Gas collection tank for gas extraction and gas collecting and water discharging device for gas extraction

A gas and gas box technology, which is applied in the fields of gas pumping and collecting gas boxes and gas pumping and collecting gas and water discharge devices, can solve the problems that the drainage capacity of the drainage device cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

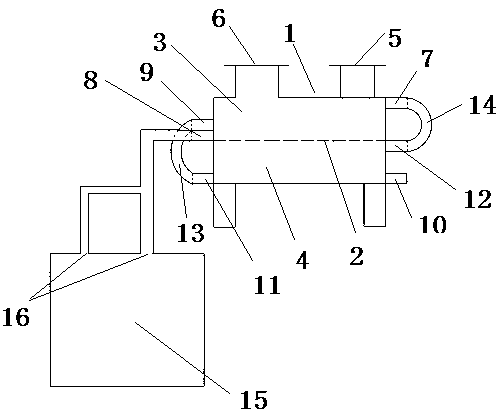

[0044] A specific embodiment of the gas pumping gas collection and water release device of the present invention, as figure 1 As shown, the gas collection and release device for gas pumping includes an automatic water release device 15 and a gas collection tank for gas pumping. The automatic water release device 15 can collect liquid through the water discharge device water inlet 16, and realize the accumulation of water after the liquid inside it reaches a set height. Automatic discharge, the automatic water release device 15 has two water release device water inlets 16, and the two water release device water inlets 16 are jointly connected with the automatic water outlet 8. The structure of the automatic water release device 15 is a common structure in the prior art, and will not be repeated here repeat.

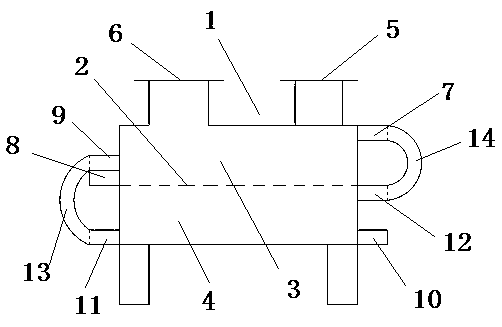

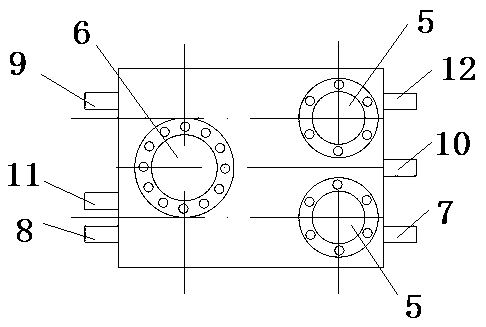

[0045] like figure 2 and image 3 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com