Vertical wall and gigh-slope afforestation method and aggregate container, shelf assembly and water supply device used thereto

A water supply device, vertical wall technology, applied in the field of water supply devices, aggregate containers, highly inclined surfaces or various types of vertical walls, frame components, can solve the problem of no obvious difference in the soil part and poor adhesion of aggregates , It is difficult to form permeable parts and other problems, to achieve the effect of preventing vegetation soil from falling, good greening conditions, and preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

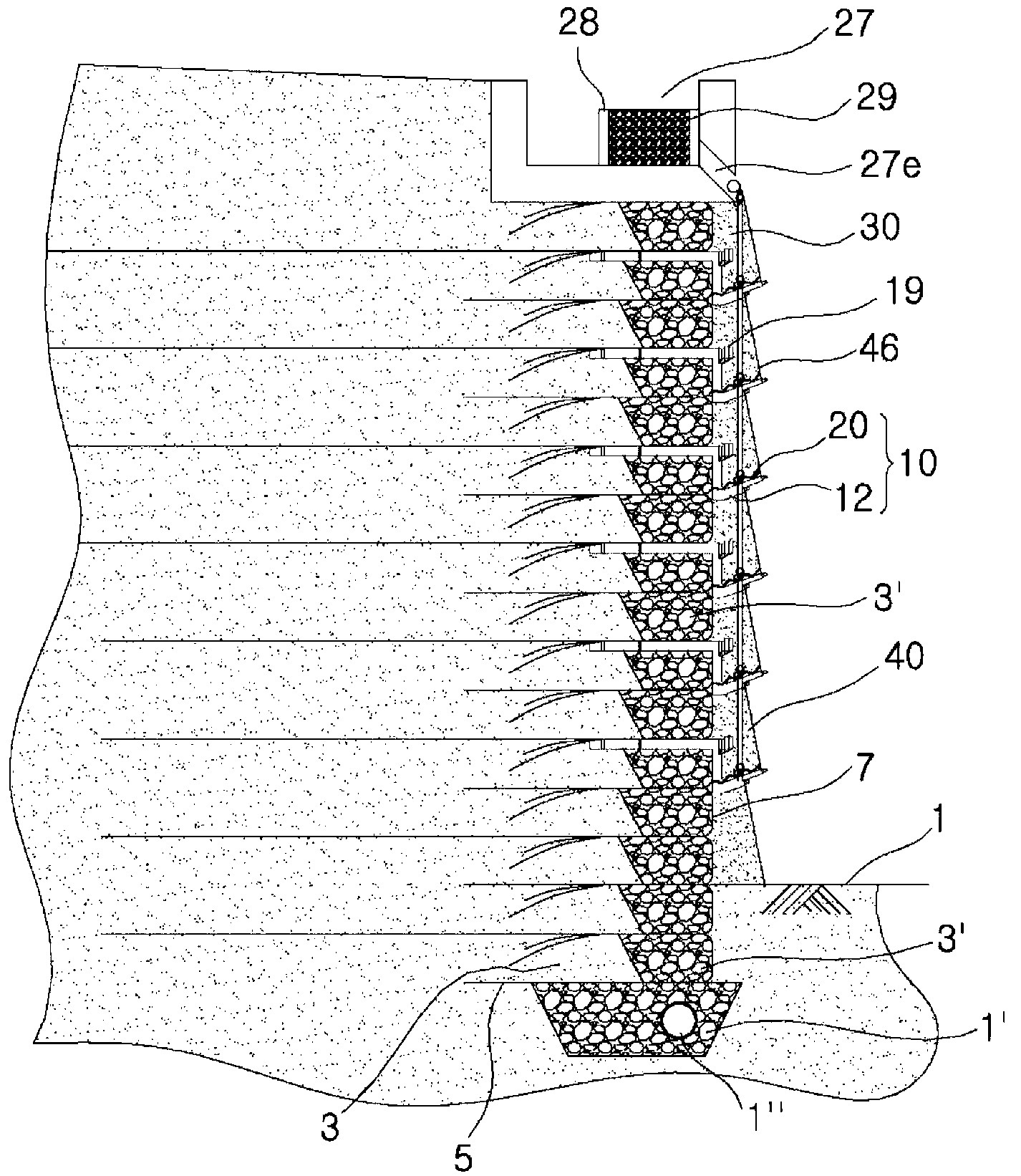

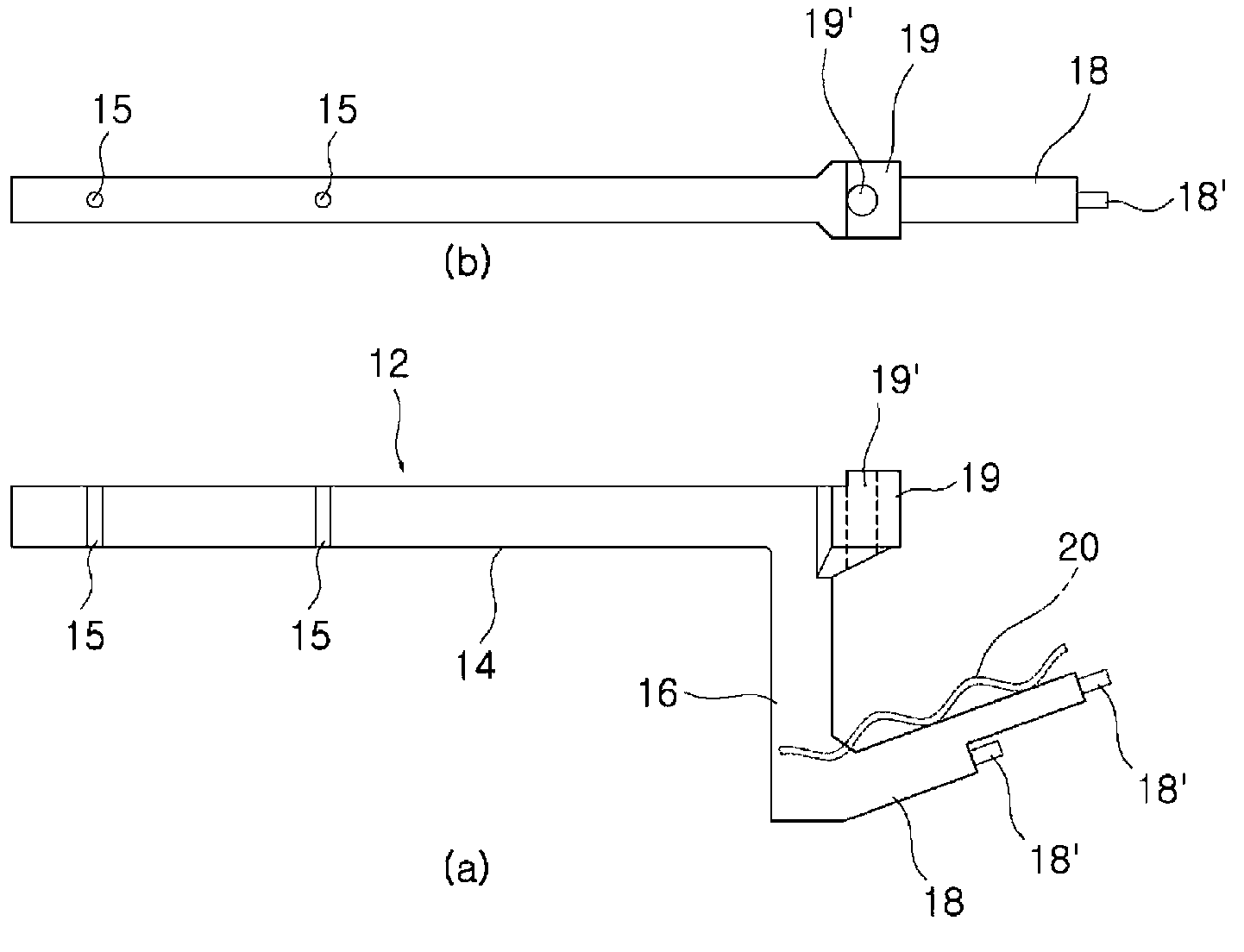

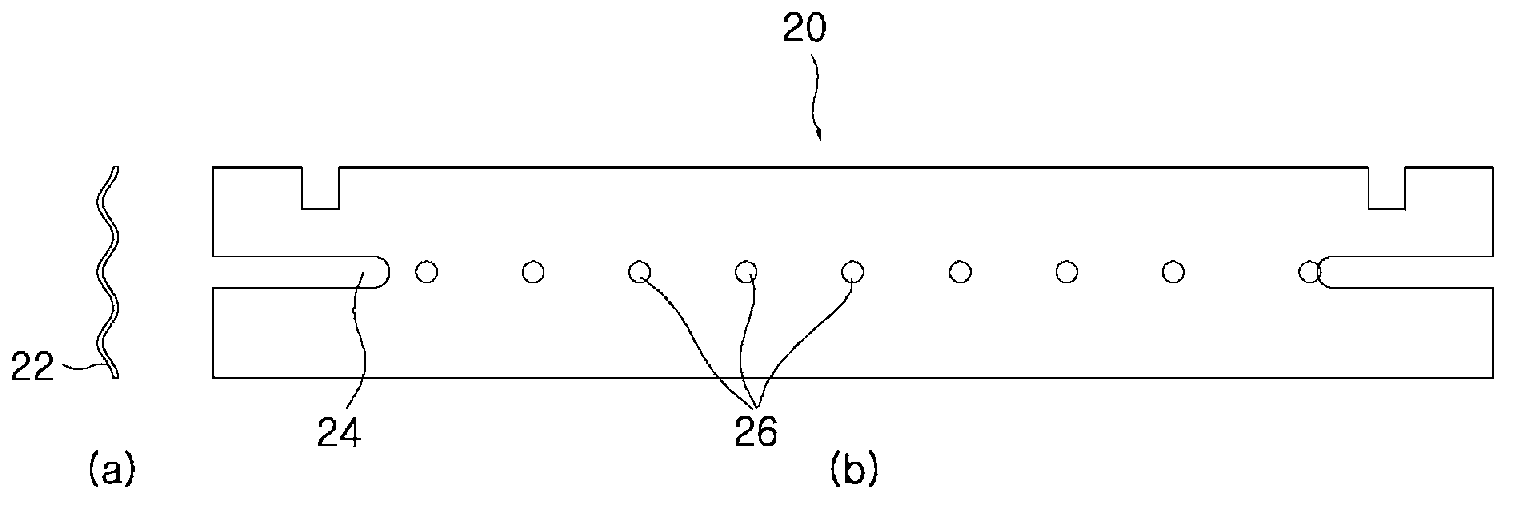

[0057] Hereinafter, a method of greening on a vertical wall and a highly inclined surface, a rack assembly and a water supply device therefor according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0058] As shown in the accompanying drawings, a crushed stone foundation 1' is usually formed on the ground 1, and a reinforced soil layer 3 of predetermined thickness is continuously formed on the crushed stone foundation 1', so that the front end of the reinforced soil layer 3 constitutes a vertical wall 7 or sloped surfaces. For reference, a gravel foundation 1' is formed at a position corresponding to the front end of each reinforced soil layer 3. As shown in FIG. The permeable part 3' is formed at the front end of each reinforced soil layer 3 and corresponds to the gravel foundation 1'. The permeable part 3' is made of the same material as the gravel foundation 1', such as gravel, to facilitate drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com