Space joint support structure and support method for water-rich broken strata tunnel

A combined support and tunnel technology, applied in the direction of tunnel, tunnel lining, drainage, etc., can solve the problems of endangering the stability of the tunnel structure and the safety of the operators, the difficulty of effective prevention and control of water leakage, and the poor self-stabilization ability of the surrounding rock, etc., to achieve High rigidity and bearing capacity, stable support performance, and the effect of preventing the deterioration of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

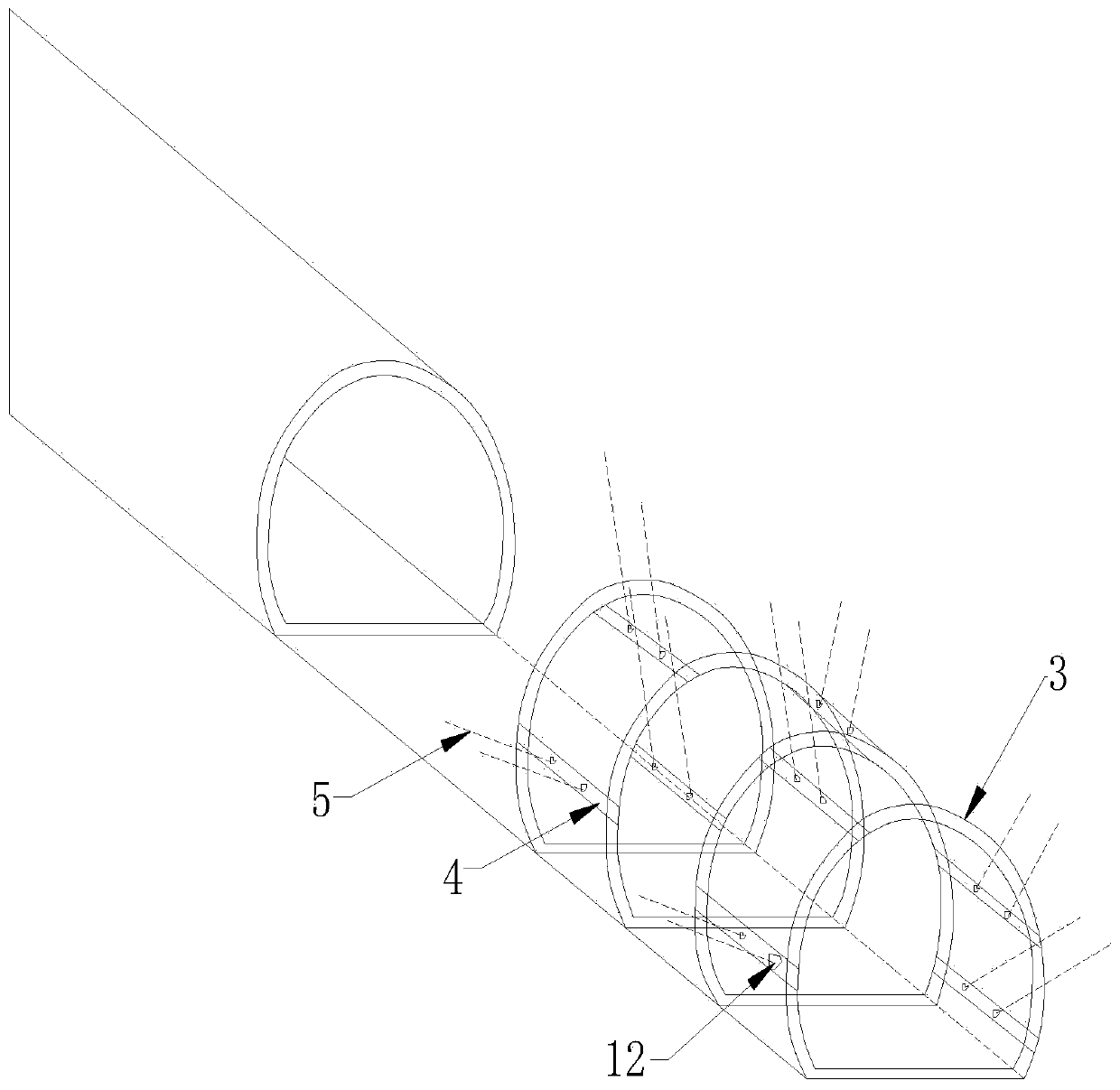

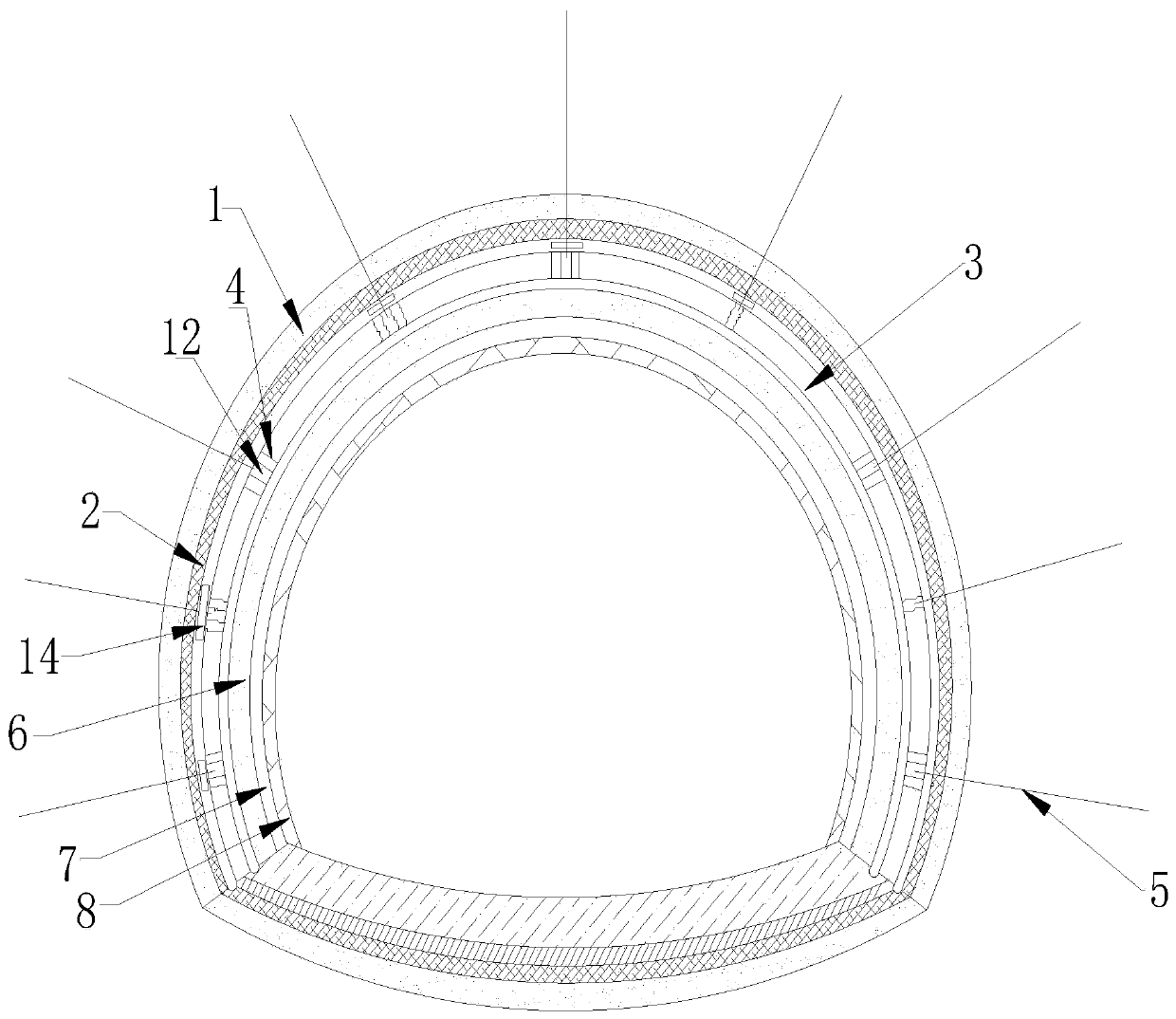

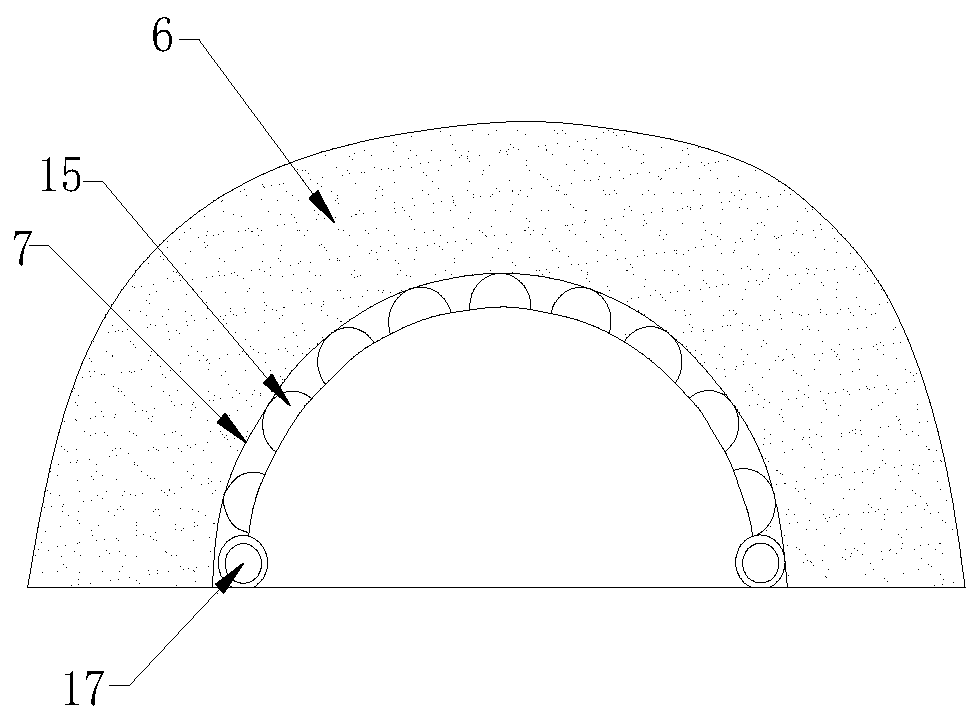

[0043] Embodiment 1: A kind of spatial combined support structure of water-rich fractured formation tunnel, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, it includes a primary concrete layer 1 with a thickness of 3-5cm sprayed on the surface of the surrounding rock in the tunnel, a steel mesh 2 laid on the surface of the primary concrete layer 1, and a plurality of steel arches 3 arranged at intervals. 3 is in contact with the surface of the steel mesh 2. Between the steel arch 3 and the steel arch 3, longitudinal connecting steel beams 4 are circumferentially installed, and the longitudinal connecting steel beams 4 are staggered along the axis of the tunnel. The longitudinal connecting steel beam 4 is connected with an anchor rod 5 whose anchoring section is located inside the surrounding rock of the tunnel. The surface of the steel mesh 2 is sprayed with a steel fiber concrete layer 6 covering the steel arch 3, the steel mesh 2...

Embodiment 2

[0057] Embodiment 2: A support method for a space joint support structure of a water-rich fractured stratum tunnel, such as Figure 7 shown, including the following steps:

[0058] 1) Implement flexible support for the first layer, that is, spray concrete with a thickness of 3-5cm on the inner wall of the tunnel to seal the surrounding rock.

[0059] 2) Laying steel mesh 2, erecting steel arch 3, laying steel mesh 2 with a grid size of 25cm on the concrete surface in step 1), and then erecting multiple meshes in contact with the surface of steel mesh 2 at intervals of 50-70cm. A steel arch 3.

[0060] 3) A two-story rigid support structure is constructed, and longitudinal connecting steel beams 4 are arranged in a circular direction along the tunnel axis at a designed interval between every two steel arches 3, and then the longitudinal connecting steel beams 4 are connected to the tunnel by bolts. The overlapping parts of the steel support parts of the steel arch 3 are initi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grid size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com