Tea green-removing machine and fuzzy control method thereof

A technology of fuzzy control and fuzzy controller, applied in the direction of tea processing before extraction, can solve the problems of insufficient combustion of gas, potential safety hazards, affecting the quality of tea leaves, etc., to improve efficiency and quality of tea leaves, fast response time, and safety. Low risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

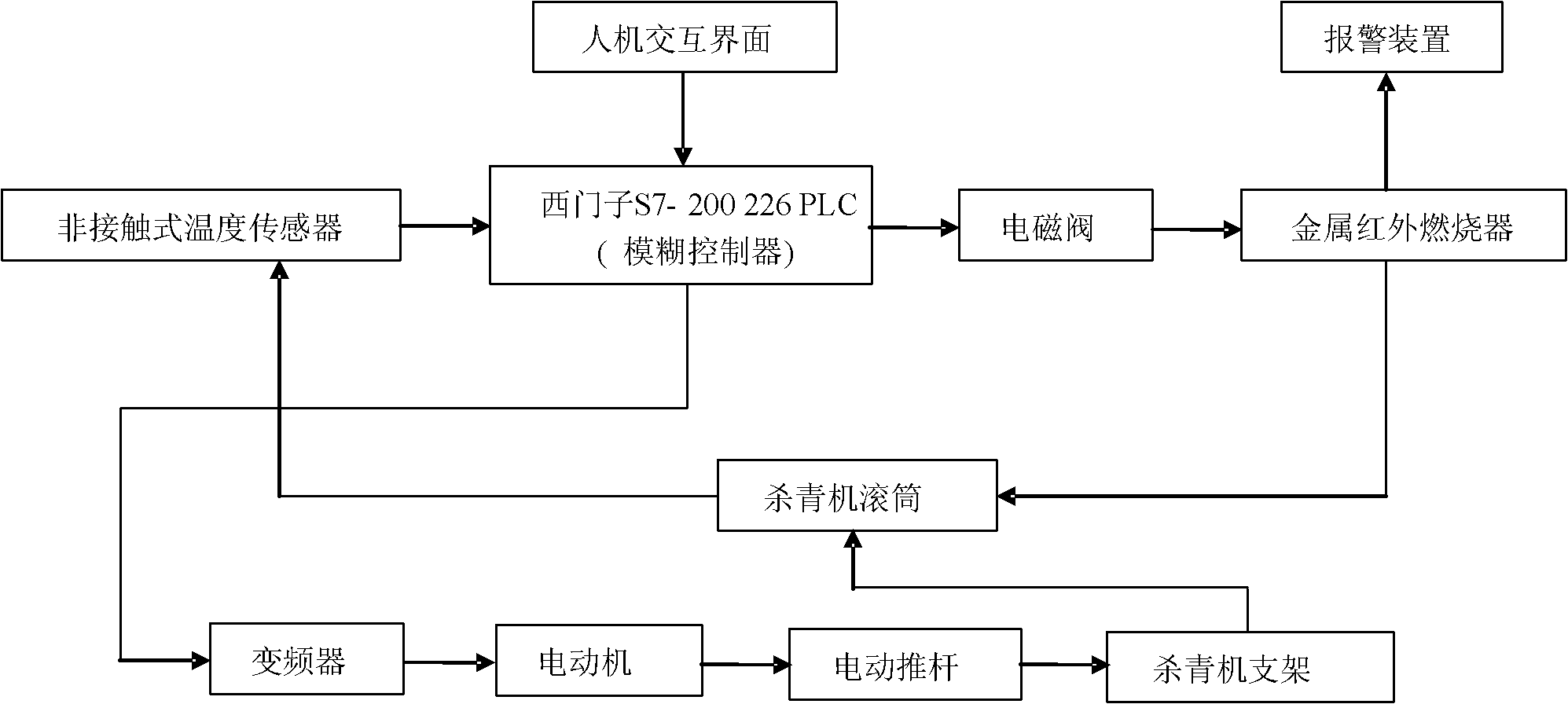

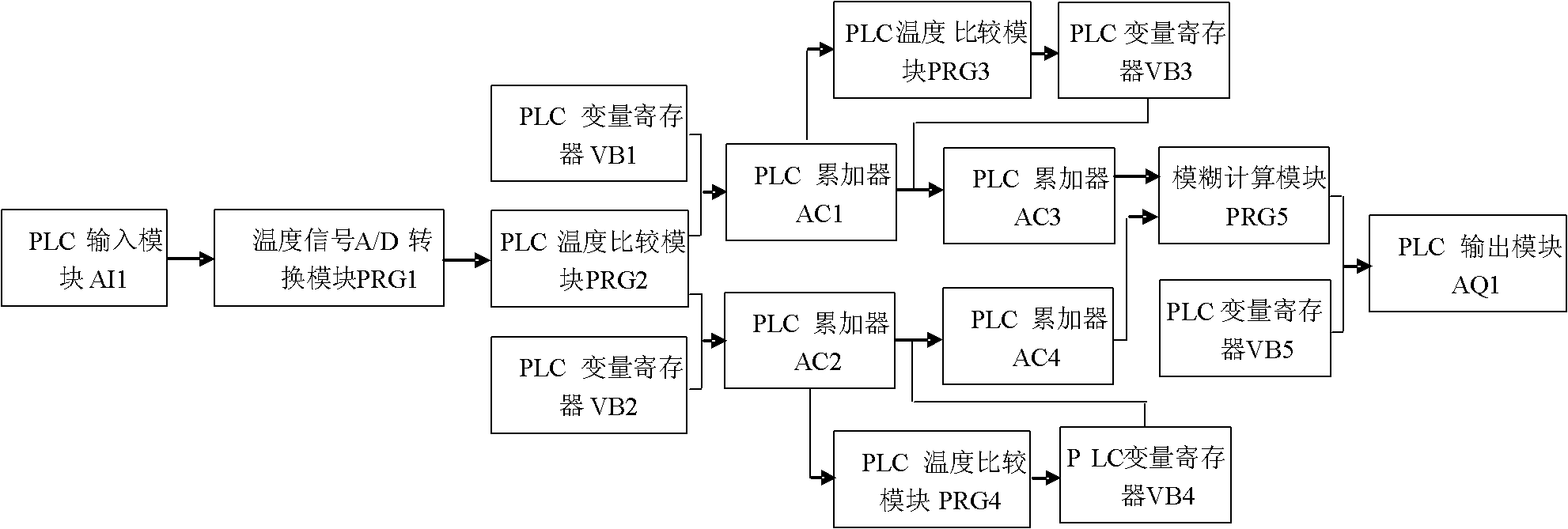

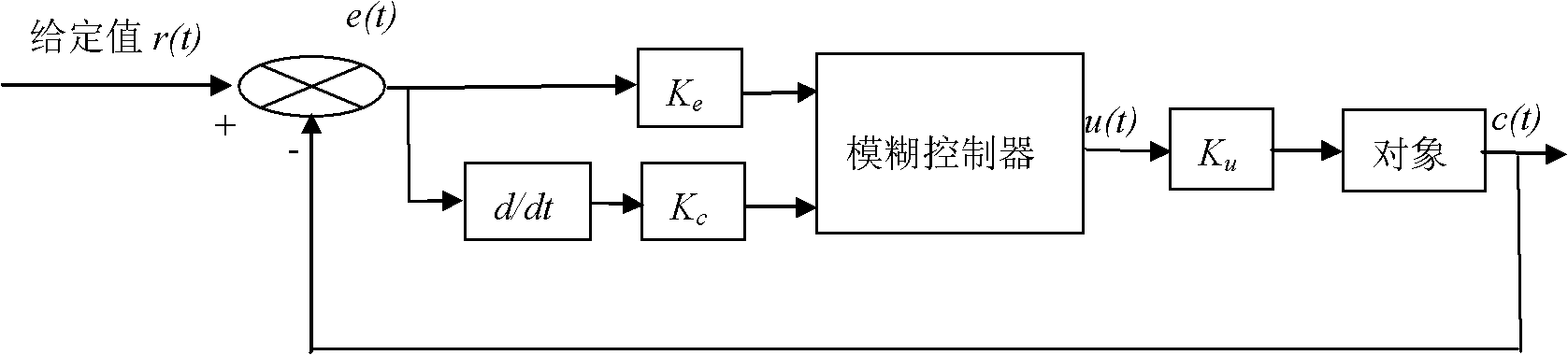

[0024] A complete set of infrared automatic tea greening machine control system includes man-machine interface, non-contact temperature sensor, fuzzy controller, solenoid valve, metal infrared burner, alarm device, frequency converter, motor, electric push rod 9, greening machine Bracket 10 and greening machine drum 11. Among them, the non-contact temperature sensor, fuzzy controller, solenoid valve and metal infrared burner form the heating system of the greening machine. The non-contact temperature sensor adopts Omron ES1 series, its measurement accuracy is 0.5°C, and the response speed is 0.4 seconds, which can feedback the real-time temperature value better; the fuzzy controller adopts Siemens S7-200 series, and the chip is CPU226 PLC for automatic control ;The solenoid valve adopts a flow-adjustable solenoid valve, and its structure is as follows: 1. Valve body; 2. Electromagnetic coil set outside the valve body; 3. Permanent magnet steel in the valve body cavity; 4. Smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com