Pressure-resistant corrugated case

A corrugated box and pressure-resistant technology, which is applied in the field of corrugated box, can solve the problems of easy cracking and deformation, inconvenient opening, poor pressure resistance, etc., and achieve the effect of improving structural strength, expanding expansion range, and improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

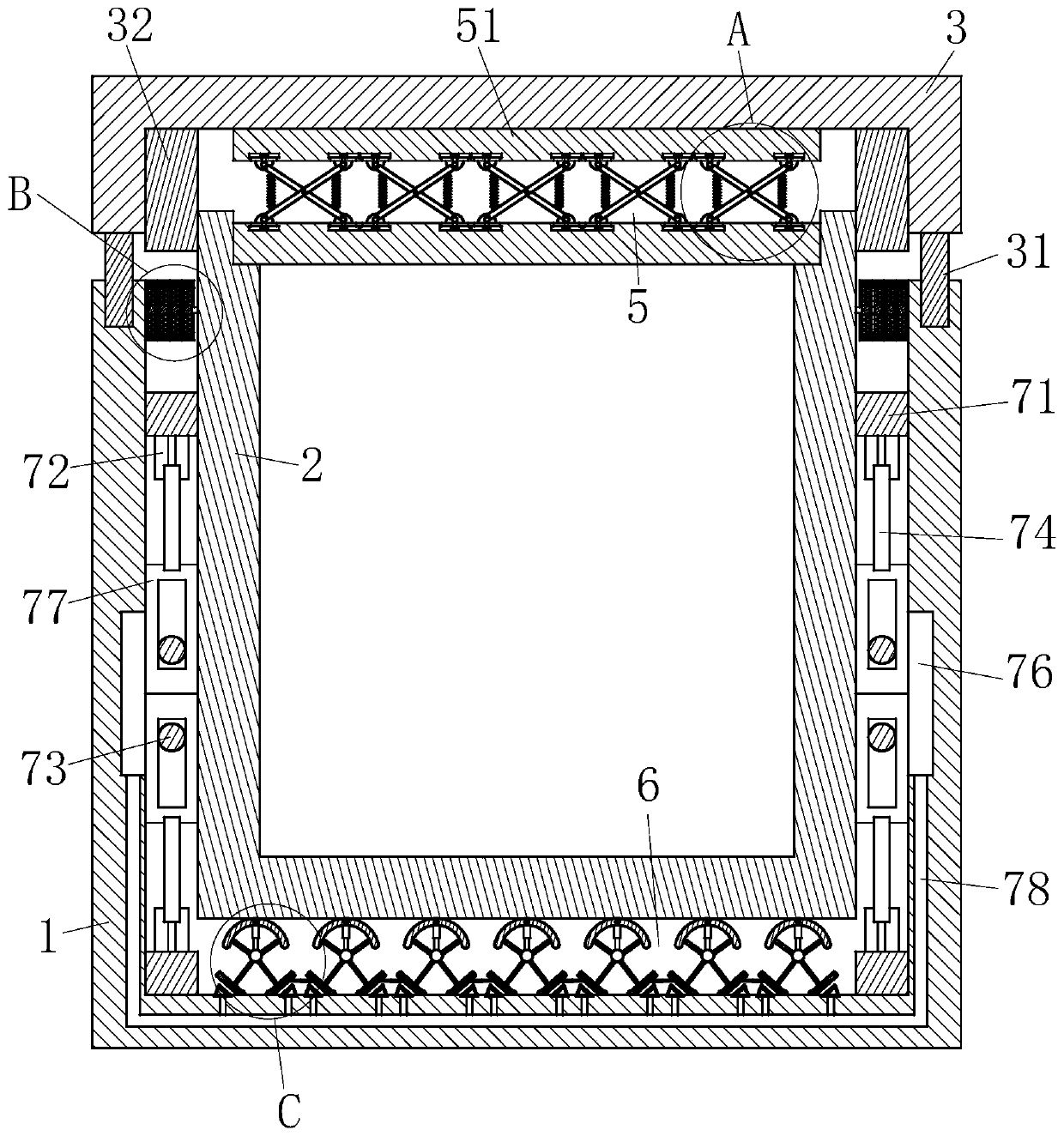

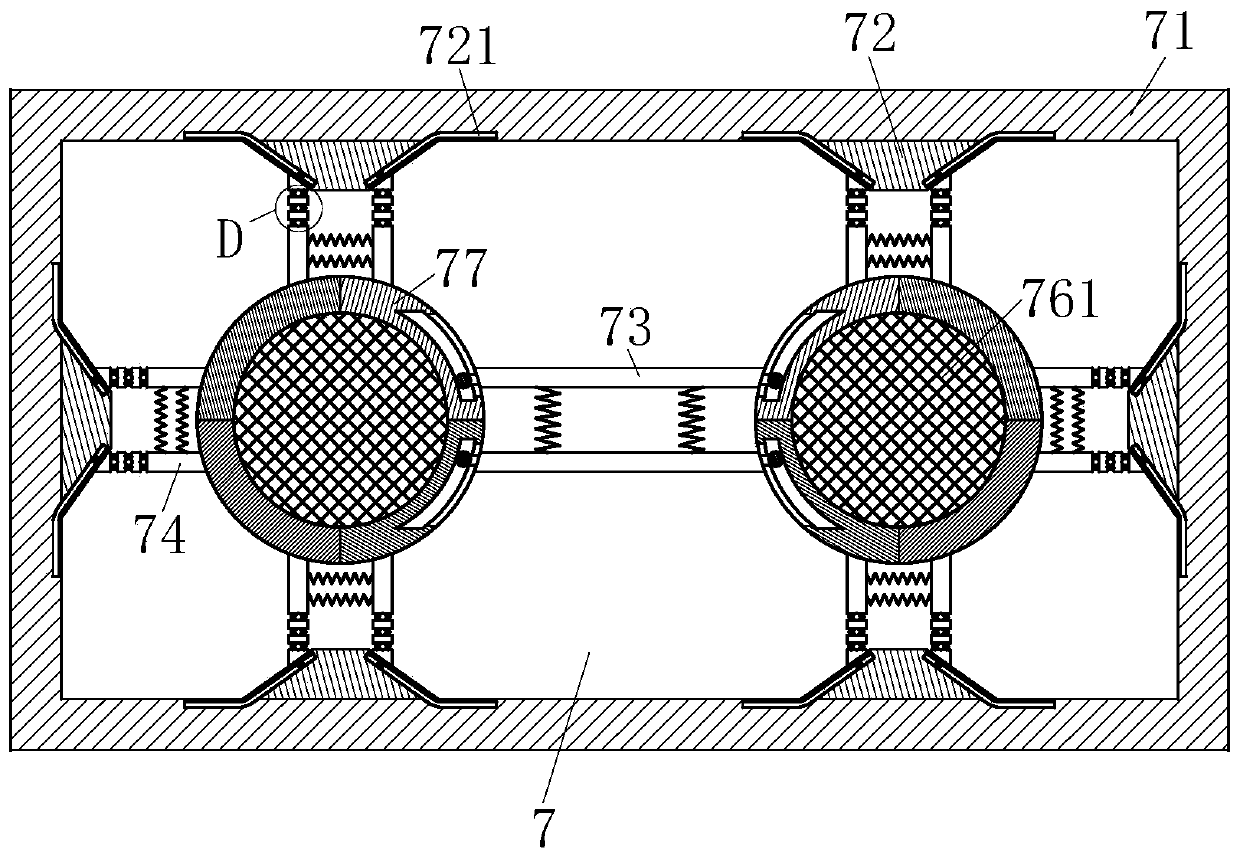

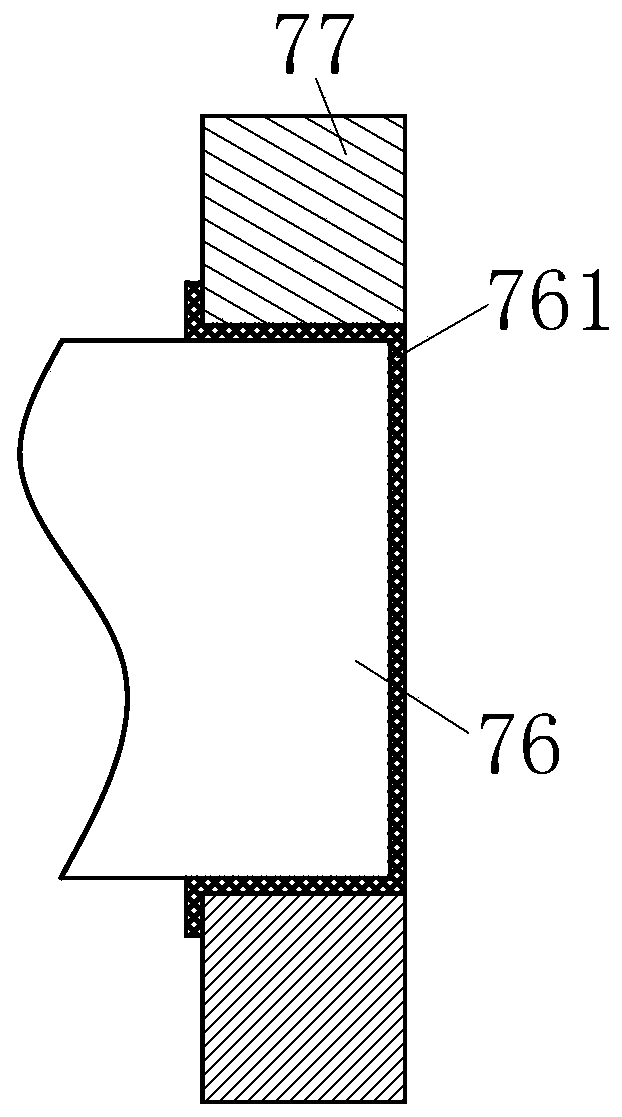

[0023] use Figure 1-Figure 8 A pressure-resistant corrugated cardboard box according to an embodiment of the present invention will be described as follows.

[0024] Such as Figure 1-Figure 8 As shown, a pressure-resistant corrugated cardboard box according to the present invention includes an outer box body 1, an inner box body 2, a box cover 3, a sliding rebound mechanism 4, a first support mechanism 5, a second support mechanism 6 and a third Support mechanism 7; the box cover 3 is slidably connected to the upper end of the outer box body 1 through a plug-in plate 31; the inner box body 2 is arranged below the box cover 3, and the inner box body 2 is slidably installed on the outer box body through a sliding rebound mechanism 4 Inside the body 1, the lower end of the inner box body 2 is provided with a second support mechanism 6; the second support mechanism 6 is a group of seven, and the second support mechanism 6 includes a first metal shrapnel 61, a first elastic tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com