Construction method of static drilling root planting drainage pile

A construction method and technology of drainage piles, applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve the problem of affecting the bearing capacity and stability of prefabricated pipe piles, shortening the growth period of cement-soil strength, and slow growth of cement-soil strength To achieve the effect of accelerating cement curing speed, accelerating drainage consolidation, and shortening the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

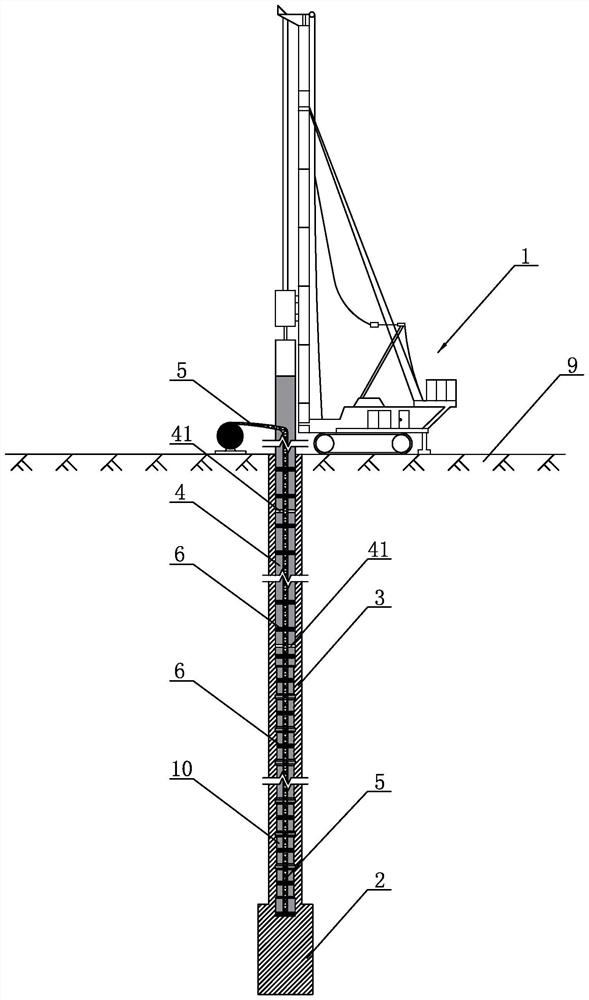

[0032] The construction method of static drilling rooting drainage pile of embodiment 1 may further comprise the steps:

[0033] (1) Position the drill bit of the piling machine 1. After positioning, the drill bit starts to drill in the deep soft soil foundation 9. While drilling, the hole body generated by drilling is trimmed and the wall is protected;

[0034] (2) After the hole is drilled to the design elevation, the piling machine 1 opens the expansion wing to ream the hole. After the reaming is completed, the drill bit is inserted into the bottom of the hole, and the solidified cement slurry at the pile end is injected into the bottom of the hole through the grouting pipe and stirred evenly to form an outer surface. Pile end cement soil 2 with a diameter of 1.0 m;

[0035] (3) Rotate and lift the drill pipe while retracting and expanding the wings, and at the same time inject the solidified cement slurry into the hole through the grouting pipe and stir evenly to form a pi...

Embodiment 2

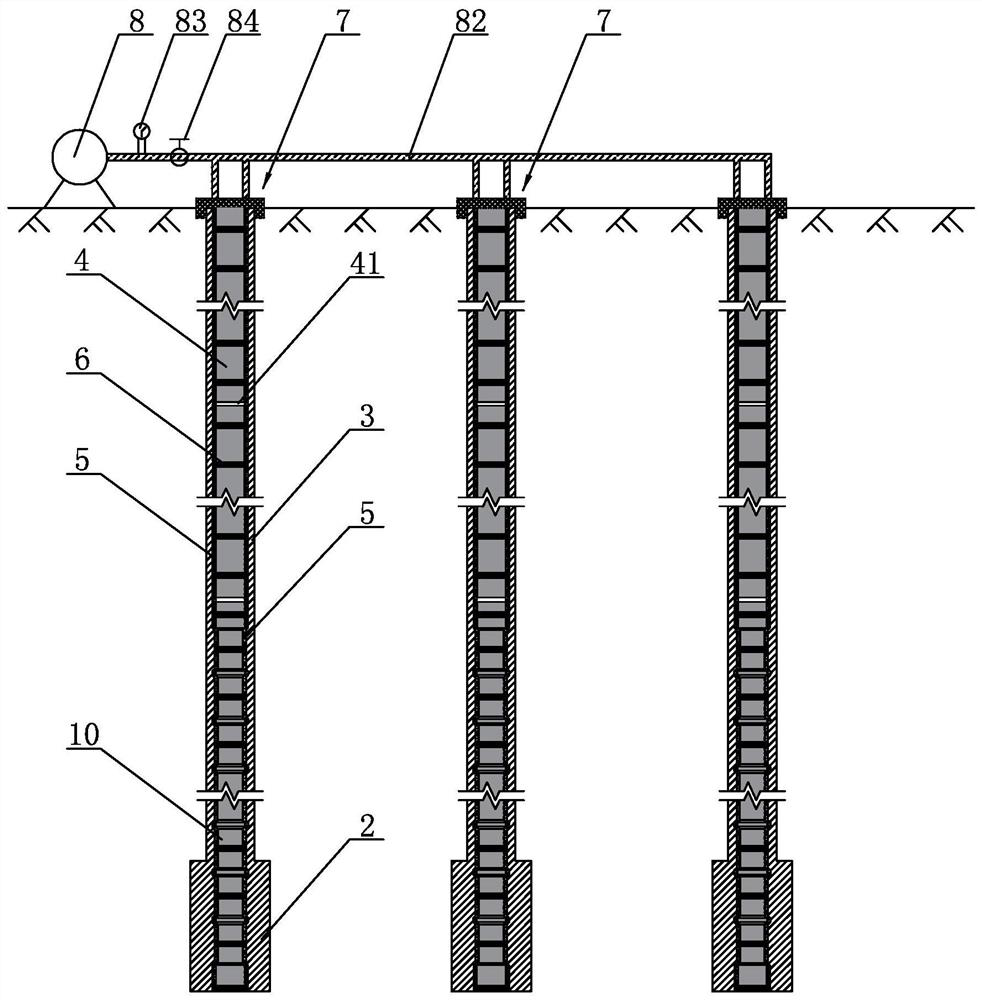

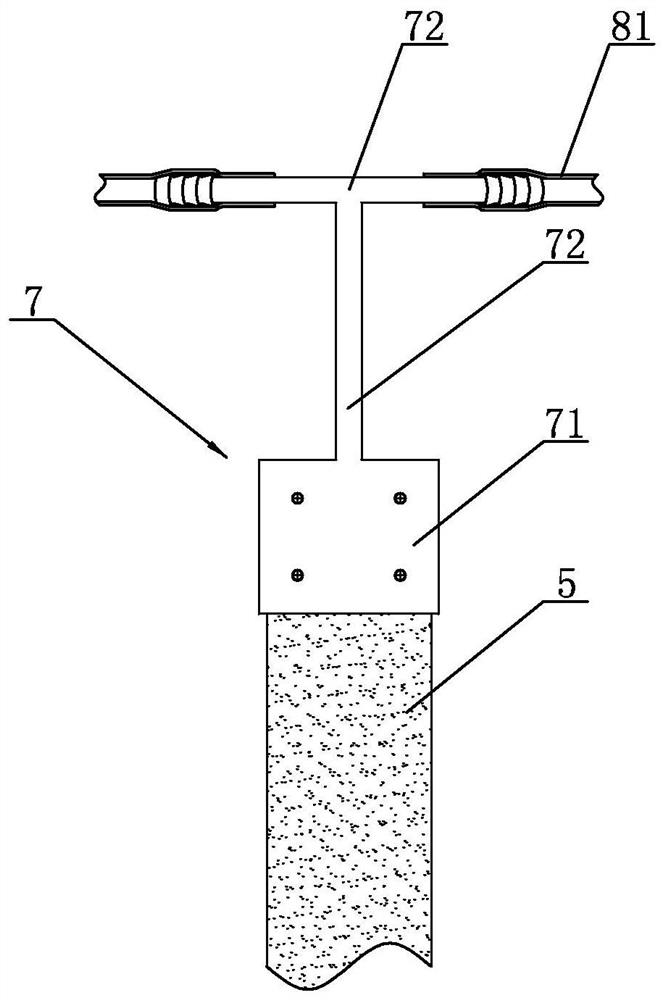

[0039] The difference between the static drilling and rooting drainage pile construction method of embodiment 2 and embodiment 1 is that in embodiment 2, there are multiple prefabricated pipe piles 4 used in step (4), and the prefabricated pipe piles at the bottom are Bamboo pile 10, during the pile sinking process, a plurality of prefabricated pipe piles 4 are sequentially sunk into the hole, and at the same time of pile sinking, binding straps 6 are continuously tied on both sides of the pile circumference of each prefabricated pipe pile 4 to vertically fix the drainage The board 5, the drainage board 5 symmetrically fixed on both sides of each prefabricated pipe pile 4 is two continuous drainage boards 5. In this embodiment, the bottom of each prefabricated pipe pile 4 is fixed with a pile connecting piece 41 , and the pile connecting piece 41 is used to connect the prefabricated pipe pile on the lower side of the prefabricated pipe pile 4 . like image 3As shown, each pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com