3D printing auxiliary method and device and 3D printing equipment

A 3D printing and auxiliary device technology, applied in the field of devices, 3D printing equipment, and 3D printing auxiliary methods, can solve the problems of consuming printing materials, affecting the appearance of final molded objects, and printing support structures occupying printing time, so as to achieve uniform support and save energy. Printing materials and printing time, the effect of improving the quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

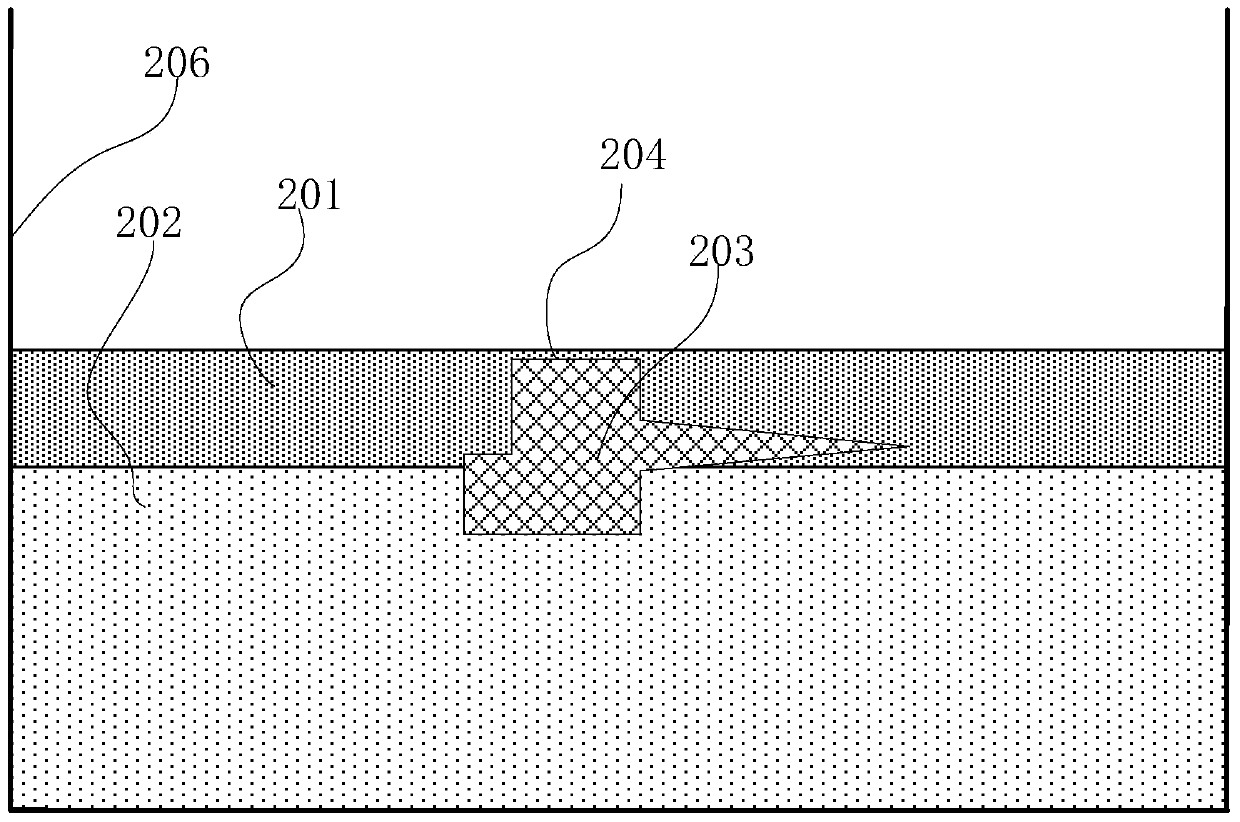

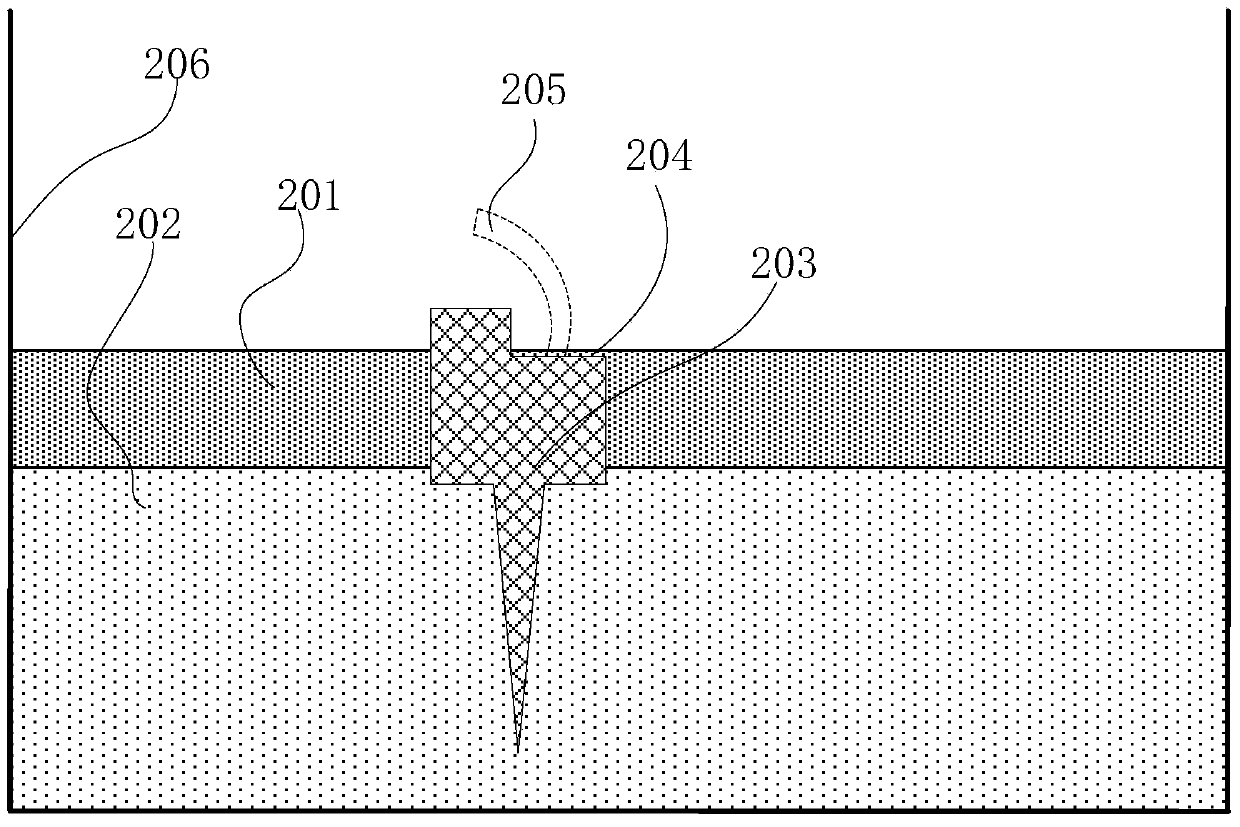

[0017] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings (the same symbols in several drawings represent the same elements) and embodiments. The following examples are used to illustrate the present application, but not to limit the scope of the present application.

[0018] Those skilled in the art can understand that terms such as "first" and "second" in this application are only used to distinguish different steps, devices or modules, etc., and neither represent any specific technical meaning, nor represent the inevitable relationship between them. logical order.

[0019] The inventors of the present application have found that various problems will be encountered during the 3D printing process, for example, the newly printed part may be slightly deformed under the action of gravity due to incomplete curing; In the case of partial support, the support structure needs to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com