Additive layer manufacturing method for producing three-dimensional object and three-dimensional object

A technology for 3D object, layer-by-layer manufacturing, used in machining, tooling, additive manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

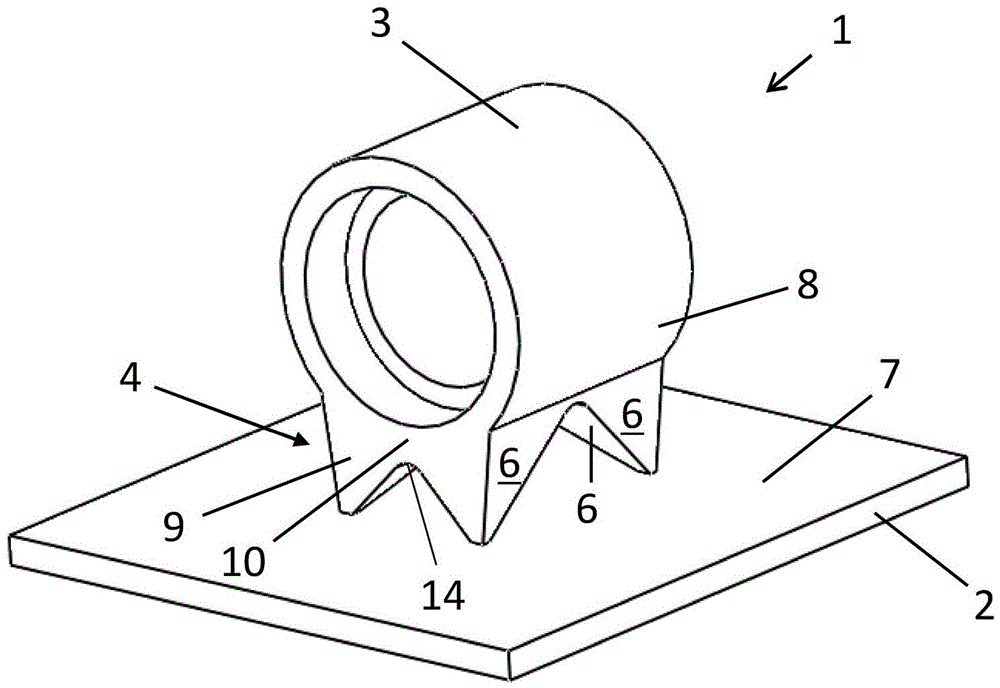

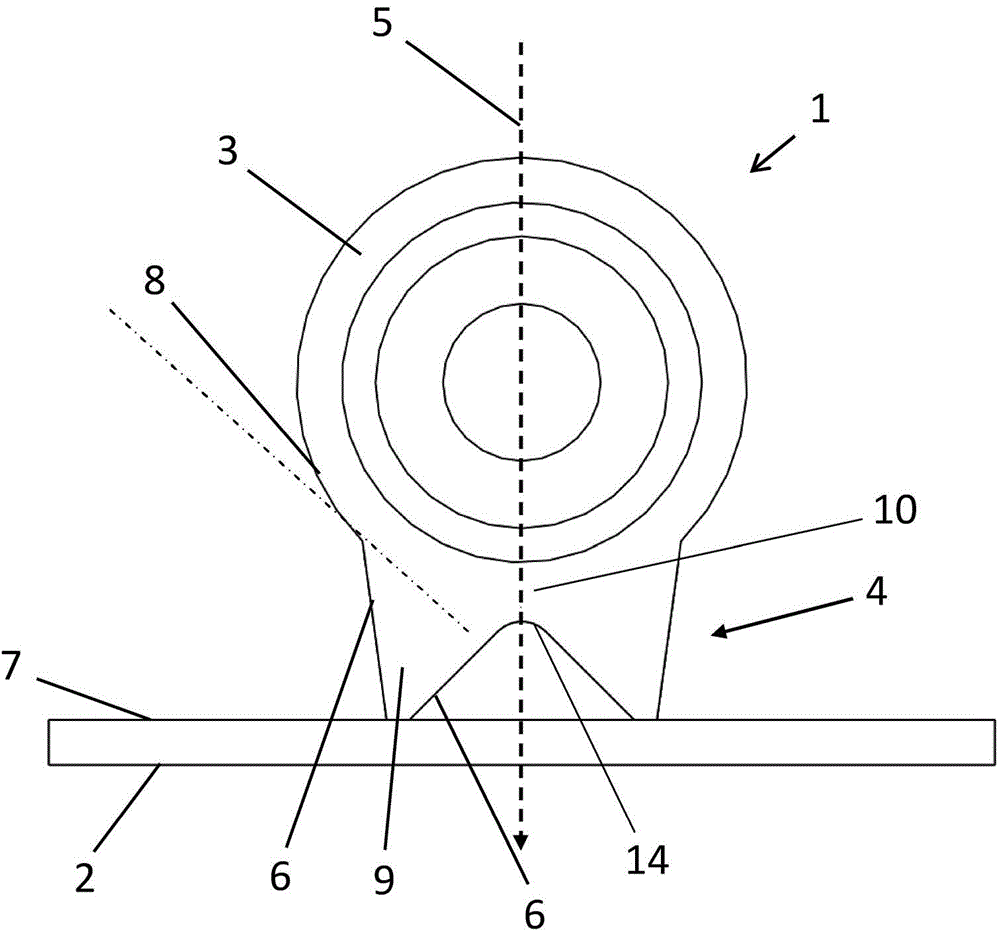

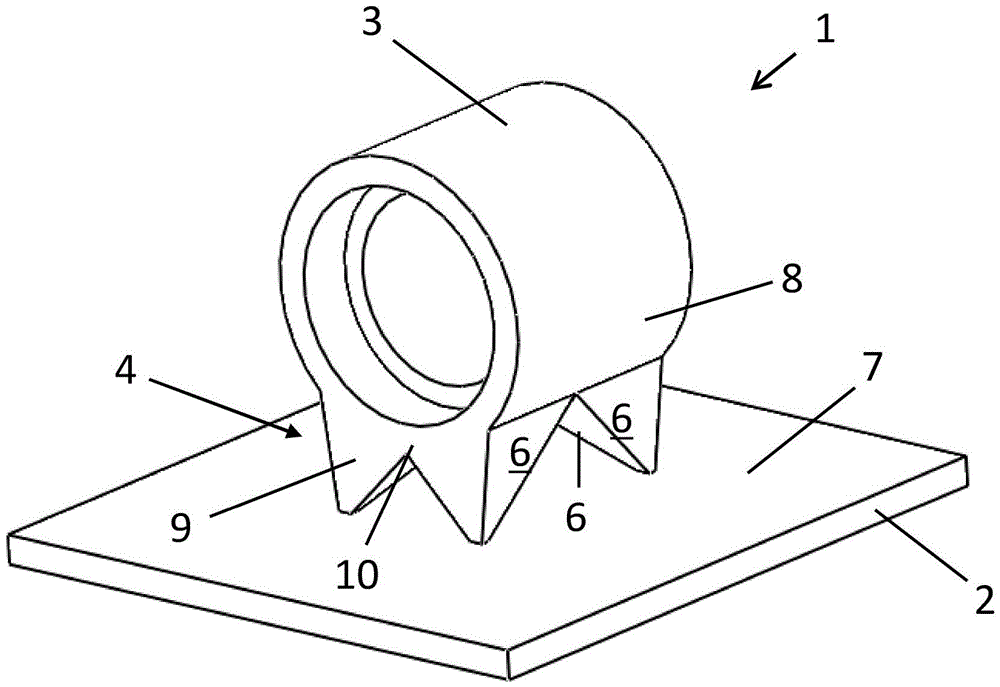

[0044] Figure 1a with 1b The three-dimensional object 1 in has a first section 2 in the form of a flat plate with a constant thickness, a second section spaced apart from the first section 2 in the form of a straight pipe section with circular inner- and outer diameters A section 3 and a support structure 4 extending between the plate 2 and the pipe section 3 along the entire length of the pipe section 3 . The plate 2 is designed to hold the object 1 on another object, and the tube section 3 is designed to guide fluid flow between its ends. They are therefore functional sections or components, unlike the support structure 4 . The object 1 is preferably a hydraulic distribution system or a component of a hydraulic distribution system.

[0045] exist Figure 1b The schematic cross-section of the object 1 is shown in this orientation, that is, it is always in this orientation during the layer-by-layer construction of the object, ie during the implementation of the additive ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com