Weft knitting machine

A flat knitting machine and needle bed technology, applied in the field of flat knitting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments applicable to the present invention will be described in detail with reference to the following drawings.

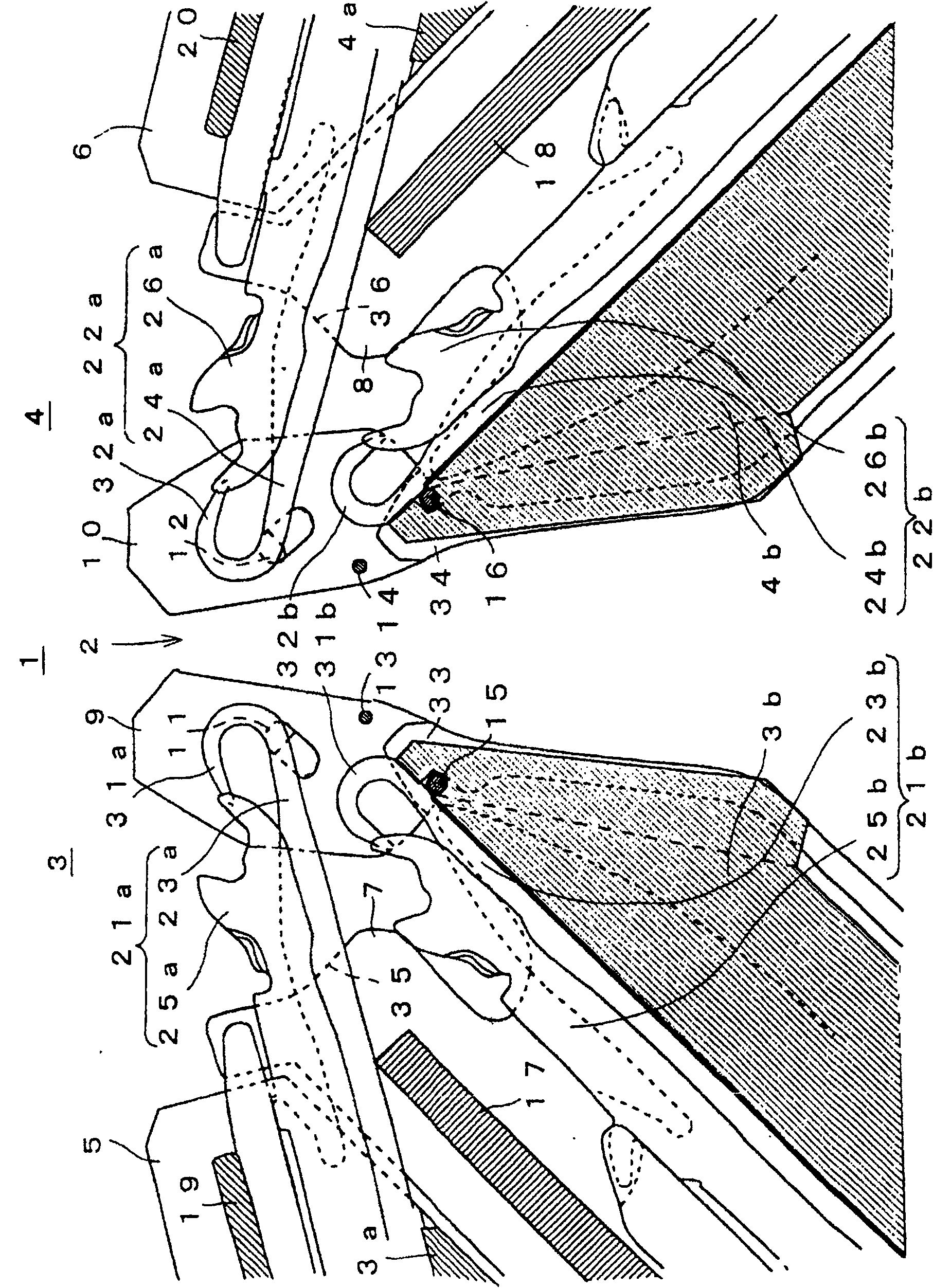

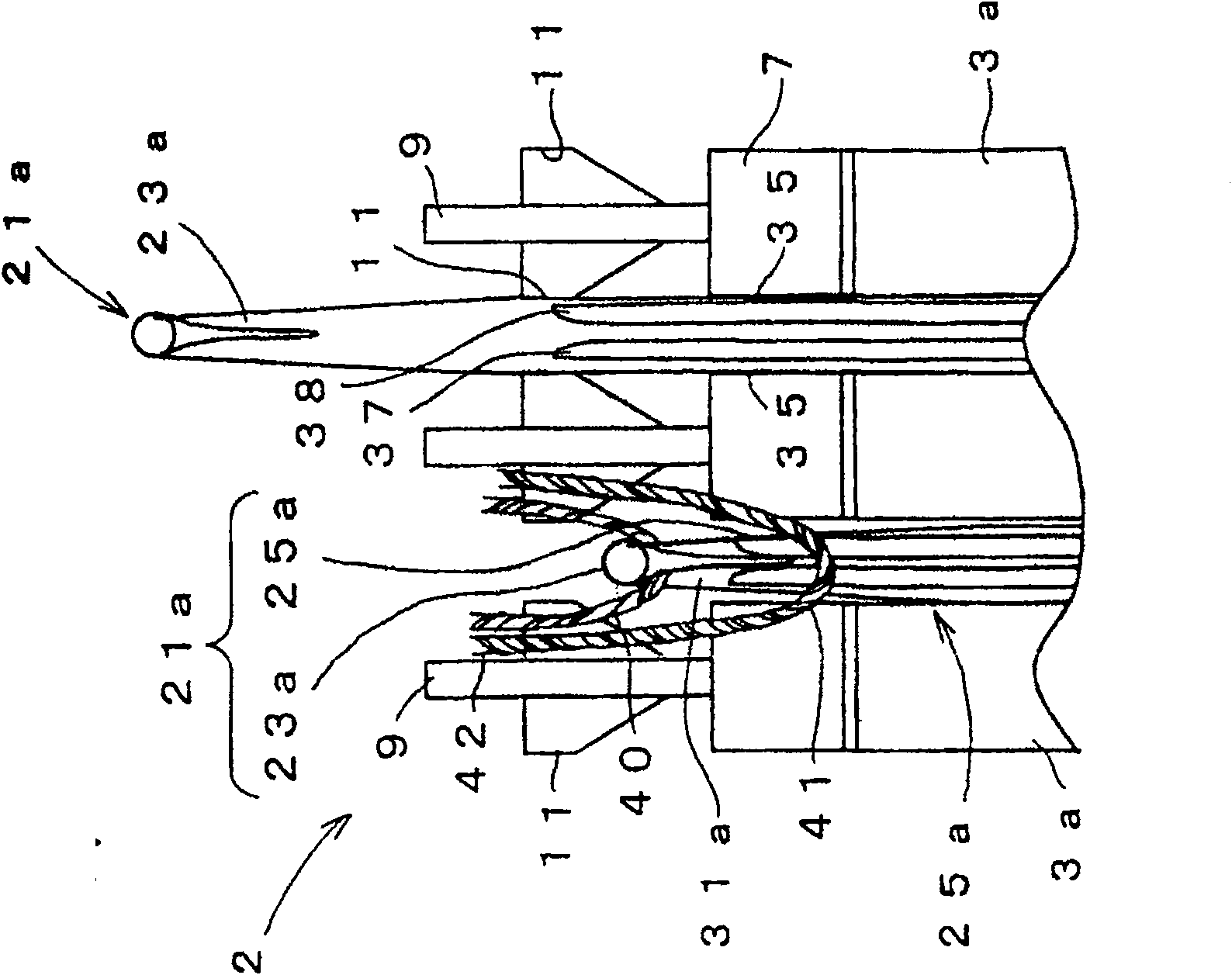

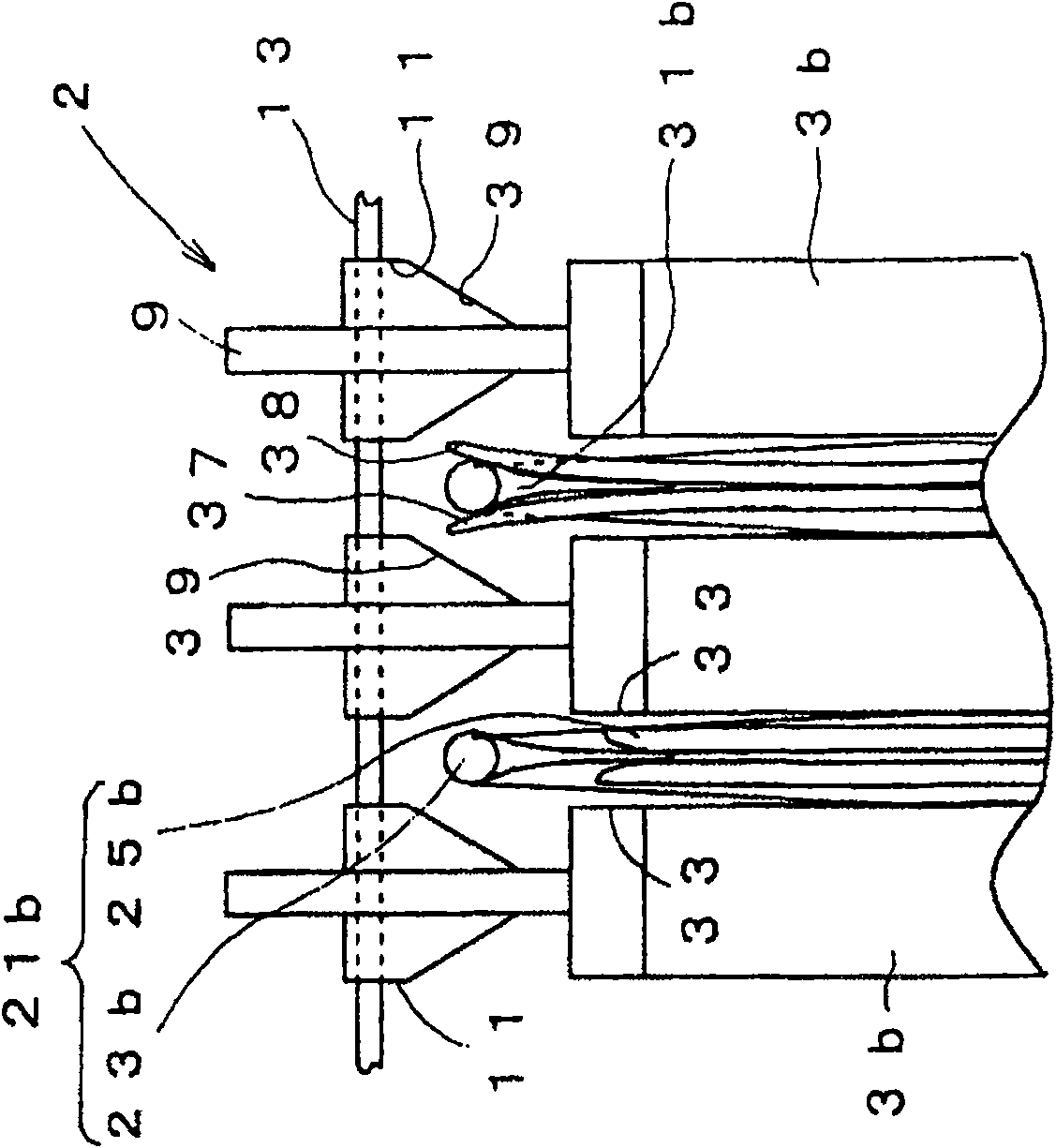

[0025] figure 1 A schematic configuration of a four-needle bed flat knitting machine 1 according to an embodiment of the present invention is shown in a cross section near the needle bed 2 . In the four-needle-bed flat knitting machine 1, the front needle beds 3 and the rear needle beds 4 facing each other across the needle bed 2 have upper needle beds 3a, 4a and lower needle beds 3b, 4b, respectively. In addition, in the following description, the front side is shown by the odd-numbered serial number, and the rear side is shown by the even-numbered serial number about the structural part which is paired front and back across the tooth gap 2. As shown in FIG. For components that are the same up and down, a is added to the upper layer side and b is added to the lower layer side, but a and b may be omitted when collectively referring to them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com