Prefabricated concrete-filled steel tube composite column and building thereof

A technology of steel pipe concrete and prefabrication, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of difficult to guarantee the quality of concrete pouring, high labor intensity, and a lot of construction waste, and achieve good application prospects, wide application range, Good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

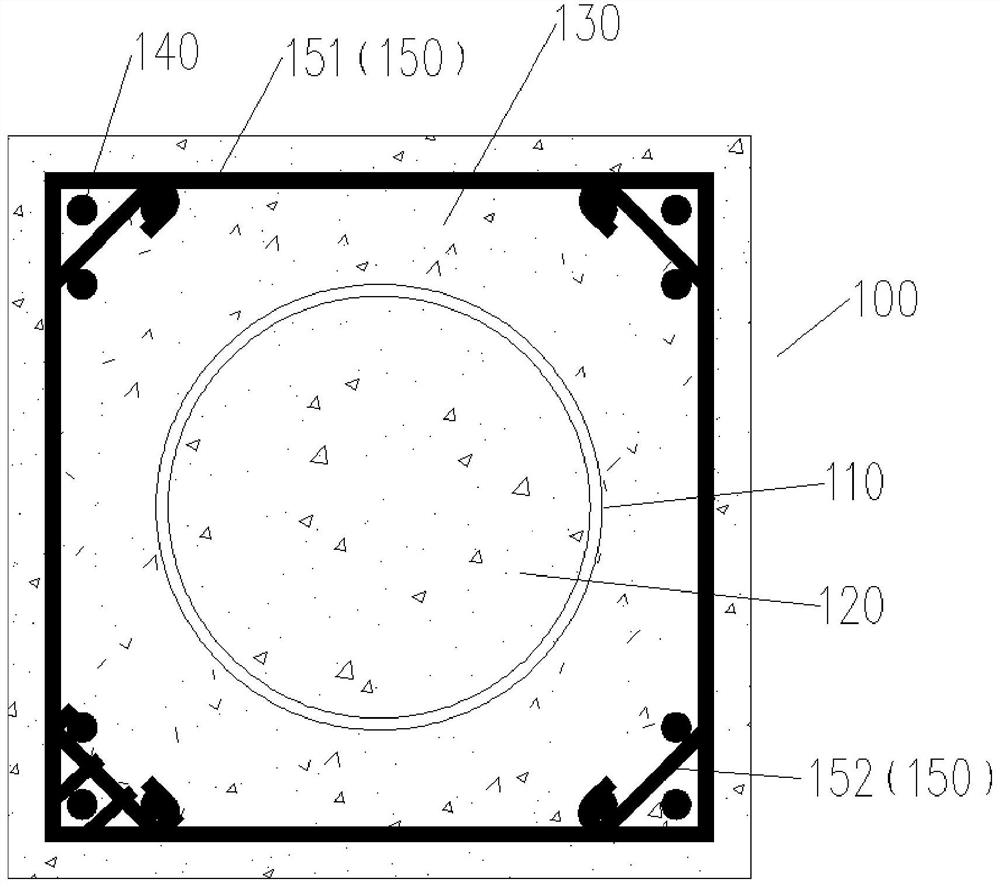

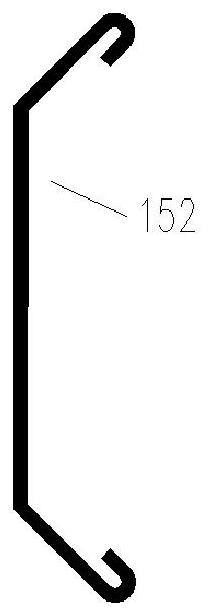

[0067] like figure 1 As shown, a prefabricated concrete-filled steel tube composite column 100 provided in this embodiment includes: a steel tube 110, a concrete column 120 filled in the tube, a concrete layer 130 outside the tube, and a steel skeleton; Concrete columns 120 are filled inside the pipe; the outer concrete layer 130 is wrapped on the outside of the steel pipe 110; the steel skeleton is buried in the outer concrete layer 130; the two ends of the steel pipe 110 are respectively provided with connecting structures for connecting with foundations, steel beams or columns .

[0068] The concrete column 120 filled in the pipe is formed by pouring self-compacting concrete; the concrete layer 130 outside the pipe is made of ordinary strength concrete, and the concrete grade is from C35 to C50. The steel pipe 110 is a circular steel pipe, a rectangular steel pipe or a polygonal steel pipe.

[0069] The reinforcement skeleton includes: column longitudinal bars 140 and sti...

Embodiment 2

[0091] This embodiment is basically the same as Embodiment 1, the difference is:

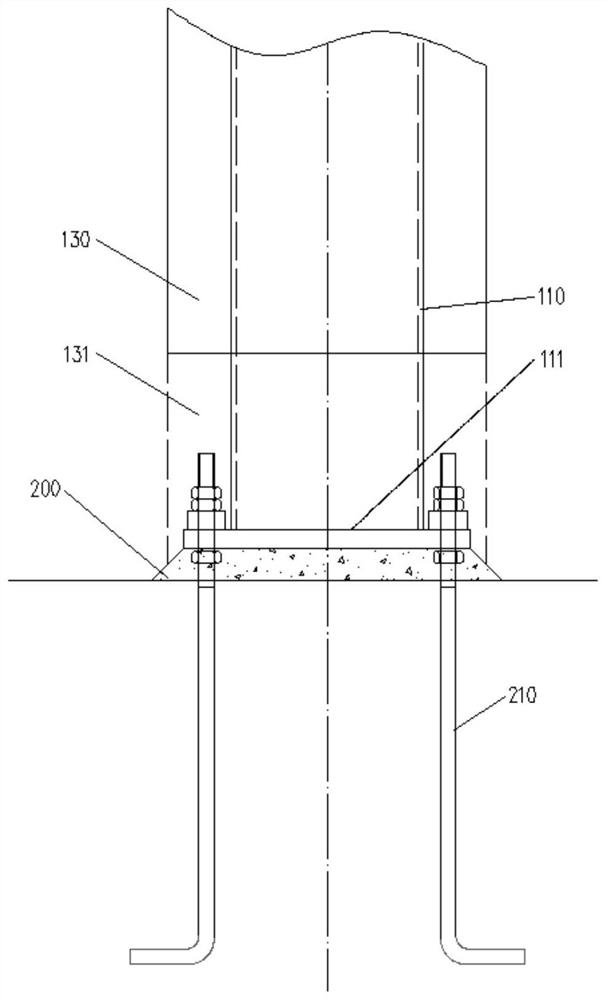

[0092] like Figure 9 As shown, the column longitudinal reinforcement 140 is an angle steel 141 inside the column. More preferably, the angle steel 141 in the column is an equilateral angle steel. To facilitate the vertical splicing of the upper and lower section superimposed columns 100. like Figure 10 As shown, the concrete layer 130 outside the pipe is provided with a post-cast section 131 at one or both ends of the steel pipe 110 in the column (that is, the laminated column 100); the angle steel 141 in the column is reserved with a connection hole on the exposed part of the post-cast section; When two adjacent stacked columns 100 are docked, the steel pipe 110 is fixedly connected through the connecting flange 112; after the upper and lower column inner angle steels 141 are butted, the upper and lower butted column inner angle steels 141 are fixedly connected by using the connecting angl...

Embodiment 3

[0095] This embodiment discloses a building using the above-mentioned prefabricated steel pipe concrete composite column, refer to Figure 7 and 11 As shown, it includes a steel beam 20 and a floor 10 ; both ends of the steel beam 20 are connected to the steel pipe 110 through the outstretched corbels 160 , and the steel beam 20 is hidden within the height range of the floor 10 .

[0096] The floor 10 includes a concrete precast slab 11 and an existing structural layer; the steel beam 20 includes an upper flange 22, a lower flange 21, and a web 23; Connected to the lower flange 21; the existing structural layer is laid above the concrete prefabricated slab 11, and the upper flange 22 is embedded in the existing structural layer. The web 23 is provided with reinforcement holes 23a and pipeline holes 23b at intervals, which are respectively used for piercing the perforated steel bars and the pipelines of the floor heating layer 14, and makes the concrete on both sides of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com