Automotive front-cabin upper side beam assembly

A technology for beam components and automobiles, which is applied to vehicle parts, superstructures, subassemblies of superstructures, etc., can solve the problems of poor control, poor control of gaps and complicated welding processes for front cabin structures, etc., and achieve simple structure, The effect of strength satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

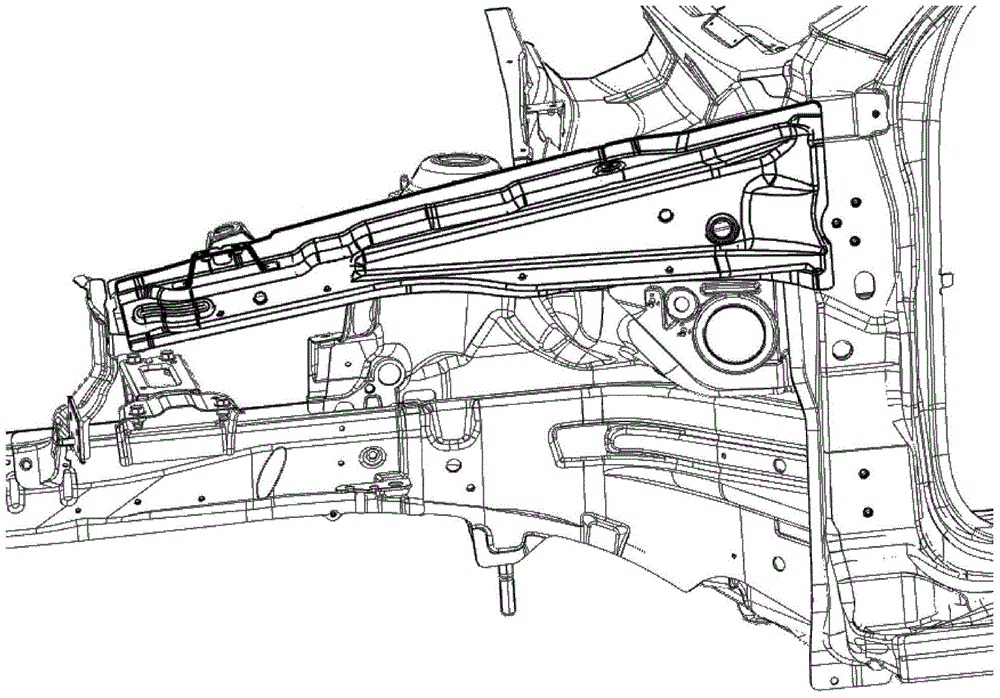

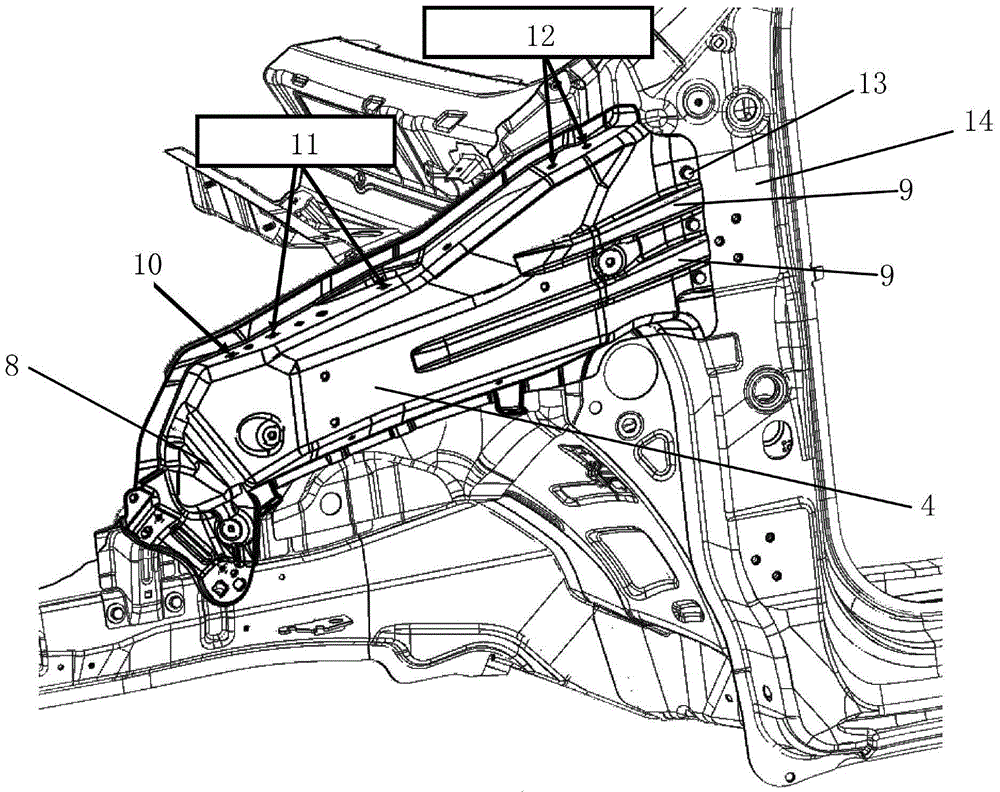

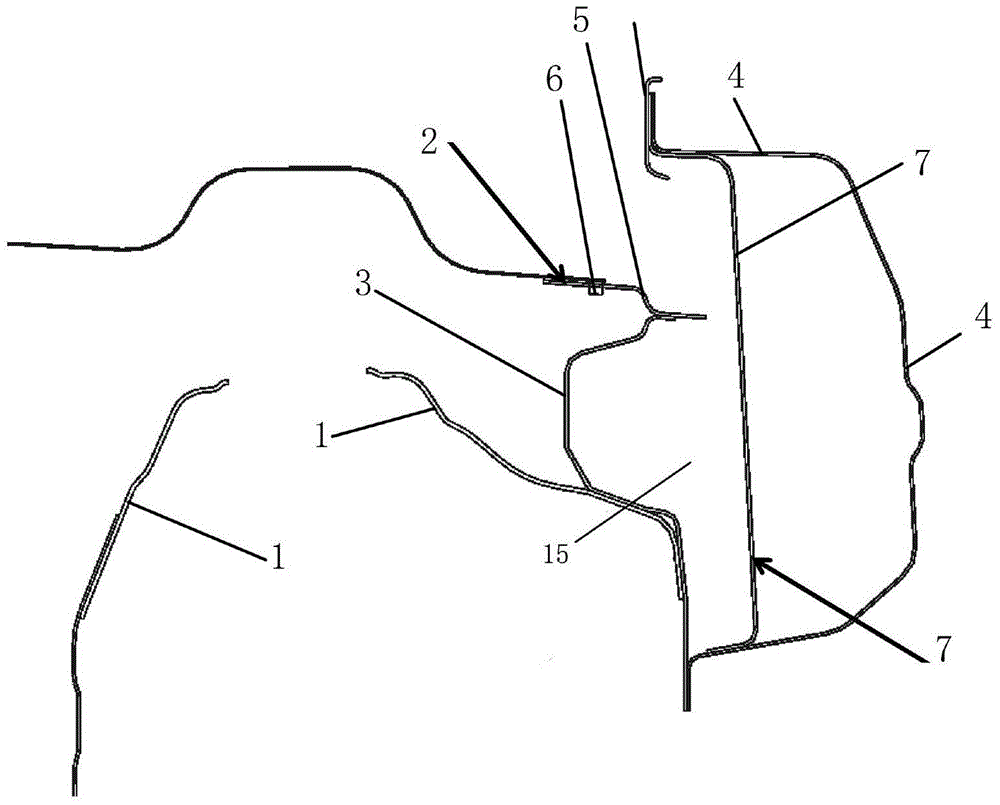

[0030] The following with attached Figure 1 to Figure 4 The automobile front cabin upper side beam assembly of the present invention will be further described in detail.

[0031] For the automobile front cabin upper side beam assembly of the present invention, please refer to Figure 1 to Figure 4 , including the upper side sill inner panel 3 and the upper side sill outer panel 4, the upper side sill inner panel 3 is respectively connected with the gutter assembly 2 in the front cabin of the automobile, the front wheel cover 1 and the hair cover hinge reinforcement plate 7, the upper side The beam outer plate 4 is respectively connected with the hood hinge reinforcement plate 7 in the front cabin of the automobile and the upper side sill inner plate 3, and the front of the lower part of the upper side sill outer plate 4 is provided with a collision-inducing rib 8, and the upper side sill inner plate 3 forms a cavity 15 that can accommodate the water flowing down from the gut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com