Patents

Literature

169results about How to "Fully supported" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

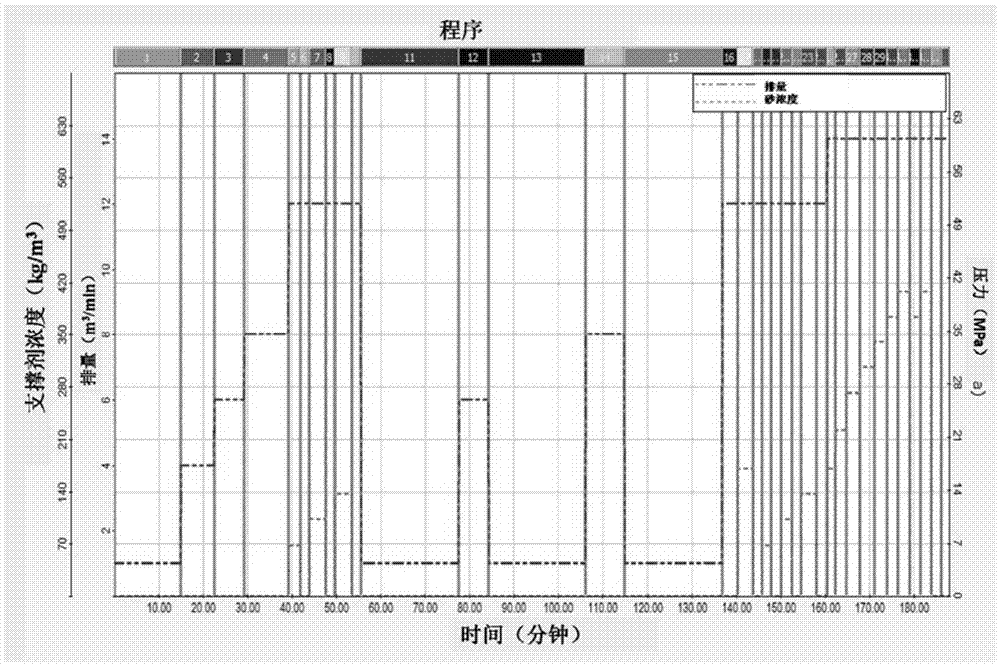

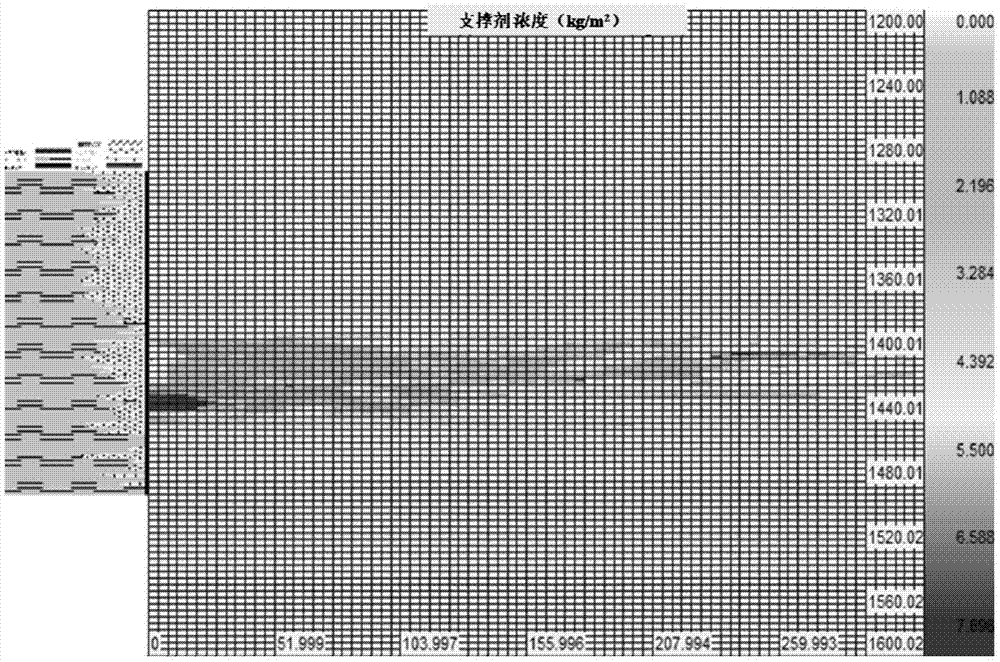

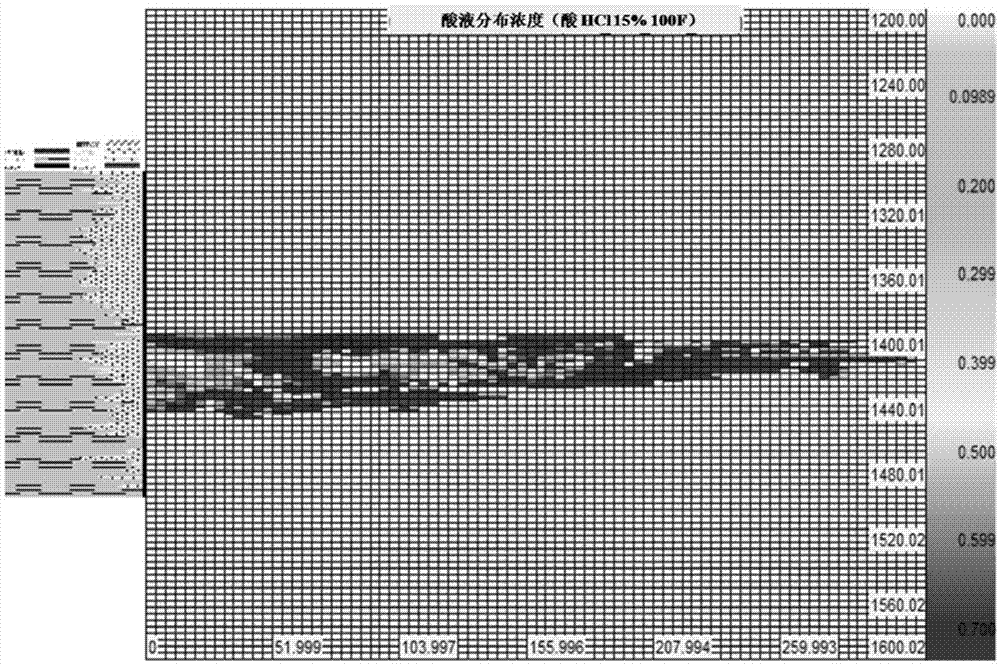

Method suitable for effective flow guide for fractures in fracturing of shale oil pool reservoir

ActiveCN106907137AImprove diversion capacityIncrease "retrofit volumeFluid removalMicro fractureFracturing fluid

The invention relates to the technical field of hydraulic fracturing capacity increasing revamping of oil and gas reservoirs, in particular to a method suitable for effective flow guide for fractures in fracturing of a shale oil pool reservoir. The method includes the following steps that A, the reservoir is pretreated through acid liquor; B, the main fracture is constructed through low-viscosity fracturing fluid; C, the micro fractures and the branch fractures are opened by injecting low-viscosity slickwater; D, slugging is conducted by injecting low-viscosity acid liquor and low-viscosity slickwater alternately; E, low-viscosity slickwater carrying a proppant and low-viscosity fracturing fluid carrying a proppant are injected in sequence so as to support a micro fracture system and a branch fracture system, and the first proppant is different from the second proppant; F, intermediate-viscosity fracturing fluid carrying proppants is injected so as to support a main fracture system; and G, the fourth proppant in a shaft is completely displaced to the openings of the fractures by means of the low-viscosity slickwater.

Owner:CHINA PETROLEUM & CHEM CORP +1

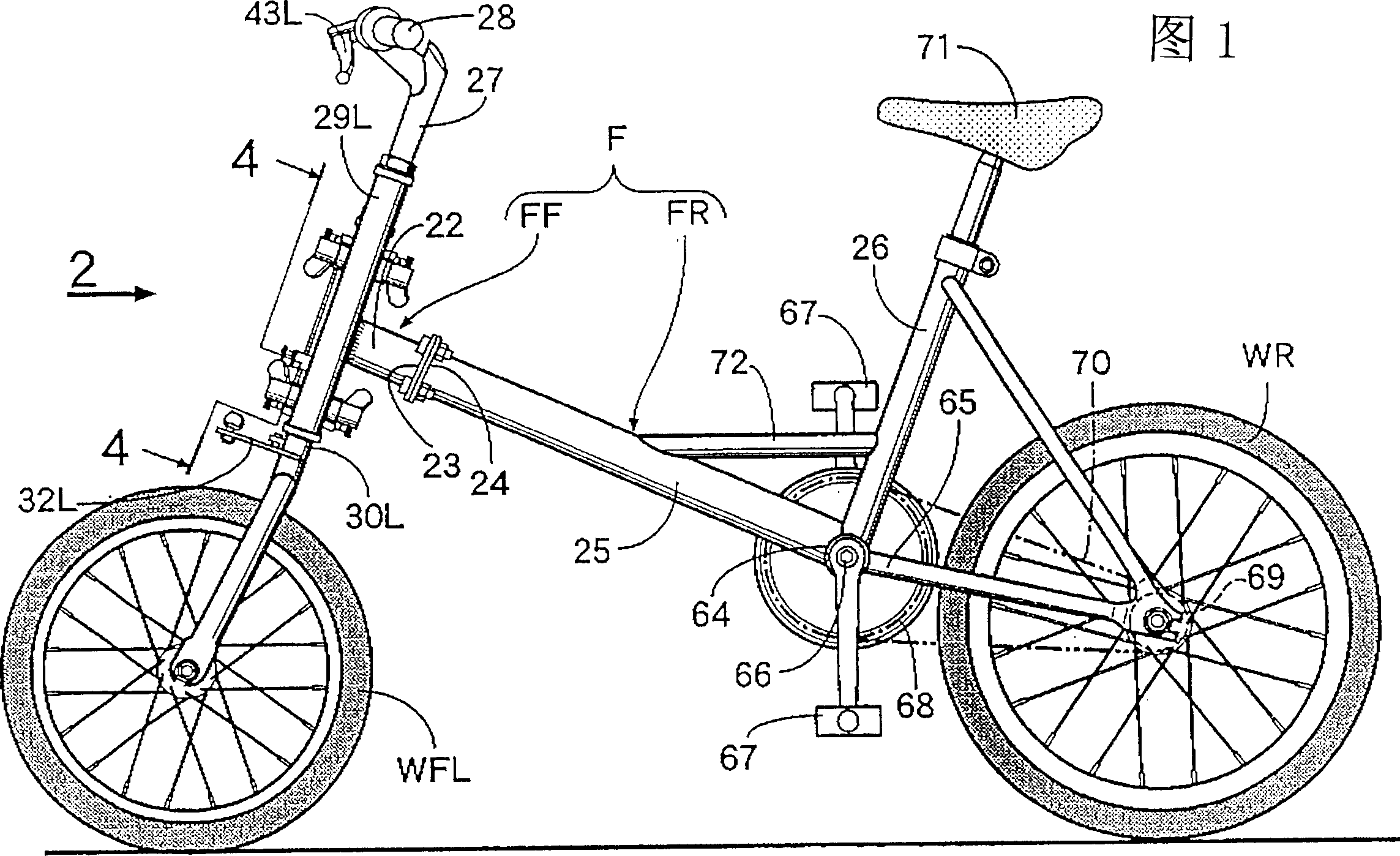

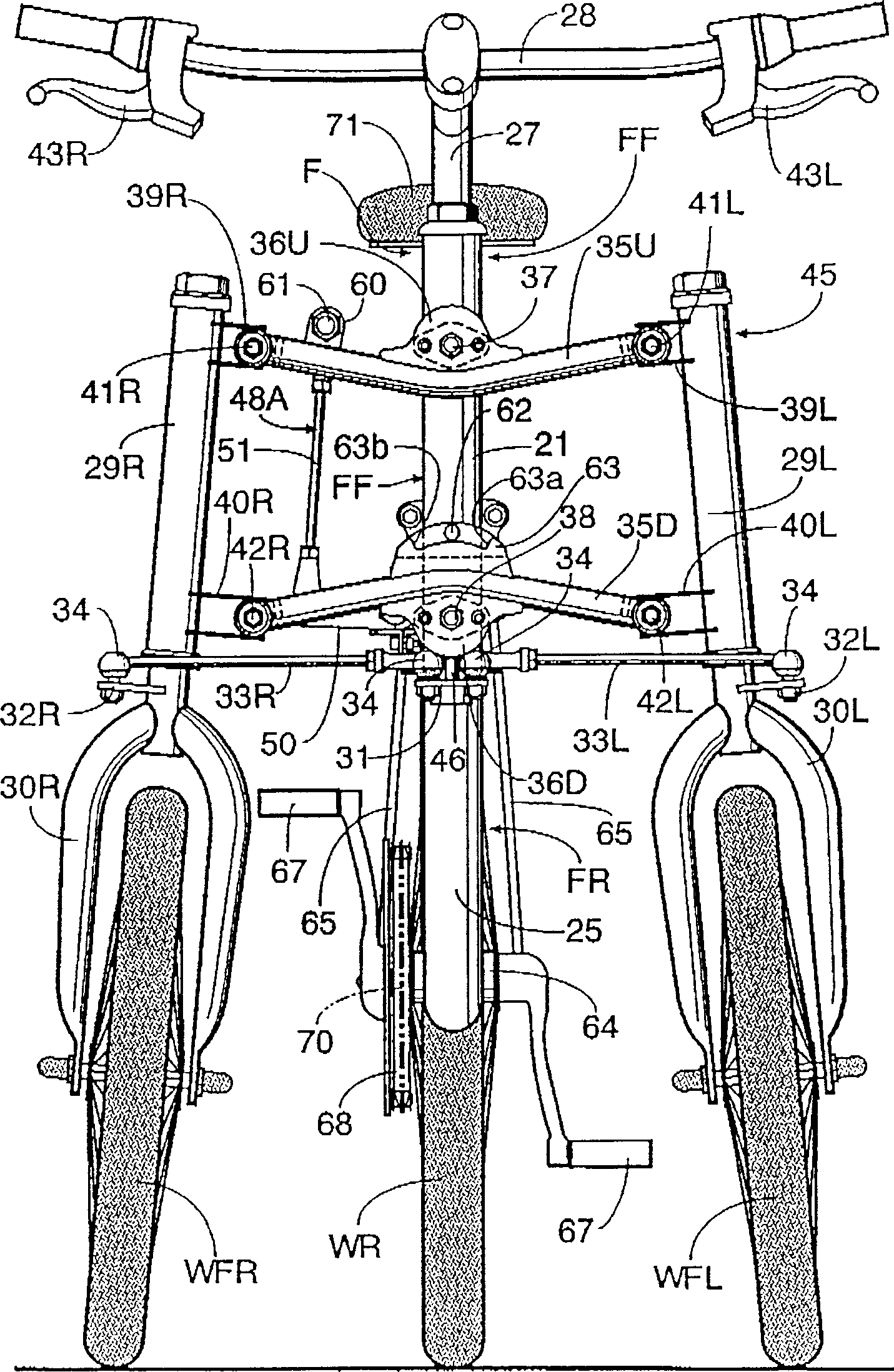

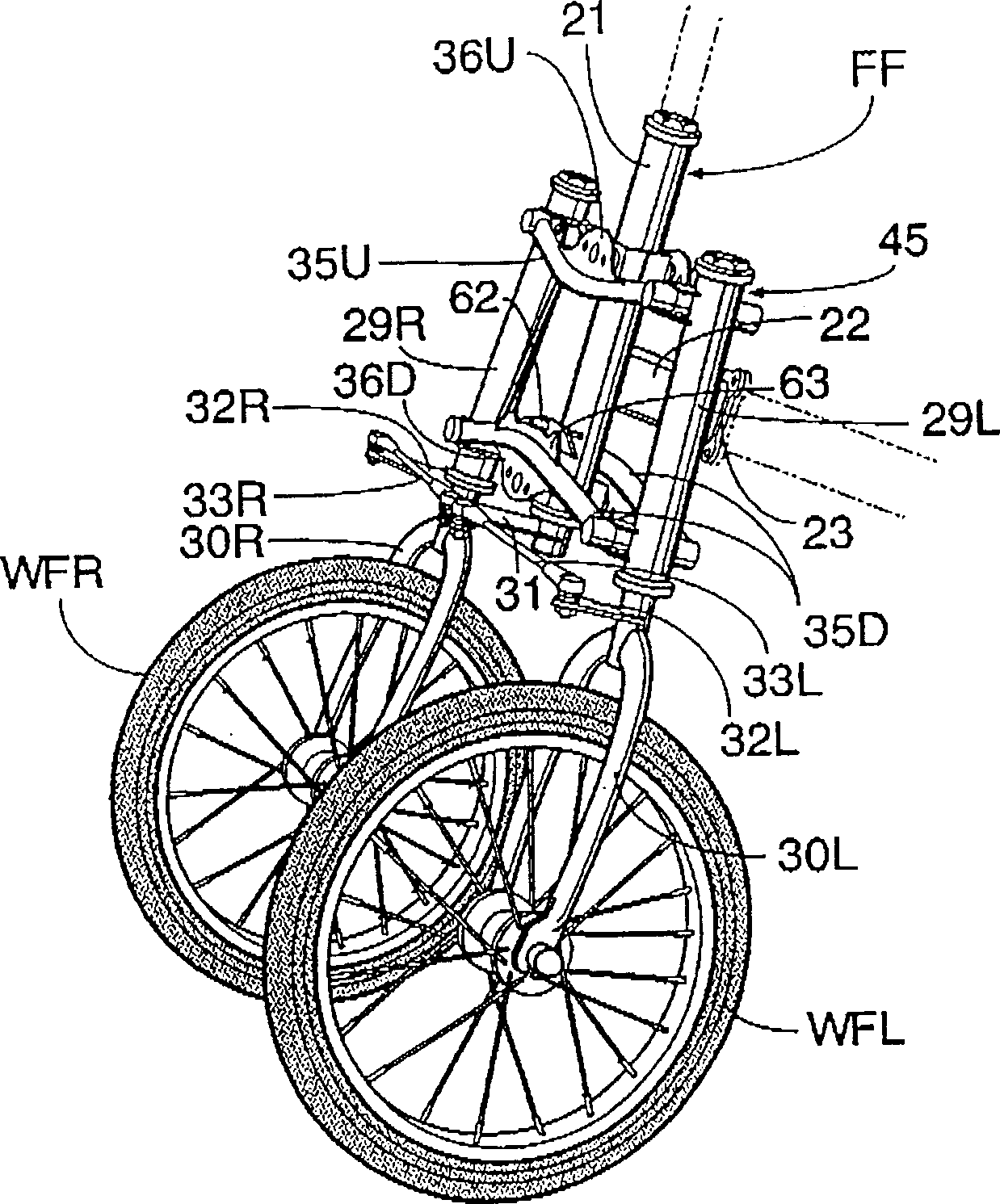

Tricycle

InactiveCN1386668AFully supportedSteering deviceConvertible cyclesSteering columnAgricultural engineering

A tricycle, the left and right front forks respectively supporting the left and right front wheels freely rotatable are arranged on the left and right sides of the steering column to extend up and down, and are respectively rotatably supported on the left side supported by the steering column and the right side column, the central part of the upper link connecting both ends to the left and right column and the central part of the lower link connecting both ends to the left and right column are rotatably connected to the steering column ; Wherein, the left side and the right side column are arranged obliquely as the distance between the columns on both sides decreases as they go upward, so as to be fully supported by the front wheel on the inner wheel side when walking obliquely.

Owner:AVANTECH INC

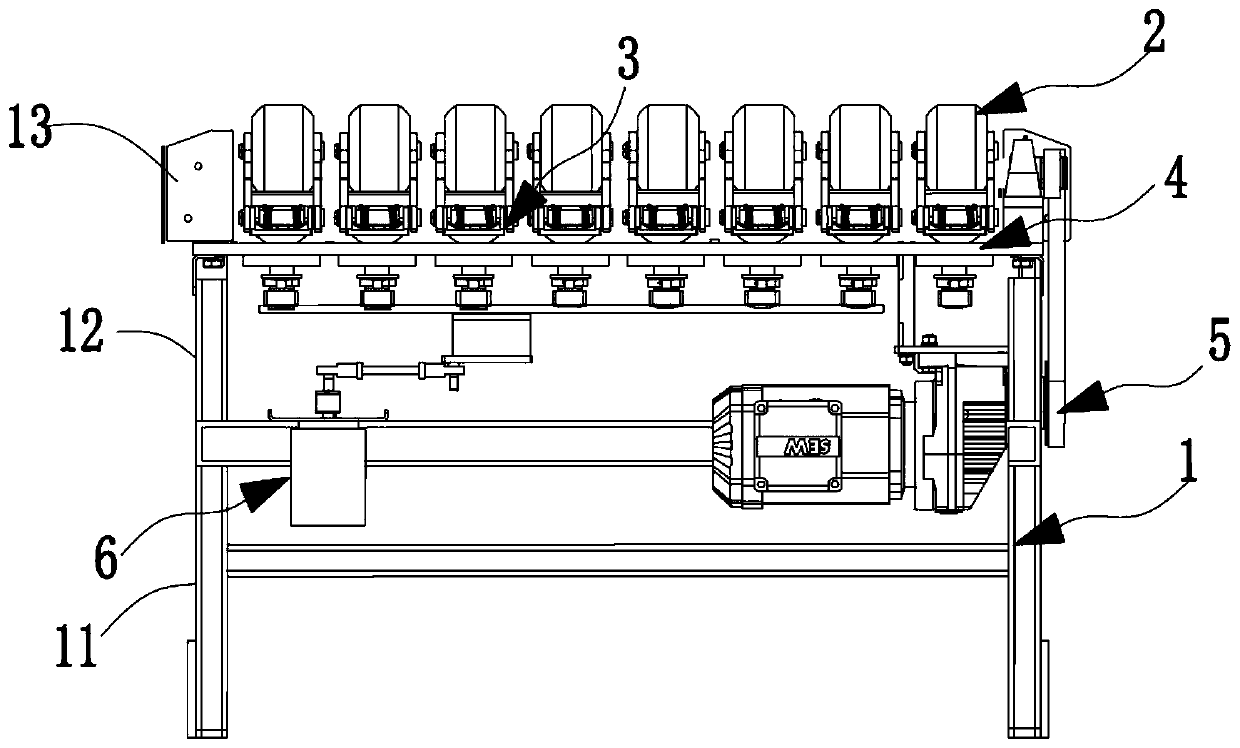

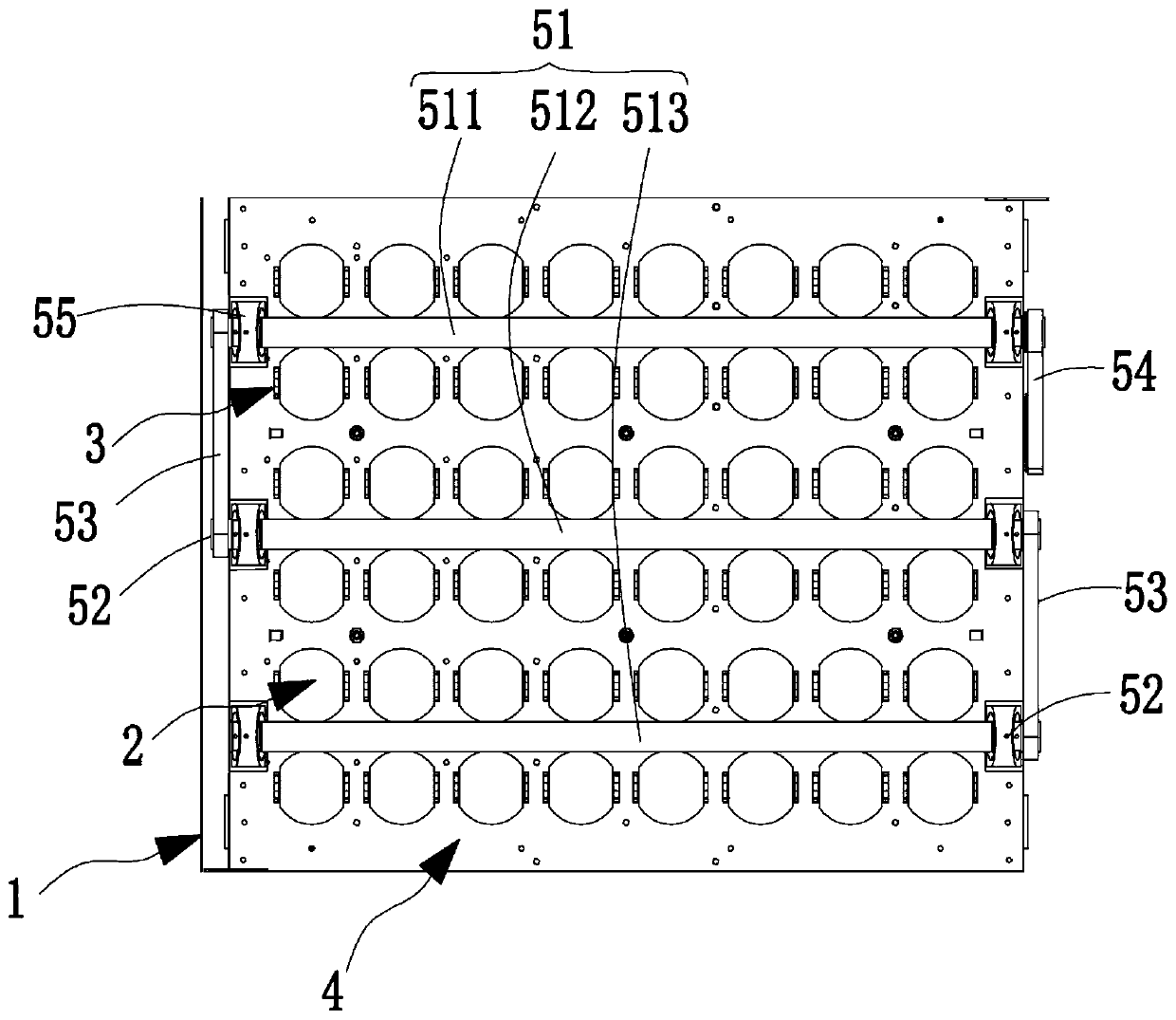

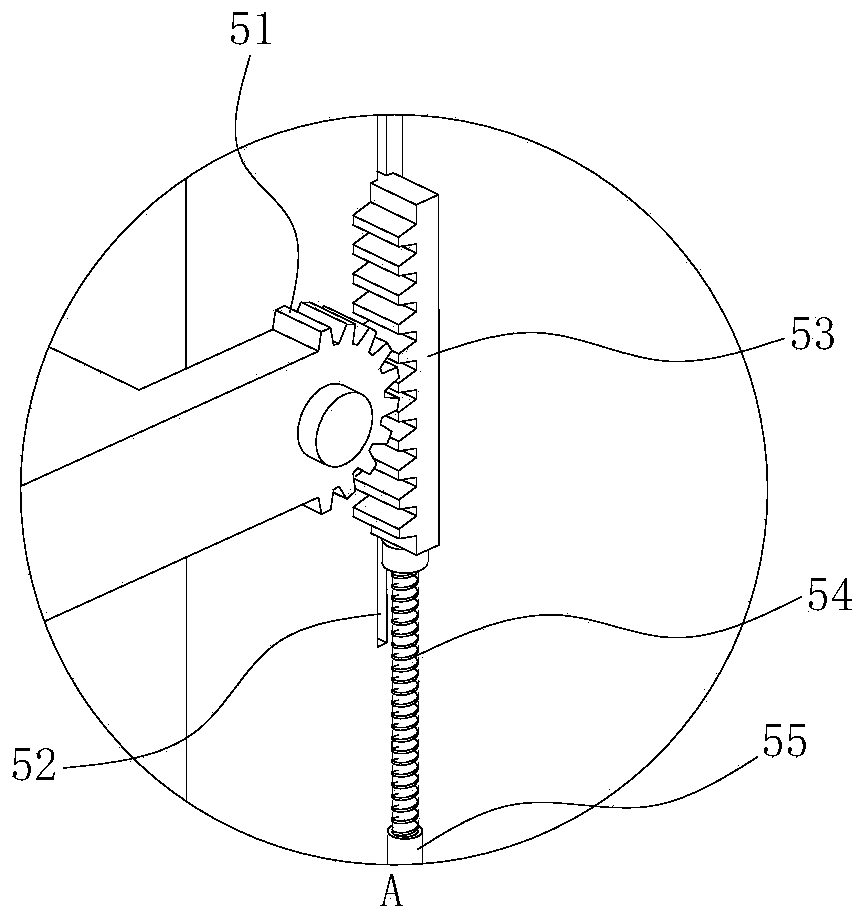

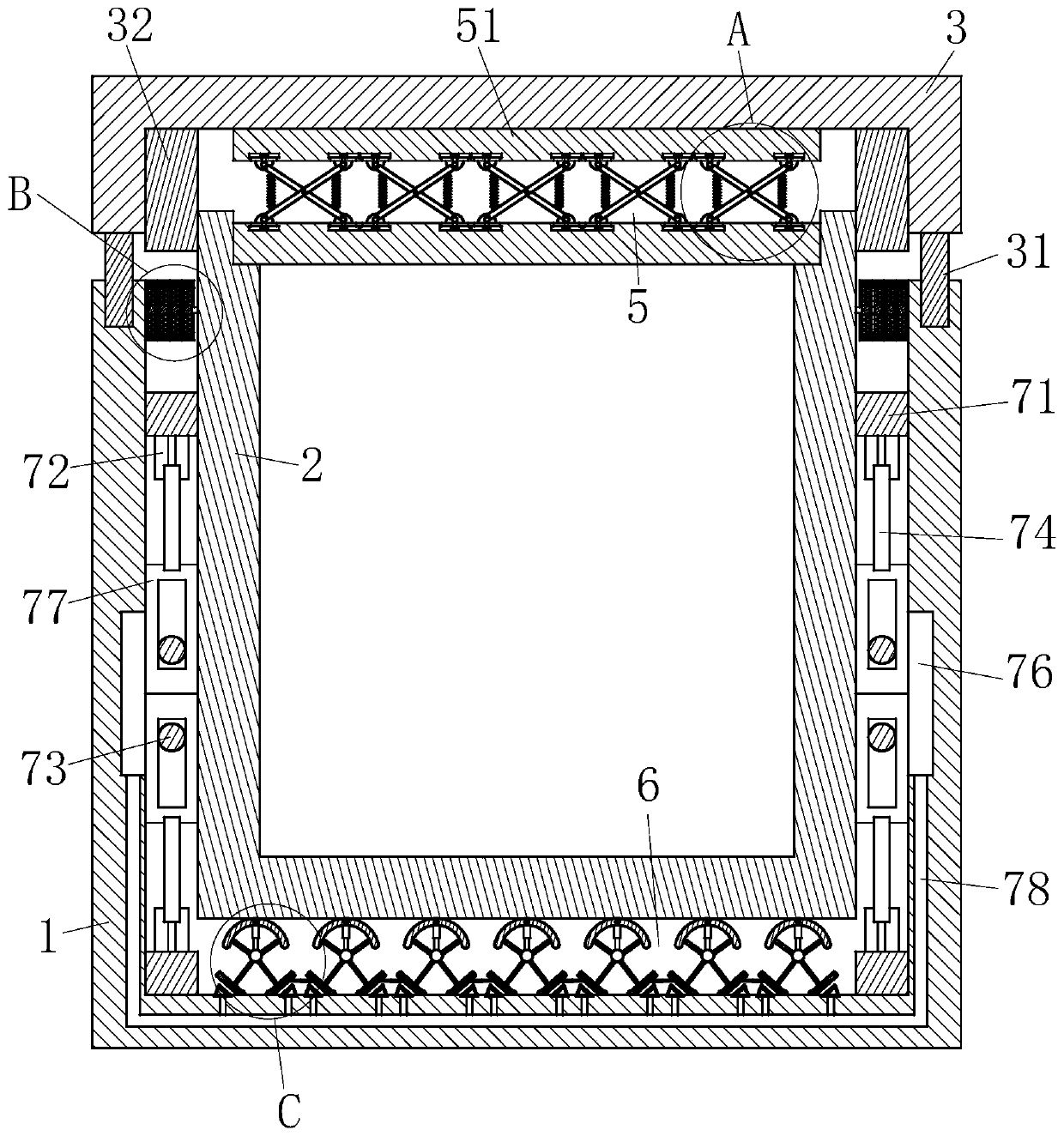

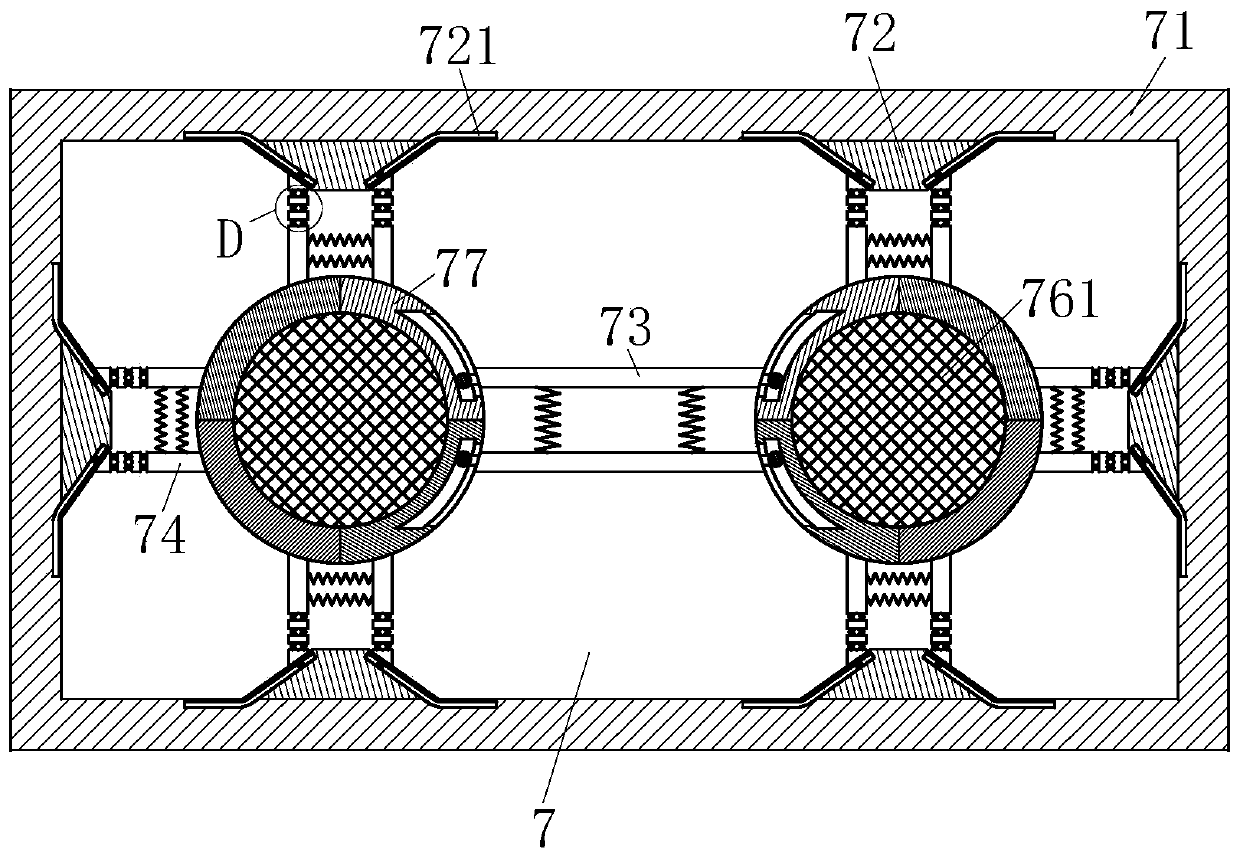

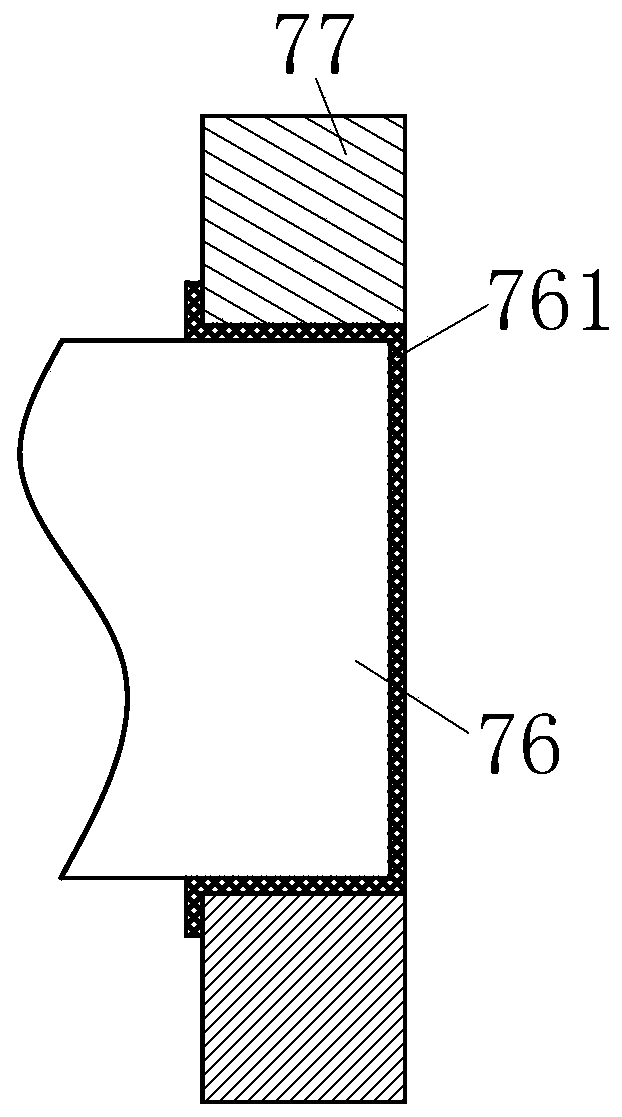

Wheel type conveying line

PendingCN110015540AEasy to assembleGuaranteed reliabilityConveyor partsRoller-waysSelf adaptiveFriction force

The invention discloses a wheel type conveying line which comprises a rack. Multiple rows of eccentric rotating wheels are arranged on the rack in an equal height manner. The axes of all the eccentricrotating wheels are parallel to one another and are parallel to the horizontal plane. Each eccentric rotating wheel is arranged on an installing frame located on the rack in the manner of rotating around the axis of the eccentric rotating wheel. The eccentric rotating wheels on each row are attached to a driving roller, the driving roller makes contact with the lower semicircle of each eccentricrotating wheel, the driving roller is affected by upward elastic force, and thus the eccentric rotating wheels are attached to the driving roller in a self-adapting manner, or the driving roller makescontact with the upper semicircle of each eccentric rotating wheel, the eccentric rotating wheels are affected by the upward elastic force, and the eccentric rotating wheels are attached to the driving roller in a self-adapting manner. The driving roller rotates under the driving of a first power source, and the eccentric rotating wheels are driven to rotate through friction force. According to the wheel type conveying line, the design of the scheme is elaborate, the eccentric rotating wheels or the driving roller are affected by the upward elastic force, thus the eccentric rotating wheels always keep being attached to the driving roller, after abrasion is caused or when the installing position precision is poor, self-adaptive adjusting is achieved, rotating between the eccentric rotatingwheels and the driving roller is effectively ensured, and the conveying stability is improved.

Owner:SUZHOU GP LOGISTICS SYST

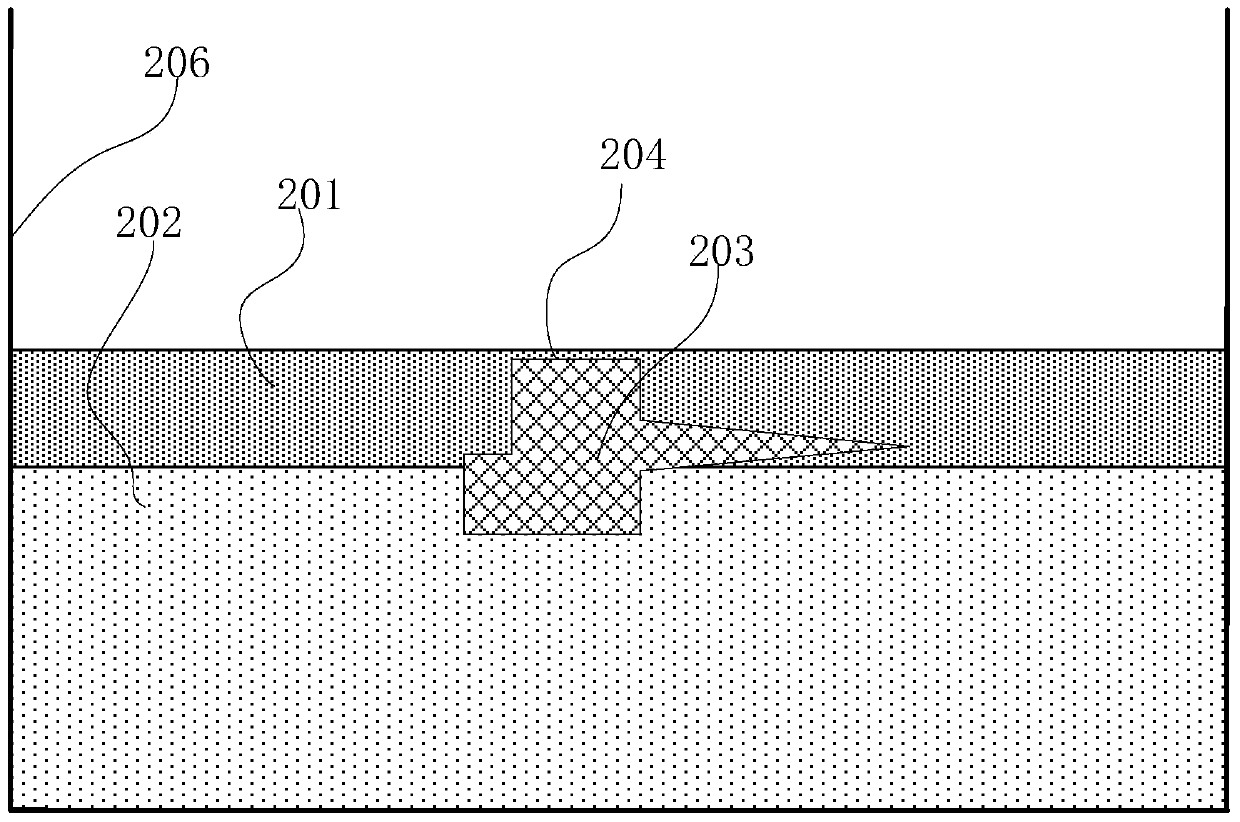

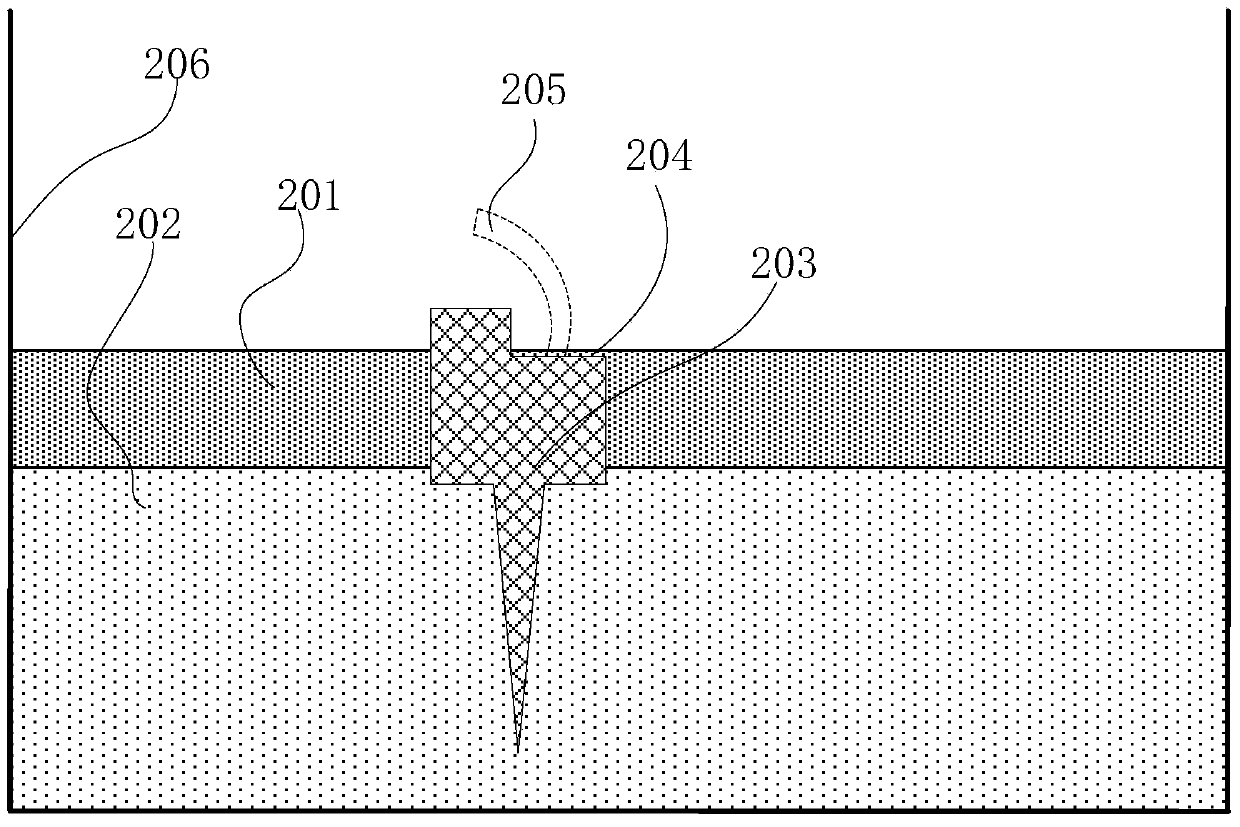

3D printing auxiliary method and device and 3D printing equipment

The embodiment of the invention discloses a 3D printing auxiliary method and device. The method comprises the steps that supporting liquid is provided, and the supporting liquid is used for providing buoyancy support for a printed object which is immersed into the supporting liquid at least in part in the printing process and keeping the printed object in the floating or suspending state in the supporting liquid. According to the technical scheme, printing of a supporting structure can be omitted at least in part, and printing materials and printing time are saved; the printed object is evenly and softly supported through the supporting liquid, the printed object is comprehensively supported, meanwhile, the shape of the printed object which is not completely cured is not prone to be damaged, and the printing finished product quality is improved. On the premise that liquid supporting exists, the printing face is changed, and a high-quality finished product is more easily obtained, operation like rotation can be conveniently performed on the printed object, and the shape of the printed object which is not completely cured is not prone to be damaged.

Owner:BEIJING ZHIGU TECH SERVICE

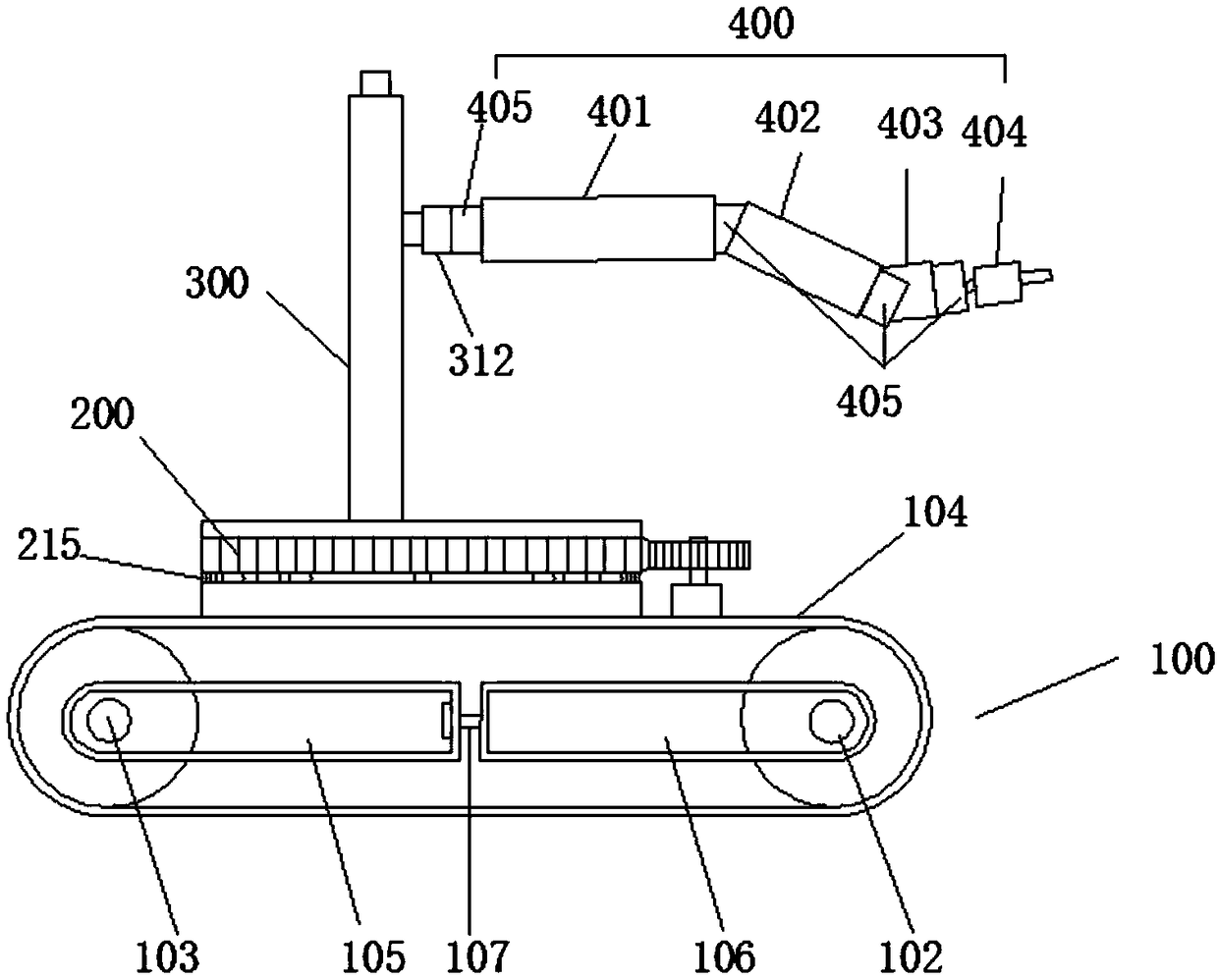

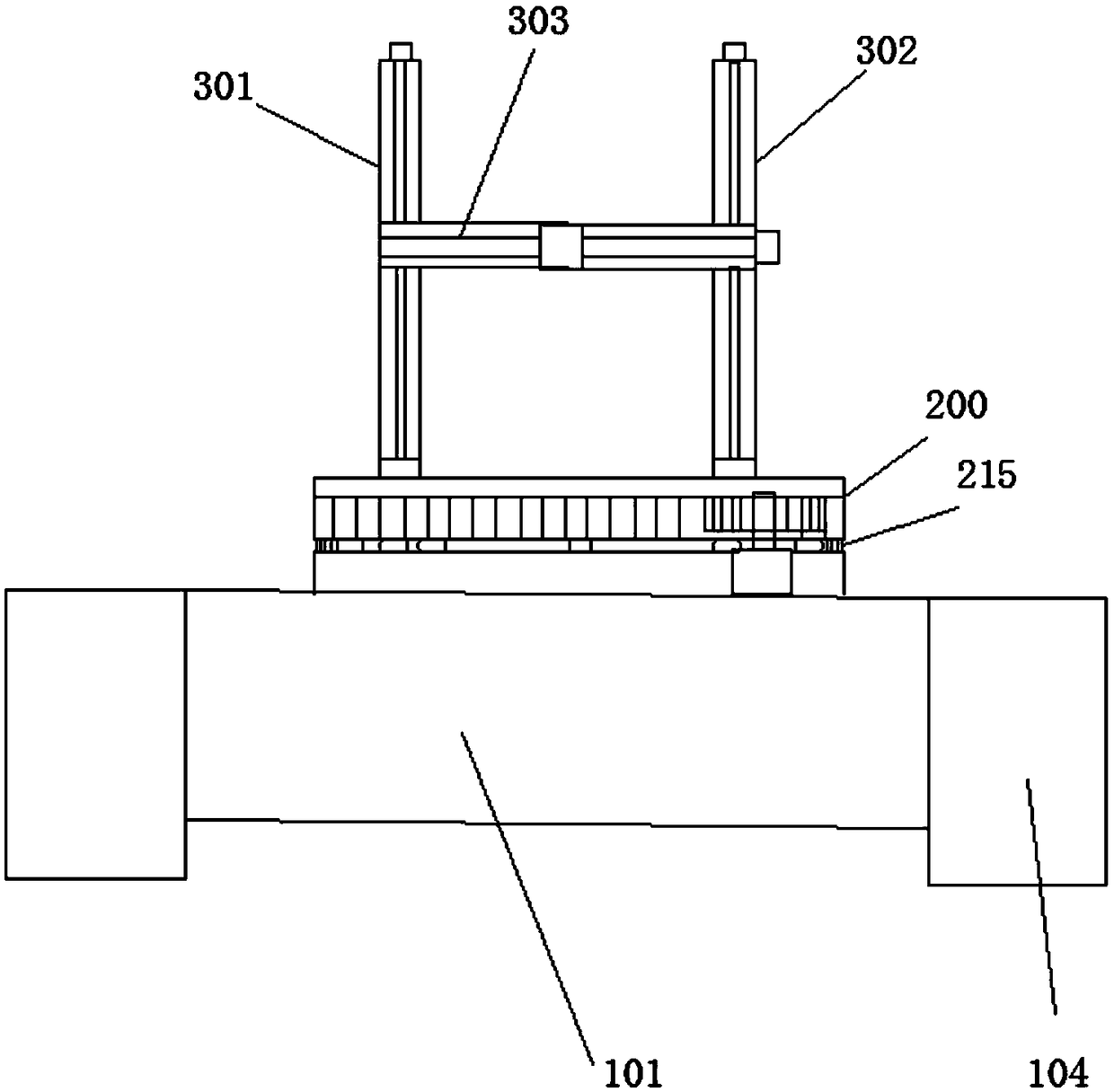

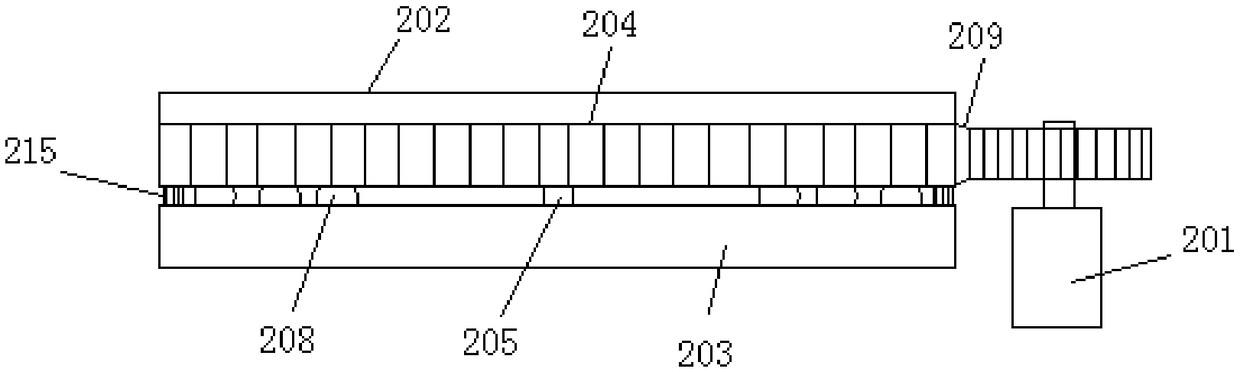

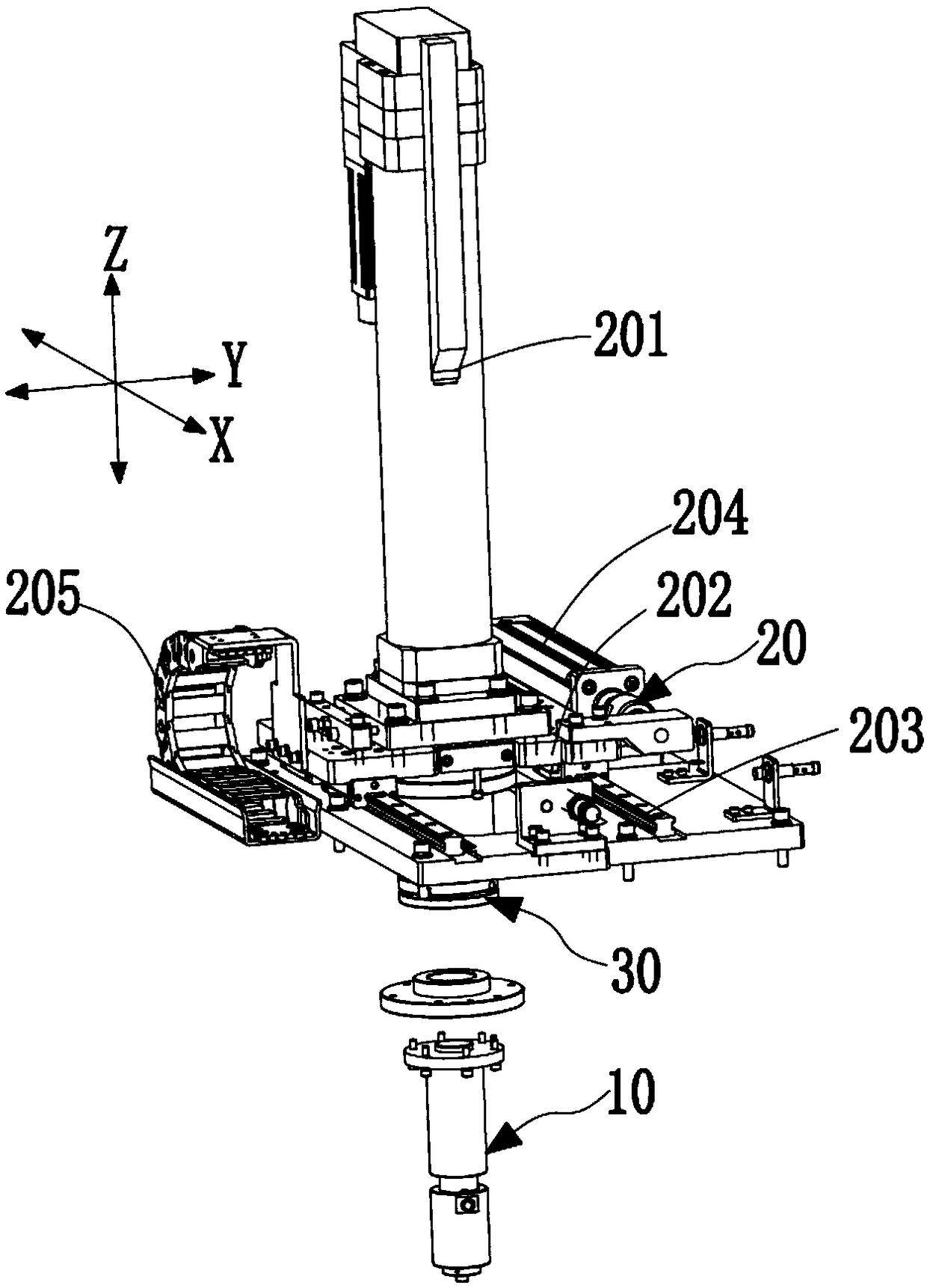

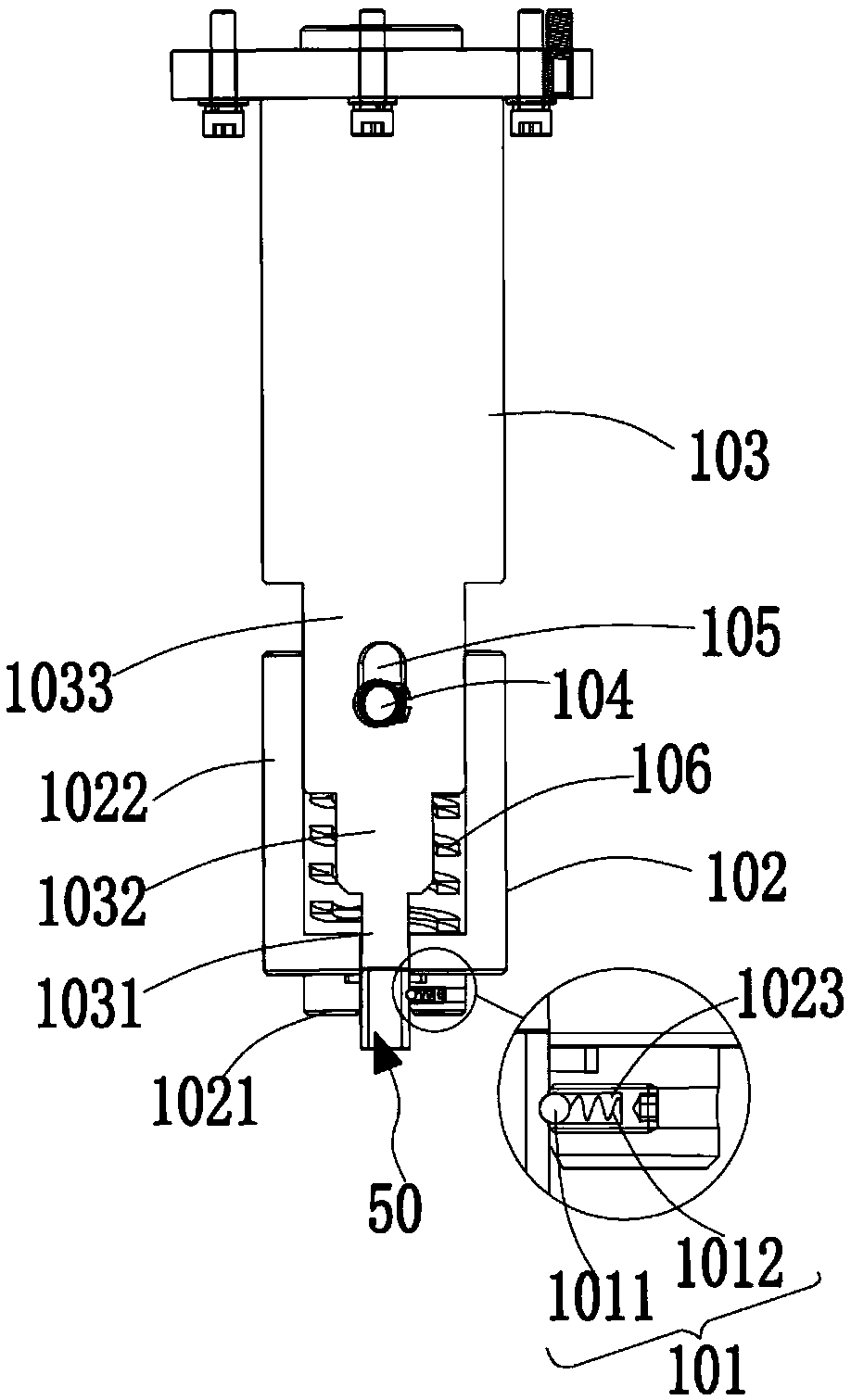

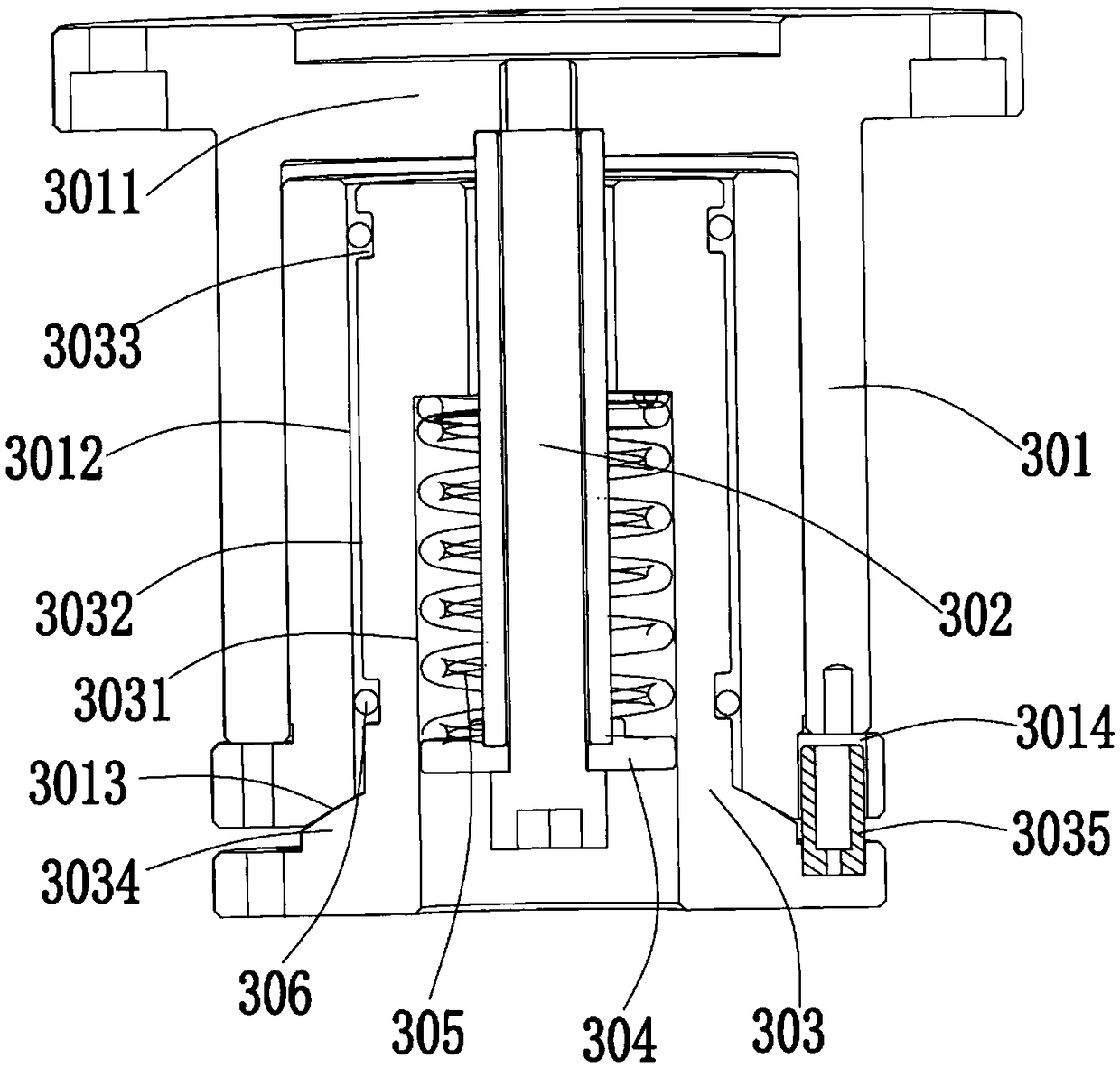

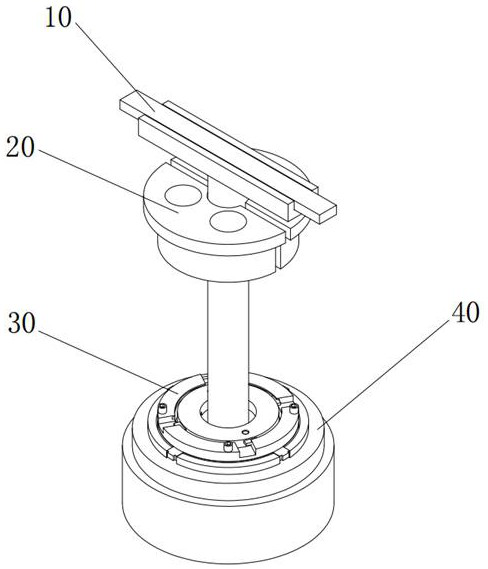

Industrial robot

InactiveCN109015594AImprove weight capacityFully supportedProgramme-controlled manipulatorArmsRobotic armEngineering

The invention provides an industrial robot and belongs to the field of robots. The industrial robot comprises a moving device, a rotating supporting device, a lifting device and a mechanical arm. Therotating supporting device is arranged on the moving device, the lifting device is arranged on the rotating supporting device, and the mechanical arm is connected with the lifting device. The rotatingsupporting device comprises a rotating driving mechanism, a rotating transmission mechanism and a supporting platform. The lifting device comprises a first lifting device body, a second lifting device body and a horizontal moving device. The mechanical arm utilizes a mechanical large arm body, a mechanical small arm body, a wrist joint and a mechanical claw to realize multiple degrees of freedomof movement and realize arranging and carrying of cargos, the cargo arranging efficiency is improved, and a lot of manpower and material resources are saved.

Owner:李友朋 +1

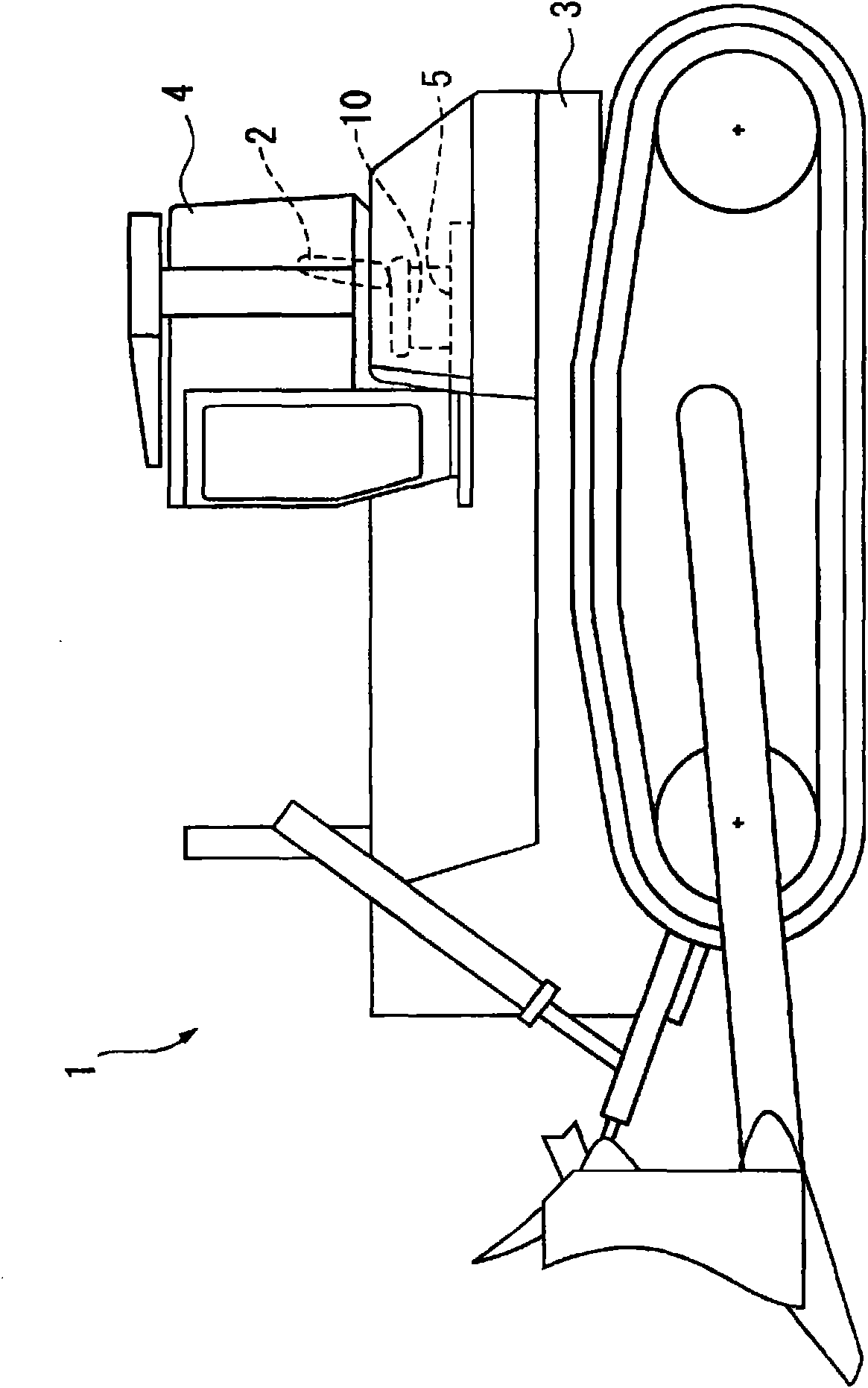

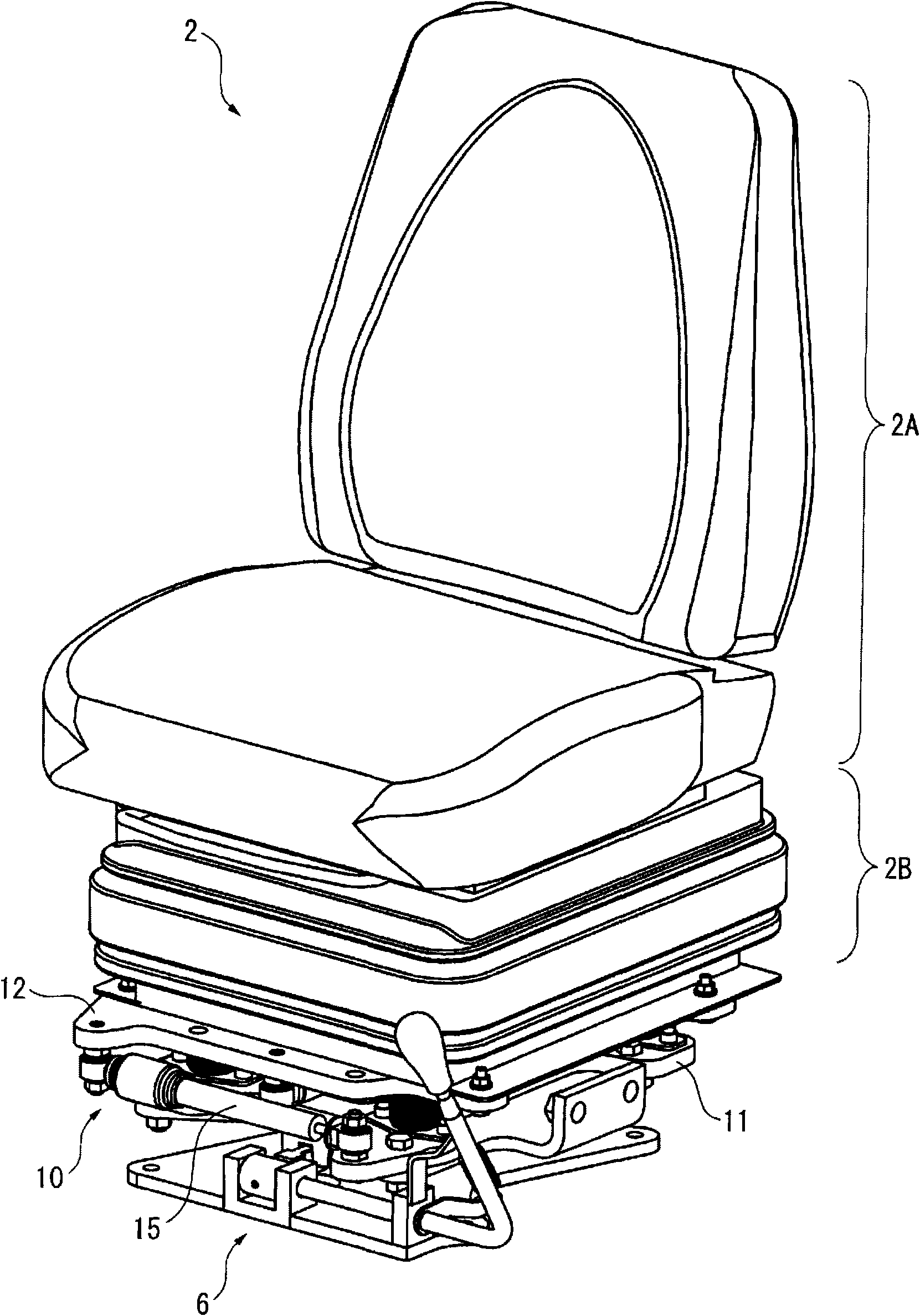

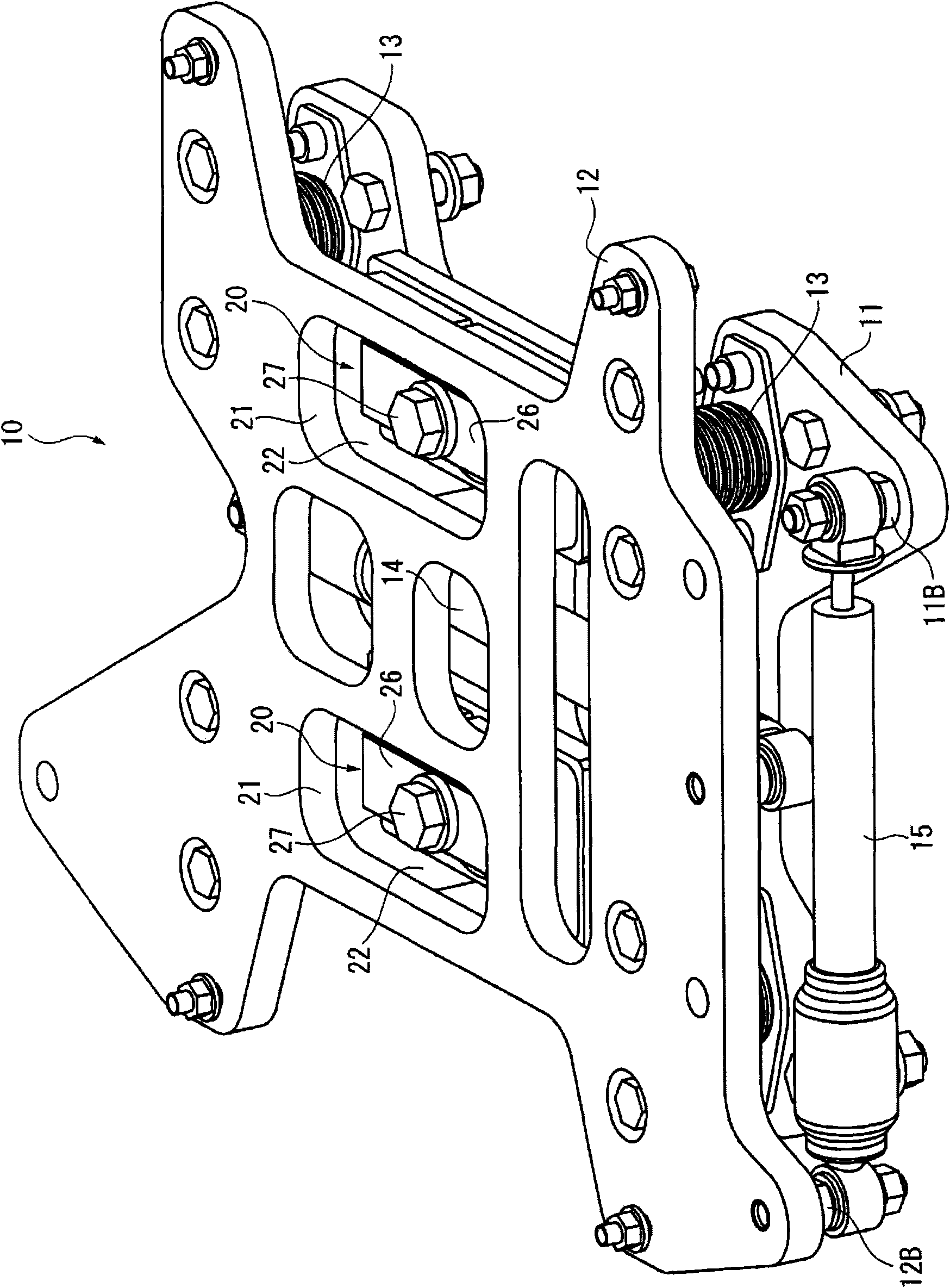

Damping device

InactiveCN101641482AReduce the impactImprove impact absorption performanceVehicle seatsNon-rotating vibration suppressionLeft directionEngineering

A damping device (10) comprises laminated rubbers (13) interposed at four corners between a support having the floor plate of a construction machine and a movable body having the seat body of operator, and a pair of dampers (14, 15) having one end fixed to the lower supporting plate (11) on the support side and the other end fixed to the upper supporting plate on the movable body side.The laminated rubbers (13) are arranged while spaced apart in the front / back direction and the right / left direction with reference to the seating direction of the operator. One damper (14) is arranged along the front / back direction at a position corresponding to the center in the right / left direction between the laminated rubbers (13) arranged in the right / left direction, and the other damper (15) is arrangedalong the right / left direction on the front side of the center in the front / back direction between the laminated rubbers (13) arranged in the front / back direction.

Owner:KOMATSU LTD

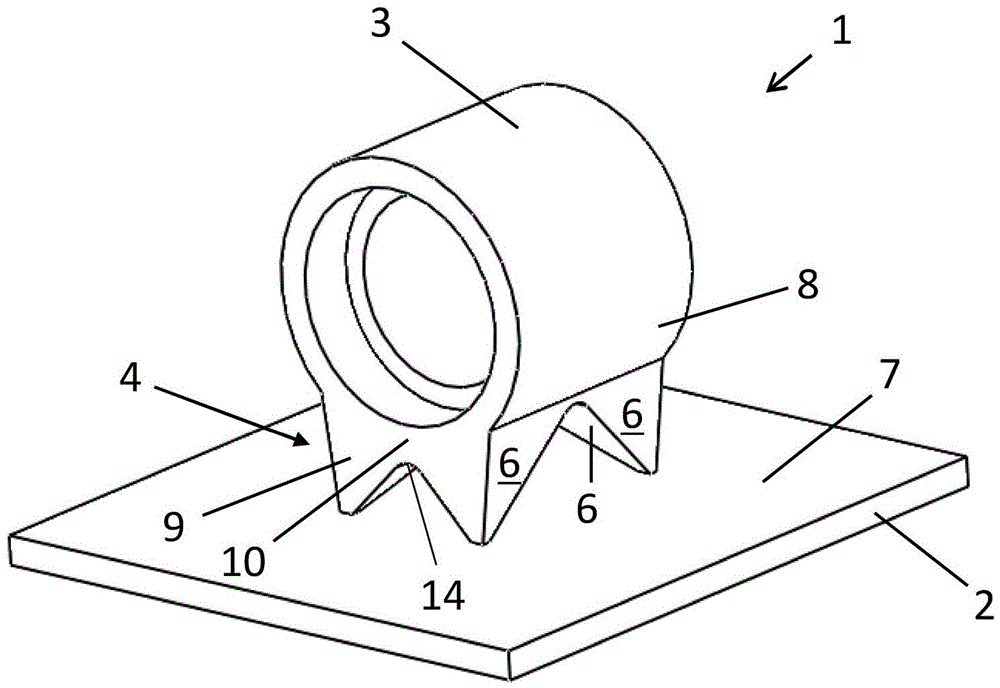

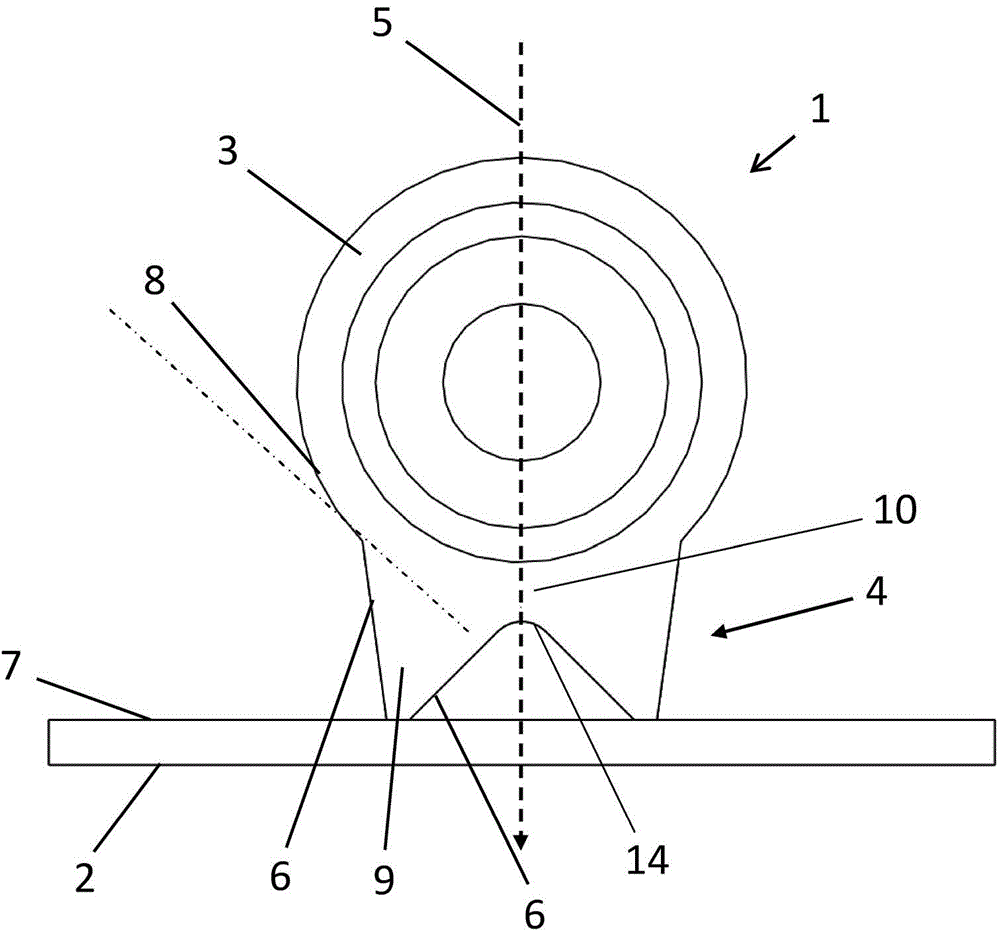

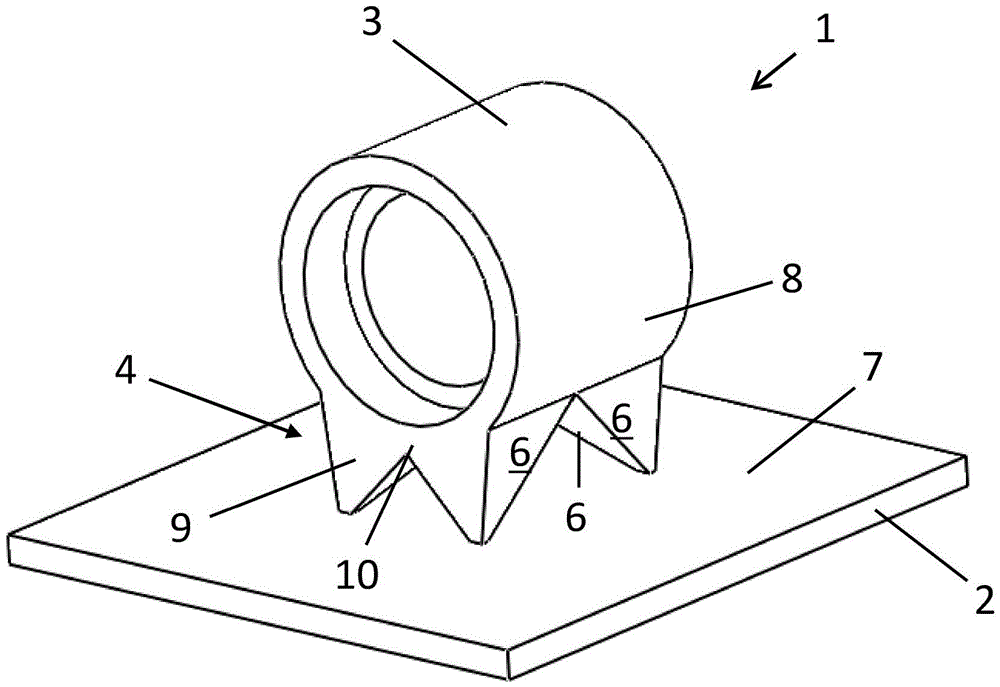

Additive layer manufacturing method for producing three-dimensional object and three-dimensional object

ActiveCN104028756AReduce investmentAdd supportPipe supportsAdditive manufacturing apparatusParticle beamIrradiation

An additive layer manufacturing method is disclosed for producing a three-dimensional object (1) and to a corresponding object. Layers of a powder material are sequently applied to a carrier and irradiated, before the following layer is applied, with a laser beam or particle beam selectively only in the areas of the layer which correspond to the three-dimensional object to be produced. Irradiation occurs such that the powder material in the corresponding areas is locally melted or sintered. The object (1) is provided with a first portion (2), a second portion (3) and a support structure (4) which is arranged between the two portions and used for the connection between the two portions. When the layers are constructed layer by layer, the first portion is constructed before the second portion or the first portion is provided as a separate component, on which the support structure and second portion are constructed. The support structure is constructed in the form of a plurality of support legs (9), which extend from the first portion to the second portion and are connected thereto at their opposite ends and are spaced apart from one another at least along part of their length.

Owner:AIRBUS OPERATIONS GMBH

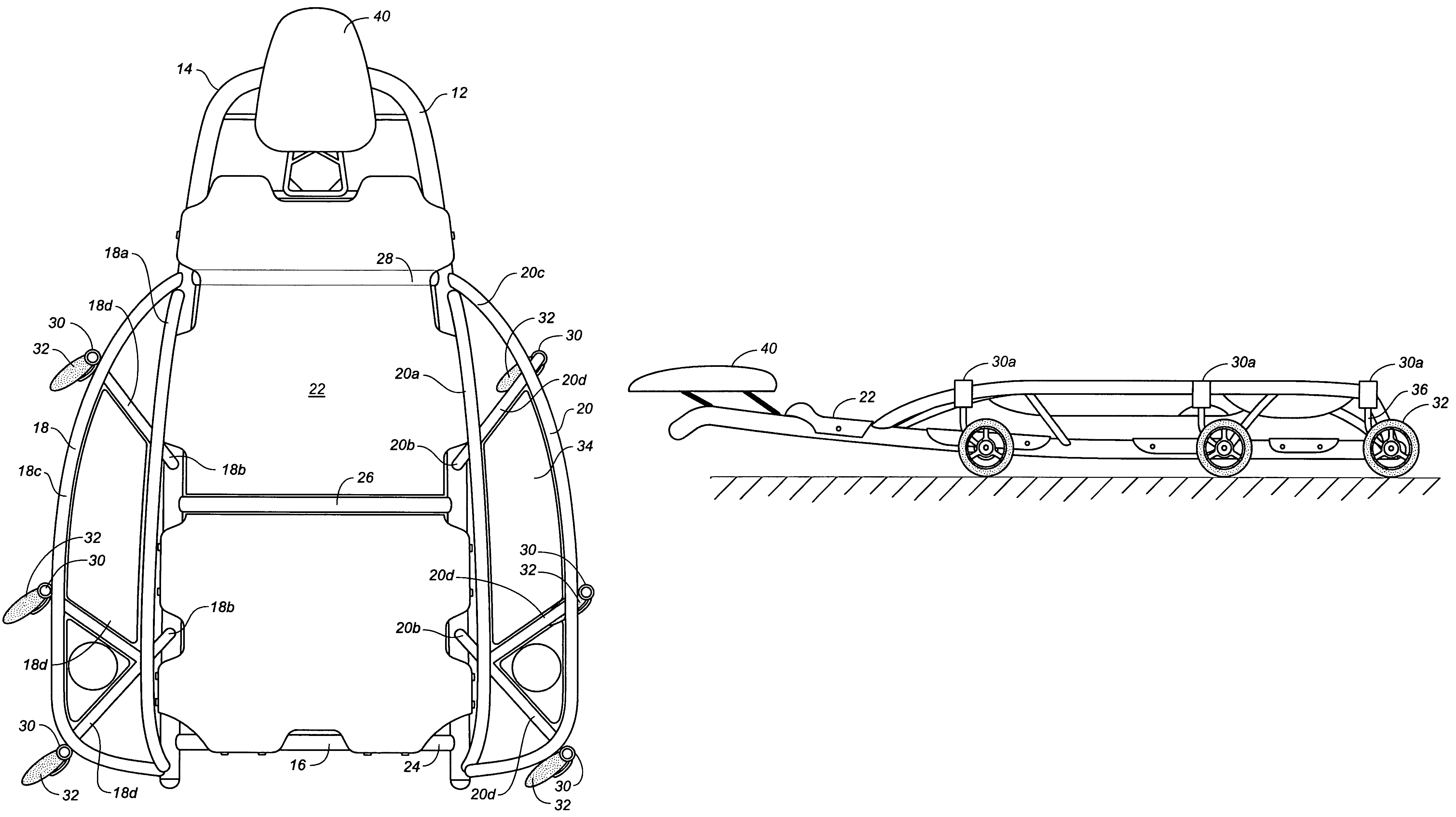

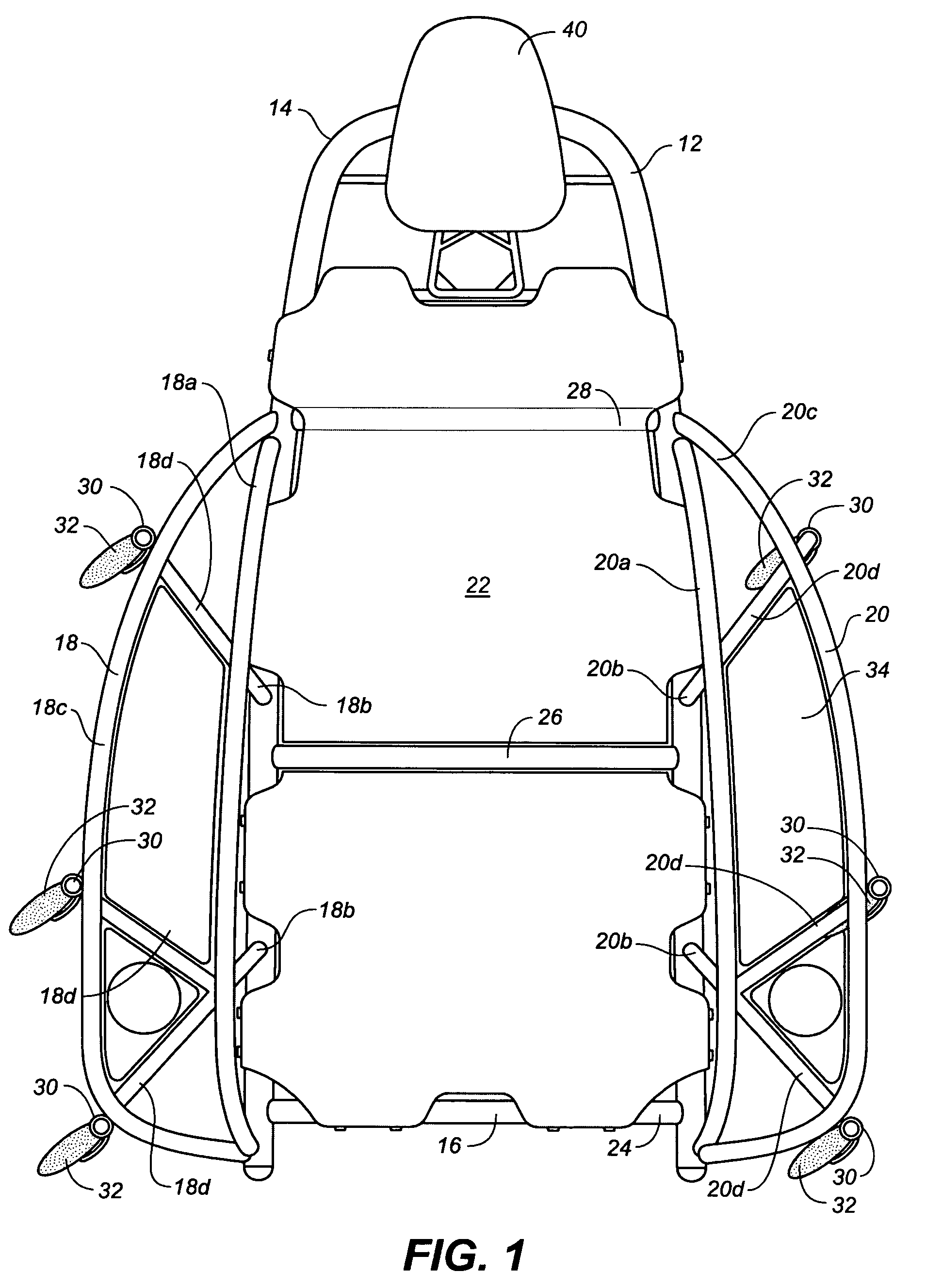

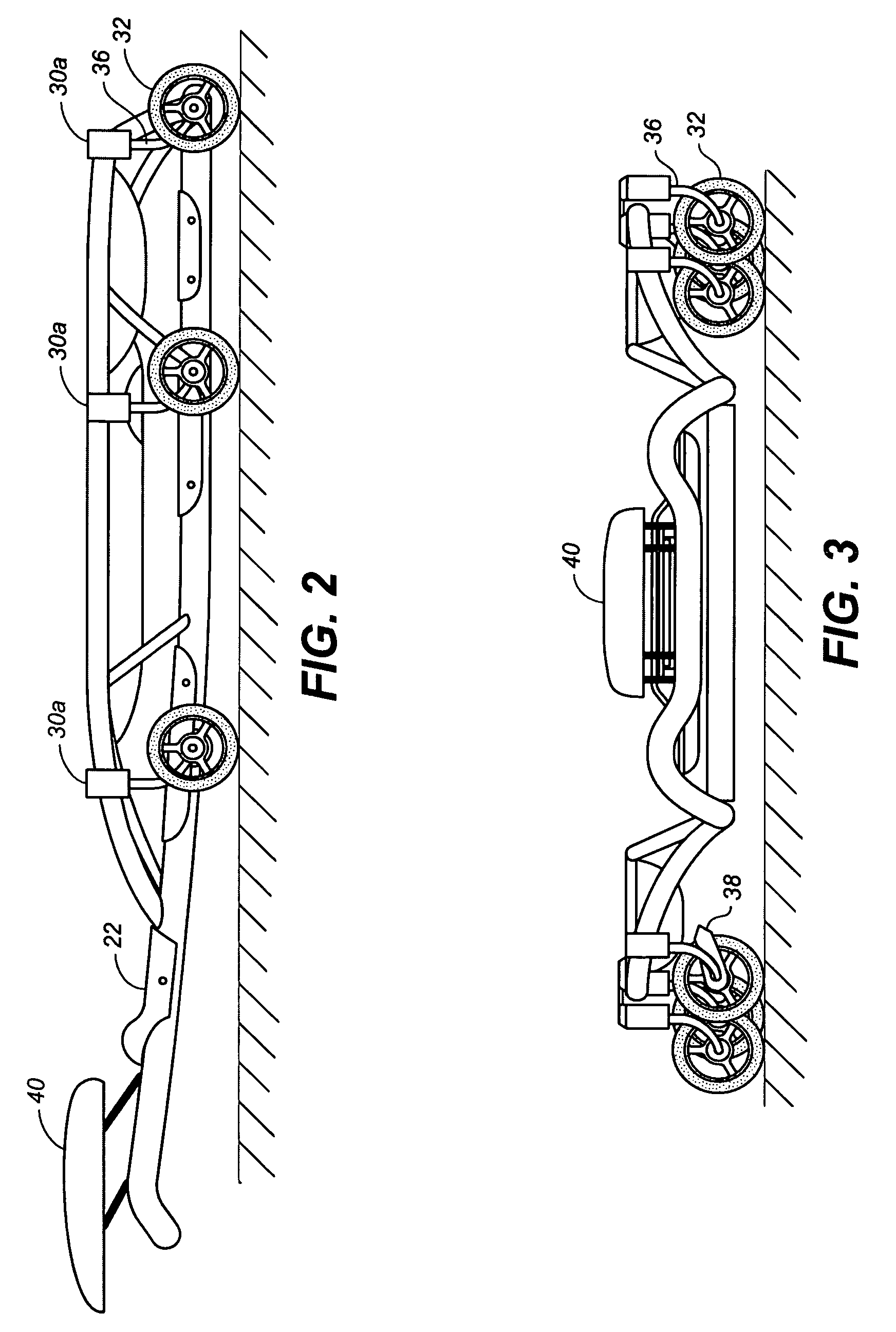

Mechanic's creeper

InactiveUS7434817B2Avoid captureLight weightHarvestersAgricultural undercarriagesEngineeringExpansion joint

Owner:RUSH GARLAND

Construction device for compensating loss of anchor cable prestress and compensation construction method

PendingCN107447756AAnchorage reductionCompensation for prestress lossBulkheads/pilesArchitectural engineeringPier

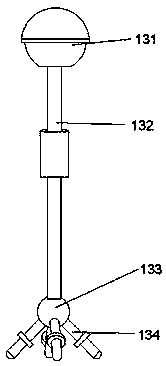

The invention relates to the technical field of anchor cable tension construction, in particular to a construction device for compensating loss of anchor cable prestress and a compensation construction method. The construction device is arranged at the outer side of a supporting-retaining structure, and comprises jacking equipment and an anchorage tool, a compression-bearing member is connected to the anchorage tool, an installation space is formed between the compression-bearing member and an anchorage pier, the jacking equipment is installed on the anchorage pier and is in contact with the compression-bearing member, so that the jacking equipment drives the anchorage tool to draw an anchor cable while jacking, the construction device draws the anchor cable outwards through the jacking equipment, the loss of the anchor cable prestress is compensated, the problems in the prior art that the loss of prestress in the using process of the anchor cable cannot be compensated and hidden safety hazards and fracture of the anchor cable exist in the compensation process of the loss of prestress in the tension process of the anchor cable are solved so that the loss of anchor cable prestress can be continuously compensated in real time, in the compensation process, the anchor cable and the anchorage tool are kept relatively fixed all the time, and the personal safety of construction personnel and the safety of the anchor cable itself are ensured.

Owner:SOUTHWEST PETROLEUM UNIV

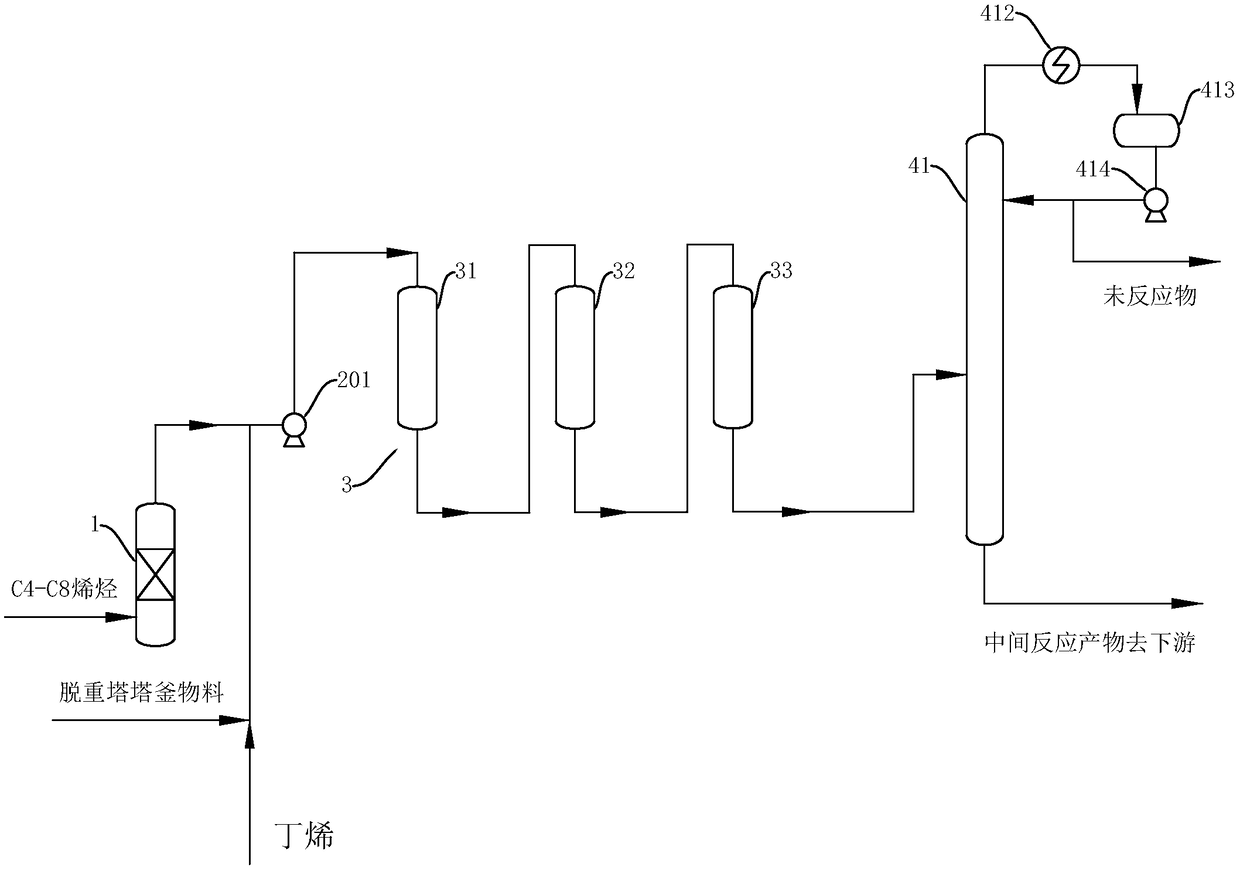

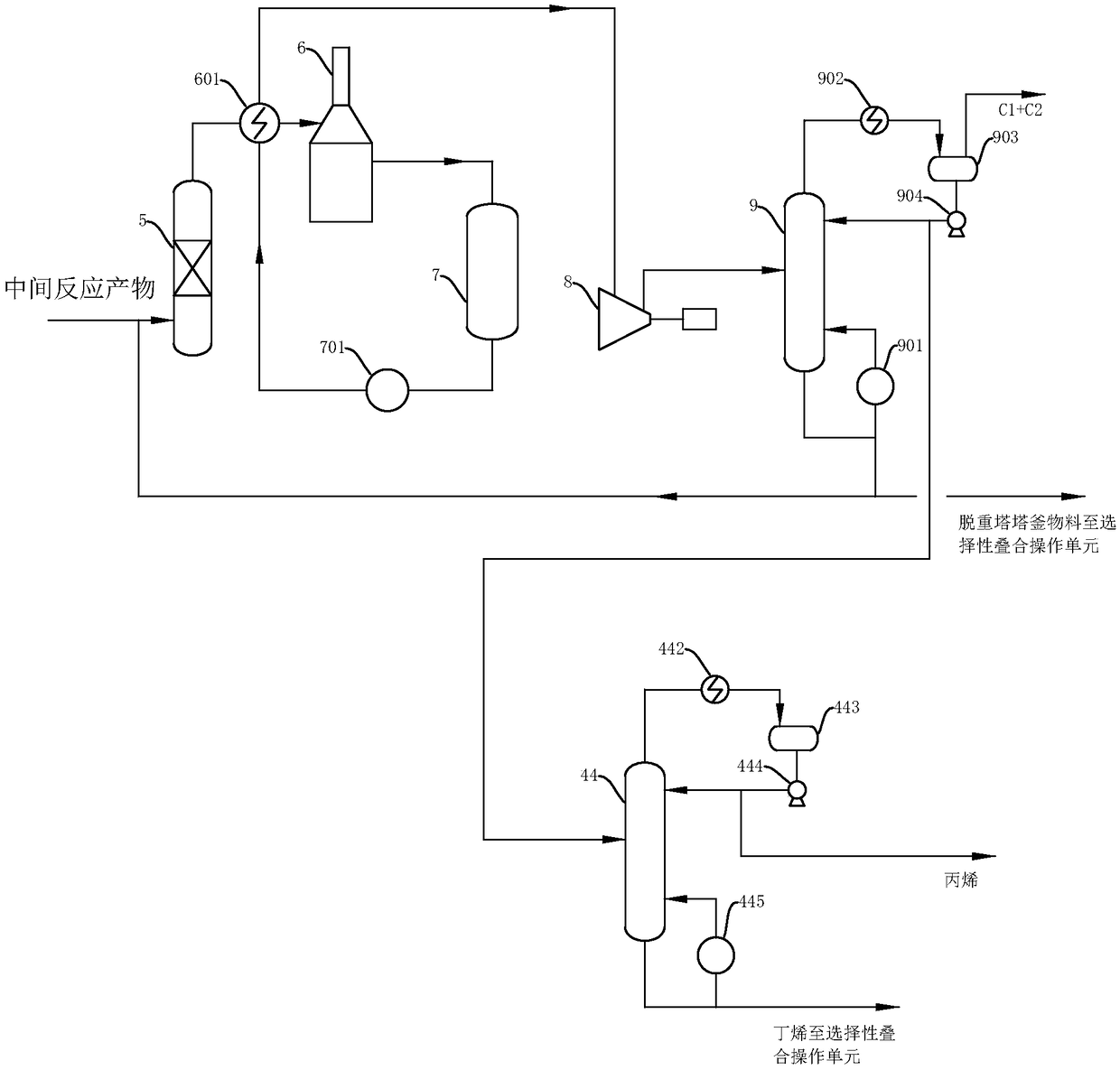

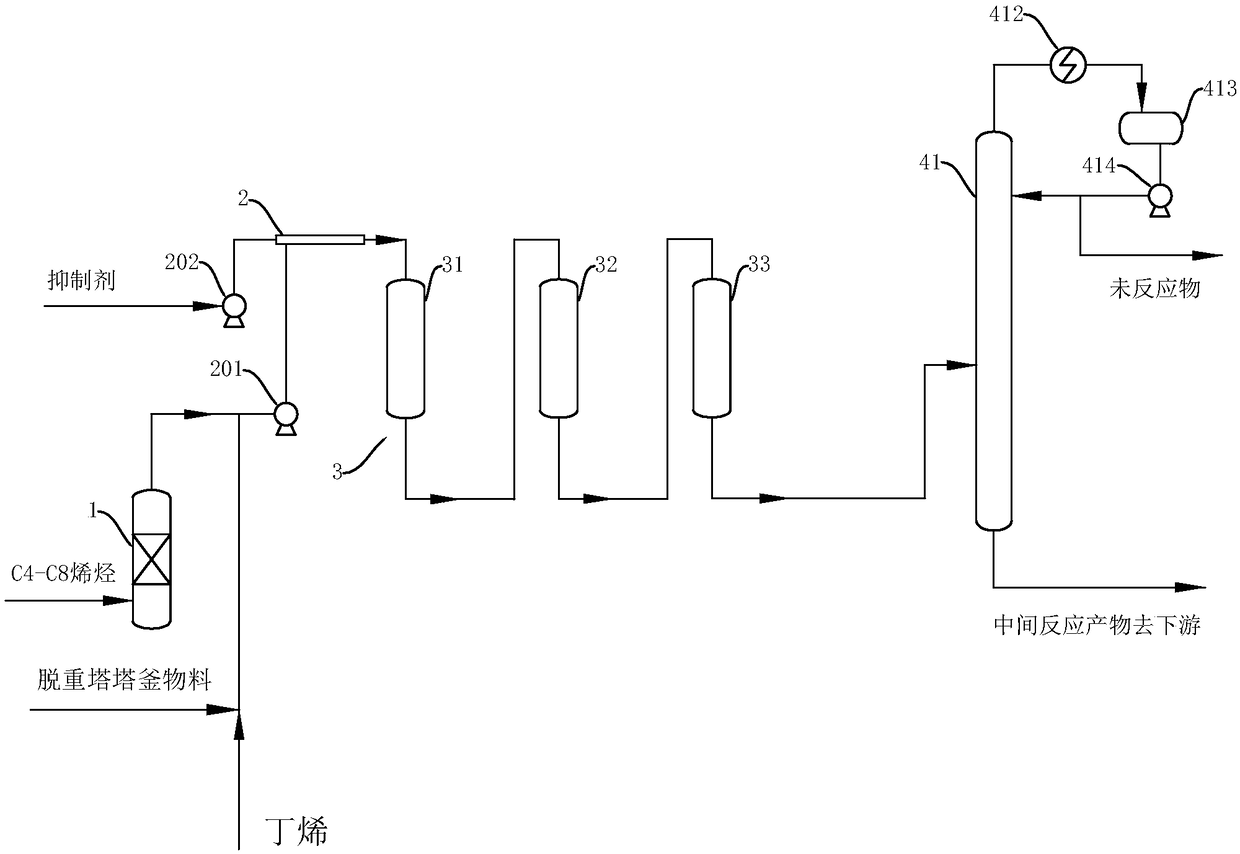

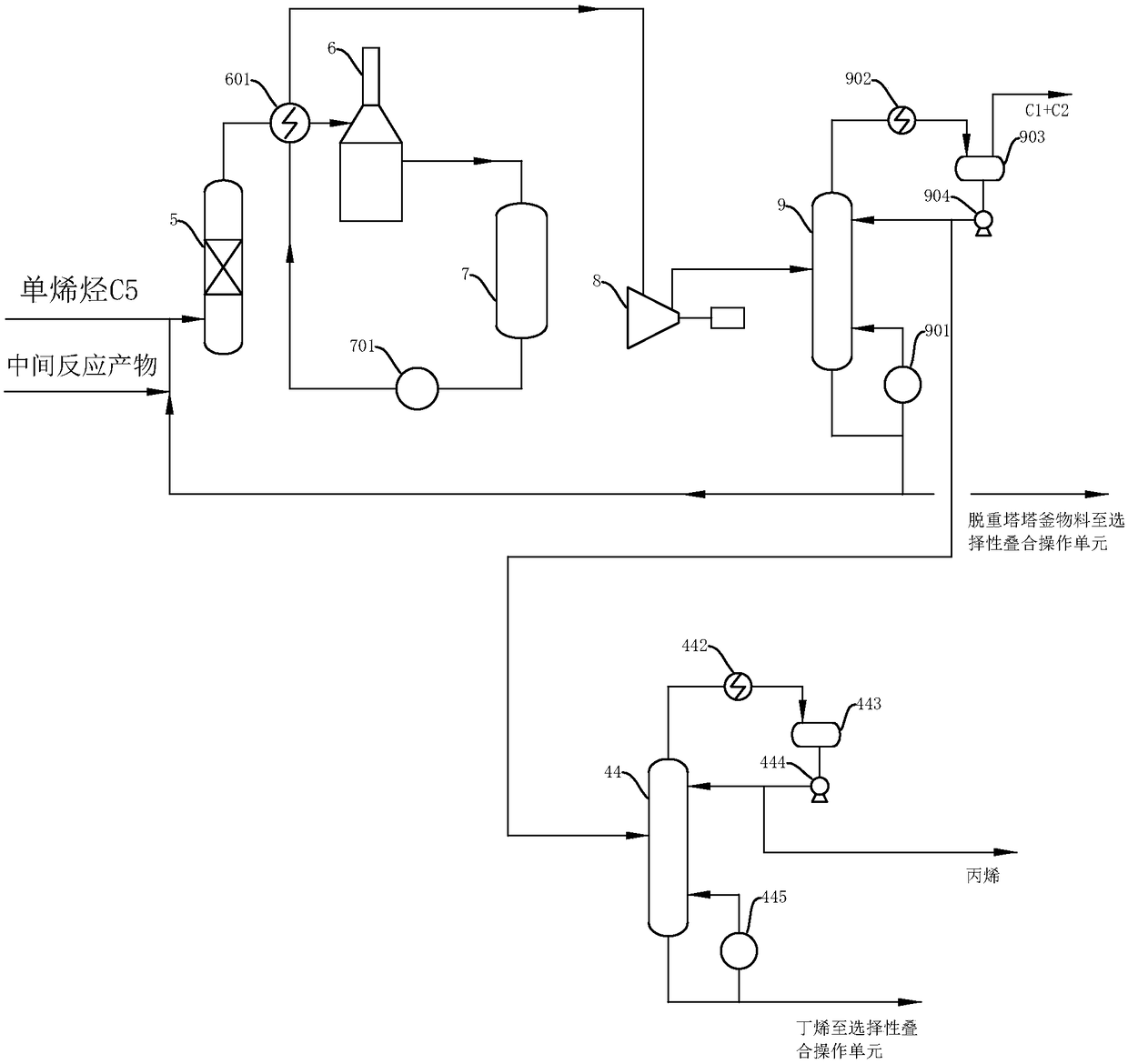

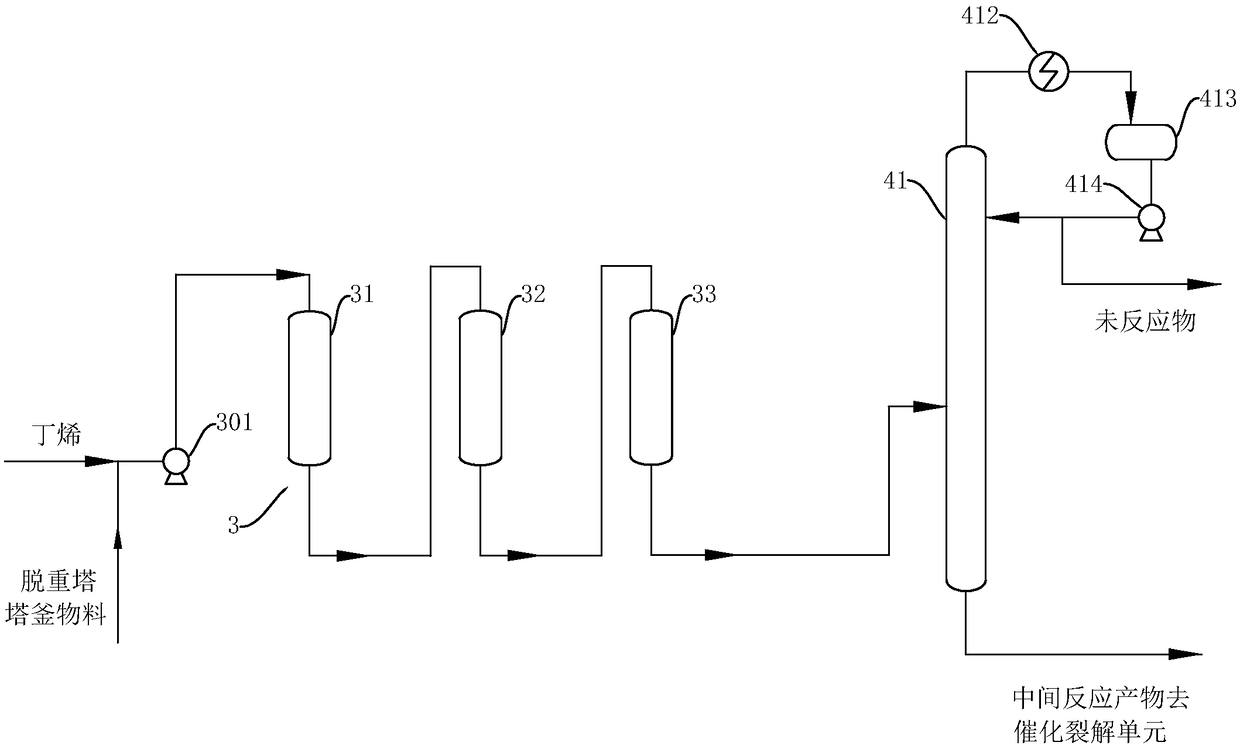

Method for producing propylene maximally with C4-C8 olefin as raw material

ActiveCN109369319AEasy to operateFully supportedMolecular sieve catalystDistillation purification/separationOperabilityOxygen

The invention discloses a method for producing propylene maximally with C4-C8 olefin as a raw material. The method comprises the following steps that S1, the C4-C8 olefin raw material is injected introduced injected into a purifier to be subjected to adsorption operation, so that impurities such as oxygen-contained compounds in the raw material are removed; S2, the purified raw material is delivered into a pre-reactor and a catalytic rectifying tower, selective polymerization of the C4-C8 olefin is conducted, and an intermediate reaction product is obtained at the tower bottom of the catalyticrectifying tower; S3, the intermediate reaction product is repurified and preheated sequentially, and then delivered to a catalytic cracking reactor to be subjected to cracking reaction, and thus a cracking product containing the propylene is obtained; and S4, after cooling compression, propylene separation and purification are conducted in a de-heavy fractionator and the rectifying tower sequentially, thus purified high-purity propylene and residual butane are obtained, and the residual butane returns to the step S2 to be subjected to polymerization. According to the method for producing thepropylene maximally with the C4-C8 olefin as the raw material, the yield of the propylene is 85m% or above of the raw material, equipment adopted by a system is simple, operability is high, investment is small, and the operation cost is low.

Owner:宁波旭合瑞石化工程有限公司

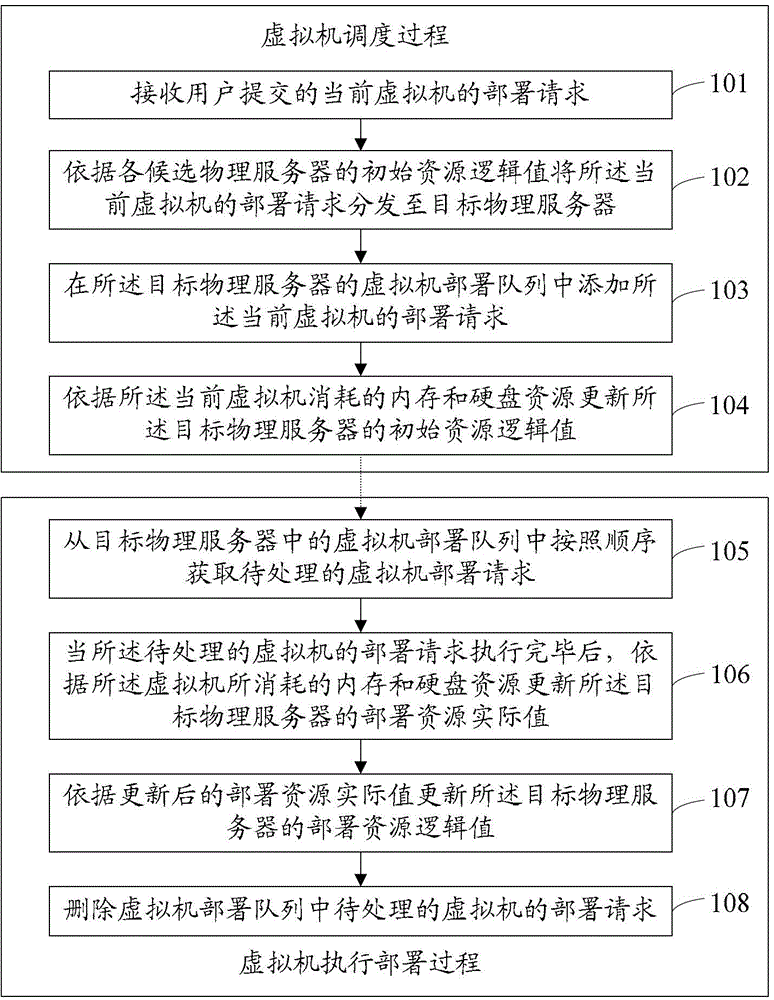

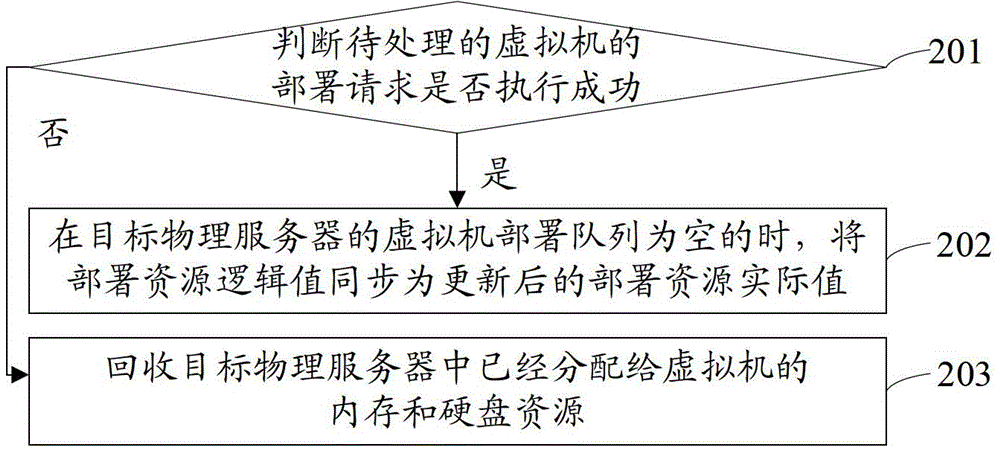

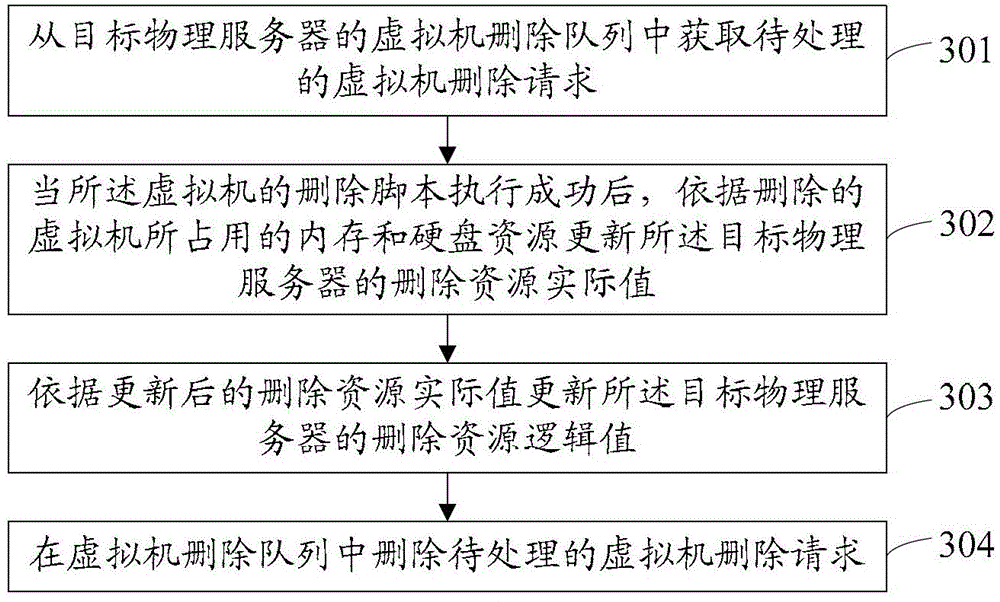

Method and system for resource preprocessing in dispatching and deployment performing process of virtual machine

ActiveCN102946413AReduce the probability of resource competitionFully supportedProgram initiation/switchingData switching networksDecision takingVirtual machine scheduling

The embodiment of the invention discloses a method and a system for resource preprocessing in the dispatching and deployment performing process of a virtual machine. The method comprises a virtual machine dispatching process and a virtual machine deployment performing process, wherein the virtual machine dispatching process comprises the steps of receiving a current virtual machine deployment request submitted by a user, transmitting the current virtual machine deployment request to a target physical server according to an initial resource logic value of each candidate physical server, adding the current virtual machine deployment request to a virtual machine deployment queue of the target physical server, and updating the initial resource logic value of the target physical server according to memory and hard disk resources consumed by the current virtual machine. Through the adoption of the embodiment of the invention, accurate data support can be provided for virtual machine dispatching decision through tracking a resource actual value and recording available resources of the physical server according to the resource logic value.

Owner:BEIJING SOHU NEW MEDIA INFORMATION TECH

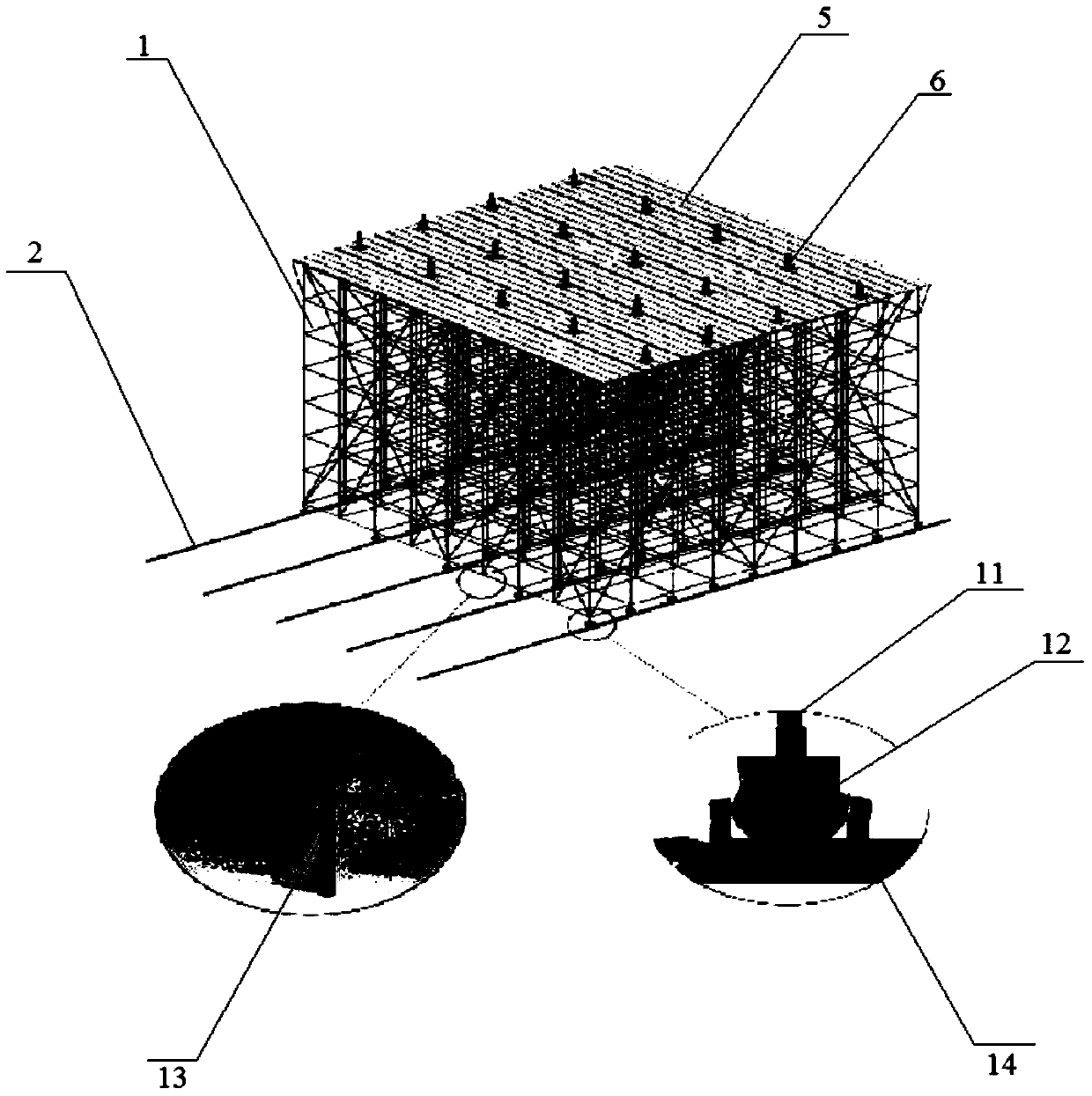

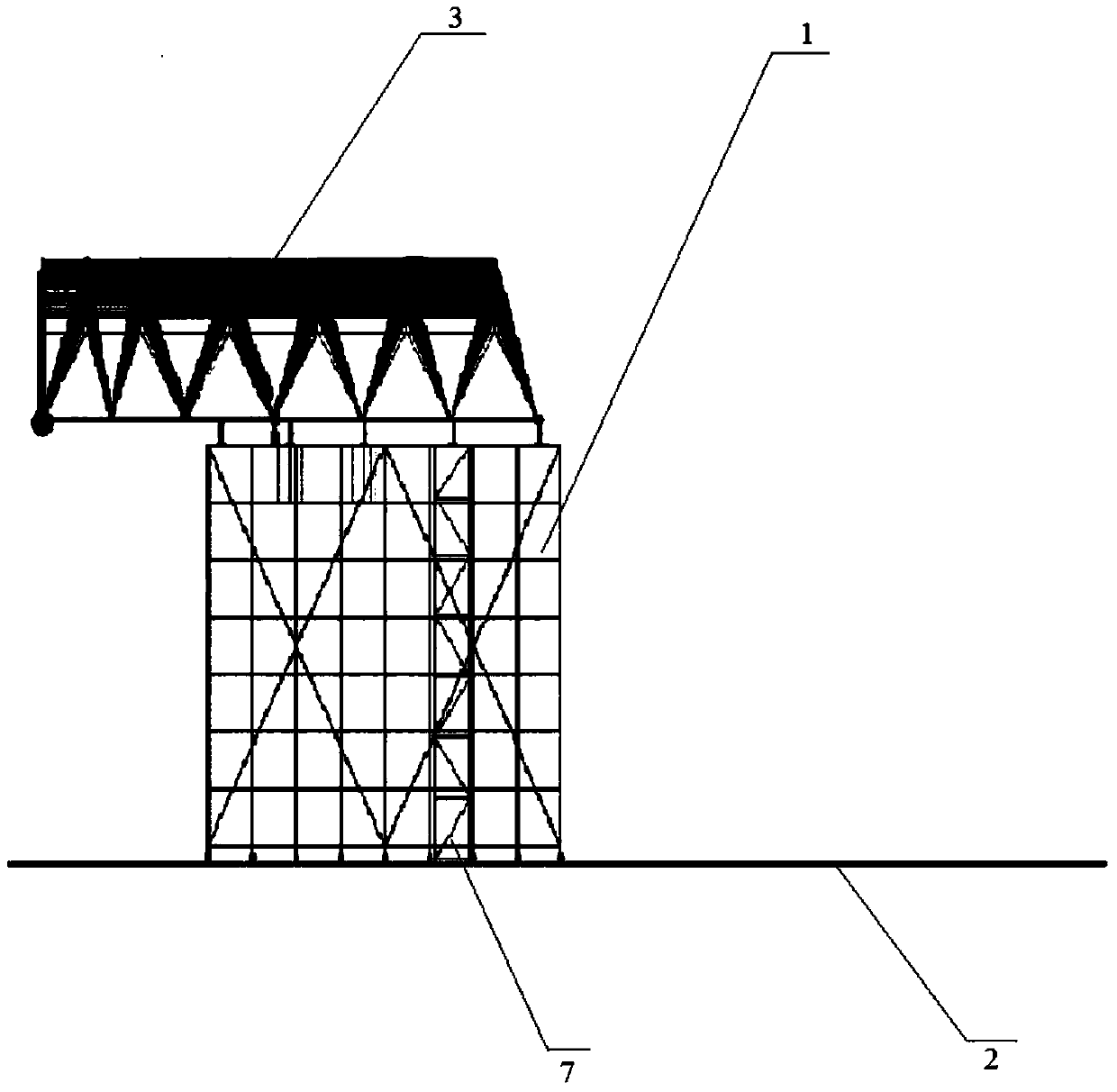

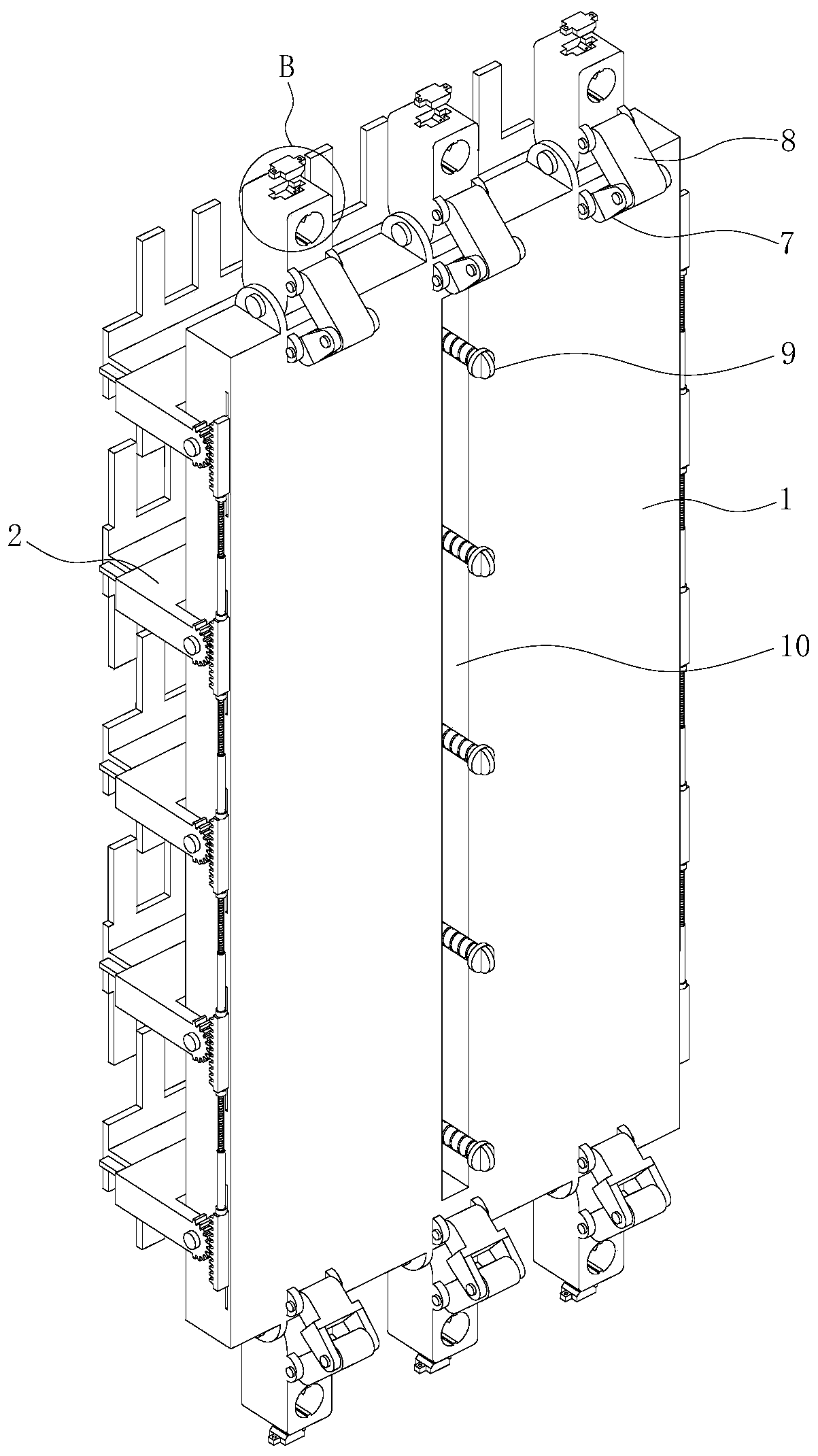

Sliding scaffold platform for mounting wire frame and wire frame mounting method

ActiveCN104213706AFully supportedAvoid deformationBuilding material handlingBuilding scaffoldsClassical mechanicsWood plank

The invention discloses a sliding scaffold platform for mounting a wire frame. The sliding scaffold platform comprises a scaffold body and rails, wherein roller wheels are fixedly arranged at the bottoms of upright rods of the scaffold body, the rails are fixedly arranged on the ground through steel plates, the scaffold body does longitudinal movement along the rails, the top of the scaffold body is dense and is laid with wood boards, wire frame locating devices are further arranged at locations, corresponding to wire frame bottom-chord balls, of the wood boards, each wire frame locating device is formed through nesting two steel tubes, a corresponding inner tube of the corresponding two steel tubes can slide up and down in a corresponding outer tube, and the corresponding two steel tubes are fastened and loosened through a corresponding fastening bolt arranged on the corresponding outer tube and are used for locating and supporting a corresponding wire frame bottom-chord ball. According to the sliding scaffold platform for mounting the wire frame, the wire frame locating devices are arranged on the scaffold platform, and locations of the wire frame bottom-chord balls are located through adjusting the heights of the inner tubes of the wire frame locating devices, so as to further locate the height of the entire wire frame.

Owner:JIANGSU HUNING STEEL MECHANISM

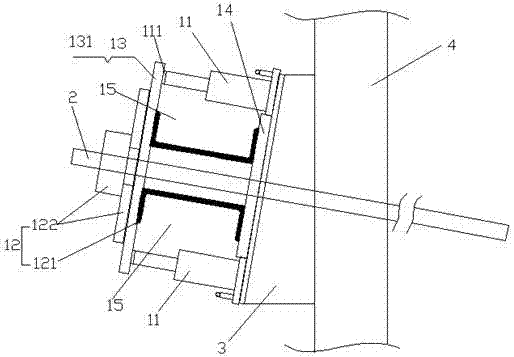

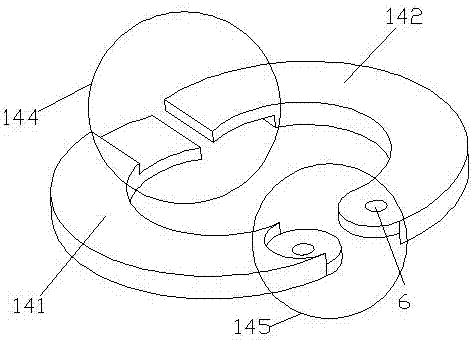

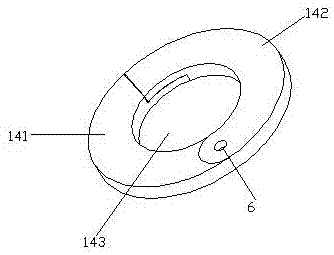

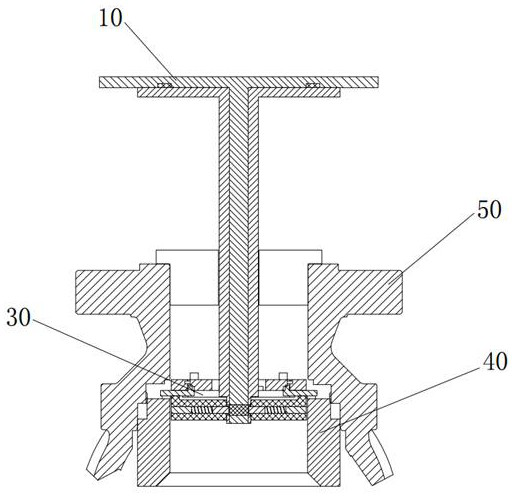

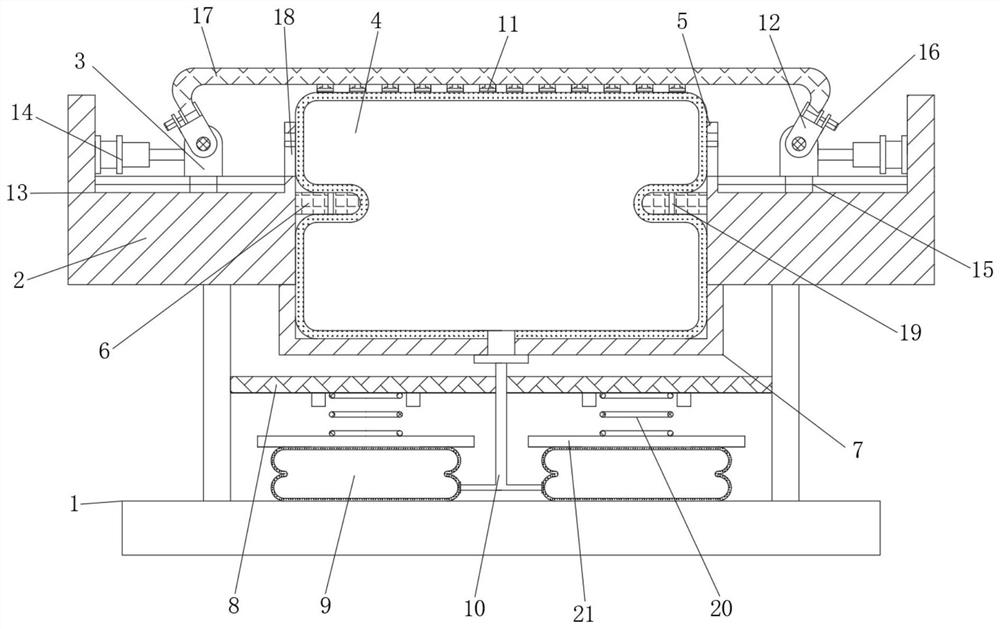

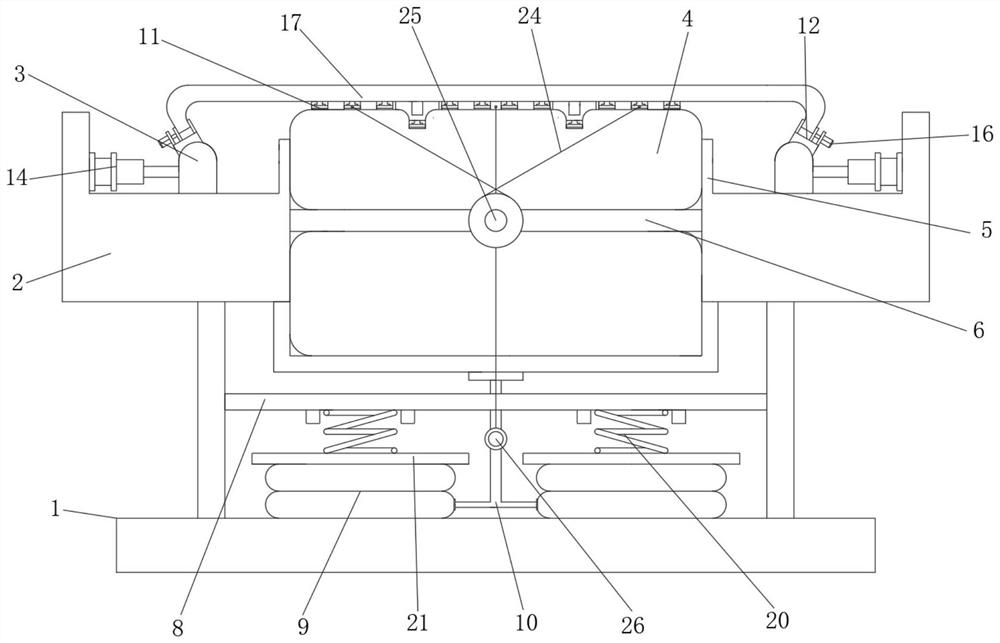

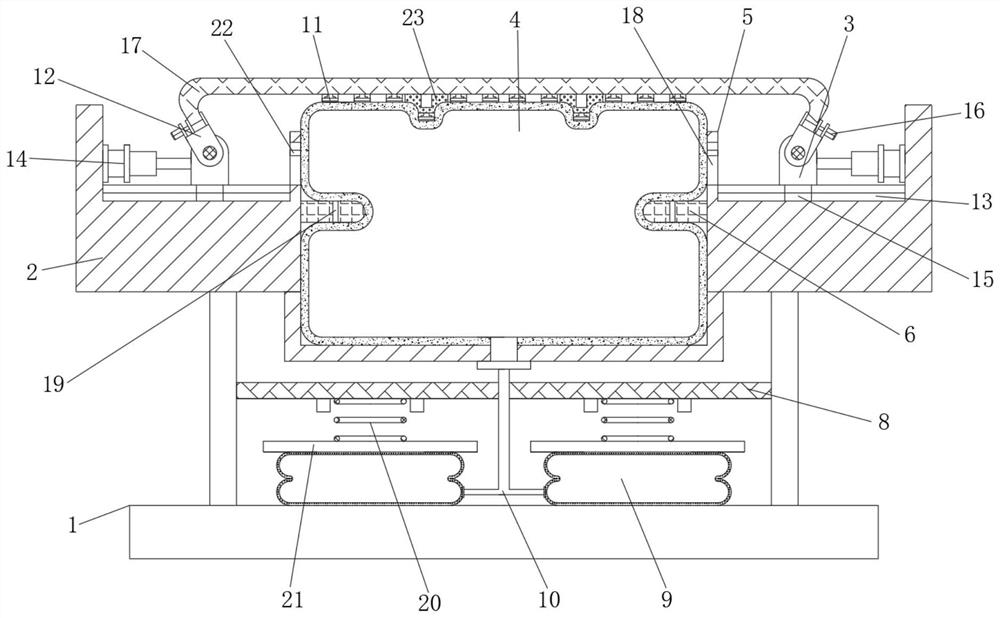

Self-adaptive press-fitting machine, automatic press-fitting system and press-fitting method thereof

The invention discloses a self-adaptive press-fitting machine, an automatic press-fitting system and a press-fitting method thereof. The self-adaptive press-fitting machine comprises a pressure head and a driving device for driving the pressure head to move in a first direction and a second direction in a reciprocating mode, the pressure head is connected with the driving device through a coaxiality fine adjustment device. According to the scheme, the design is ingenious, the structure is simple, and the coaxiality fine adjustment device is arranged between the pressure head and the driving device, so that the pressure head can swing slightly with respect to the driving device; when press fitting is carried out, if a column-shaped body and a hole or a groove are not in a co-axial state, the column-shaped body clamped by the pressure head can be coaxial with the hole or the groove through slight swinging of the pressure head, so that the coaxiality is improved, and smooth press fittingis facilitated; and meanwhile, the damage of the column-shaped body or a workpiece easily caused by direct rigid pressing can be avoided, and the safety of press fitting is guaranteed.

Owner:KUNSHAN JIEYUN INTELLIGENT EQUIP CO LTD

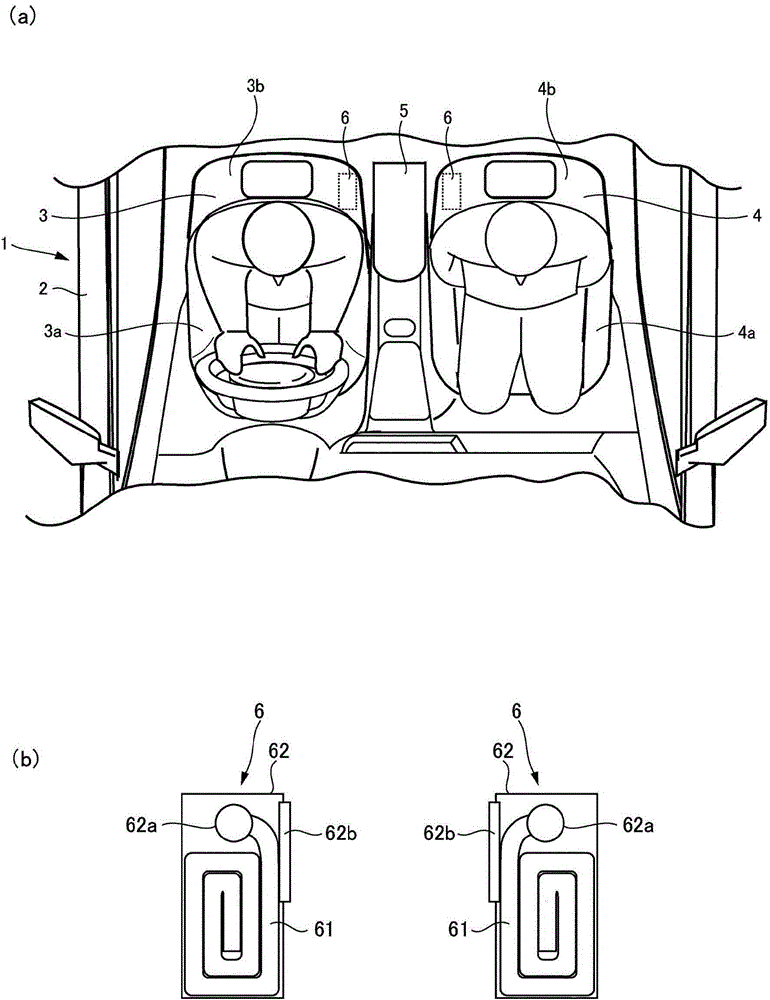

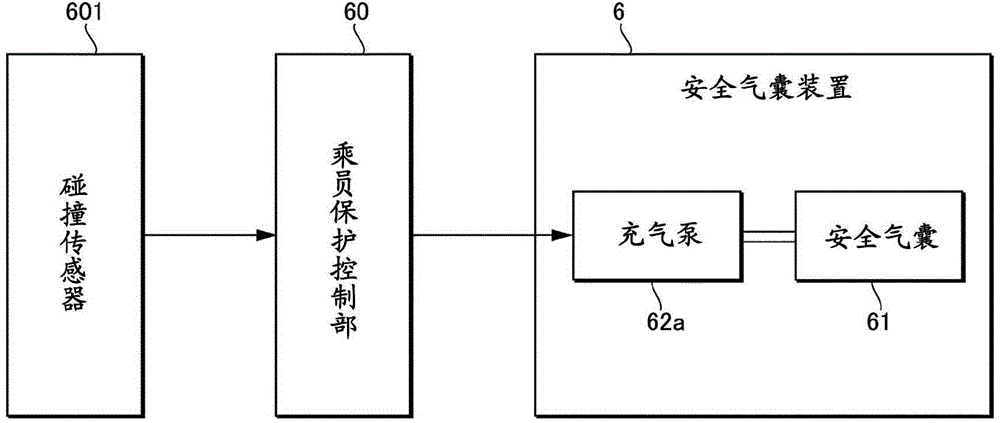

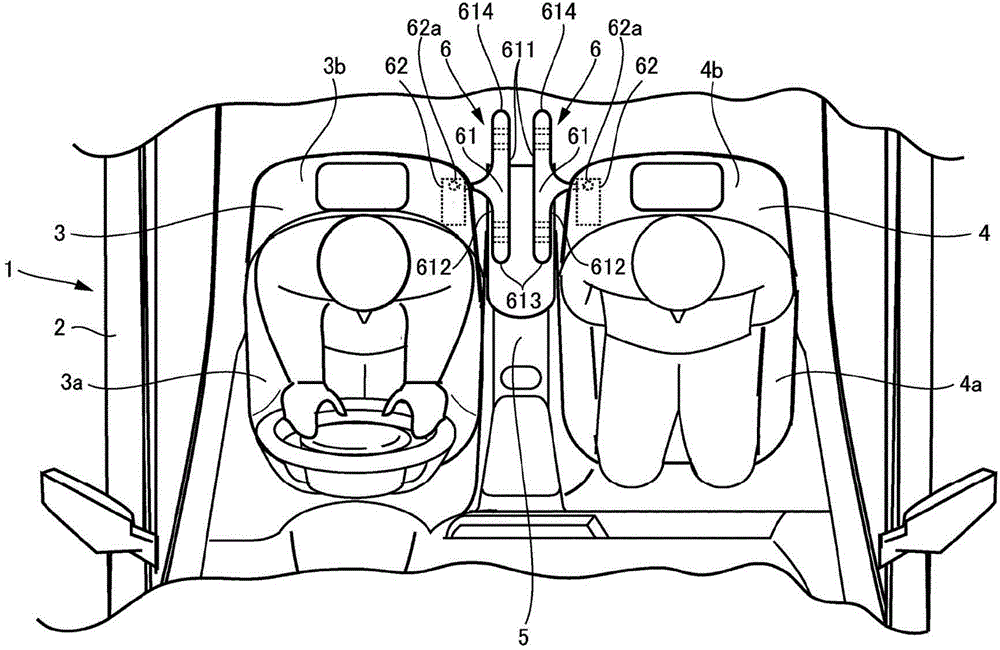

Airbag device

Airbag housings that each house an airbag are respectively provided beneath the lateral face of the driver's seat backrest and the lateral face of a front passenger seat backrest inward in a vehicle width direction. The airbags are inflatable and deployable inwardly in the vehicle width direction as well as in a fore-and-aft direction and a vertical direction of the vehicle.

Owner:SUBARU CORP

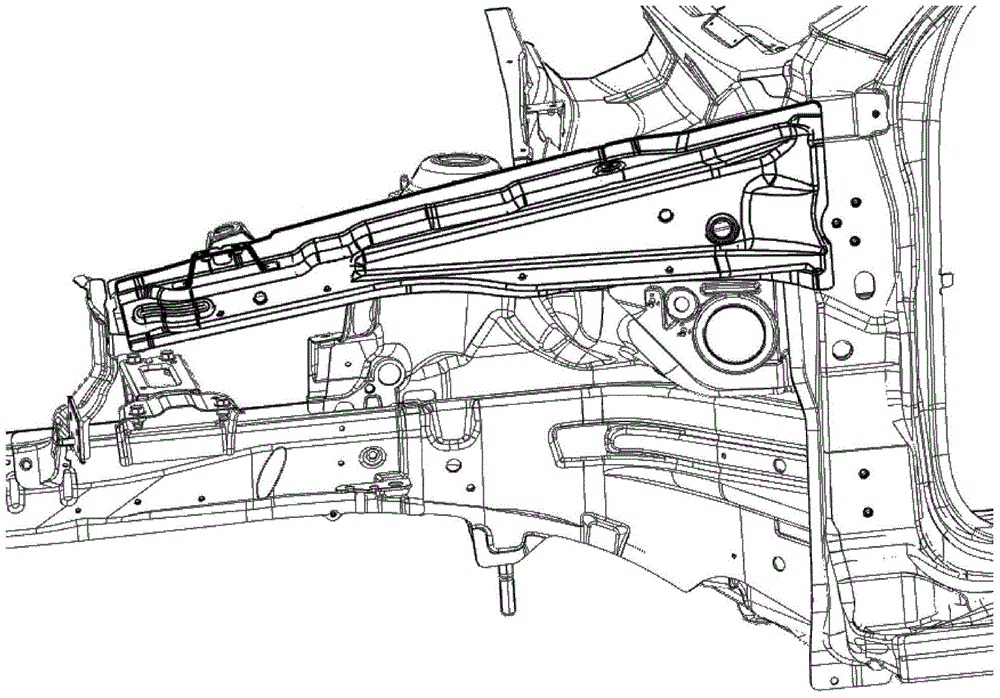

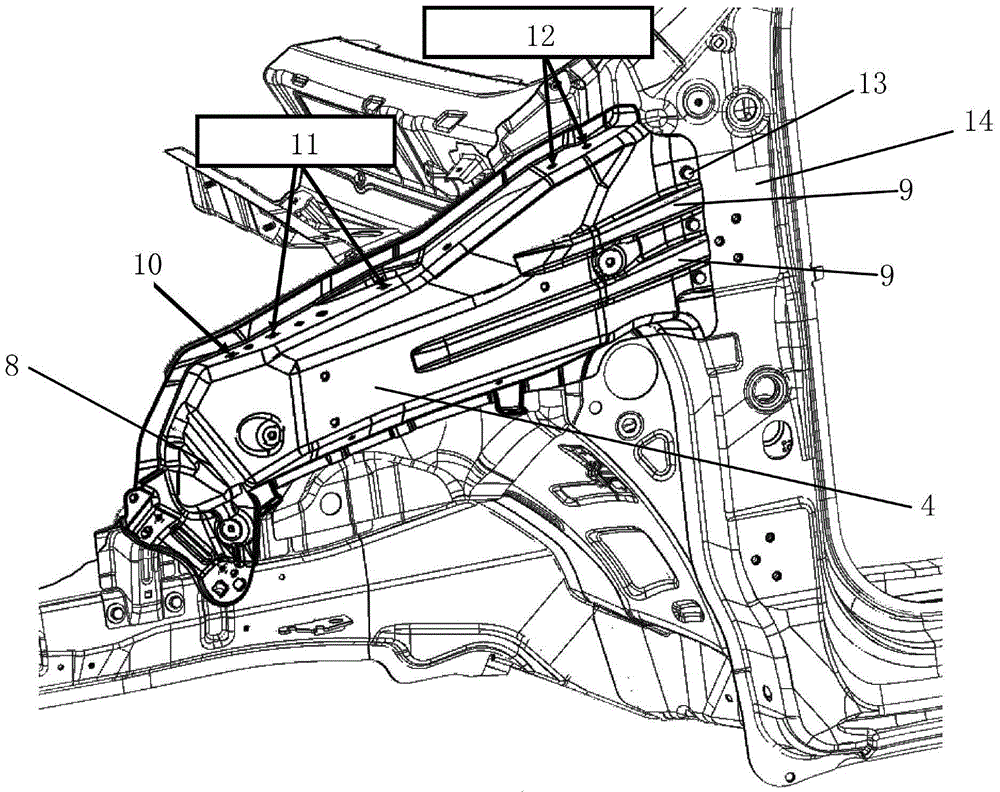

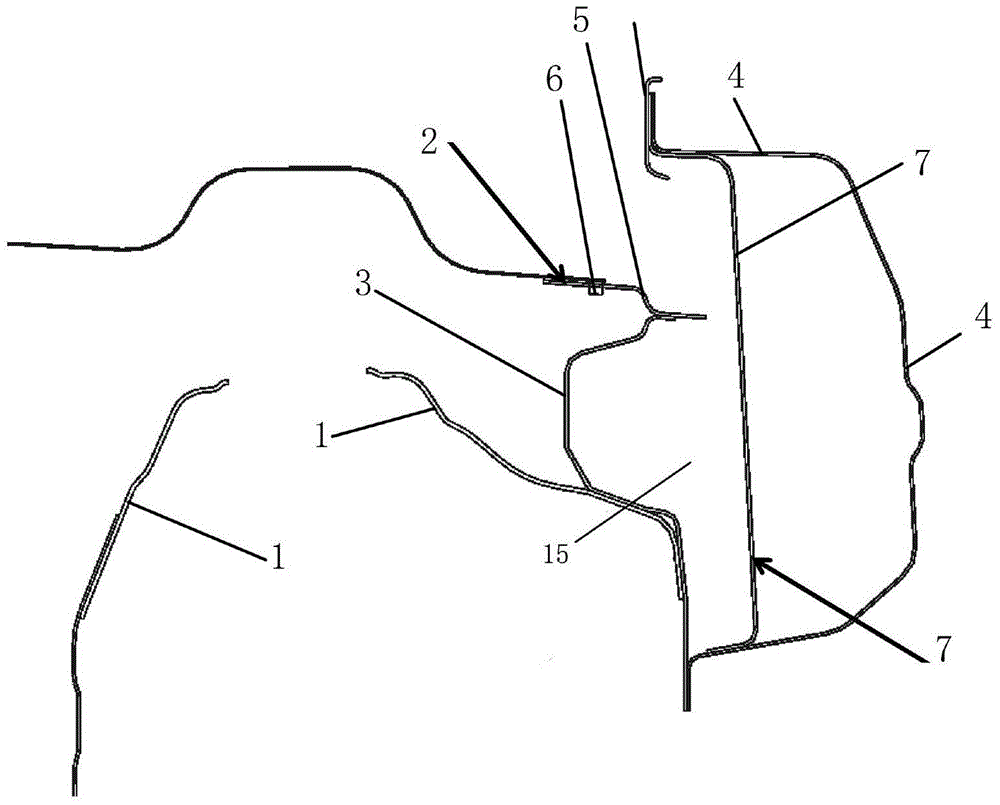

Automotive front-cabin upper side beam assembly

ActiveCN105313978AMeet drainage needsFully supportedSuperstructure subunitsWater flowMechanical engineering

The invention discloses an automotive front-cabin upper side beam assembly which comprises an upper side beam inner plate and an upper side beam outer plate. The upper side beam inner plate is connected with a gutter channel assembly, a front wheel cover and a hood hinge reinforcing plate in an automotive front cabin respectively, the upper side beam outer plate is connected with the hood hinge reinforcing plate in the automotive front cabin and the upper side beam inner plate respectively, collision induction ribs are arranged in front of the lower portion of the upper side beam outer plate, a cavity capable of accommodating water flowing down from the gutter channel assembly and draining the water is formed between the upper side beam inner plate and the hood hinge reinforcing plate and the upper side beam outer plate, and the end, connected with the upper side beam inner plate, of the gutter channel assembly is located at the upper portion of the cavity. The automotive front-cabin upper side beam assembly is simple in structure and capable of meeting the water draining demand of a gutter channel of the front cabin, meets the star-level collision demand in strength, meanwhile can provide support for a front wheel cover and can effectively reduce the stress in a front wheel cover area.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

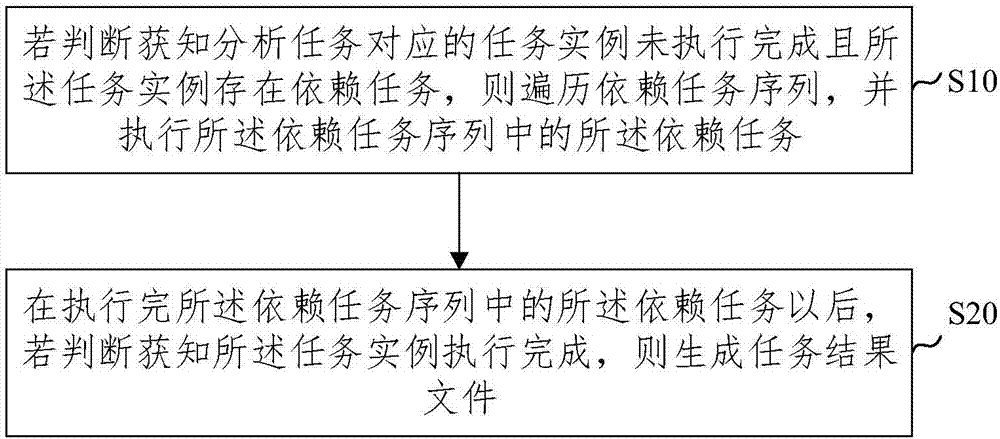

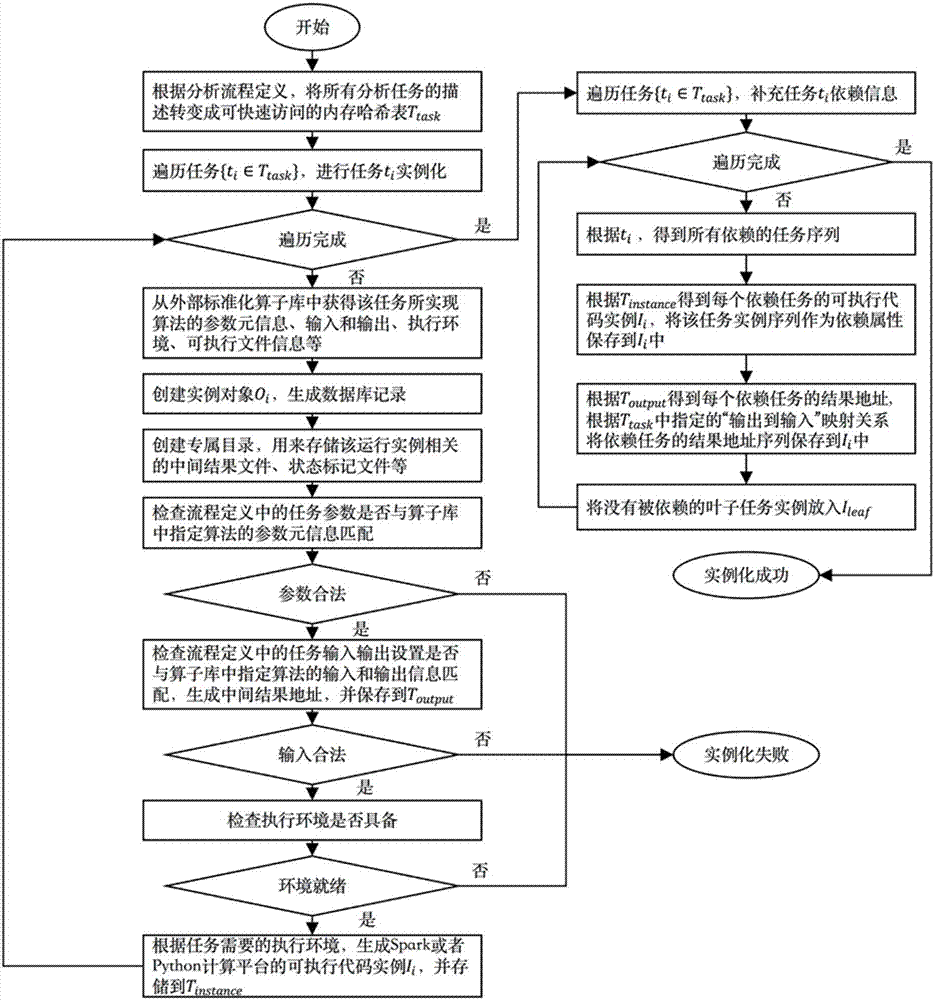

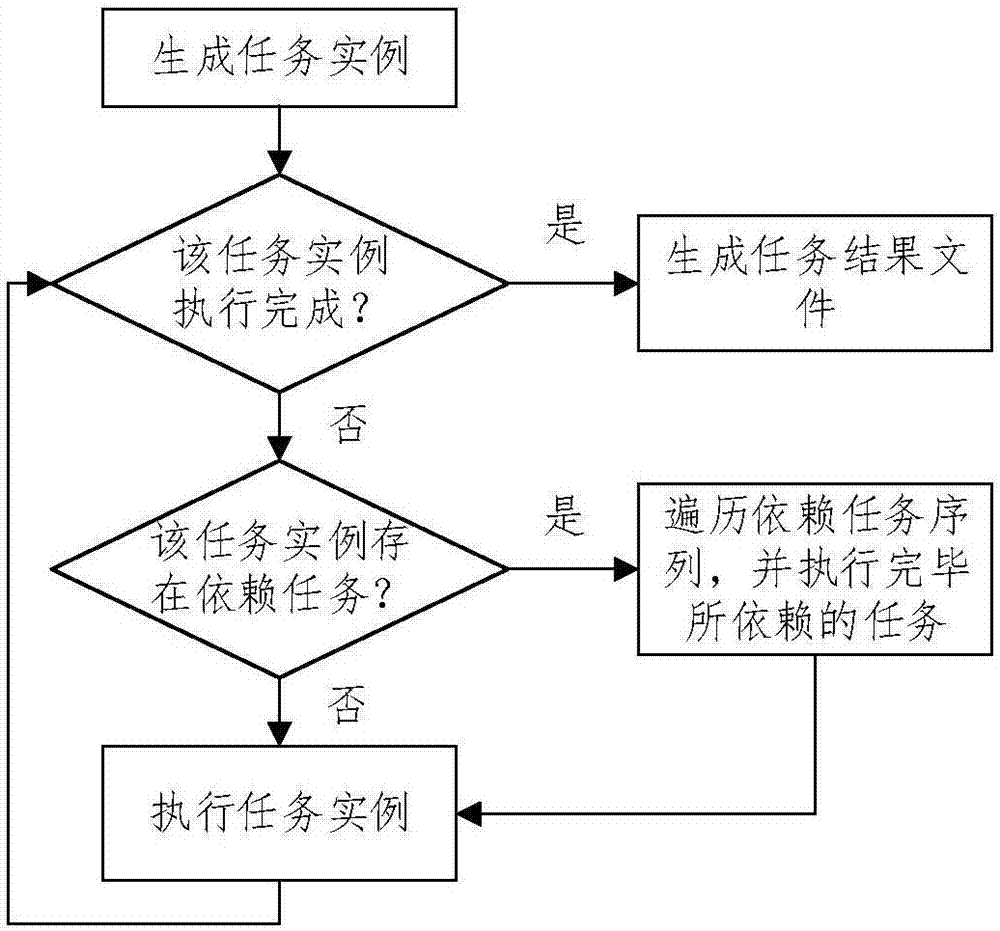

Executive plan generation method for big data analysis process

ActiveCN107885587AImprove analysis efficiencyLower skill requirementsProgram initiation/switchingOffice automationExecution planProgram planning

The invention provides an executive plan generation method for a big data analysis process. The method comprises the steps of generating executable task instances according to analysis tasks; according to dependency relationships stored in the task instances, establishing a directed acyclic graph; according to the dependency relationships, traversing a dependency task sequence, and executing dependency instances, wherein the dependency instances are task instances of dependency tasks, and the dependency tasks are other analysis tasks depending on the analysis tasks in the dependency task sequence; and executing the task instances to generate a task result file. According to the executive plan generation method for the big data analysis process, provided by the invention, a data associationrelationship among the analysis tasks is enhanced in a rule form according to a characteristic that the analysis tasks in the big data analysis process have a data transmission relationship; the bigdata analysis efficiency is improved; the requirements of big data analysis on technician skills are lowered; the data is prevented from being revealed to big data analysis providers; and the securityrisk is lowered.

Owner:TSINGHUA UNIV

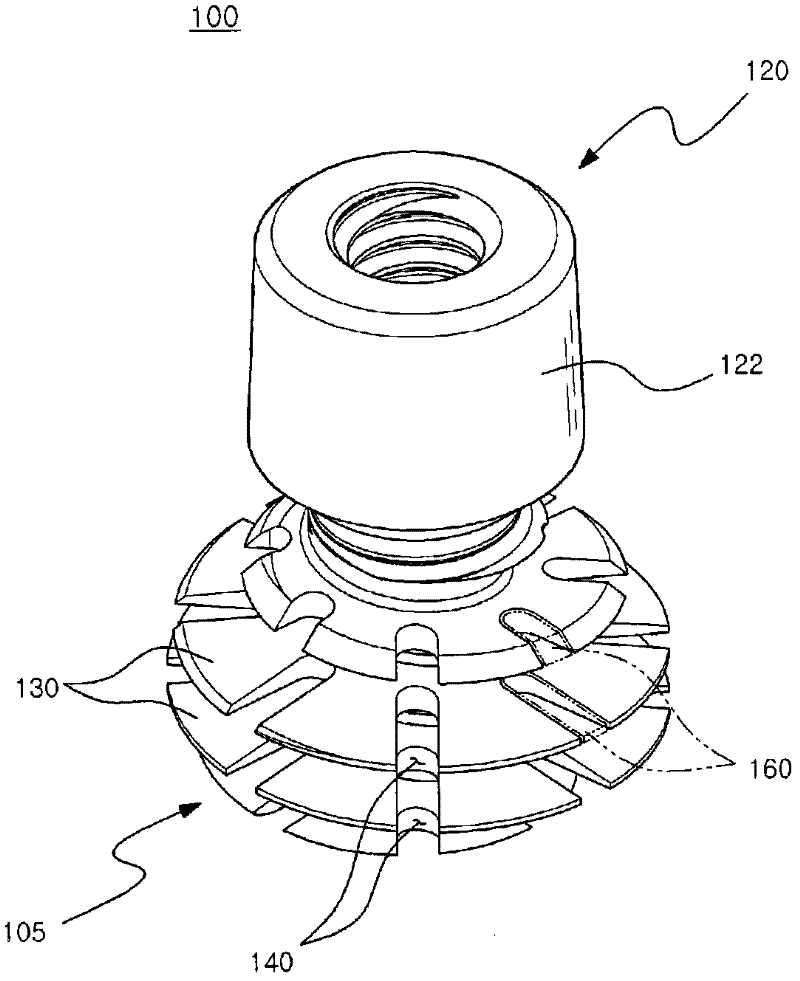

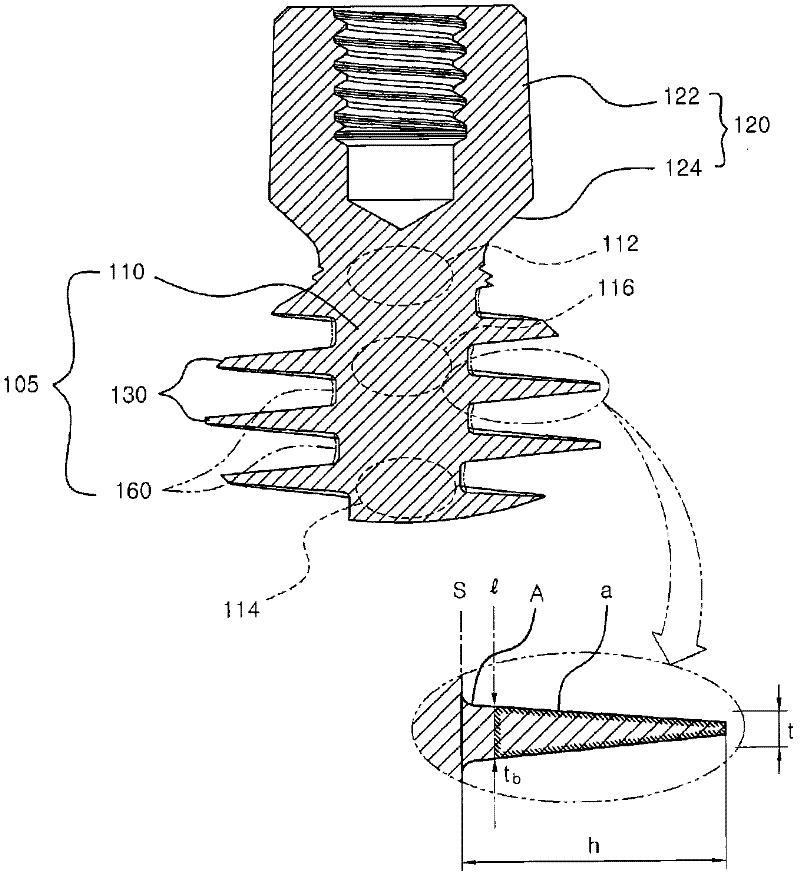

Dental implant

The dental implant of the present invention has been devised to allow masticatory function directly after placement in the bone structure and to be able to be used effectively even in thin and short alveolar bone without the need for a second operation; and is characterised in that: the implant comprises a body part for insertion into the bone structure and a bonding part integrally formed on the upper part of the body part; the body part incorporates a narrow and short core part and a screw blade formed in the shape of a wide and deep screw along the outer surface of the core; the screw blade has a linking part formed with a plurality of holes or recesses which allow passage vertically through the circumference and can contain bone growth factor; the outer circumference of the proximal part (proximal portion), which constitutes the uppermost part of the body part, is smaller than the maximum diameter of the body part; and the bonding part comprises a gum-attaching part for protecting bone tissue and a post part for connecting to an abutment or restoration.

Owner:NEOBIOTECH

Fertilizer and pesticide composition

The present invention discloses one kind of fertilizer plus farm chemical composition, which consists of ferrous sulfate 15-45 weight portions, ammonium molybdate 0.5-5 weight portions, magnesium sulfate 5-15 weight portions, composite amino acids 5-14 weight portions, zinc sulfate 1-10 weight portions, copper sulfate 0.5-5 weight portions and polymyxin 1-5 weight portions, and may include optional carrier, surfactant, dispersant and agricultural auxiliary agent. The fertilizer plus farm chemical composition has excellent preventing and controlling effect on the fungal, bacterial and physiological diseases of soybean and other plants.

Owner:徐平

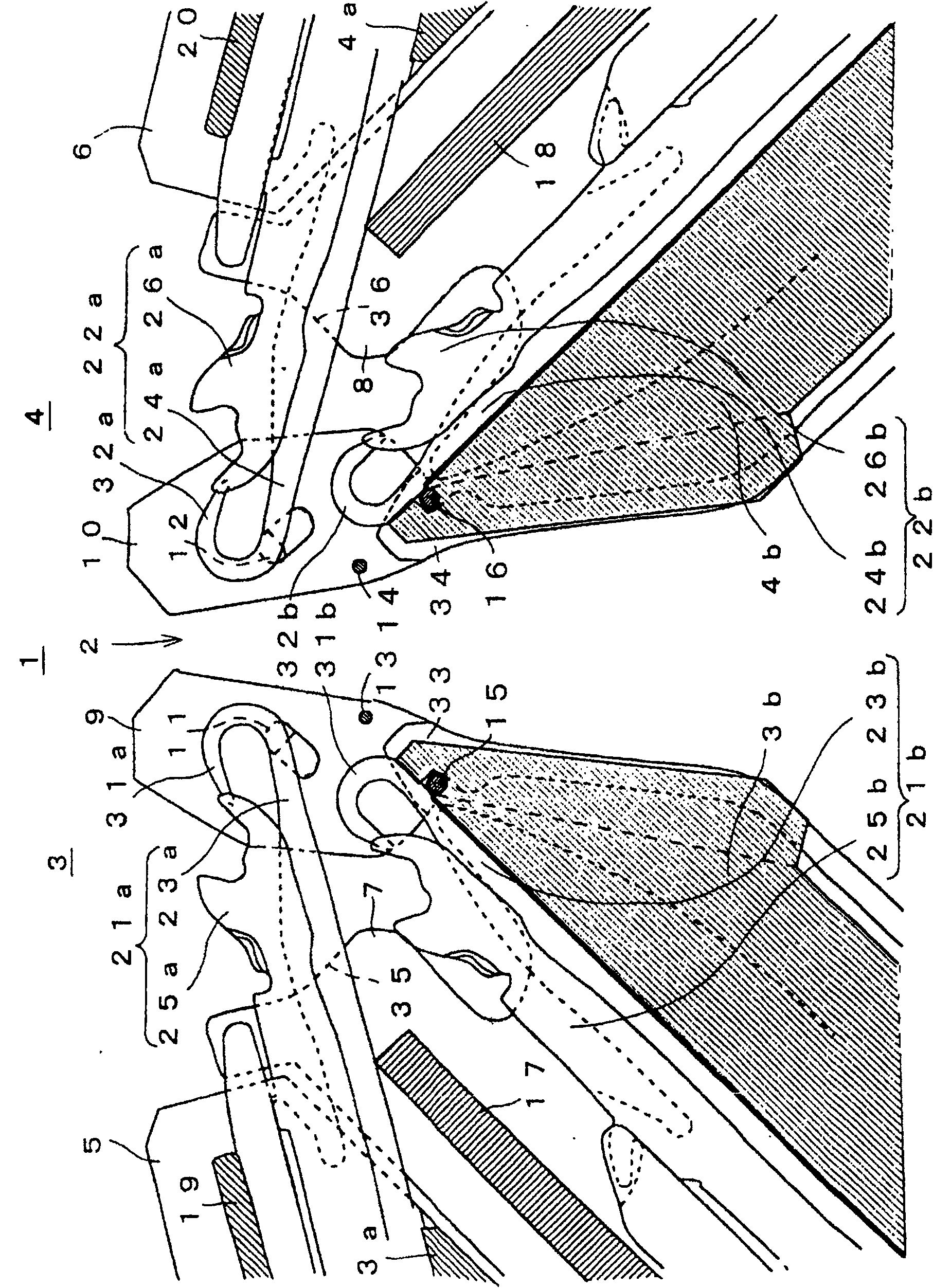

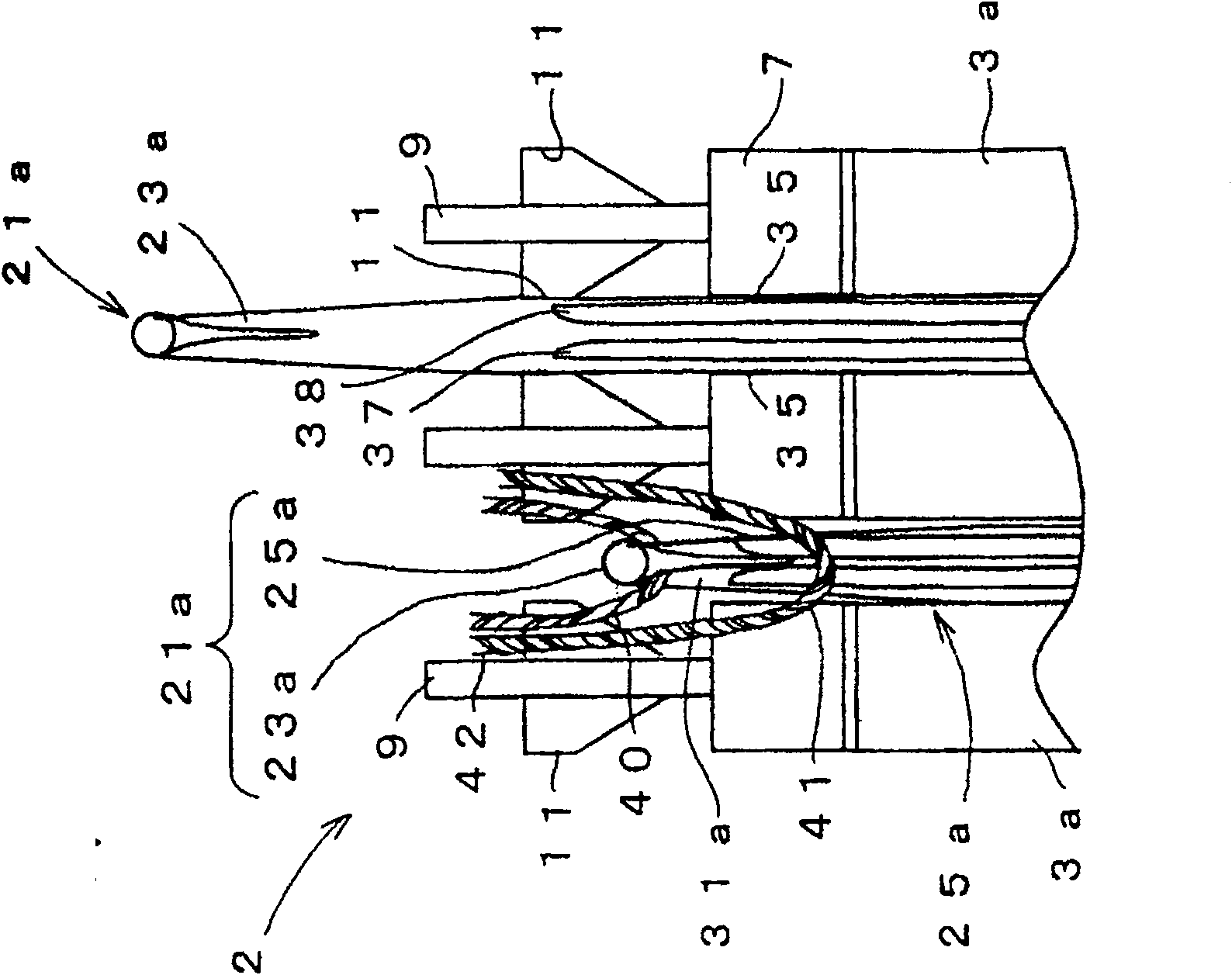

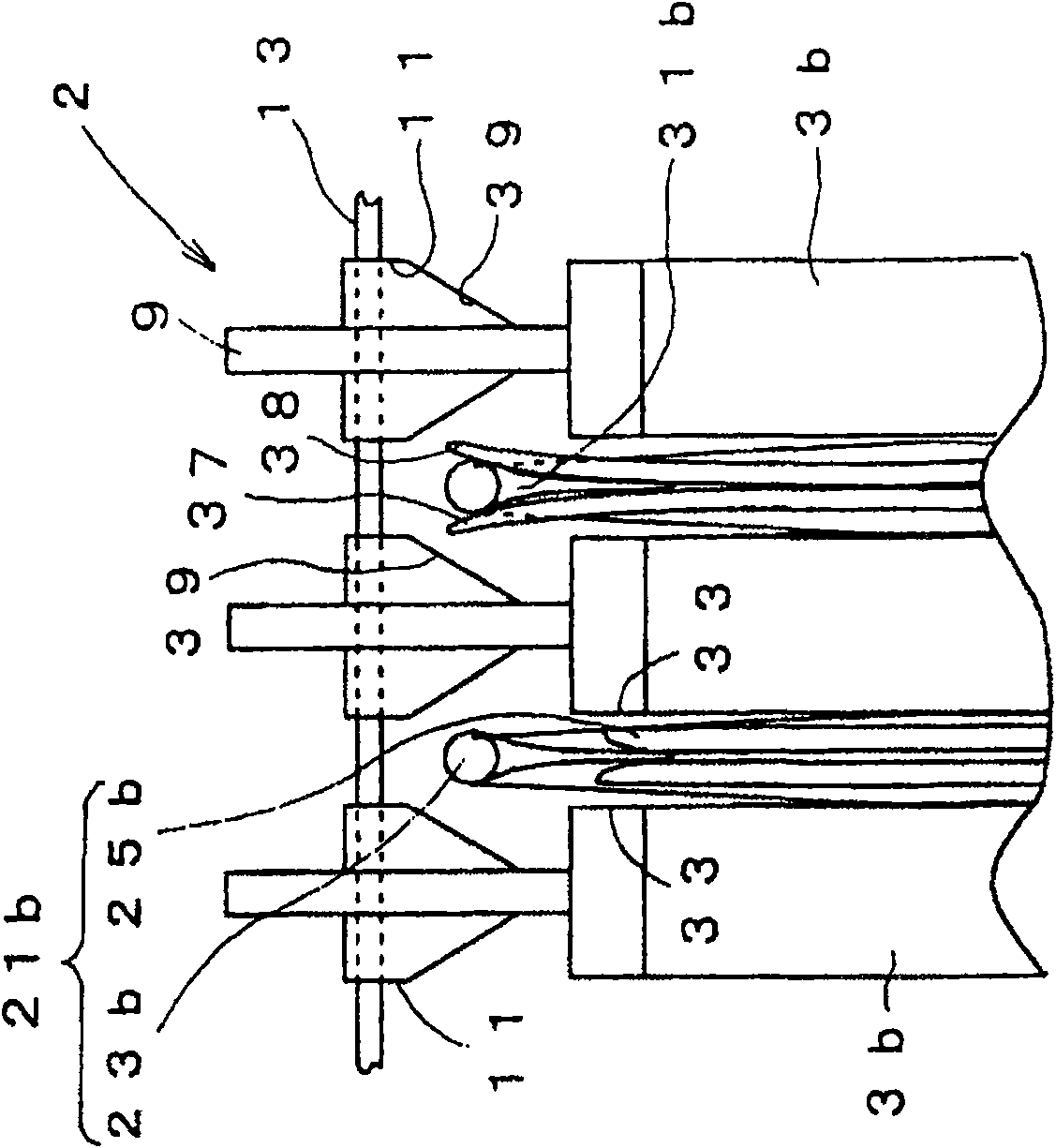

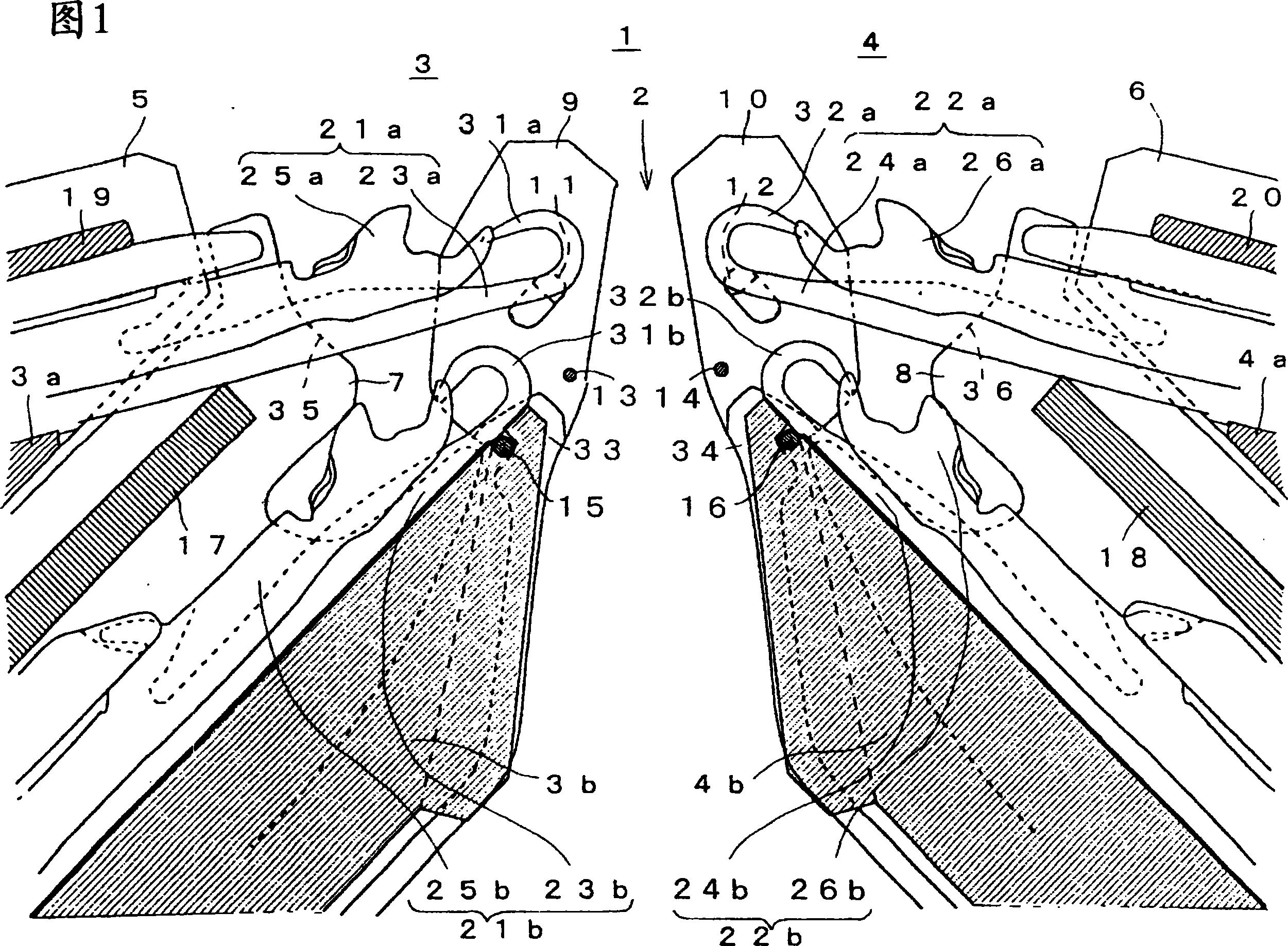

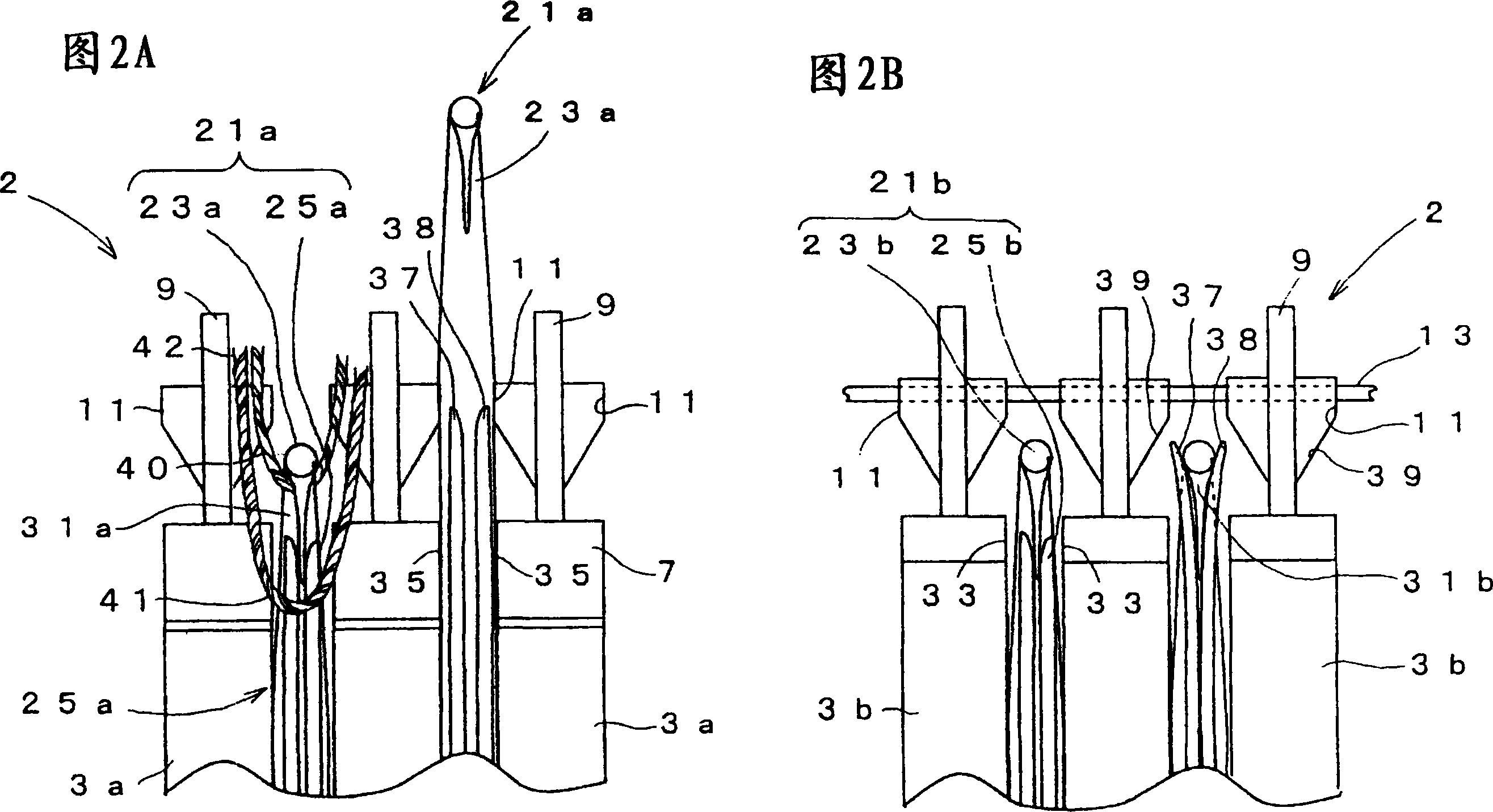

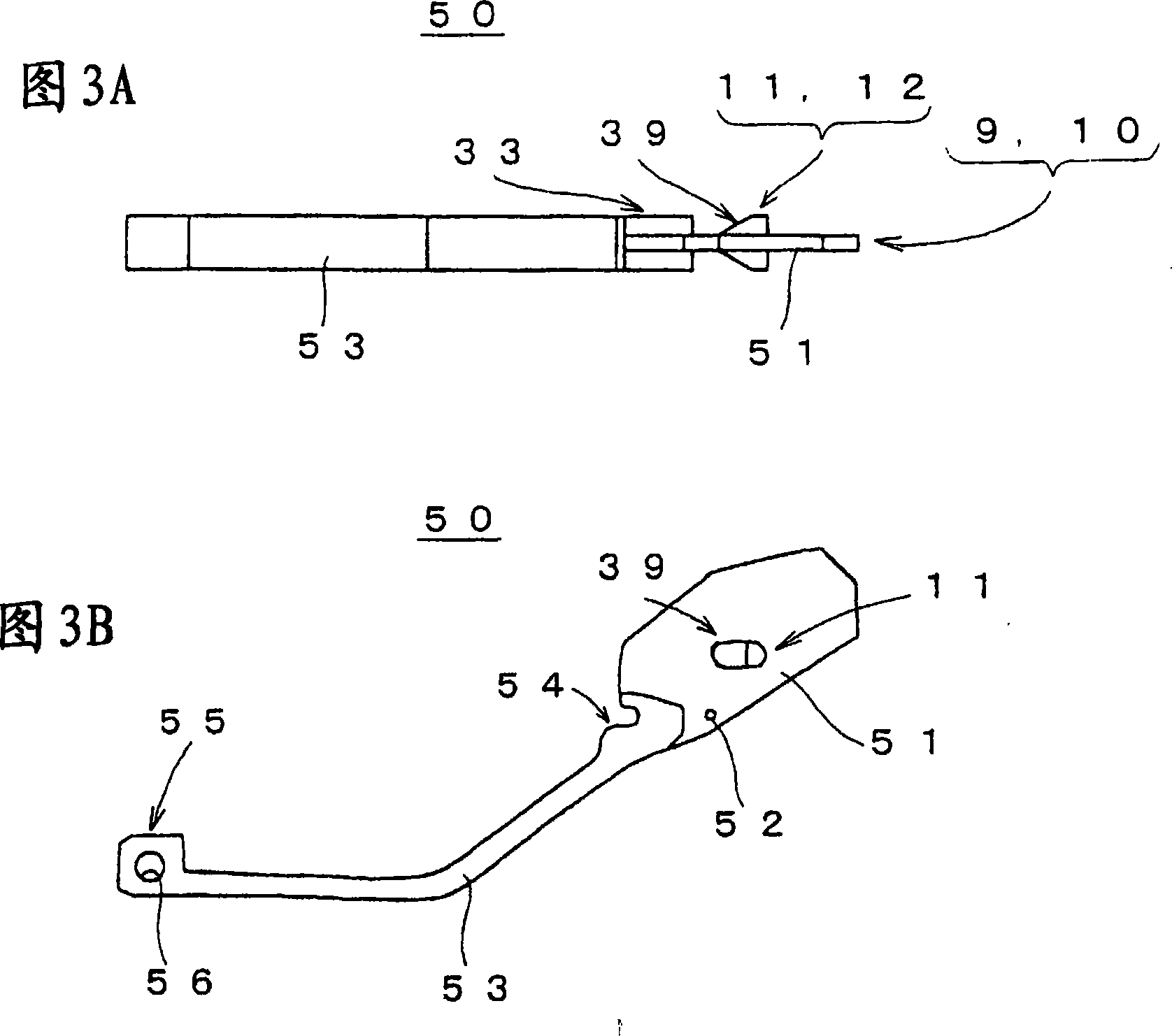

Weft knitting machine

A weft knitting machine capable of supporting the knitting needles of needle beds against sufficient side loads even if multiple stages of needle beds are formed on the same side of a trick gap space. Fixed sinkers (9) and (10) are mounted at the tips of lower stage needle beds (3b) and (4b) and knitting needle supporting projections (11) and (12) are formed on the fixed sinkers (9) and (10) so that needle bodies (23a) and (24a) advancing from upper stage needle beds (3a) and (4a) to the trick gap space (2) can be supported from the side. The knitting needle supporting projections (11) and (12) are formed at positions where they are not interfered with the operation of the compound needles (21b) and (22b) of the lower stage needle beds (3b) and (4b). Thus, even if the needle bodies (23a) and (24a) of the upper stage needle beds (3a) and (4a) receive a load to the side, the large bending thereof can be suppressed by the contact thereof with the knitting needle supporting projections (11) and (12) and sufficient side support can be performed for the needle bodies.

Owner:SHIMA SEIKI MFG LTD

Weft knitting machine

A weft knitting machine capable of supporting the knitting needles of needle beds against sufficient side loads even if multiple stages of needle beds are formed on the same side of a trick gap space. Fixed sinkers (9) and (10) are mounted at the tips of lower stage needle beds (3b) and (4b) and knitting needle supporting projections (11) and (12) are formed on the fixed sinkers (9) and (10) so that needle bodies (23a) and (24a) advancing from upper stage needle beds (3a) and (4a) to the trick gap space (2) can be supported from the side. The knitting needle supporting projections (11) and (12) are formed at positions where they are not interfered with the operation of the compound needles (21b) and (22b) of the lower stage needle beds (3b) and (4b). Thus, even if the needle bodies (23a) and (24a) of the upper stage needle beds (3a) and (4a) receive a load to the side, the large bending thereof can be suppressed by the contact thereof with the knitting needle supporting projections (11) and (12) and sufficient side support can be performed for the needle bodies.

Owner:SHIMA SEIKI MFG LTD

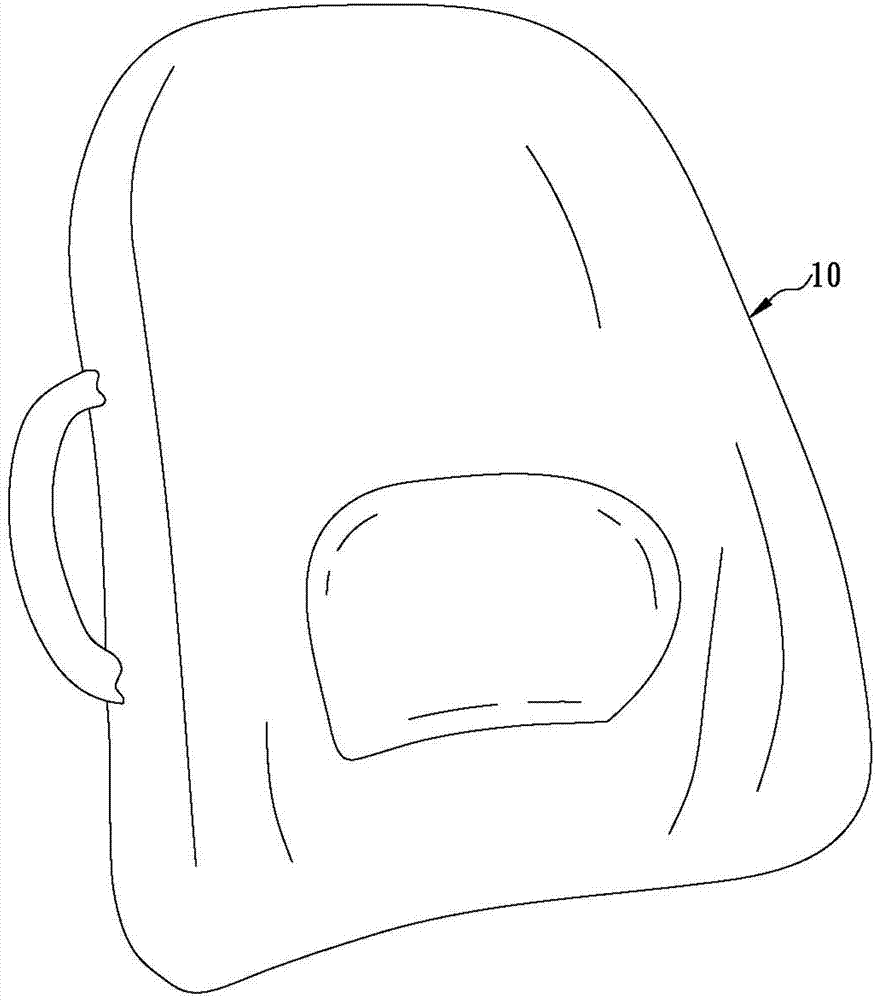

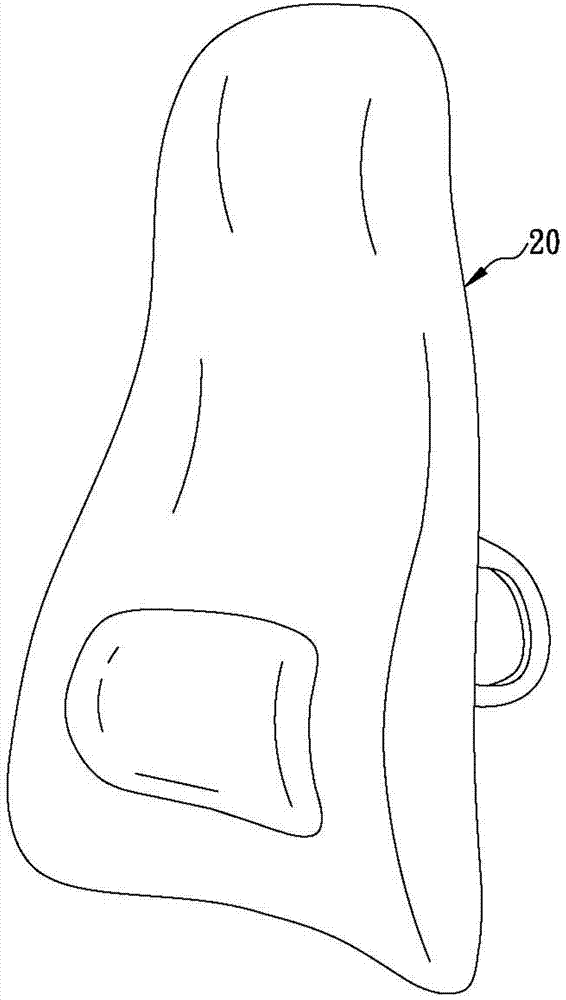

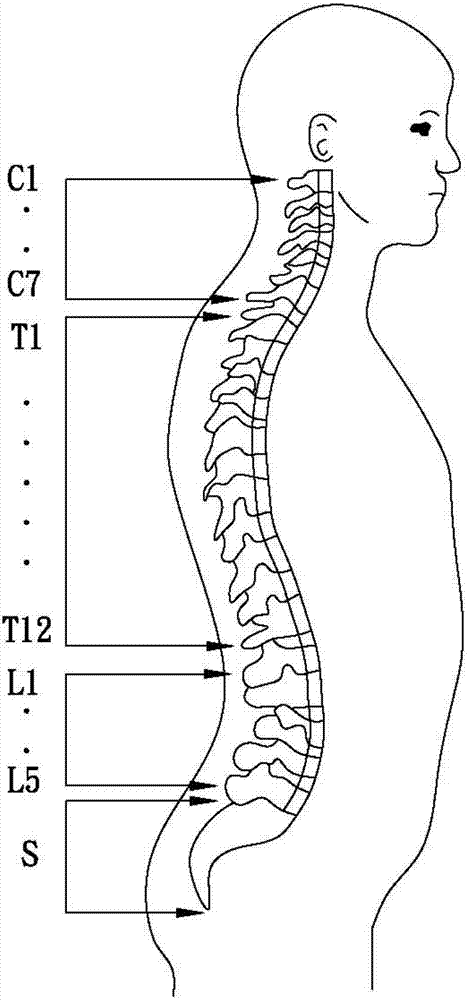

Portable spinal orthotic backrest

ActiveCN104706496AFully supportedEnough seating spaceChiropractic devicesArtificial respirationHuman backPlastic materials

The invention provides a portable spinal orthotic backrest. The portable spinal orthotic backrest comprises a back support plate which is integrally formed by a plastic material, and the back support sheet comprises an upper portion and a lower portion from top to bottom in the vertical direction; the inside radian of the central longitudinal section of the upper portion in the vertical direction is consistent with the radian of the thoracic vertebrae of a human body, and the inside radian of the transverse section of the upper portion in the horizontal direction is consistent with the radian of the human back corresponding to the thoracic vertebrae in the horizontal direction; and the inside radian of the central longitudinal section of the lower portion in the vertical direction is consistent with the radian of the lumbar vertebrae of the human body, and the inside radian of the transverse section of the lower portion in the horizontal direction is consistent with the radian of the human back corresponding to the lumbar vertebrae in the horizontal direction. The backrest not only is simple in structure but also does not occupy space; the back support plate can correctly and integrally support the thoracic vertebrae and the lumbar vertebrae of a user; and through a waist and back muscle relaxation mechanism, the purpose of fine-tuning the thoracic vertebrae and the lumbar vertebrae to the correct positions is further achieved.

Owner:GUANGZHOU XINBO ELECTRONICS CO LTD

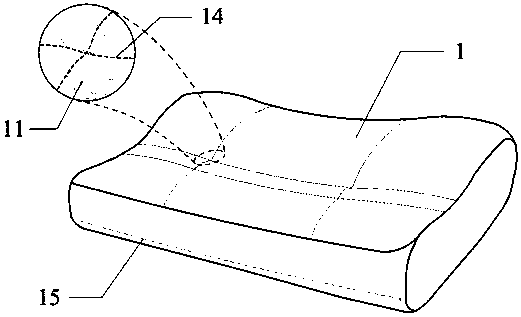

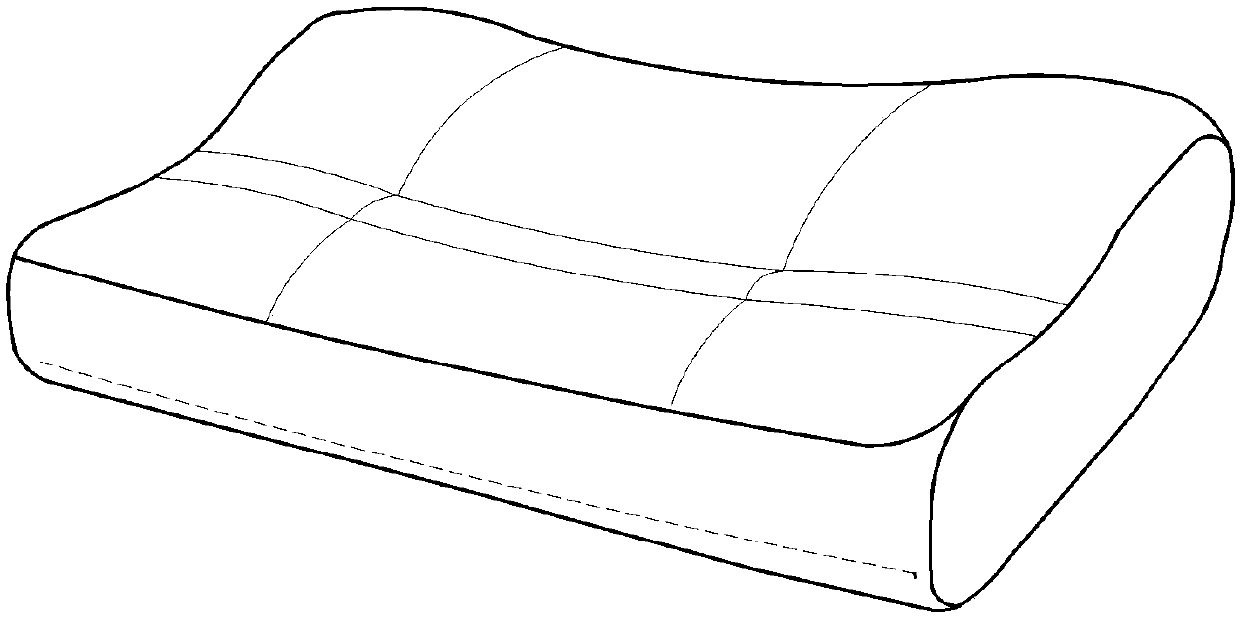

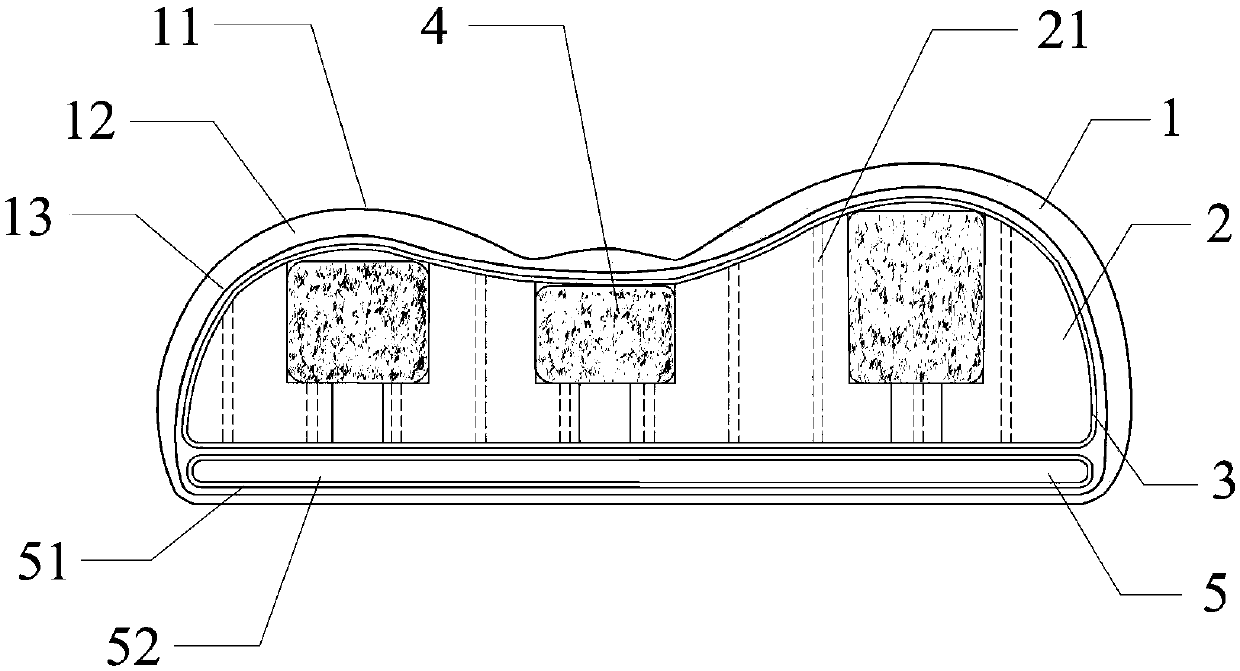

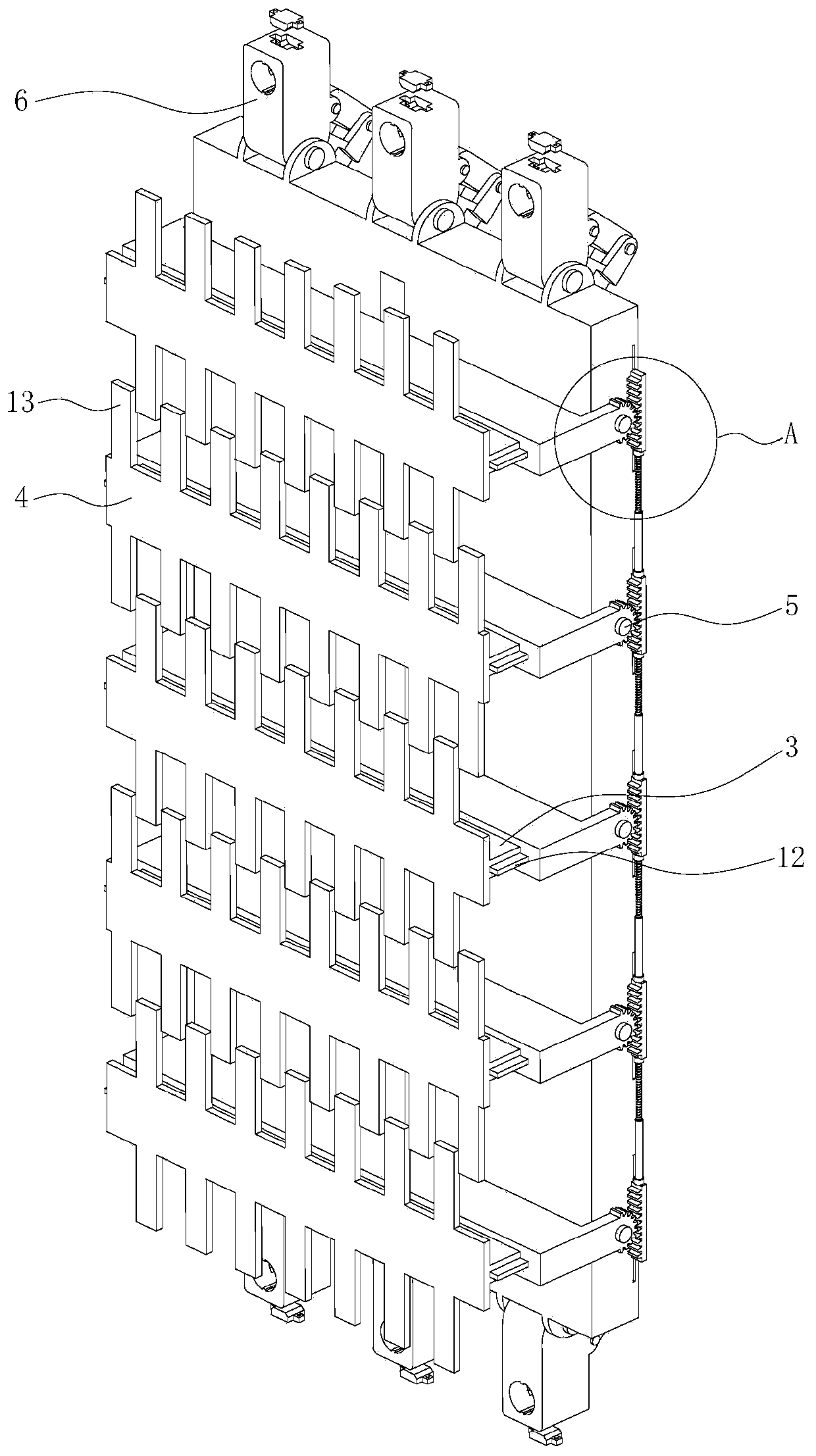

Pillow inner with loofah sponge functional modules and pillow with pillow inner

PendingCN110025179AGood hygroscopicityImprove dehumidification effectPillowsBed-coversMoisture absorptionEnergy exchange

The invention discloses a pillow inner with loofah sponge functional modules and a pillow with the pillow inner. The pillow inner is characterized in that counter bores are arranged in a pillow innerbody, the loofah sponge functional modules are arranged in the counter bores, and each loofah sponge functional module comprises cylindrical outer sleeve fabric and an internal filling loofah sponge.The pillow comprises the pillow inner, an outer pillow case for accommodating the pillow inner and a height adjusting module. The pillow inner and the pillow have the advantages that the moisture absorption, dampness dispersing performance and breathability of the pillow are increased, heat and dampness energy exchanging between a person and the pillow is benefited, and the dryness and comfortableness of the pillow surface are guaranteed.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Foundation pit supporting framework for building foundation construction

The invention belongs to the technical field of building construction equipment, and particularly relates to a foundation pit supporting framework for building foundation construction. The foundationpit supporting framework comprises a rectangular base plate, wherein the two sides of the base plate are rotatably connected with strip-shaped mounting plates; sliding plates parallel to the mountingplates are in sliding fit in the mounting plates; a strip-shaped pressing plate is fixedly arranged on the outer end surface of each corresponding sliding plate perpendicularly; an angle adjusting mechanism is arranged at the joint of each mounting plate and the base plate correspondingly; a plurality of mounting blocks for fixing supporting anchor rods are rotatably arranged at the top and the bottom of the base plate respectively through pin shafts; one ends of first connecting rods are rotatably connected to positions, corresponding to the mounting blocks, of the back surface of the base plate through pin shafts; the mounting blocks are rotatably connected with one ends of second connecting rods through pin shafts; and the ends of each first connecting rod are hinged to the ends of thecorresponding second connecting rod. According to the foundation pit supporting framework for building foundation construction, the angle can be adjusted according to different surface radians of an arc-shaped foundation pit, so that the strip-shaped pressing plates are attached to the surface of the foundation pit, and the surface of the side wall of the arc-shaped foundation pit is fully supported.

Owner:NINGBO CONSTR GRP

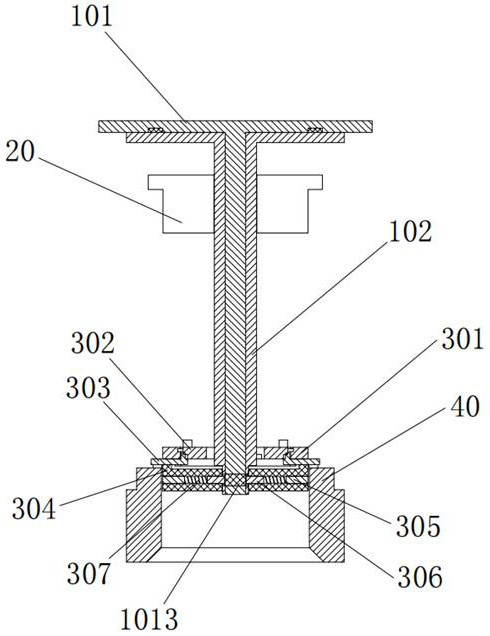

Quick assembly tool for valve seat support

The invention provides a valve seat support rapid assembling tool which comprises a wrench assembly and a driving assembly, the driving assembly is used for installing a valve seat support on a valve body, the wrench assembly enables the driving assembly to rotate through a vertical rod part, the rod part of the wrench assembly is further sleeved with a positioning disc, and the positioning disc makes contact with a valve body channel in the valve body. A driving head at the front end of the wrench assembly acts on the driving assembly, and the driving assembly drives the valve seat support to rotate, so that the valve seat support is connected into the valve body in a threaded mode. According to the quick assembling tool for the valve seat support, the magnetic steel block on the inner wrench is attracted to the sliding clamping block arranged in the bottom plate made of the ceramic material, it is ensured that the wrench assembly is connected with the driving assembly, and the valve seat support is driven by the driving key to be tightly connected to the valve body in a threaded mode.

Owner:CHENGDU CHENGGAO VALVE +1

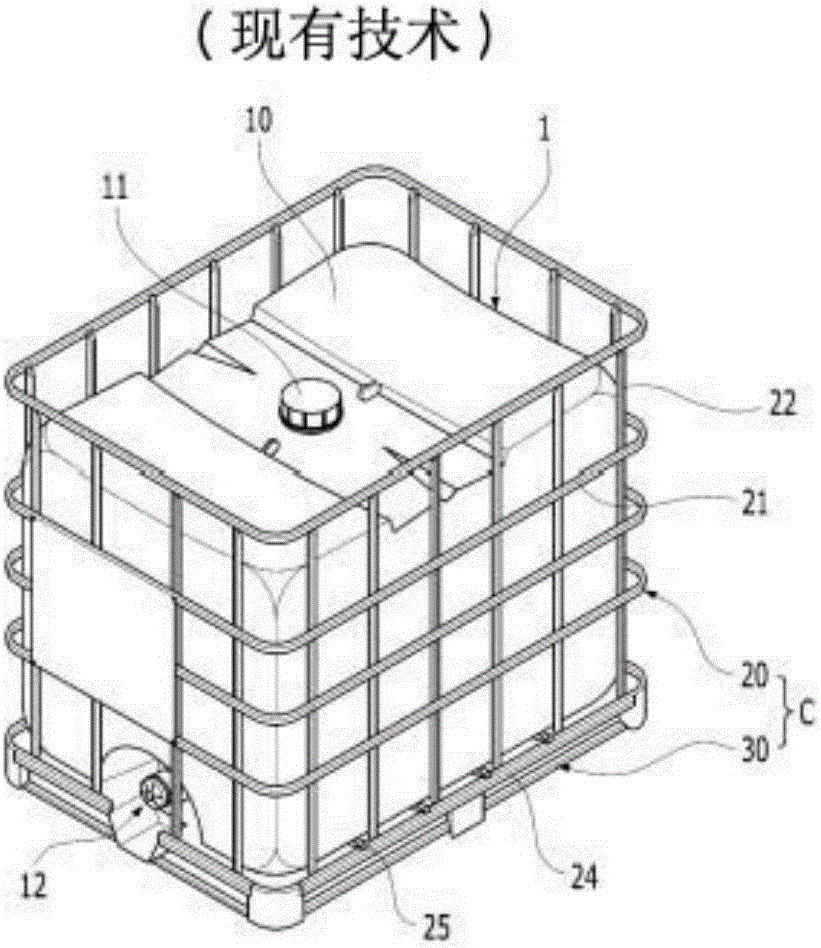

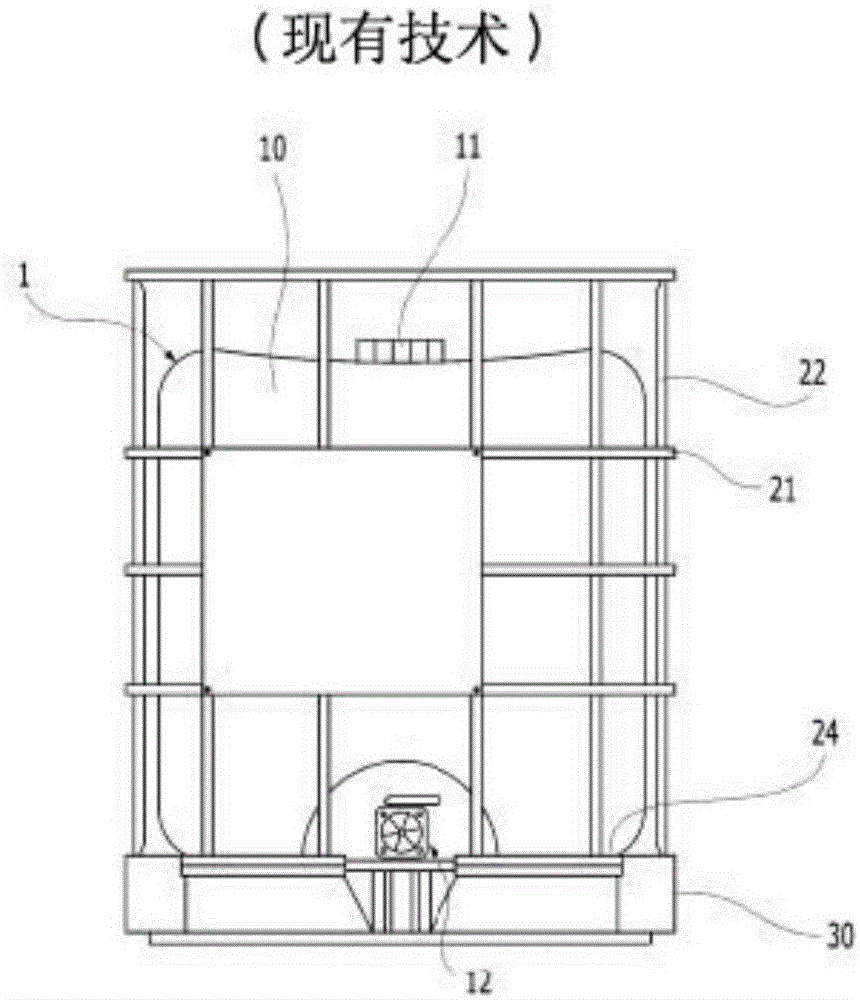

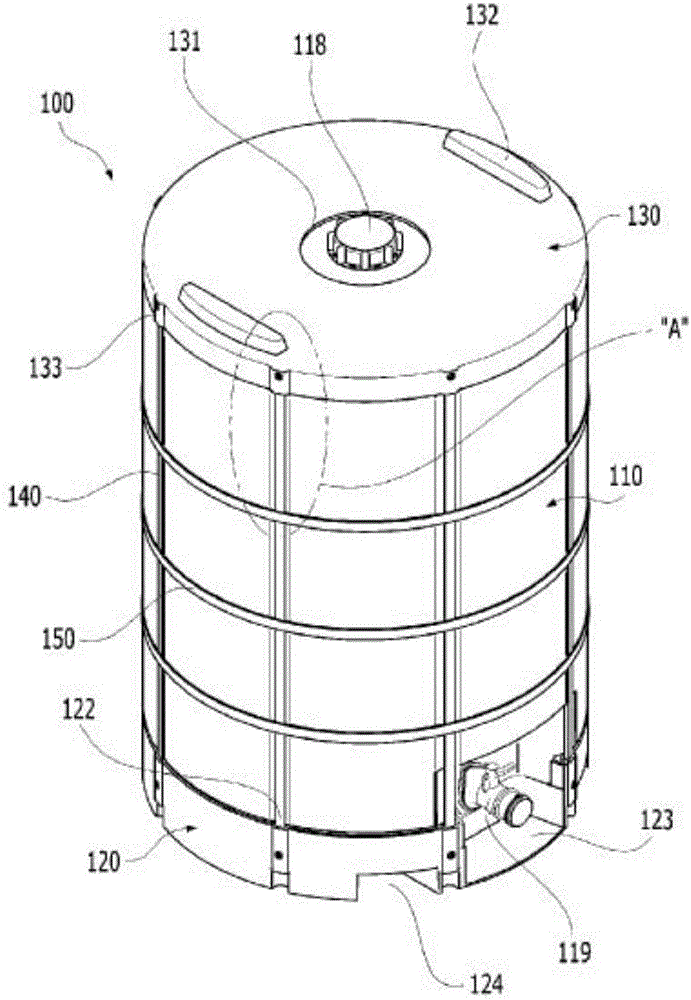

Intermediate bulk container

InactiveCN105980268AReduce weightReduce manufacturing costBagsSacksIntermediate bulk containerSynthetic resin

The present invention relates to an intermediate bulk container which can contain and store dangerous articles such as liquid chemicals or other various kinds of liquid content and can be vertically stacked and, more specifically, to an intermediate bulk container which is configured to: reduce the total weight of the container such that manufacturing costs are reduced by forming most of components except for vertical support bars are made of synthetic resin materials with respect to an intermediate bulk container formed in a size capable of containing approximately one ton of content; and stably maintain a stacked state even though the intermediate bulk container which is heavy due to approximately one ton of liquid contained therein is stacked in a plurality of layers by preventing a container body formed from a synthetic resin material from expanding so as to rupture or from being damaged. The present invention comprises: a plurality of vertical mounting grooves which are placed at certain intervals in a circumferential direction of the container, and which are formed in a longitudinal direction of the container; a plurality of vertical support bars mounted in the vertical mounting grooves; a plurality of horizontal mounting grooves which are placed at certain intervals in the longitudinal direction of the container, and which are formed in the circumferential direction of the container; and a plurality of horizontal support bands mounted in the horizontal mounting grooves, wherein the vertical support bars and the horizontal support bands are installed so as to cross each other.

Owner:HANS ENG

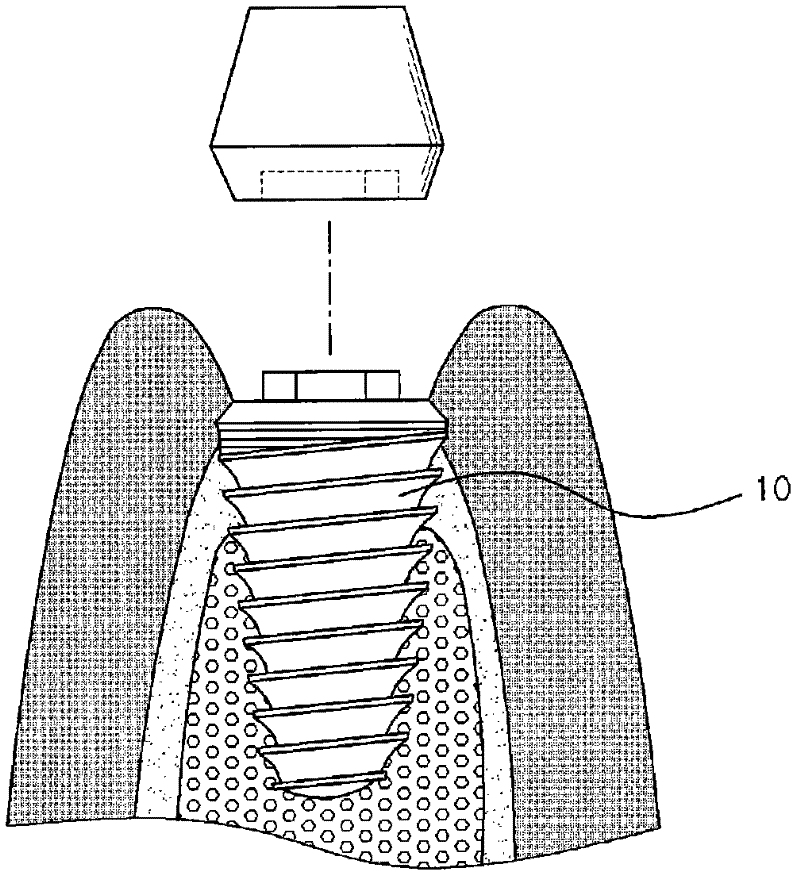

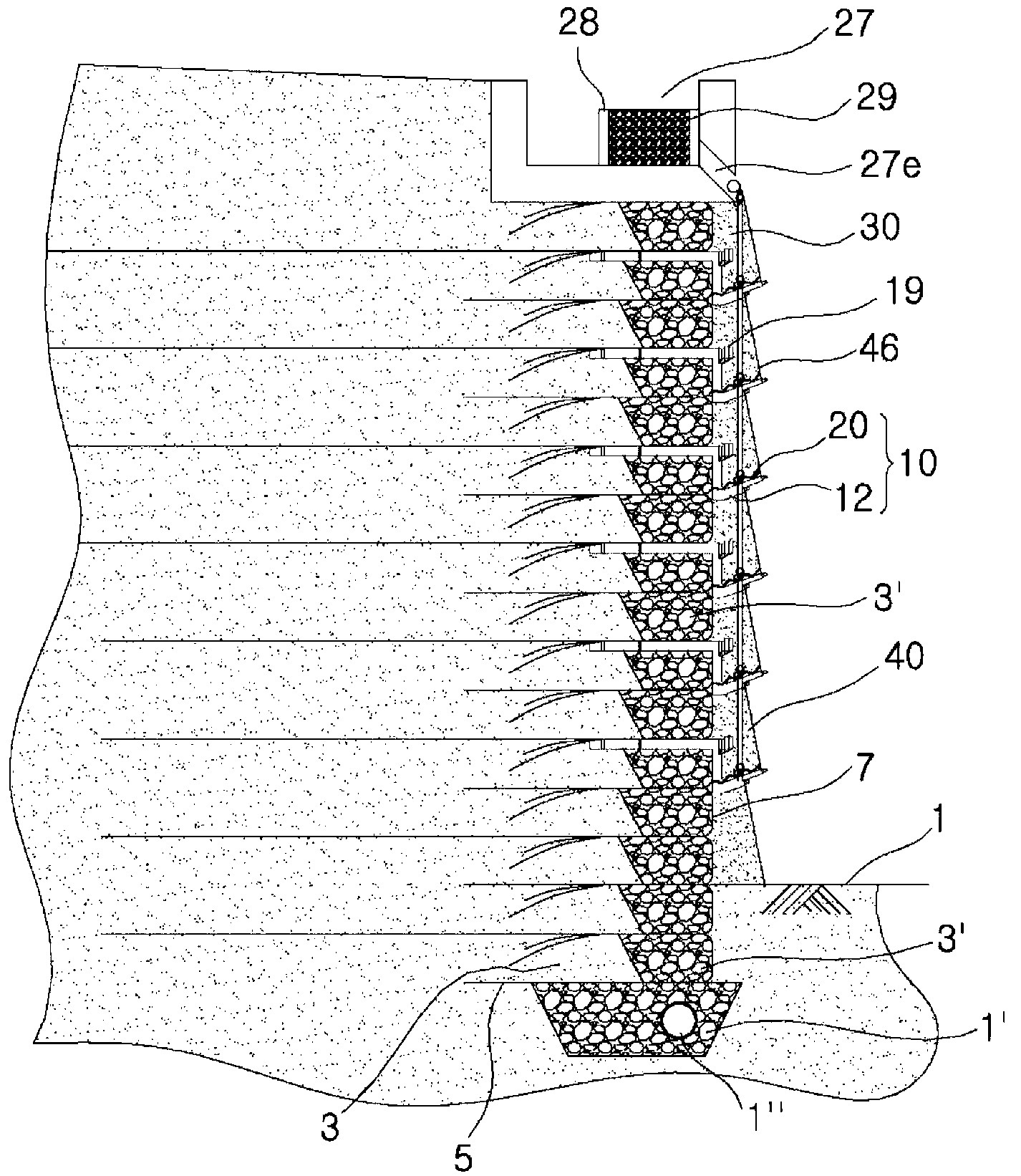

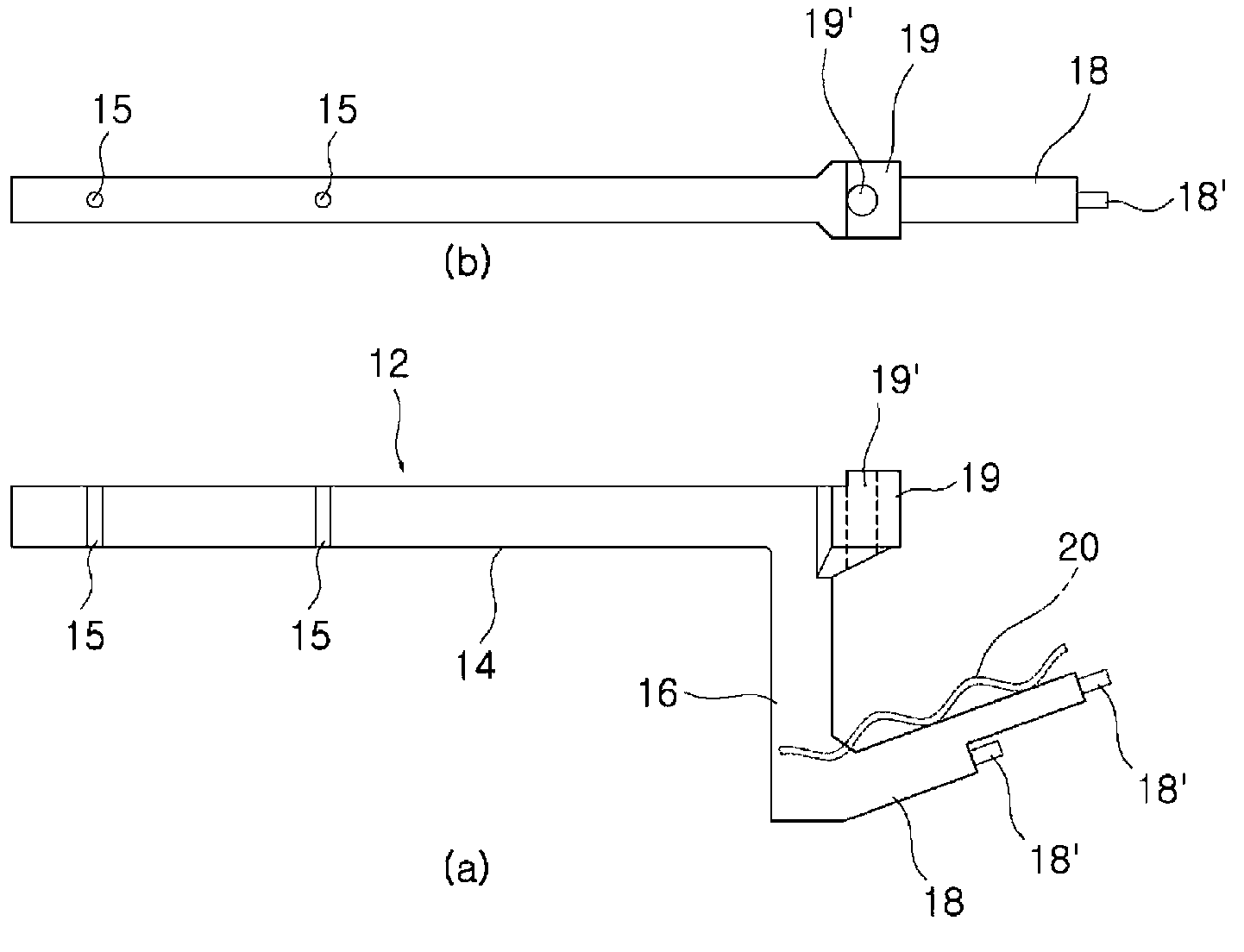

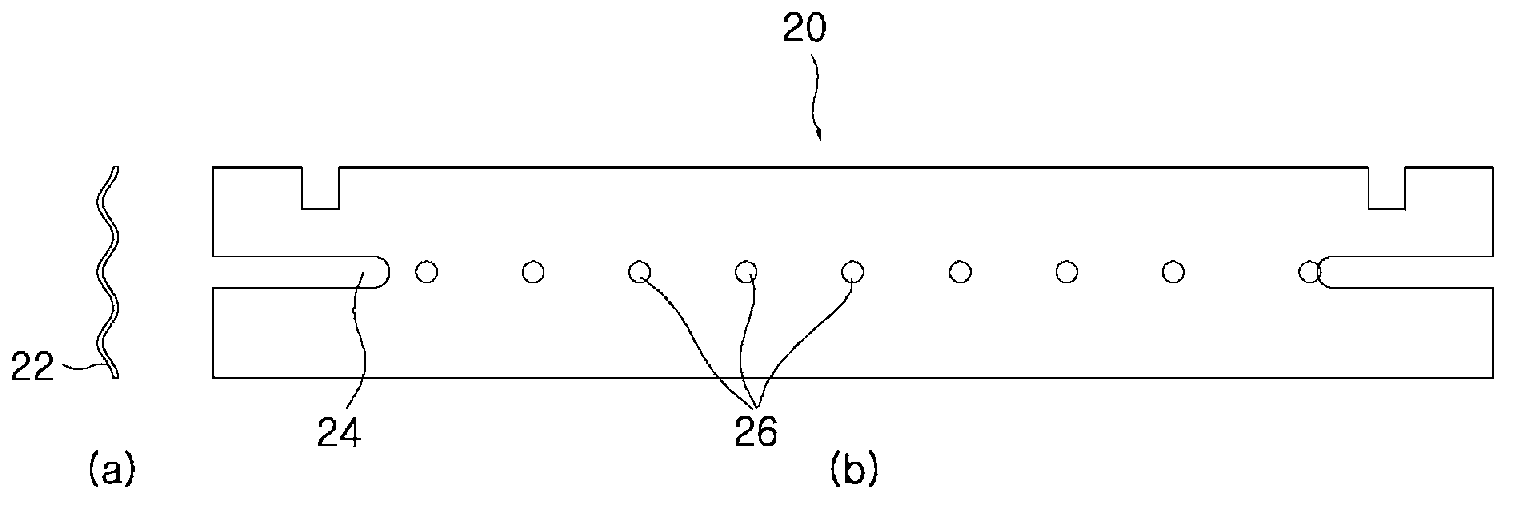

Vertical wall and gigh-slope afforestation method and aggregate container, shelf assembly and water supply device used thereto

InactiveCN102917580ABeautiful appearanceHealthy growthSelf-acting watering devicesAgriculture gas emission reductionVegetationStructural engineering

Disclosed is a method for foresting a vertical wall and a highly-inclined surface and an aggregate container, a shelf assembly, and a water supply apparatus used for the method. The shelf assembly (10) includes a support unit (12) and a support plate (20). The support unit (12) has a fixing leg (14) fixed to a reinforcement soil layer (3), and a load support unit (16) is positioned at the front end of the fixing leg (14) and is forced against and supported on a vertical wall (7) or an inclined surface at the front end of the reinforcement soil layer (3). The load support unit (16) has a support leg (18) extending from its front end to be inclined in the opposite gravitational direction. The support plate (20) is supported on the support leg (18), and vegetation soil (40) is placed on the support plate (20). A horizontal supply tube (36) is positioned inside the vegetation soil (40) with both ends connected to vertical supply tubes (30), which have a predetermined interval between them. Water supply tubes (38) are installed on the horizontal supply tube (36). The water supply tubes (38) are filled with a filler (38), and pressure-reduction valves (37') are installed on connection tubes (37), which connect the water supply tubes (38) and the horizontal supply tube (36). The shelf assembly (10) can support the load of the vegetation soil (40) more efficiently, and water is supplied into the vegetation soil (40) more effectively.

Owner:GREEN INFRA LIMITED +1

Tool clamp for clamping irregular arc plate of automobile and method

InactiveCN114012477APrevent blastingFully supportedPositioning apparatusMetal-working holdersBilateral symmetryMachining

The invention belongs to the technical field of automobile arc plate machining and mounting and relates to a tool clamp for clamping an irregular arc plate of an automobile and a method. The tool clamp comprises a clamping base, a pressure-bearing air bag is arranged in a gap between a pair of clamping tables which are in bilateral symmetry, the lower end of the pressure-bearing air bag is communicated with a pair of buffering air bags which are in bilateral symmetry through a three-way pipe, the outer wall of the middle section of the pressure-bearing air bag is connected with an annular limiting ring in an extruding and clamping mode, the upper end of the pressure-bearing air bag is provided with a plurality of sets of pressing strips which are linearly distributed, the upper ends of the buffering air bags are provided with pressing plates which perform pressing downwards, and the upper ends of the pressing strips are connected with reinforcing strips with storage grooves in an inserted mode. According to the tool clamp, through the cooperation of a pulling rope and a hanging ring, the bottom of the pressure-bearing air bag is adjusted; and the pressing strips are used for supporting a workpiece, a machining position is limited through the insertion cooperation of the pressing strips and the reinforcing strips, so that the air bag is prevented from being affected by a cutter or machining chippings, and meanwhile unified recycling of the machining chippings is achieved.

Owner:新昌县维斯机械有限公司

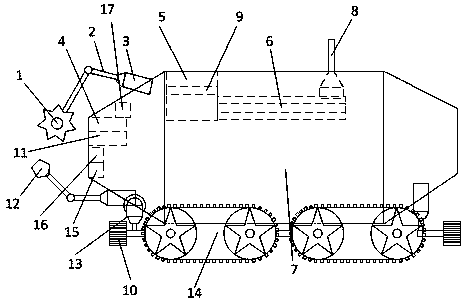

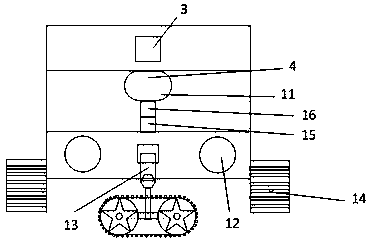

Deep-sea mining vehicle with auxiliary moving device

PendingCN111236945ATurn in placeAchieve self-helpMineral miningEndless track vehiclesDeep sea miningInformation repository

The invention discloses a deep-sea mining vehicle with an auxiliary moving device, and relates to the technical field of mining equipment. Hydraulic crawler wheels are arranged on the lateral sides ofa mining vehicle body, transverse crawler wheels are added to the vehicle head and the vehicle tail of the mining vehicle body, and the transverse crawler wheels rise or fall through a hydraulic lifting device. The vehicle head of the mining vehicle body is connected with a drill bit through a three-dimensional mechanical arm, the three-dimensional mechanical arm is driven by a hydraulic oil cylinder, the vehicle head of the mining vehicle body is provided with a hydraulic ore collector and an underwater illumination lamp, and a main controller is arranged in a main control room of the miningvehicle body. The mining vehicle body is provided with a multi-sensor information fusing system, data collected by various sensors is input into a fusing information library to be processed, and a result is conveyed to the main controller after processing. The deep-sea mining vehicle has the advantages that the pivot steering in seabed walking and the self-rescue in distress of the deep-sea mining vehicle can be realized, the deep-sea mining vehicle can perform route planning and correcting during operation, and the accuracy and safety of the deep-sea mining vehicle in seabed walking are improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

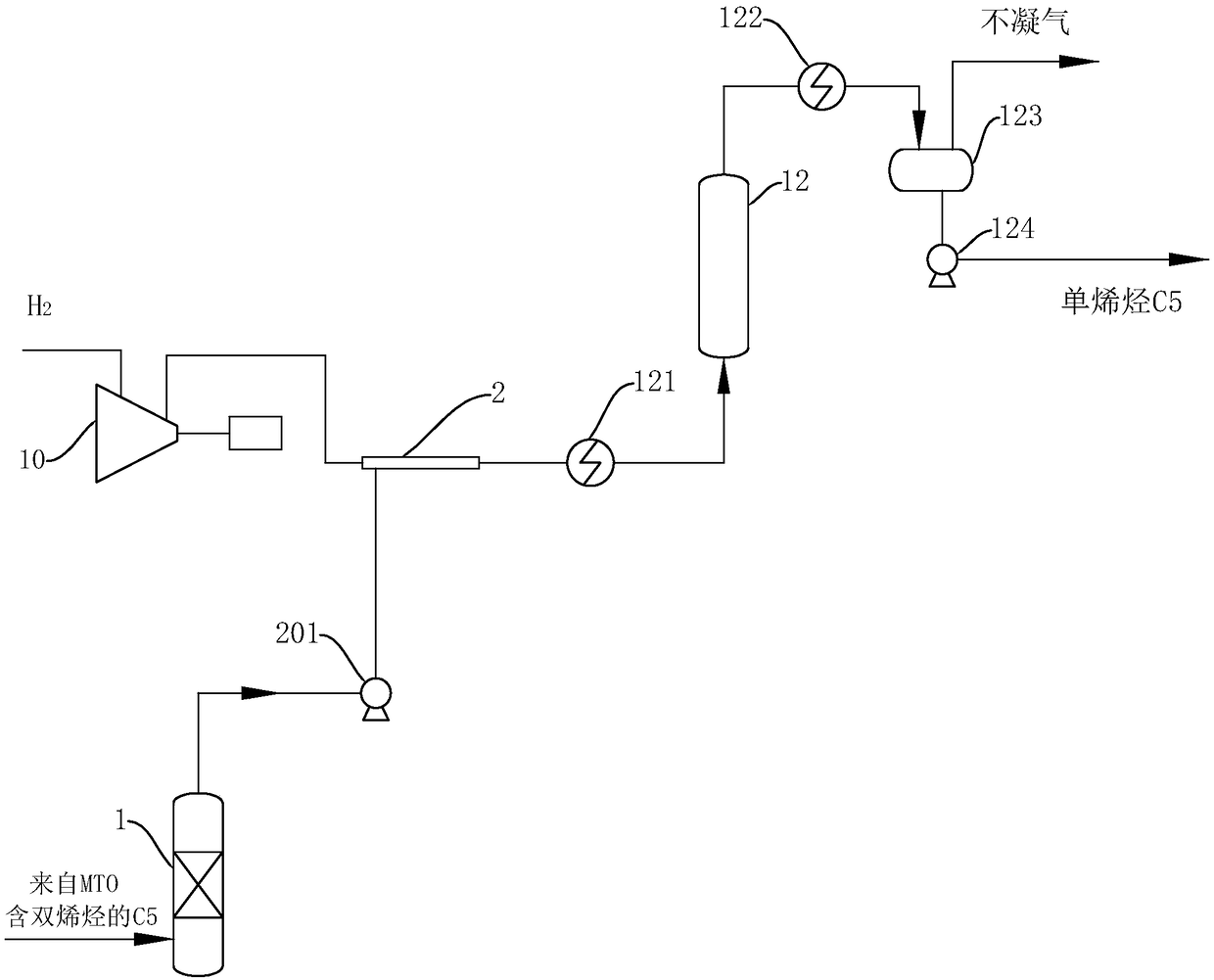

Method for producing propylene maximally with C5 olefin as main raw material

ActiveCN109369318AEasy to operateFully supportedMolecular sieve catalystHydrocarbon by hydrogenationButeneHydrogenation reaction

The invention discloses a method for producing propylene maximally with C5 olefin as a main raw material. The method comprises the following steps that S1, the C5 olefin raw material is injected intoa purifier for removing impurities such as oxygen-contained compounds; S2, selective hydrogenation reaction is conducted in a hydrogenation reactor, and thus a mono-olefin C5 material is obtained; S3,after being heated, the mono-olefin C5 material is delivered to a catalytic cracking reactor to be subjected to cracking reaction, and thus a cracking product containing ethylene and propylene is obtained; and S4, after cooling compression, propylene separation and purification are conducted in a de-heavy fractionator and athe rectifying tower sequentially, and thus purified high-purity propyleneand residual butane are obtained; S5, and the residual butane and materials at a fractionator kettle of the de-heavy fractionator are mixed and then delivered to the pre-reactor, selective polymerization of the olefin is conducted, and an obtained intermediate reaction product returns to the step S3 to be subjected to cracking reaction. According to the method for producing the propylene maximally with the C5 olefin as the main raw material, the yield of the propylene is 60m% or above of the raw material, meanwhile, less than 30m% of the ethylene is produced secondarily, equipment adopted bya system is simple, operability is high, investment is small, and the operation cost is low.

Owner:宁波旭合瑞石化工程有限公司

Pressure-resistant corrugated case

ActiveCN109775091AReduced service lifeMaximize structural strengthSealingRigid containersSplit shapeGeotechnical engineering

The invention belongs to the technical field of corrugated cases, and particularly relates to a pressure-resistant corrugated case. An outer box body, an inner box body, a box cover, a sliding springback mechanism, a first supporting mechanism, second supporting mechanisms and a third supporting mechanism are included; the upper ends of first elastic telescopic rods are fixedly connected to the lower surfaces of first metal elastic pieces, and the lower ends of the first metal elastic pieces are fixedly connected to the upper ends of first rotating shafts; the two sides of each first metal elastic piece are provided with supporting rods; the upper ends of the supporting rods are fixedly connected to the lower surfaces of the two ends of the first metal elastic pieces, and the lower ends ofthe supporting rods are fixedly connected to the first rotating shafts; sliding rods are symmetrically and rotationally connected to the lower end of each first rotating shaft; the lower ends of thesliding rods are installed in inclined plates in a sliding manner; the lower ends of the inclined plates are hinged to the lower surface in the outer box body; and each connection telescopic rod is hinged to the corresponding inclined plates in every two adjacent second supporting mechanisms. The pressure-resistant corrugated case is mainly used for solving the problems that an existing corrugatedcase is poor in pressure resisting capacity, prone to breakage and deformation in the transporting way, and inconvenient to open.

Owner:RAOPING COUNTY TONGYI PAPER PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com