Patents

Literature

170results about How to "Increase the support point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

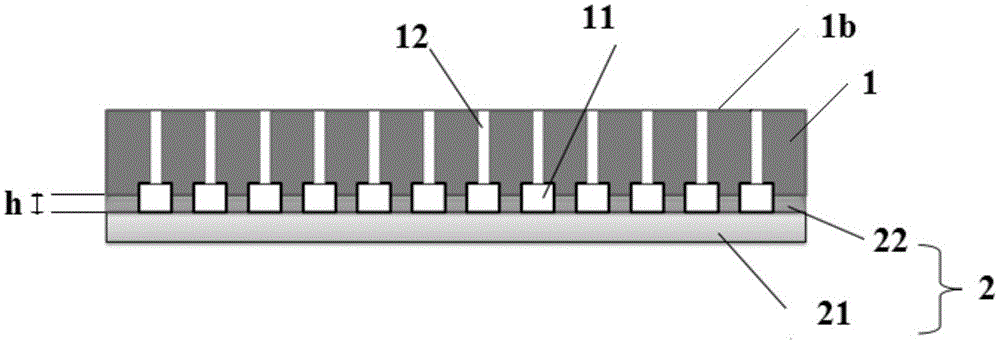

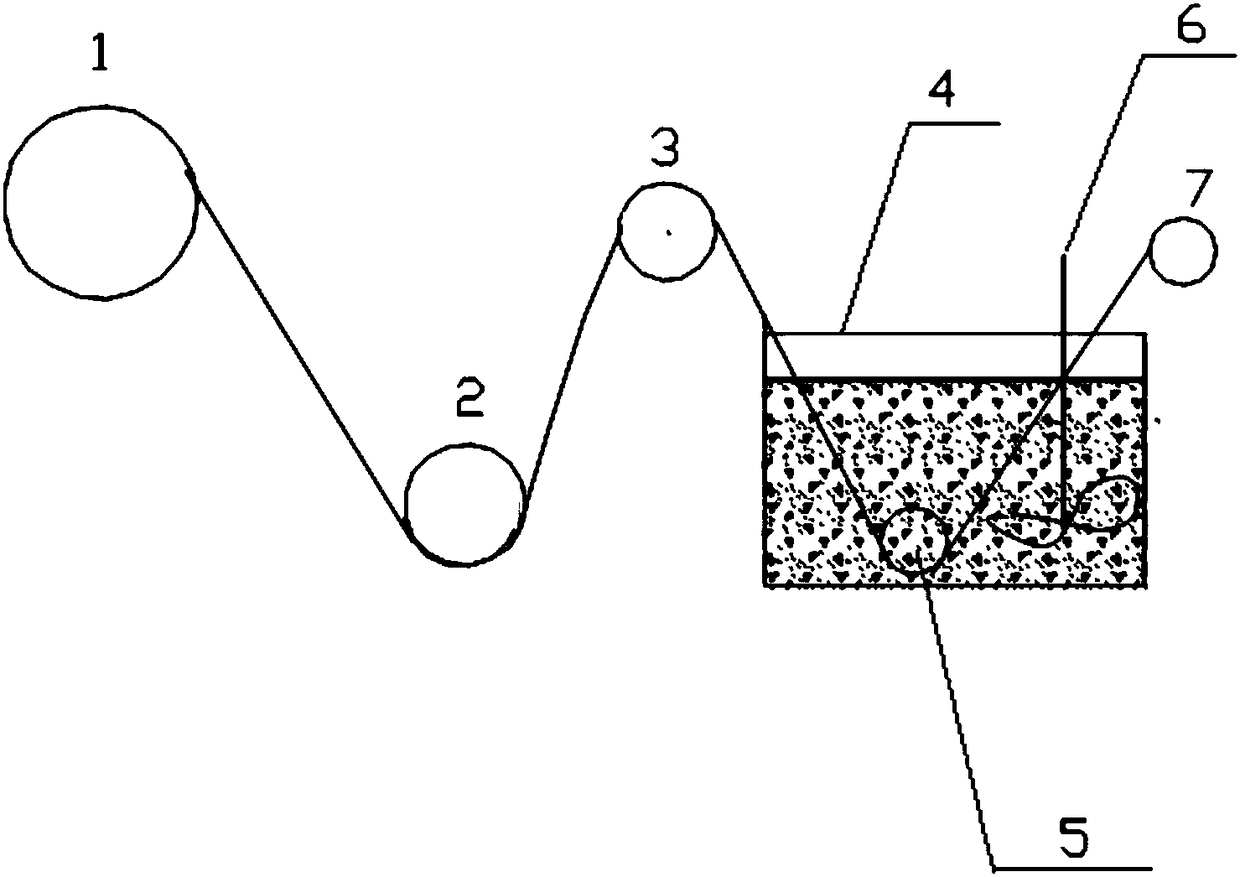

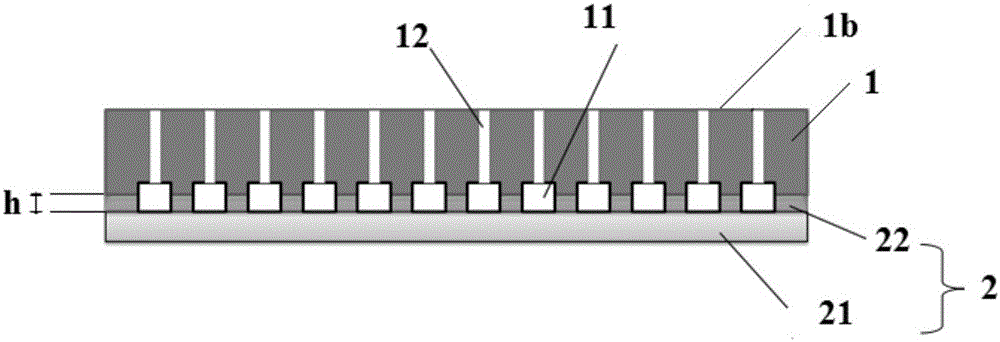

Manufacturing method of unimolecular sequencing chip

ActiveCN105112290AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsOxygen plasmaEngineering

The invention provides a manufacturing method of a unimolecular sequencing chip. The manufacturing method includes the following steps: (1), taking a baseplate, and adopting a photoetching method to make an anodic film of a reaction tank array on the surface of the baseplate; (2), using model glue to pour the anodic film, curing for 1-3h at 90-100 DEG C after vacuum degassing, uncovering the anodic film to obtain a groove with multiple runners, punching a hole in each of two ends of each runner to form fluid input and output holes, and obtaining a substrate; (3), taking a transparent base, and preparing a polymethylglutarimide (PMGI) layer on the surface of the transparent base to obtain a transparent base with the surface modified; (4), subjecting the substrate and the transparent base to oxygen plasma cleaning and press-fitting, and injecting a reagent into each runner to clean the corresponding PMGI layer contacting with each runner to obtain the unimolecular sequencing chip. The manufacturing method is simple in process and low in manufacturing cost.

Owner:GENEMIND BIOSCIENCES CO LTD

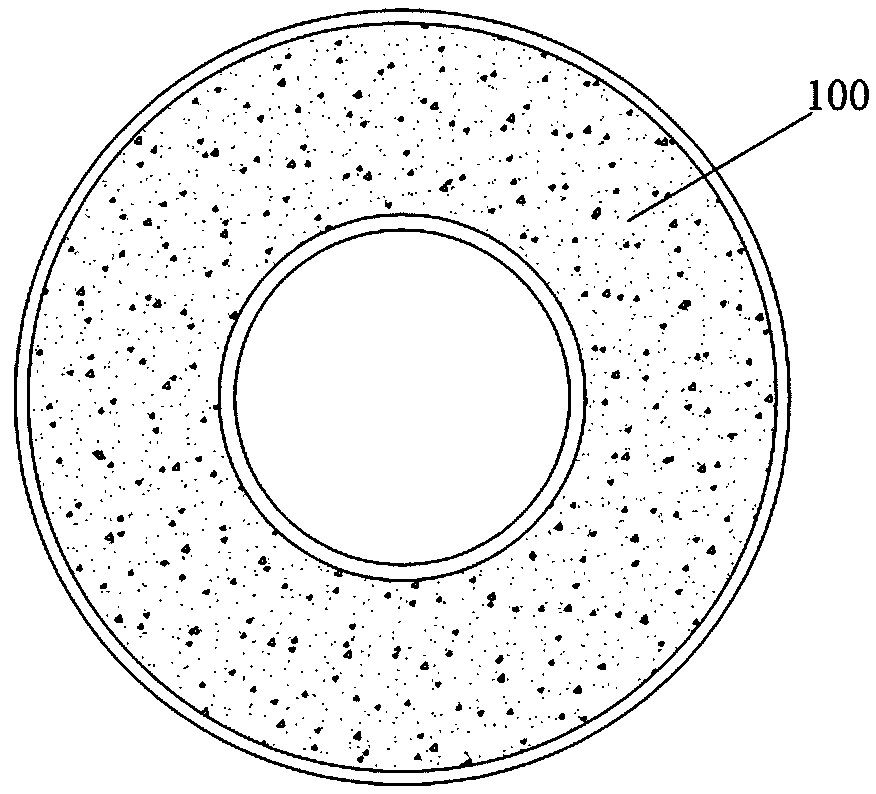

Continuous fiber-reinforced high-temperature ceramic fiber filter element and preparation method thereof

ActiveCN108939697AHigh strengthIncrease stiffnessMembrane filtersFiltration separationFiber bundleSlurry

The invention discloses a continuous fiber-reinforced high-temperature ceramic fiber filter element and a preparation method thereof. Continuous ceramic fibers combined with ceramic staple fiber slurry are subjected to winding combination molding on a vacuum die, and then drying demoulding and high-temperature thermal treatment are carried out, so that the high-temperature ceramic fiber filter element is prepared. Through reasonable design of raw materials, the Tex, the winding tension, the proportion of short fiber slurry, the ratio of long fibers to short fibers, the continuous fiber windingangle, the step spacing, the thermal treatment temperature and the like of continuous fiber bundles are continuously controlled, so that the volume density of the finally prepared high-temperature ceramic fiber filter material is controlled to be 0.4-0.7 g / cm<3>, the porosity is 60-75%, the pore diameter is 20-60 microns, the mechanical strength is 5-8 MP, the initial filter resistance is lower than 600 Pa under a standard wind speed condition of 1 m / min (air temperature of 25 DEG C), and the maximum using temperature of the filter element can reach 900 DEG C or above.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

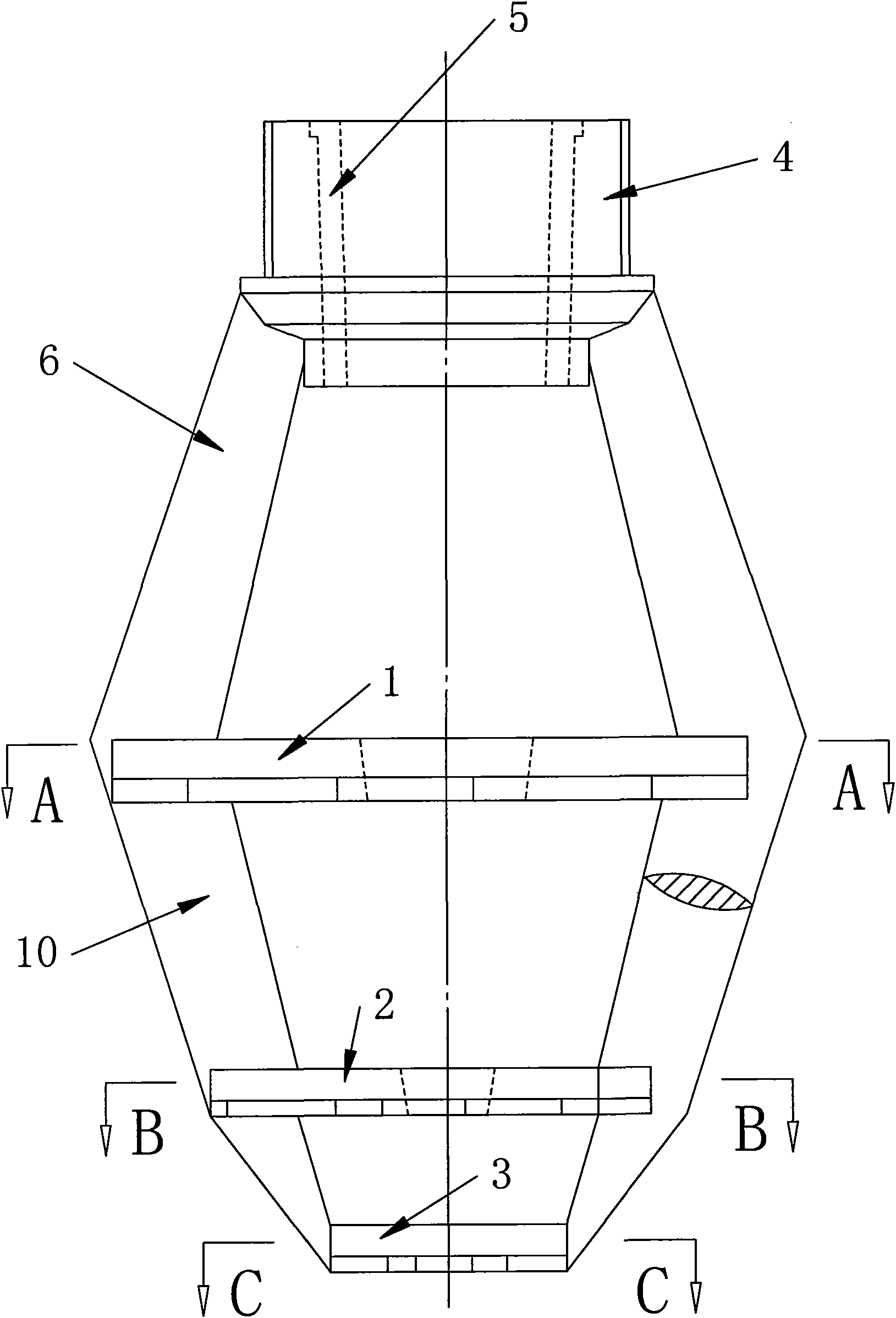

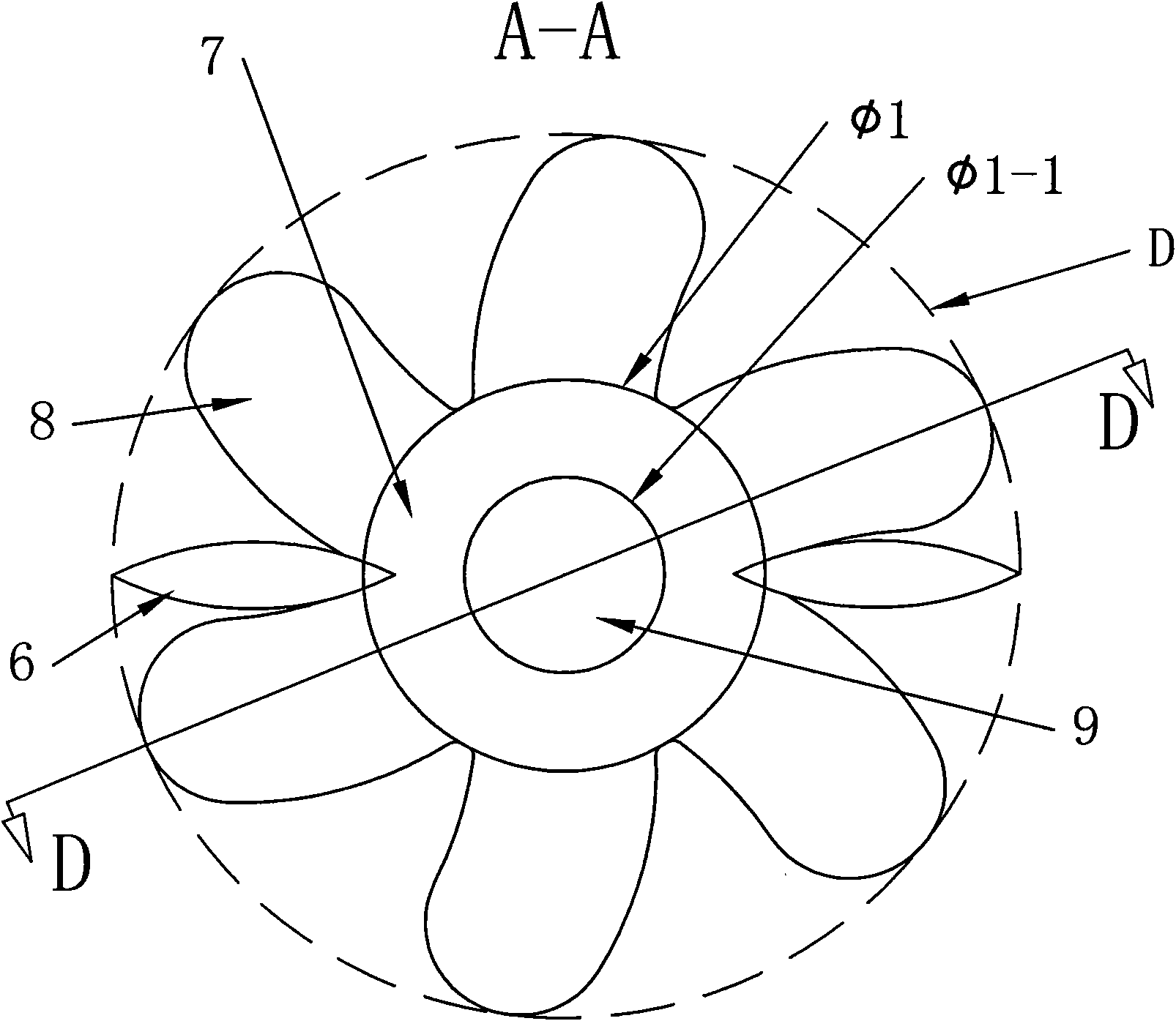

Polygonal counter flow cooling tower

The invention provides a polygonal counter flow cooling tower which has small ventilation resistance, favorable thermal performance and low energy consumption and can be completely combined with a building. The polygonal counter flow cooling tower comprises a framework, an air duct arranged at the top of the framework and a blower arranged in the air duct; wall boards are arranged on the periphery at the upper part of the framework; air inlet windows are arranged on the periphery at the lower part of the framework; packing comprising a plurality of alternate filler pieces is arranged in the frames of the wall boards; a water distribution pipe is arranged above the packing; a water distribution spray head for spraying water into clearances among the filler pieces is arranged at the bottom of the water distribution pipe; a water collector is arranged above the water distribution pipe; a reception basin is arranged at the bottom of the framework and supported by a bottom beam; a water outlet is arranged at the lower part of the reception basin; and the periphery of the framework is octagonal.

Owner:南京大洋冷却塔股份有限公司

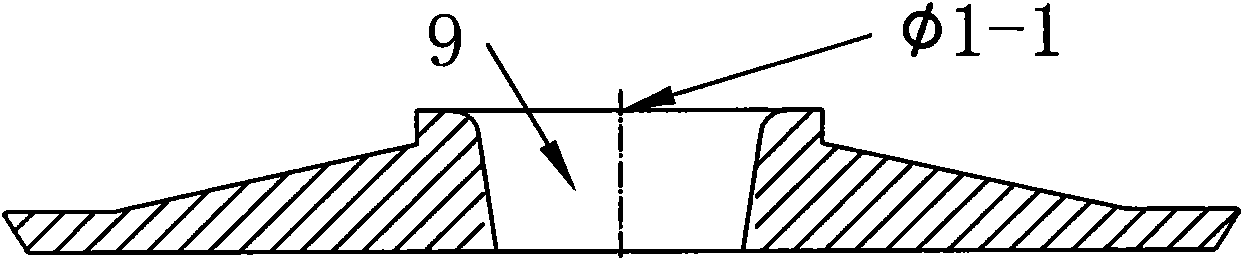

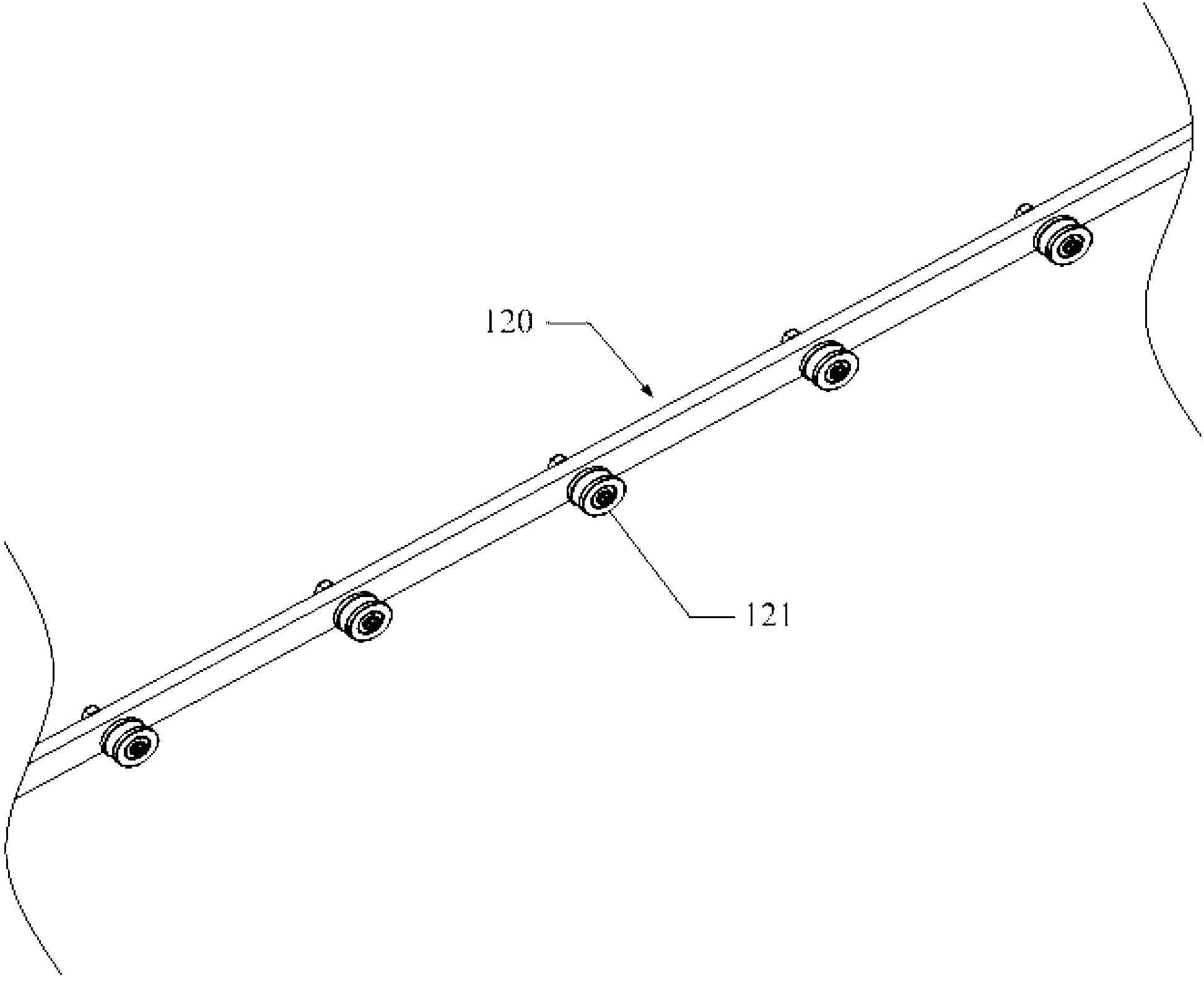

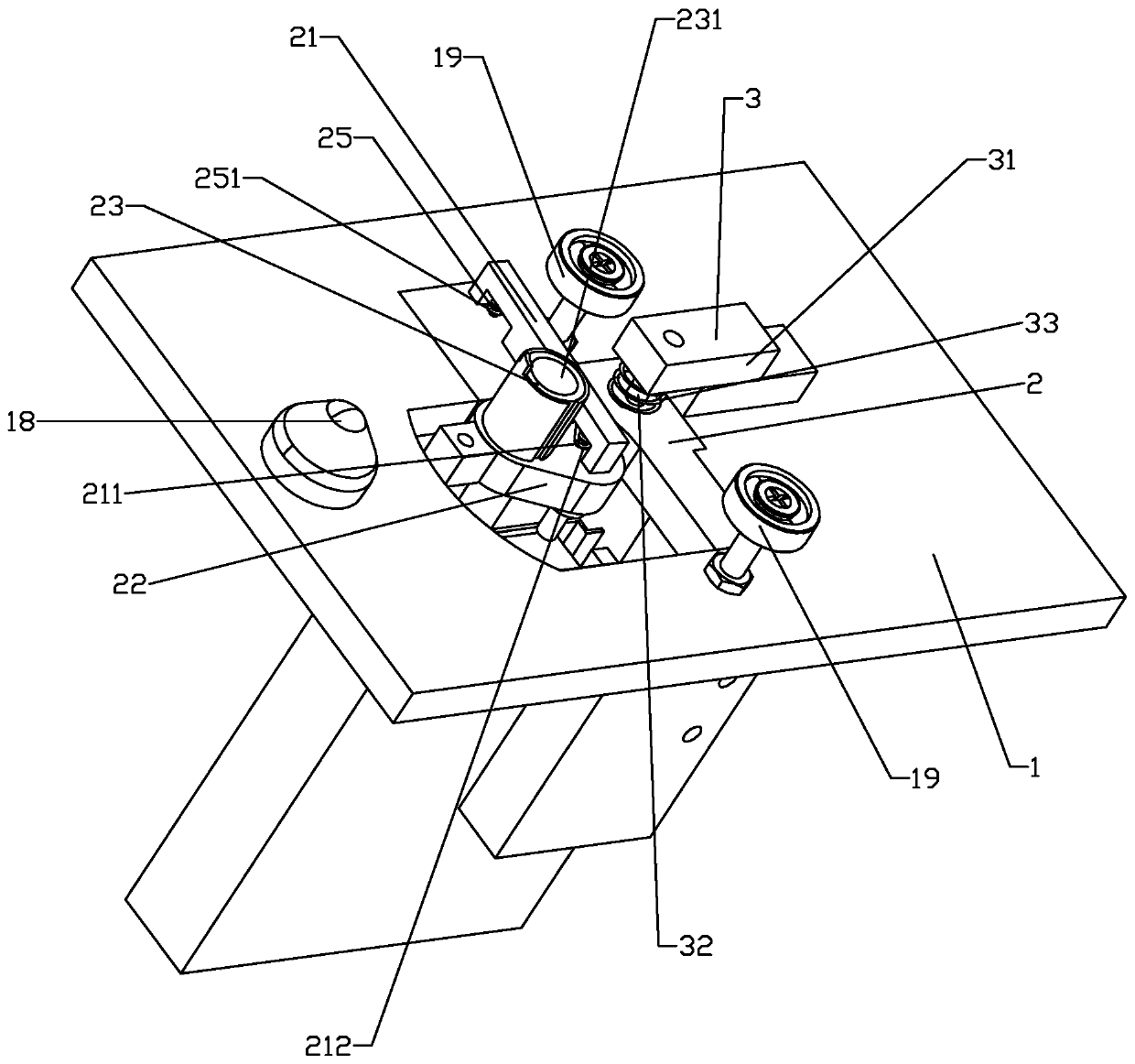

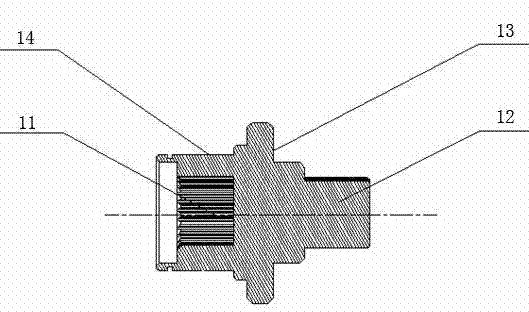

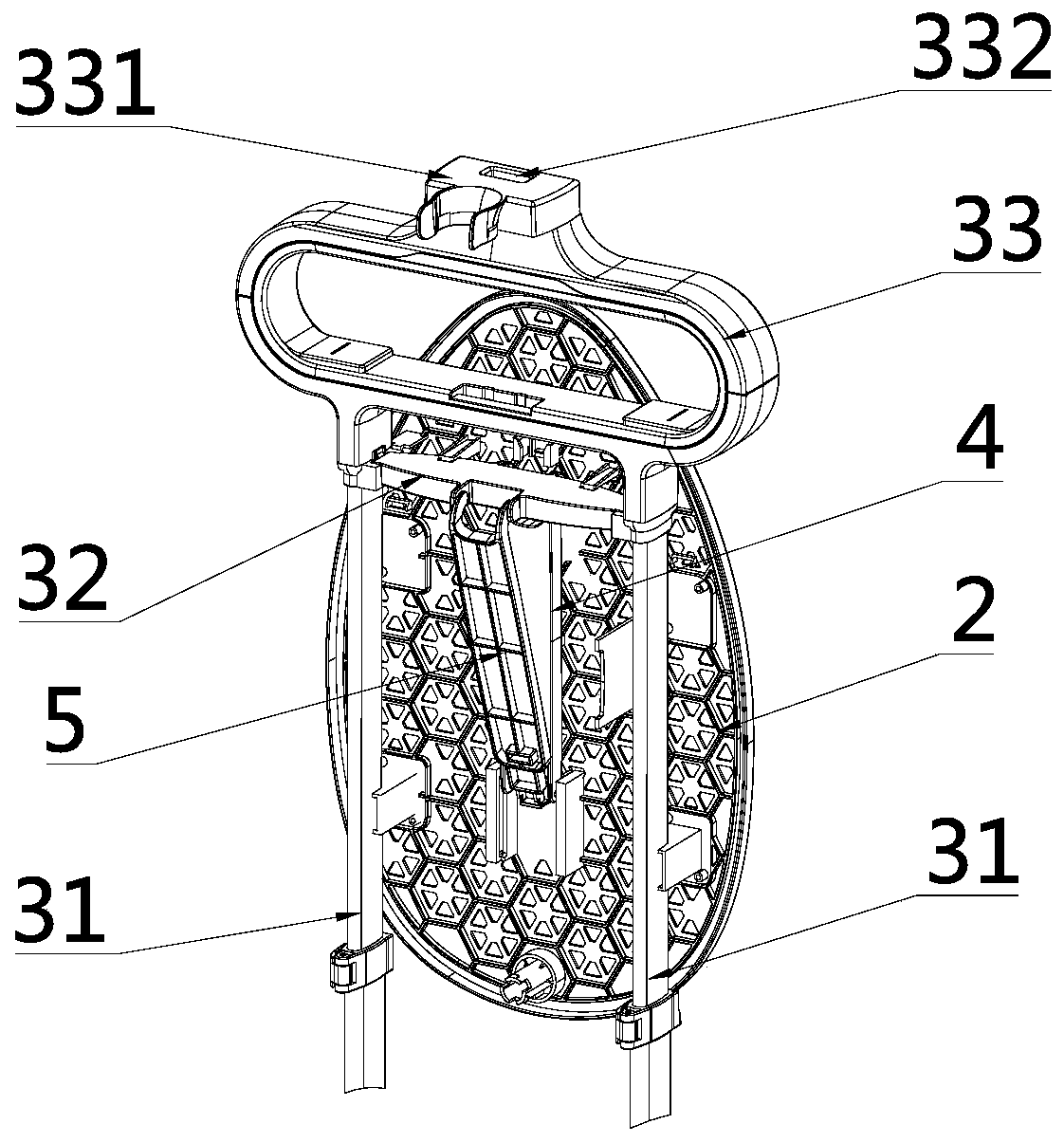

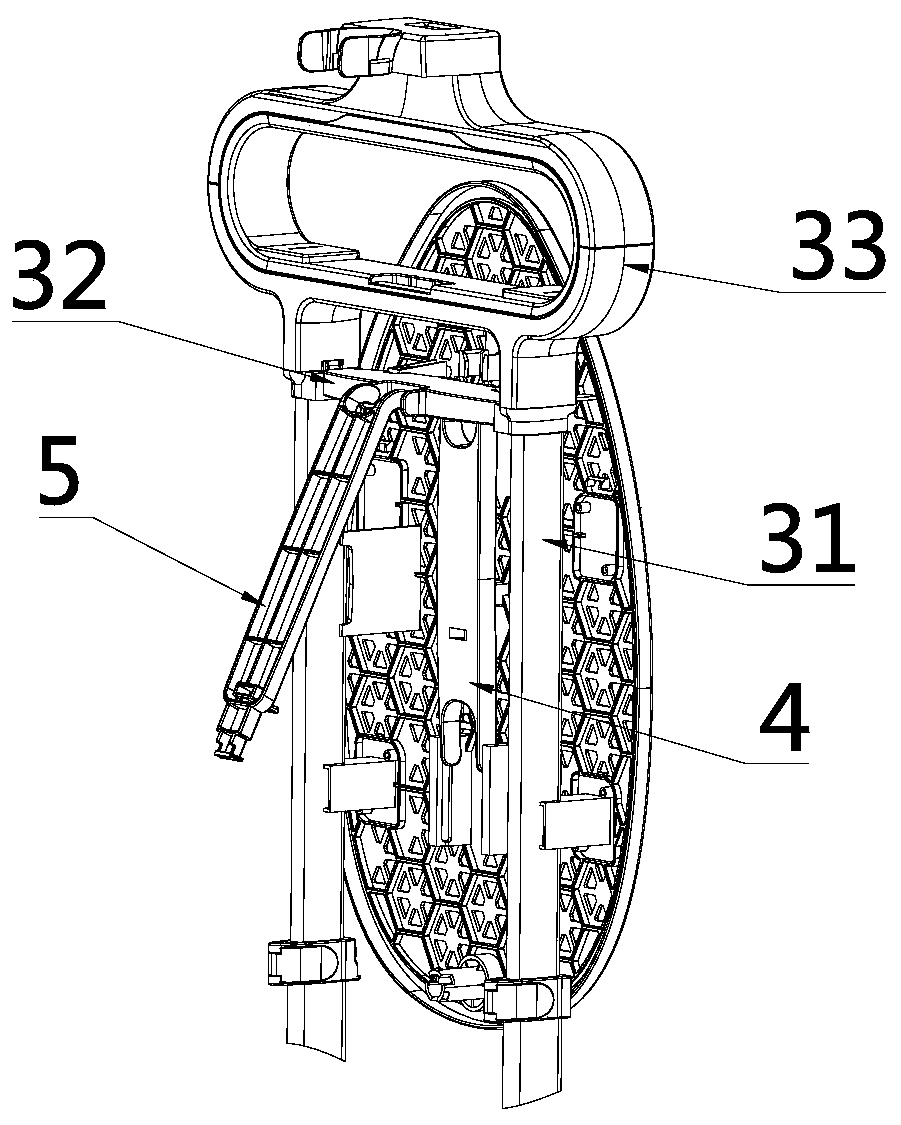

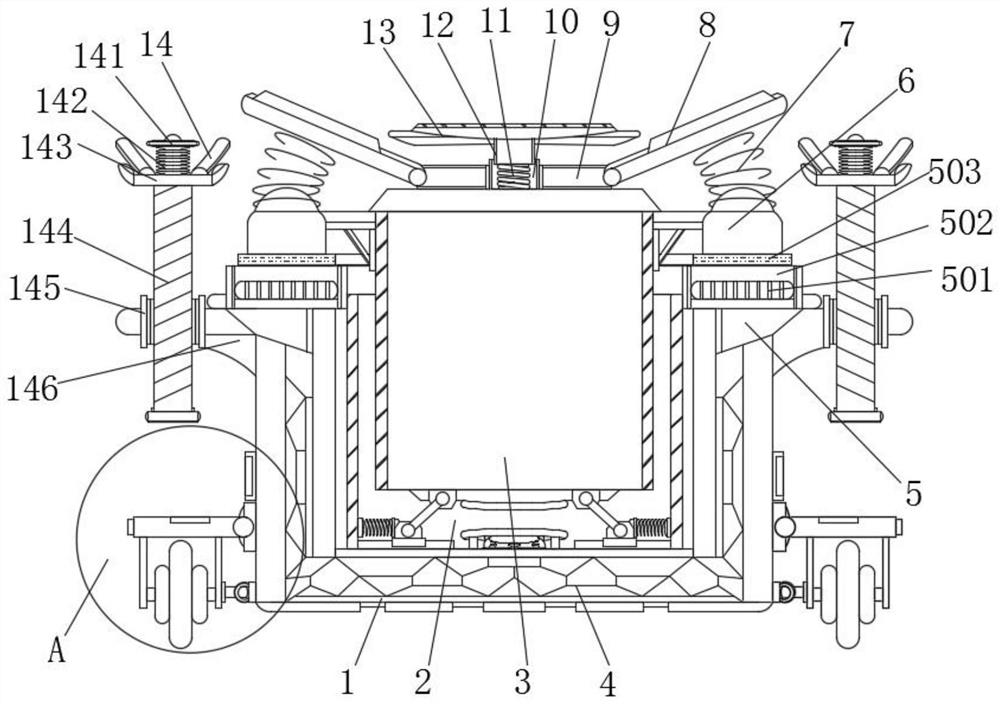

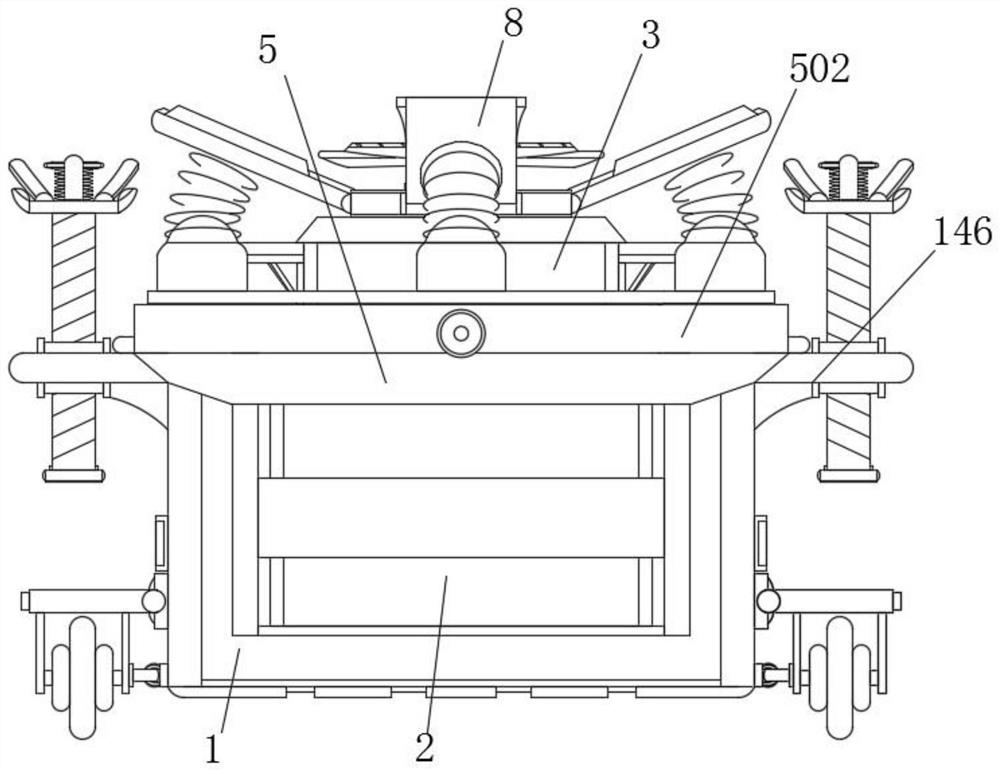

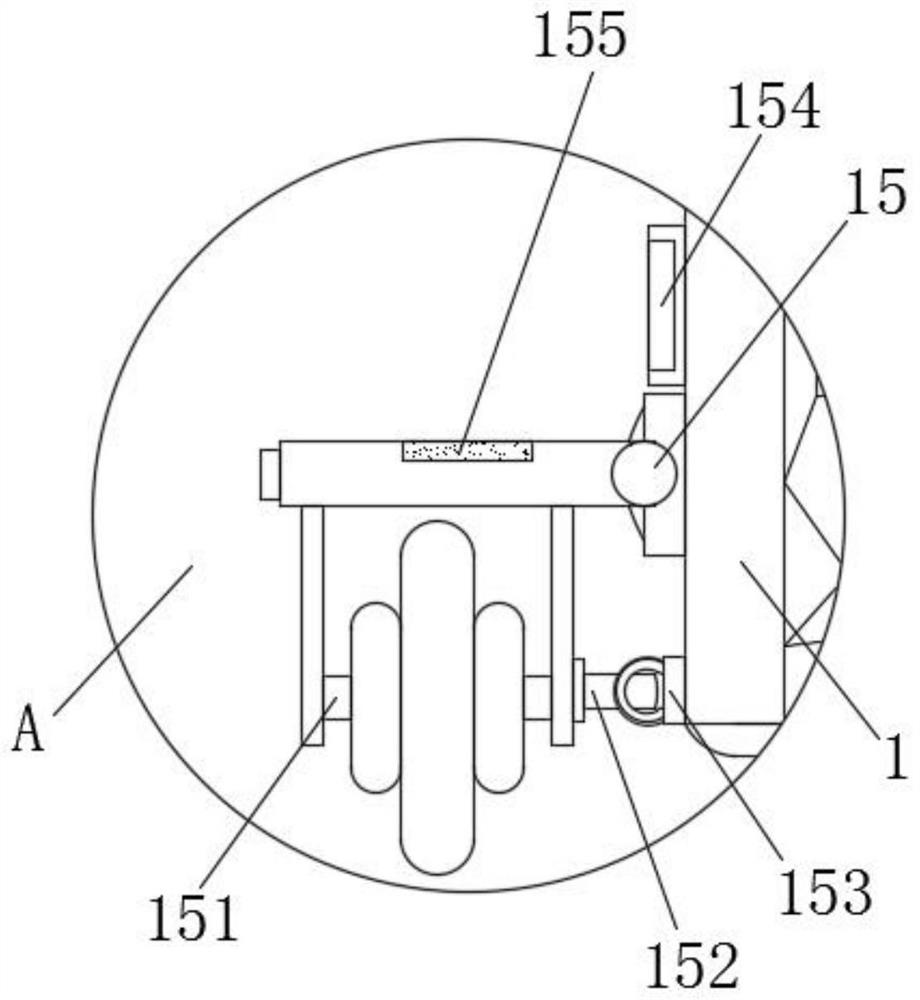

Carbon sliding plate support assembly with high applicability

ActiveCN107804173AIncrease the support pointEasy to adjustPower current collectorsClassical mechanicsSlide plate

The invention relates to the field of carbon sliding plates, in particular to a carbon sliding plate support assembly with high applicability. According to the carbon sliding plate support assembly with high applicability, support roller wheels are installed in rotary mounting grooves formed in the surfaces of support rods, and clamping grooves are formed in the surfaces of the support roller wheels for fixing the position of a carbon sliding plate, so that the carbon sliding plate is supported; lateral adjusting support pieces are respectively arranged at the inner sides of the support rods,so that the support points of the carbon sliding plate are increased; rotary connecting pieces, which separately consist of a locating piece and a rotating shaft, are respectively used for realizing the rotary connection between the support rods and the lateral adjusting support pieces, and adjusting components are respectively arranged between the sides walls of the support rods and the side walls of the corresponding lateral adjusting support pieces for driving the lateral adjusting support pieces to realize angle adjustment, so that the different support positions can be adjusted accordingto the demands; adjusting rods separately consist of a fixed rod and a sliding rod, a sliding limit slot is formed in the fixed rod, a slide stretching space is reserved for each sliding rod, and thesliding rods are driven by means of electric push rods, so that the carbon sliding plate support assembly is convenient to adjust by people.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

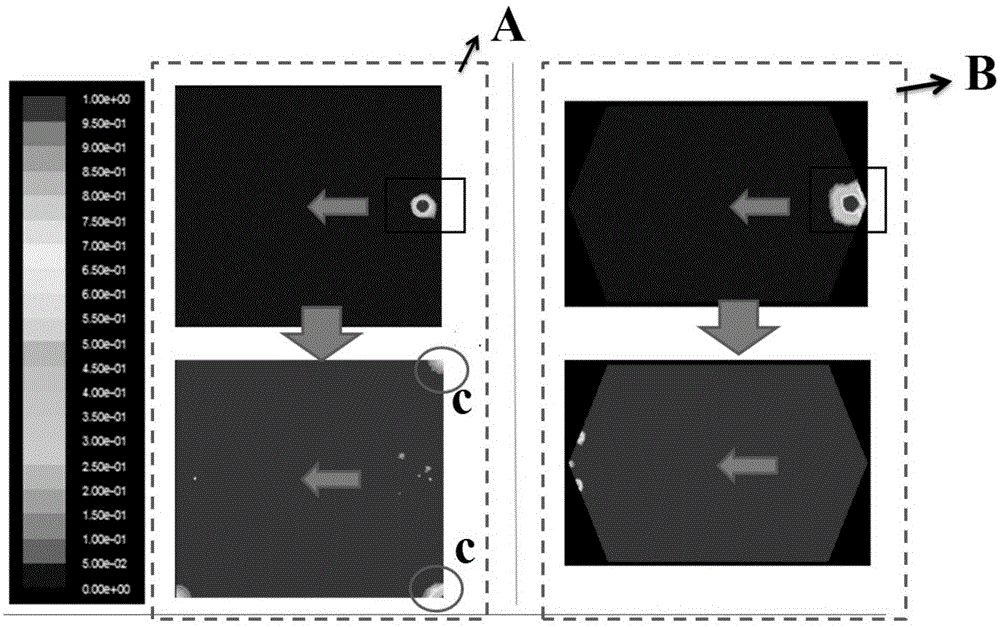

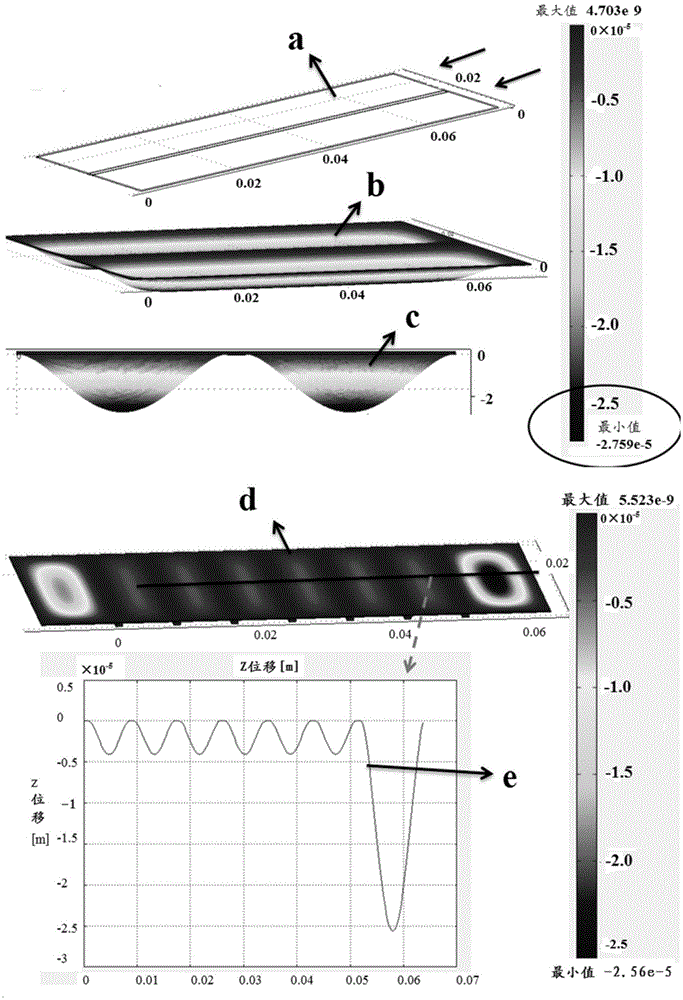

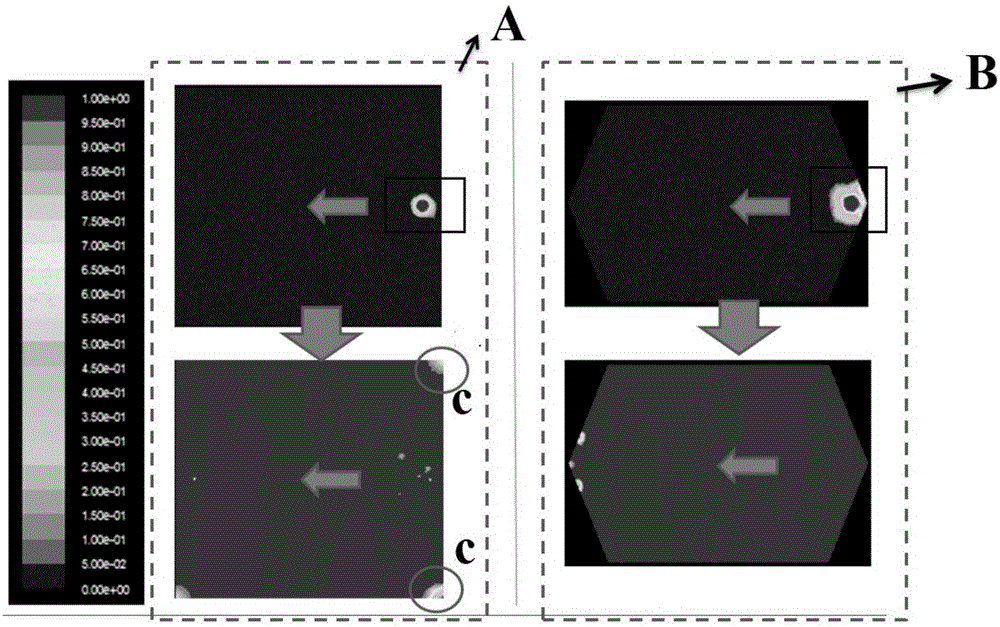

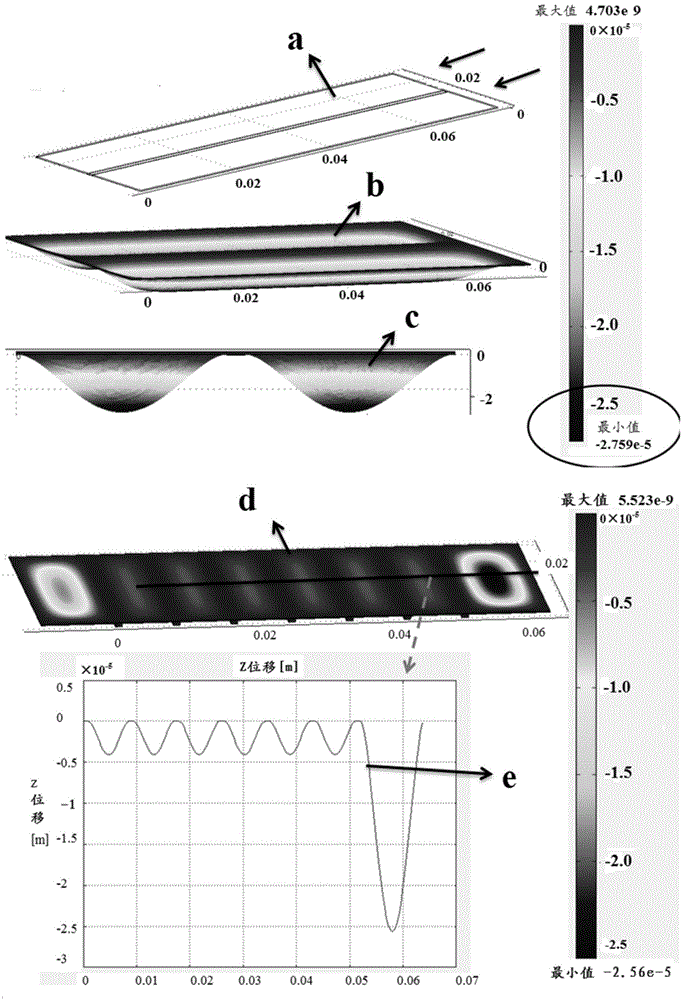

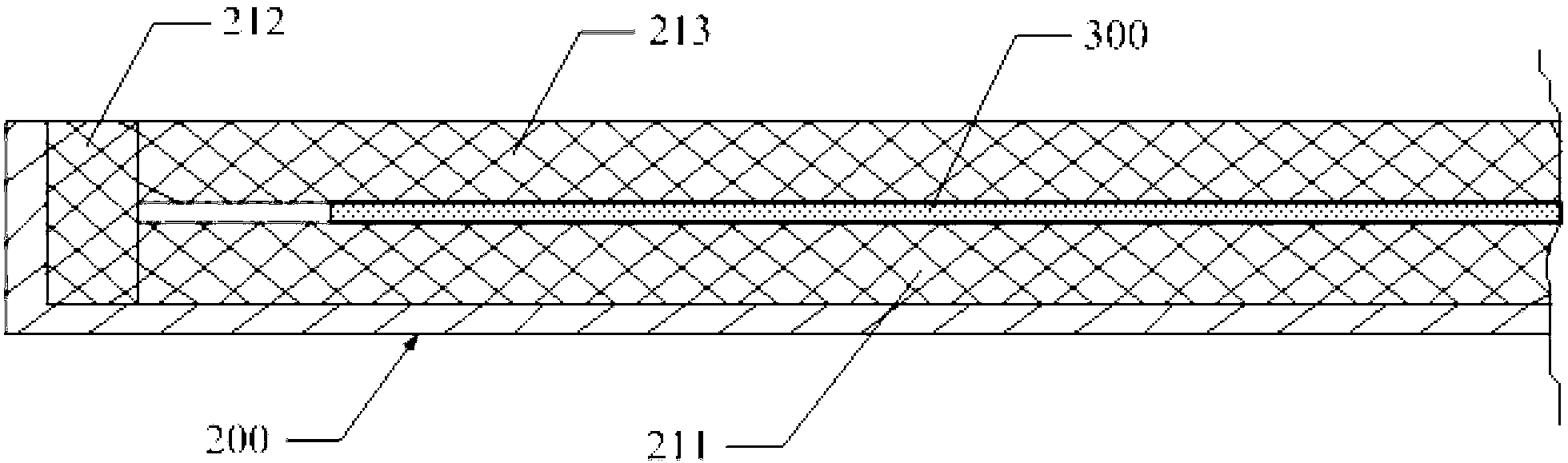

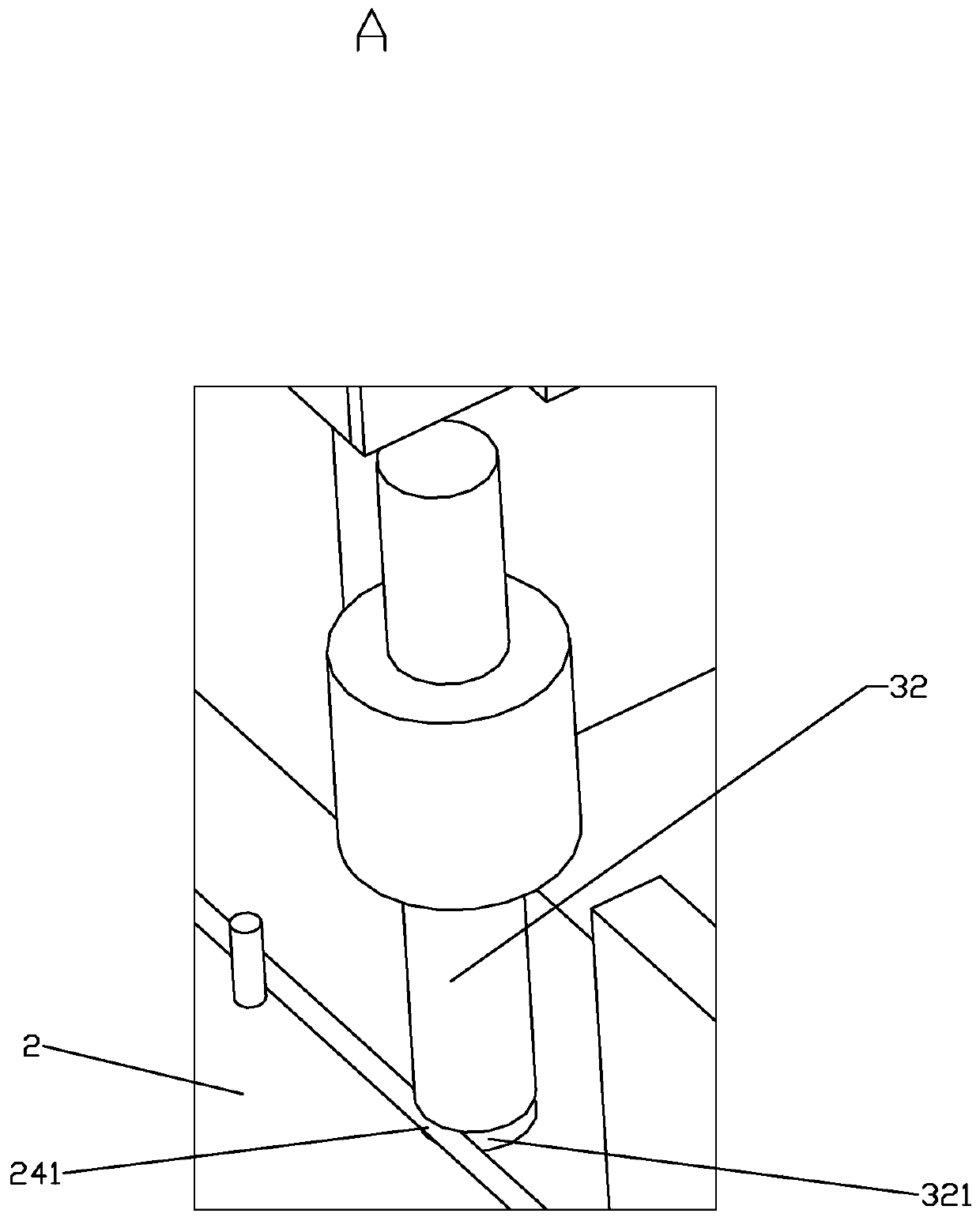

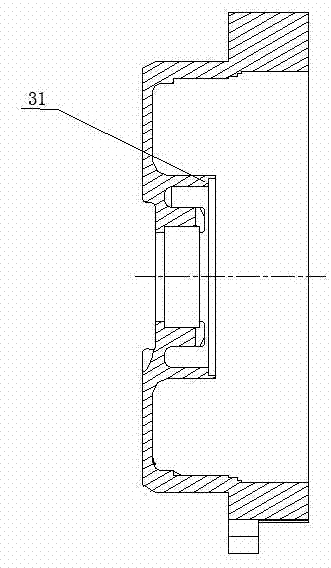

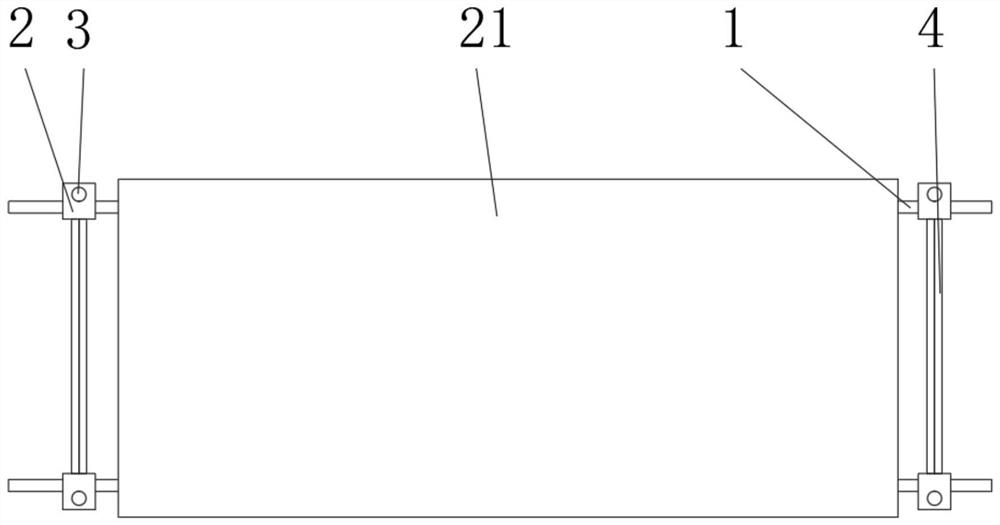

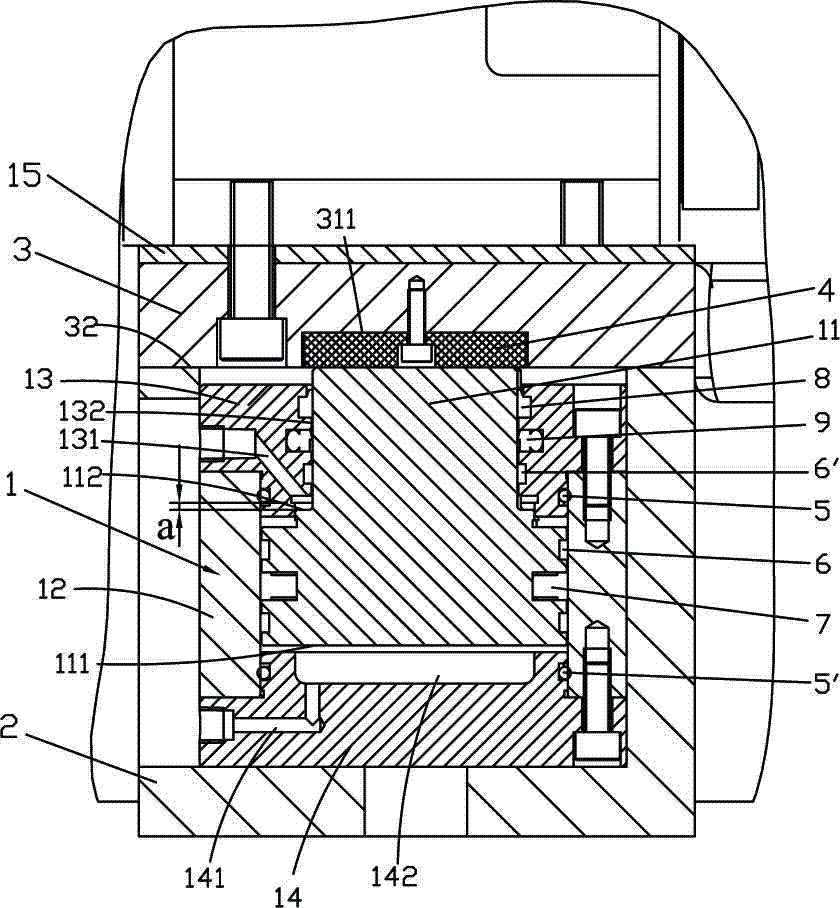

Single-molecule sequencing chip

ActiveCN105154323AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFluid input

The invention provides a single-molecule sequencing chip, which comprises a substrate and a base layer which is arranged in a mode of being laminated with the substrate, wherein the substrate comprises a first surface and a second surface which are oppositely arranged; a reaction tank array which is formed by a plurality of runners is arranged on the first surface of the substrate in a spacing mode; two opposite sidewalls of each runner extend in the length direction of the runner and are intersected at two ends of the runner to form two conical tail ends having included angles; fluid input holes and fluid output holes which are communicated with the second surface of the substrate are respectively formed in the surfaces of the two conical tail ends; the base layer comprises a transparent base and a spacing layer which is arranged on the surface of the transparent base; and the spacing layer is contacted with the first surface of the substrate and the spacing layer, corresponding to the locations of the runners, is formed with corrosion grooves. The chip is good in flow field distribution, the base in the chip is low in deformation rate and fluid in the chip is thorough in flushing switching.

Owner:GENEMIND BIOSCIENCES CO LTD

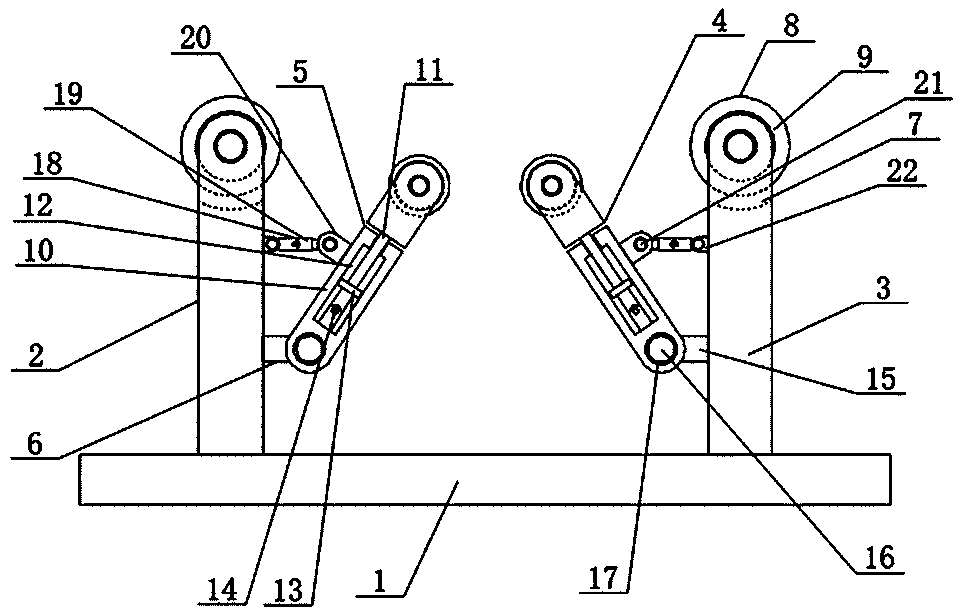

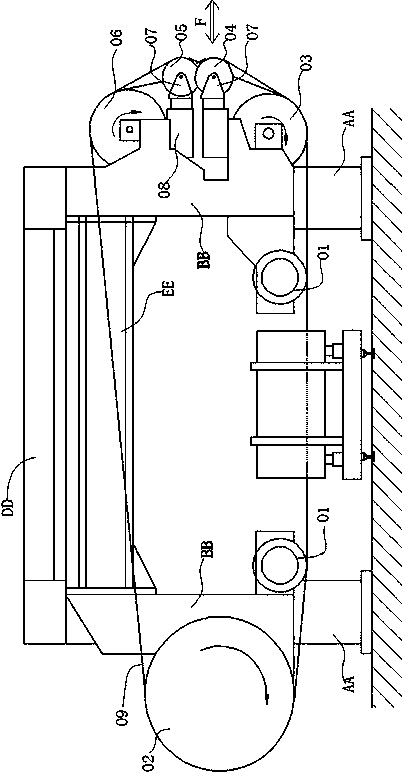

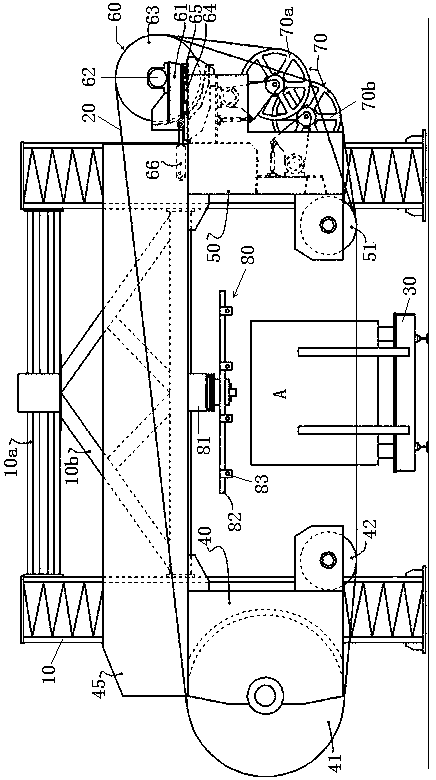

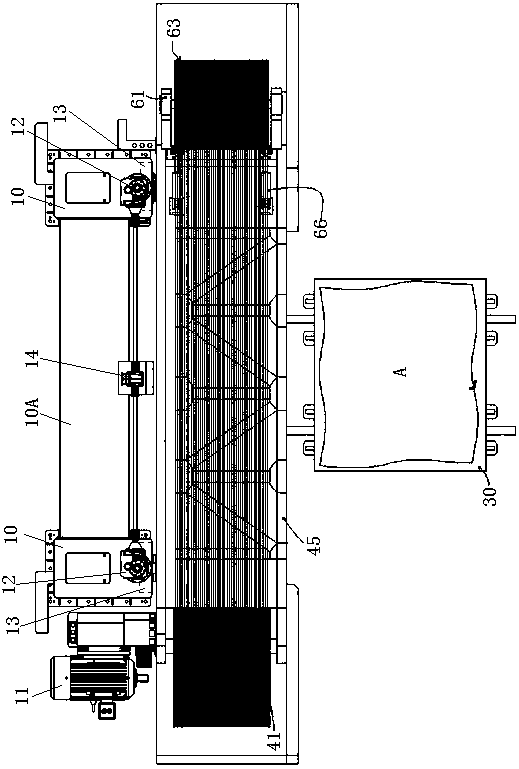

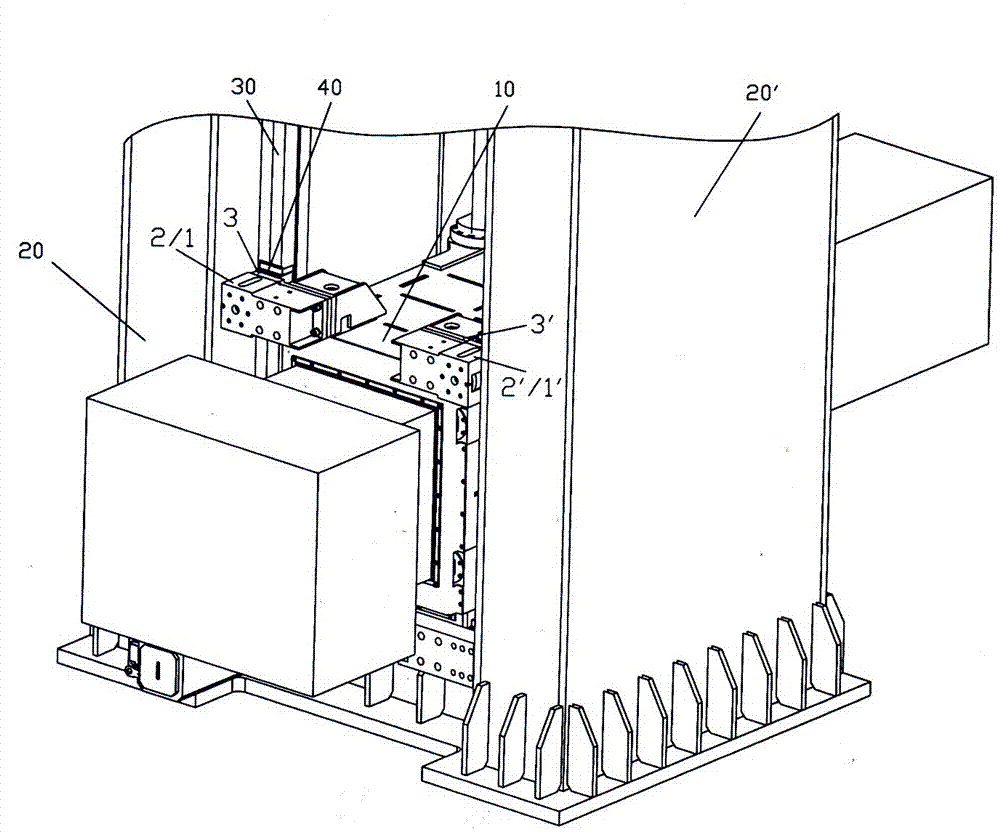

Multi-set-rope sawing machine and control method thereof

PendingCN108481571AEasy to change ropeLower yieldWorking accessoriesStone-like material working toolsWheel trainEngineering

The invention relates to a multi-set-rope sawing machine and a control method thereof. The multi-set-rope sawing machine comprises a gantry rack and a plurality of diamond string bead ropes. The lowerside of the gantry rack is provided with a trolley used for storing stone blocks and capable of longitudinally sliding. A first rack box and a second rack box which are connected through a truss andcan be lifted are arranged on the front portions of the two sides of the gantry rack correspondingly. The first rack box is internally provided with a main driving wheel. The upper portion of the second rack box is provided with a pre-tensioning wheel train assembly. The lower portion of the second rack box is provided with a micro-tensioning wheel train assembly for providing tensioning and supporting. Guiding wheels are further arranged on the inner sides of the lower portions of the first rack box and the second rack box correspondingly. The diamond string bead ropes are wound in wheel grooves corresponding to the main driving wheel, the pre-tensioning wheel train assembly, the micro-tensioning wheel train assembly and a guiding wheel set. The gantry rack is further provided with a water spraying cooling device. The multi-set-rope sawing machine is compact in structure, the purpose of stably cutting a plate can be achieved, and control is convenient.

Owner:FUJIAN XIAPU ZHONGYUAN MACHINERY

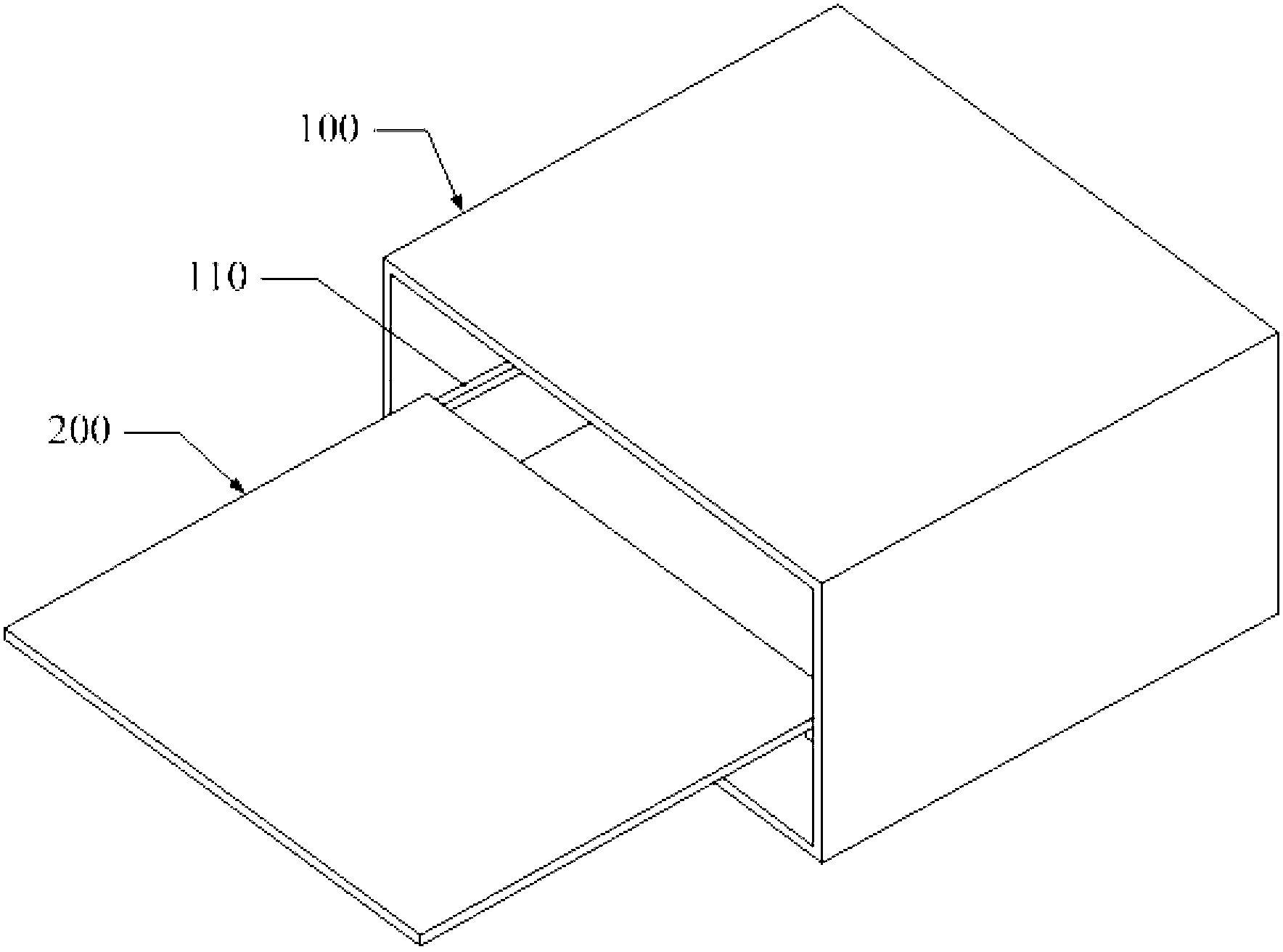

Conveying jig of liquid crystal display panel

ActiveCN103213768AIncrease the support pointReduce vibration amplitudeRigid containersDamagable goods packagingLiquid-crystal displayLiquid crystal

The invention discloses a conveying jig of a liquid crystal display panel. The conveying jig of the liquid crystal display panel comprises a drawer cage and a tray, wherein the tray is used for accommodating the liquid crystal display panel, supporting pieces are respectively arranged on two opposite lateral walls of the drawer cage, and the tray is placed on the supporting pieces. According to the conveying jig of the liquid crystal display panel, a smooth supporting surface is provided for the liquid crystal display panel, the number of supporting points of the liquid crystal display panel is increased, vibration amplitude can be reduced when the liquid crystal display panel is conveyed, deformation or fracture of the liquid crystal display panel can be effectively avoided, force only needs to be applied to the tray when the liquid crystal display panel is placed into or taken out of the jig, and the situation of the fracture of the liquid crystal display panel caused by improper force applying when the liquid crystal display panel is placed into or taken out of the jig is effectively avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

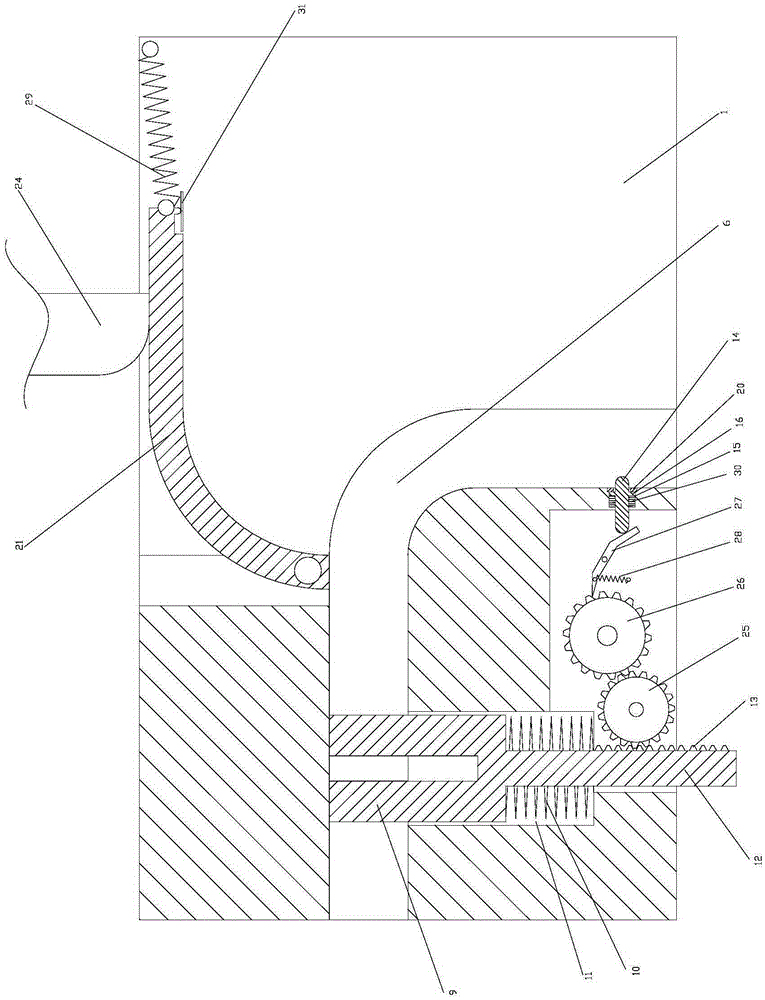

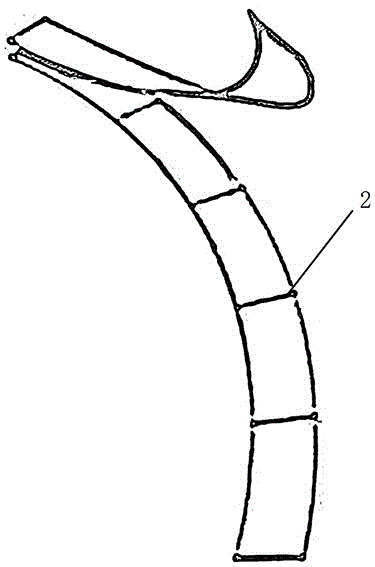

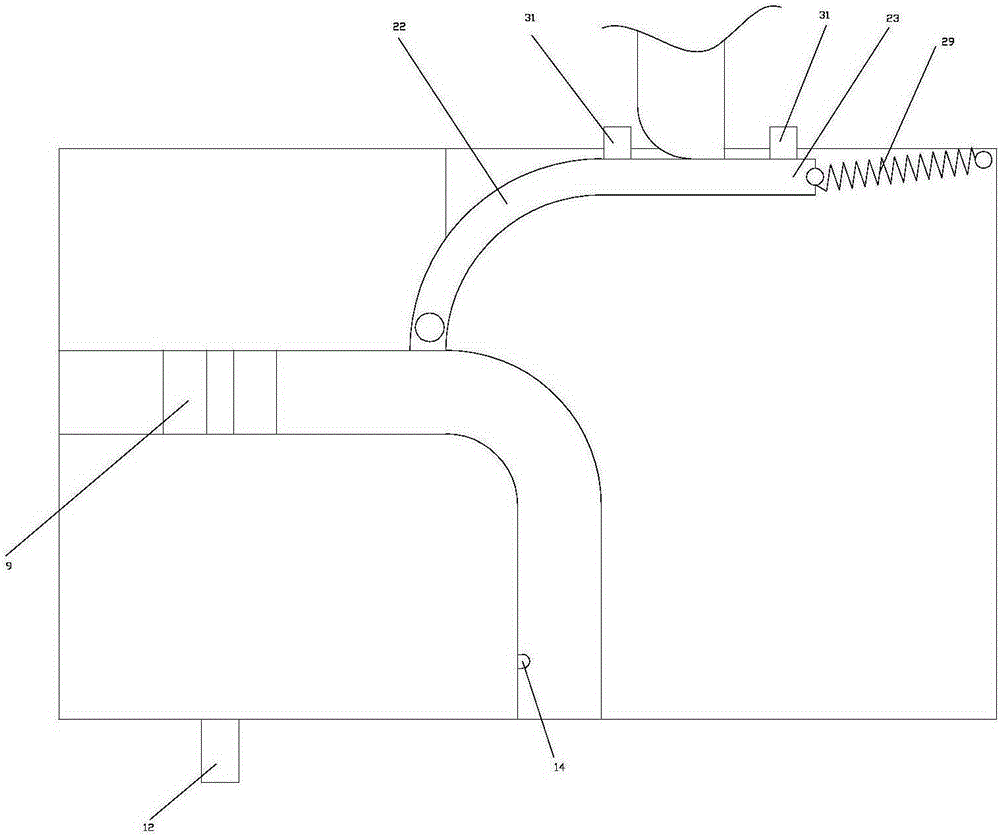

Bending discharging device

InactiveCN105290171ASimplified operational requirementsImprove securityStripping-off devicesEngineering

The invention discloses a bending discharging mechanism. The bending discharging mechanism comprises a base (1). The base (1) is provided with a reference face (3) used for containing the free end of a pipe (2), and the free end of the pipe (2) rotates through the reference face (3). The base (1) is provided with a boss (4) which is higher than the reference face (3) and is used for positioning the other end of the pipe (2). The boss (4) is provided with an opening (5). The base (1) is provided with a through hole (6) for the bent pipe (2) to slide in the vertical direction. The bending discharging mechanism is low in maintaining cost and easy and convenient to operate, and manual pipe taking is not needed.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

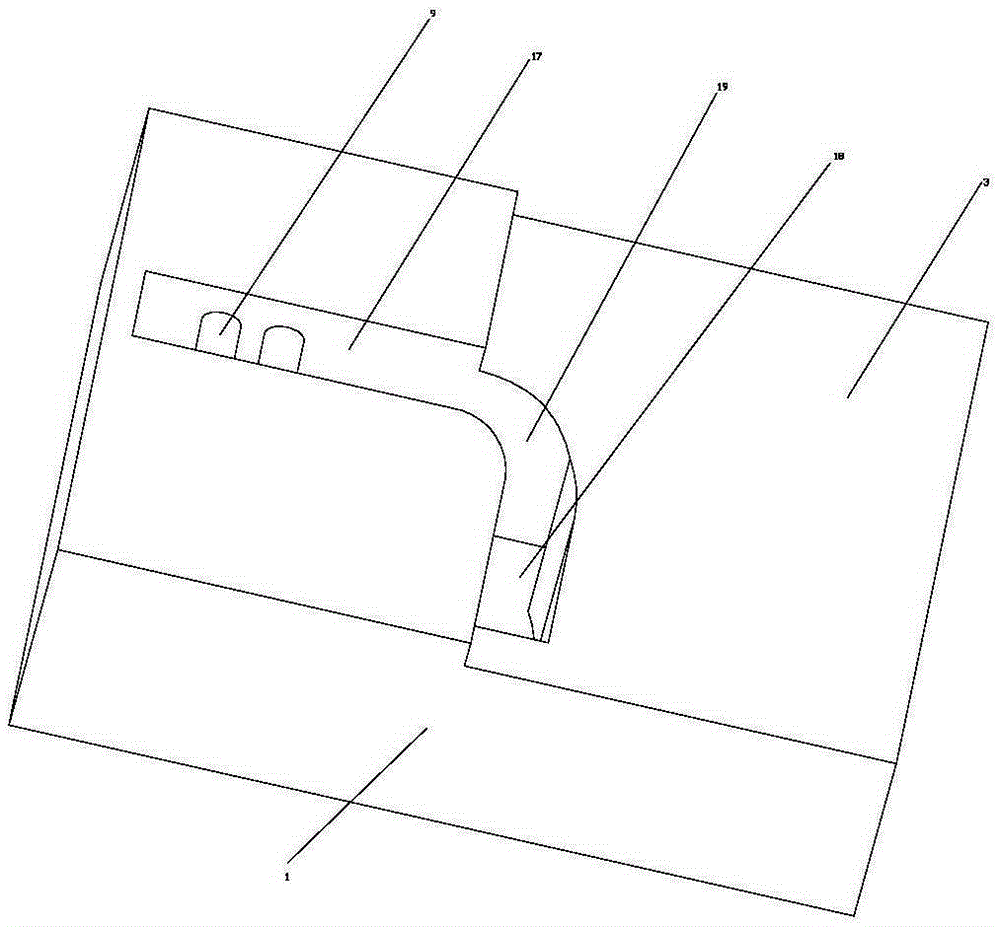

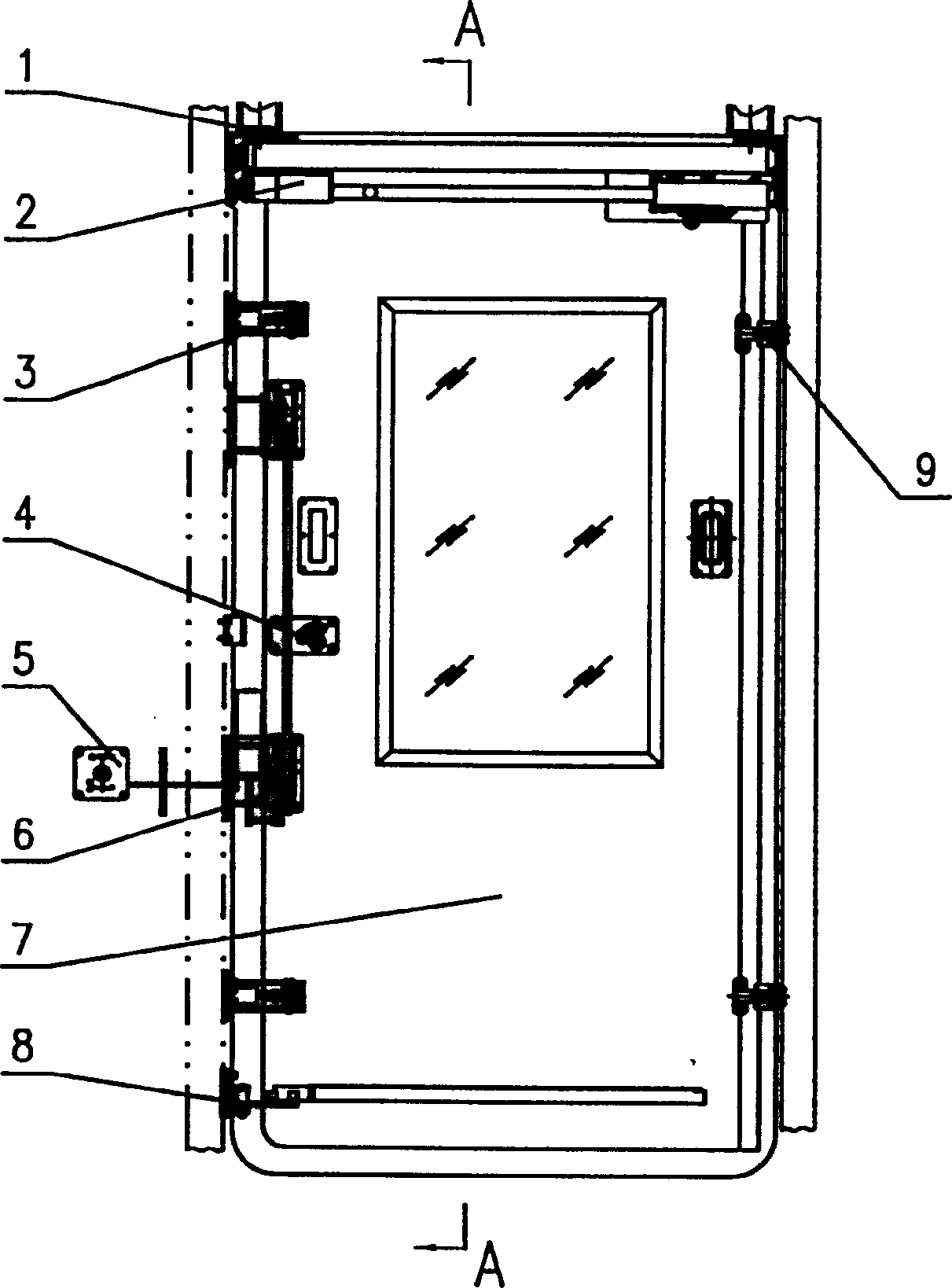

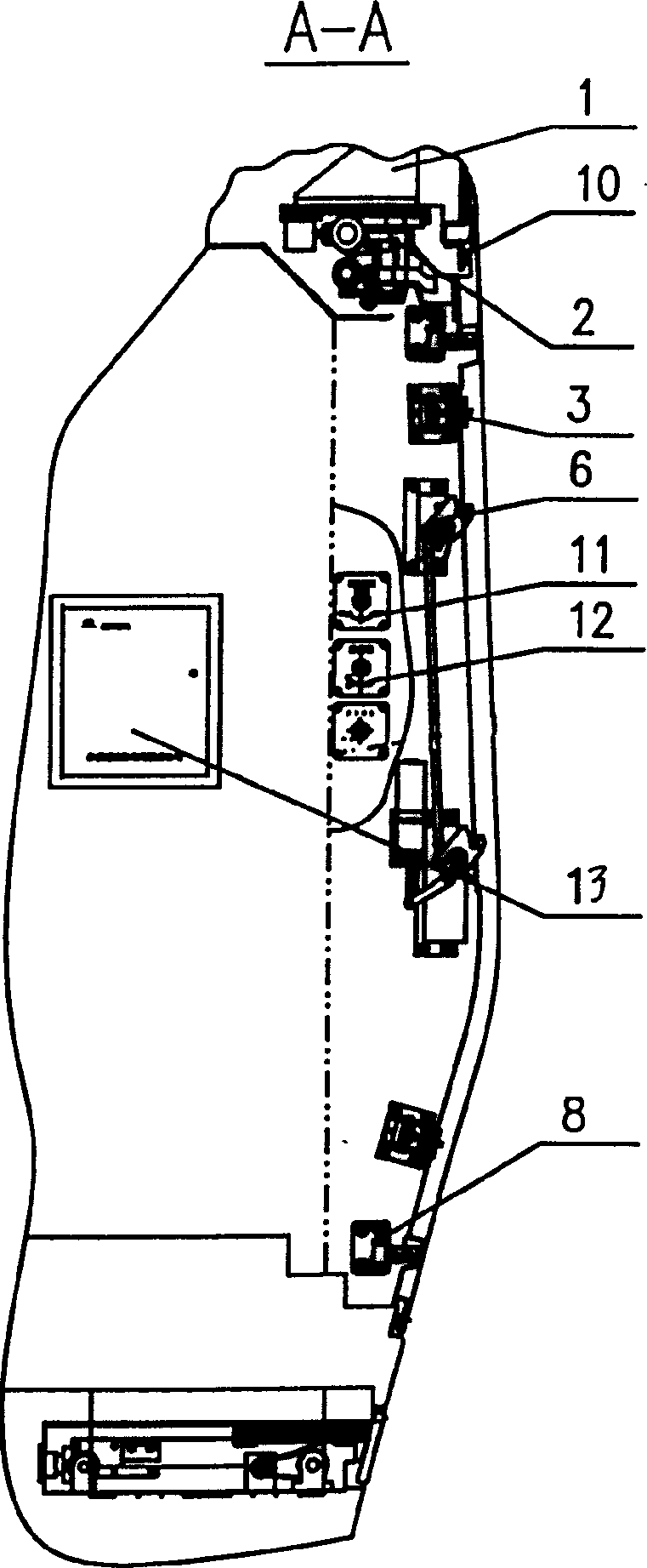

Door system of high-speed railway vehicle

A door system for the high-speed passenger train is composed of a door bearing and driving unit, a door with isolating lock, external and internal operation units, dual-point synchronous locking unit with upper and lower locks, emergency unlcoking unit, and intelligent door controller with network control function.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

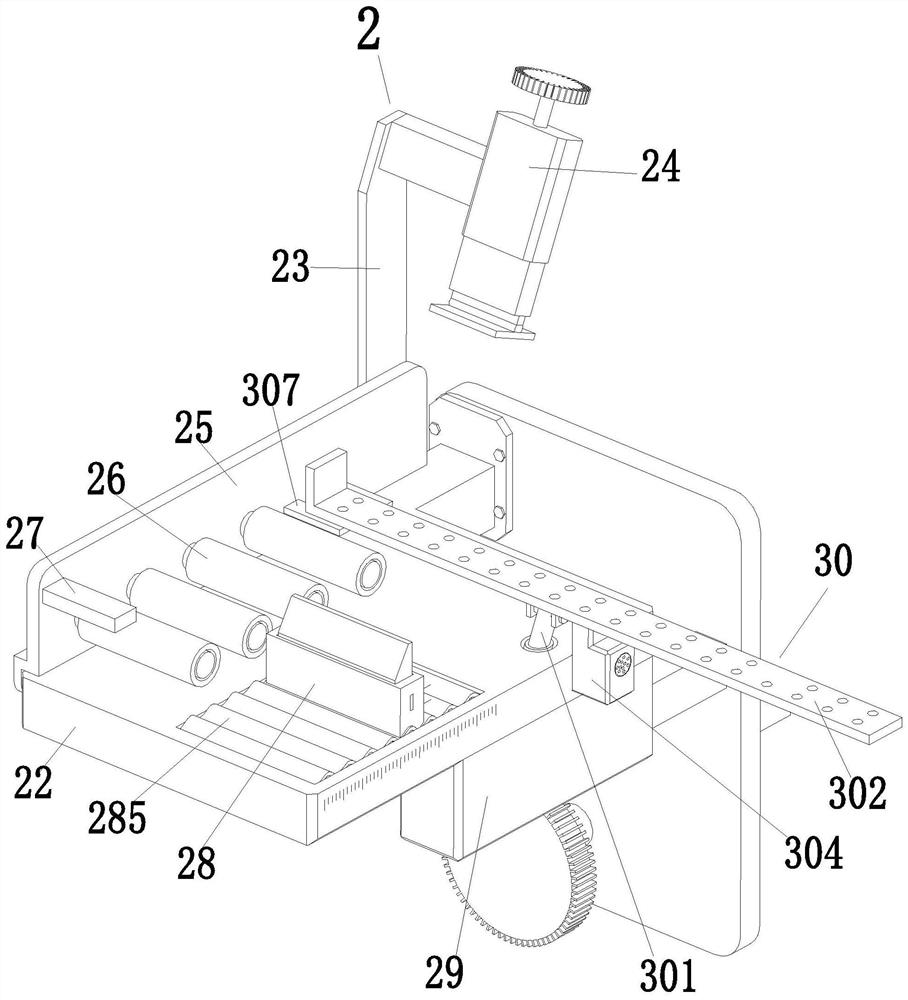

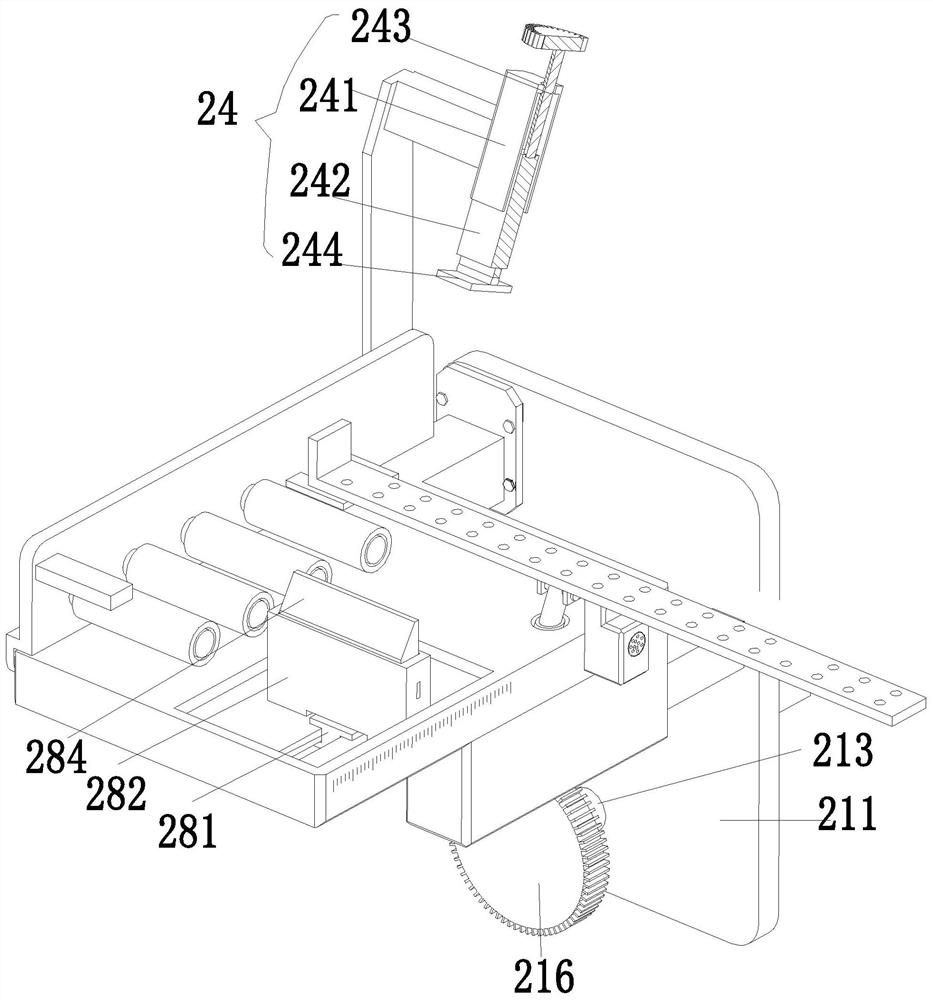

Automatic feeding device of spring grinding machine

ActiveCN110355689ASmooth swingFully protectedGrinding feed controlGrinding feedersEngineeringMechanical engineering

The invention relates to an automatic feeding device of a spring grinding machine. The automatic feeding device comprises a feeding platform, a linkage arm, a side swing arm, a movable feeding pipeline, a fixed feeding pipeline, a lifting seat, a first induction mechanism, a second induction mechanism, a lifting device and a first alarm mechanism, wherein the lifting device is arranged between thelifting seat and the feeding platform, and used for lifting the lifting seat upwards; a swing cavity penetrating through vertically is formed in the feeding platform; the linkage arm is used for linking the side swing arm with the lifting seat; the side swing arm horizontally swings in the swing cavity; a fixed feeding pipeline is arranged on the side swing arm; the two ends of the horizontal swing track of the side swing arm are respectively a first position and a second position; and when a spring to be processed is clamped between the tail end of the movable feeding pipeline and a clamp, the side swing arm is driven to swing to the second position, and the lifting seat is lifted by the lifting device to separate the spring to be processed from the clamp. By adopting the scheme, the automatic feeding device is high in feeding efficiency and capable of avoiding spring deformation and equipment damage.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

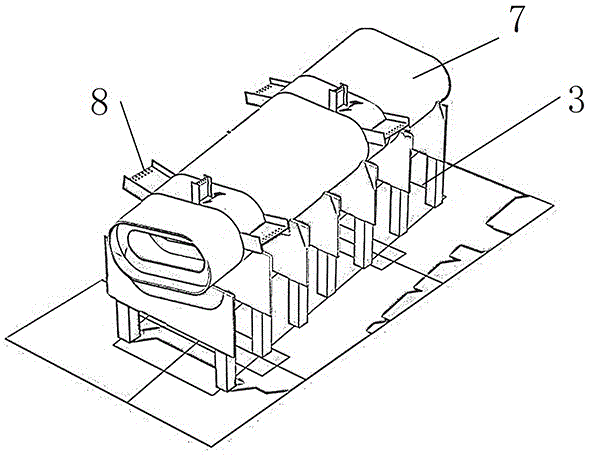

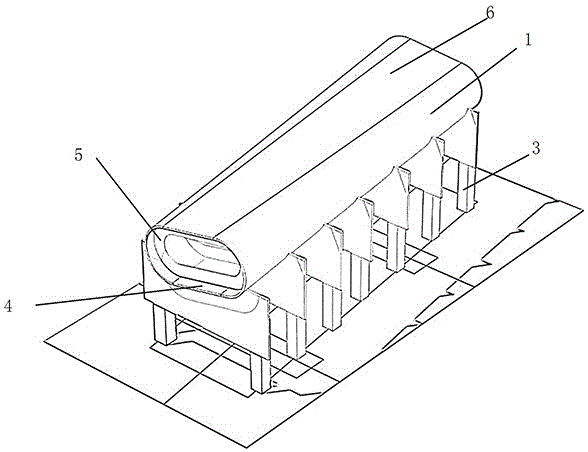

Twisted combined steel pipe column and manufacturing method thereof

InactiveCN105155775AGuarantee the construction qualitySimple structureStrutsOther manufacturing equipments/toolsEngineeringReference line

The invention discloses a twisted combined steel pipe column. The twisted combined steel pipe column comprises wall plates, a support jig frame, a baseplate, an inner separation plate, a positioning sealing plate and brackets, wherein assembly control wires are arranged on the wall plates; the support jig frame is fixed in an appointed construction site; the baseplate is arranged above the support jig frame; the wall plates are arranged at the two sides of the baseplate; the inner separation plate is arranged between the two wall plates; the positioning sealing plate is arranged at the tops of the two wall plates to form a cylinder; and the brackets are arranged at the upper side and two sides of the cylinder. The twisted combined steel pipe column forms the wall plates through twisting blanked parts, the assembly control wires for twisting a box mold are arranged on the wall plates, and detection reference lines are arranged on the molded wall plates, so that the machining precision is improved; the inner separation plate is elliptical, and is arranged between two twisted parts; and the size thereof is matched with a gap between the two twisted parts, so that the support capacity of the cylinder in the twisted steel pipe column is further improved, and the construction requirements are preferably satisfied.

Owner:JIANGSU HUNING STEEL MECHANISM

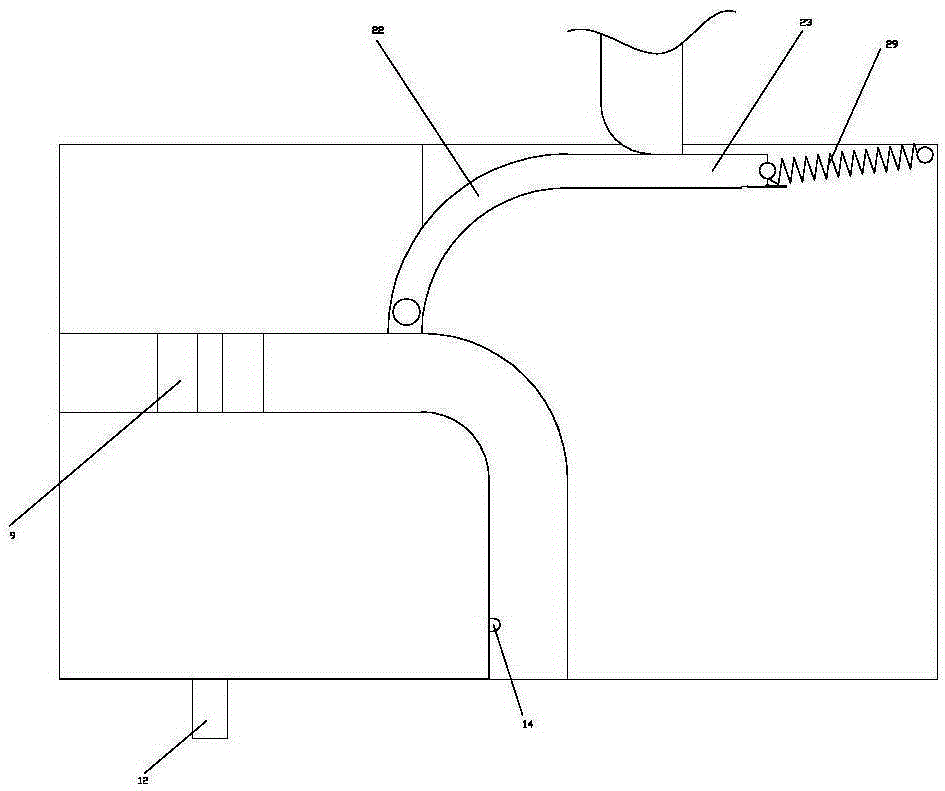

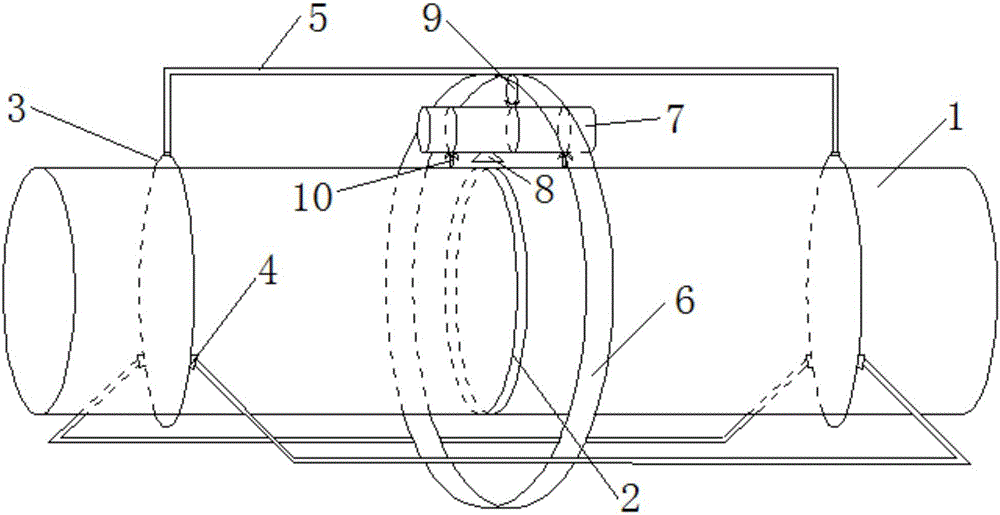

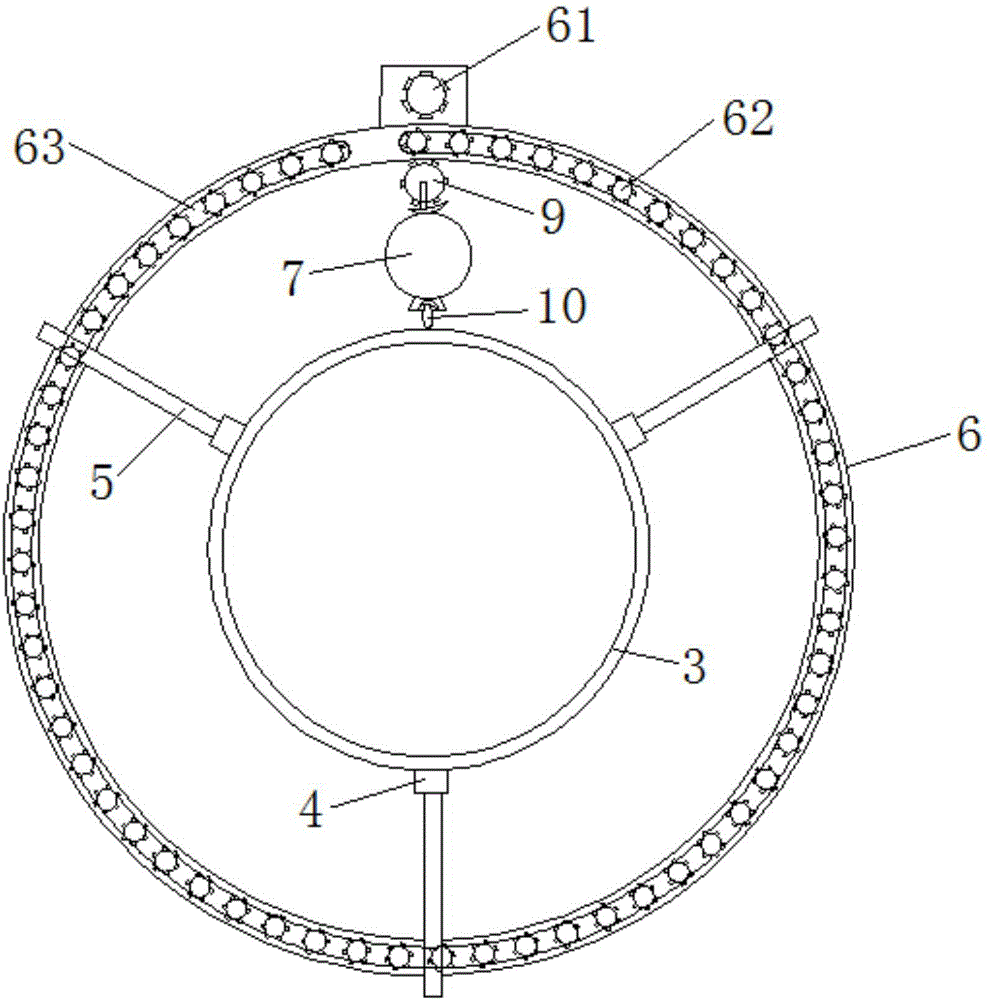

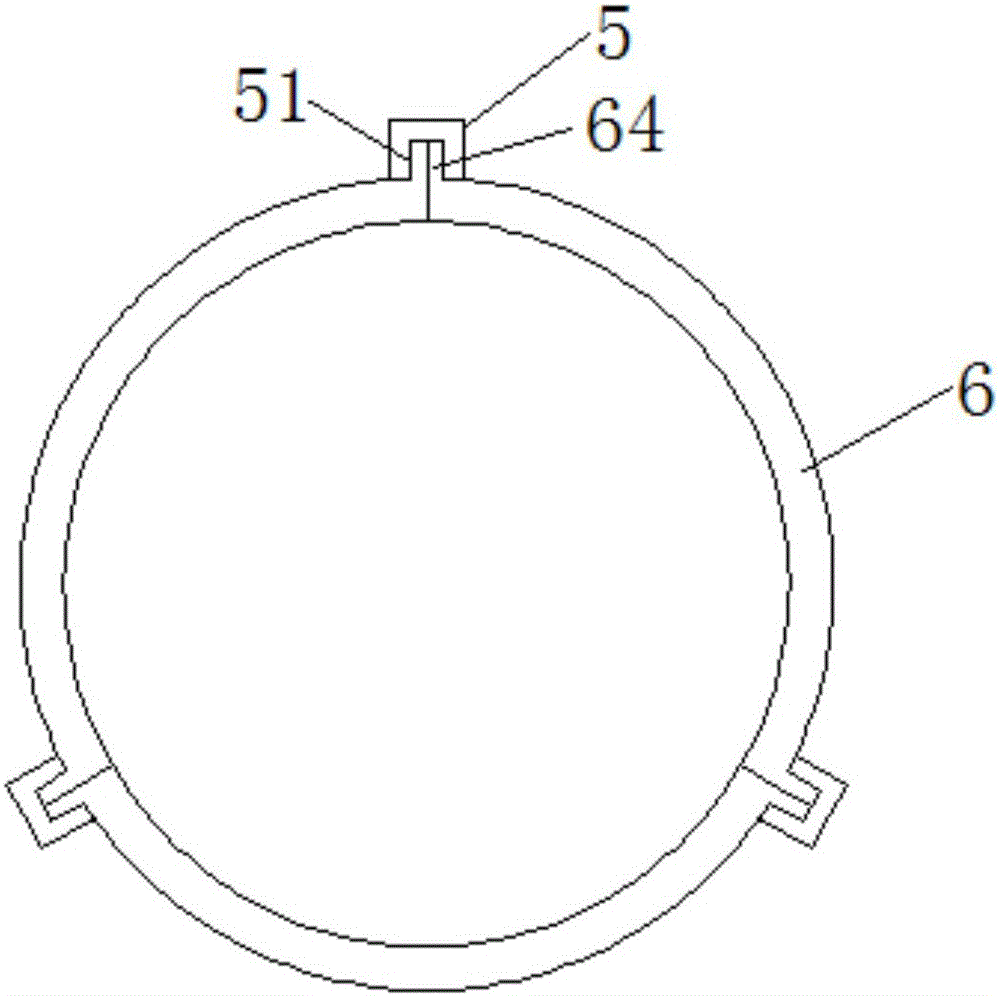

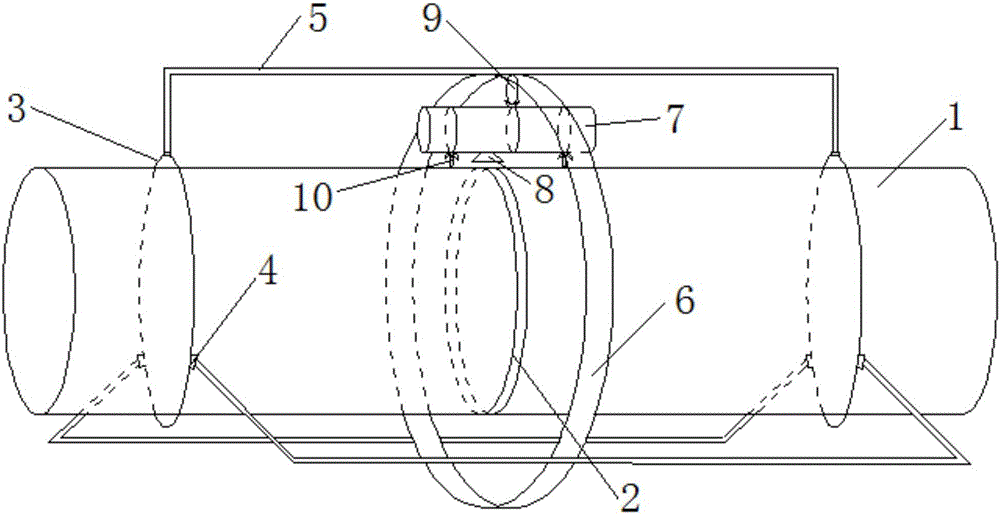

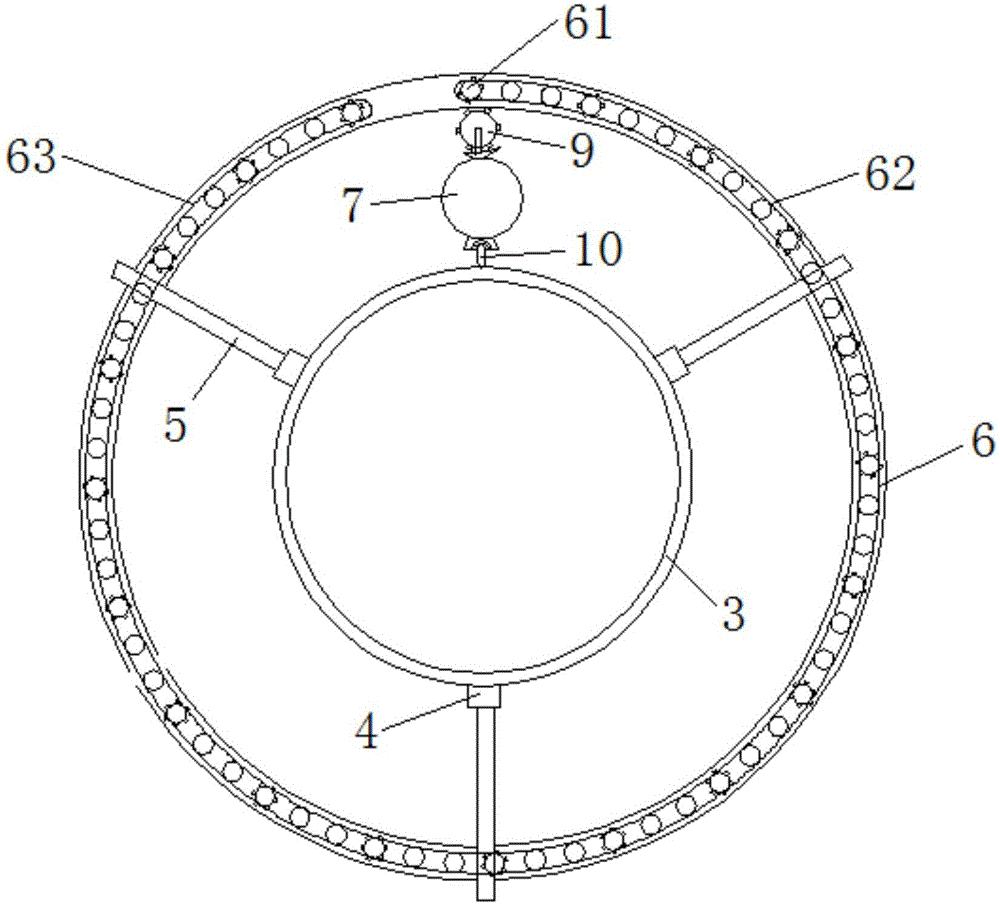

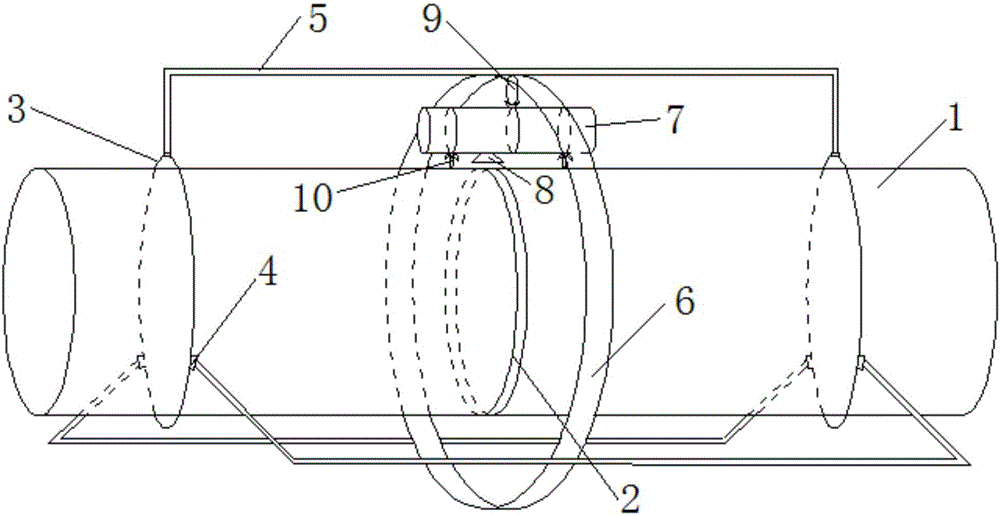

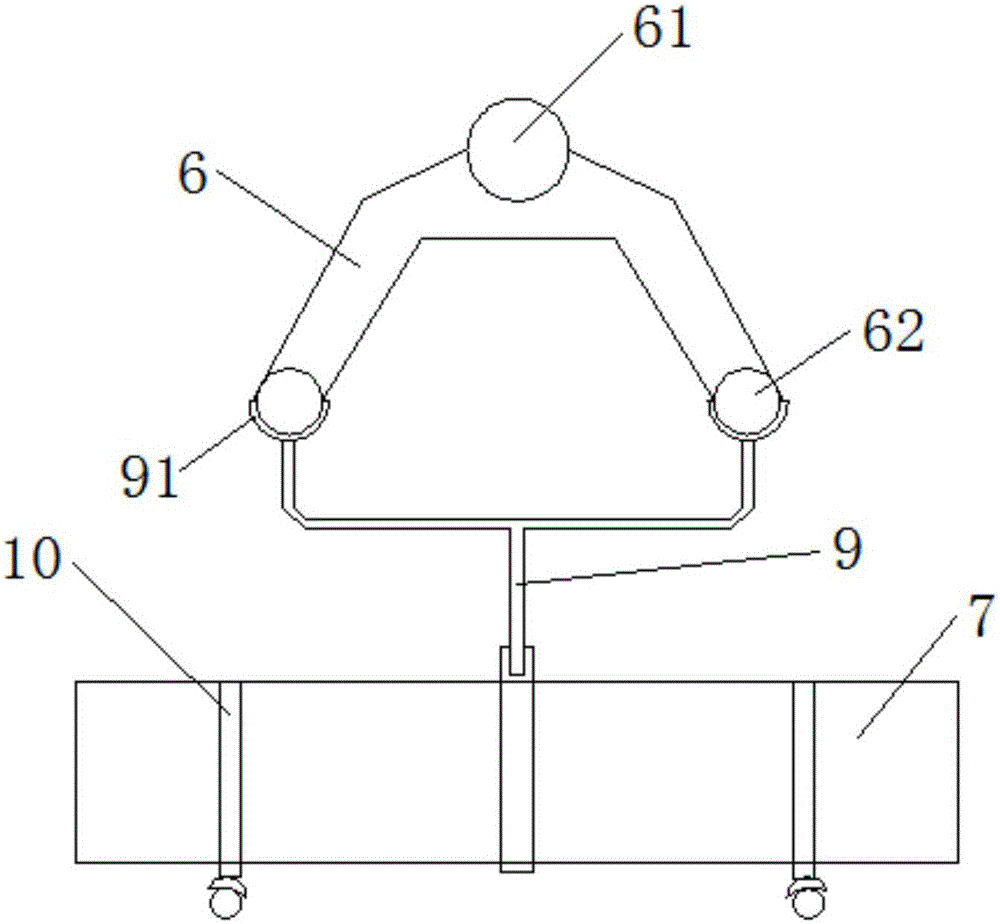

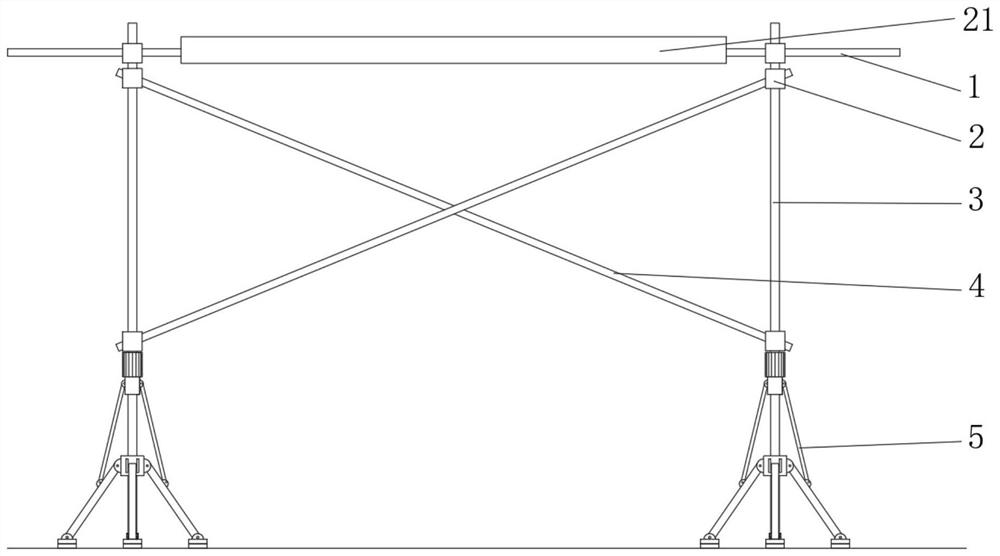

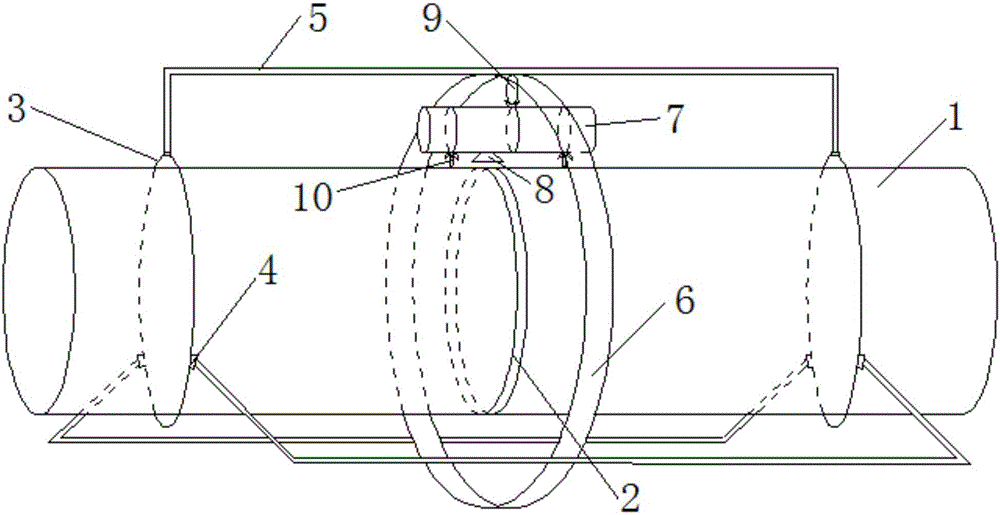

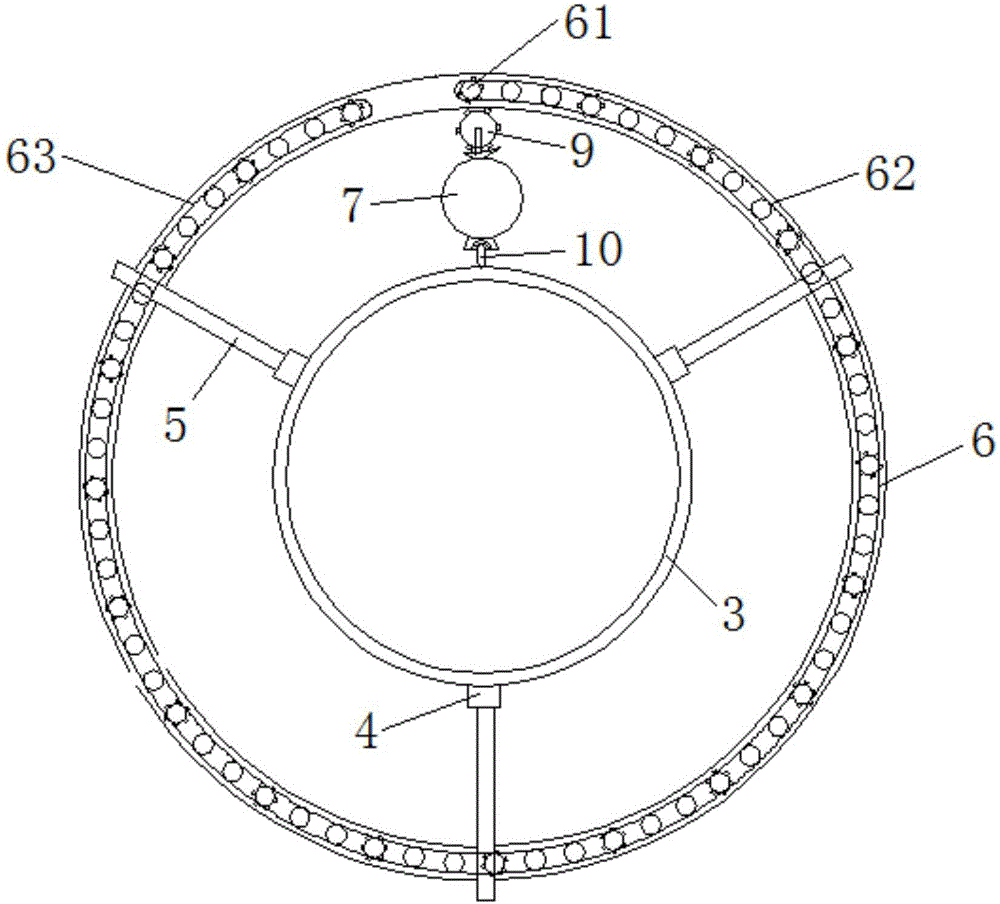

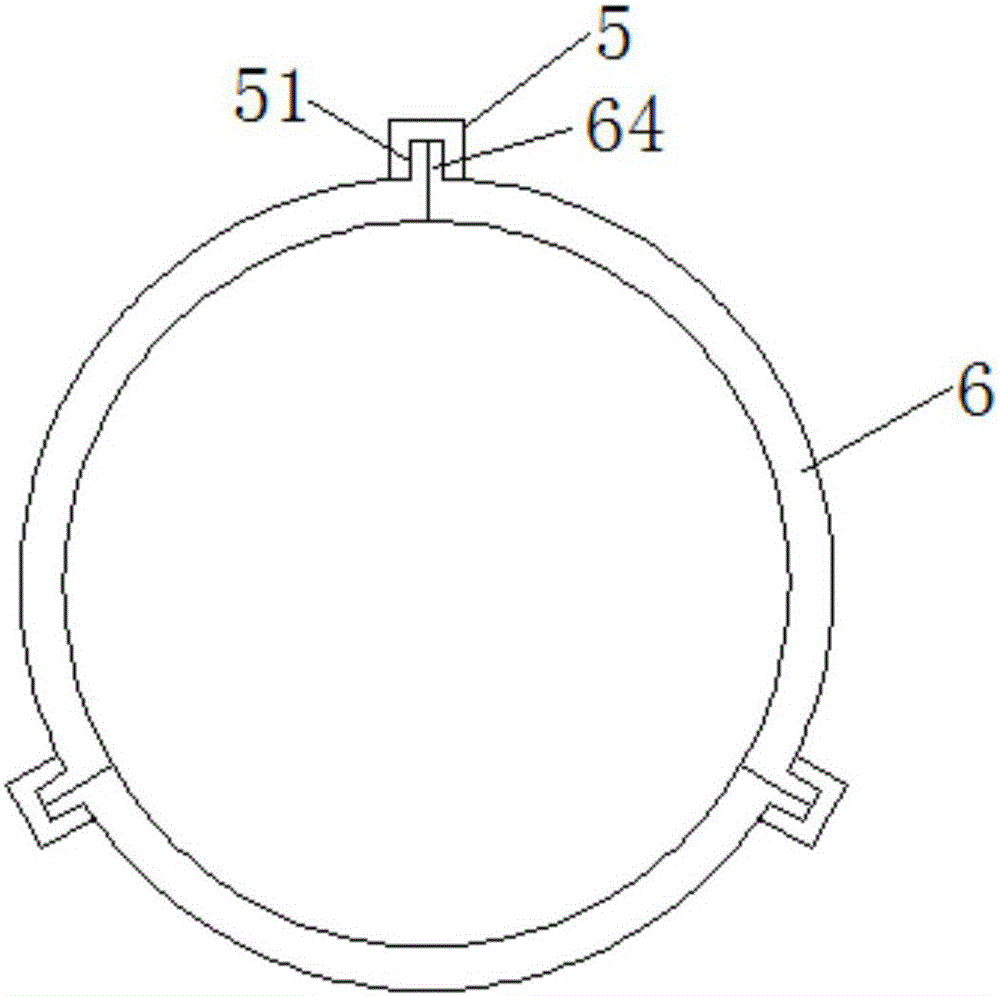

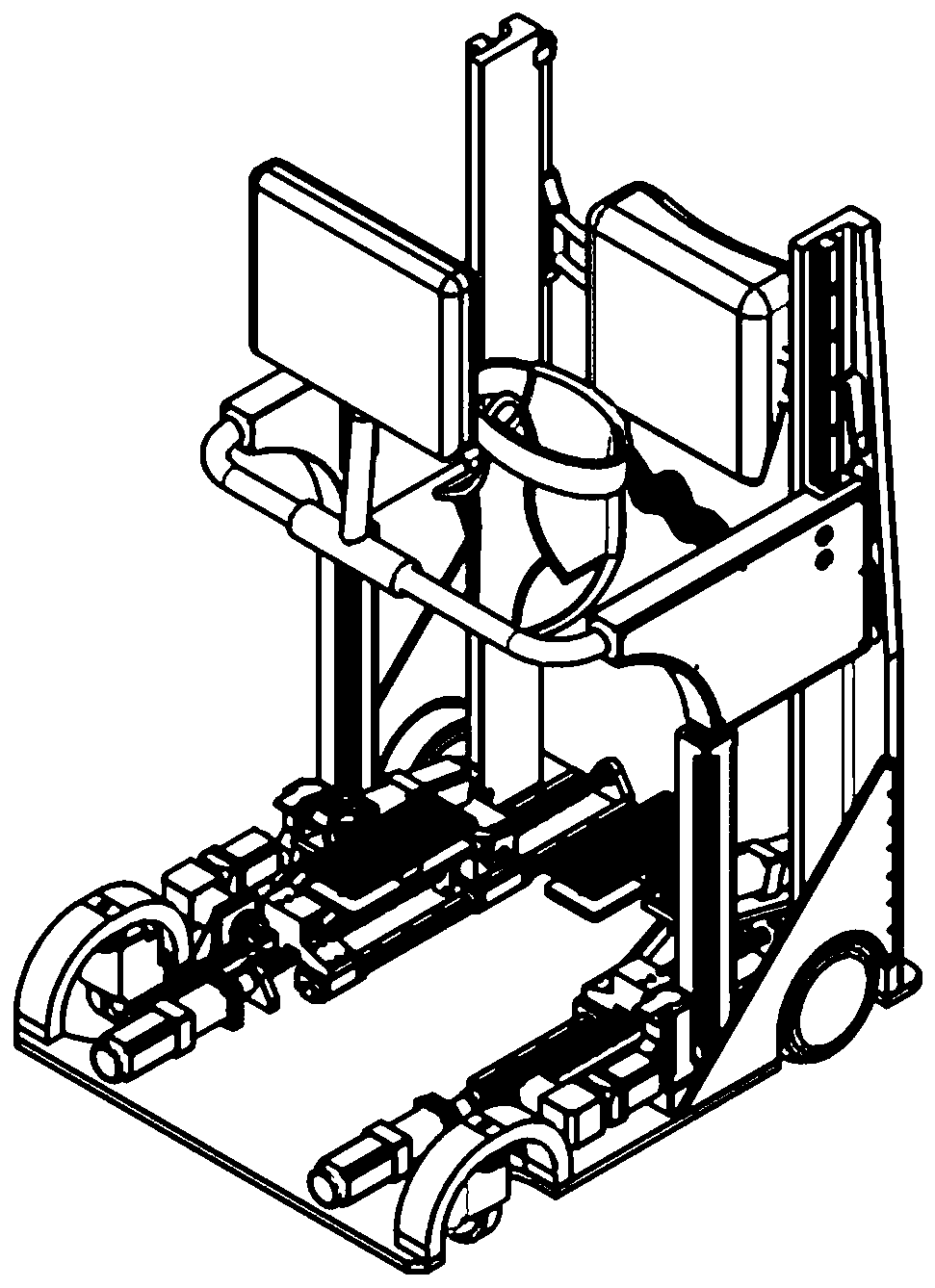

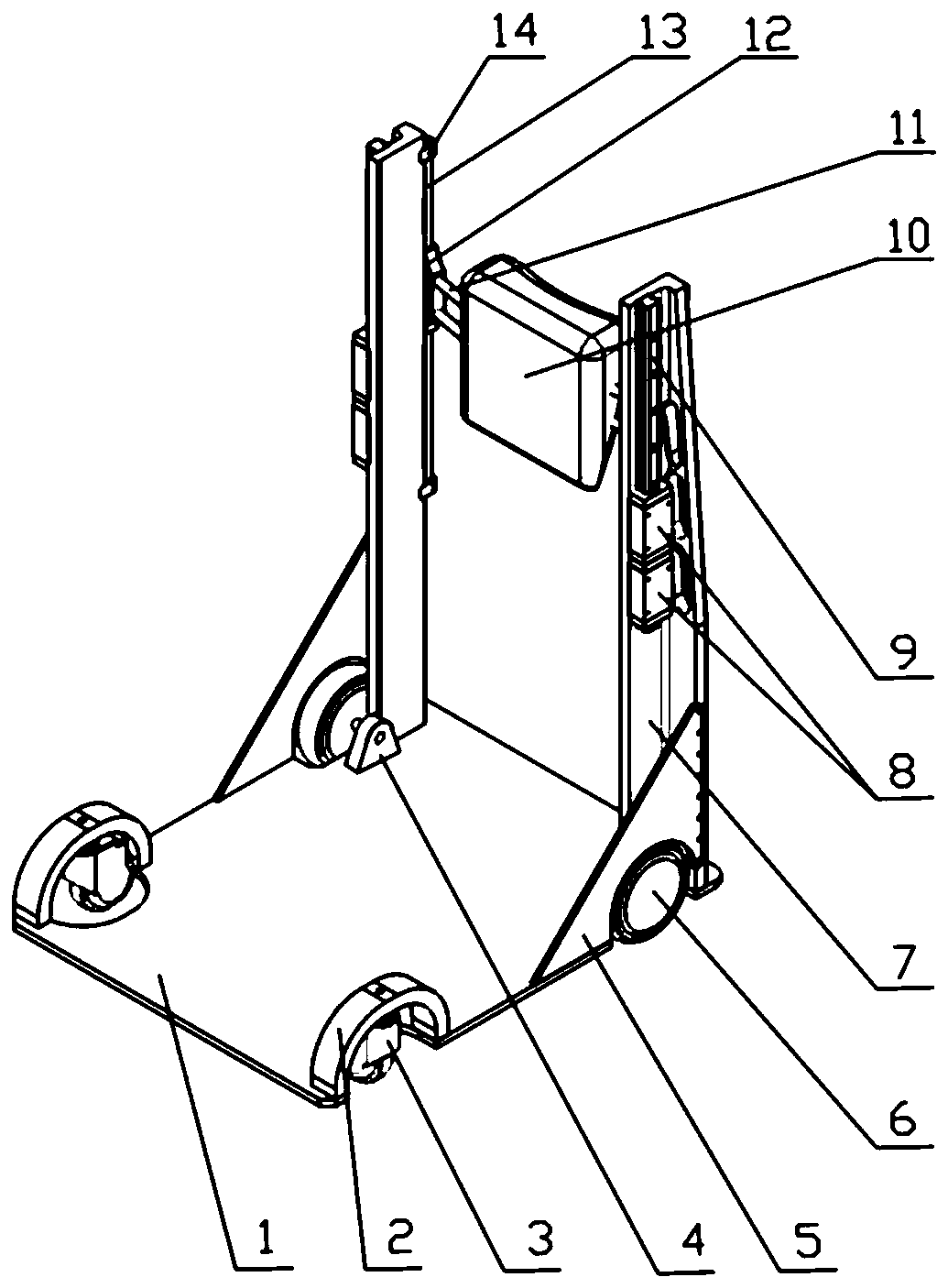

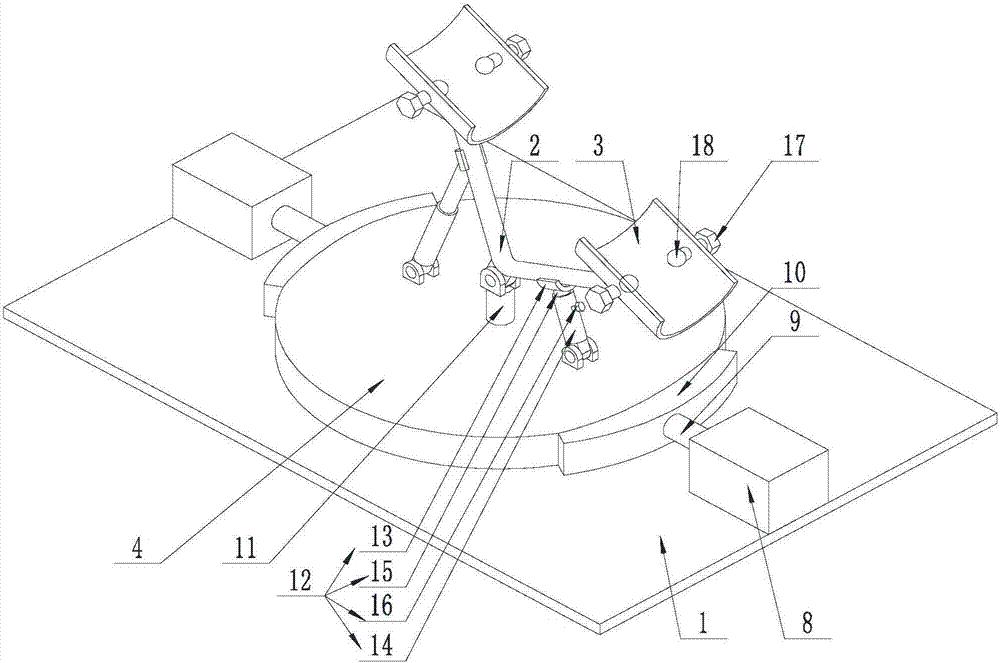

Movable field X-ray rolling shooting device for pipeline

ActiveCN105866143AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a movable field X-ray rolling shooting device for a pipeline, and belongs to the technical field of flaw detection. The movable field X-ray rolling shooting device for the pipeline comprises a supporting frame, an operating mechanism and a walking mechanism, wherein the supporting frame is mounted on the external surface of a to-be-detected pipeline; the operating mechanism is mounted on the supporting frame; the walking mechanism is located between the operating mechanism and the to-be-detected pipeline. The movable field X-ray rolling shooting device for the pipeline, which is provided by the invention, is reasonable in structural design and is simple to make; not only can the special putting up of a detecting platform for an X-ray flaw detector be avoided and can the engineering cost be reduced, but also the all-around flaw detection for welds on the pipeline is realized; when the flaw detection is carried out on the welds on the same pipeline, the trouble of repeated disassembly and assembly is omitted; the flaw detection efficiency is greatly promoted; the engineering progress is quickened; a detector is enabled to keep far away from an area to be subjected to the flaw detection in a flaw detection process; the injury of radiographic flaw detection to the detector is reduced; a strong guarantee is provided for engineering safety.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

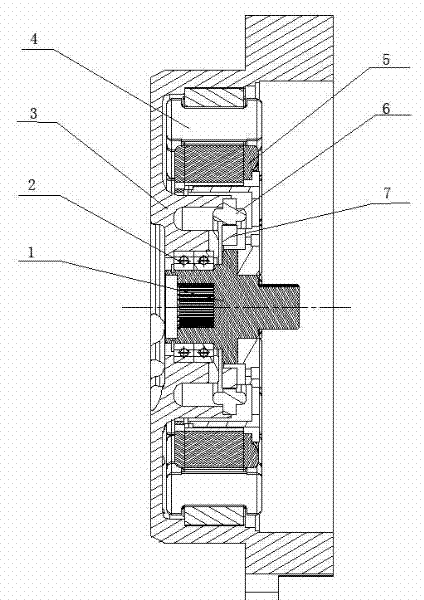

Motor integrated structure of hybrid electric vehicle

InactiveCN102358157AReduce axial sizeMeet layout requirementsHybrid vehiclesGas pressure propulsion mountingMotor driveElectric vehicle

The invention aims at providing a motor integrated structure of a hybrid electric vehicle, which comprises a motor drive shaft, a motor stator assembly, a motor rotor assembly, a motor revolver stator and a motor revolver rotor, wherein the motor drive shaft, the motor stator assembly, the motor rotor assembly, the motor revolver stator and a motor revolver rotor are integrated and assembled in an integrated shell and are respectively connected with a vehicle engine cylinder and a transmission installation shell through installation terminal surfaces at two sides of the integrated shell, one end of the motor drive shaft is connected with an engine through a vehicle dual-mass flywheel by adopting an external spline, and the other end of the motor drive shaft is connected with a transmission by adopting an internal spline. The motor integrated structure has the advantages of compact structure, convenience for installation, small arrangement space and the like, and solves the problem that motor assemblies are arranged in a limited space of an integral vehicle forecabin.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

Rolling photographing device for on-site pipeline flaw detection

ActiveCN105784739AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a rolling photographing device for on-site pipeline flaw detection, and belongs to the technical field of flaw detection. The rolling photographing device comprises a supporting frame, a running mechanism and a walking mechanism, wherein the supporting frame is mounted on the outer surface of the pipeline to be detected; the running mechanism is mounted on the supporting frame; the walking mechanism is positioned between the running mechanism and the pipeline to be detected. The rolling photographing device for on-site pipeline flaw detection is reasonable in structural design and easy to manufacture; a special detection platform does not need to be built for an X-ray flaw detector, so that the engineering cost is reduced; furthermore, all-round flaw detection for pipeline welds is realized, the flaw detection efficiency is greatly improved, and the engineering progress is accelerated; meanwhile, a detection person can get away from a flaw detection region in the flaw detection process, so as to relieve the harm of ray flaw detection to the detection person and provide great insurance for the safety of the engineering.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

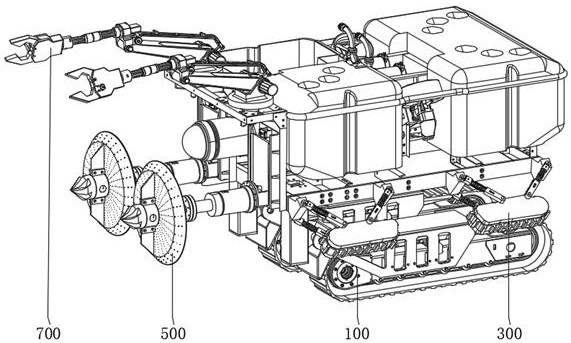

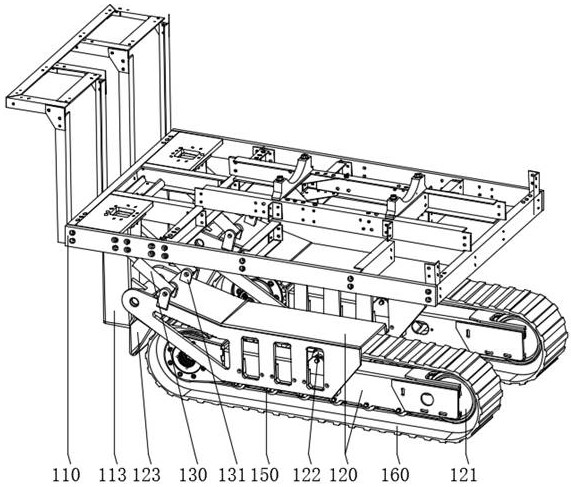

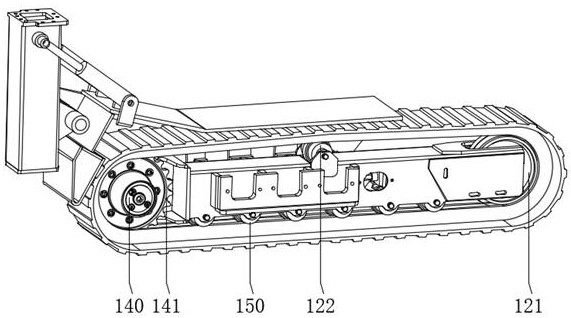

Drainage pipeline detecting and cleaning robot

ActiveCN113175068AAccelerated disengagementImprove job stabilitySewer cleaningWithdrawing sample devicesHydraulic cylinderPipe water

The invention provides a drainage pipeline detecting and cleaning robot, and belongs to the technical field of pipeline cleaning. The drainage pipeline detecting and cleaning robot comprises a climbing assembly and a balancing assembly. The climbing assembly comprises a platform frame, a load bearing frame, a first hydraulic cylinder, a first motor, a thrust wheel and a load bearing crawler belt. The drainage pipeline detecting and cleaning robot has the beneficial effects that by the adoption of the crawler climbing adjusting design, the overall gravity center of the robot is adjusted through angles, the contact area between the robot and a pipeline is increased, the traffic capacity is improved, meanwhile, the working stability of the pipeline cleaning robot is improved, the multi-propeller boosting design is adopted, a power source is added, the pipeline cleaning robot is convenient to break away from obstacles, meanwhile, the pipeline cleaning robot is suitable for stable balance under water flow impact of various pipelines, the damping supporting guide design is adopted, multi-point supporting is carried out on the inner wall of a pipeline wall, the stability of the gravity center of the pipeline cleaning robot is kept, the pipeline cleaning robot is suitable for pipeline cleaning under various complex working conditions, the pipeline cleaning work stability of the pipeline cleaning robot is high, and the pipeline cleaning effect of the pipeline cleaning robot is better.

Owner:SHENZHEN INVESTIGATION & RES INST

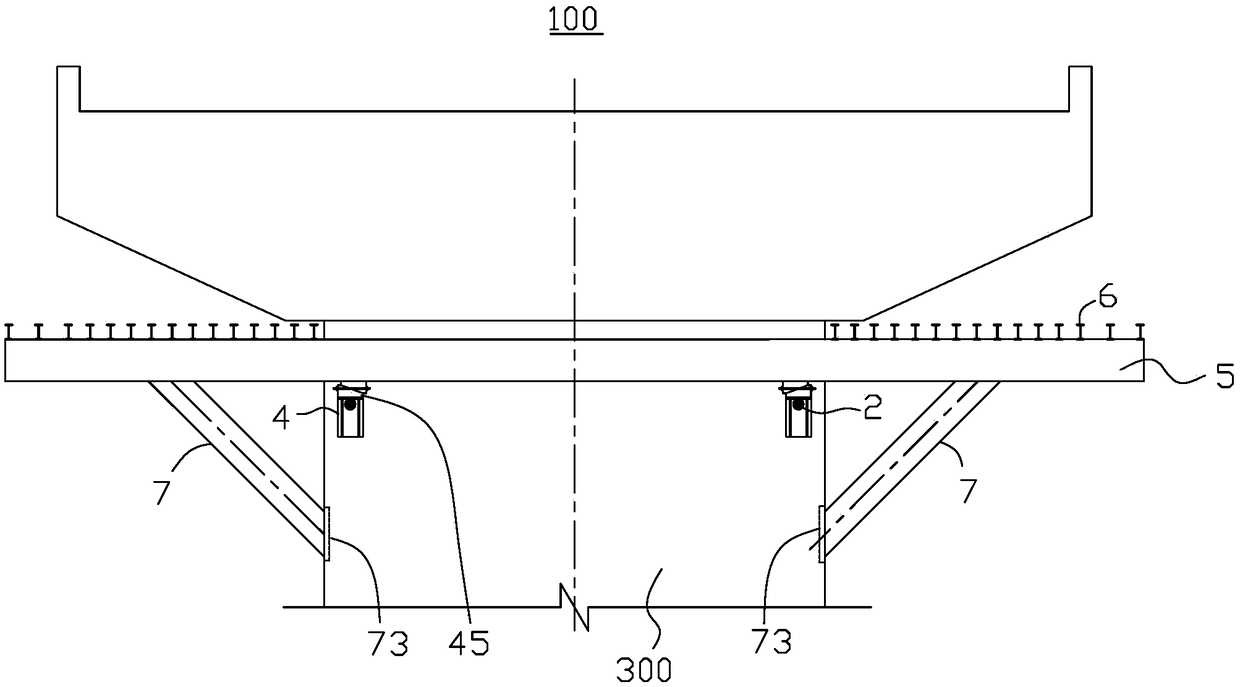

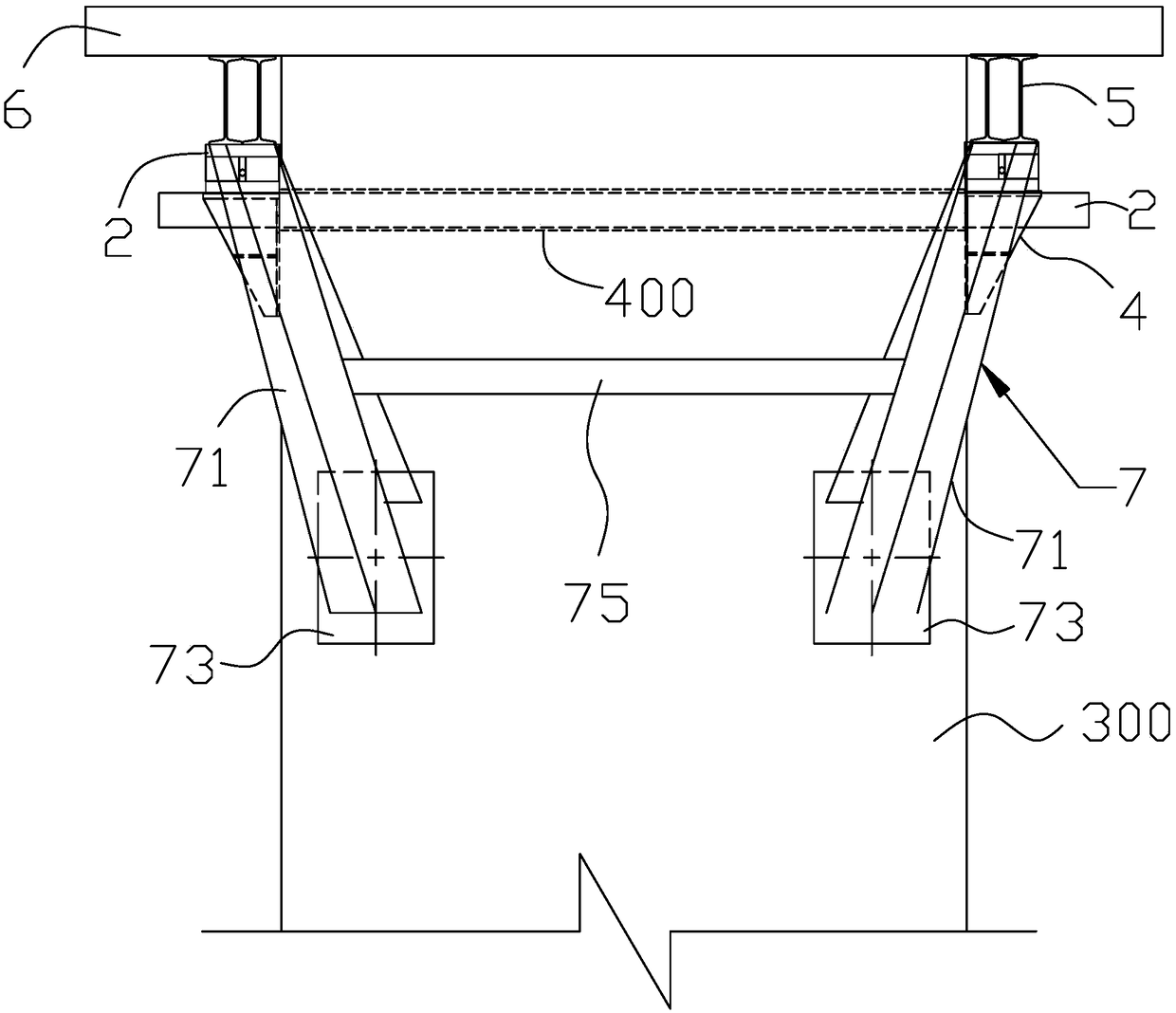

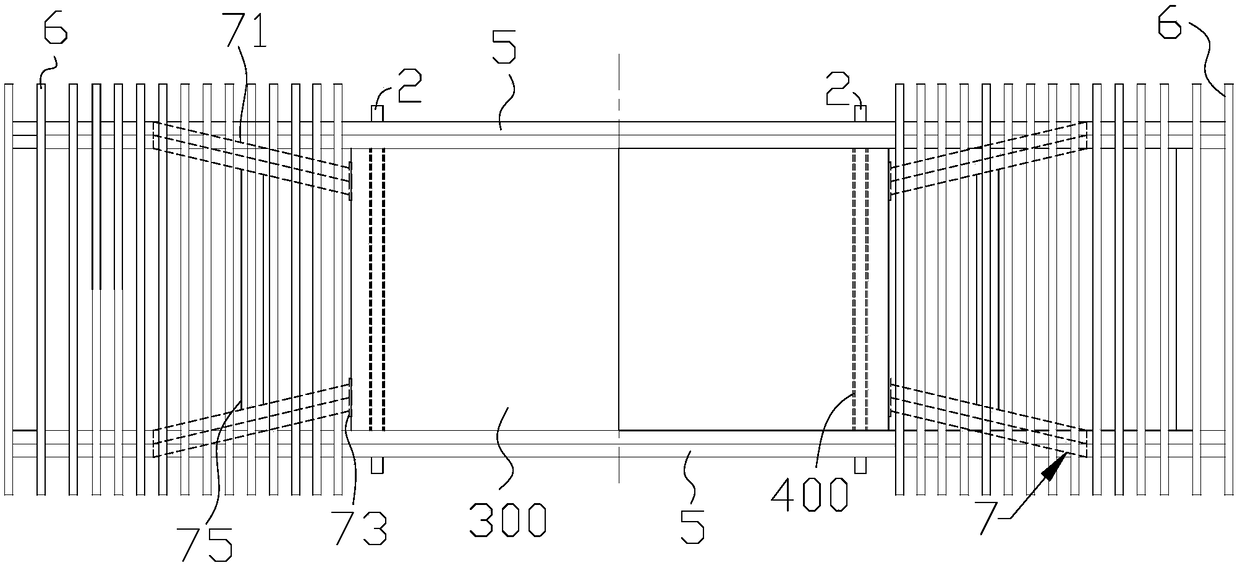

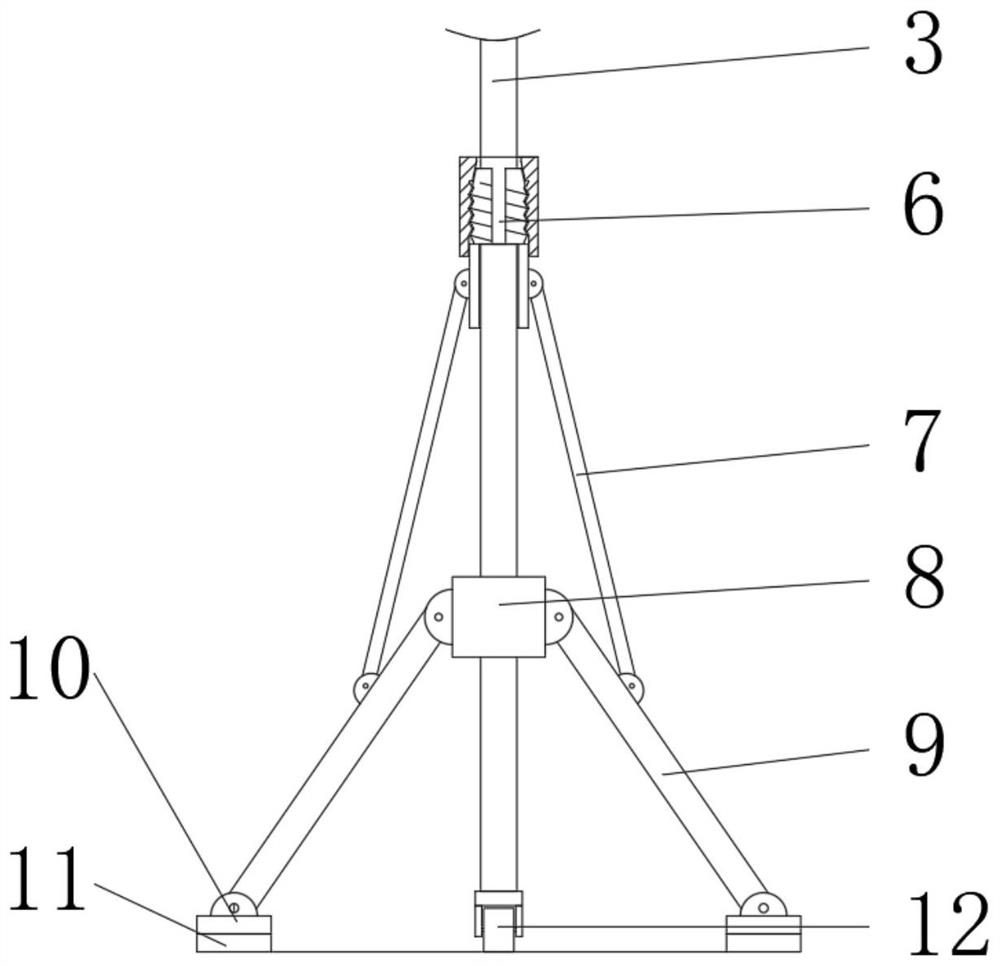

Construction method of T-shaped capping beam

InactiveCN109468953AConstruction applicableEven by forceBridge erection/assemblyBridge materialsSteel barEngineering

The invention provides a construction method of a T-shaped capping beam. The method comprises the steps of pre-burying of a pre-buried piece on a bridge pier, steel bar installing, stand installing, installing of a sizing block device, installing of a bearing beam, installing of a distributive girder, installing of an oblique leg supporting frame and installing of a template. The steel bar and thestand sleeving the steel bar are utilized for supporting the bearing beam, two oblique leg supporting frames arranged on the two opposite sides of the bridge pier in the direction perpendicular to the steel bar are utilized for supporting a suspending part, located outside the bridge pier, of the bearing beam, supporting points of a template bearing frame are increased, so that the stability andstrength of the template bearing frame of the capping beam are improved, and the method is suitable for construction of the T-shaped capping beam.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

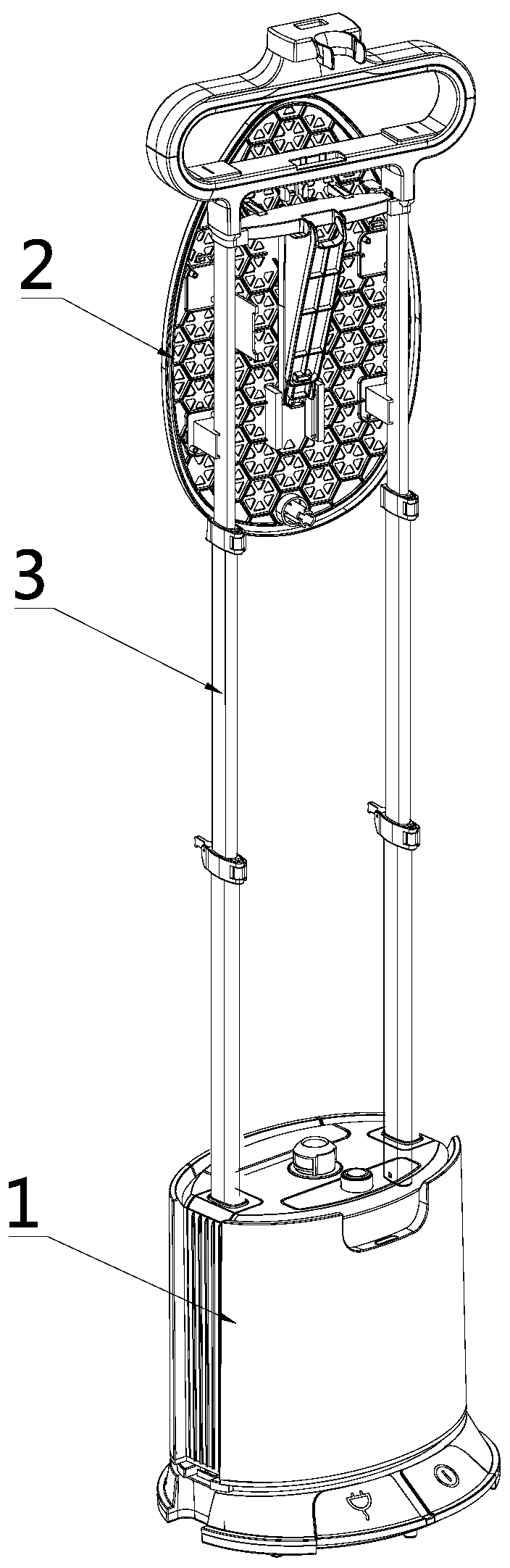

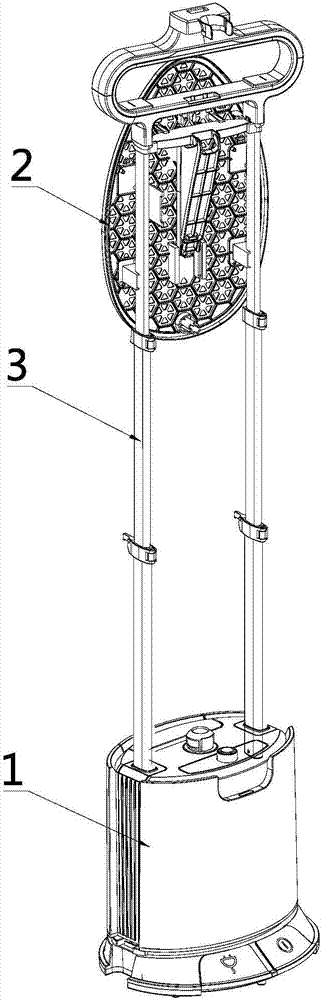

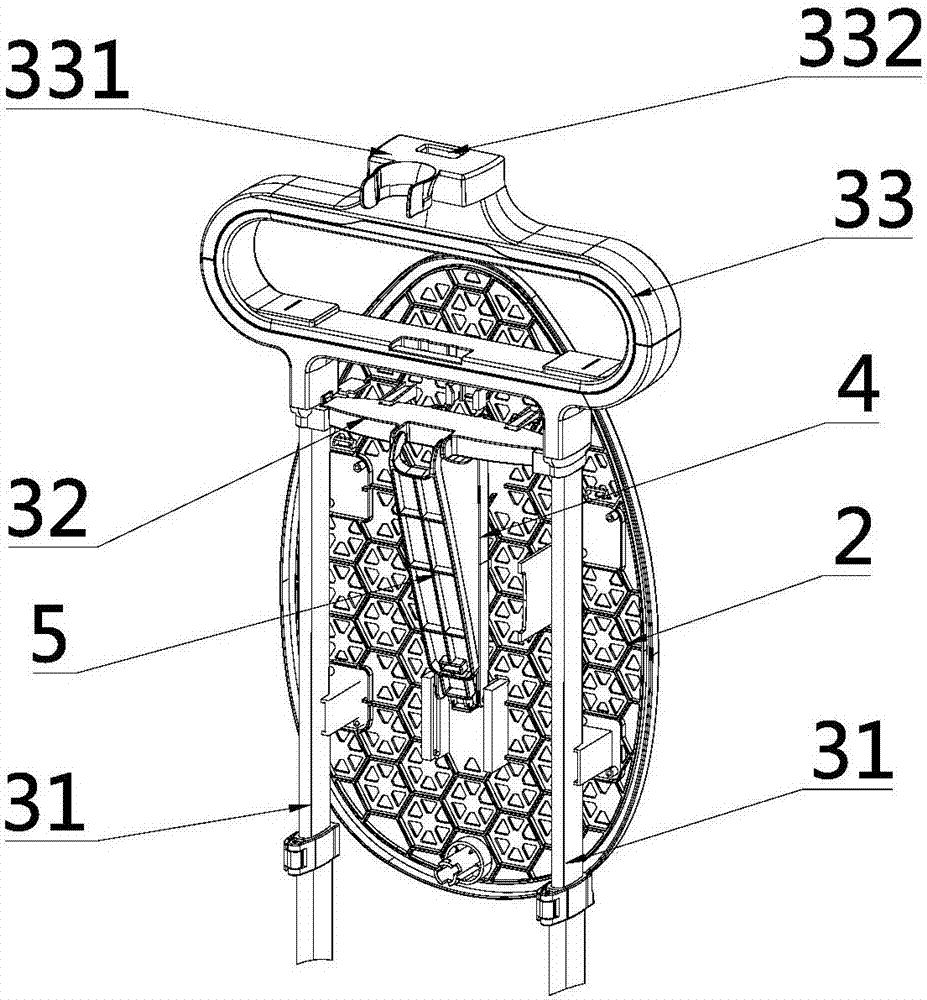

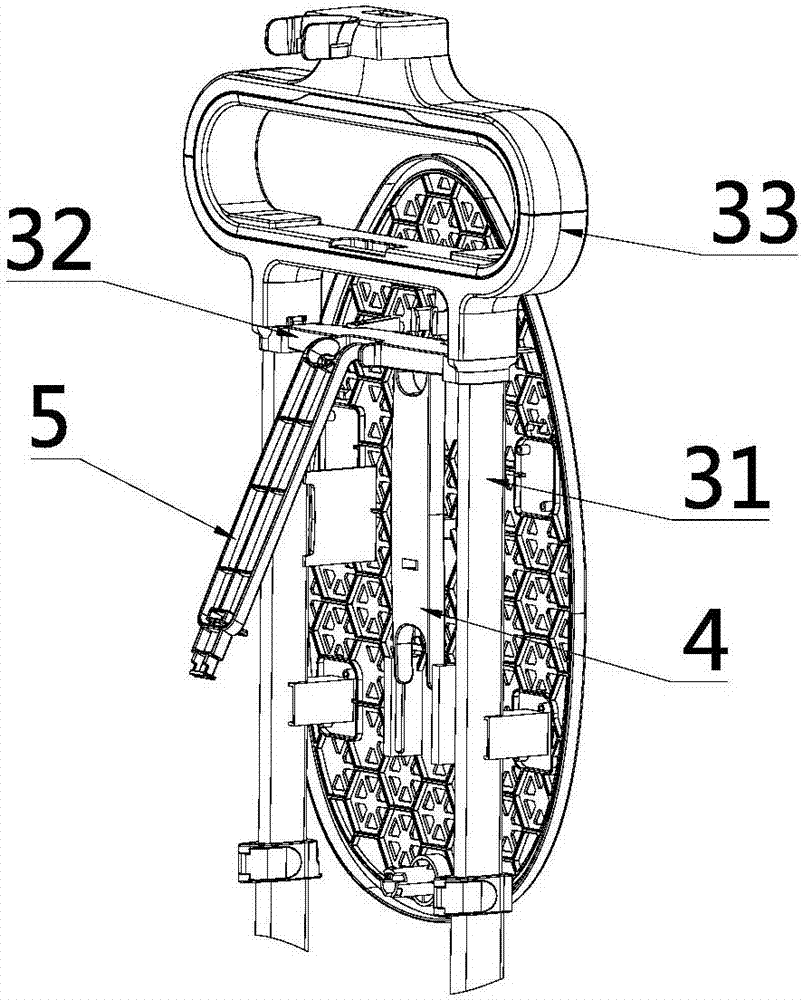

A steam ironing machine with a reversible ironing board

The invention discloses a steam ironing machine with a reversible ironing plate. The machine solves the problem of low stability of the ironing plate. The technological scheme which solves the problem mainly comprises a main body, the ironing plate, and a supporting frame disposed on the main body, wherein the front face of the ironing plate is an ironing face; the supporting frame is in rotatable connection with a first connecting part and a second connecting part; joints between the first connecting part and the second connecting part and the supporting frame are located on two sides of the supporting frame; the first connecting part is in rotatable connection with the back face of the ironing plate; when the ironing plate stays at a first installation state, the first connecting part is stored between the ironing plate and the supporting frame; the second connecting part is connected to the first connecting part and limits rotation of the first connecting part relative to the supporting frame; and the first connecting part and the second connecting part support the ironing plate when the ironing plate stays at a second installation state. According to the invention, through mutual coordination and mutual limiting of the first connecting part and the second connecting part, stability of the ironing plate at the first installation state and the second installation state can be ensured.

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

Field pipeline flaw detection device

InactiveCN105699405AIncrease the support pointFind the flaw detection positionMaterial analysis by transmitting radiationX-rayEngineering

The invention discloses a field pipeline flaw detection device and belongs to the technical field of flaw detection. The device comprises a supporting frame, a track and a traveling mechanism, wherein the supporting frame is installed on the outer surface of a pipeline to be detected, the track is installed on the supporting frame, and the traveling mechanism is located between the track and the pipeline to be detected. The device is reasonable in structural design, easy to manufacture, and capable of avoiding the construction of a detection platform special for an X-ray flaw detector so as to reduce engineering cost, achieving comprehensive flaw detection of pipeline welding seams, improving flaw detection efficiency greatly, accelerating work progress, and allowing detection staff to be away from the flaw detection area during flaw detection so as to reduce the harm of radiographic inspection to detection staff, so that engineering safety is guaranteed reliably.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

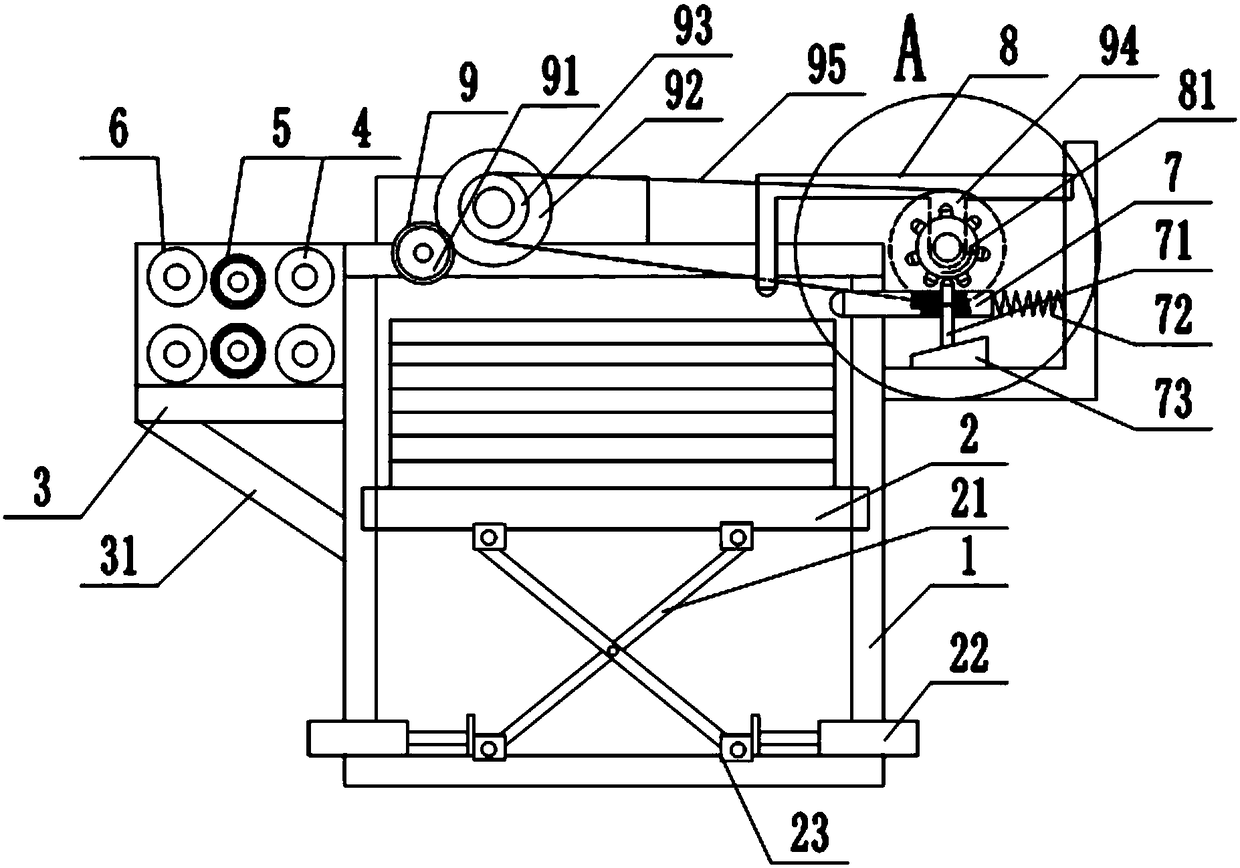

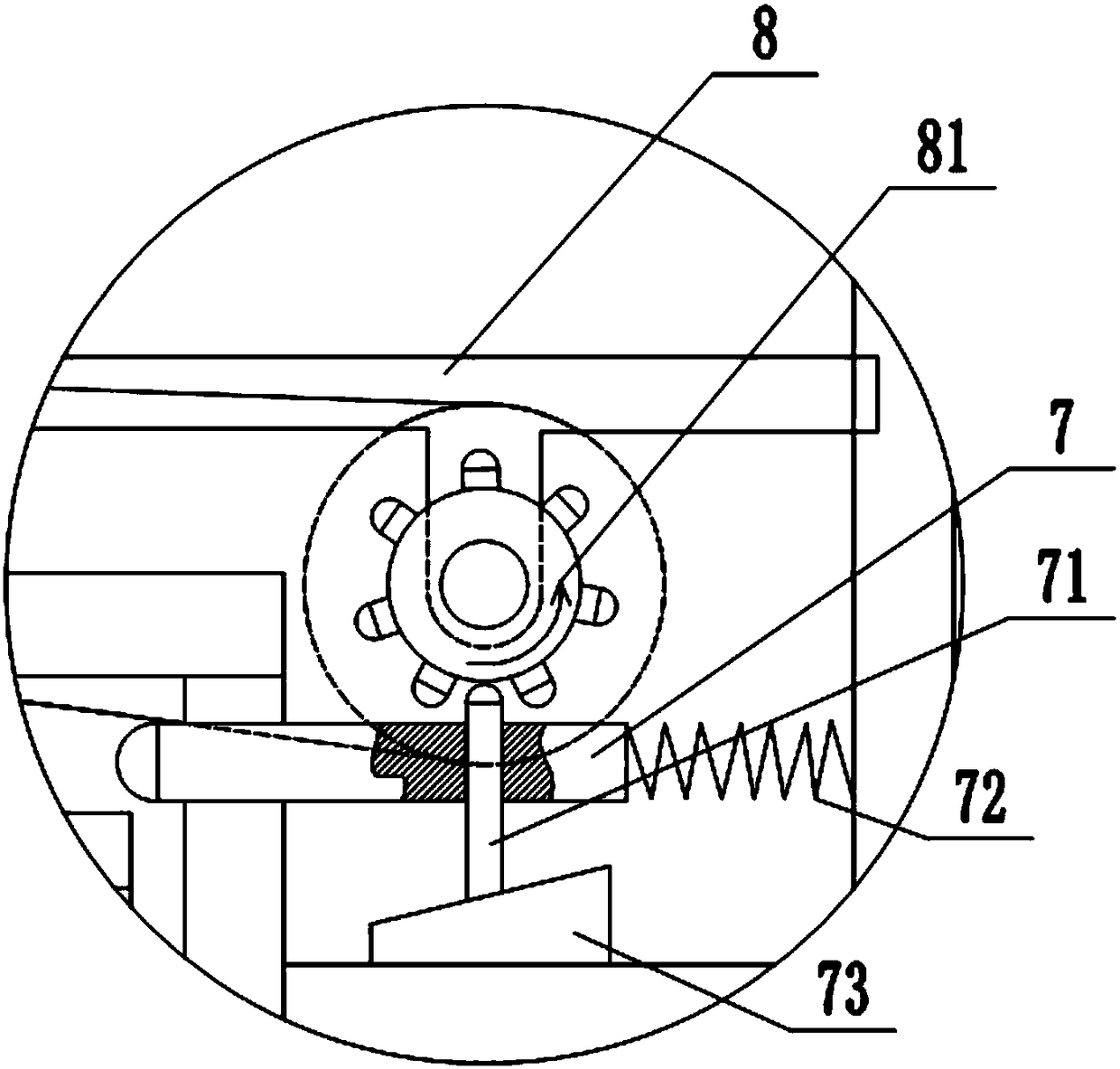

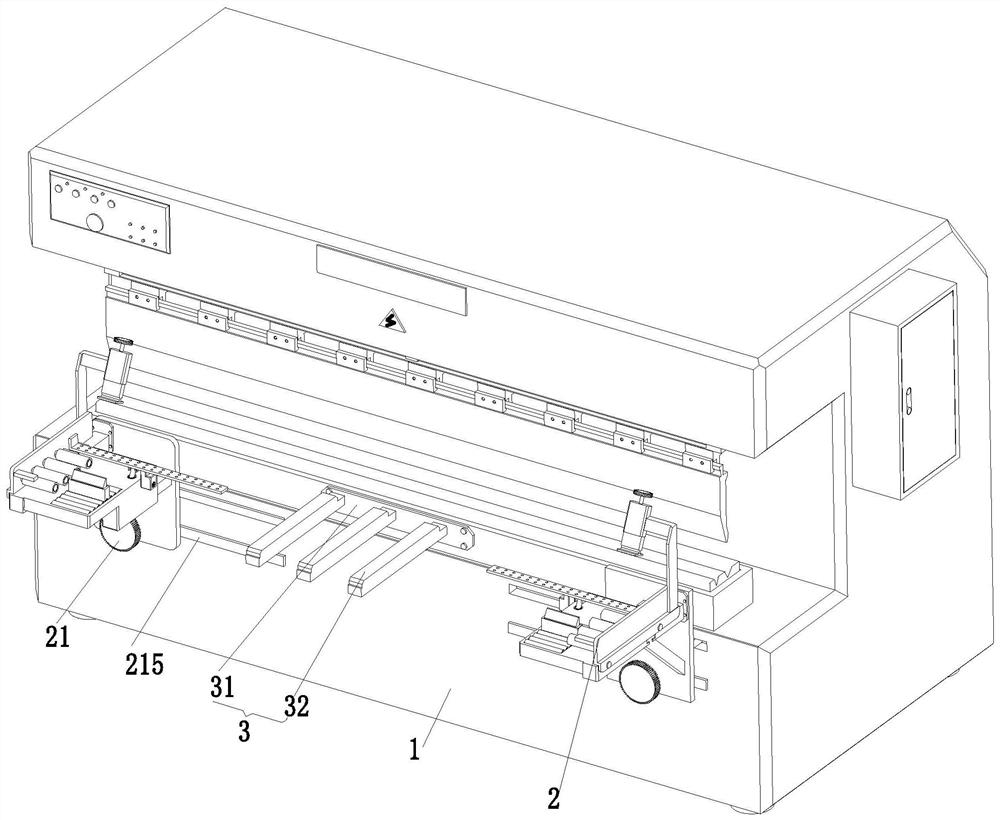

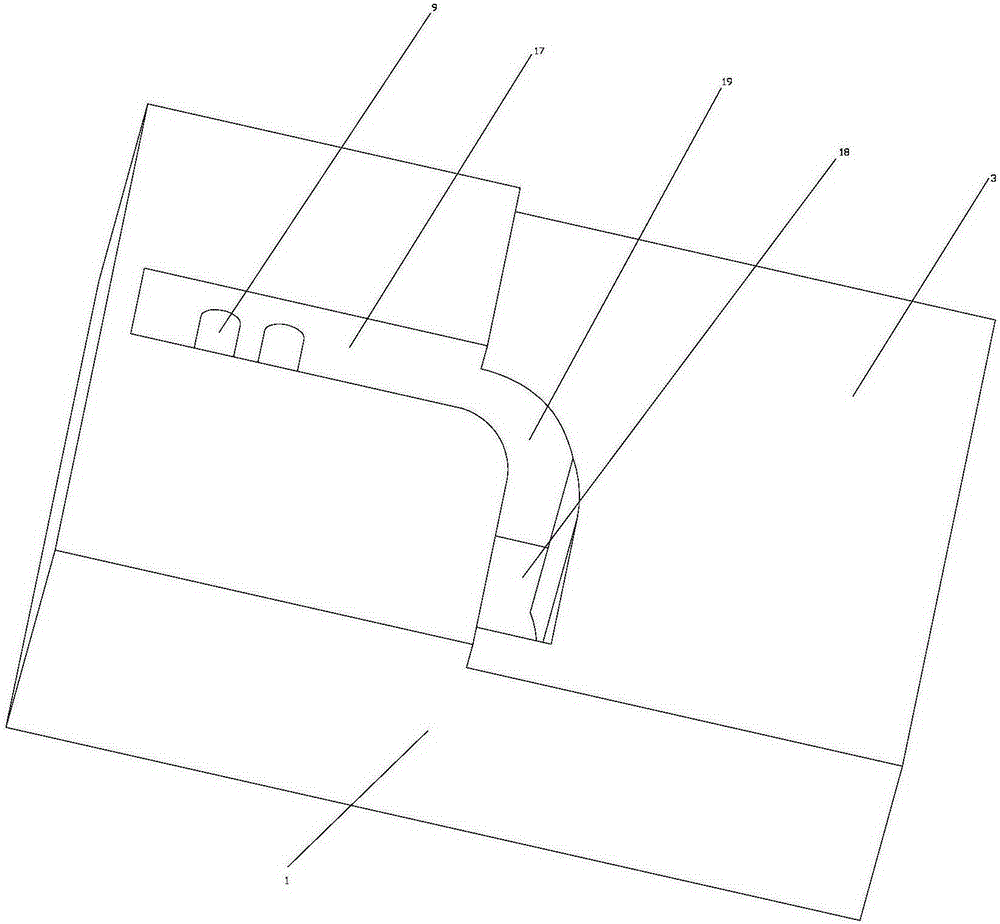

Automatic plate feeding device

PendingCN108480867AGuaranteed separation effectSolve the problem that can not be loaded one by oneLaser beam welding apparatusMechanical engineeringEngineering

The invention relates to the technical field of machining devices of cutting machines, and discloses an automatic plate feeding device. The automatic plate feeding device comprises a machine frame, alifting mechanism and a conveying mechanism; the lifting mechanism is arranged in the machine frame, and the conveying mechanism is arranged on one side of the upper end of the machine frame; the device further comprises a pushing mechanism and a reset mechanism, wherein the pushing mechanism and the reset mechanism are installed on the machine frame; the pushing mechanism comprises a push rod, aplug pin and a spring, the push rod is slidably connected to the machine frame, and one end of the push rod extends into the machine frame; the end, far away from the interior of the machine frame, ofthe push rod is connected to the machine frame through the spring, and the plug pin is connected to the rod surface of the push rod. According to the automatic plate feeding device, through the cooperation of the pushing mechanism and the reset mechanism, the plate layer on the uppermost layer can be pushed out periodically, each plate in the plate layer is separated one by one is guaranteed, conveying is realized, and the problem that plates cannot be fed one by one in the prior art is solved.

Owner:宁波隆锐机械制造有限公司

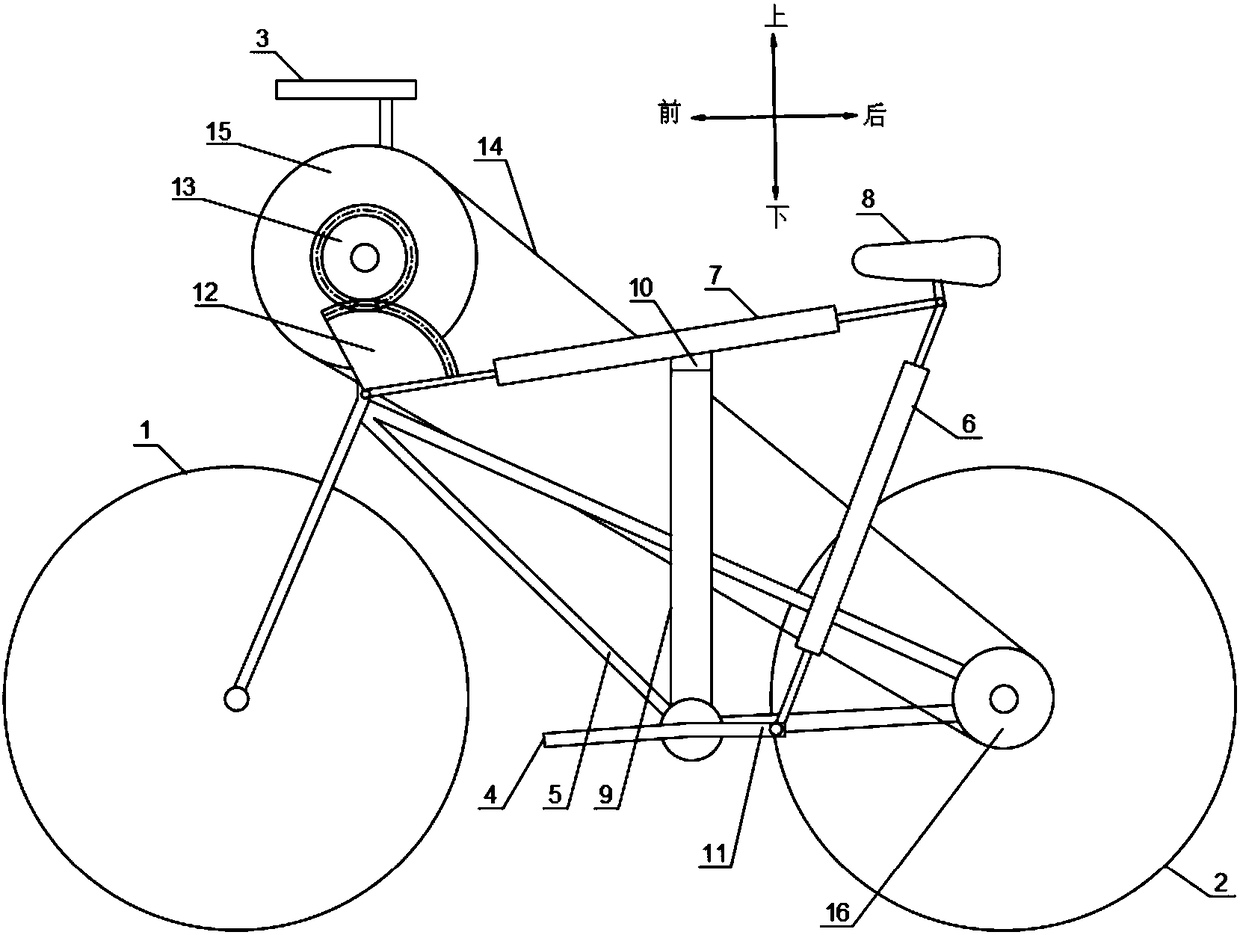

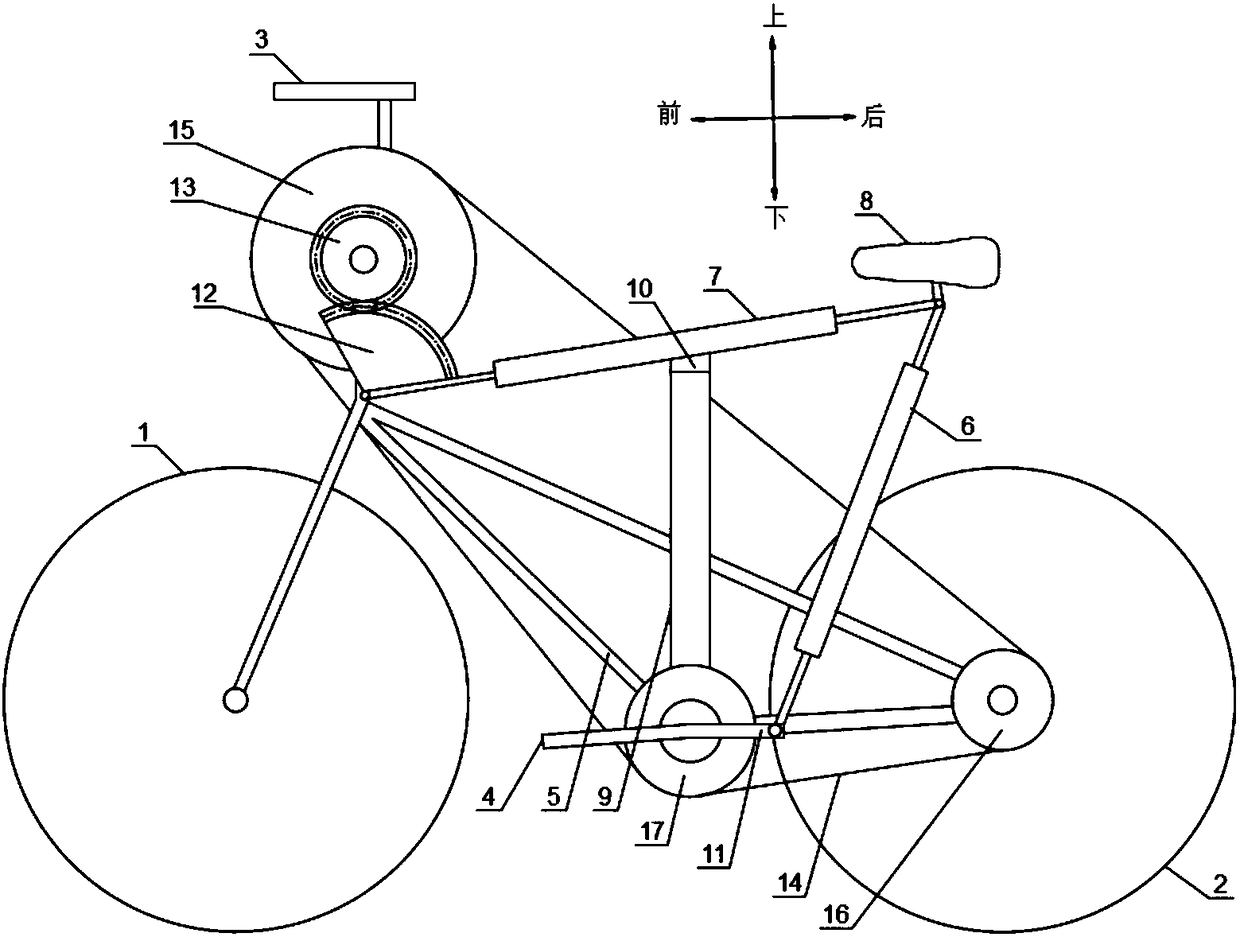

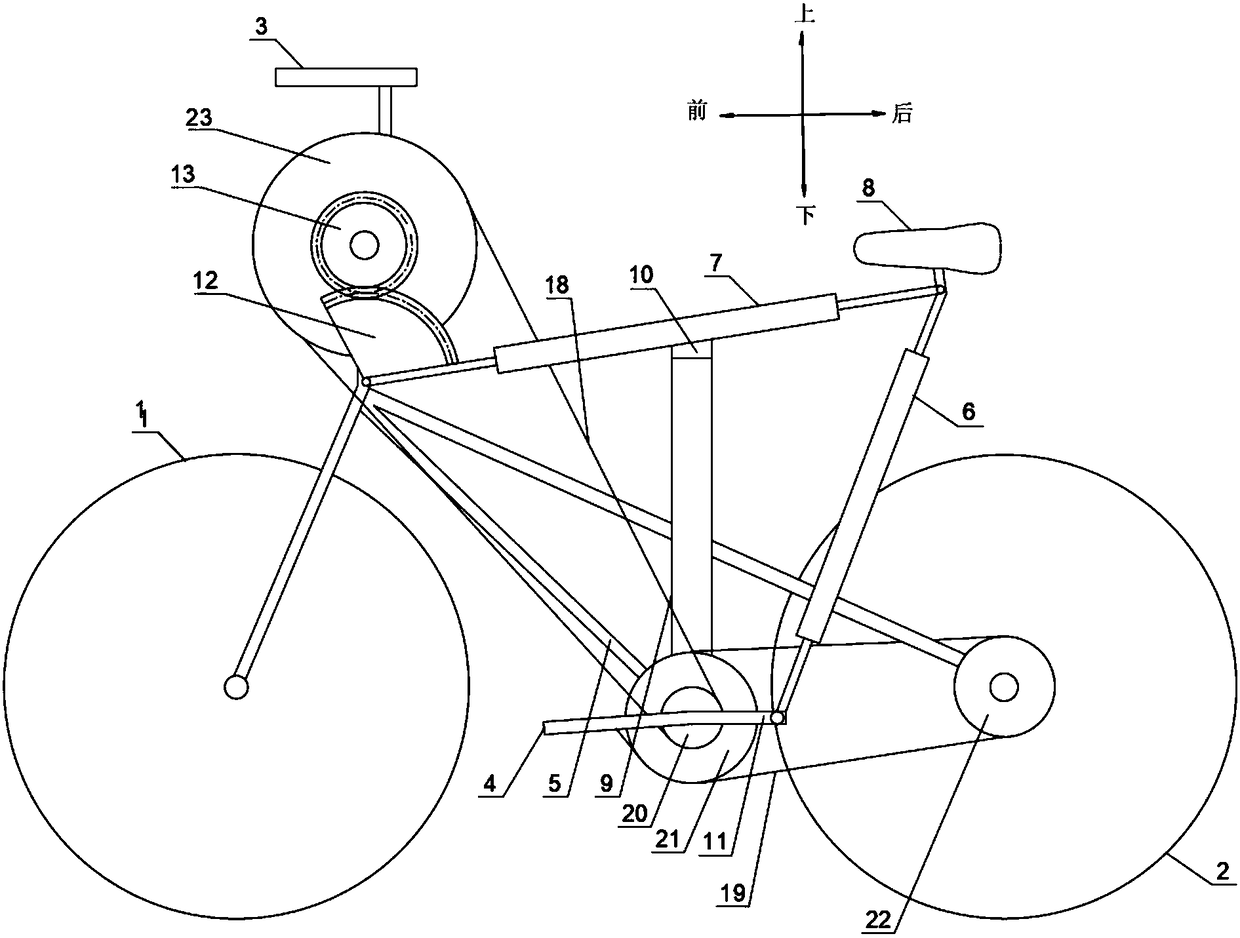

Super-labor-saving bicycle

InactiveCN108454769AEffort-saving ridingImprove exercise effectCycle saddlesRider propulsionVehicle frameWhole body

The invention discloses a super-labor-saving bicycle which comprises a front wheel assembly, a rear wheel assembly, a handle, pedals, a frame, a connecting rod, a swinging rod, a seat and a transmission mechanism, wherein the transmission mechanism is used for transferring swinging force of the swinging rod to the rear wheel assembly. The front wheel assembly and the rear wheel assembly are mounted at the front end and the rear end of the frame, the pedals are rotatably mounted at the lower end of the middle of the frame, the swinging rod and the pedals are hinged to two ends of the connectingrod, the seat is fixed at a hinging end of the connecting rod and the swinging rod, and one end, far away from the seat, of the swinging rod is hinged to the front end of the frame and in transmission connected with the rear wheel assembly through the transmission mechanism. According to the bicycle, force is generated by the weight of a human body, so that the bicycle is easily ridden, long-timemovement of feet is omitted, the bicycle is ridden by movement of a whole body, and good exercising effects can be achieved.

Owner:曾东斌

Hydraulic numerical control bending machine

ActiveCN114011916AAvoid unnecessary bendsAffect the aestheticsMetal-working feeding devicesPositioning devicesNumerical controlStructural engineering

The invention relates to a hydraulic numerical control bending machine comprising a bending machine body, active material supporting frames and an auxiliary material supporting frame, the active material supporting frames are symmetrically arranged on the left side and the right side of the front end of the bending machine body, and the auxiliary material supporting frame is installed in the middle of the front end of the bending machine body. The hydraulic numerical control bending machine can solve problems that a traditional material supporting frame is fixed in structure and difficult to deform and adjust, the material supporting frame can support a plate before bending, however, the material supporting frame cannot support the plate synchronously along with bending of the plate in the bending process, at the moment, parts on the two sides of the bending position are usually in a suspended state, and due to the fact that the front half part of the plate is usually long and heavy, the plate of the part may be excessively bent due to the fact that the suspended part is too large or too heavy, then the bending precision is influenced; after each time of bending, a worker needs to take out a detection tool to detect the bending degree of the plate, the situation that the bending degree does not reach the standard is prevented, and the situation that the efficiency of an assembly line is influenced by manual detection is prevented.

Owner:FUYANG QIANGSONG MACHINERY MFG

Anti-toppling scaffold for decoration

InactiveCN112160573AEasy to moveEasy to fixScaffold accessoriesClassical mechanicsStructural engineering

The invention discloses an anti-toppling scaffold for decoration, and relates to the technical field of scaffolds. The anti-toppling scaffold comprises vertical rods, the number of the vertical rods is four, the four vertical rods are distributed in a rectangular array, universal wheels are fixedly connected to the bottom ends of the vertical rods, and anti-inclination devices are arranged on theouter sides of the bottom ends of the vertical rods. The anti-inclination devices are composed of fastening devices, movable rods and supporting legs, one end of each supporting leg is rotationally connected with a first fixed block, the other end of each supporting leg is rotationally connected with a second fixed block, and the sides, away from the supporting legs, of the second fixed blocks arefixedly connected with anti-skid gaskets. The first fixed blocks are fixedly connected to the outer sides of the bottom ends of the vertical rods, the fastening devices are arranged above the first fixed blocks, the fastening devices are connected to the outer sides of the vertical rods in a sliding manner, and the fastening devices are composed of sleeves and sliding blocks. According to the anti-toppling scaffold for decoration, the problems that an existing scaffold is inconvenient to move and topples and slides in the using process are solved.

Owner:北京点域科技有限公司

Movable shooting device for on-site pipeline flaw detection

InactiveCN105758878AFind the flaw detection positionIncrease the support pointMaterial analysis by transmitting radiationX-rayPetroleum engineering

The invention discloses a movable shooting device for on-site pipeline flaw detection and belongs to the technical field of flaw detection.The movable shooting device comprises a supporting frame, a running mechanism and a traveling mechanism, the supporting frame is mounted on the outer surface of a to-be-detected pipeline, the running mechanism is mounted on the supporting frame, and the traveling mechanism is positioned between the running mechanism and the to-be-detected pipeline.The movable shooting device is reasonable in structural design, setting up of a detection platform special for an X-ray flaw detector can be avoided, engineering cost is reduced, and omnibearing flaw detection of pipeline welding joints is realized; when flaw detection is performed on welding joints on a same pipeline, trouble of repeated mounting and demounting is omitted, flaw detection efficiency is improved greatly, engineering process is accelerated, detection personnel can be away from a flaw detection area in the flaw detection process, damage to the detection personnel by ray flaw detection is reduced, and a powerful guarantee is provided for engineering safety.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

Building construction supporting device with damping function

The invention discloses a building construction supporting device with a damping function. The building construction supporting device comprises a base, wherein a concrete reinforcing layer is arranged on the inner side of the base; an outer sleeve is arranged on the inner side of the concrete reinforcing layer; an inner sleeve column matched with the outer sleeve is arranged on the inner side ofthe outer sleeve in a sleeving mode; a fixing seat is arranged in the middle of the top of the inner sleeve column; a sleeve is arranged in the middle of the interior of the fixing seat; an inner sleeve matched with the sleeve is arranged on the inner side of the sleeve in a sleeving mode; and a spring A connected with the sleeve is arranged at the bottom of the inner sleeve. According to the building construction supporting device with the damping function, through sleeving connection of the outer sleeve and the inner sleeve column, during attaching supporting of the device, a pressing damping assembly and an attaching damping assembly are combined with each other and matched in a linkage mode, so that the supporting effect and strength of the device are greatly improved, impact force andvibration force which are generated during supporting are relieved, the overall structural strength of the device is enhanced, and the buffering function and the compression resistance effect of thedevice are improved.

Owner:云南六洲建筑劳务有限公司

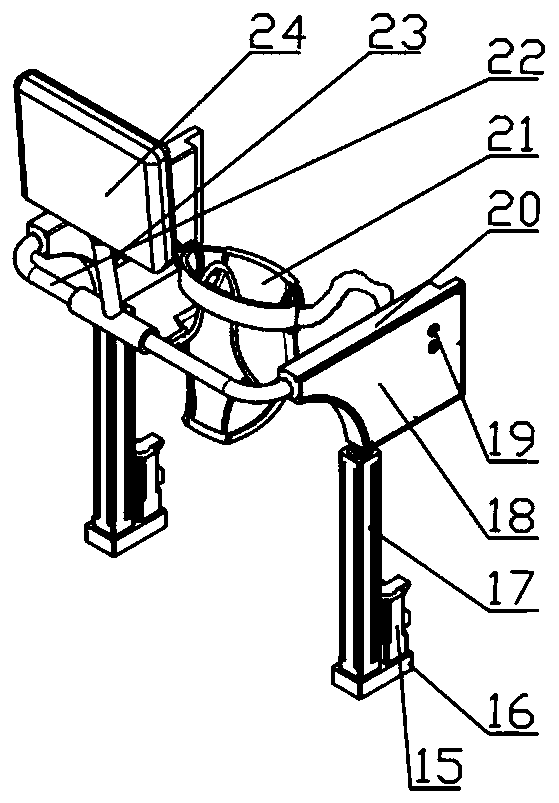

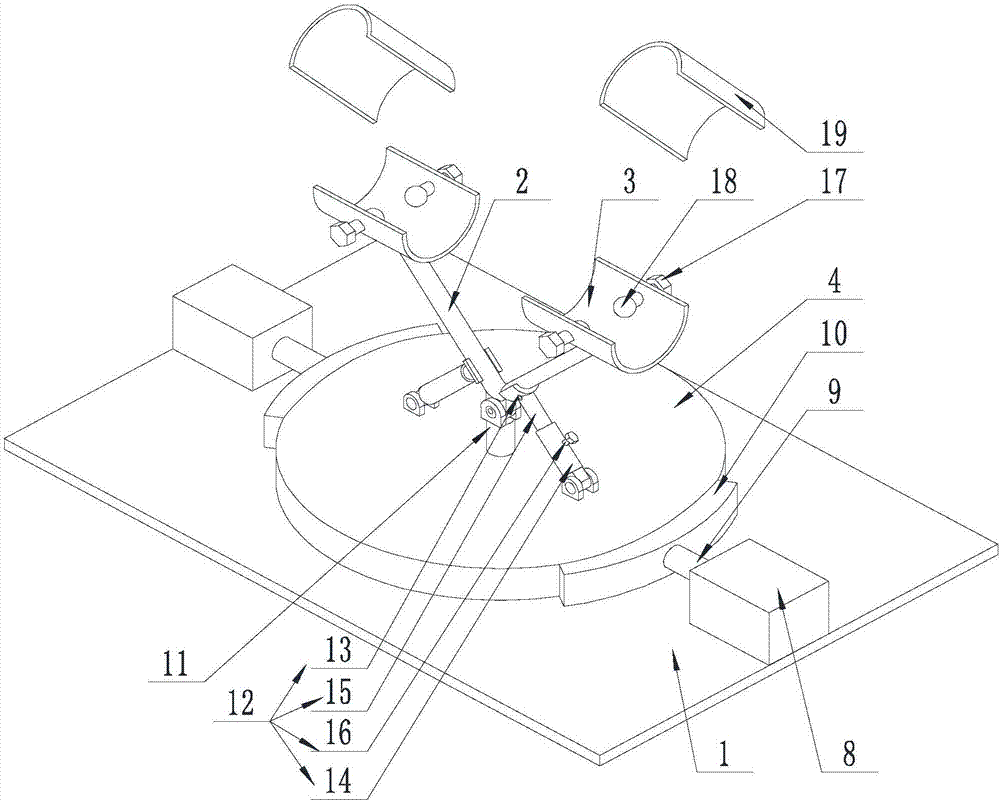

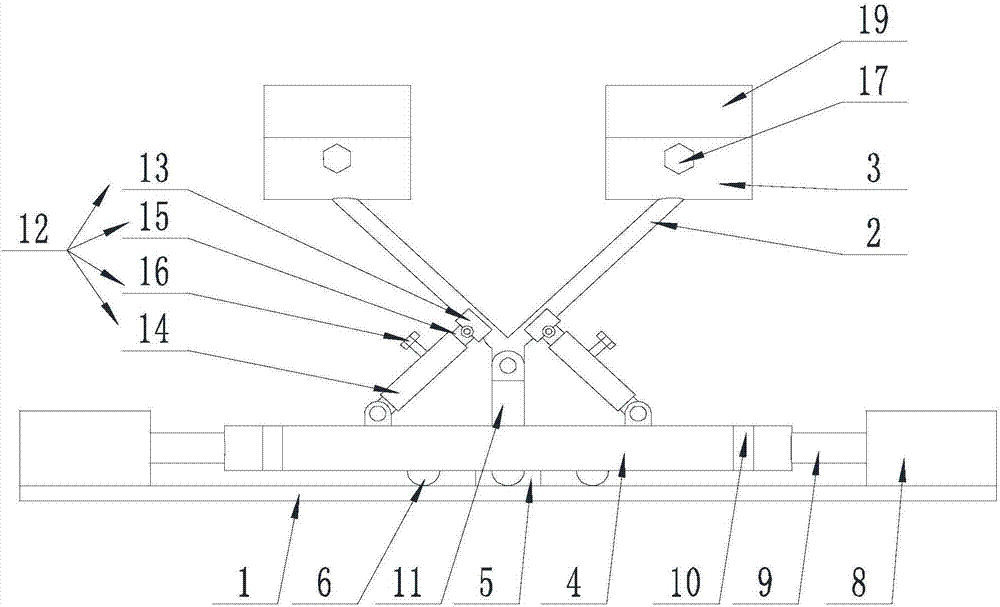

Walking-aid training device for spinal injury patients

PendingCN111067764APlay a compensatory rolePlay a role in maintainingWalking aidsSpinal columnEngineering

The invention relates to a walking-aid training device for spinal injury patients. The device comprises a walking-aid advancing frame, an upper limb supporting and lifting assembly, a horizontal driving assembly and a pedal assembly, wherein the upper limb supporting and lifting assembly is arranged on the walking-aid advancing frame; the horizontal driving assembly is arranged on the walking-aidadvancing frame, the horizontal driving assembly comprises a front sliding block fixing block, a front sliding block fixing block driving piece, a rear sliding block fixing block and a rear sliding block fixing block driving piece, the front sliding block fixing block driving piece and the rear sliding block fixing block driving piece drive the front sliding block fixing block and the rear slidingblock fixing block to move horizontally; and through cooperative operation of the front sliding block fixing block and the rear sliding block fixing block, the pedal assembly obtains fluctuating displacement during walking. Compared with the prior art, the device provides driving force for a spinal injury patients, standardizes gait of the patients, can help the patients to train the normal walking gait, and helps the patients to walk normally.

Owner:SHANGHAI CHANGZHENG HOSPITAL

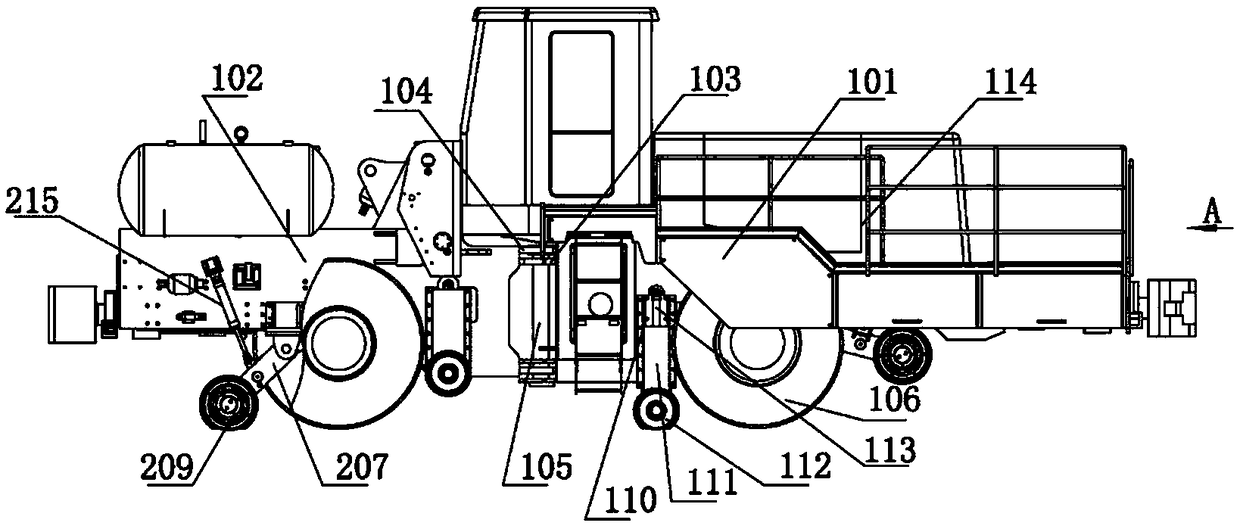

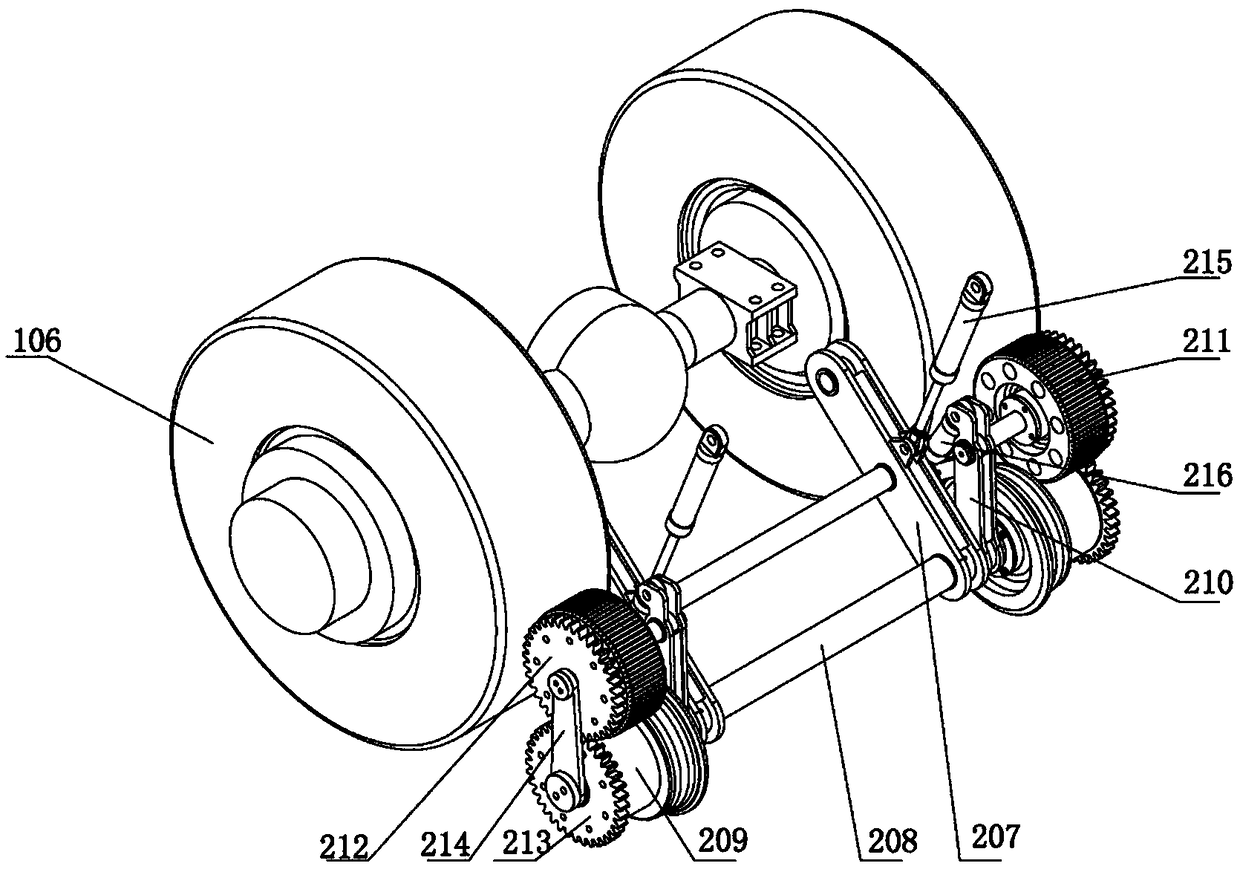

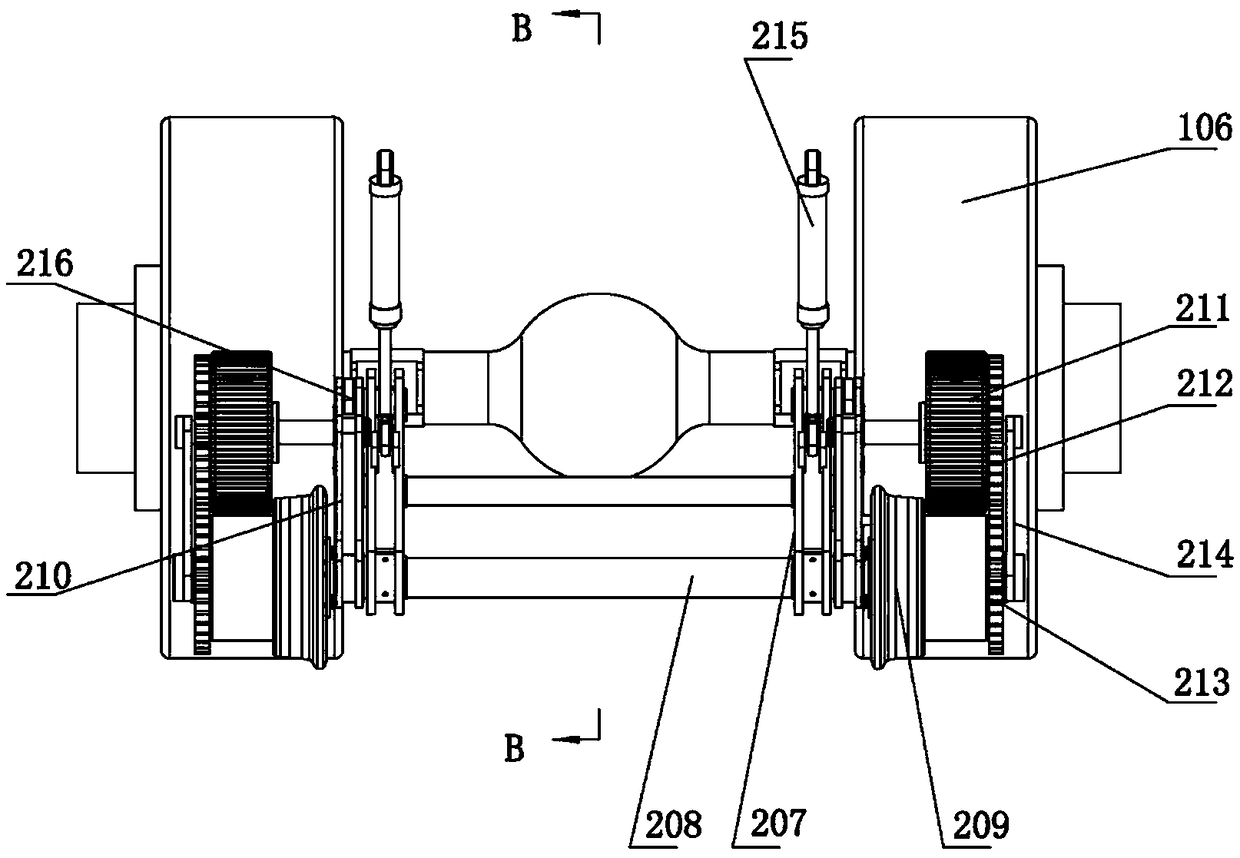

Bus with idler gear mechanism

ActiveCN109177667AEasy and safe transportationEasy to uninstallRail and road vehiclesFluid steeringVehicle frameEngineering

The invention provides a bus with an idler gear mechanism, comprising a power car and a tractor, wherein the power car and the tractor are connected through an articulated shaft; first track wheel mechanisms are arranged at the bottom of the power car and the tractor, and two sets of second track wheel mechanisms are arranged between the two sets of the first track wheel mechanisms; and the frontand rear frames are adopted and the hydraulic steering system is cooperated to realize flexible steering on the highway. The bus with an idler gear mechanism has the advantages that: the bus with an idler gear mechanism can ensure that no traveling resistance will be generated during the turning process of the high-speed railway car, and allows for smaller corners; the first track wheel mechanismsand the second track wheel mechanisms are respectively arranged at the bottom of the power car and the tractor; and the second track wheel mechanisms are positioned between the first track wheel mechanisms, thereby reducing the span distance between the track wheels, and making the highway car more stable and safe in the turning process.

Owner:SHANDONG JIAOTONG UNIV +2

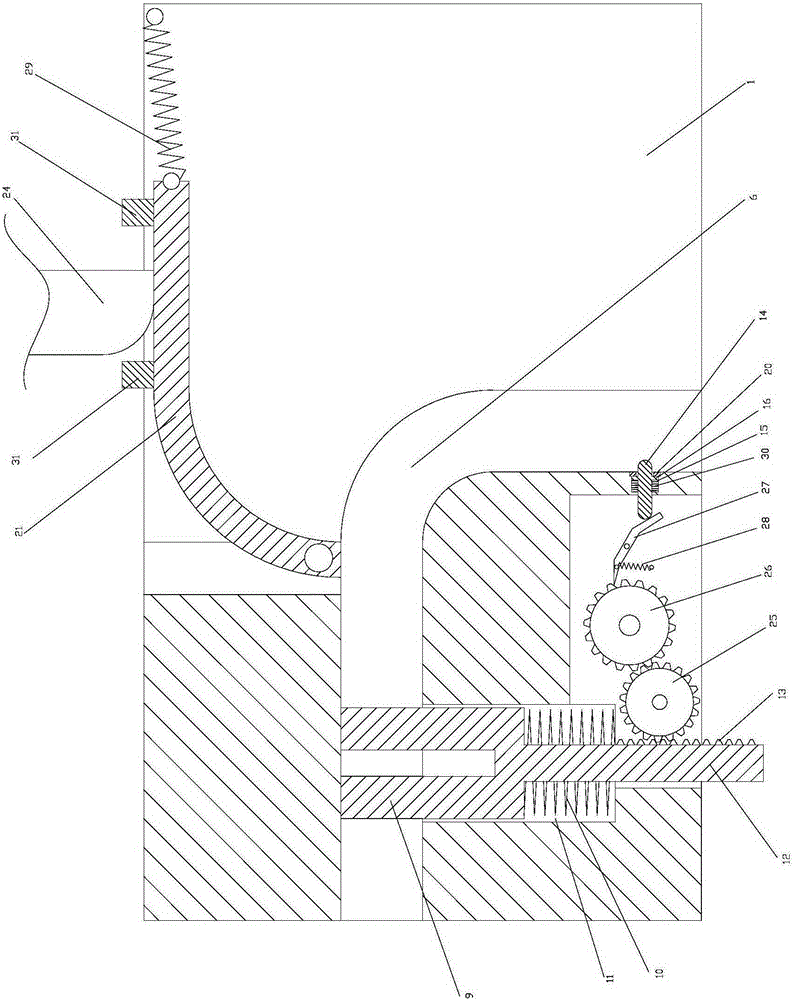

Bending and blanking device

InactiveCN105251819ASimplified operational requirementsImprove securityMetal-working feeding devicesStripping-off devicesEngineeringReference surface

The invention discloses a bending and blanking device. The device comprises a base (1), wherein the base (1) is provided with a reference surface (3) for placing a free end of a pipe (2) and rotating the free end of the pipe (2); the base (1) is provided with a boss (4) higher than the reference surface (3) for positioning the other end of the pipe (2); the boss (4) is provided with an opening (5) for accommodating the end part of the pipe (2); the base (1) is provided with a through hole (6) for sliding the bent pipe (2) in the vertical direction; the shape of the through hole (6) is consistent with the bending shape of the pipe (2); and the through hole (6) penetrates through the upper surface and the lower surface of the base (1) in the vertical direction, and is communicated with the opening (5) in the vertical direction. The invention provides the bending and blanking device with low maintenance cost, simple operation and no need of manual pipe taking.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Tool facilitating assembly of aero model

The invention discloses a tool facilitating assembly of an aero model. The tool comprises a supporting plate. A supporting rod is arranged on the upper surface of the supporting plate. The supporting rod is bent into a V-shaped rod. The tip end of the supporting rod is connected with the supporting plate. The tail ends of the supporting rod are each provided with a connecting plate. Pressing plates are arranged over the connecting plates. The pressing plates and the connecting plates are all provided with magnets. The pressing plates are arranged over the connecting plates to make the pressing plates and the magnets on the connecting plates attract mutually so as to press the pressing plates onto parts and fix related components. Thus, in the process of manufacturing the aero model, the aero model can be supported and fixed through a working table designed by the invention so that a user can assemble the aero model conveniently, and the related components or an airplane body can be fixed; meanwhile, the conditions that installation mistakes and deviation of a preset position of model parts are caused by hand shaking and other reasons are avoided, and the assembly efficiency is improved; installation of overall components of the aero model meets the design requirements, and flying of the aero model is facilitated.

Owner:黎昀菡

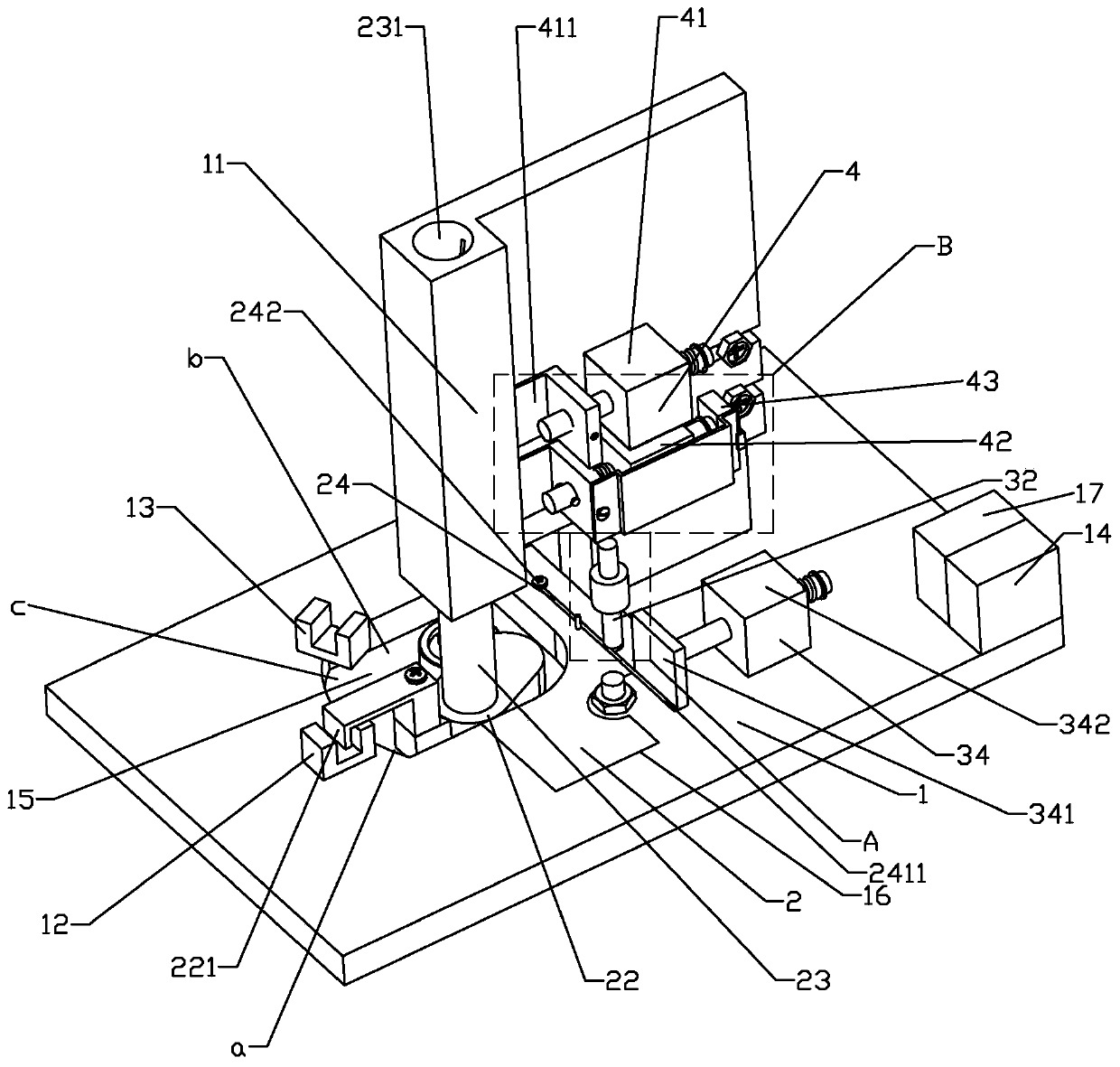

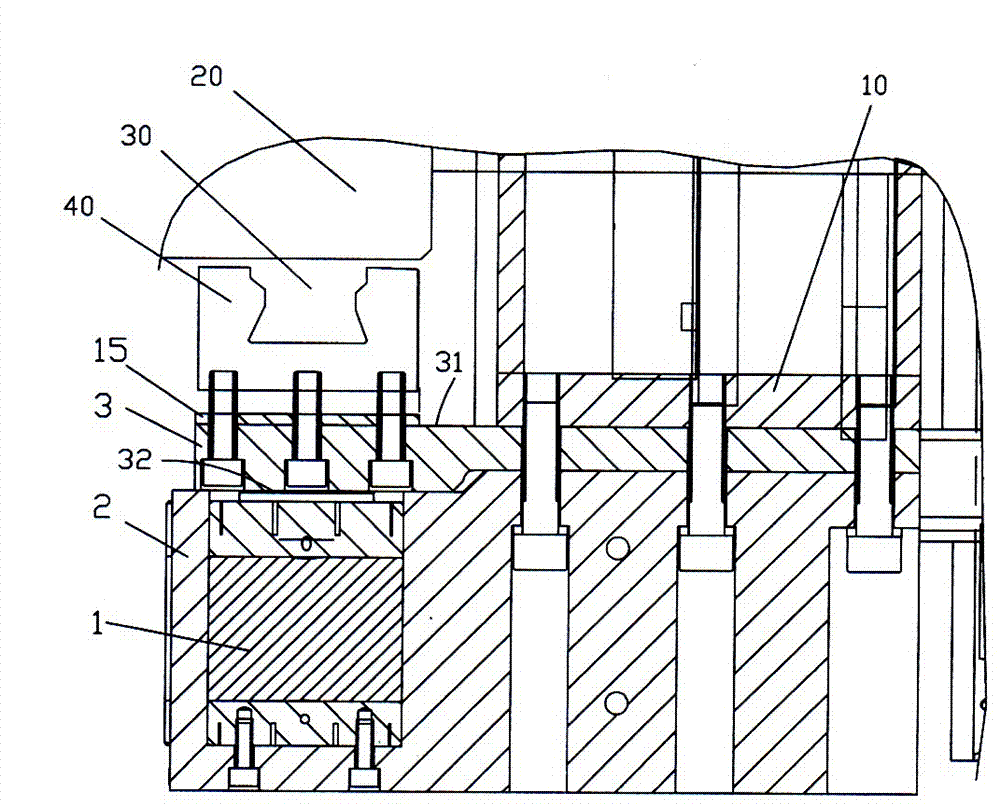

Compensation mechanism for stress deformation of spindle box of machine tool

InactiveCN102179719BOffset deformationIncrease the support pointLarge fixed membersMaintainance and safety accessoriesThermal deformationGravity center

The invention relates to a compensation mechanism for stress deformation of a spindle box of a machine tool, wherein the spindle box is arranged between two upright columns, thereby forming a gate-type thermal deformation symmetrical structure; two guide rails and sliding blocks are respectively arranged on front and back contact walls between the spindle box and the two upright columns, thereby forming a vertical guiding support; the compensation mechanism further comprises two compensation cylinders, two transition connection plates and two support shells; the two compensation cylinders arerespectively arranged in the two support shells; the two support shells are symmetrically arranged at two sides of the upper end face on the rear part of the spindle box; two ends on one side wall ofeach transition connection plate are respectively connected to two sides of the upper end face on the rear part of the spindle box and corresponding to the sliding blocks of the guide rails; the two support shells, in which the compensation cylinders are arranged, are respectively arranged on the other side walls of the transition connection plates corresponding to the sliding blocks; and the piston rod ends of the compensation cylinders prop against the other side walls of the transition connection plates corresponding to the sliding blocks. According to the compensation mechanism provided by the invention, the deformation compensation mechanism is arranged inside a sliding sleeper. The compensation mechanism provided by the invention can be used for solving the problem of suspension stretching flexible deformation caused by the change of gravity center of a spindle component in the moving process of the spindle box and can be used for dynamically compensating the stress deformation generated by the spindle box in real time.

Owner:SANY GRP

Steam ironing machine with reversible ironing plate

The invention discloses a steam ironing machine with a reversible ironing plate. The machine solves the problem of low stability of the ironing plate. The technological scheme which solves the problem mainly comprises a main body, the ironing plate, and a supporting frame disposed on the main body, wherein the front face of the ironing plate is an ironing face; the supporting frame is in rotatable connection with a first connecting part and a second connecting part; joints between the first connecting part and the second connecting part and the supporting frame are located on two sides of the supporting frame; the first connecting part is in rotatable connection with the back face of the ironing plate; when the ironing plate stays at a first installation state, the first connecting part is stored between the ironing plate and the supporting frame; the second connecting part is connected to the first connecting part and limits rotation of the first connecting part relative to the supporting frame; and the first connecting part and the second connecting part support the ironing plate when the ironing plate stays at a second installation state. According to the invention, through mutual coordination and mutual limiting of the first connecting part and the second connecting part, stability of the ironing plate at the first installation state and the second installation state can be ensured.

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com