the perimeter of the joint surface is long, press it for about 50-60 seconds to reach the bonding strength. Be careful not to apply too much glue to make the glue joint smooth and easy to dry, and to prevent out of shape. According to the pourin...

Embodiment 2

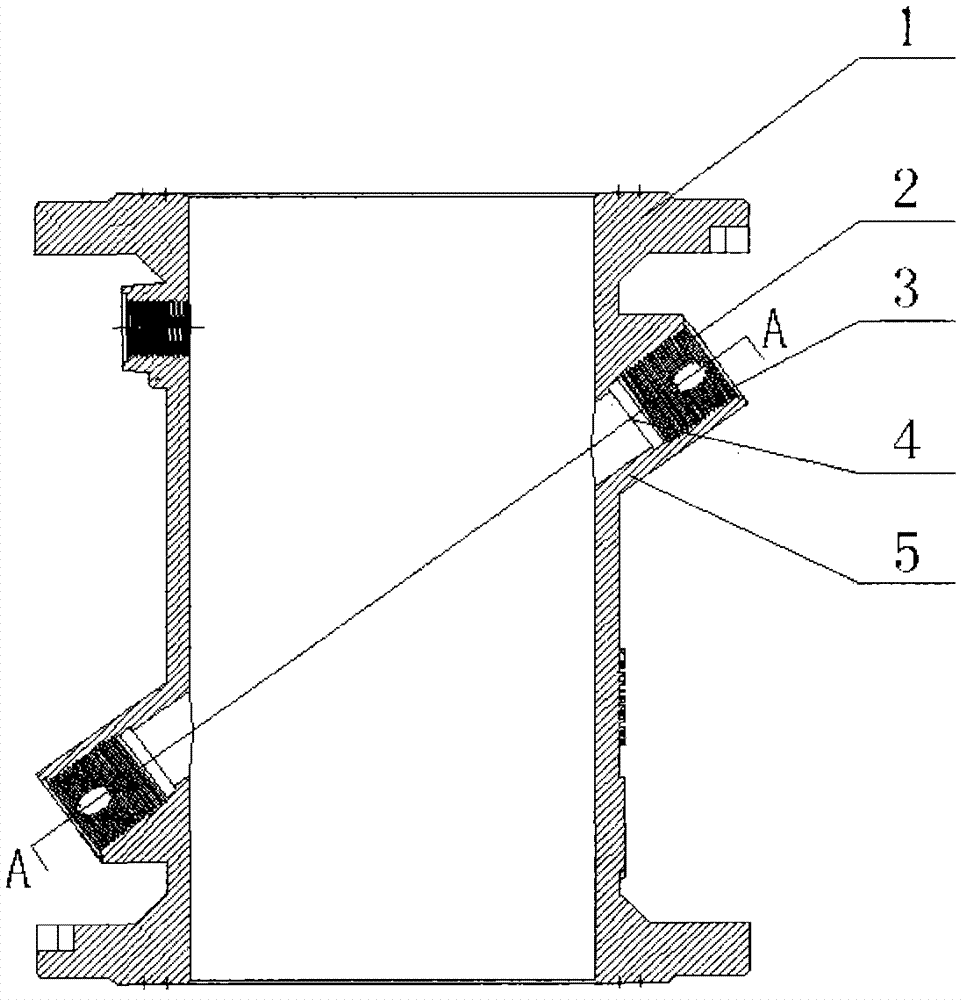

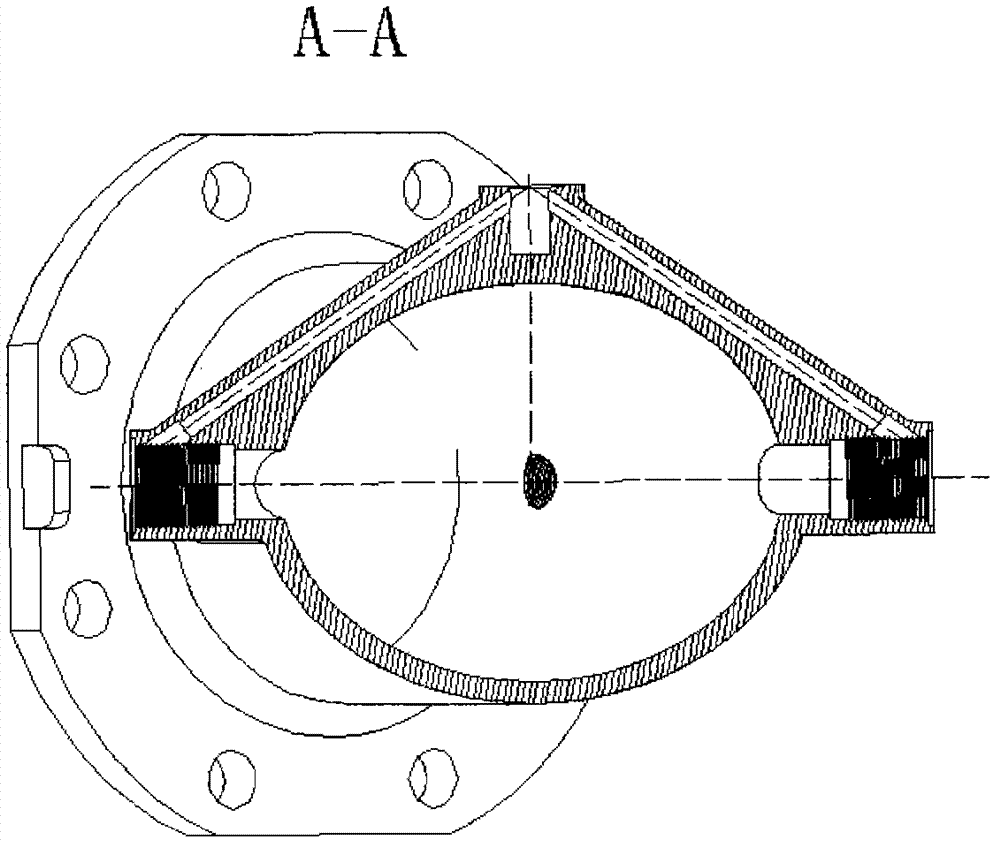

[0053] A stainless steel water meter housing, which includes a water inlet, a water outlet, a transducer, and an electronic control device, is characterized in that a transducer insertion tube (3) with inner and outer wires is arranged in the inclined tube of the water meter housing, and the insertion tube The inner end is provided with a head (4), and the outer end of the intubation tube is provided with a nozzle (2) with a peripheral wall thickness of 3-10 mm. After the transducer is inserted, it will not directly contact with the water fluid, thereby improving the energy conversion To ensure the service life of the device, the intubation tube can be made of polytetrafluoroplastics.

[0054] According to the method of Example 1, the transducer insertion tube is set in the lost foam in advance, and directly fixed in the inclined tube on the water meter casing after casting.

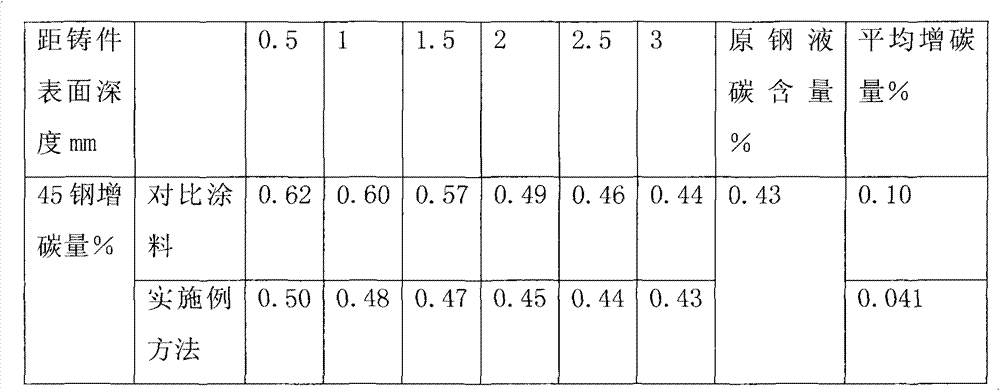

[0055] According to embodiment 1 lost foam preparation method, provide and adopt the coating of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com