Pillow inner with loofah sponge functional modules and pillow with pillow inner

A functional module and loofah technology, applied in the field of bedding, can solve the problems of poor air permeability, poor permeability, easy breeding of mites and bacteria, etc., and achieve the effect of ensuring dryness and comfort and improving hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

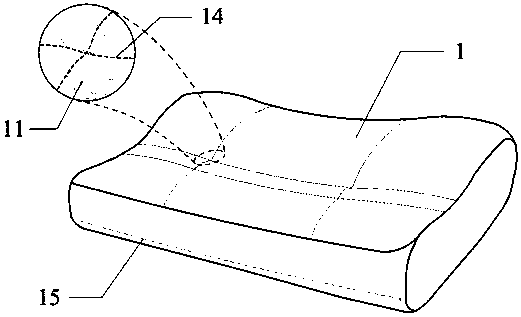

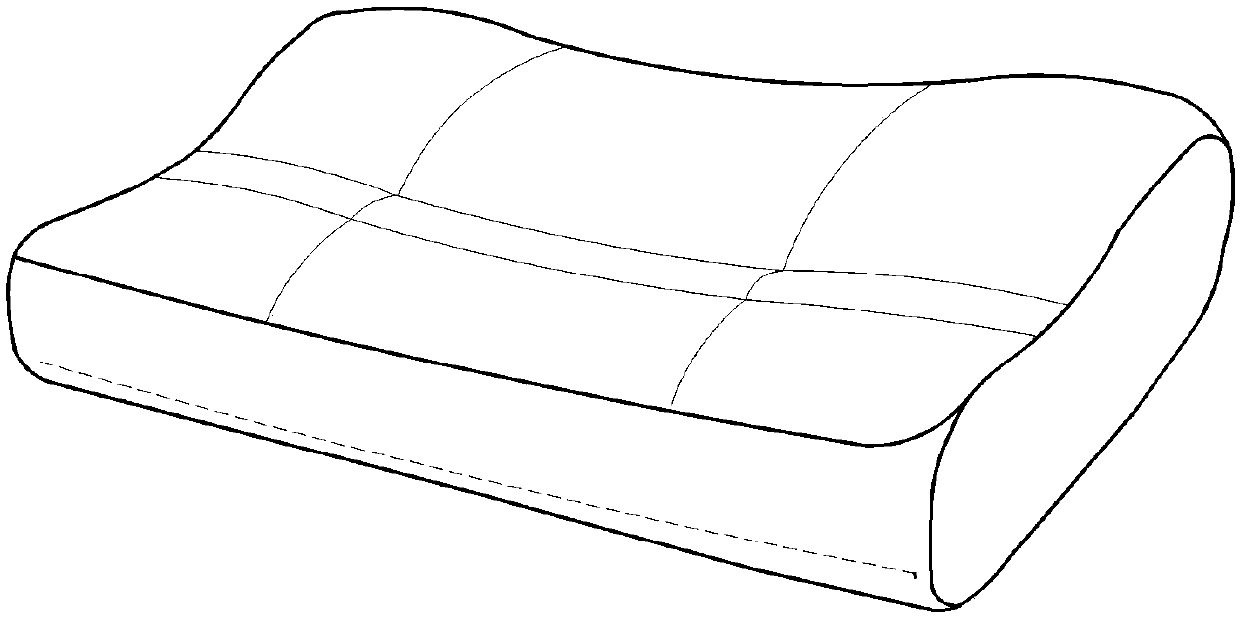

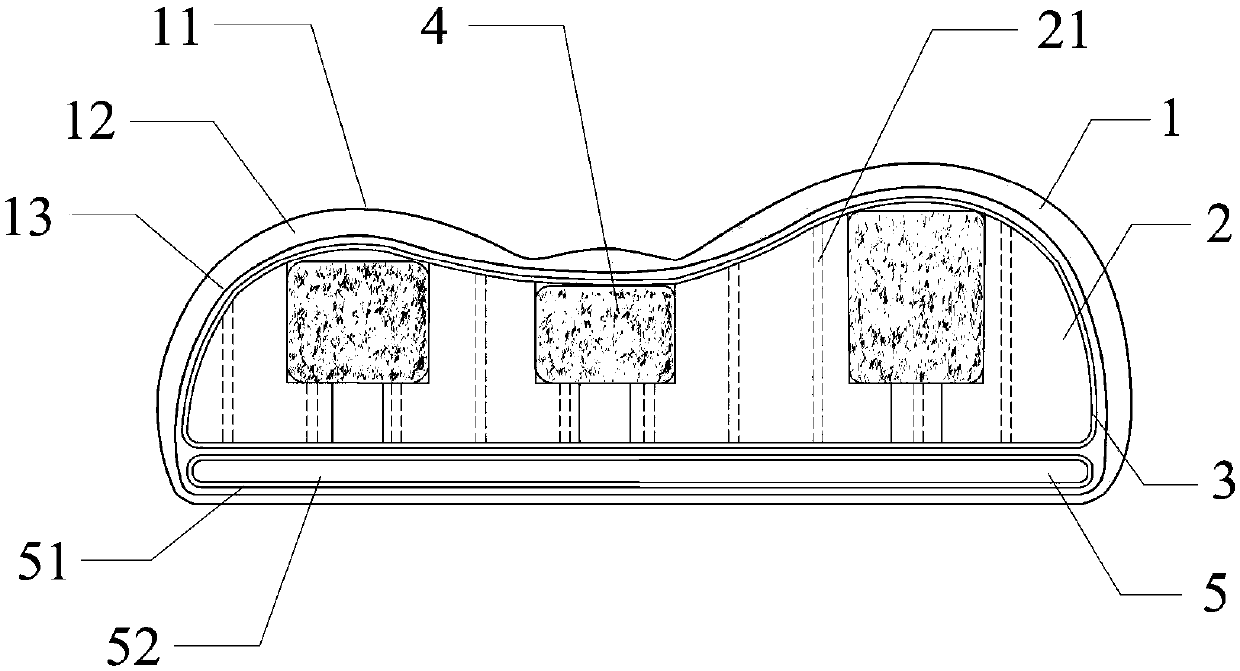

[0049] Referring to the accompanying drawings, the loofah functional module pillow in this embodiment includes a pillow body 2, and counterbores 22 are arranged on the pillow body 2, and a melon functional module 4 is placed in the counterbore 22, wherein the loofah functional module 4 consists of Cylindrical outer coat fabric 41 and inner filling loofah 42 are formed. The upper surface of the loofah functional module placed in the counterbore 22 is preferably slightly lower than the upper surface of the deep hole. The inner filling loofah is preferably loofah velvet or loofah tendon block. The upper surface of the pillow body has a B-shaped streamline shape, and the radian of the streamline is 45° from the horizontal, and one end is 3-5cm higher than the other end; the lower surface of the pillow body is horizontal.

[0050] In this embodiment, the pillow body is made of latex or memory foam, and there are through air holes 21 distributed on the pillow body; if the pillow bo...

Embodiment 2

[0055] A loofah functional modular pillow, comprising a pillow core 2 and an outer pillow case 1 for accommodating the pillow core. The pillow core is the loofah functional modular pillow core described in Embodiment 1.

[0056] Wherein, the upper surface of the outer pillowcase is made of inner and outer fabrics 11 and 13 to form a double-layer structure, and the lower surface is a single-layer fabric structure. The loofah filling material 12 is filled between the inner and outer fabrics 11 and 13; Stitches are evenly spaced and spaced.

[0057] The pillow in this embodiment also includes a number of height adjustment modules 5, which are located at the bottom of the pillow core and are accommodated together with the pillow core in the outer pillow case.

[0058] Wherein, the height adjustment module 5 includes fabrics and loofah filling materials. The loofah filling material of the height adjustment module is a composite material obtained by mixing loofah fiber velvet and l...

Embodiment 3

[0064] Embodiment 3 high-density loofah preparation and softening method

[0065] The loofah velvet in the embodiment of the present invention 1-2, the loofah tendon block raw material are all high-density loofah (density range is 31-65Kg / m 3 ). Studies have shown that high-density loofah (density range of 31-65Kg / m 3 ) fibroblasts have more abundant methylene groups, relatively low crystallinity of cellulose, and low content of fibroblast parenchyma, all of which indicate that loofah fibrous cells are soft and have good resilience. But because the diameter of high-density loofah fiber bundle is larger, the wall layer is thicker, and the hardness of high-density loofah fiber bundle is larger. Therefore, it must be softened through softening treatment to make the fiber bundles loose, so that the characteristics of the loofah fiber cells can be fully exerted and the loofah becomes soft and comfortable.

[0066] The present invention is to high-density loofah (density scope is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com