Connecting method of prefabricated concrete member

A technology of precast concrete and connection method, which is applied in the direction of building structure and construction, can solve the problems of difficult to guarantee construction quality, difficult to guarantee grouting quality, and affect the mechanical performance, so as to improve the integrity of the connection, increase the anchoring performance, strengthen the holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method for connecting precast concrete components of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

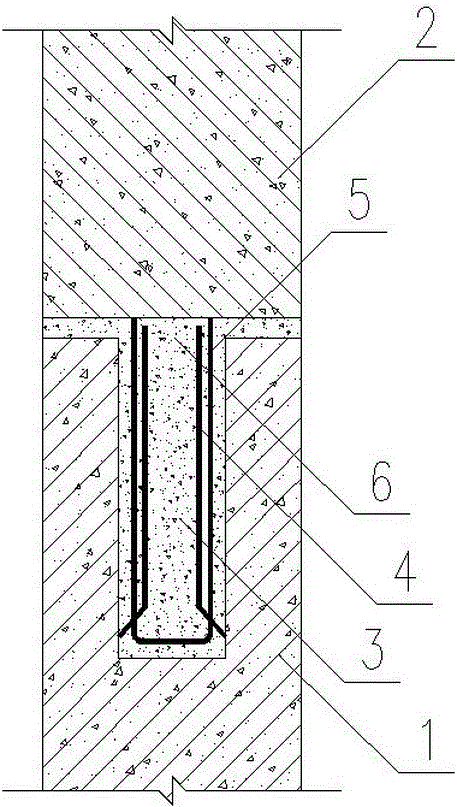

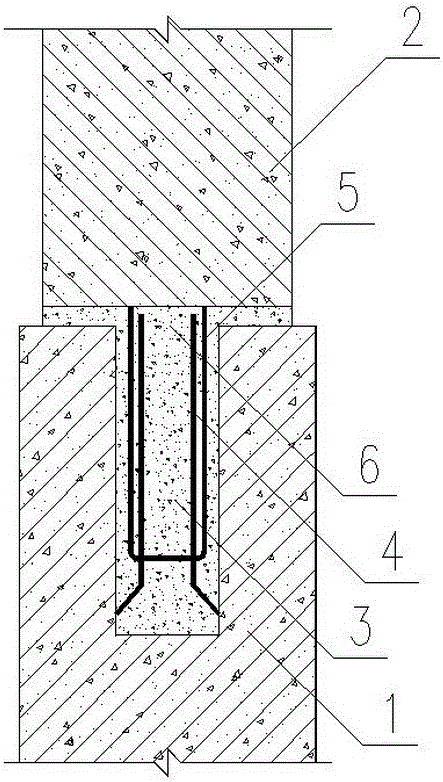

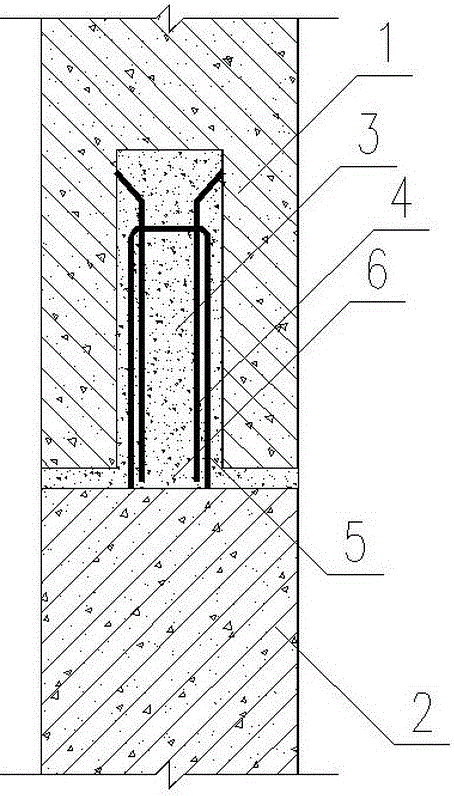

[0028] A kind of embodiment of the prefabricated concrete member connection method that the present invention proposes, as figure 1 or figure 2 or image 3 , there is at least one non-through hole 3 on the first prefabricated concrete member 1, a steel bar 4 is arranged in the hole 3, and the steel bar 4 is anchored in the side wall concrete of the hole 3; the second prefabricated concrete member 2 protrudes from the anchored steel bar 5; The first prefabricated concrete element 1 is filled with concrete 6 or grouting material in the hole 3; the second prefabricated concrete element 2 is installed, and the anchoring steel bars 5 of the second prefabricated concrete element 2 are stretched into the hole 3, which can be overlapped with the steel bar 4 or Connect or be close to the steel bar 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com