Method for producing propylene maximally with C5 olefin as main raw material

A raw material, propylene technology, used in ethylene production, bulk chemical production, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

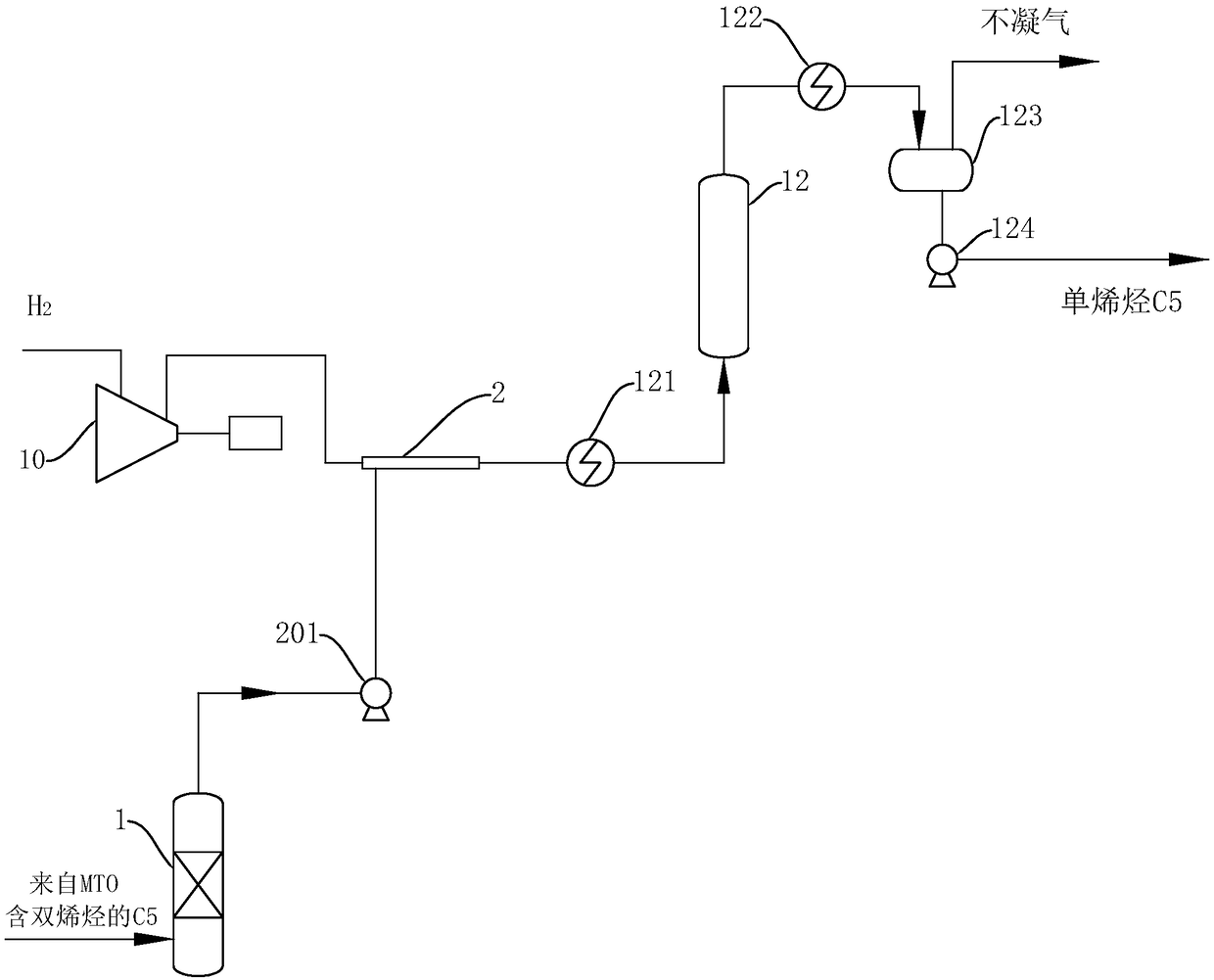

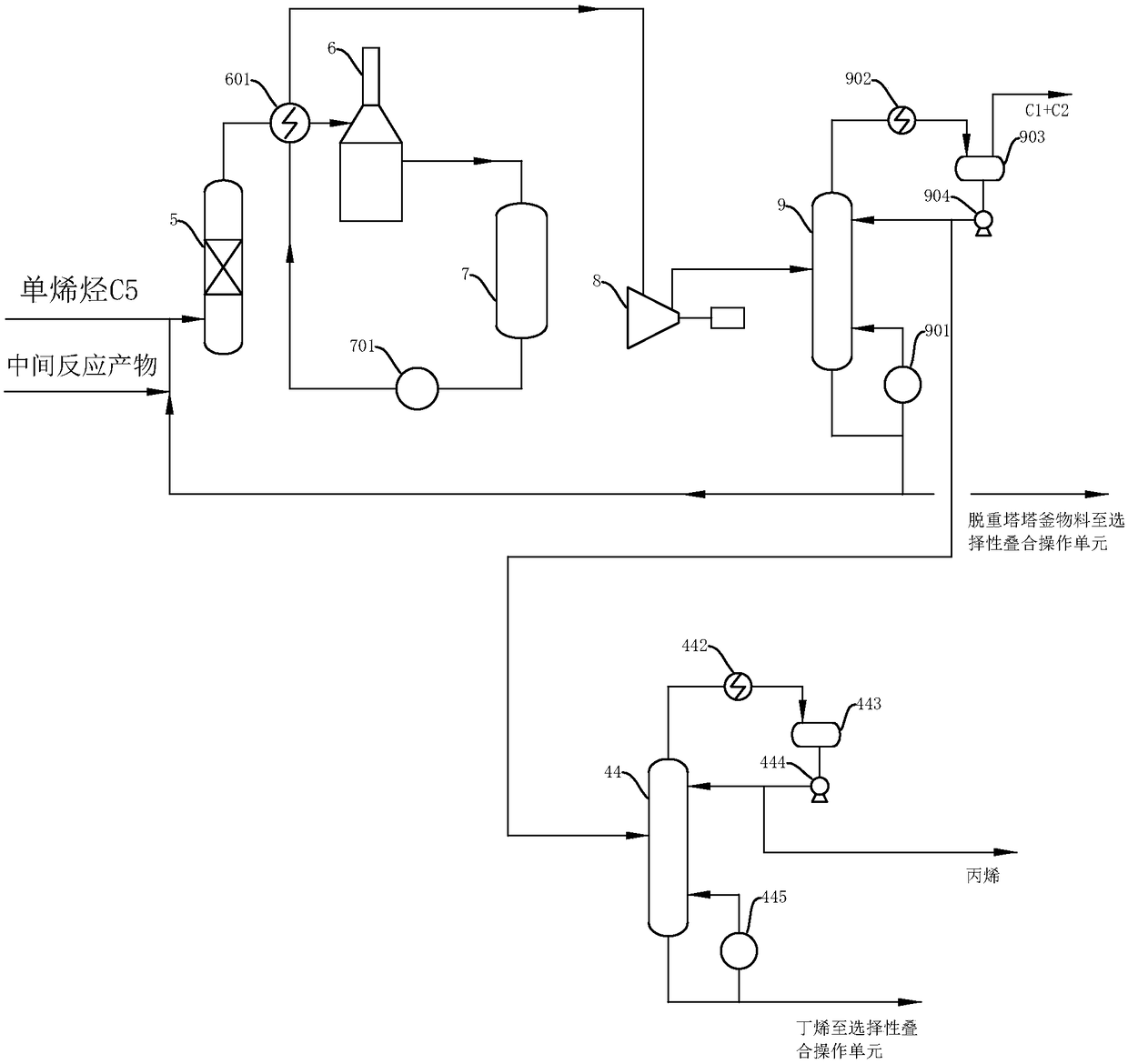

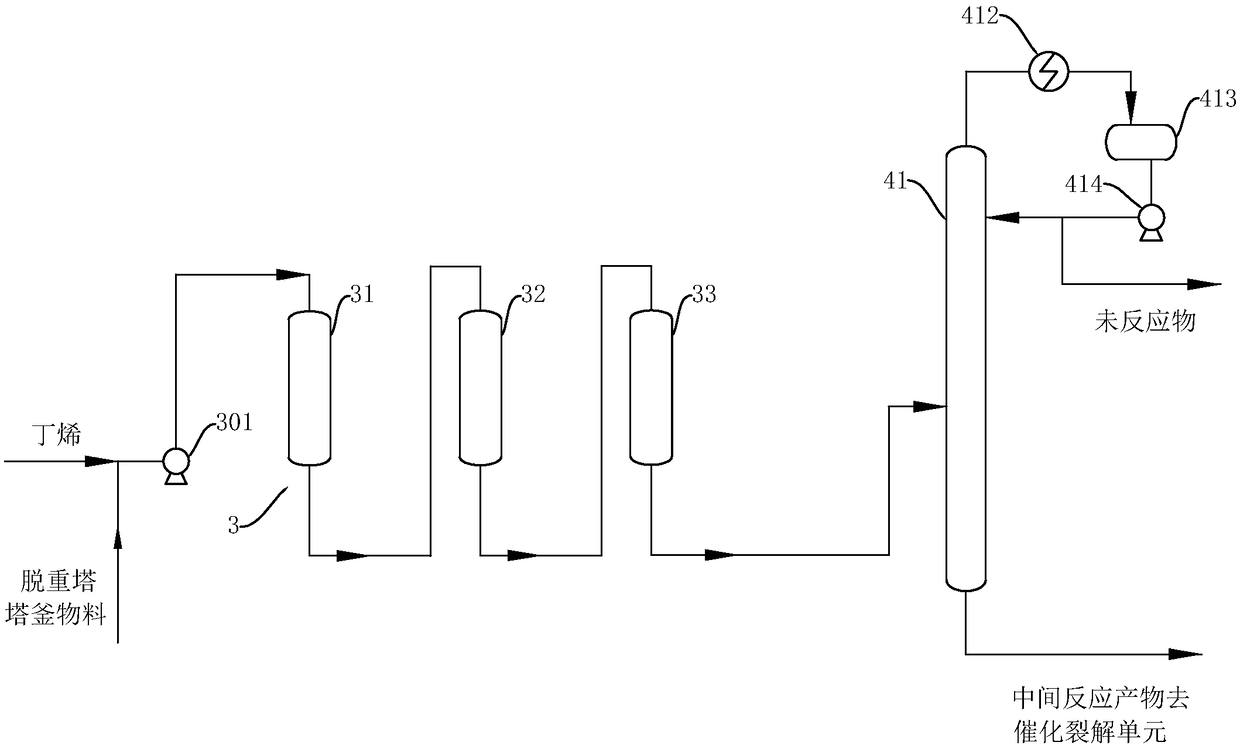

[0055] Such as Figure 1 to Figure 3 Shown, a kind of method based on C5 olefin-based raw material to maximize the production of propylene, comprising the following steps:

[0056] S1 pretreatment unit operation: pass the C5 raw material from MTO containing diolefins into the purifier 1 for adsorption operation to remove impurities such as oxygen-containing compounds in the raw material. The adsorbent filled in the purifier 1 is 3A molecular sieve Adsorbent;

[0057] S2 Selective hydrogenation unit operation: The purified C5 raw material is transported to the mixer 2 by the raw material pump 201 and mixed with the hydrogen compressed by the hydrogen compressor 10, and the above mixture is preheated in the hydrogenation preheater 121 Pass into the hydrogenation reactor 12 to carry out the selective hydrogenation reaction of the C5 raw material. After the obtained monoolefin C5 material is cooled by the hydrogenation cooler 122, gas-liquid separation is carried out in the hydro...

Embodiment 2

[0063] Such as Figure 4 As shown, the method for maximizing the production of propylene with C5 olefins as the main raw material in this example is basically similar to that of Example 1, the main difference being that 30m% of the intermediate reaction product obtained at the bottom of the rectifying tower 41 in the step S5 is returned to The inlet to the multistage prereactor 3 is again subjected to selective superposition reaction.

[0064] The catalyst loaded in the catalytic cracking reactor 7 is MCM22 and MCM41 molecular sieve composite catalyst, the reaction temperature of the selective hydrogenation reaction is 100°C, the reaction pressure is 1.8MPa, and the space velocity is 20h -1 ; The reaction temperature of the selective superposition reaction is 60°C, the reaction pressure is 1.2MPa, and the space velocity is 1.2h -1 The temperature at the top of the rectifying tower 41 is 50°C, the temperature at the bottom of the tower is 210°C, and the pressure at the top of ...

Embodiment 3

[0067] Such as Figure 5 As shown, the method of maximizing the production of propylene with C5 olefins as the main raw material in this example is basically similar to that of Example 2, the main difference being that the materials at the outlet of the tower bottom of the first pre-reactor 31 are transported by the first circulation pump 311 Return to the tower top of the first prereactor 31 after the cooling of the first superimposed cooler 312, and the tower bottom outlet part material of the second prereactor 32 is transported by the second circulation pump 321 and the second superimposed cooler 322 and return to the top of the second prereactor 32 after being cooled, and part of the material at the outlet of the tower bottom of the third prereactor 33 is transported by the third circulating pump 331 and cooled by the third stacked cooler 332 and then returned to the third The top of the pre-reactor 33.

[0068] The catalyst loaded in the catalytic cracking reactor 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com