Machining method for improving form and position precision of large gearbox body device

A gear box and semi-finishing technology, applied in metal processing equipment, manufacturing tools, workshop equipment, etc., can solve the problems of secondary alignment error, difficulty in alignment and machining accuracy, and difficulty in adjustment and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

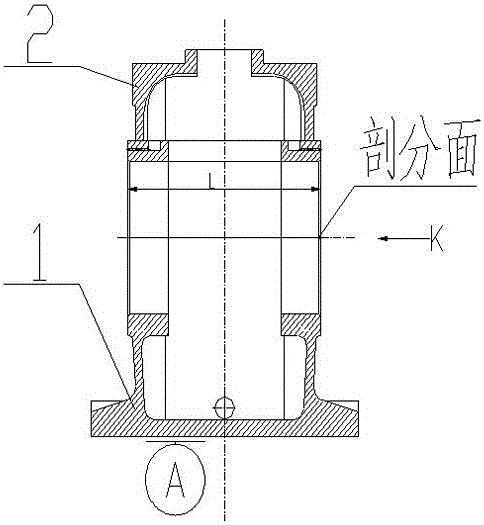

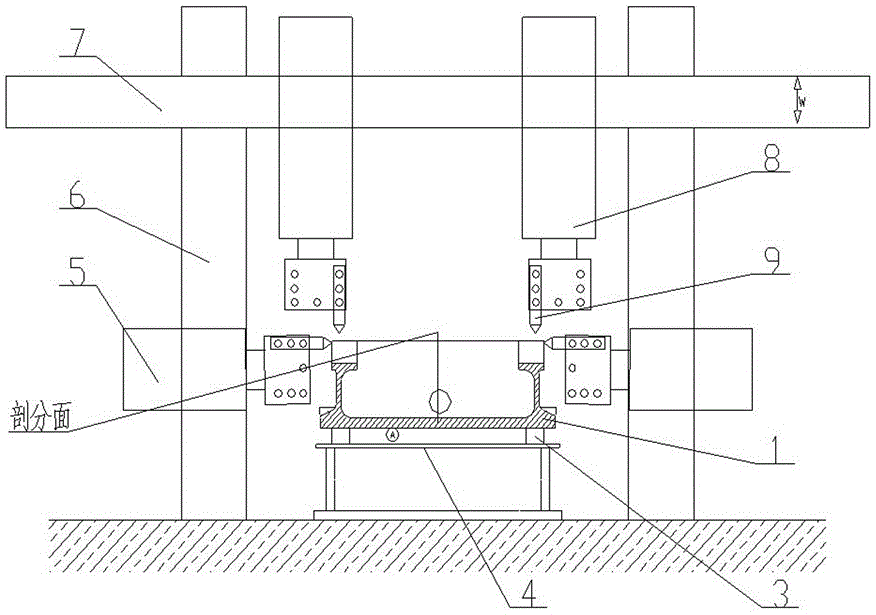

[0059] As shown in the figure, the specific implementation method is as follows:

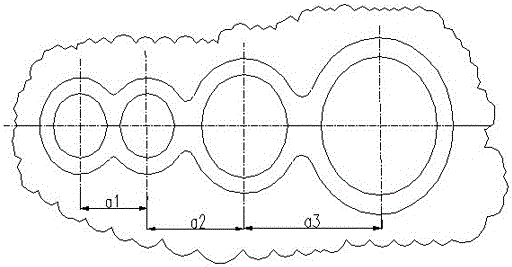

[0060] The geometric parameters of the present invention are: the present invention (as Figure 8-10 (shown) is different from the previous gearbox box device, which is composed of the lower box 20, the lower middle box 21, the upper middle box 22, and the upper box 23. The shaft holes are distributed in space, and the shaft holes Size 4-Φ880H7 (M1, M2, N1, N2) and 4-Φ1090H7 (K1, K2, L1, L2), the maximum span of shaft holes in the same axis direction is 3550mm, the center distance of shaft holes on the same side is 2486.97~2487.22mm, box The maximum geometric size of the volume division plane: length × width = 7000 × 4150mm.

[0061] The accuracy requirements of the present invention: the shape and position accuracy of the subdivision surface is 4 to 6 grades, and the shape and position accuracy of the shaft hole is as high as 3 to 6 grades. The parallelism tolerance of B is 0.08mm, the roundn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com