Patents

Literature

1226results about How to "Guaranteed support effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

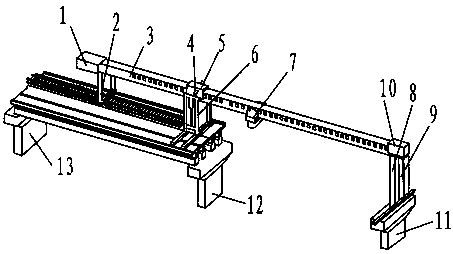

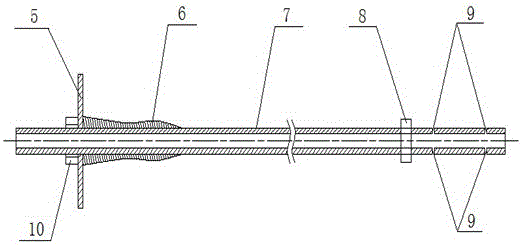

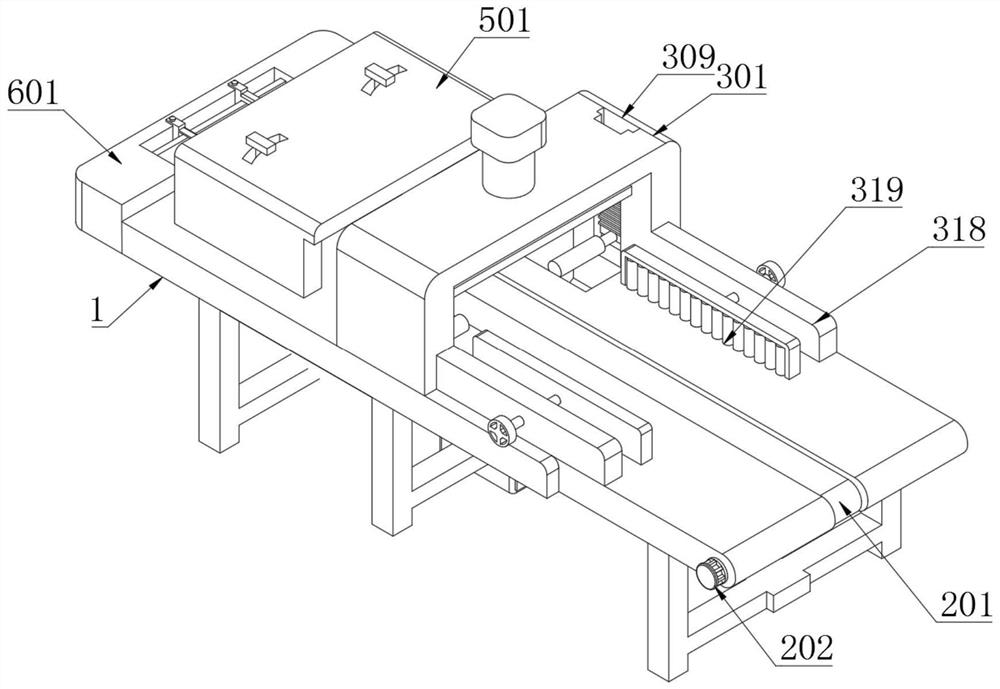

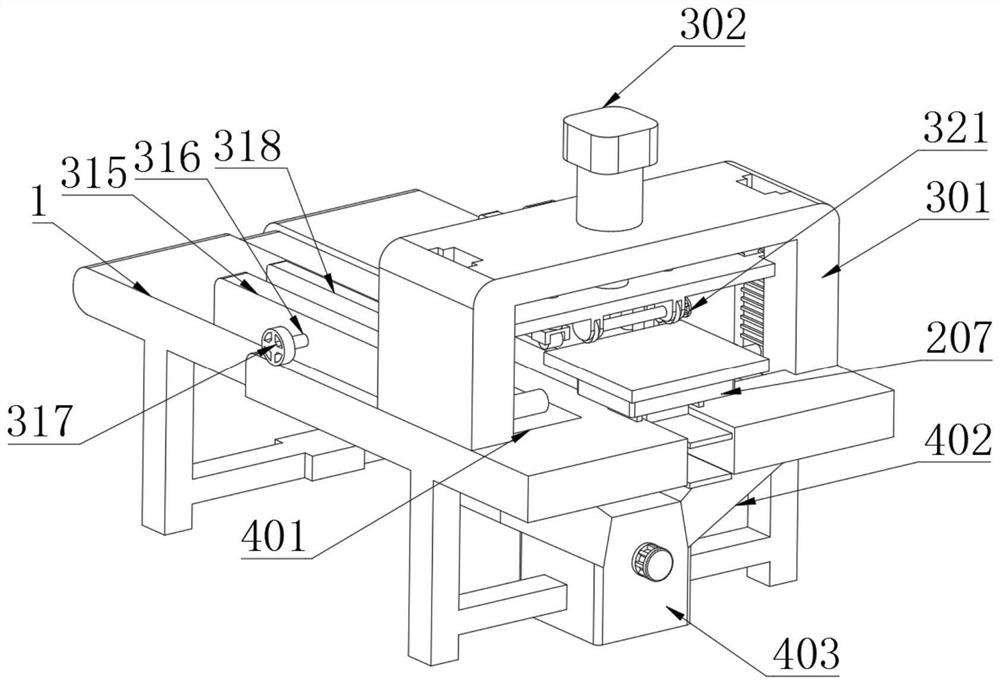

Full-automatic pipe cutting machine

ActiveCN102814547ARealize automatic controlPrecise deliveryMetal sawing devicesCircular sawEngineering

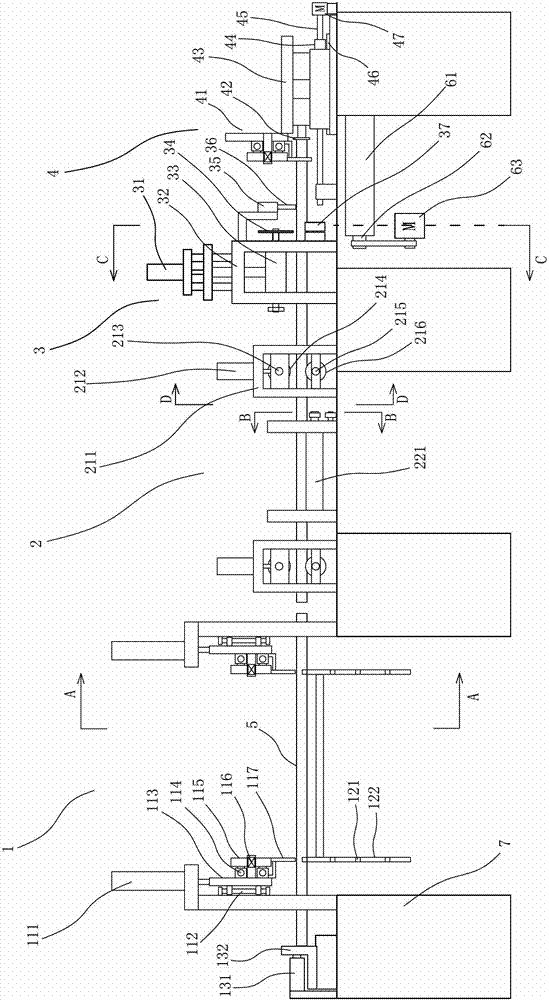

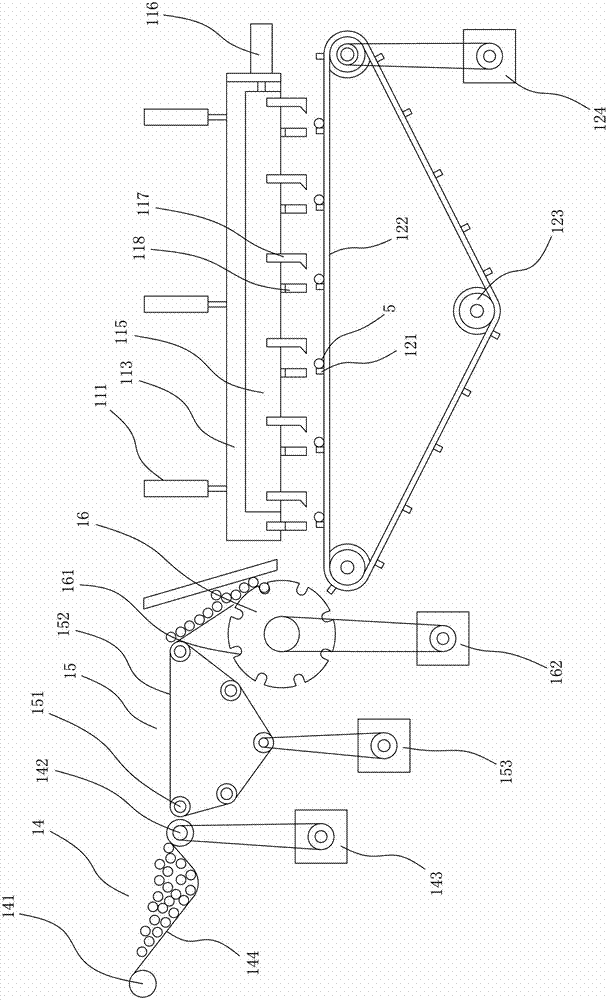

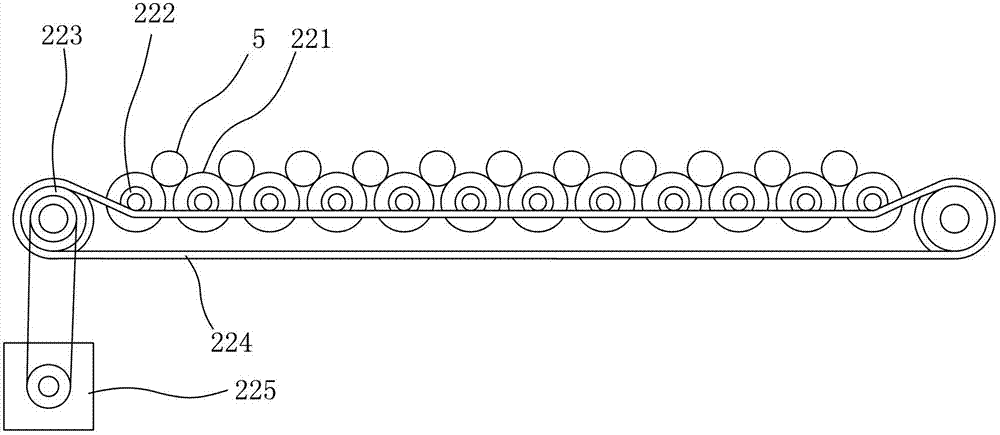

The invention provides a full-automatic pipe cutting machine comprising a frame, and a charging device, a feeding device, a cutting device, a measuring device and a control device which are sequentially arranged on the frame horizontally; the cutting device comprises a cutter holder which is arranged on the frame, a plurality of first motors which are lined horizontally along a longitudinal direction and can be arranged on the cutter holder by moving up and down, a first cylinder which is connected with and drives each first motor to move up and down synchronously, a circular saw blade which is arranged on the output shaft of each first motor, a second motor which is in transmission connection with the input shaft of each first motor through a first transmission mechanism, and a bearing piece which is arranged on the tool rest below each circular saw blade and is used for bearing a pipe at a cut part; and the measuring device comprises a guide rail which is horizontally arranged on the frame, a slide frame which is movably arranged on the guide rail, a driving mechanism which is connected with and drives the slide frame to move along the guide rail, a pipe baffle which is arranged on the slide frame and a first pipe clamping mechanism which is horizontally arranged on the slide frame along the longitudinal direction. According to the full-automatic pipe cutting machine, more than one pipe can be cut at one time, and the machine has the advantages of high cutting efficiency, good cutting quality and the like.

Owner:冠达星股份有限公司

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

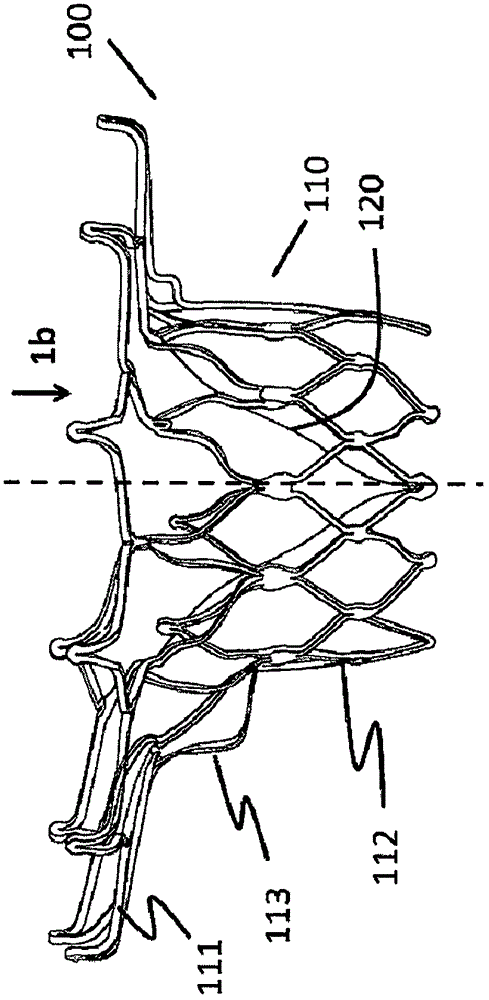

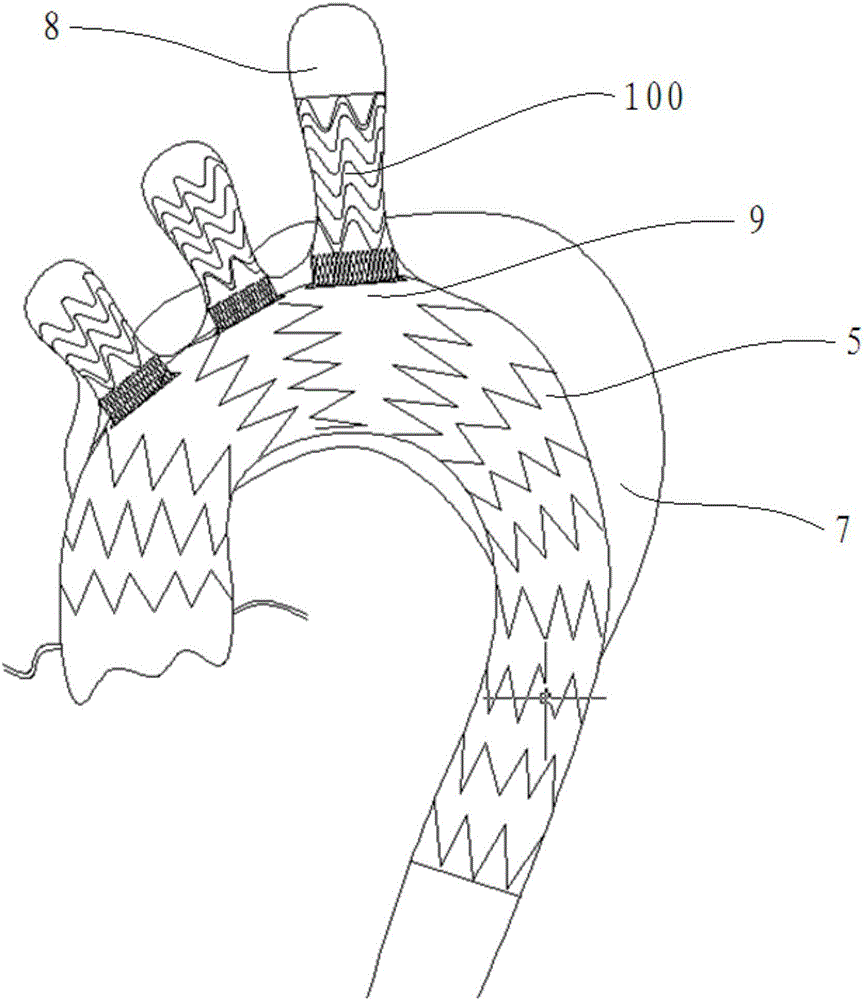

Anti-coagulation stainless steel coronary arterial bracket and uses thereof

ActiveCN101385669AAvoid postoperative restenosisGood biological compatibilityStentsProsthesisMedicineWhole body

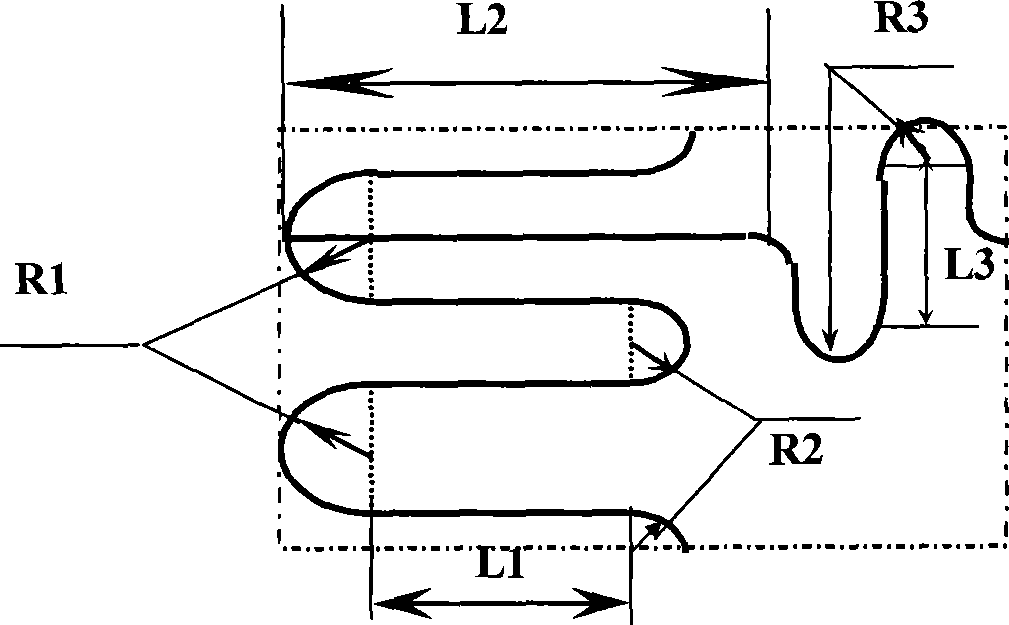

The invention relates to a medical apparatus, in particular to an anticoagulant stainless steel coronary support which is made from a high-nitrogen nickel-free austenitic stainless steel material with good blood compatibility. The support is of tubular structure with a mesh surface which is formed by orderly arranging a unit figure on the side surface of a tube along the circumference and axial direction, the primary supporting function is provided by U-shaped corrugated mesh wires extending along the axial direction, the corrugated mesh wires are connected into a whole body by soft mesh wires arranged at intervals, and the diameter of the mesh wire (width or thickness) is 40-100mum; and the surface of the support is passivated and coated with a medication. The anticoagulant stainless steel support has the advantages of good mechanical properties, good flexibility and good anticoagulant property, and can be used as a support for cardiovascular and cerebrovascular systems or a support for other cavity bodies.

Owner:ZHONGKE YIAN MEDICAL TECH BEIJING CO LTD

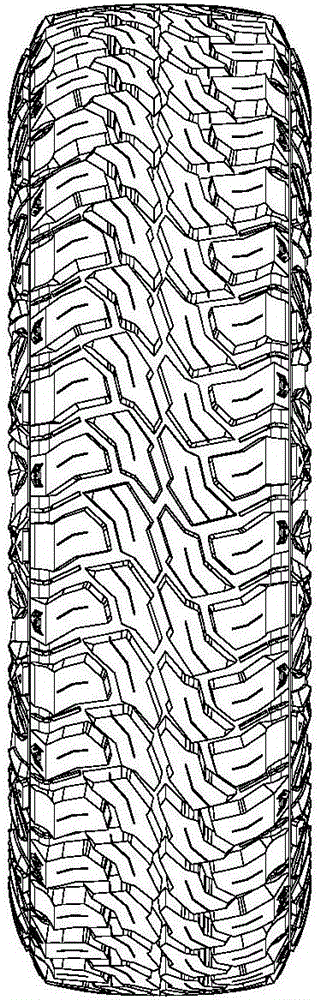

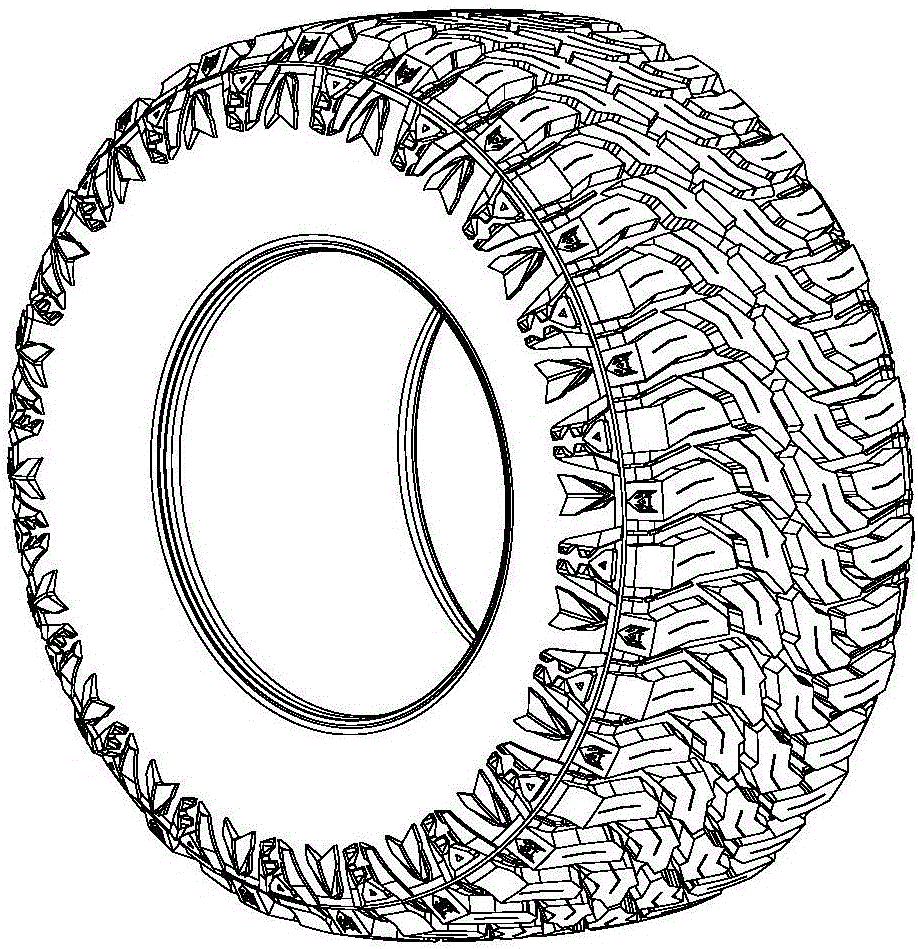

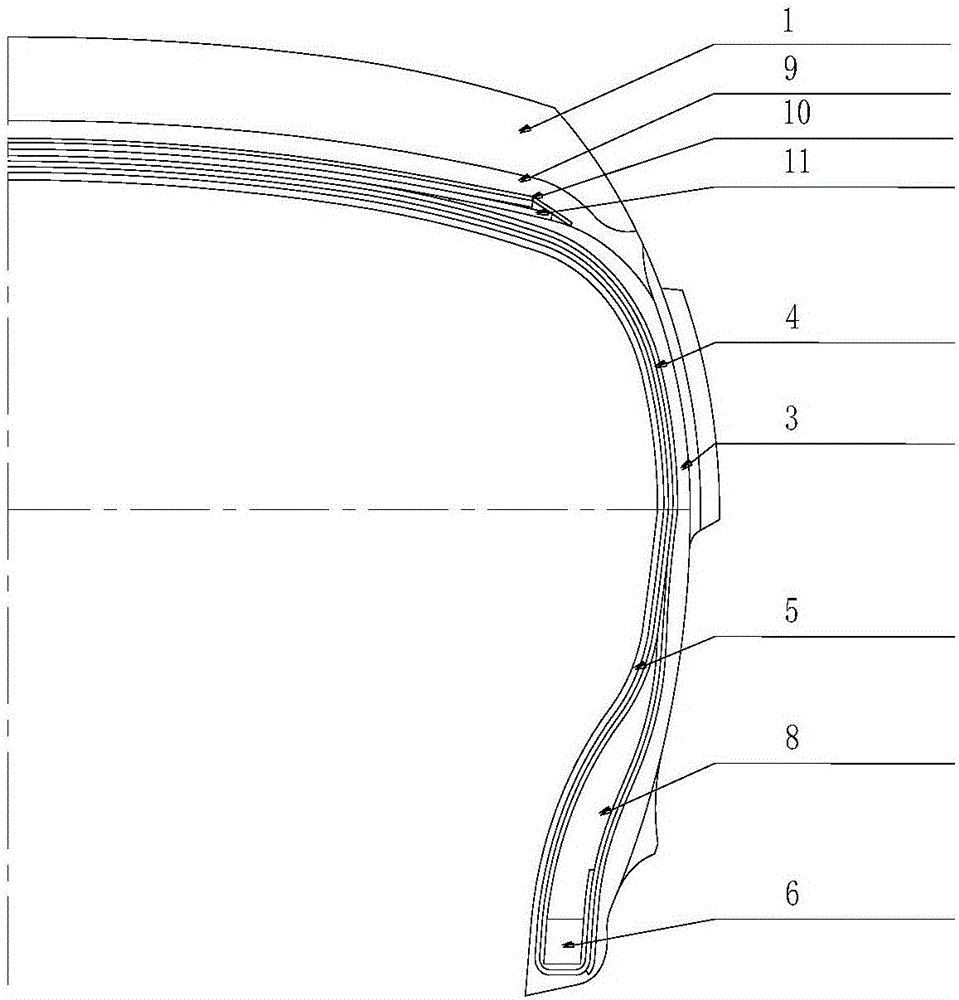

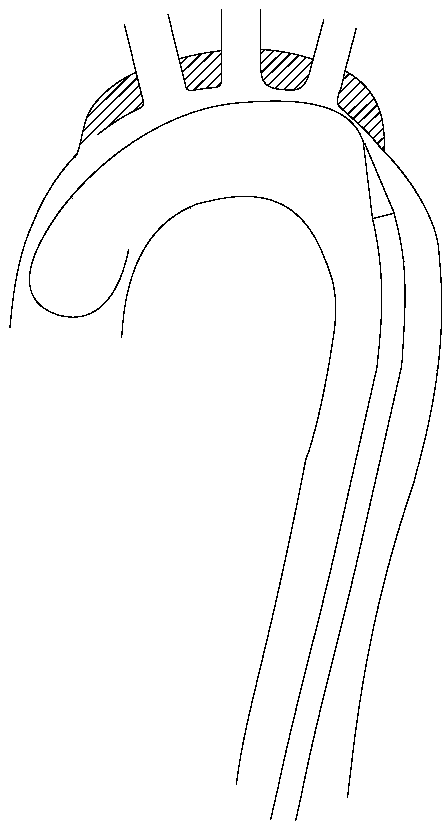

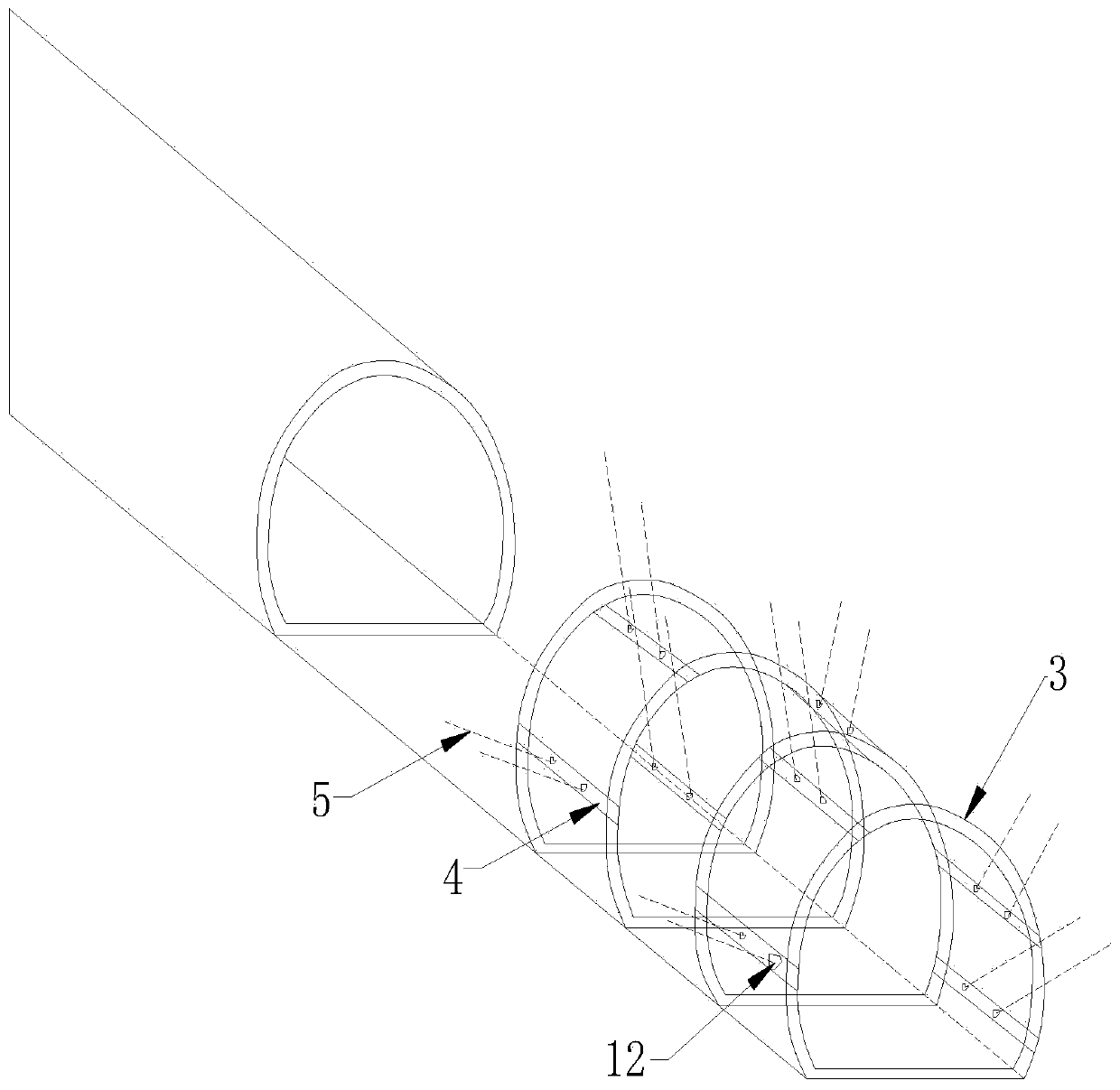

All-steel mud-field tire

InactiveCN106394128AHigh strengthImprove securityOff-road vehicle tyresPneumatic tyre reinforcementsUltimate tensile strengthTire iron

The invention provides a novel all-steel mud-field tire, and belongs to the field of tires. Through the adoption of the novel all-steel mud-field tire disclosed by the invention, improving tire strength is facilitated, impact resistance and durability of the tire are improved, and the service life of the tire is prolonged. A longitudinal section of the all-steel mud-field tire comprises a tire crown (1), a tire shoulder (2), a tire sidewall (3), a tire bead (6), and a tire body (4), wherein the tire crown (1) is located on the outer side of the upper part of the longitudinal section; the tire shoulder (2) is connected with the tire crown (1); the tire sidewall (3) is connected with the tire shoulder (2); the tire bead (6) connected with a wheel rim is arranged at the lower part of the tire sidewall (3); the tire body (4) is located on the inner side of the section of the tire; a tire shoulder pad (21) is arranged on the tire shoulder (2); a convex rib (31) is circumferentially and annularly arranged on the outer part of the tire sidewall (3); and the tire body (4) is a layer of all-steel tire body.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

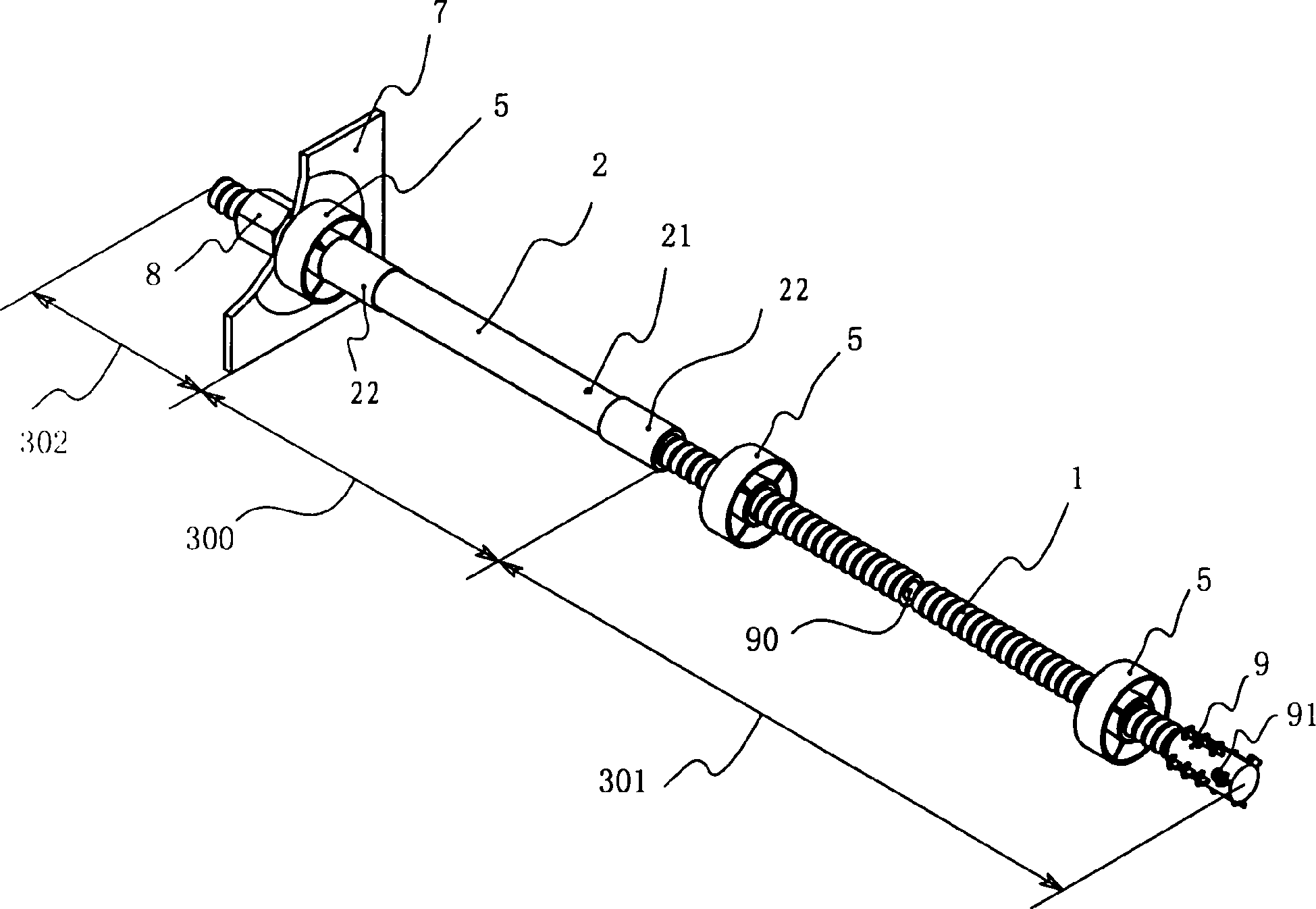

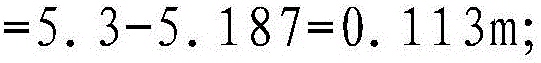

Prestress anchor device

ActiveCN1884716AGuaranteed support effectEasy to apply prestressBulkheads/pilesAnchoring boltsPre stressRebar

The invention relates to a coarse steel bar prestress anchor rod, which comprises: an anchor rod body, a support pad plate, a locking nut, a centering device, free section sleeve, and pouring discharge channel, wherein the anchor rod body is divided into outer anchor section, anchor fixing section and free section; the outer anchor section is formed by support pad plate, locking nut and one section f external anchor rod; the anchor rod of free section is sheathed with free section sleeve whose two end buckles fix the screw on the anchor rod body near one end of support pad plate, to rotate and move along tow end buckles on the anchor rod; its middle part is separated from anchor rod body to form separate chamber. The invention can be used in underground construction and rock anchor fixing, with simple process and low cost.

Owner:项小珍 +3

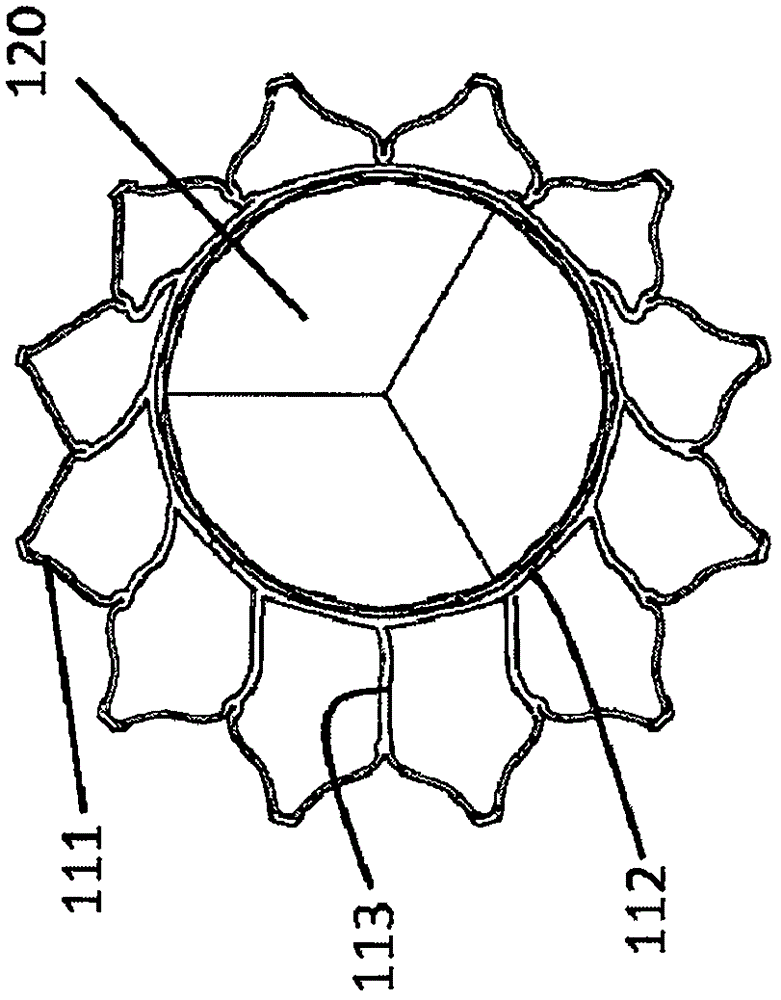

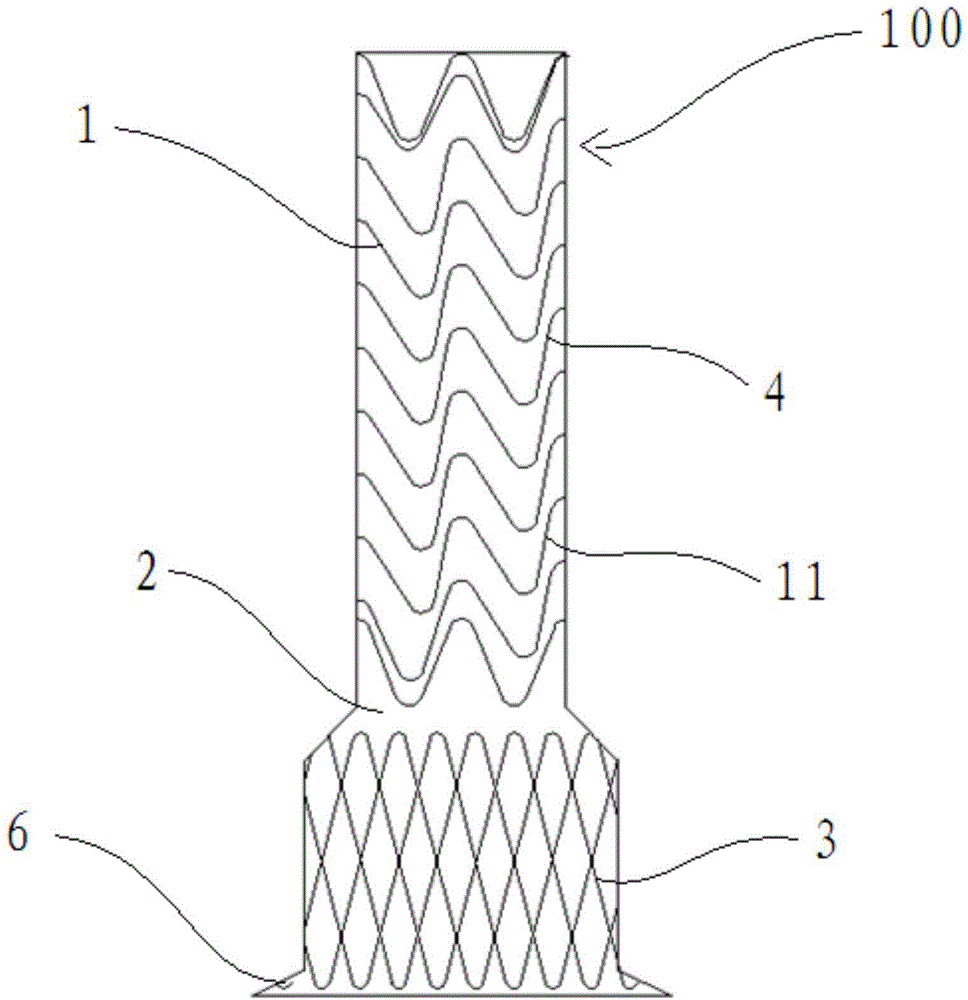

Heart valve prosthesis

ActiveCN106420114AReduced cross-sectional area requirementsImprove performanceAnnuloplasty ringsProsthetic valveFree state

The invention relates to a heart valve prosthesis. The heart valve prosthesis comprises a stent and artificial valves; the stent comprises an atrium section and a valve suturing section, the artificial valves are fixedly connected to the valve suturing section, a skeleton of the far end part of the valve suturing section extends to form a supporting section, and the supporting section and the valve suturing section are of an integrated structure; one end of the atrium section is connected with the far end of the supporting section, the other end of the atrium section is free and is located on the cross section perpendicular to the central axis of the artificial valves, the valve suturing section is located in the supporting section, the center of the valve suturing section does not coincide with that of the supporting section, the cross section area of the supporting section is larger than that of the valve suturing section, the cross section area of the atrium section is larger than that of the supporting section, the cross section area of the valve suturing section is smaller than that of valve rings of autologous valves of a patient, and in a free state, at least part of the supporting section is located among the valve rings of the autologous valves of the patient.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

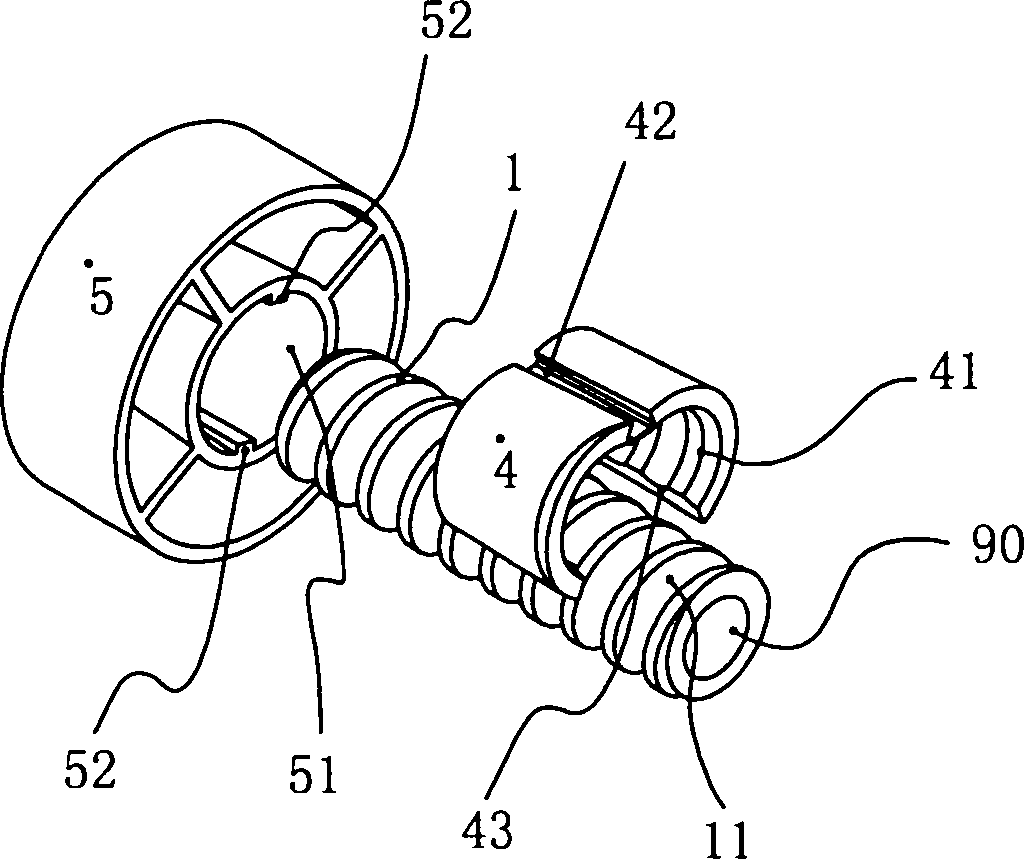

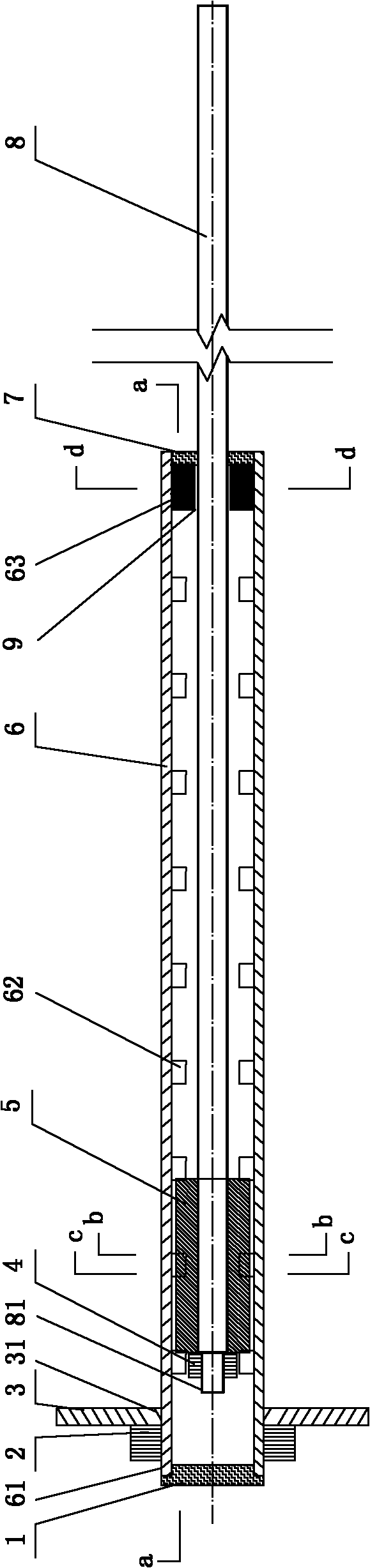

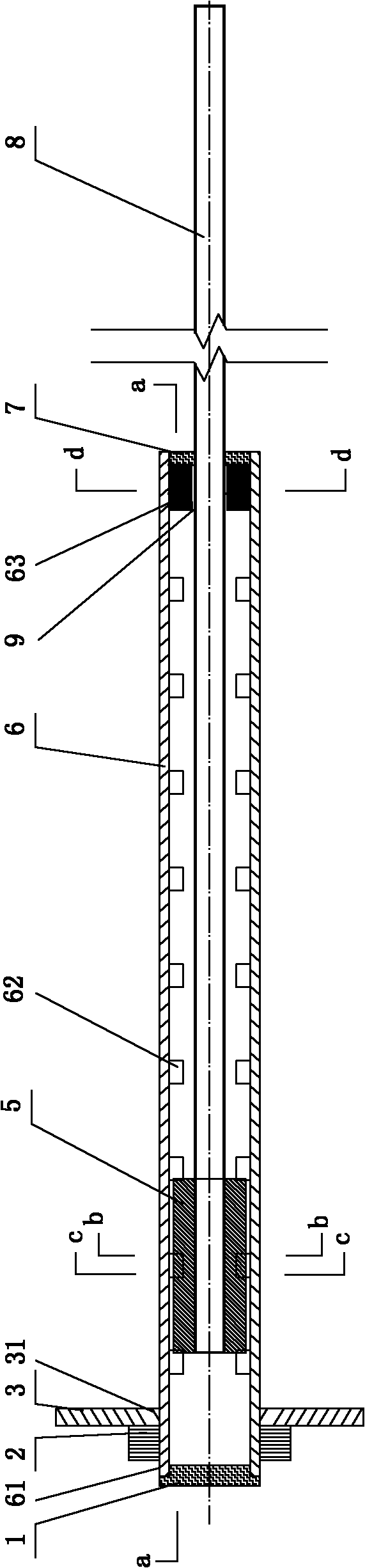

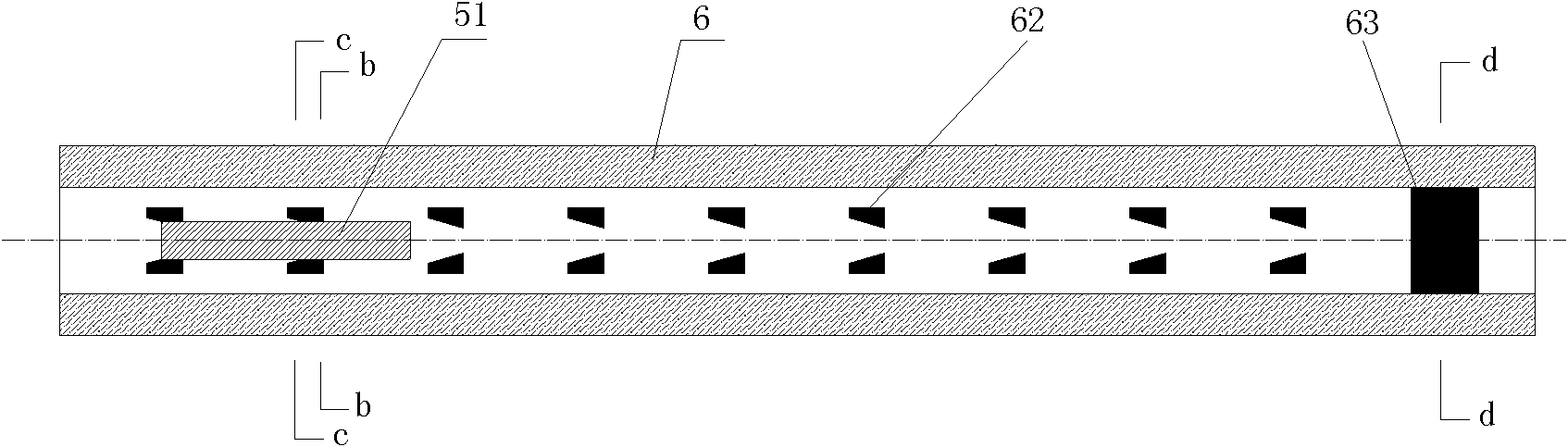

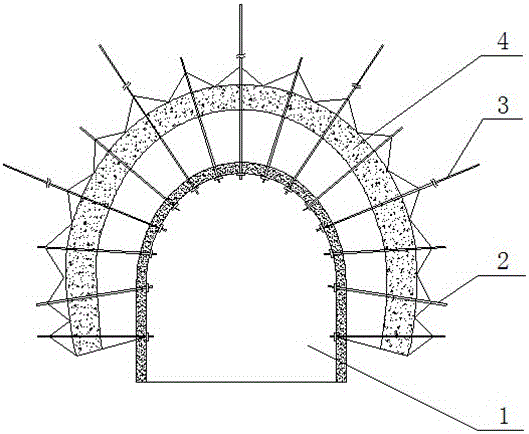

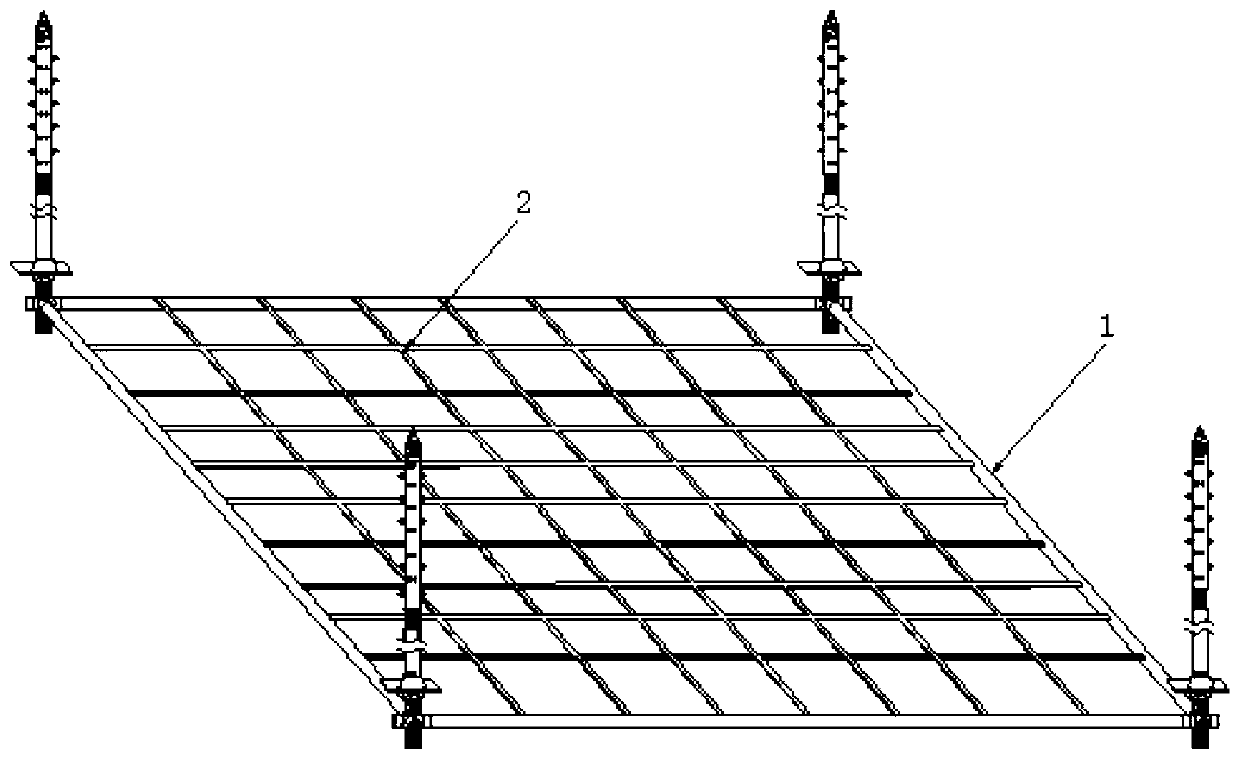

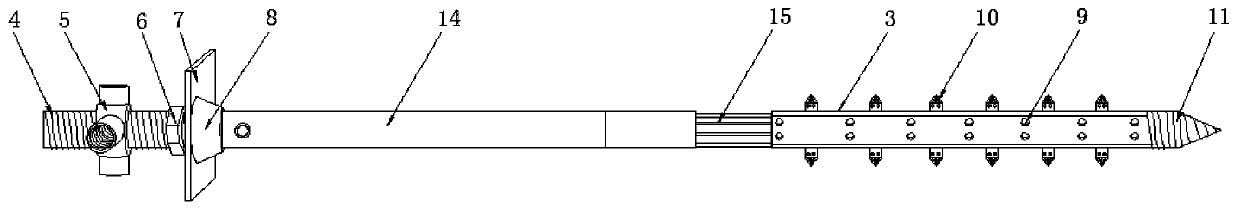

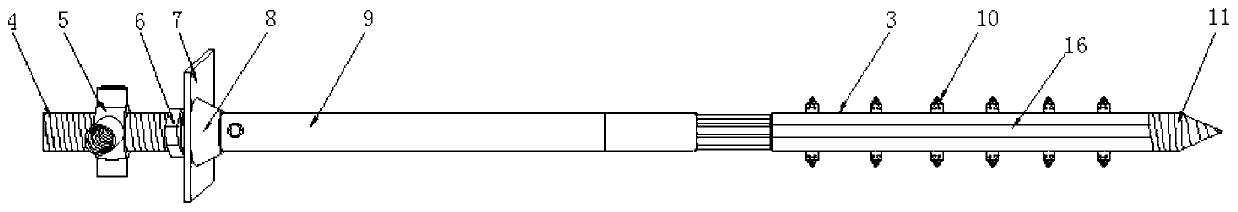

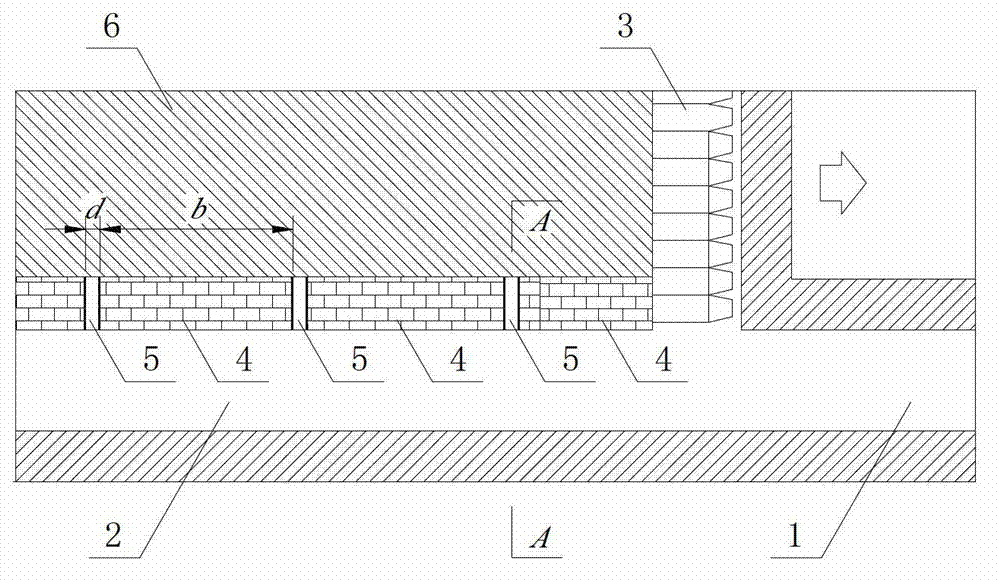

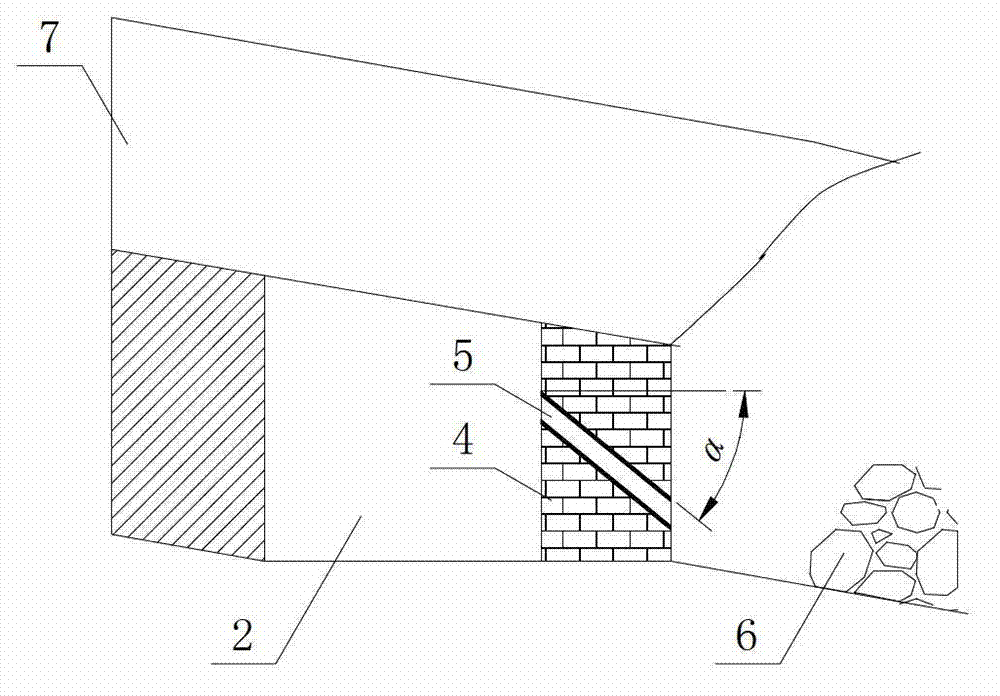

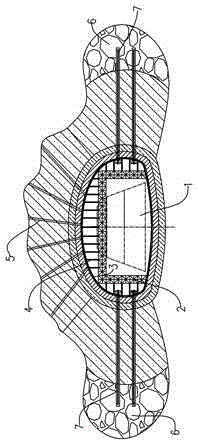

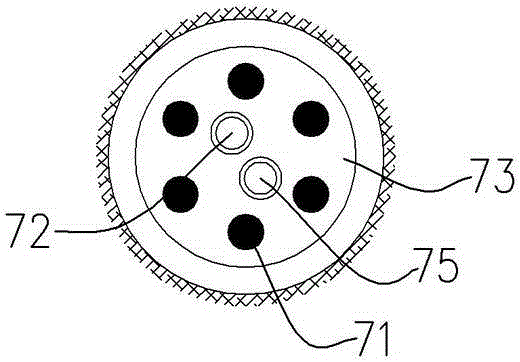

Cone resistive friction sleeve large-deformation anchor rod

The invention belongs to the field of geotechnical engineering anchoring, and relates to a supporting structure of a large-deformation rock-soil body, in particular relates to an anchor rod. The anchor rod comprises an external nut (2), a base plate (3), a cone-type-tooth friction body (5), a friction sleeve (6) and a rod body (8), and is characterized in that the inner wall of the friction sleeve (6) is provided with a plurality of sleeve friction grooves (62) along a longitudinal direction; and the cone-type-tooth friction body (5) is arranged on the rod body (8). The anchor rod provided bythe invention has the beneficial effects that large deformation of surrounding rock can be automatically adapted so as to automatically extend, and simultaneously the deformation energy of the surrounding rock can be absorbed in the deforming process, thus ensuring the supporting effects of the supporting structure.

Owner:UNIV OF SCI & TECH BEIJING

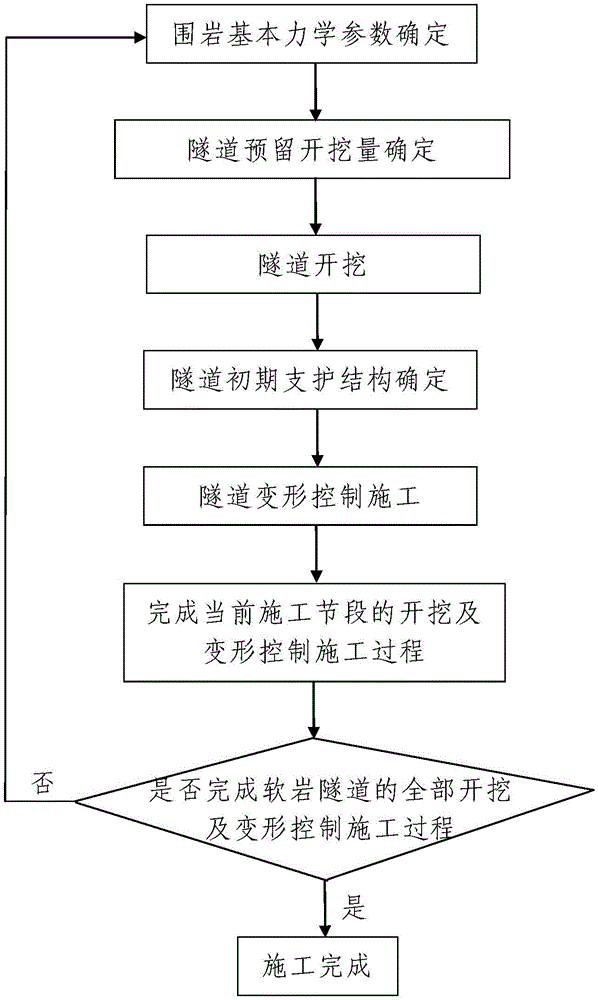

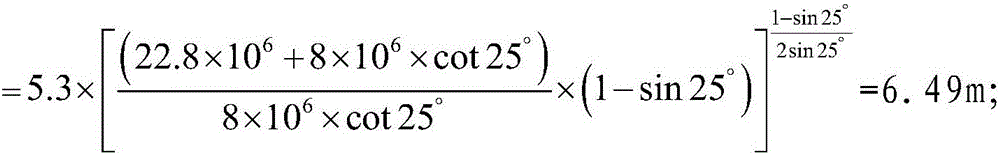

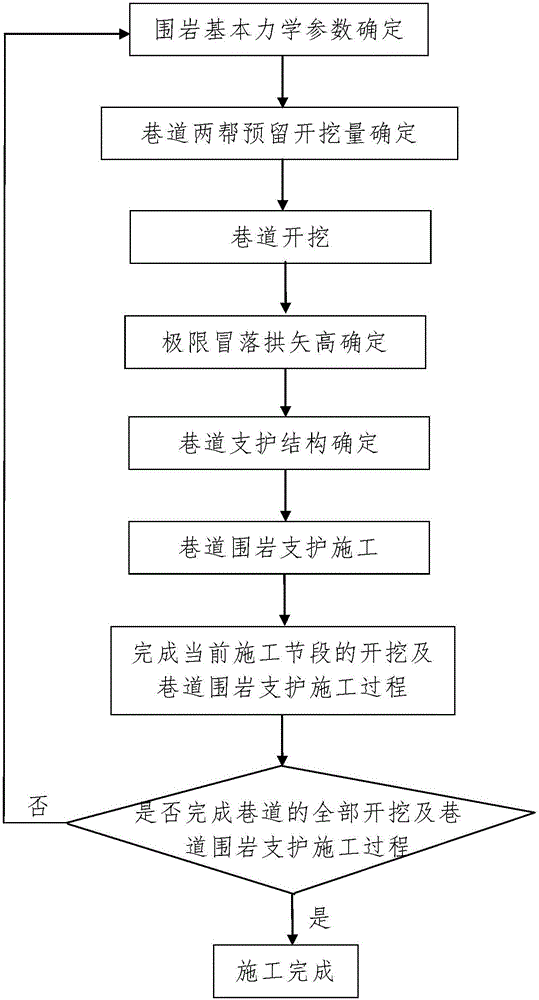

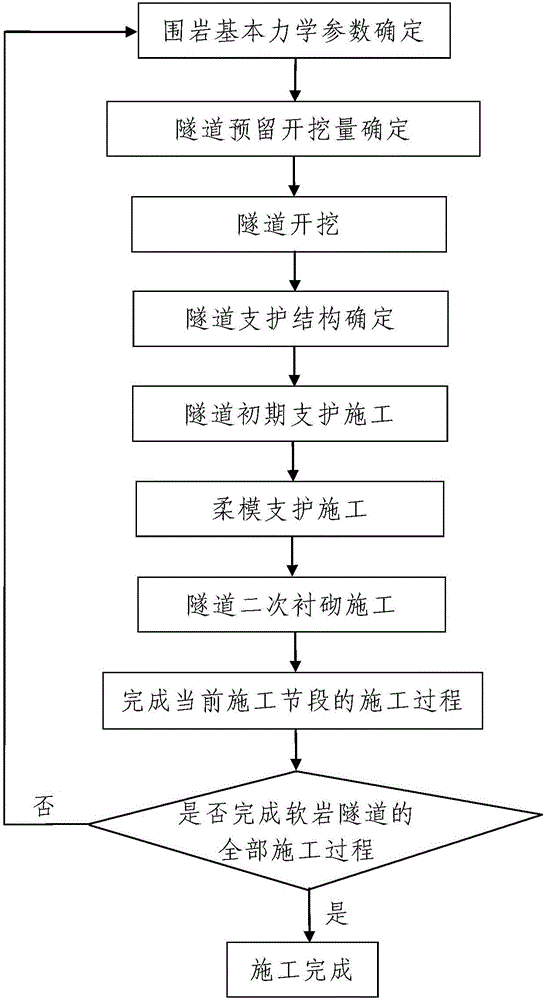

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

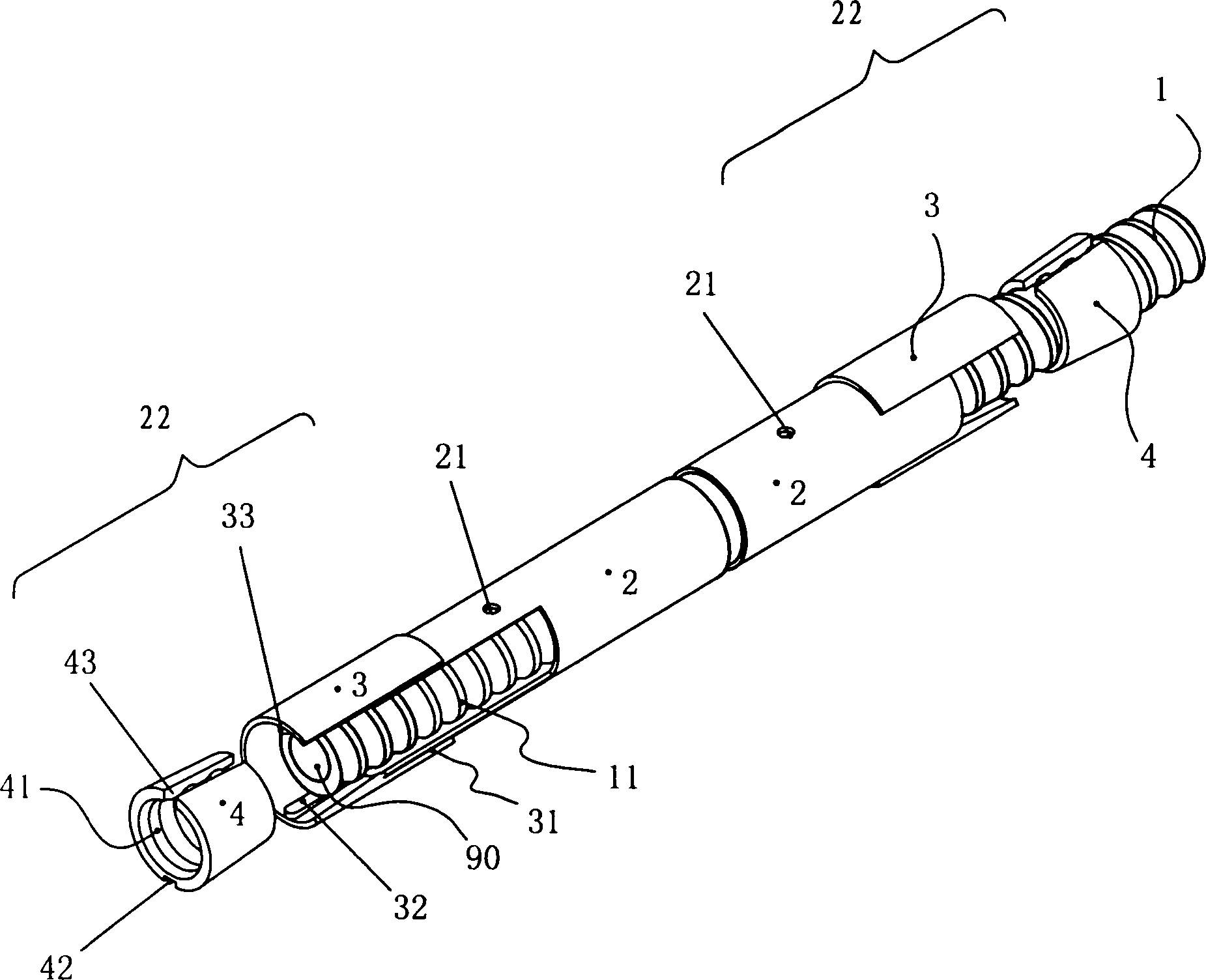

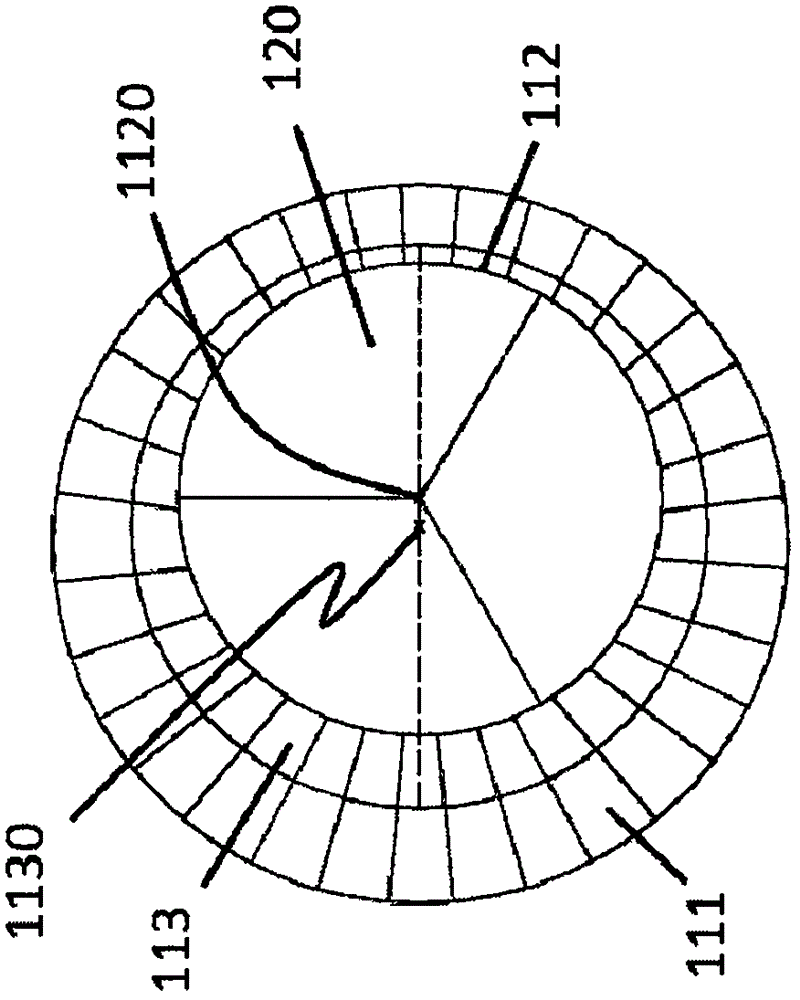

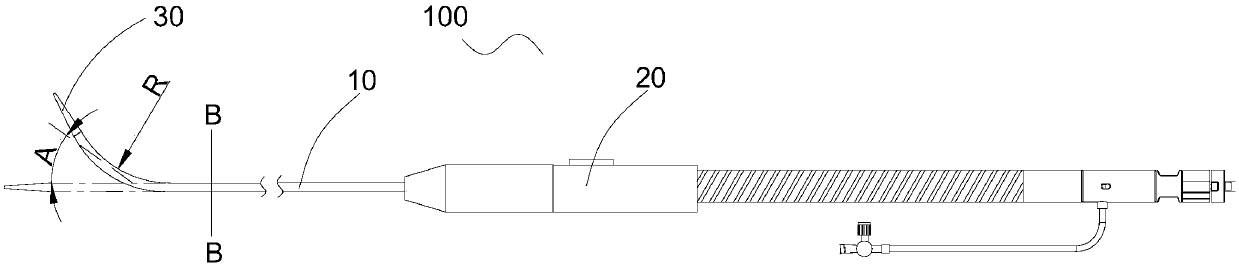

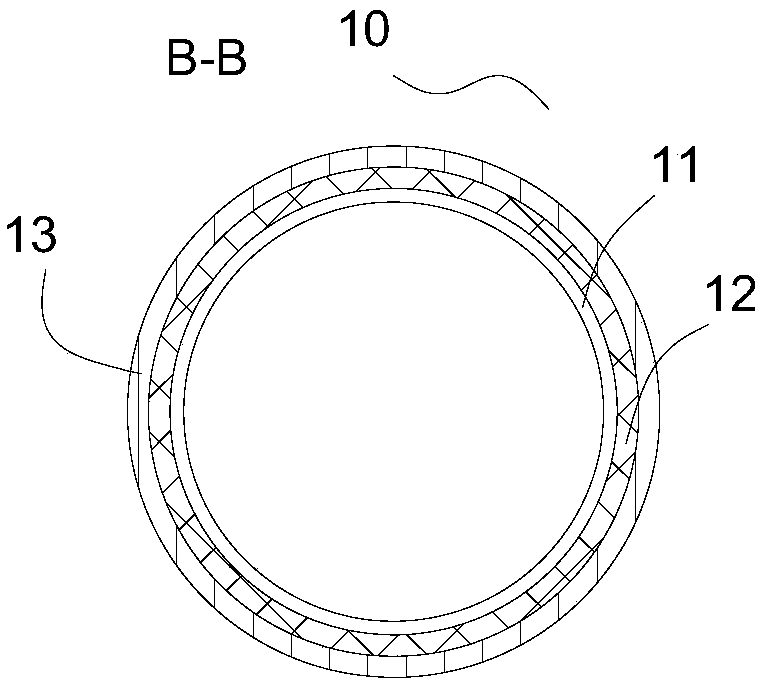

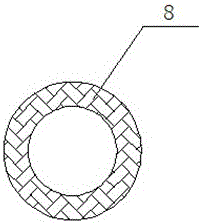

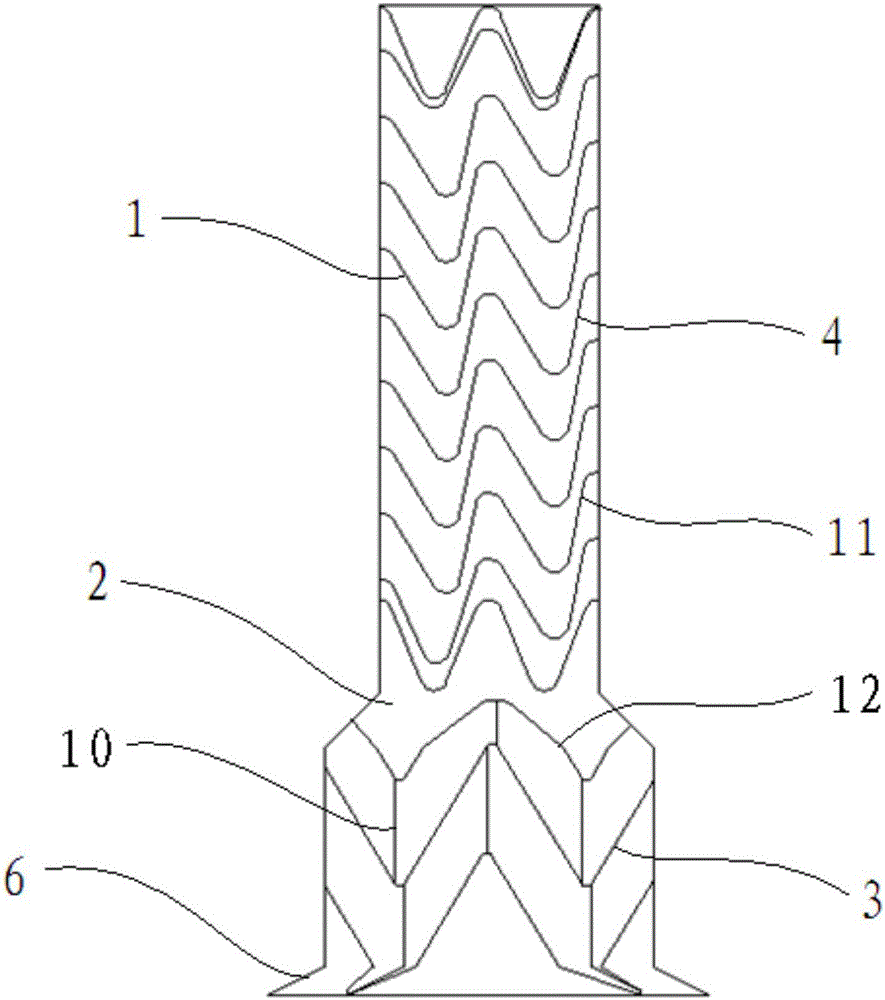

Conveying sheath

ActiveCN109567991AGood bending complianceGuaranteed support effectStentsProsthesisMechanical engineeringEngineering

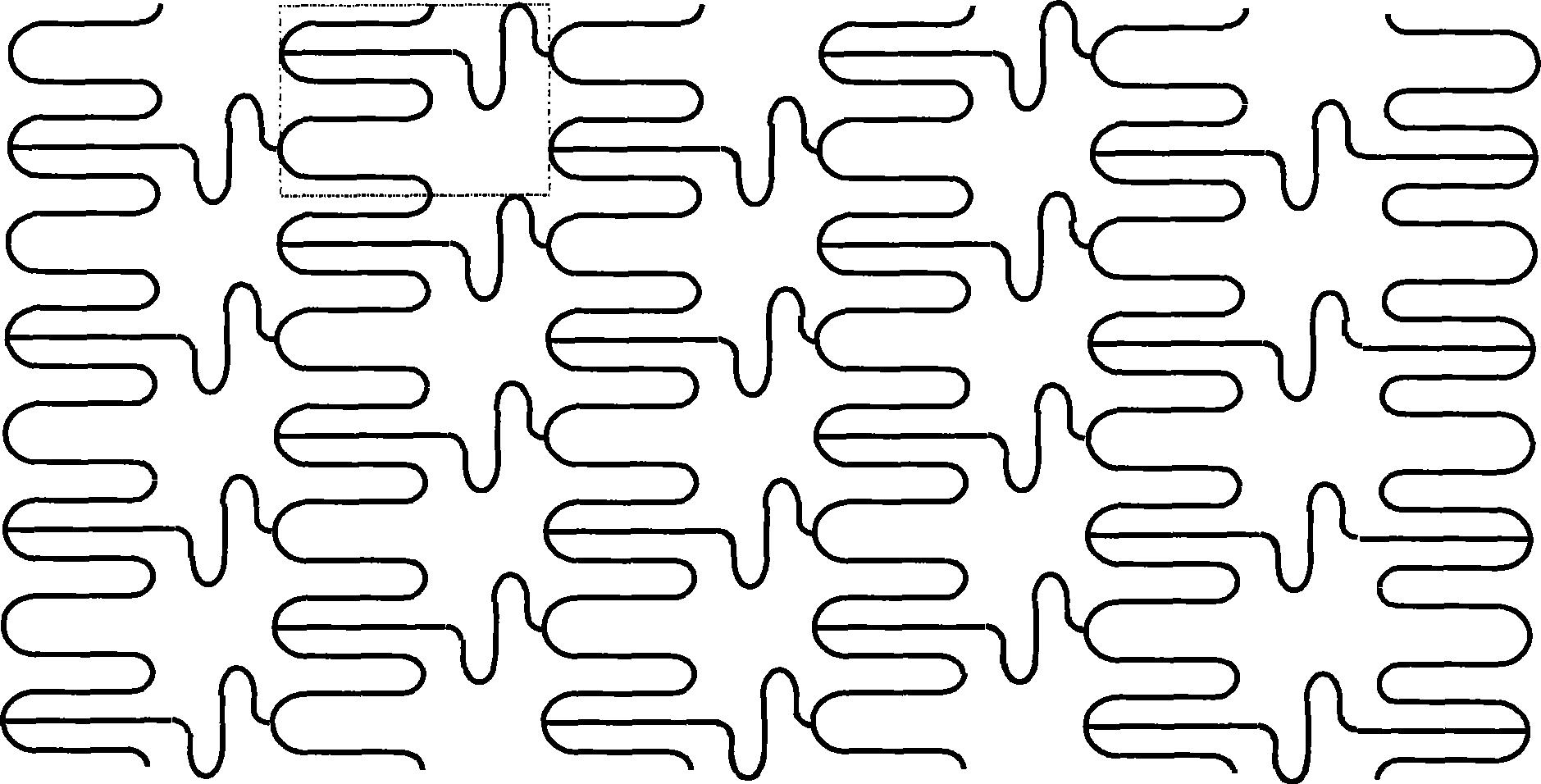

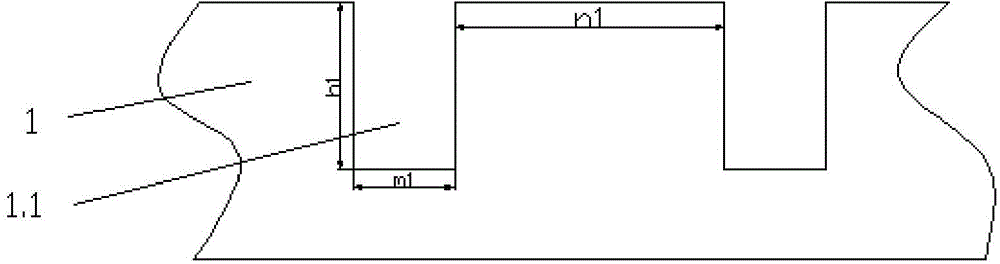

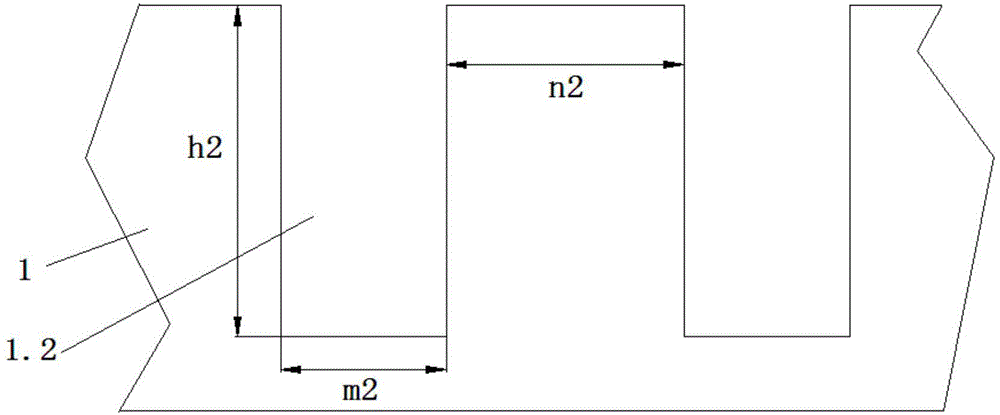

The invention discloses a conveying sheath. The conveying sheath comprises an inner layer, a middle layer and an outer layer which are arranged from inside to outside in sequence, wherein the middle layer at least comprises a first reinforced segment and a second reinforced segment which is located at the far end of the first reinforced segment and is connected with the first reinforced segment; the second reinforced segment comprises a plurality of repeated cutting units; the plurality of cutting units are arranged along the axial direction of the conveying sheath; the cutting units comprisefirst cutting areas and second cutting areas; the projection lengths of the first cutting areas on the cross section of the second reinforced segment are larger than the projection lengths of the second cutting areas on the cross section of the second reinforced segment; the average axial cutting lengths of the first cutting areas are smaller than the average axial cutting lengths of the second cutting areas. According to the conveying sheath of the invention, the bending angle is not liable to rebound and a good bending shape can be kept after the far end of the conveying sheath is bent and sized towards the first cutting areas.

Owner:东莞市先健医疗有限公司

Perforating method for erecting long-span highway box girders by using DJ180 bridge erecting machine

InactiveCN103422441AGuaranteed support effectSimple structureBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a perforating method for erecting long-span highway box girders by using a DJ180 bridge erecting machine and belongs to the technical field of highway bridge construction. When the erected highway box girders of which the span is 40 meters are perforated, in order to prevent the bridge erecting machine from tilting forward, balance weights need to be added to perforate, and a third pillar is put away when the highway box girders are perforated; before a zero driving machine arm reaches a next pier, front ends of girder bodies are hoisted by using bridge cranes, and then, the zero pillar reaches the next pier by the driving machine arm. After the zero pillar and the third pillar are supported, the balance weights are removed. The perforating method disclosed by the invention mainly aims at a straddle girder erection construction process for small-sized box girders of which the weight is not higher than 168 tons and the span is not bigger than 40 meters, and has the main characteristics that equipment is convenient to dismantle and transport and is convenient to transfer, the assembly cycle is short, the girder erection efficiency is high, the input cost is low, and the like.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

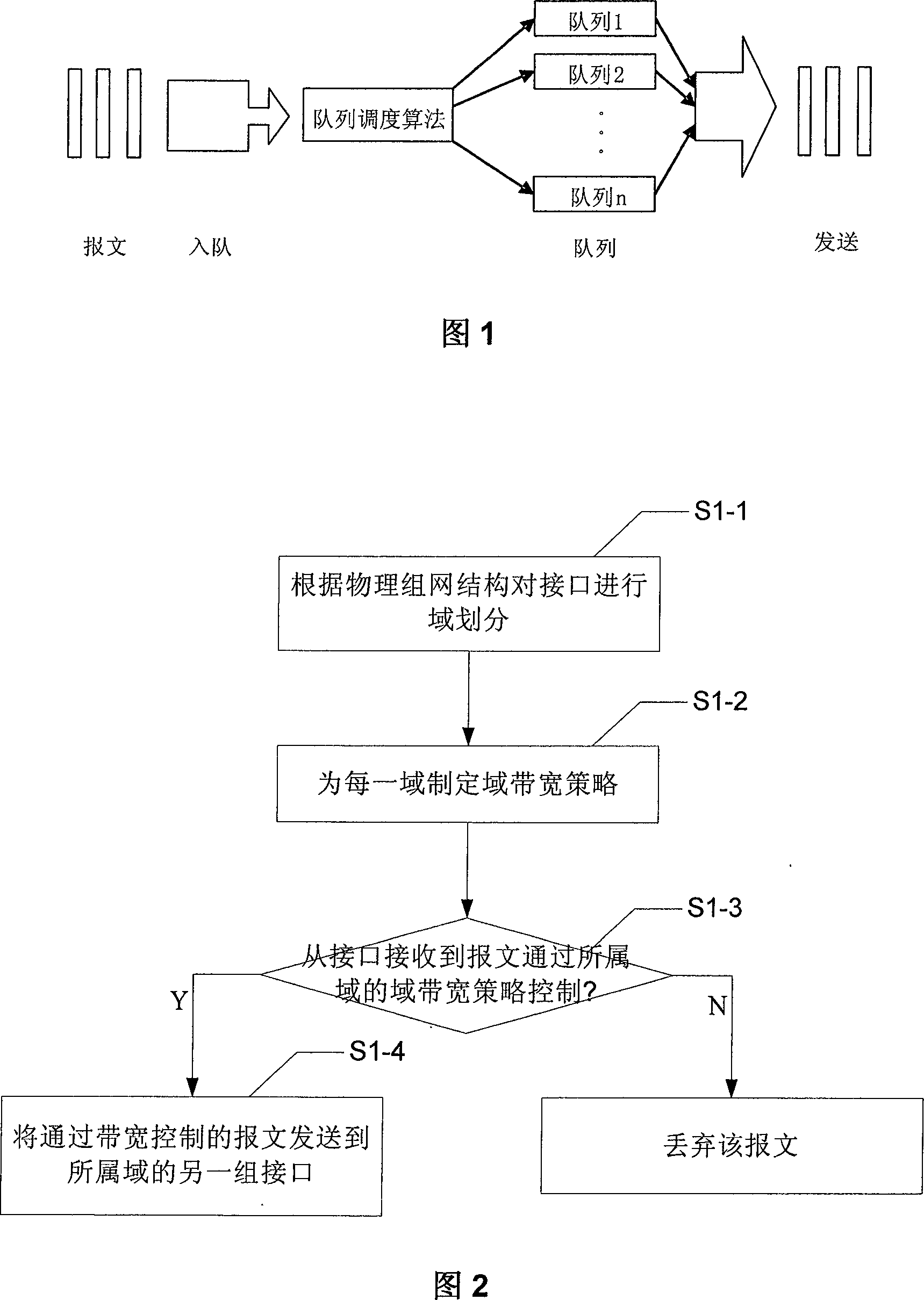

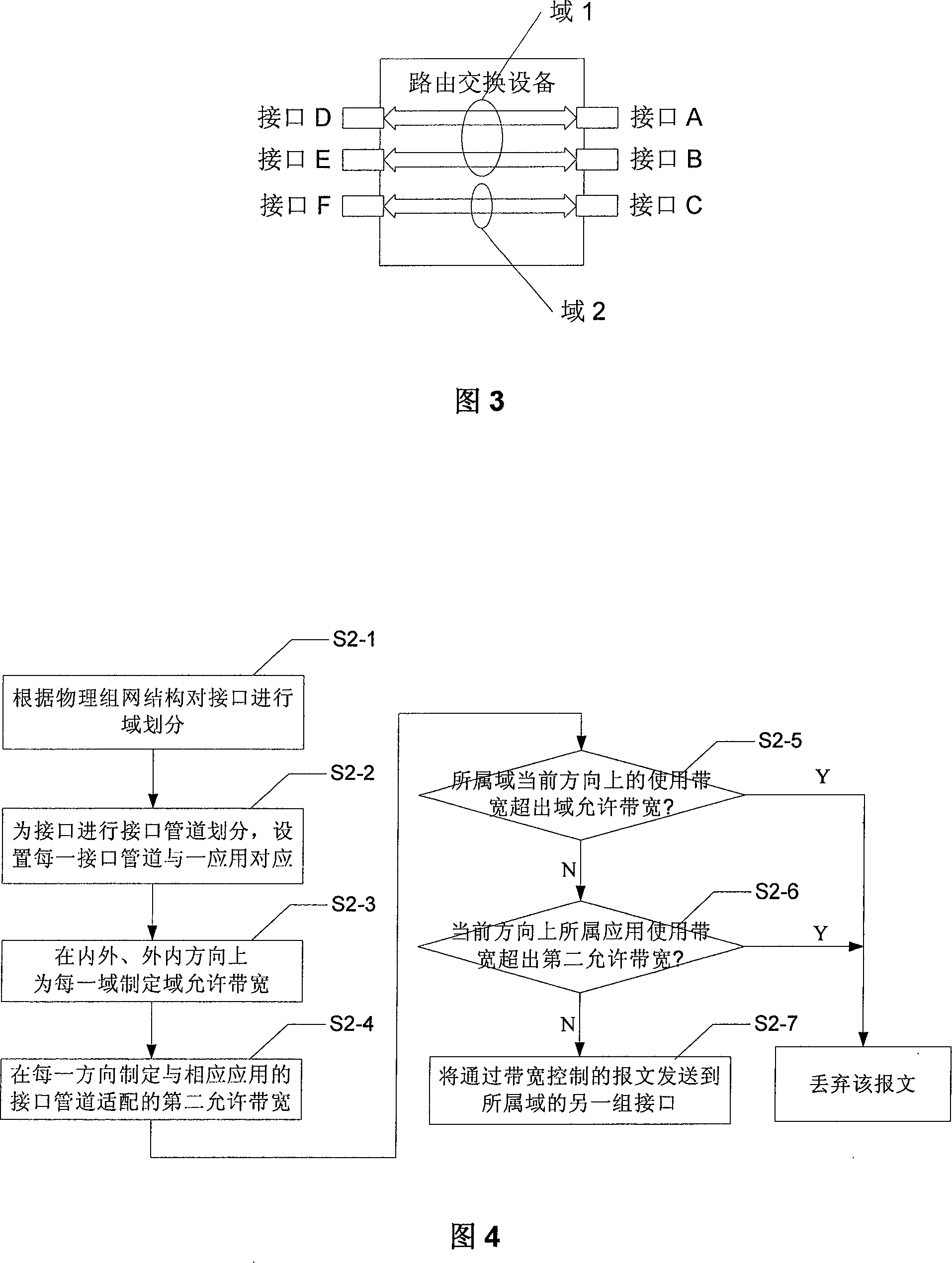

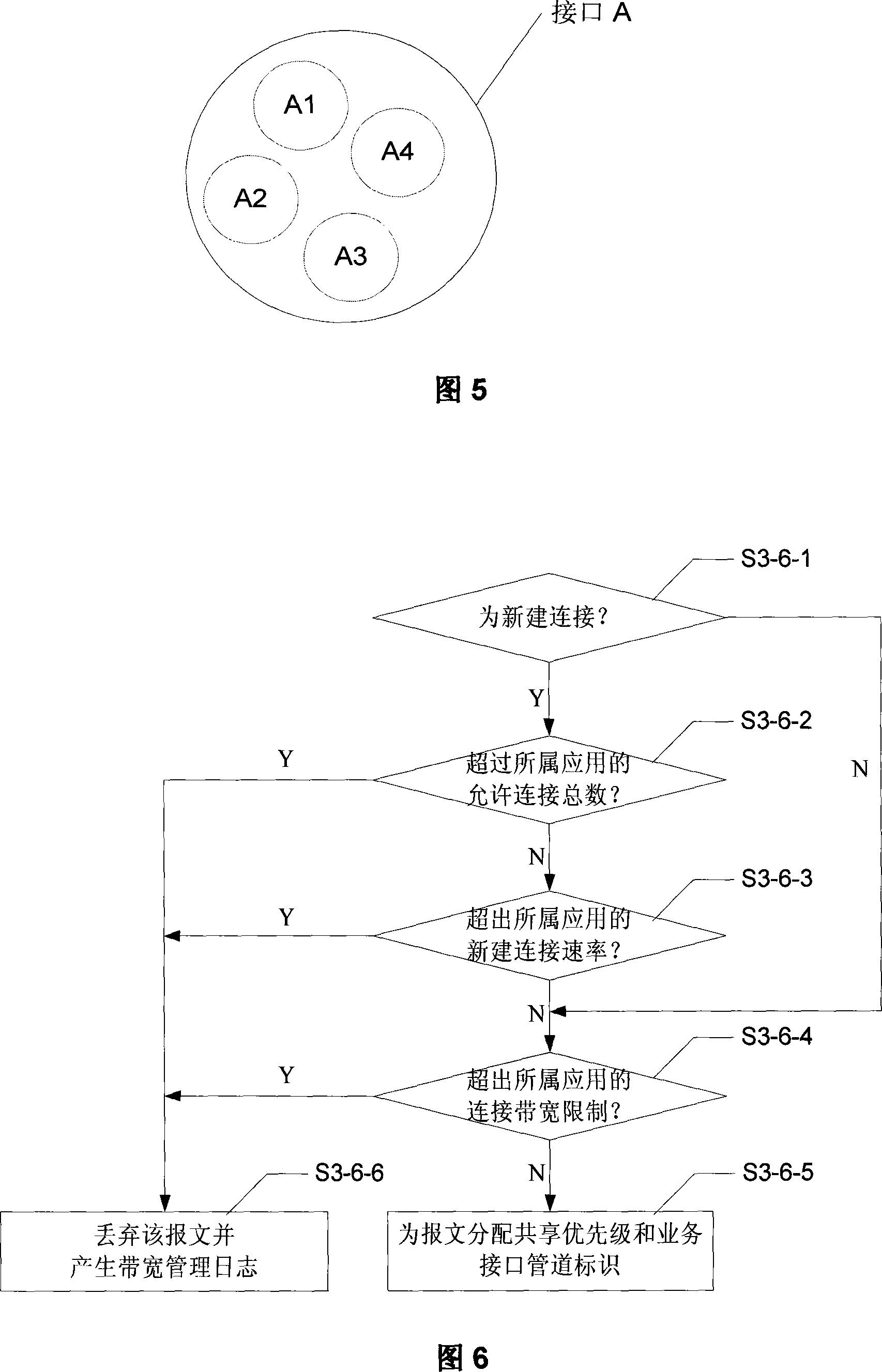

Bandwidth control method and bandwidth control device

InactiveCN101127721AGuaranteed SupportGet rid of dependenceData switching networksStructure of Management InformationPhysical network

The utility model discloses a bandwidth control method and a device, which are used on a route switching device with a plurality of interfaces. The method is to field-divide the interfaces according to the physical network structure; wherein each field comprises a group of internal interfaces and a group of external interfaces and the number of the interfaces in each group is one or more; the field bandwidth strategy is established for each field; when the packet is received from an interface, the bandwidth is controlled according to the field bandwidth strategy in the affiliated field and then the packet passing through the bandwidth controlling process is sent to the other group of interfaces in the affiliated field. The utility model considers the interface hardware limiting factors and the logical managing factors sufficiently so as to get rid of the dependency on the single interface, ensure the bandwidth stability of the conversational individual and be propitious to realize the multilayer and fine-grain interface bandwidth control.

Owner:NEW H3C TECH CO LTD

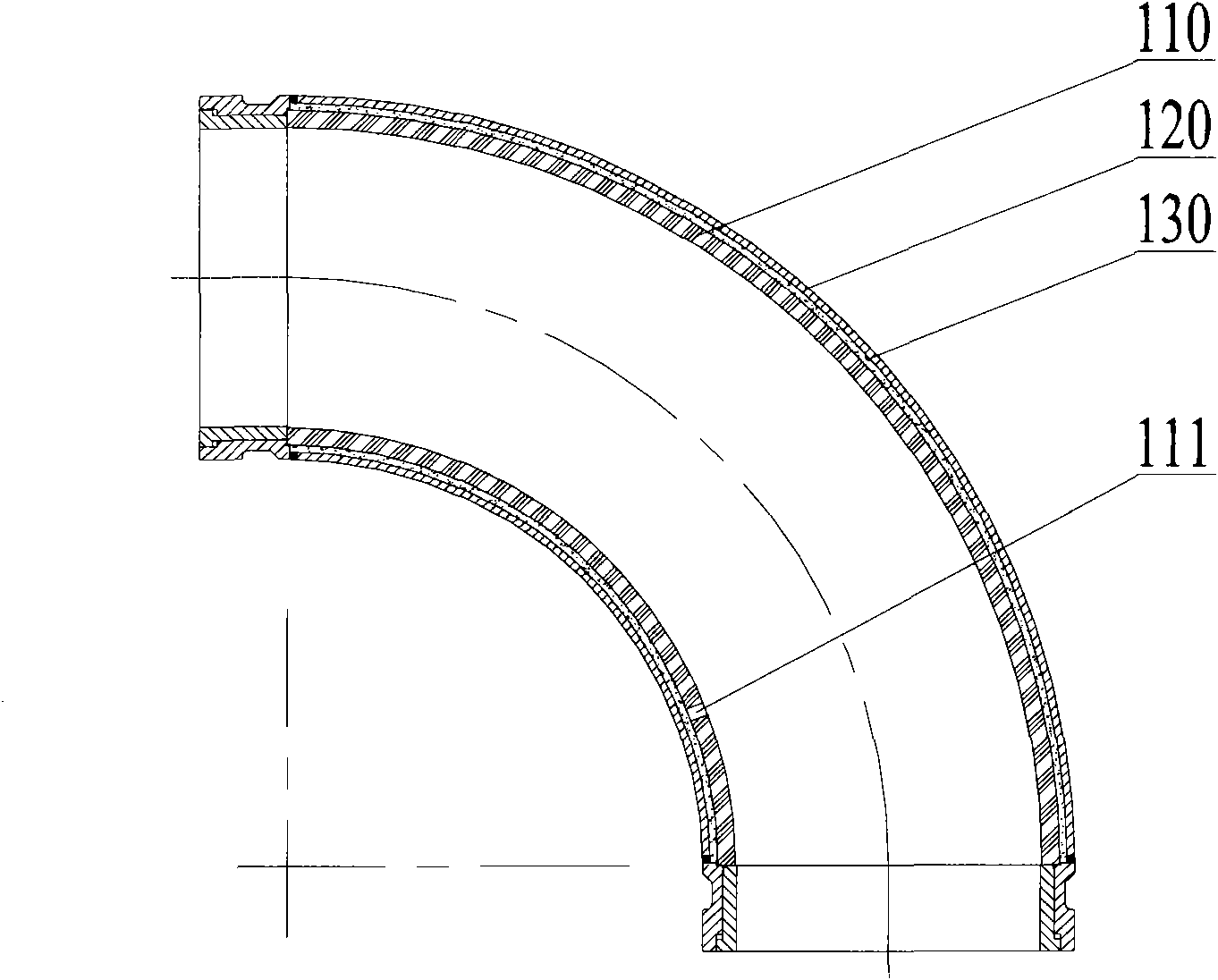

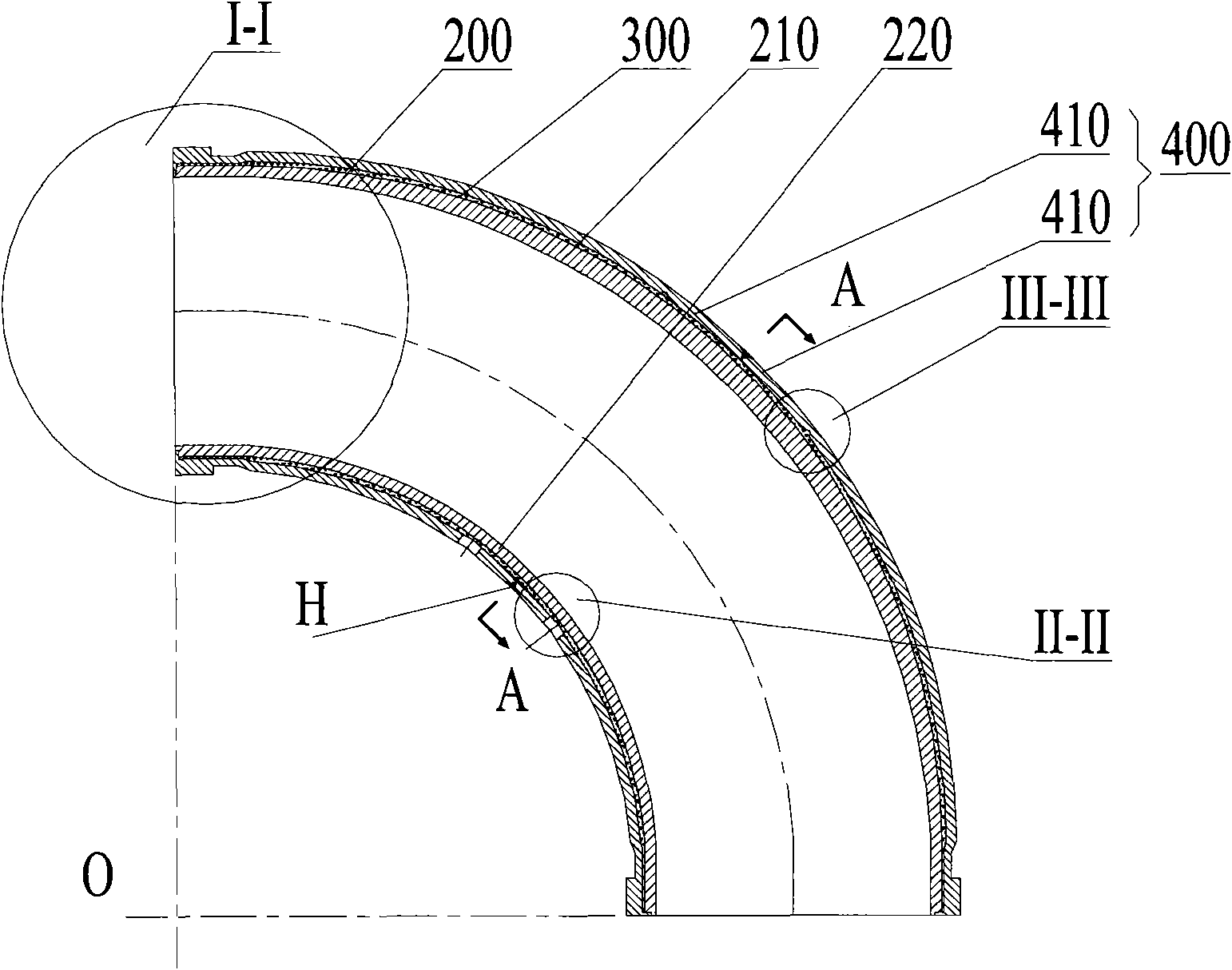

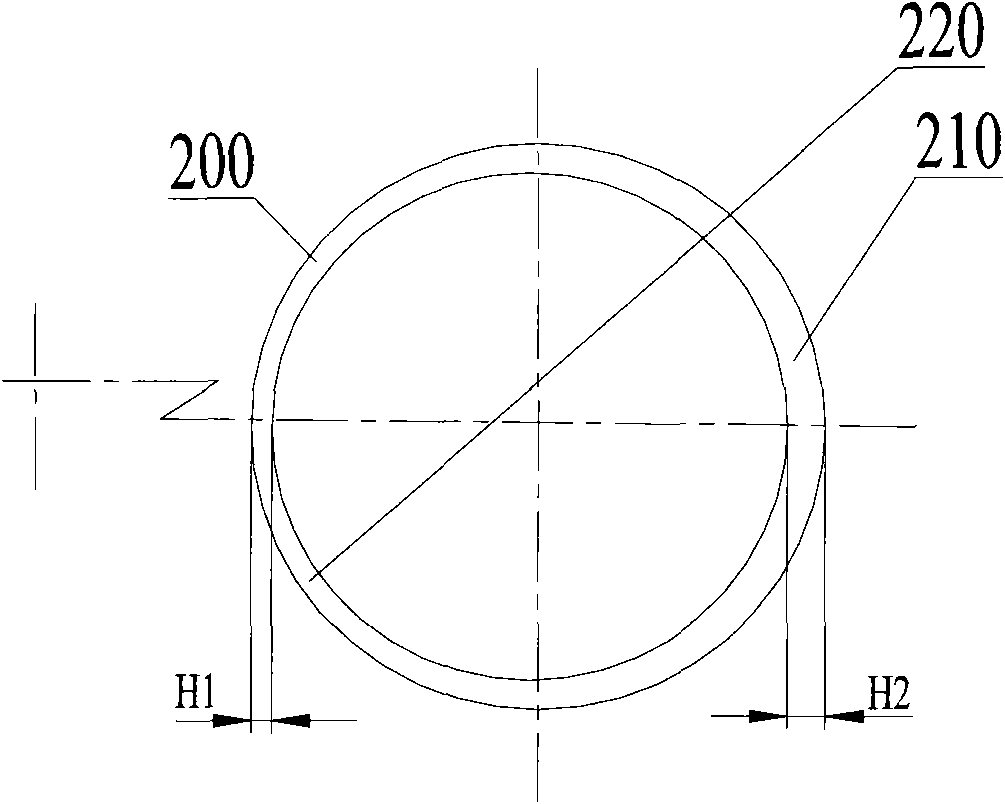

Conveying bent pipe, concrete conveyer and manufacturing method of same

InactiveCN101625060AReduce manufacturing costEasy to processBulk conveyorsRigid pipesManufacturing technologyEngineering

The invention discloses a conveying bent pipe, a concrete conveyer and a manufacturing method of the conveying bent pipe. The disclosed sequentially comprises an inner pipe, an outer pipe and a filling layer, and the outer pipe at least comprises two supporting pipes which are sequentially connected; the outer pipe of the conveying bent pipe has a split type structure and comprises two or more than two supporting pipes, thereby reducing the cost of the conveying bent pipe under the condition that the wearing resistance, the strength, the high toughness and the impact resistance are ensured. In an optimized technical scheme, the inner pipe and outer pipe are fixed by an adhesive layer to transfer the acting force of the inner pipe to the outer pipe, the supporting and protecting function of the inner pipe by the outer pipe is ensured, and safety of the conveying bent pipe can be increased. Because the inner pipe and the outer pipe can be mutually positioned by matching with an inner convex body and an inner notch, the manufacturing method of the conveying bent pipe not only can simplify a manufacturing technology in a conveying bent pipe manufacturing process, but also can reduce auxiliary mechanisms and reduce the manufacturing cost of the conveying bent pipe.

Owner:SANY HEAVY IND CO LTD (CN)

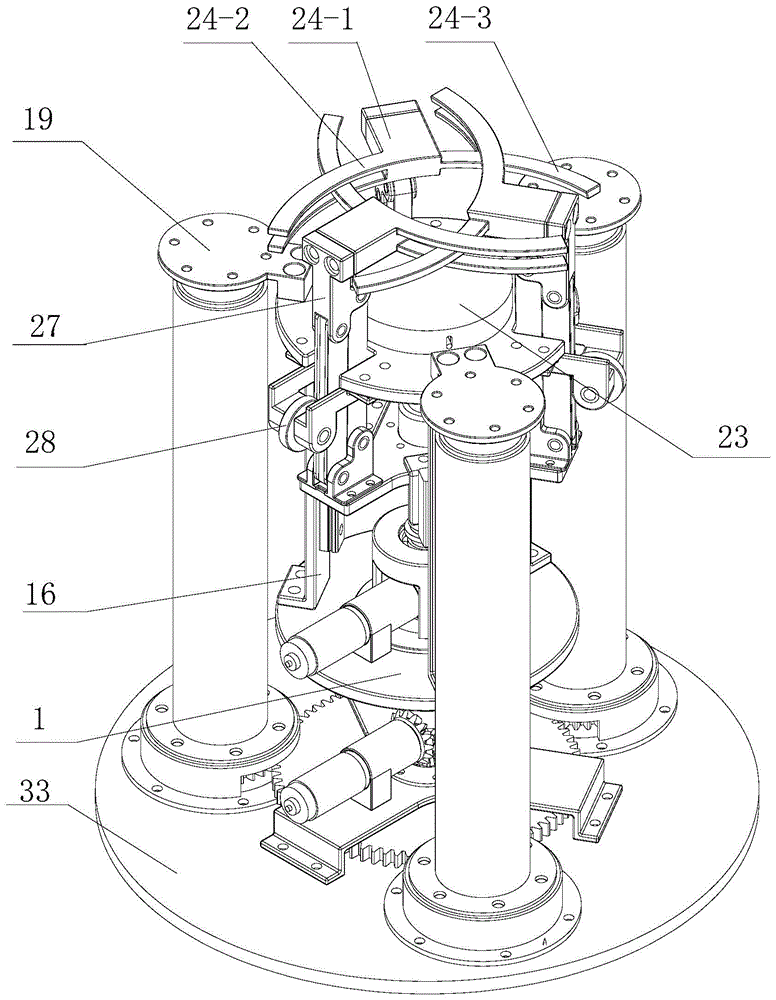

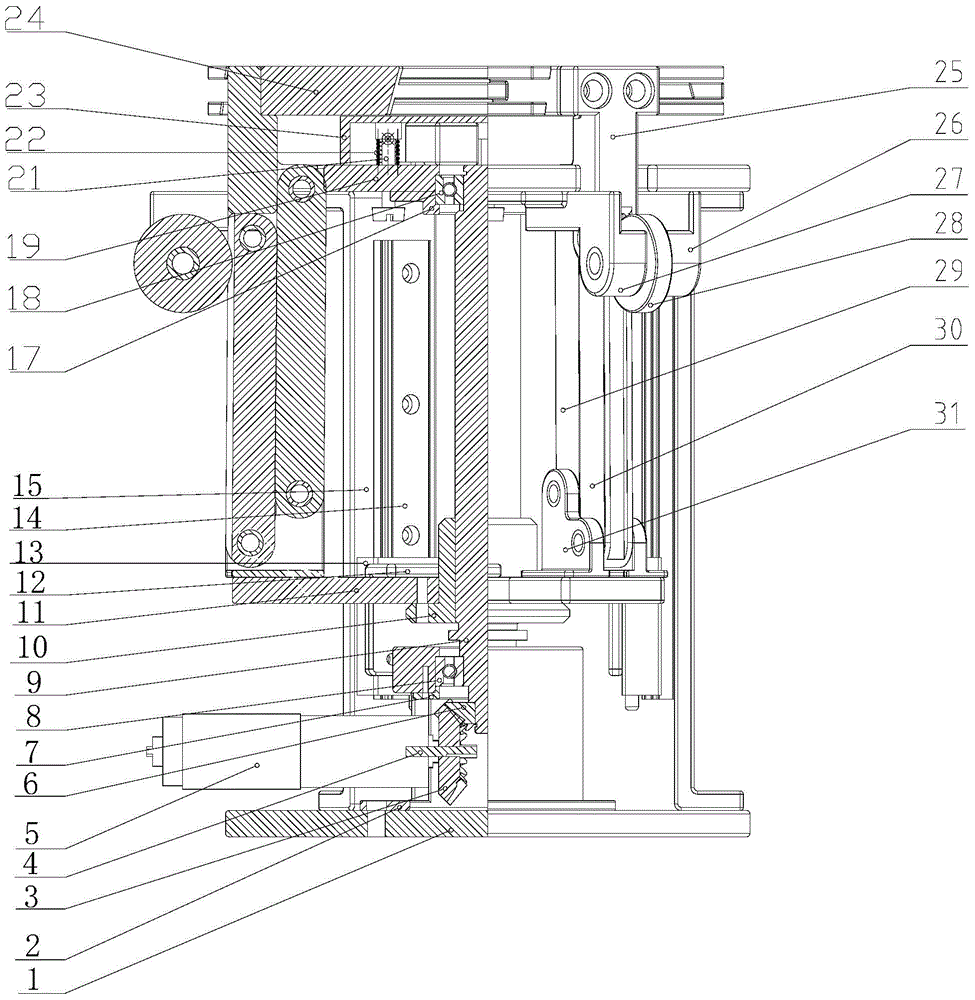

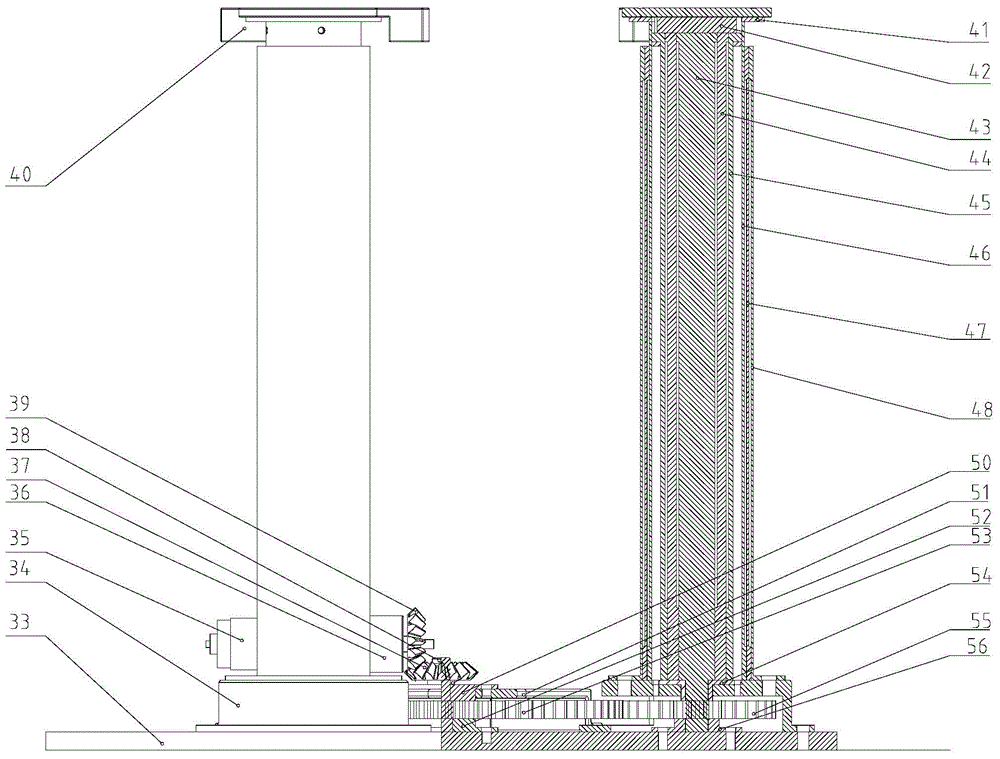

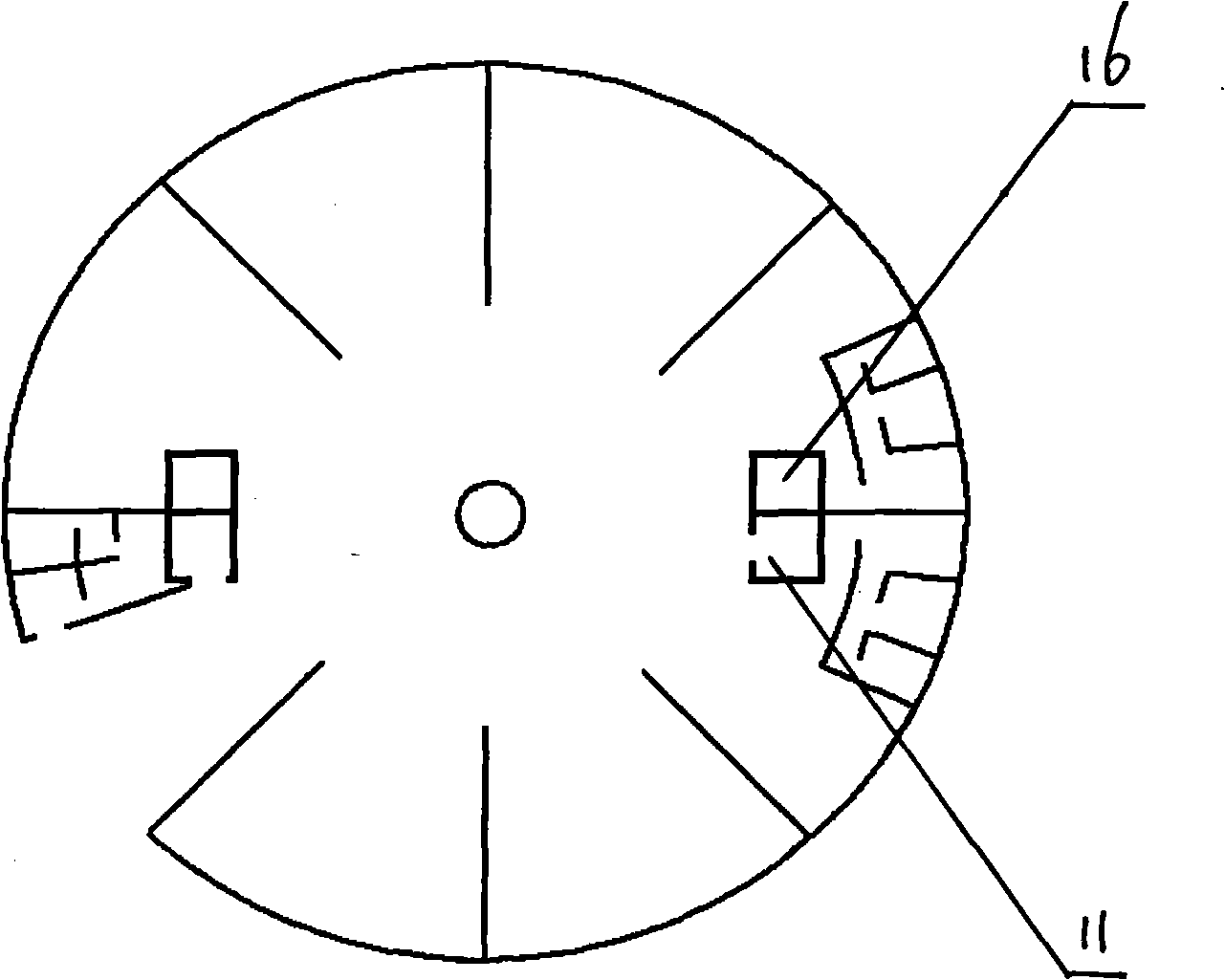

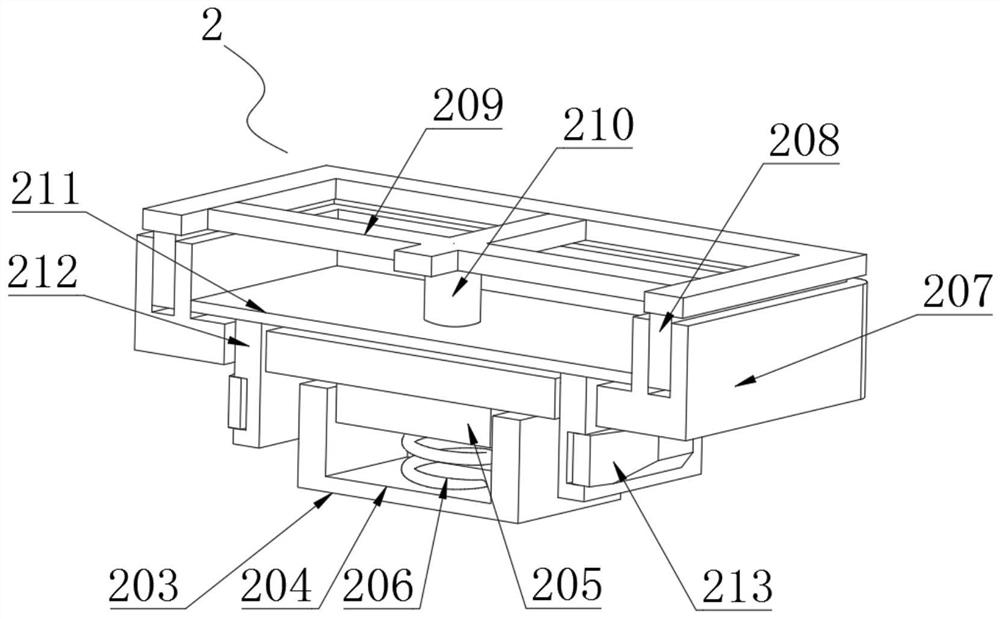

Capture mechanism and multi-level lead screw non-cooperative target docking mechanism

ActiveCN104149992AAvoid leaningAvoid void escapeCosmonautic component separationThree levelSpacecraft

The invention discloses a capture mechanism and a multi-level lead screw non-cooperative target docking mechanism, and relates to the technical field of aerospace. The mechanisms solve the problems about operation such as recognition, measurement and capture on a target under the non-cooperative situation of an existing spacecraft. According to the scheme of the capture mechanism, a first motor drives a linkage mechanism to rise to a grab portion to be in an open state, and the grab portion is driven by the linkage mechanism to rapidly fold and contract backwards. According to the scheme of the docking mechanism, the docking mechanism is composed of the capture mechanism and a telescoping mechanism, wherein the telescoping mechanism achieves stretching and contraction in the mode that a second motor drives three levels of lead screws to stretch out level by level through a bevel gear drive mechanism and a spur gear drive mechanism. The capture mechanism and the multi-level lead screw non-cooperative target docking mechanism are used for effectively capturing a long-distance jet pipe.

Owner:HARBIN INST OF TECH

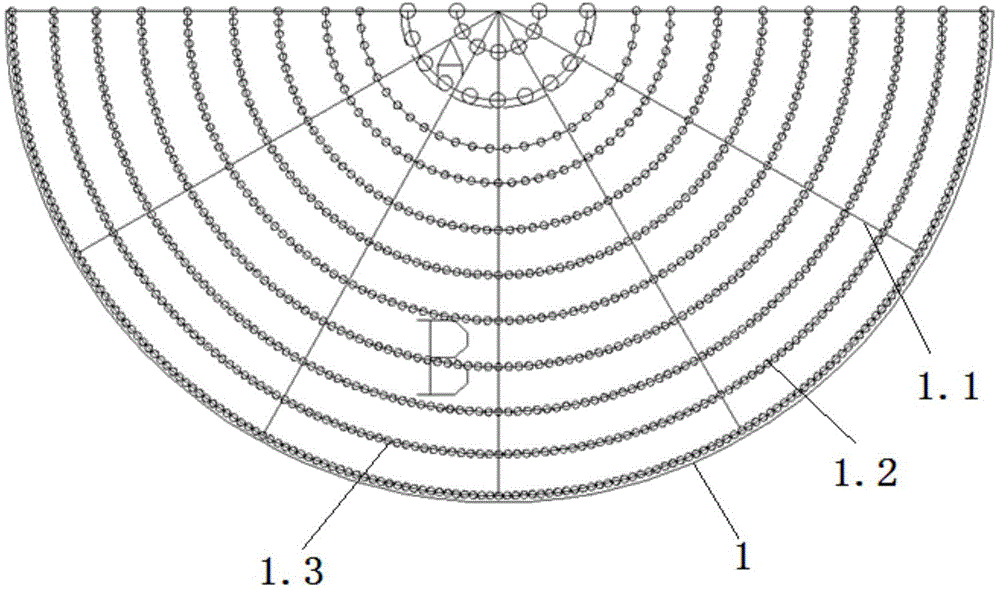

Chemical-mechanical polishing pad

The invention discloses a chemical-mechanical polishing pad and solves the problem that an existing polishing pad is scratched easily and low in polishing efficiency. According to the technical scheme, the chemical-mechanical polishing pad comprises a polishing layer, a plurality of holes are formed in the polishing surface of the polishing layer, the center of the polishing surface is a circle center, and the holes are arranged into multiple rows of concentric rings different in diameter. The center of the polishing surface is an end point, and a plurality of grooves extending to the edge of the polishing surface are evenly radiated from the end point. The surface roughness of the polishing surface is below 15 micrometers. The polishing pad is simple in structure, capable of increased polishing removing efficiency and inhibiting scratches, and long in service life.

Owner:HUBEI DINGLONG CO LTD

Antiseismic building

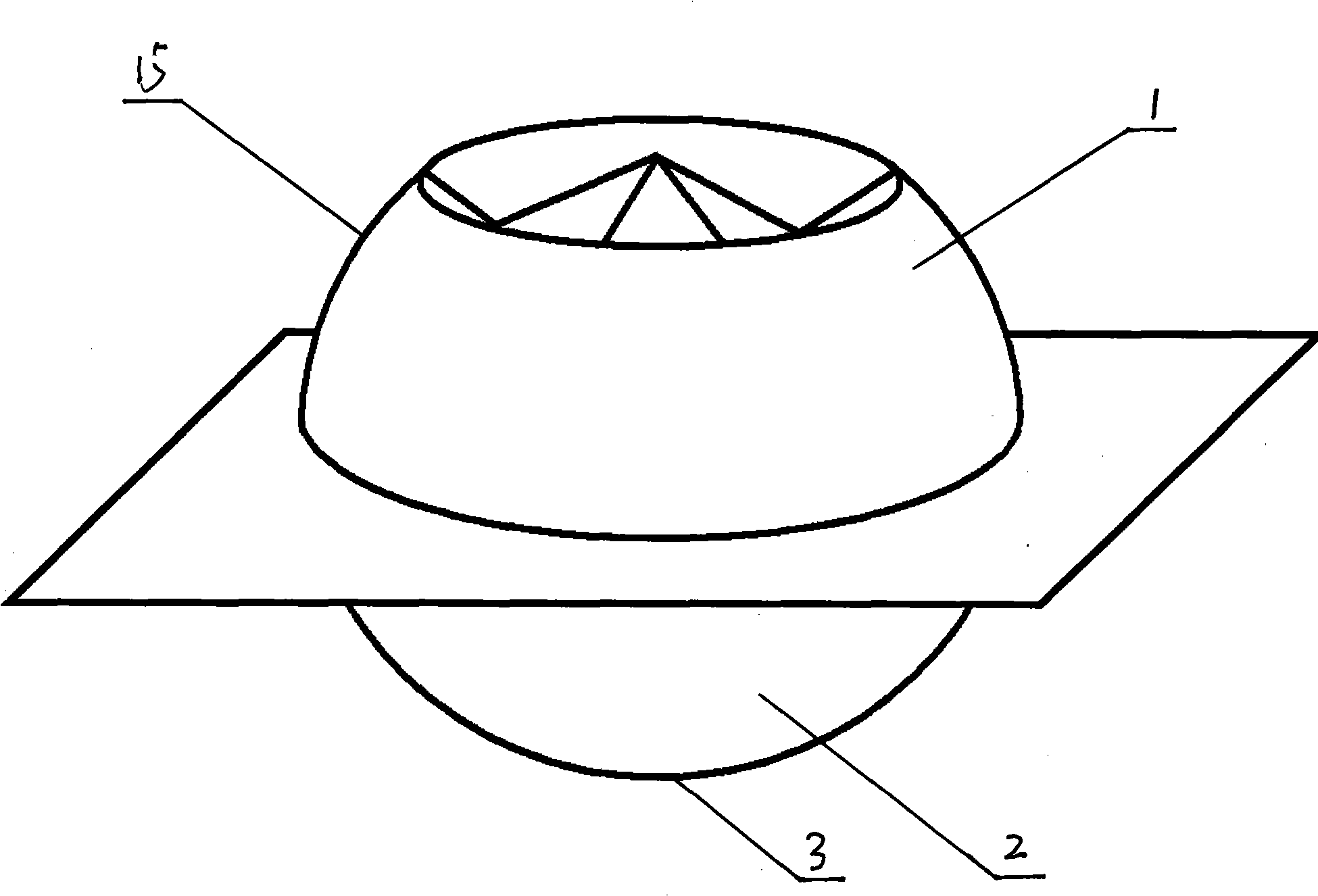

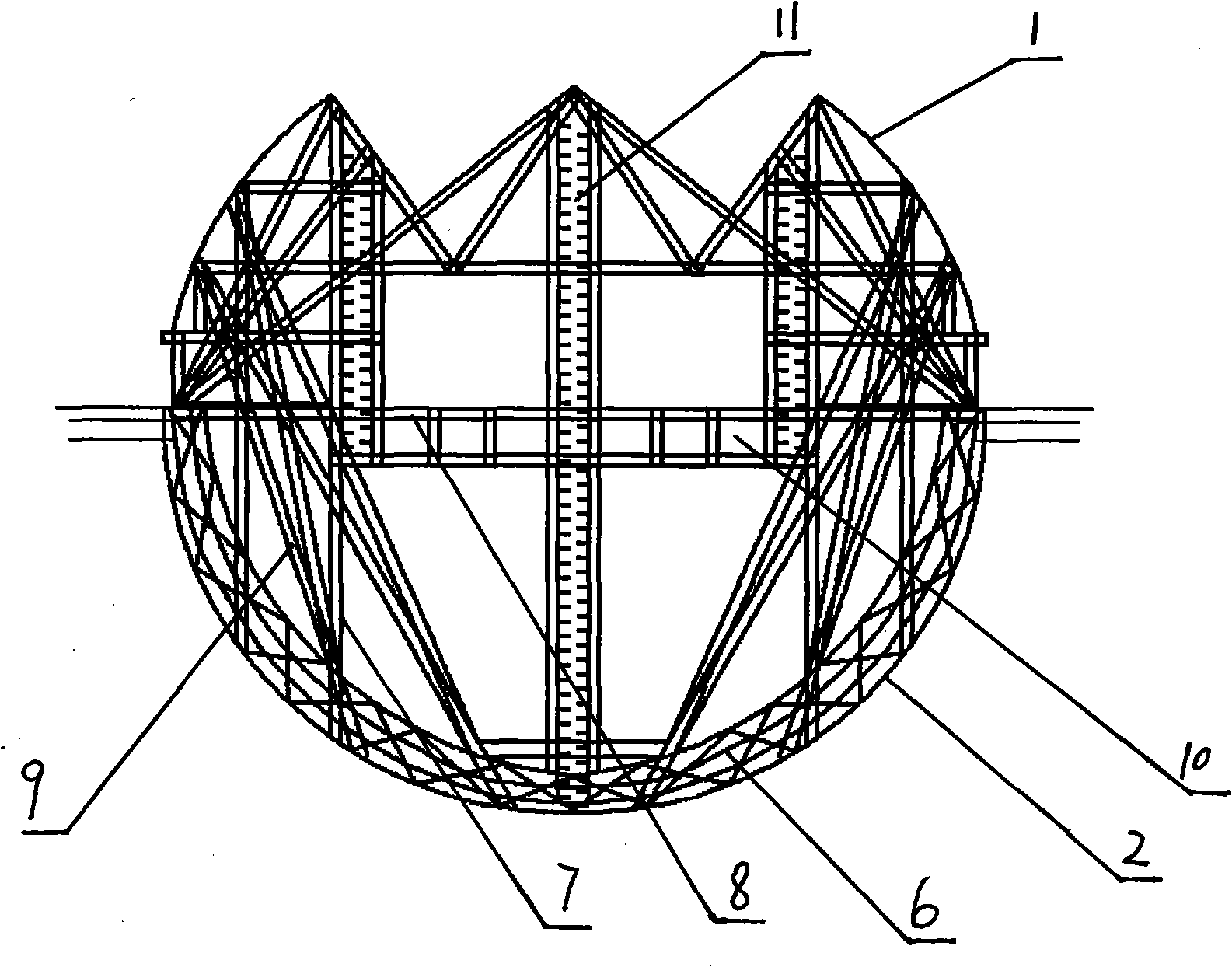

InactiveCN101654962AReduce damageGuaranteed support effectProtective buildings/sheltersSeismic waveHuman life

The invention provides an antiseismic product, and relates to an antiseismic building. Because 18 times of earthquakes above M7 and 1 to 2 times above M8 occur on the earth each year, people are in dire need of various antiseismic products. The invention provides the building capable of adopting automatic prevention measures to resist earthquakes. The entire building is designed by adopting the principle of tumblers; therefore, the building is just like a tumbler and does not collapse in a new environment when an earthquake causes ground cracks, sinking or land slides. Moreover, because the groundwork of the building is a solid hemispheroid or a laid down semicylinder, a cambered surface at the bottom can disperse the impact force of an earthquake on the building and changes the direct ofthe impact force, thereby ensuring that earthquake waves spread toward the periphery of the building; meanwhile, the earth generates powerful attraction on the inclined solid groundwork to force the building to recover and maintain erection or an inclined but not collapsed state, thereby guaranteeing the safety of human life and property. Therefore, the antiseismic building is suitable for schools, factories, city buildings and residential buildings and is particularly suitable for top-grade villas and scenic spot construction.

Owner:邹海

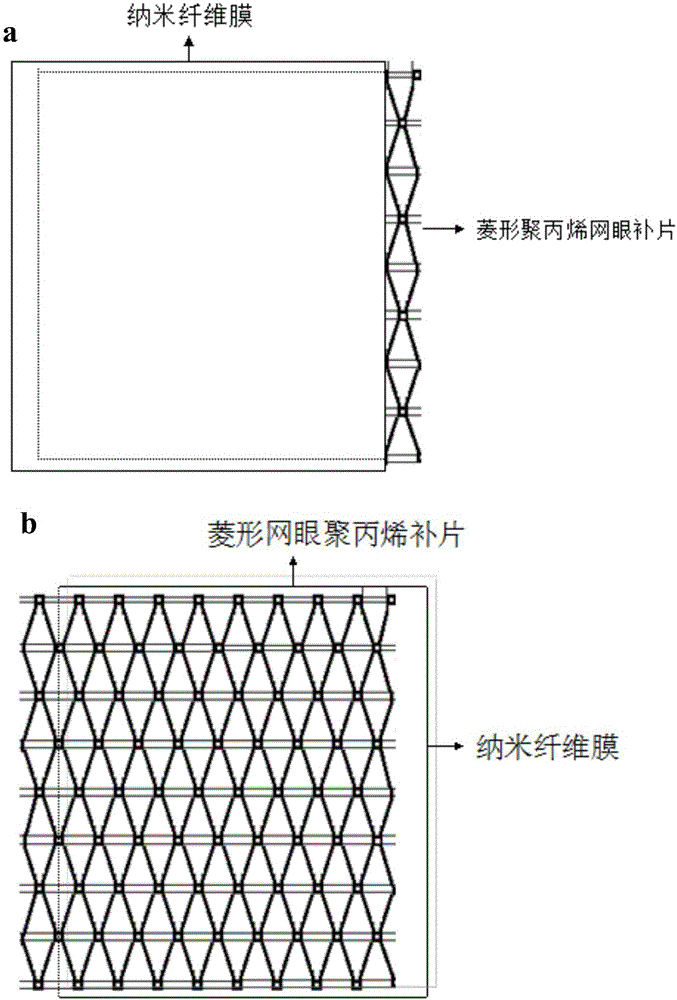

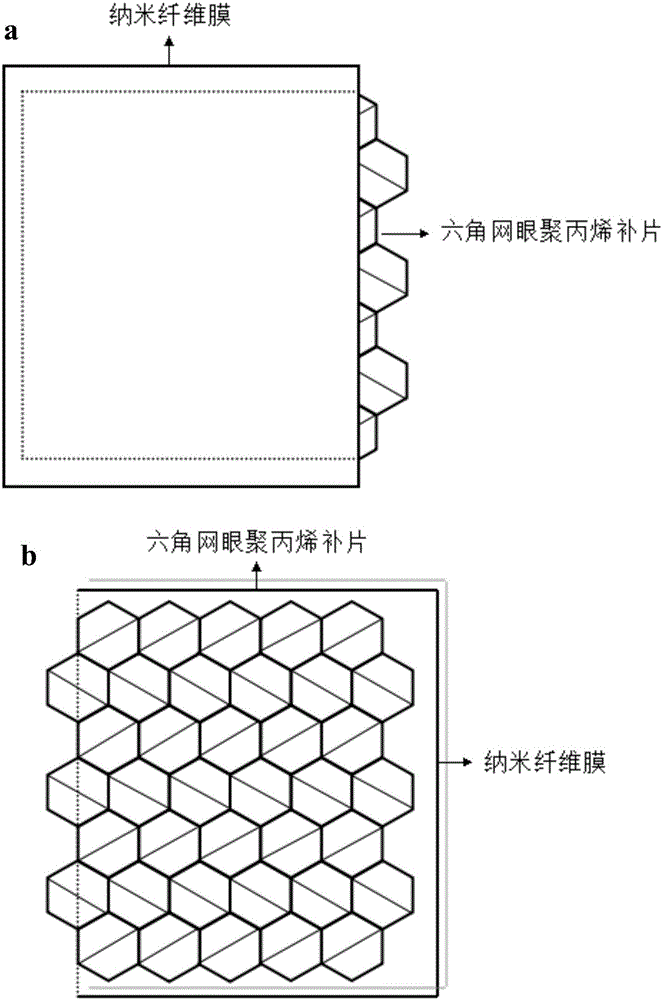

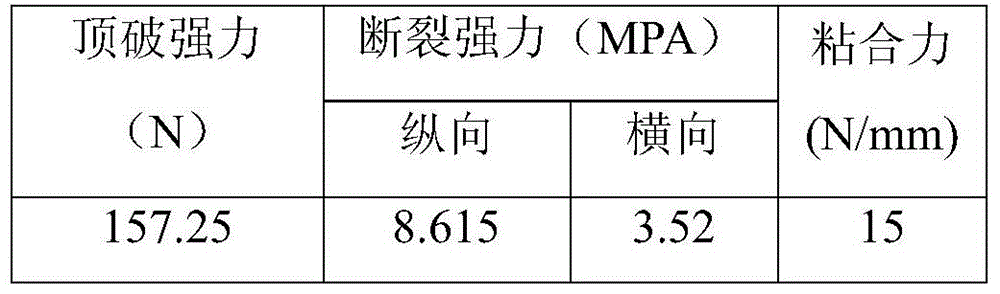

Electrostatic-spun coated composite pelvic mesh and manufacturing method thereof

InactiveCN105708581AStable mechanical propertiesGood biocompatibilityAnti-incontinence devicesPorosityElectrospinning

The invention relates to an electrostatic-spun coated composite pelvic mesh and a manufacturing method thereof. The composite pelvic mesh is composed of a coating layer and a supporting layer, wherein the coating layer is bonded on one side of the supporting layer. The manufacturing method comprises the following steps: mixing polylactic acid and polycaprolactone, dissolving the mixed polylactic acid and polycaprolactone in a solvent, and then heating and stirring, so that a polylactic acid / polycaprolactone solution is obtained; brushing a layer of binding agent on one surface of a polypropylene warp-knitted mesh and sticking the other surface on an aluminum foil which serves as an electrostatic spinning receiving device, and conducting electrostatic spinning by using the polylactic acid / polycaprolactone solution as a spinning solution; and volatilizing and disinfecting, so that the pelvic mesh is obtained. The pelvic mesh disclosed by the invention, by combining absorbable materials and non-absorbable materials and on the basis of characteristics of the electrostatic spinning which is high in specific surface area and high in porosity, has the features of being light in weight, high in porosity, soft to touch, good in biocompatibility and the like.

Owner:DONGHUA UNIV +1

Surrounding rock supporting construction method and surrounding rock supporting structure of water-contained roadway of coal mine

ActiveCN105804767APrevent intrusionImprove stabilityUnderground chambersTunnel liningStructure of the EarthRock bolt

The invention discloses a surrounding rock supporting construction method of a water-contained roadway of a coal mine and belongs to the field of surrounding rock supporting of underground engineering. The surrounding rock supporting construction method comprises the following steps that (1) primary spraying is conducted after the roadway is excavated; (2) according to the geological conditions of the water-contained roadway, a controllable grouting anchor rod structure is designed, and controllable grouting anchor rod-anchor cable supporting parameters are designed; (3) through the combination of controllable grouting anchor rods, anchor cables, metal nets and sprayed grout supporting, so that a grouting reinforcement waterproof ring is formed, and grout is sprayed onto the surrounding rock on the surface of the roadway; (4) the key portion where supporting needs to be reinforced and water insulation is needed is determined through the field observation technical means such as numerical simulation; (5) the supporting parameters of the water-contained roadway are adjusted and optimized, and grouting reinforcement supporting is conducted on the key portion; and (6) a base plate of the roadway is reasonably supported. The invention further provides a surrounding rock supporting structure. The supporting method and structure are suitable for water-contained roadways with different depths, roadways with broken surrounding rocks, and soft rock roadways; and in addition, construction is easy and convenient, and the supporting method and structure can be popularized within a wide range.

Owner:内蒙古双欣矿业有限公司

Loudspeaker module

ActiveCN104811857ALower F0BandwidthLoudspeaker transducer fixingFrequency/directions obtaining arrangementsEngineeringLoudspeaker

The invention discloses a loudspeaker module, and relates to the technical field of electric-acoustic products. The loudspeaker module comprises a shell. A vibration system and a magnetic circuit system are accommodated in the shell, the vibration system comprises a diaphragm and a voice coil, the diaphragm and the voice coil are combined with each other, an inner cavity of the integral module is divided into a front sound cavity and a rear sound cavity by the diaphragm, the edge of the diaphragm is fixed onto the shell by the aid of an annular support component, and a plurality of cavity extending portions which are formed by means of starving are distributed on the support component at intervals and are communicated with the rear sound cavity. The loudspeaker module has the advantages that the technical problem of increase of resonant frequencies F0 due to narrow rear sound cavities of loudspeaker modules in the prior art can be solved, and the rear sound cavity of the loudspeaker module is large in volume, low in resonant frequency F0, wide in frequency band, good in acoustic performance and long in service life; the loudspeaker module is low in assembling process difficulty and high in production efficiency.

Owner:GOERTEK INC

Flexible display screen and manufacturing method thereof

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

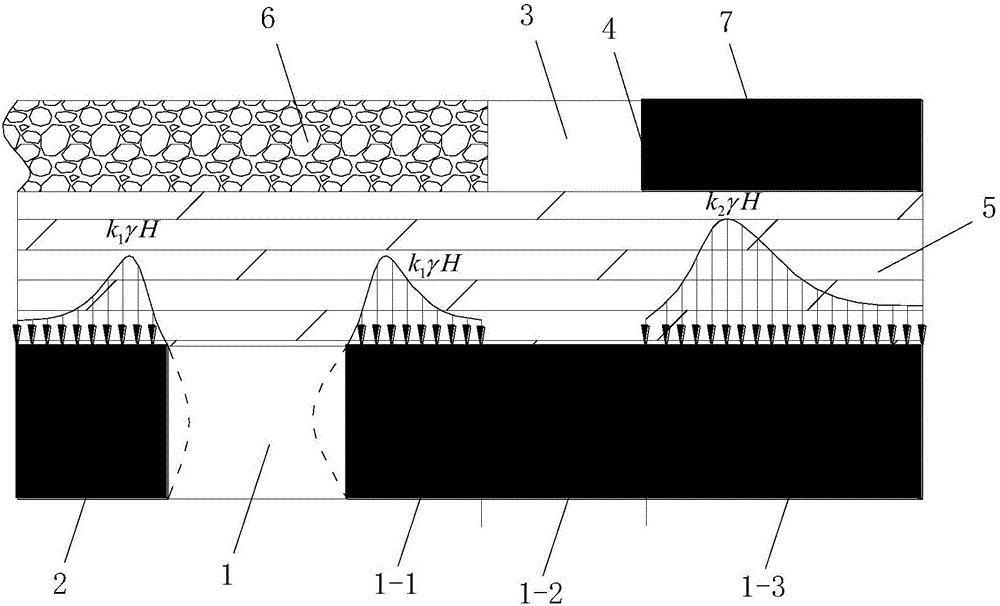

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

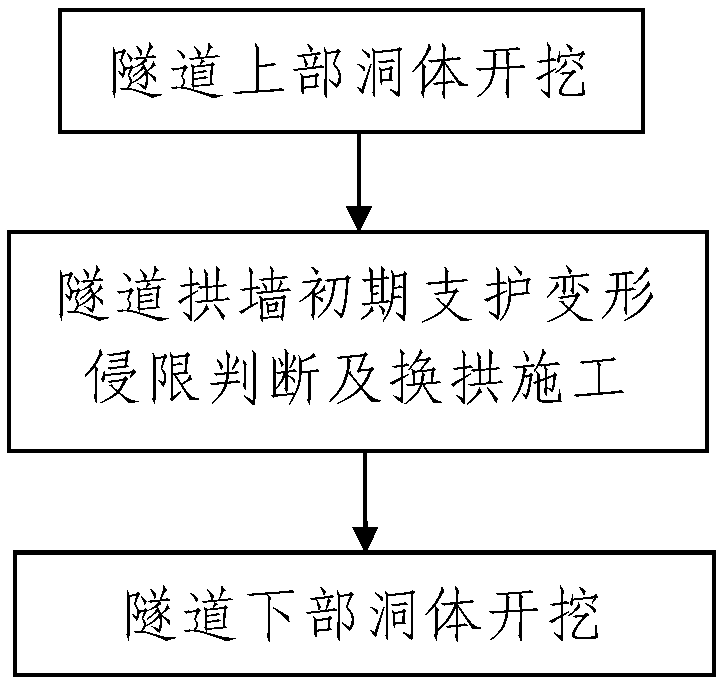

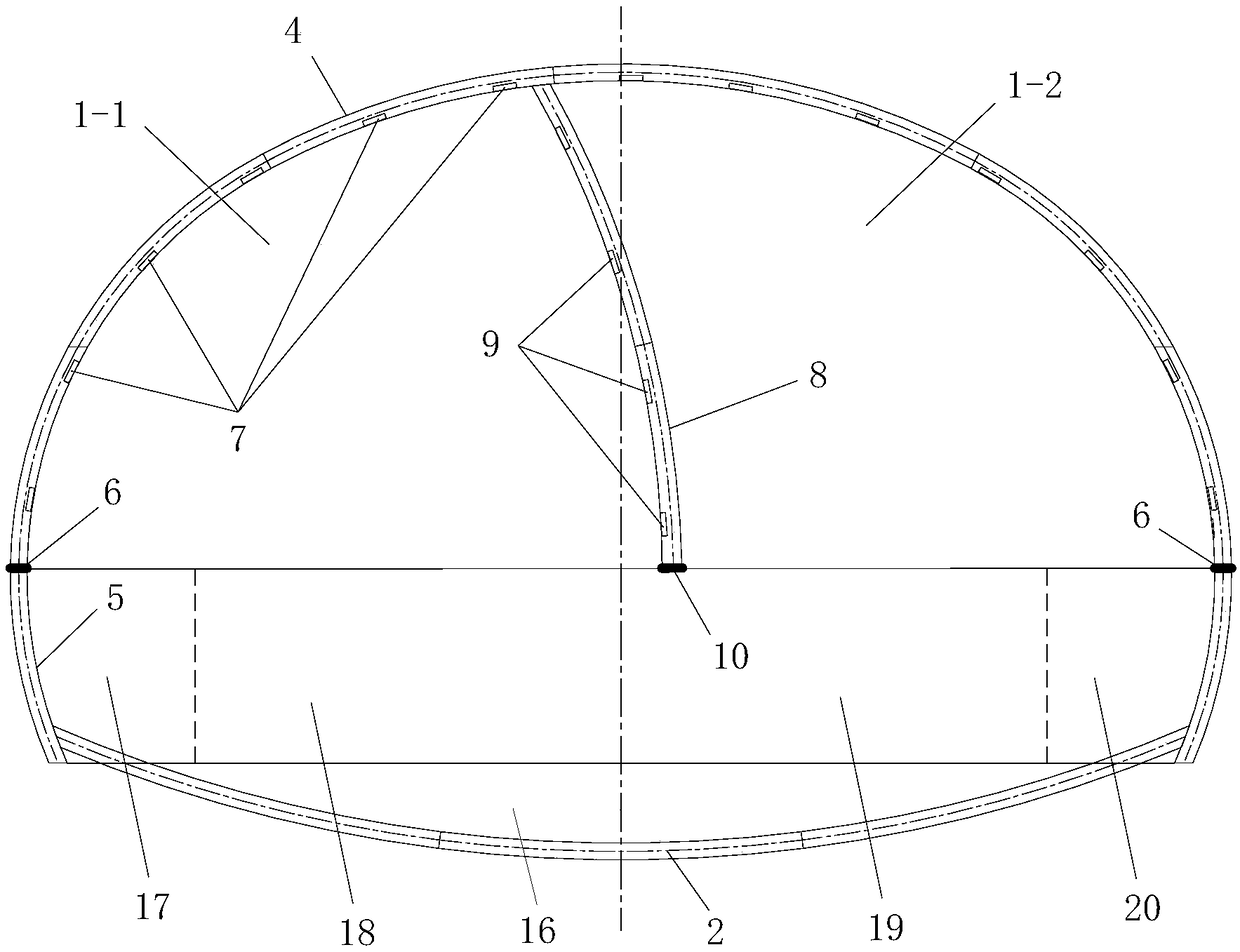

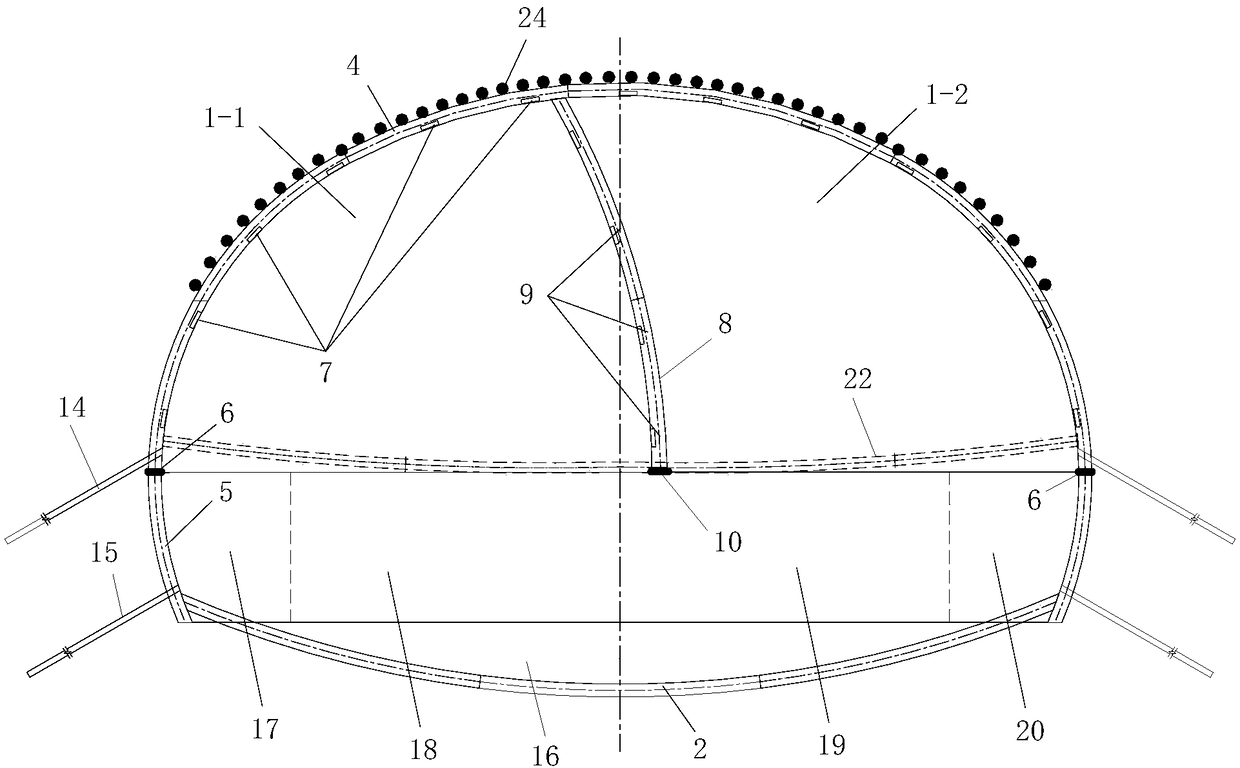

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

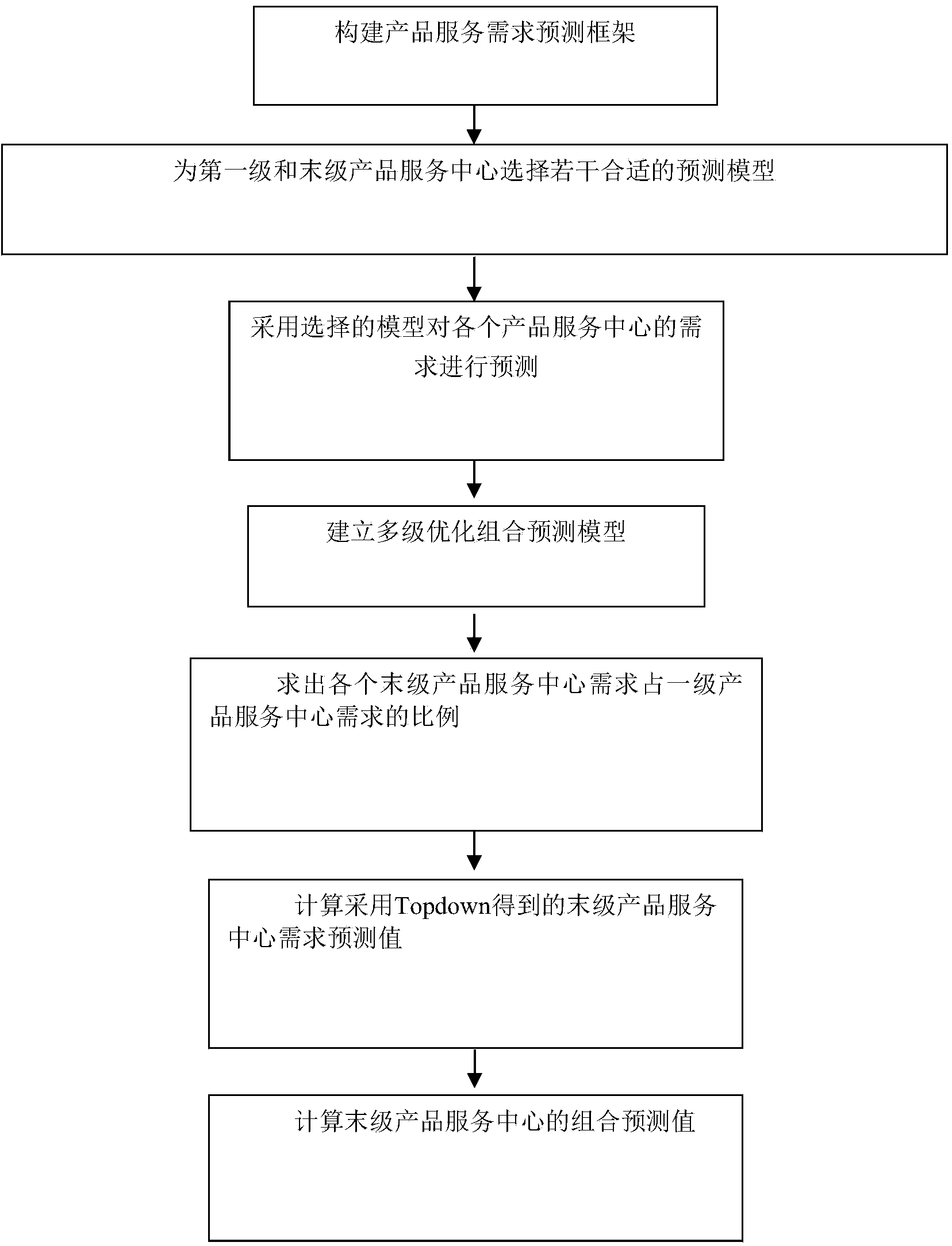

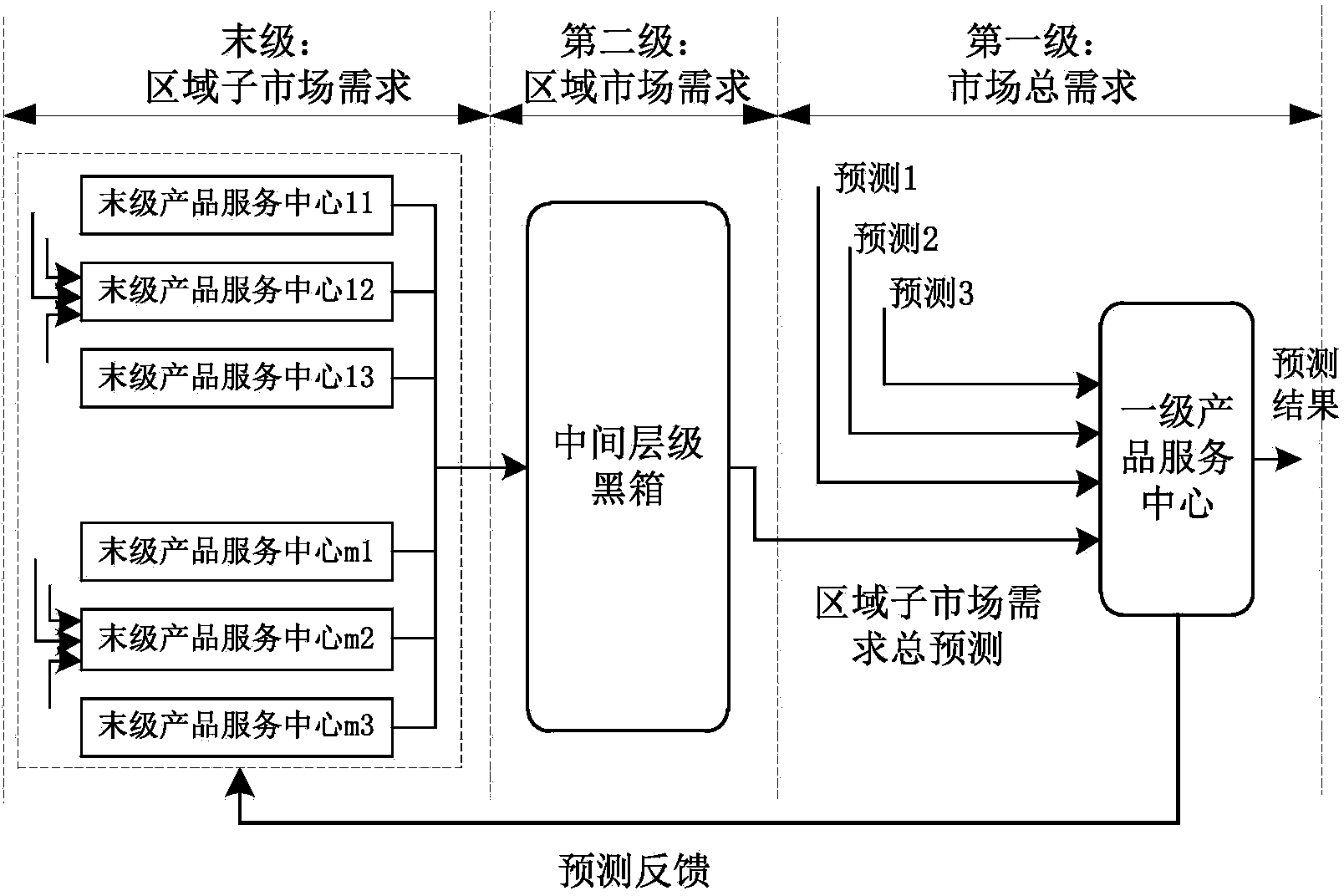

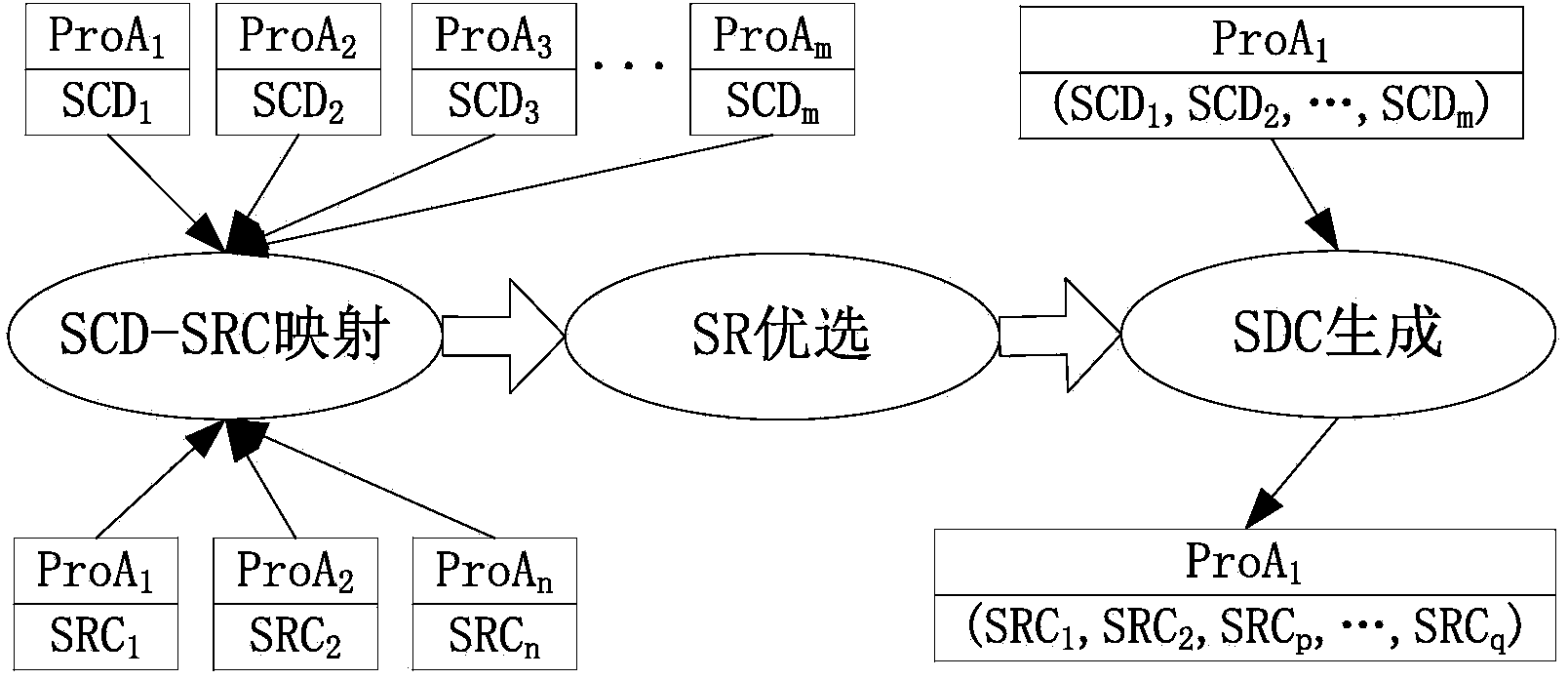

Product service demand forecasting and resource optimization configuration method

ActiveCN104008428AImprove satisfactionGuaranteed support effectForecastingBusiness forecastingComputer science

The invention provides a product service demand forecasting and resource optimization configuration method. The product service demand forecasting and resource optimization configuration method comprises the steps of 1 forecasting the product service demands based on information combination and method combination; 2 performing optimization configuration on product service resources according to different product service demands and product service resource requirements based on a ProA method. The method gives full play to the advantages of different forecasting models on the aspect of demand tendency information extraction, can fully utilize demand tendency change information at different product service demand levels and accordingly improves the demand forecasting accuracy. After the product service demands are accurately obtained, by adopting the product service resource configuration method based on the ProA method, all of product service can obtain necessary service resource support, product service resource configuration schemes can be further optimized, accordingly the customer satisfaction can be improved, and the product service cost can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

Novel coal mine high-strength anchor rod supporting device

The invention relates to the technical field of coal mine anchor rod supporting, and discloses a novel coal mine high-strength anchor rod supporting device. An anchor rod supporting mechanism comprises an outer anchorage rod, an inner anchorage sleeve and an outer blocking fixing assembly, the inner anchorage sleeve can be well connected with the inner wall of a drill hole through a reinforcing structure extending in the radial direction, the inner anchorage sleeve is of a circumferential expansion structure, can easily stretch into the drill hole and can carry out special grouting through a grouting device, integrated performance of the inner anchorage sleeve and the inner wall of an anchorage hole can be ensured, the reinforcing structure can stretch into the rock layer of the anchoragehole, the segmented grouting anchorage manner enables anchorage slurry to be more fully filled, the anchorage reliability can be improved, the combination force with the wall of the anchorage drill hole can be improved, anchorage effect is ensured, in addition, for the fragile portion at the connecting position of the inner anchorage sleeve and the outer anchorage rod, through the manner of arranging multiple radial fins, the connecting property of the connecting position can be effectively improved, and the supporting capacity is ensured.

Owner:HENAN POLYTECHNIC UNIV

Aortic windowing branch covered stent

InactiveCN105943199AAvoid damageImprove flexibilityStentsBlood vesselsMinimal access surgeryThree vessels

The invention discloses an aortic windowing branch covered stent and belongs to the technical field of vascular stents. The aortic windowing branch covered stent comprises a tubular skeleton made of thin filaments and a membrane covering the tubular skeleton. The proximal end of the tubular skeleton is suitable for being inserted into a window of the aortic windowing branch covered stent and communicated with the aortic windowing branch covered stent. The remote end of the tubular skeleton is suitable for being inserted into a branch blood vessel, and the proximal end is harder than the remote end. The aortic windowing branch covered stent lowers the operation difficulty of minimally invasive surgery in an aortic lumen with branch blood flow, solves the technical problem that in the surgery, internal leakage occurs easily, can adapt to fitting the tortuous branch blood vessel and effectively prevents damage to the branch blood vessel and occurrence of re-blocking and internal leakage.

Owner:李晓东

Obligate cavity channel gob-side entry retaining wall filling method

ActiveCN103089299APlay a supporting roleSupport does not affectMaterial fill-upUltimate tensile strengthRetaining wall

An obligate cavity channel gob-side entry retaining wall filling method is characterized in that a cylinder hole is obligated on a formwork, a thin-wall steel cylinder penetrates through the formwork, a lane is located on the high position, a goaf area us located on the low position, a filling wall with a cavity is formed after filling, wall using materials are reduced, and wall strength is not influenced. An open-close door is installed at the hole opening, when the lane deforms, cannot normally use and needs to conduct dinting, a large quantity of gangue produced after lane dinting can be thrown to the inside by opening the door, and the lane is distributed in an air return along groove. Due to existence of a coal bed pitch, inbreak gangue surges up the goaf area of the transportation along grooves under the effect of gravity, in addition, side direction breaking is carried out on the top plate during caving, a lateral breaking angle is formed, a space at a button angle of the filling wall enables the inbreak gangue to be unable to achieving a filling area, a great quantity of spaces are left on the filling wall side, throwing gangue directly enters the goaf area under the effect of gravity, and deposit spaces are provided for processing undercover gangue.

Owner:CHINA UNIV OF MINING & TECH

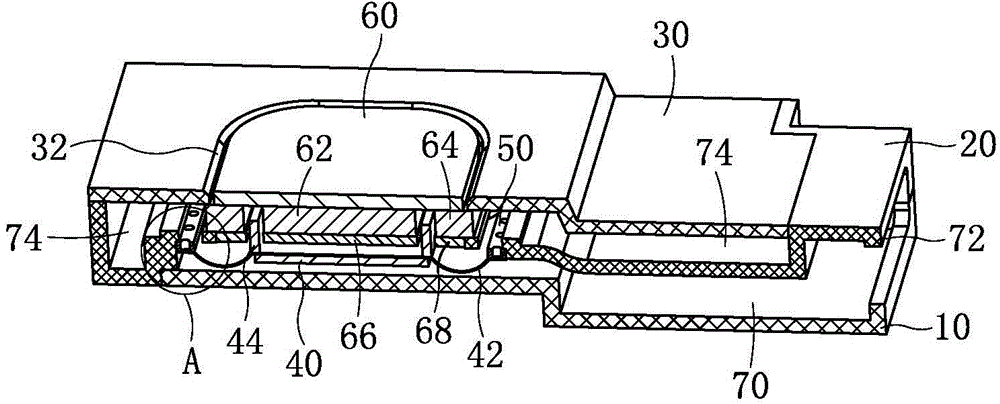

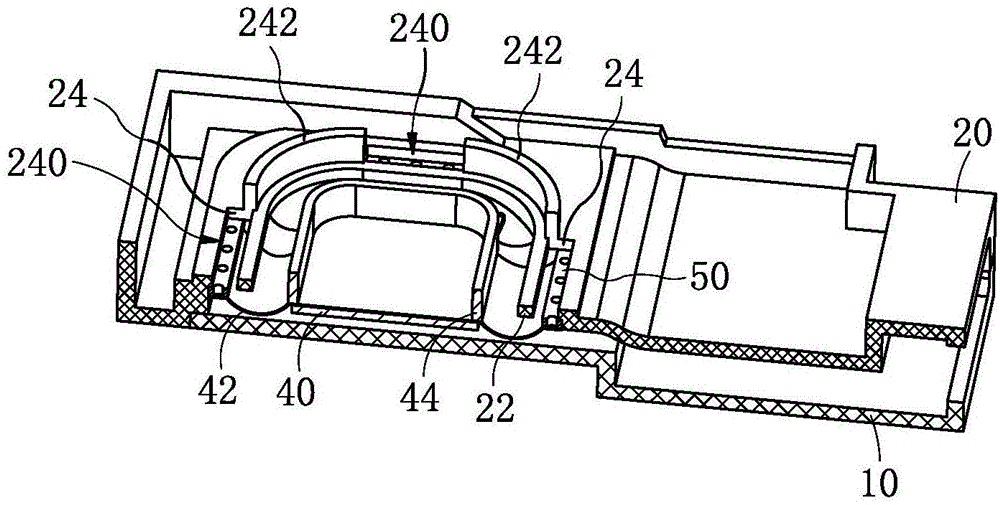

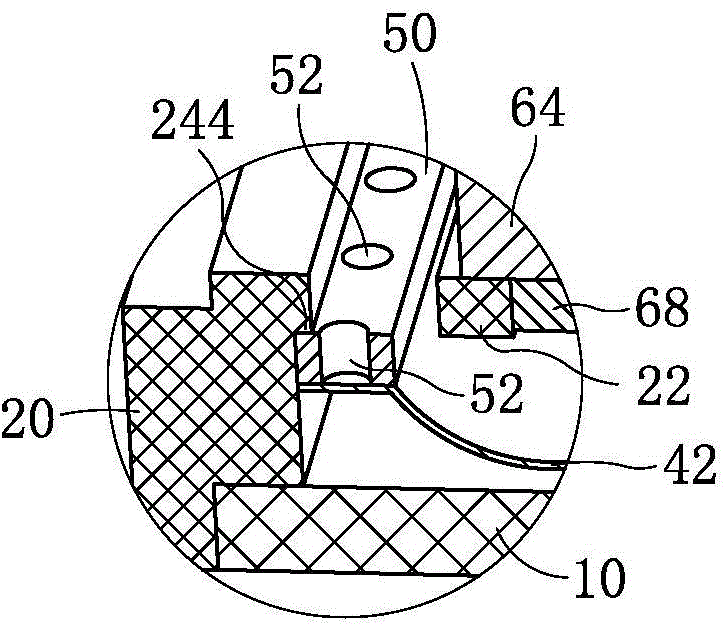

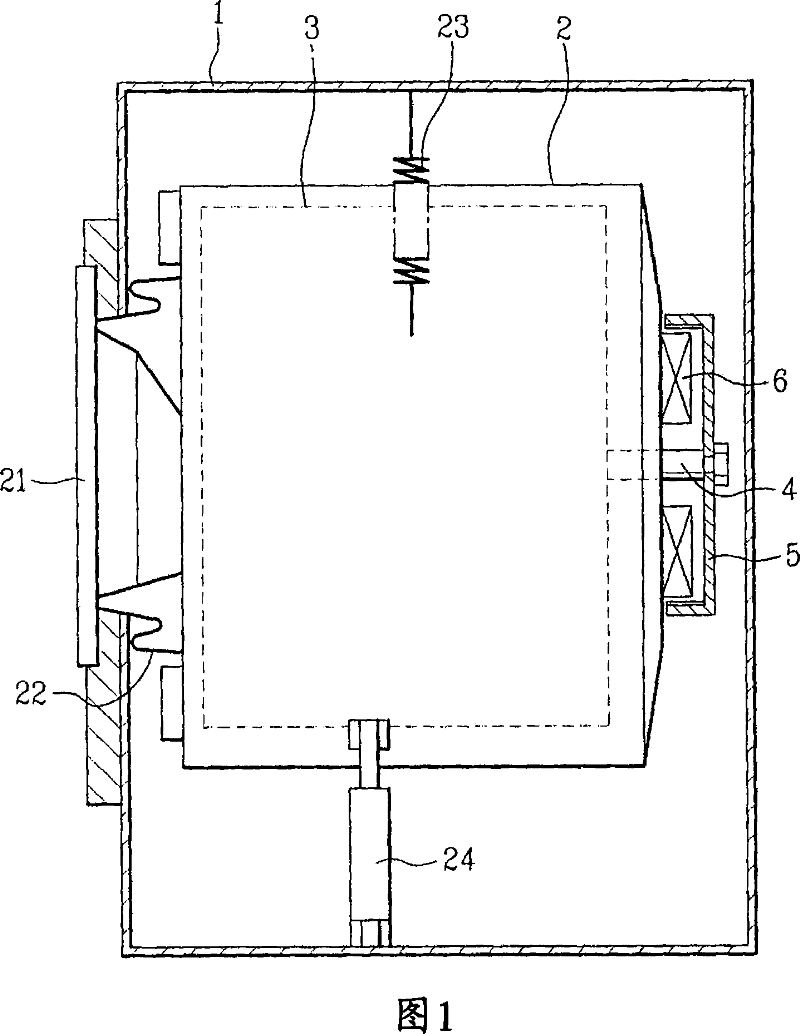

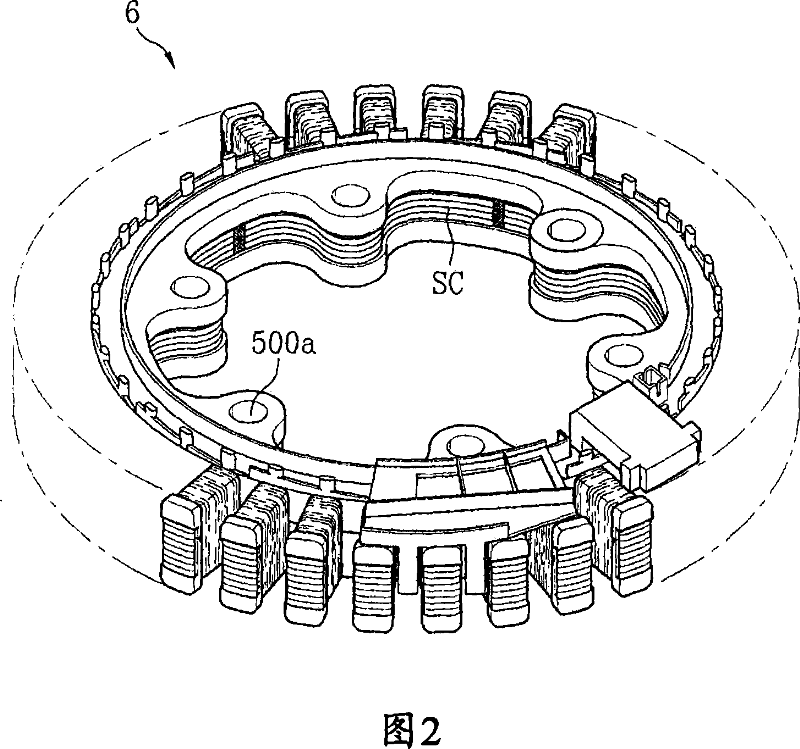

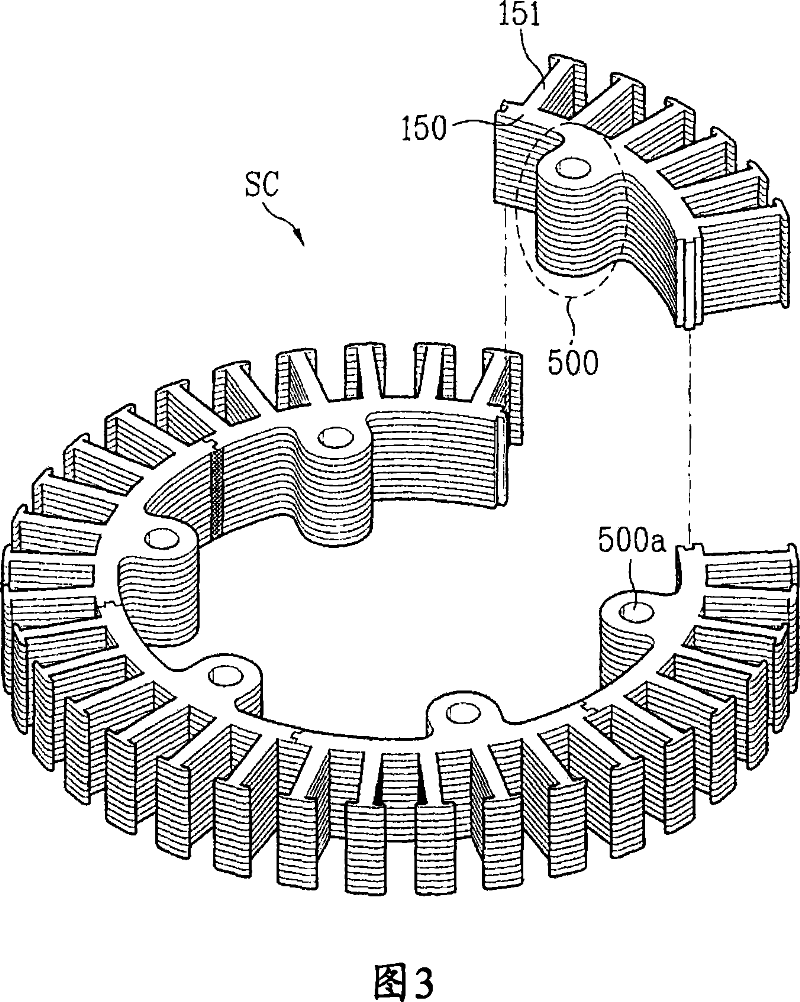

Drum type washing machine

ActiveCN101037838AGuaranteed support effectSimplify the assembly processWindings insulation shape/form/constructionMagnetic circuit rotating partsEngineeringMultiple layer

Drum type washing machine including a tub of plastic having a wall for holding washing water therein and mounting a driving part thereon, a drum rotatably arranged inside of the tub, a shaft passed through the tub and connected to the drum for transmission of a driving power from a motor to the drum, at least one bearing for supporting the shaft, a bearing housing having a sleeve form of bearing supporting part, and a stator fastening part extended in a radial direction from the bearing supporting part, wherein both of the bearing supporting part and the stator fastening part are inserted in a tub rear wall, while stator fastening holes in the stator fastening part are exposed, a rotor engaged to a rear end part of the shaft to form the motor together with the stator, and the stator mounted on the stator fastening part of the bearing housing with fastening members on an inner side of the rotor to form the motor together with the rotor, wherein the stator includes an annular helical type core having multiple layers formed by winding a steel plate having tooth portions and a base part in a helix starting from a bottom layer to a top layer, an insulator having the helical type core encapsulated therein, a coil wound on the tooth portions, and fastening parts formed as a unit with the insulator, having fastening holes projected toward an inside of the helical type core for fastening the stator to the bearing housing, thereby reducing a weight of required material, simplifying an assembly process, and assure stable mounting of the stator on the tub.

Owner:LG ELECTRONICS INC

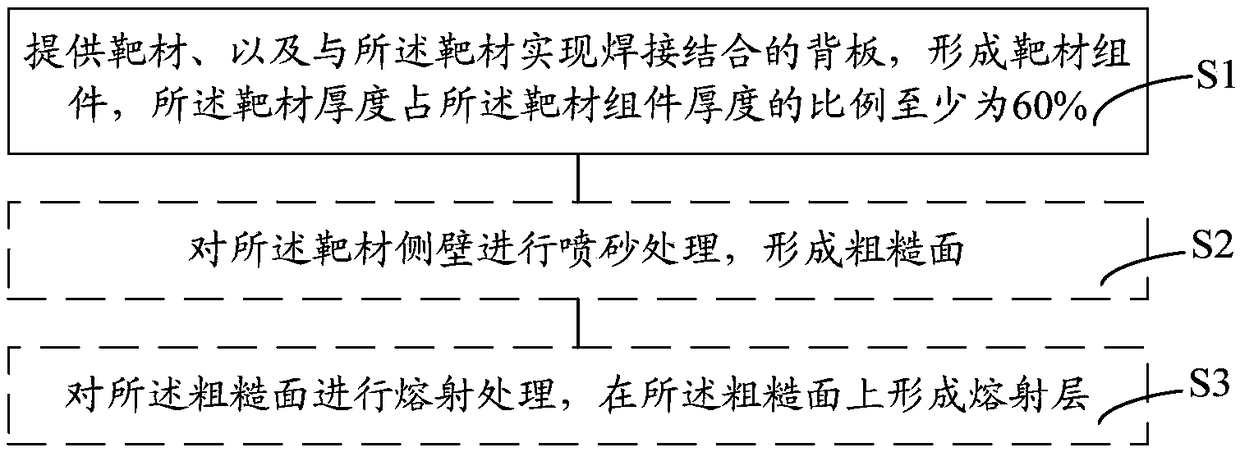

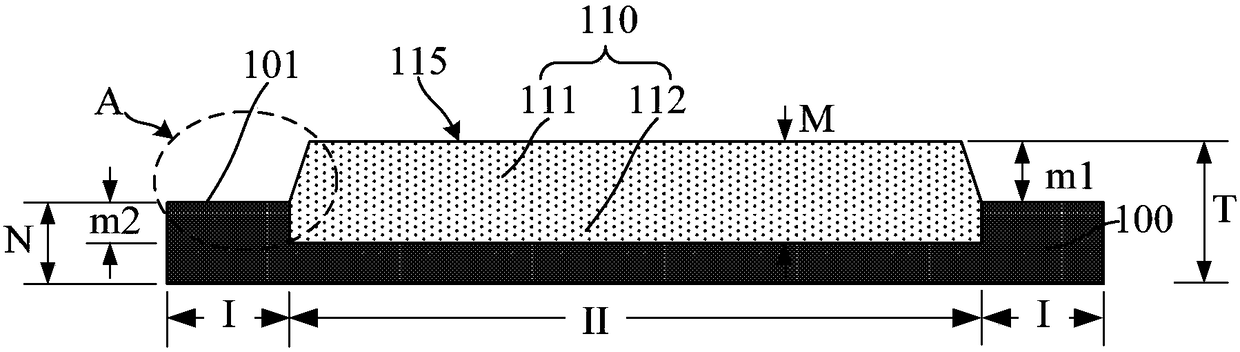

Target material assembly and manufacturing method thereof

InactiveCN109385608AUnchanged thicknessIncreasing the thicknessVacuum evaporation coatingSputtering coatingProcess efficiencyMaterials science

The invention provides a target material assembly and a manufacturing method thereof. The manufacturing method comprises the following step: providing a target material and a back plate capable of bonding with the target material in a welded manner so as to form the target material assembly, wherein the thickness of the target material accounts for at least 60% of the thickness of the target material assembly. According to the invention, the thickness of the target material accounts for at least 60% of the thickness of the target material assembly; thus, compared with a scheme that the thickness of the target material accounts for a smaller proportion of the thickness of the target material assembly, the target material assembly provided by the invention has the following advantages: the thickness of the target material can be increased under the condition that the thickness of the target material assembly is unchanged, and the part of the target material for sputtering is correspondingly increased, so the service life of the target material assembly is effectively prolonged; the replacement frequency of the target material assembly is effectively reduced; improvement of process efficiency and reduction of process cost can be easily realized; meanwhile, the thickness of the target material assembly can remain unchanged, so a sputtering machine bench does not need to adjust thespacing between the target material and a product about to undergo film formation (such as a wafer), and adverse effects on the initial sputtering rate and film-forming uniformity of the target material assembly are avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

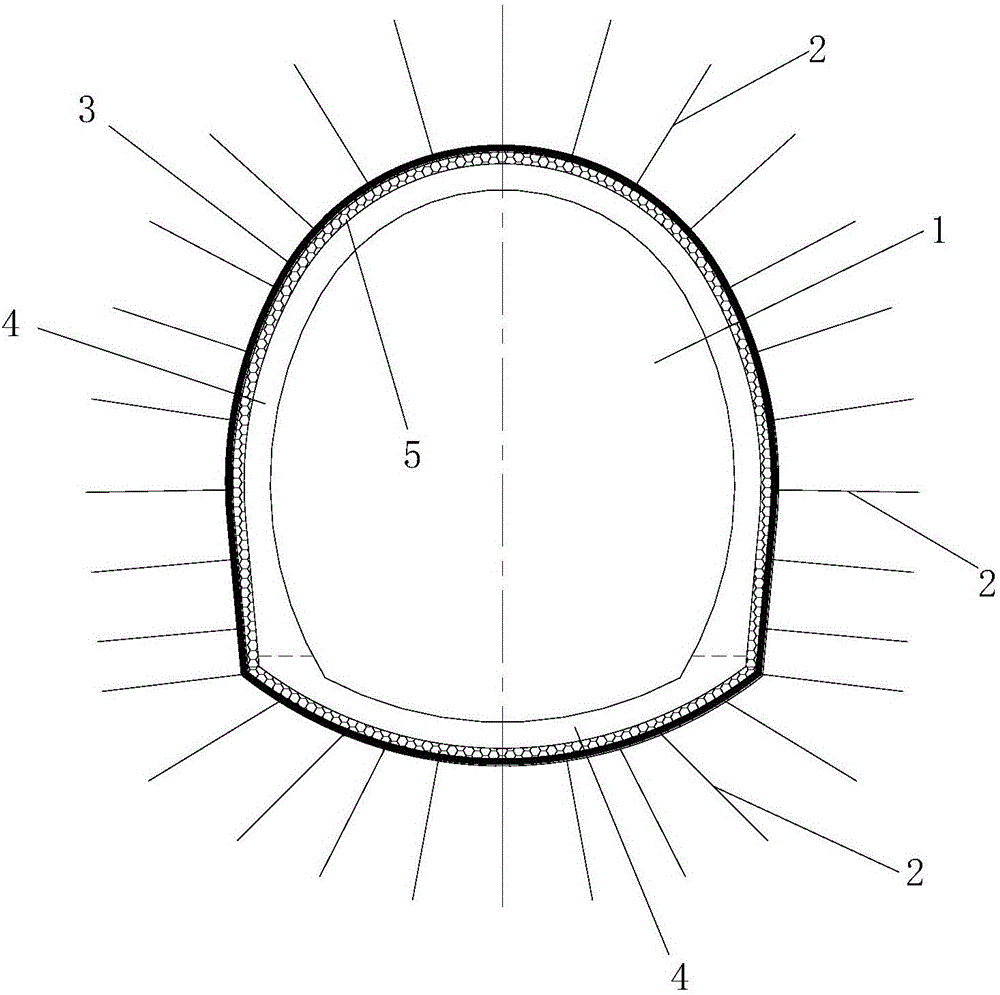

Space joint support structure and support method for water-rich broken strata tunnel

PendingCN110094213APrevent surrounding rock from deterioratingGood mechanical performanceUnderground chambersDrainageTunnel constructionRock pressure

The invention discloses a space joint support structure and support method for a water-rich broken strata tunnel, and relates to the technical field of tunnel construction. The problems that a large-scale deformation is prone to occur due to the fact that a water-rich broken surrounding rock section adopts a conventional spray anchoring to support surrounding rocks, the surrounding rock pressure is great, effective prevention and control of water leakage is difficult, and stability of a tunnel structure and safety of construction are jeopardized are solved. The key points of the technical scheme are that the space joint support structure comprises an initial concrete layer, a steel mesh, and steel arches arranged at intervals; longitudinal connecting steel beams distributed along the axialof a tunnel in a staggered mode are arranged between the steel arches in the circumferential direction; longitudinally connecting steel beams are connected with anchor rods; a steel fiber concrete layer covering the steel arches, the steel mesh, and the longitudinally connecting steel beam sprays the surface of the steel mesh; a waterproof and drainage structure layer paves the surface of steel fiber concrete; and a second lining concrete layer pours the surface of the waterproof and drainage structure layer. According to the space joint support structure and support method for the water-richbroken strata tunnel, deformation of the surrounding rocks in the tunnel can be effectively controlled, the waterproof and drainage functions are excellent, and stability of the tunnel structure andsafety of construction are ensured.

Owner:FUJIAN UNIV OF TECH

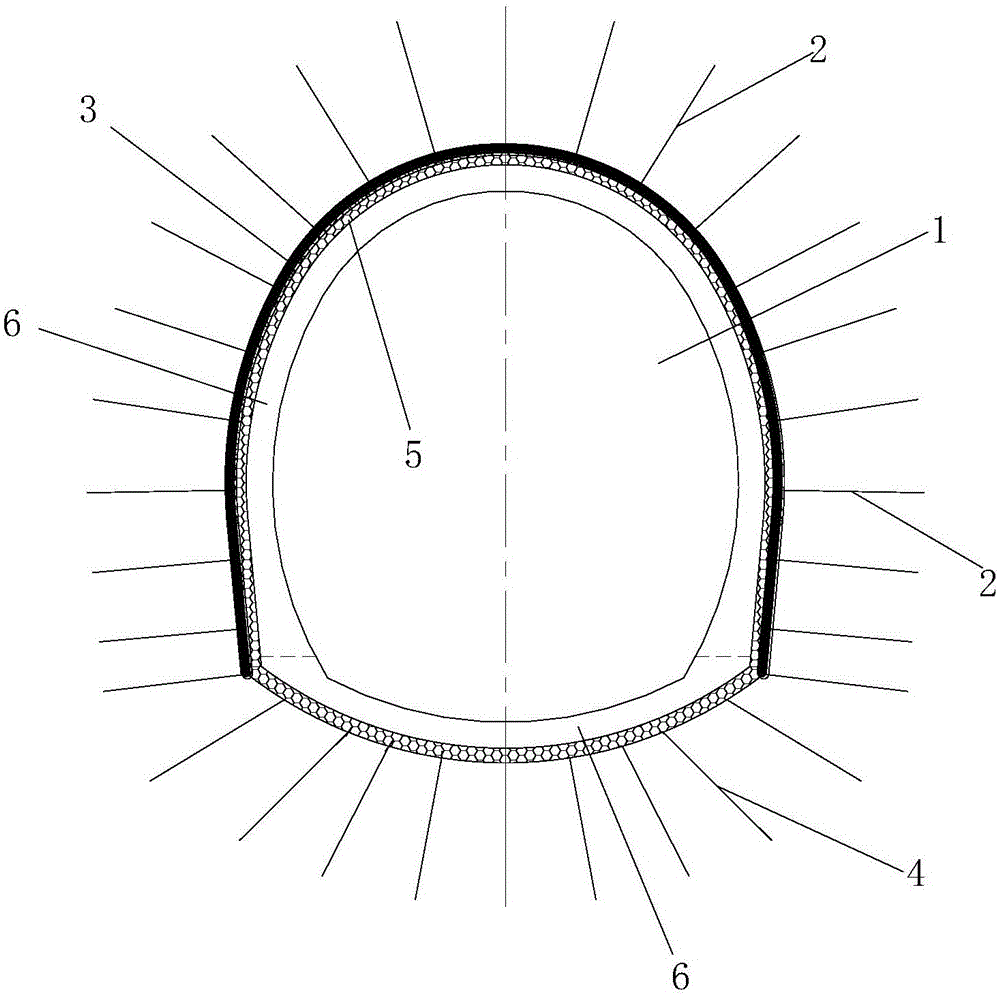

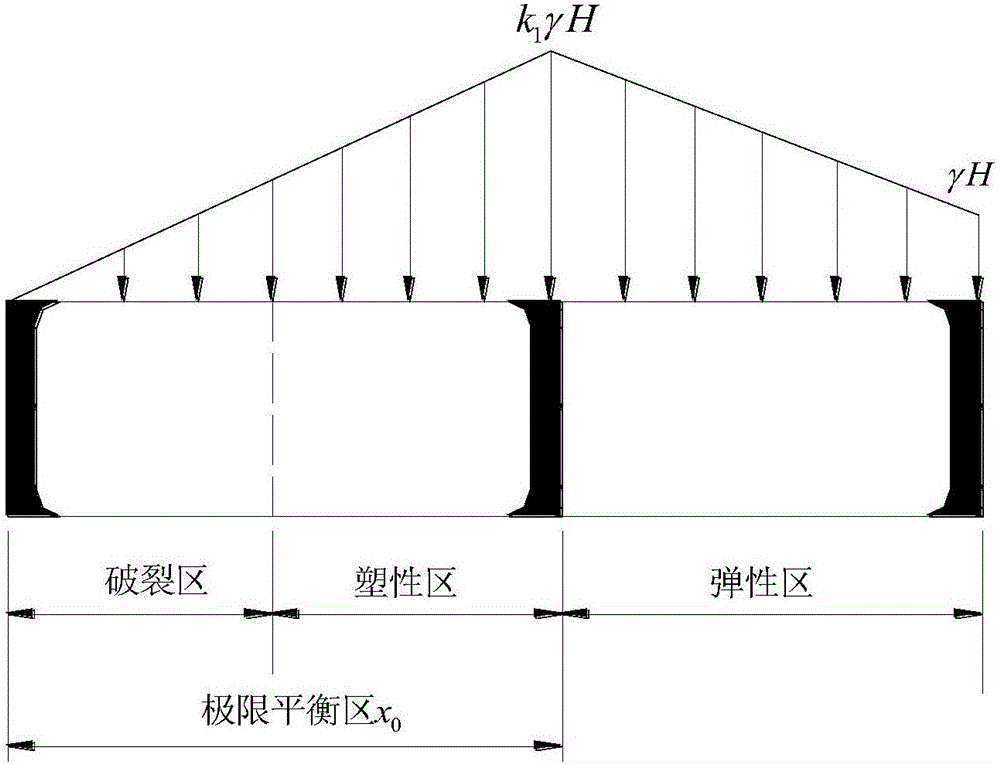

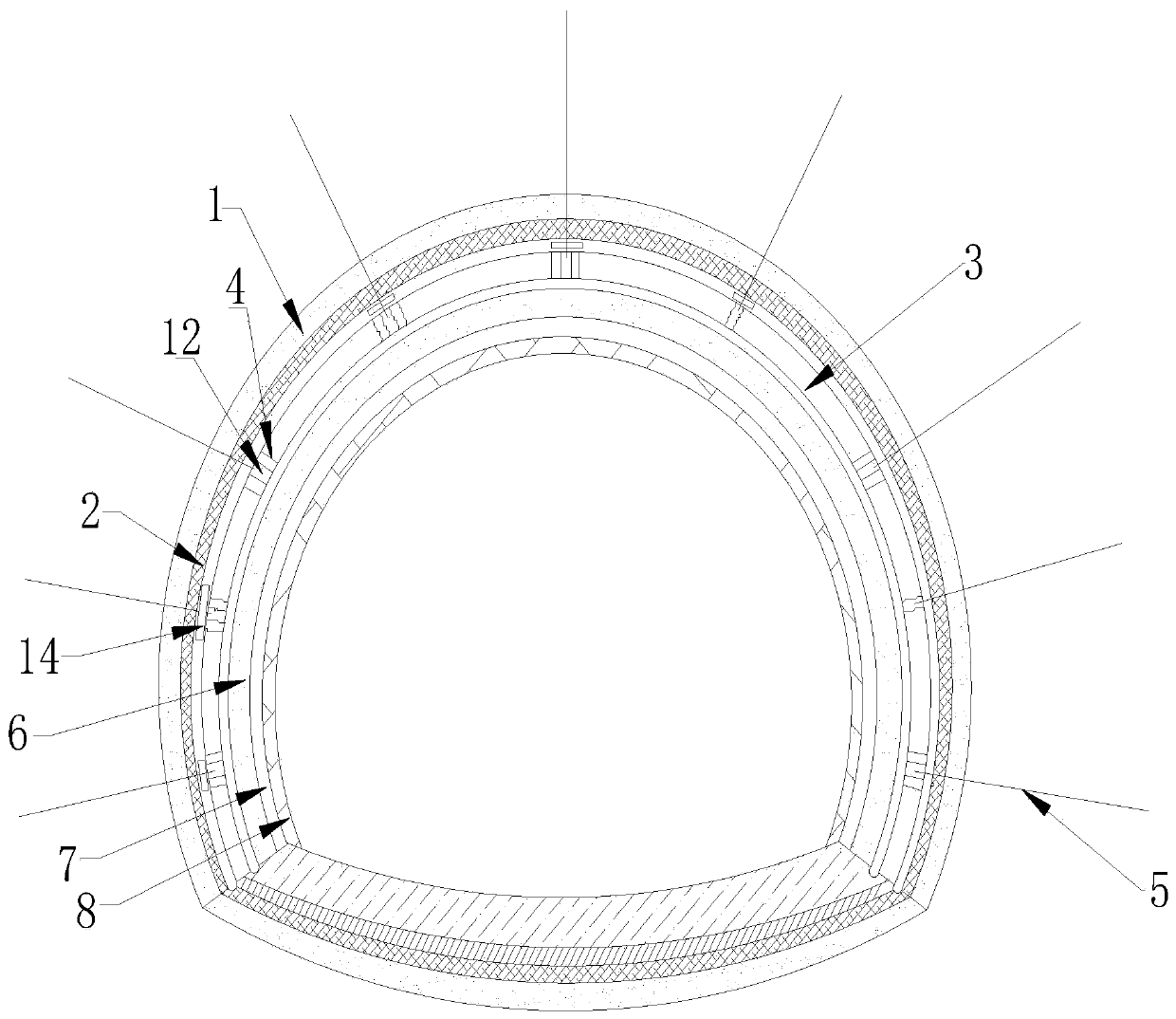

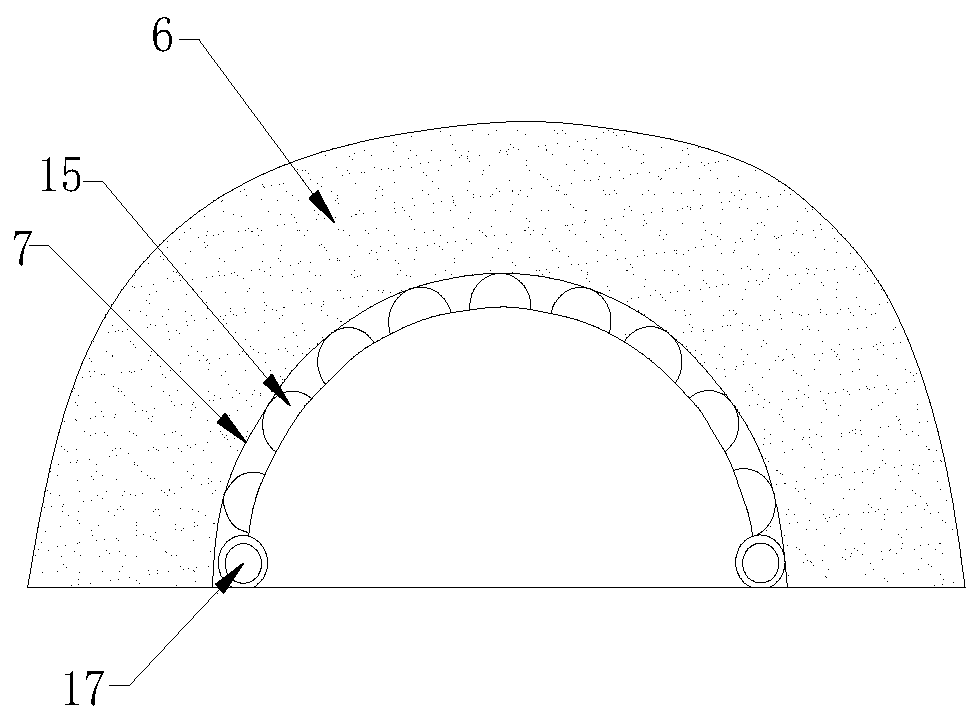

Soft rock tunnel construction method on the basis of flexible formwork support

InactiveCN106522978AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelStructural stability

The invention discloses a soft rock tunnel construction method on the basis of flexible formwork support. A soft rock tunnel is divided into a plurality of segments from back to front to be subjected to construction. Construction of any one segment comprises the following steps that (1), basic mechanical parameters of surrounding rocks are defined; (2), the tunnel reserved excavating quantity is defined; (3), the tunnel begins to be excavated; (4), A tunnel support structure is defined: the tunnel support structure comprises a tunnel incipient support structure, a flexible formwork support structure and tunnel two-time linings; (5), tunnel incipient support is constructed; (6), the flexible formwork support is constructed; (7), the tunnel two-time linings are constructed; (8), a next segment is constructed; and (9), step (8) is repeated for many times until all the construction processes of the soft rock tunnel are completed. According to the soft rock tunnel construction method on the basis of the flexible formwork support, the method and the steps are easy, design is reasonable, achieving is convenient, and the using effect is good; and the reserved excavating quantity is defined according to deformation conditions of the surrounding rocks of the soft rock tunnel, the flexible formwork support structure is adopted to support full cross sections of the tunnel and subjected to coordination deformation with the tunnel incipient support structure, and thus structure stability of the tunnel two-time linings is guaranteed.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com