Sliding scaffold platform for mounting wire frame and wire frame mounting method

A scaffolding and grid technology, which is applied in the processing of building materials, housing structure support, housing structure support, etc., can solve the problems of large span, difficult installation, and long longitudinal direction, so as to achieve complete force, avoid deformation, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

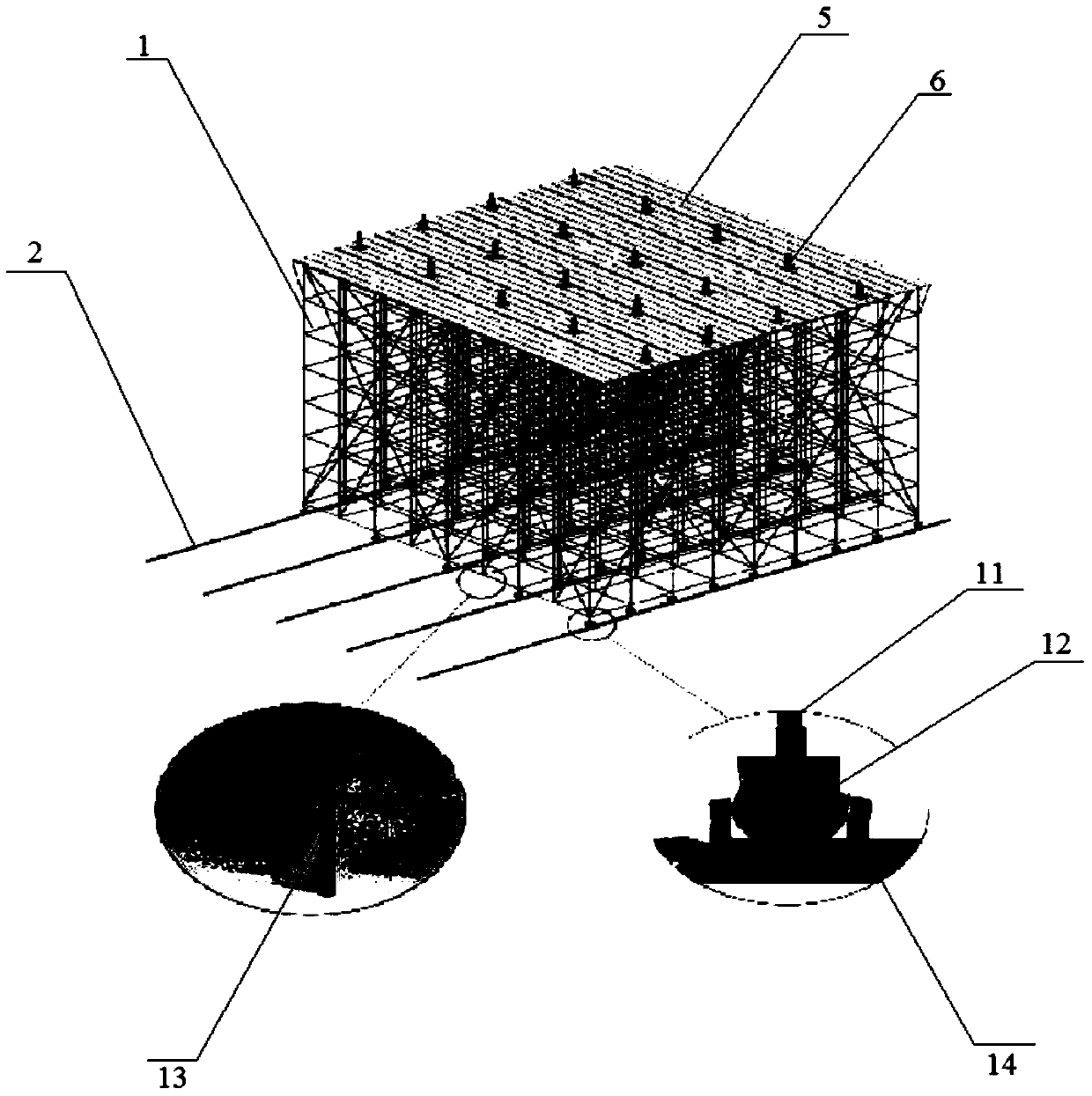

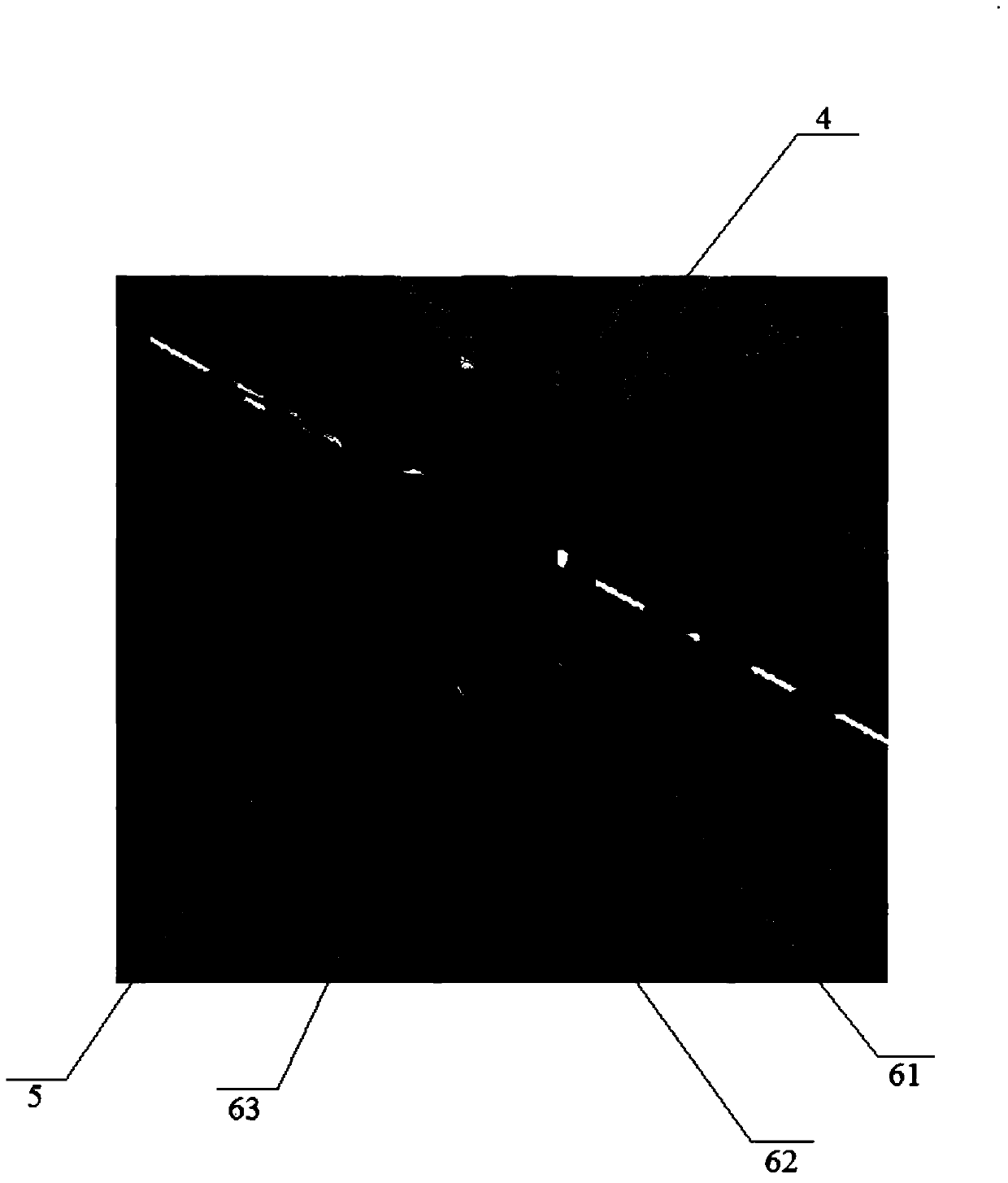

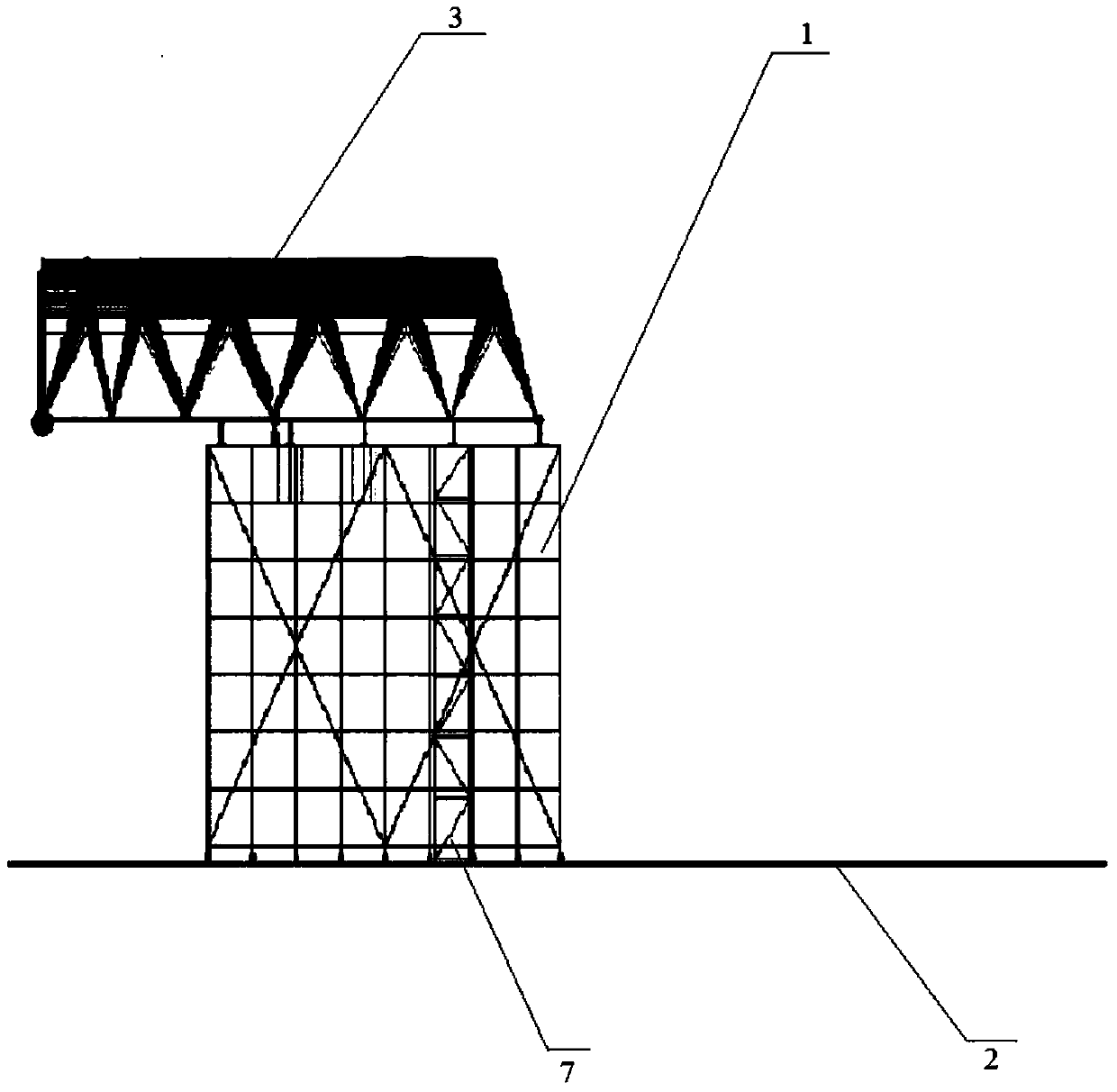

[0026] Example 1: A sliding scaffolding platform for installing a net frame, comprising a frame body 1 and a track 2, the bottom of each vertical bar 11 of the frame body 1 is provided with a roller 12, and the bottom of each column of the roller 12 is provided with a A track 2, the track 2 is fixed on the ground by a steel plate, the frame body 1 moves longitudinally along the track 2, and the bottom of the vertical bar 11 between the two tracks 2 is provided with a temporary strut 13, so Temporary fixed baffles 14 are provided on both sides of the rollers 12 at the four corners of the frame body 1 to keep the platform from sliding during the installation of the grid frame. The longitudinal width of the frame body 1 is slightly larger than that of the grid frame 3. distance, the height of the frame body 1 is slightly lower than the position of the lower string ball 4 of the grid frame, and the top of the frame body 1 is encrypted and laid with planks 5;

[0027] The plank 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com