Prestress anchor device

A prestressing and anchoring technology, which is applied in the installation of anchors, construction, mining equipment, etc., can solve the problems of complex construction and complex construction technology, and achieve a cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

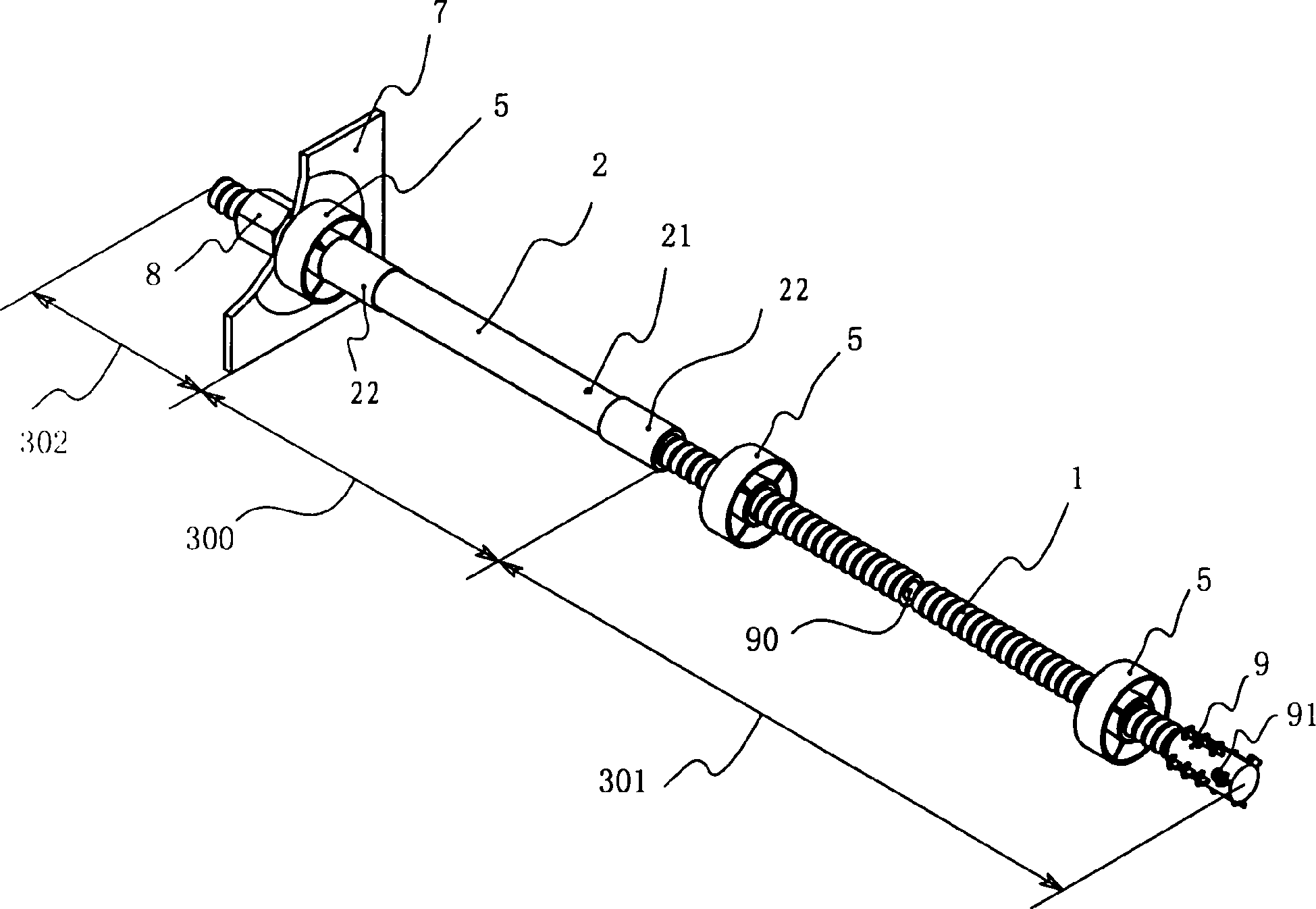

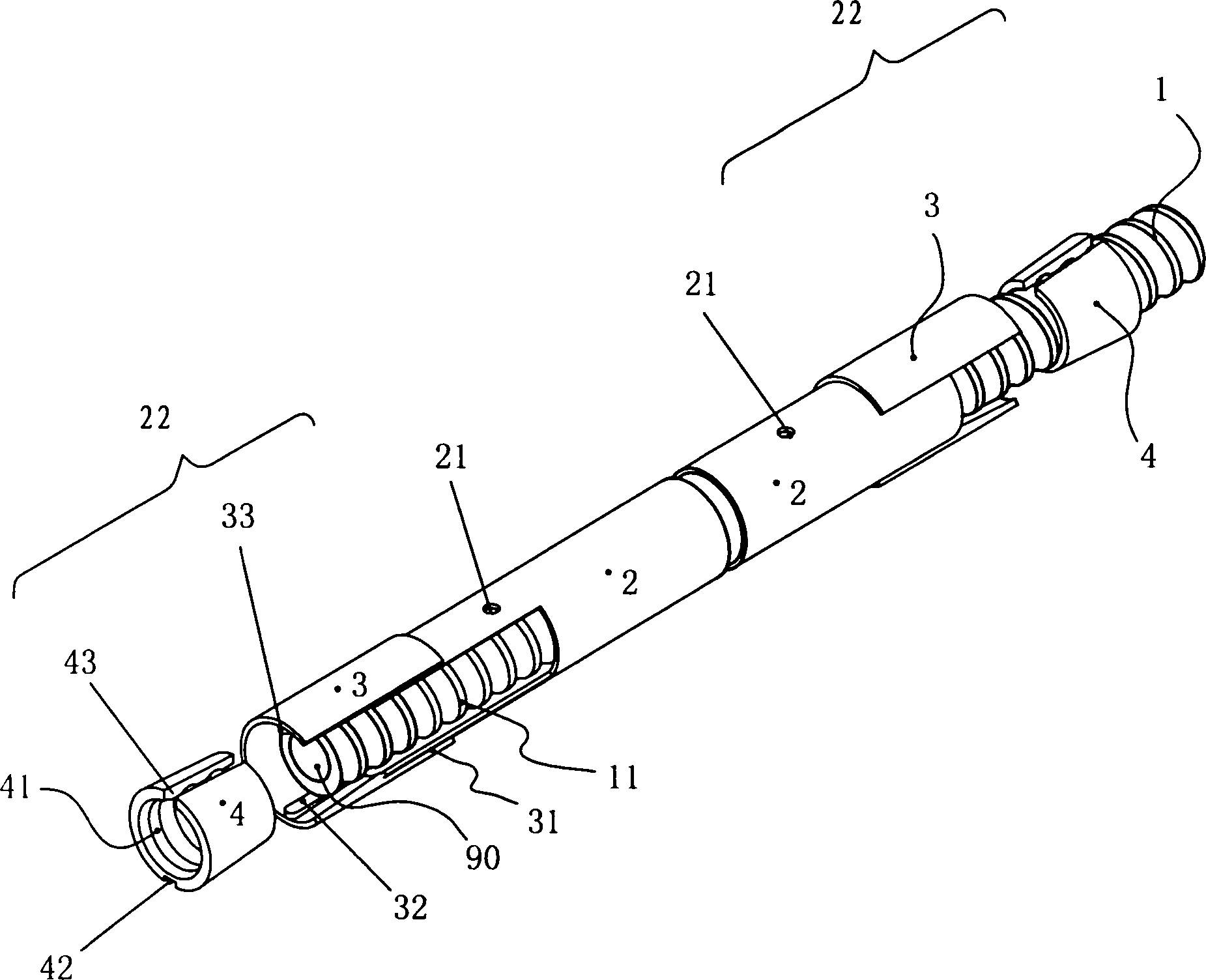

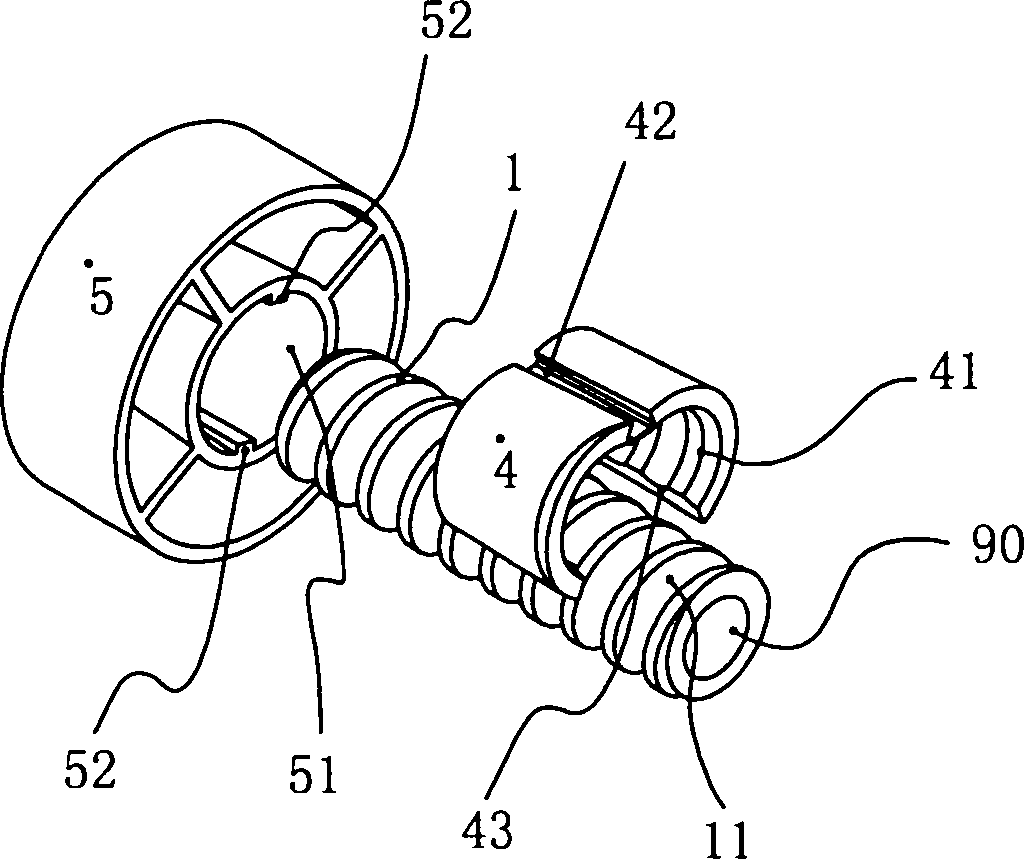

[0066] Such as Figure 1~6 As shown, a prestressed bolt device is composed of a bolt body 1, a support plate 7, a lock nut 8, a centering device 5, a free section casing device 12, a grouting and an exhaust channel, and the like. The outer anchor section 302, the anchor section 301 and the free section 300 of the prestressed anchor rod are formed after grouting consolidation and prestressing. The free section casing 2 is threaded on the anchor body 1, and its two end fastener devices 2a are threaded to fix it on the anchor body 1 near the end of the support pad 7; the free section casing 2 can be The two end fastening devices 22 rotate and move on the anchor body 1, and the middle part is separated from the anchor body 1 to form an isolation cavity; there is an oil injection hole 21 on it, which can realize oil injection isolation or non-oil injection isolation.

[0067] Such as figure 2 As shown, the terminal fastener device 22 is composed of a sleeve joint 3 and a rod bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com